Tensile Behavior and Failure Mechanism of Bamboo Fiber Bundle and Its Scrimber Under Different Strain Rates

Abstract

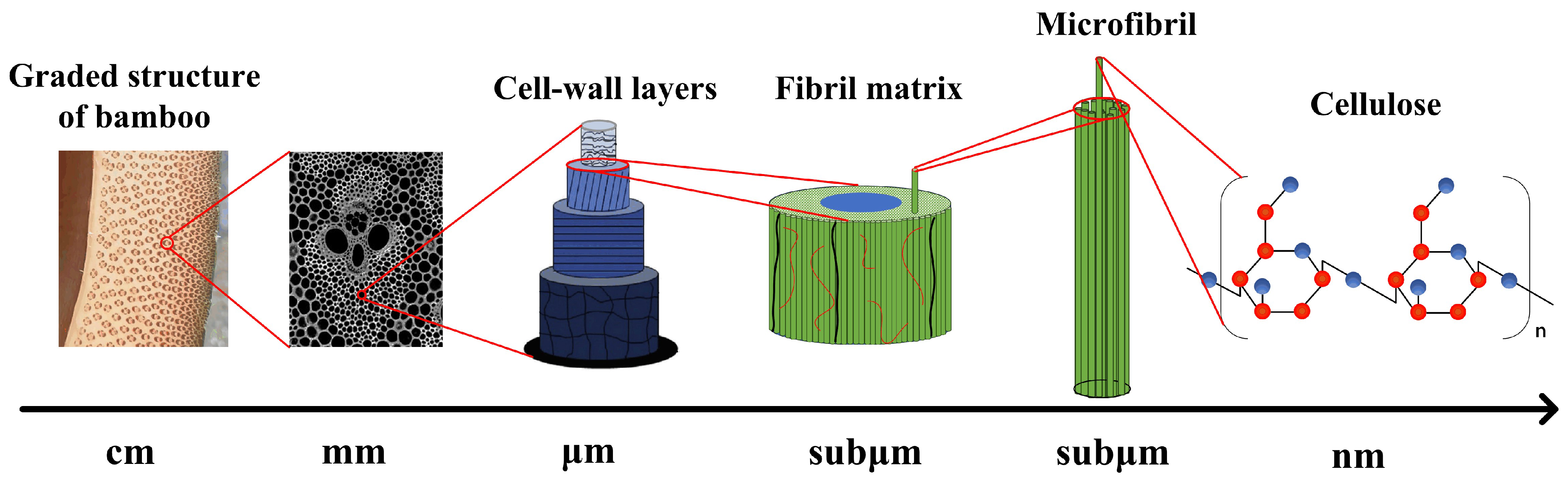

1. Introduction

2. Experimental Section

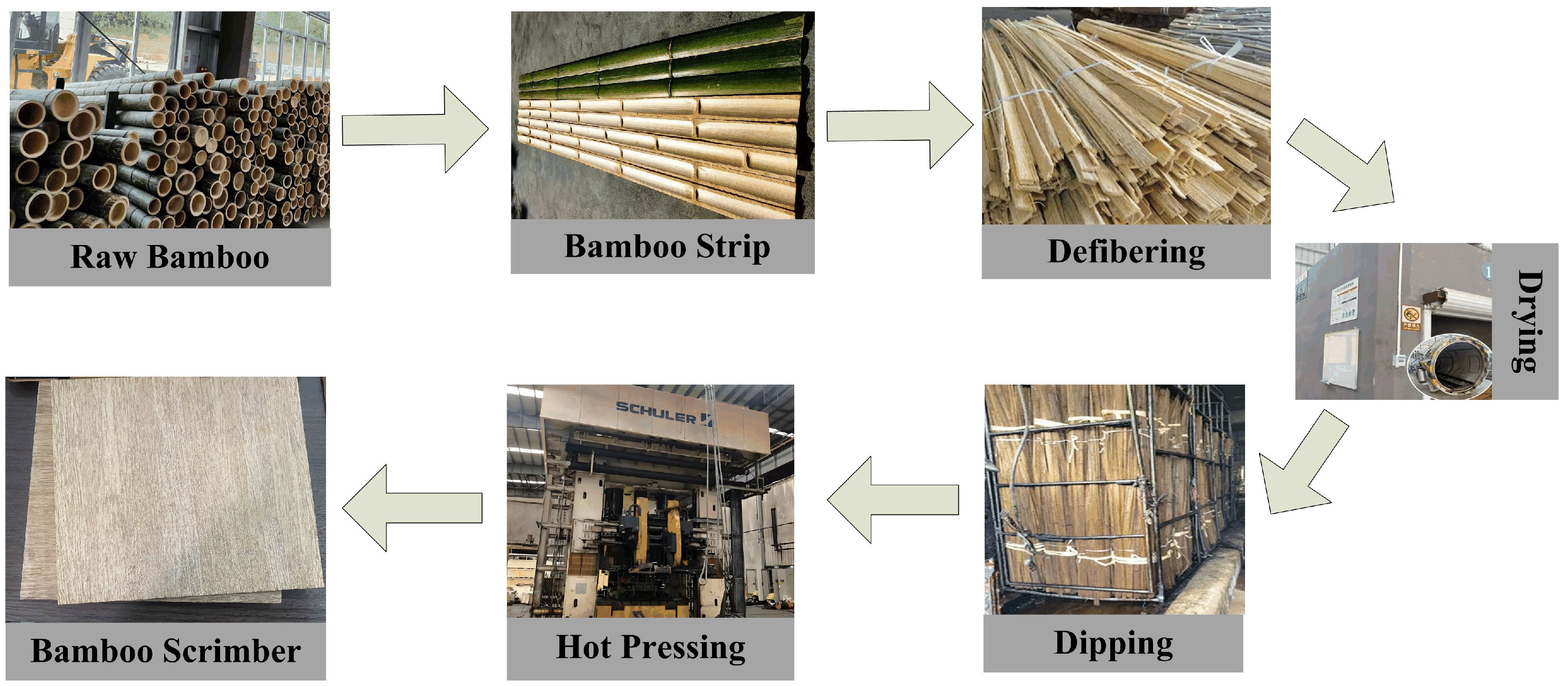

2.1. Materials Preparation

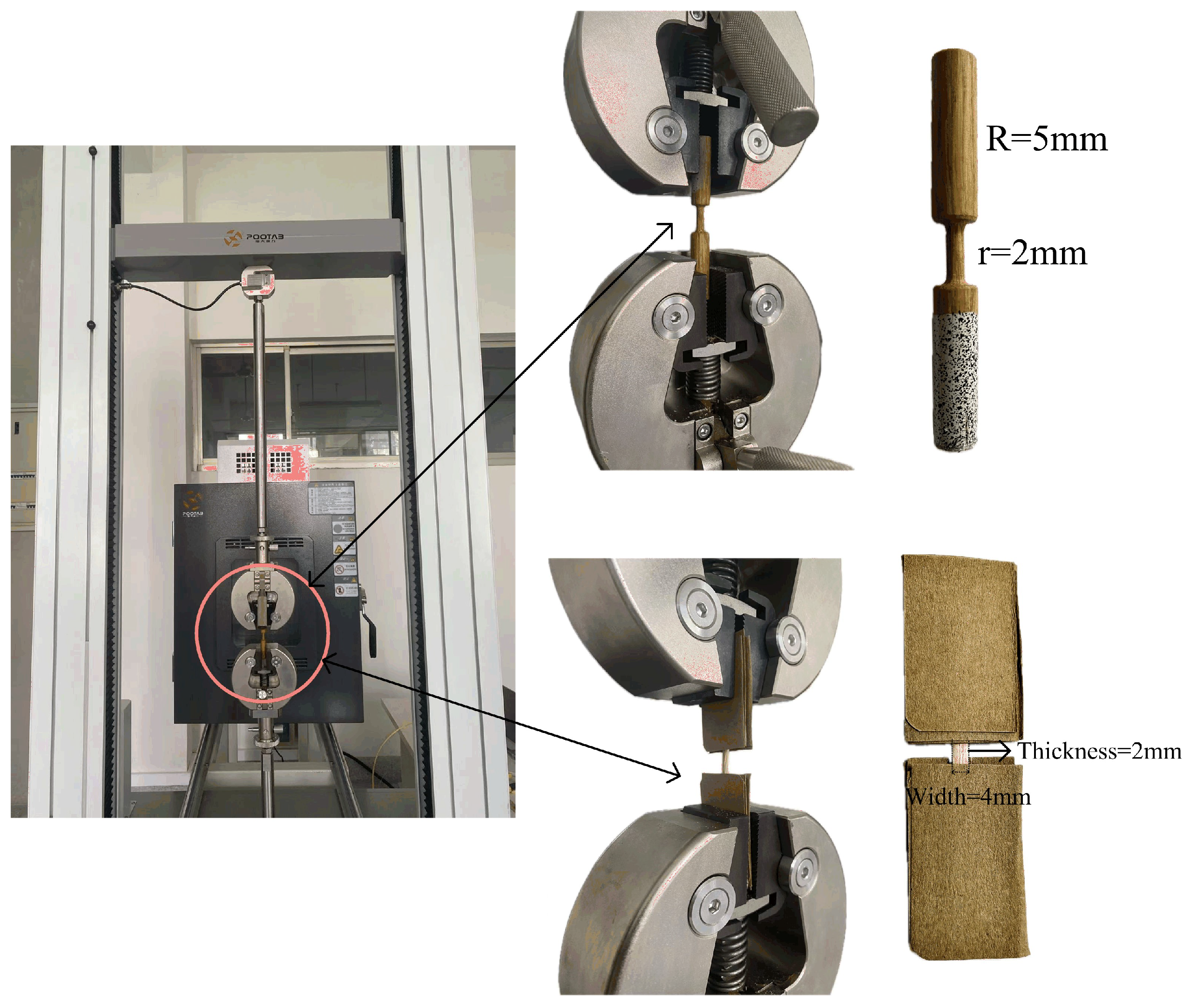

2.2. Quasi-Static Tensile Test

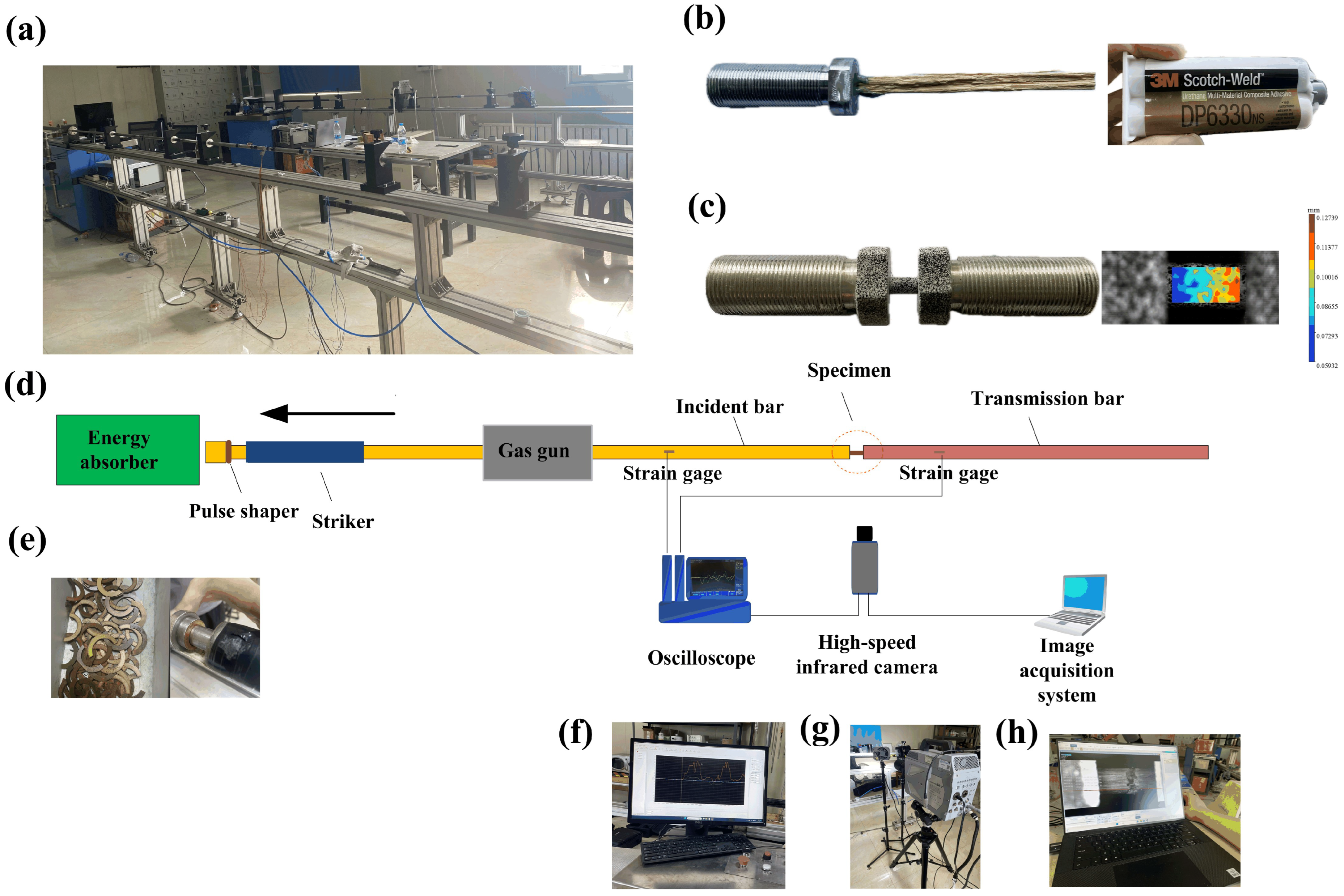

2.3. Dynamic Tensile Test

3. Results and Discussion

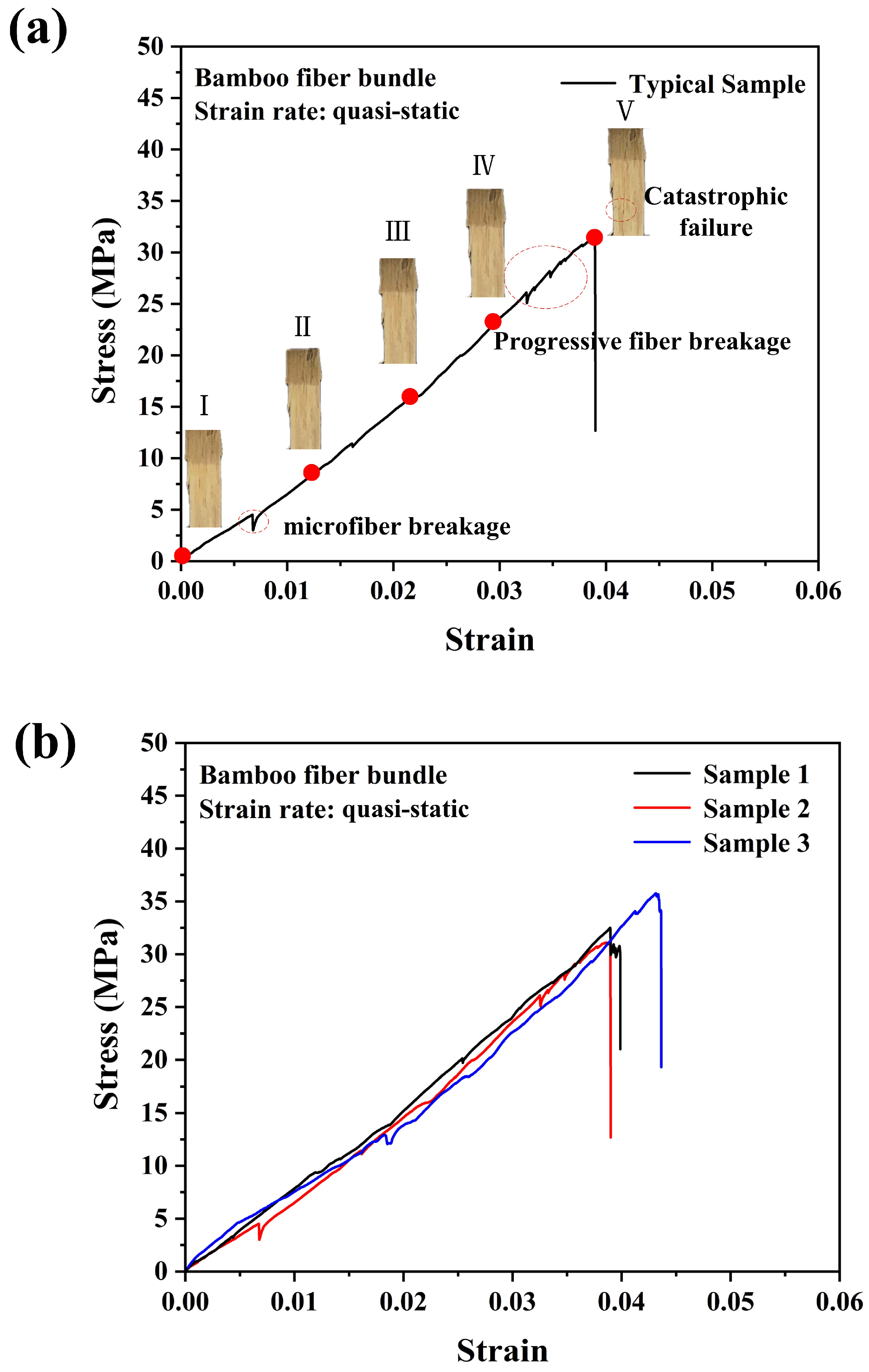

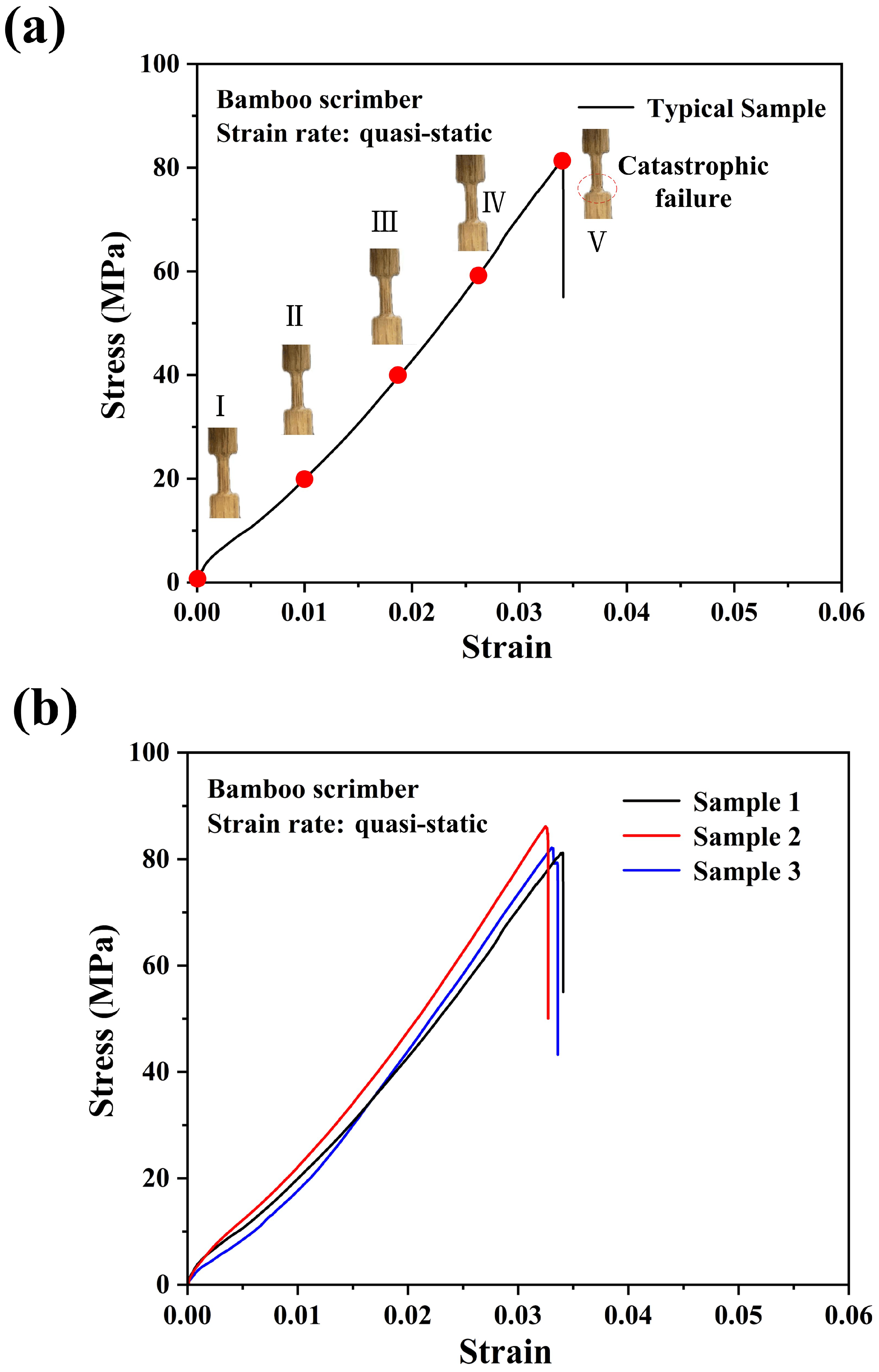

3.1. Tensile Behaviors of Single Bamboo Fiber Bundle and Its Scrimber Under Quasi-Static Loading Condition

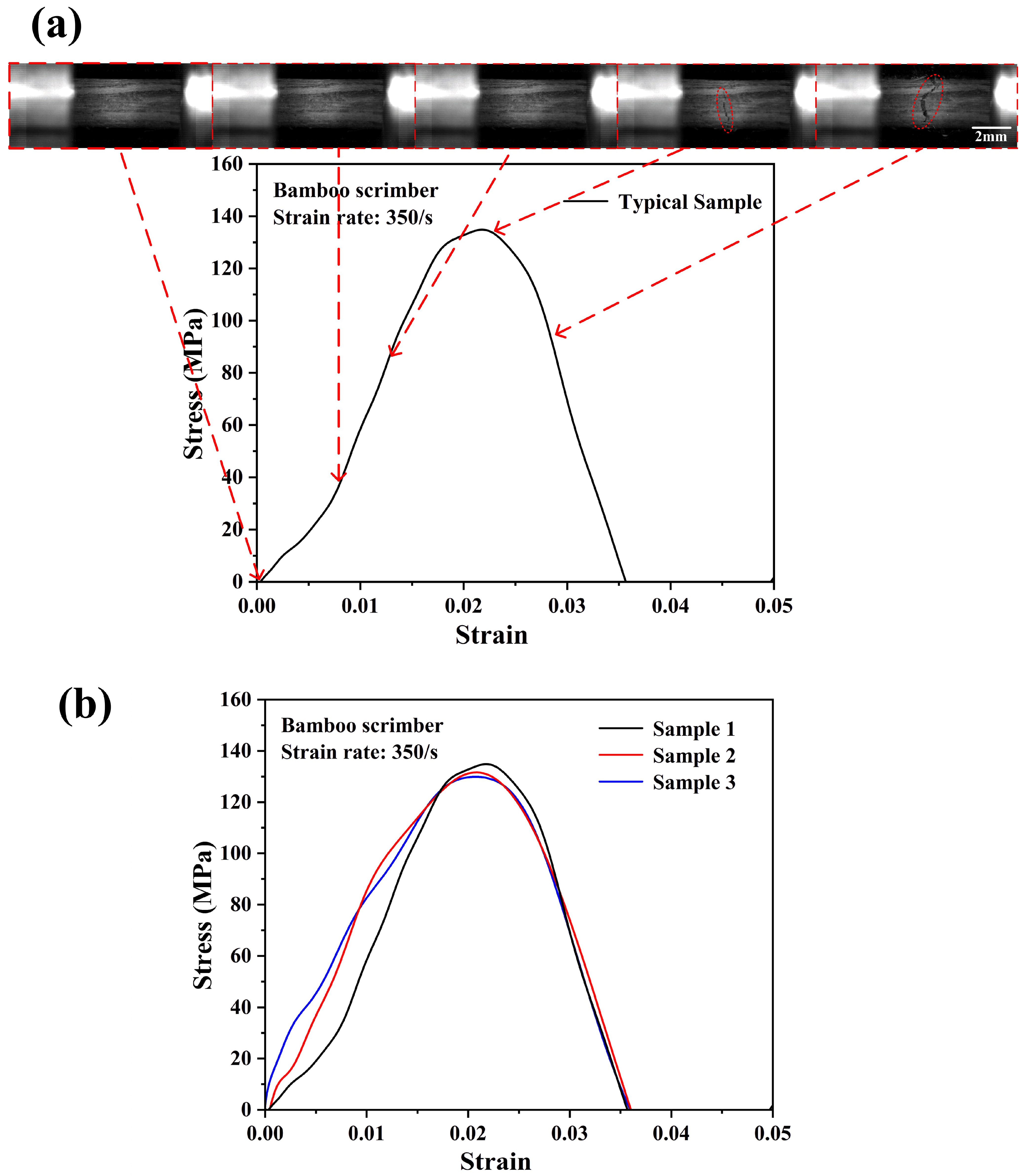

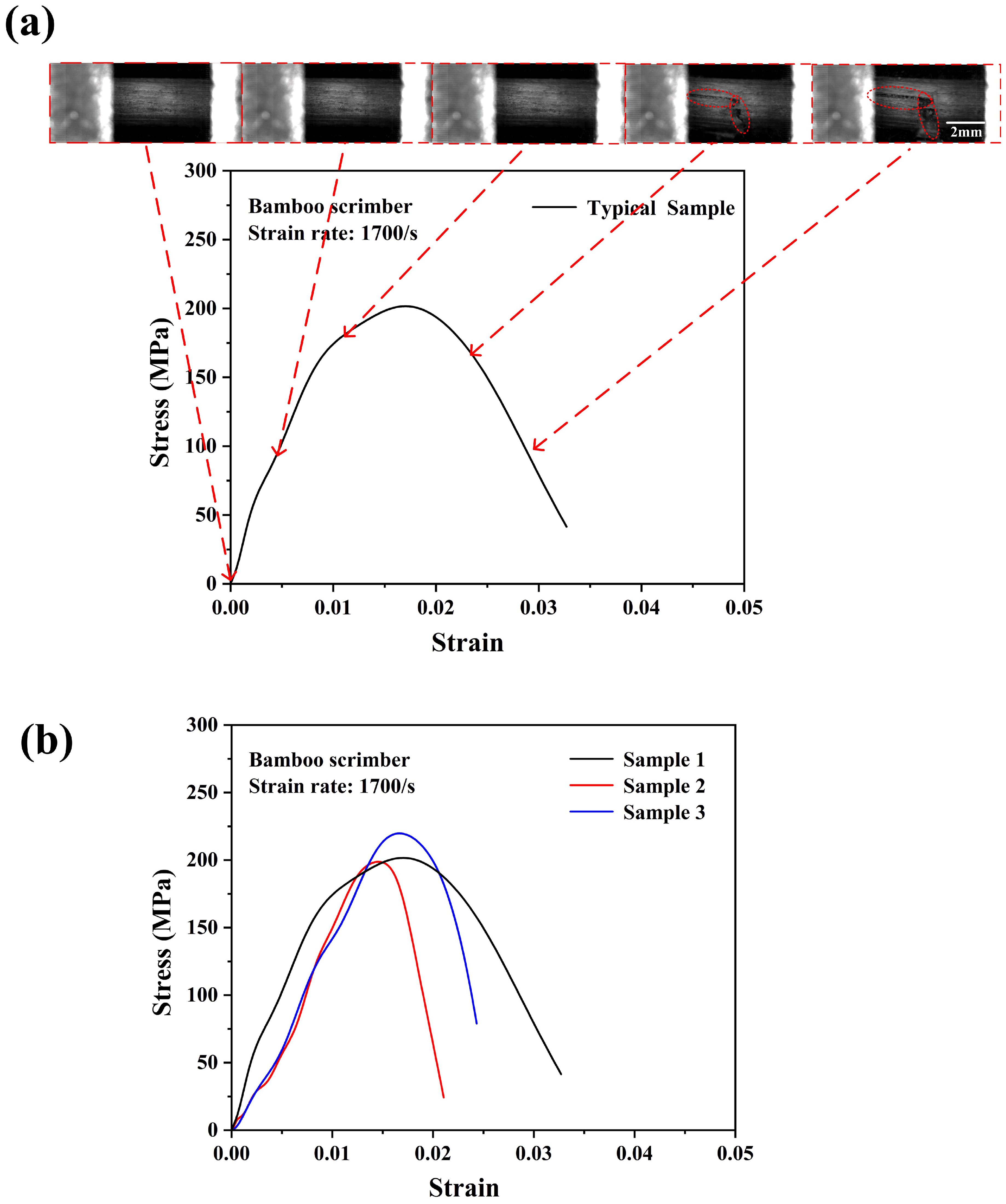

3.2. Tensile Behaviors of the Single Bamboo Fiber Bundle and Its Bamboo Scrimber Under SHTB Loading

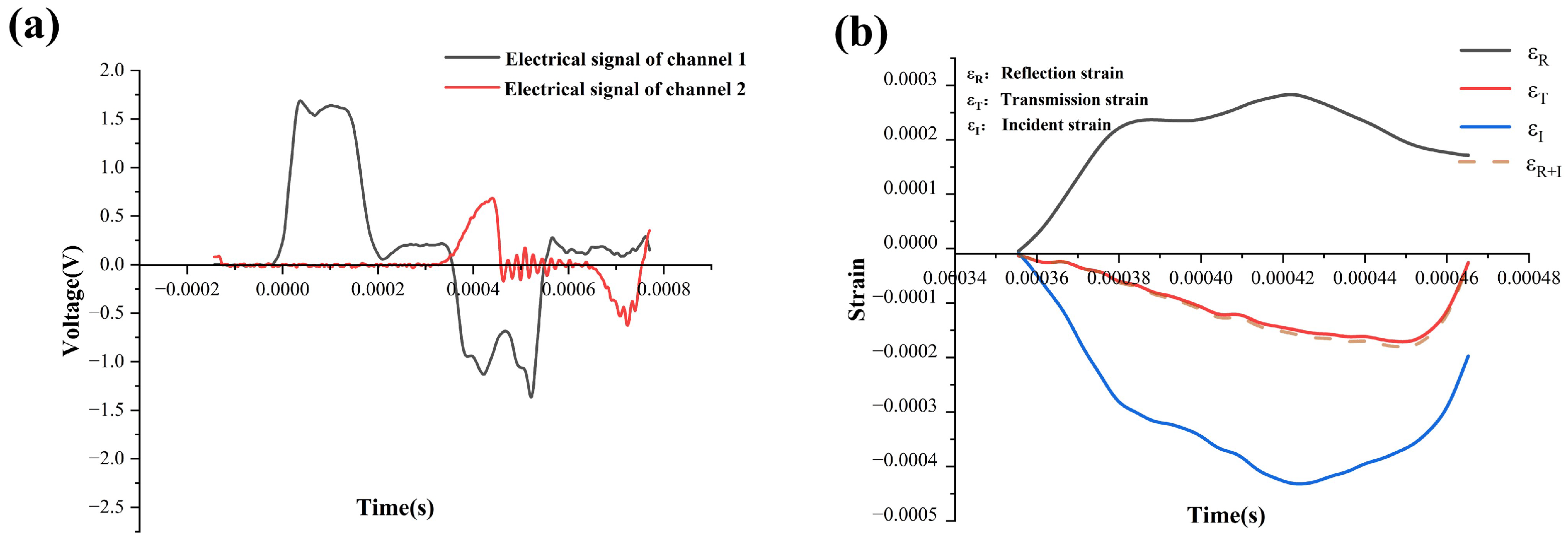

3.2.1. Stress Equilibrium in SHTB Test

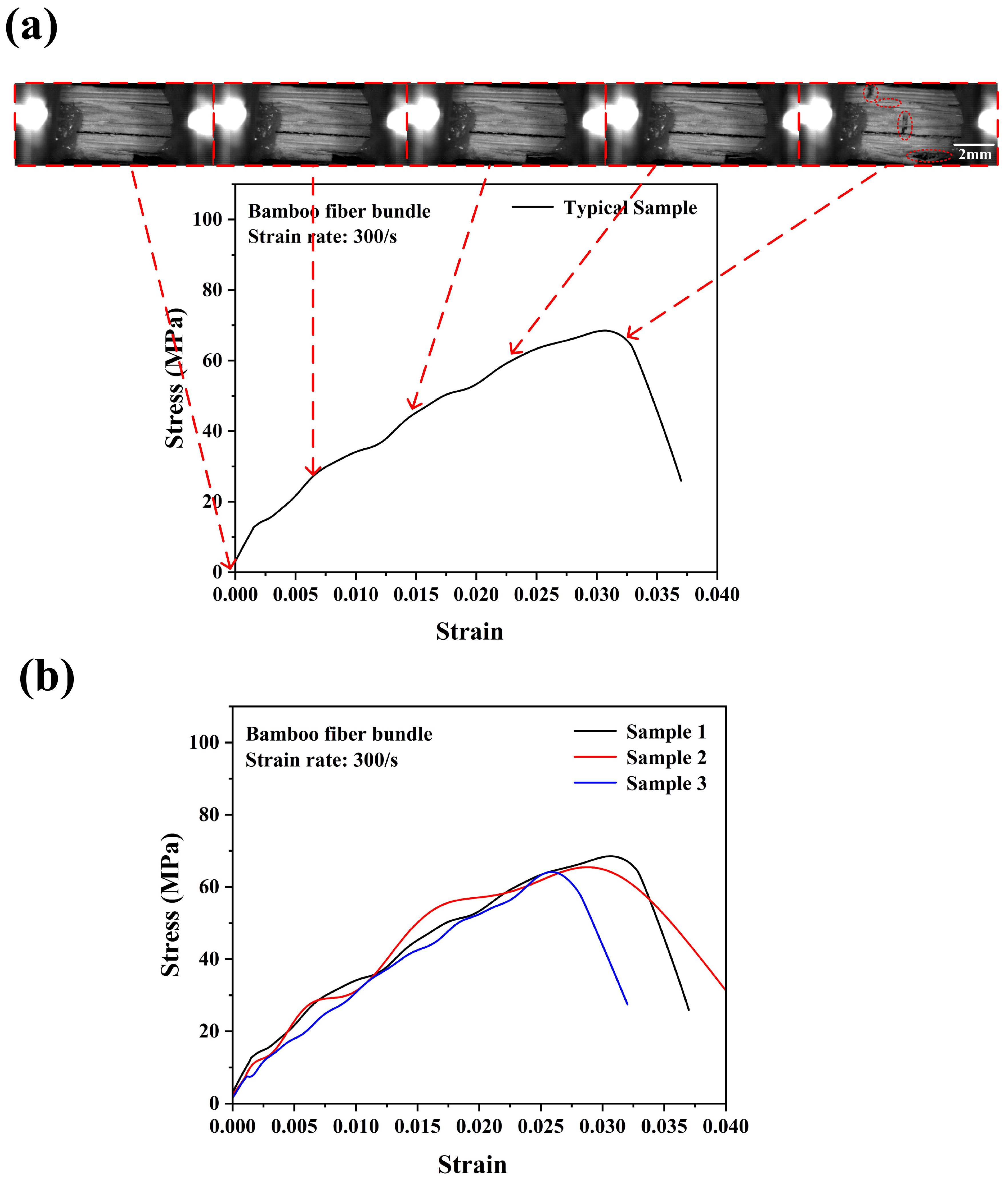

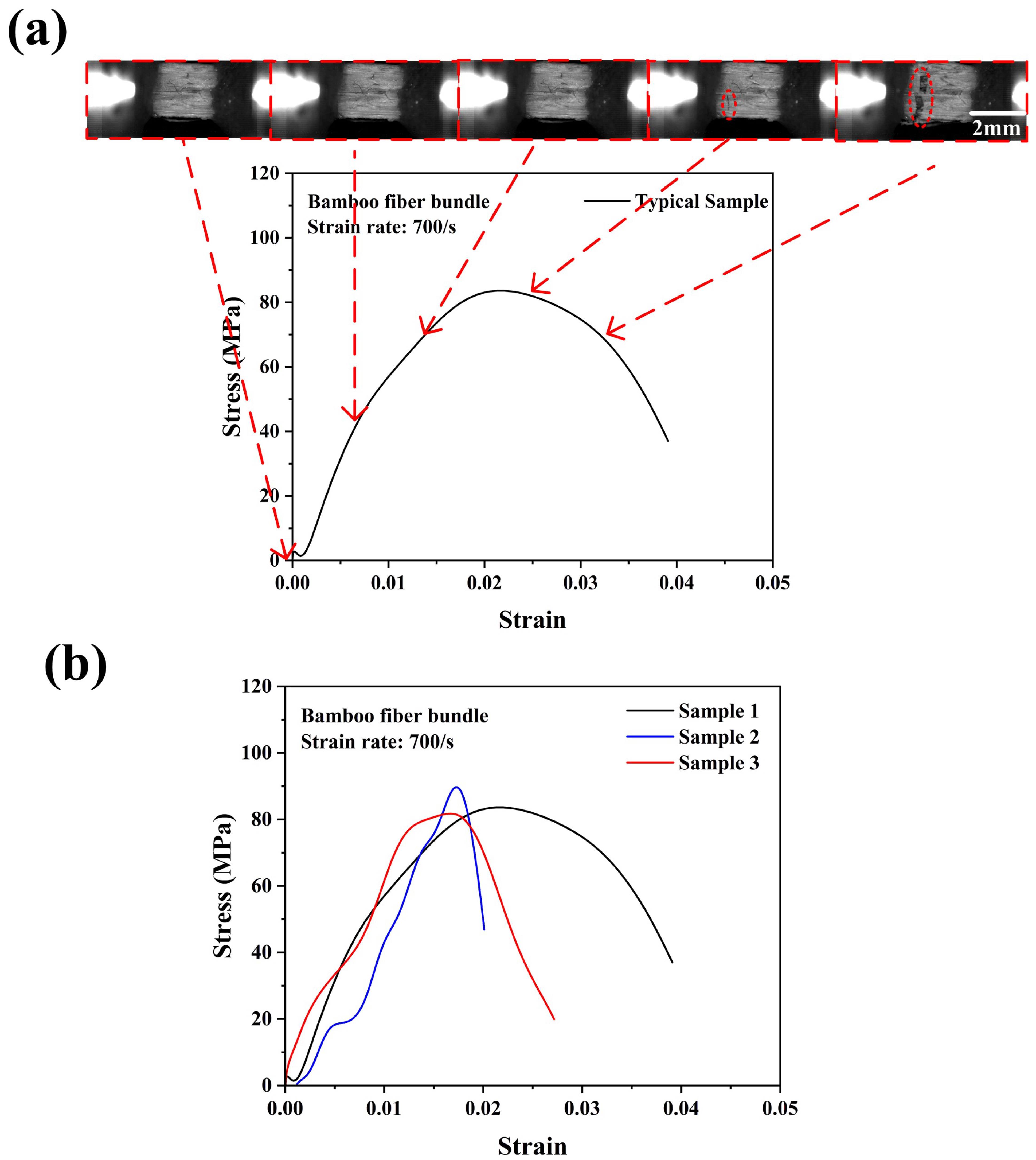

3.2.2. Dynamic Tensile Behaviors of the Bamboo Fiber Bundle and Its Scrimber

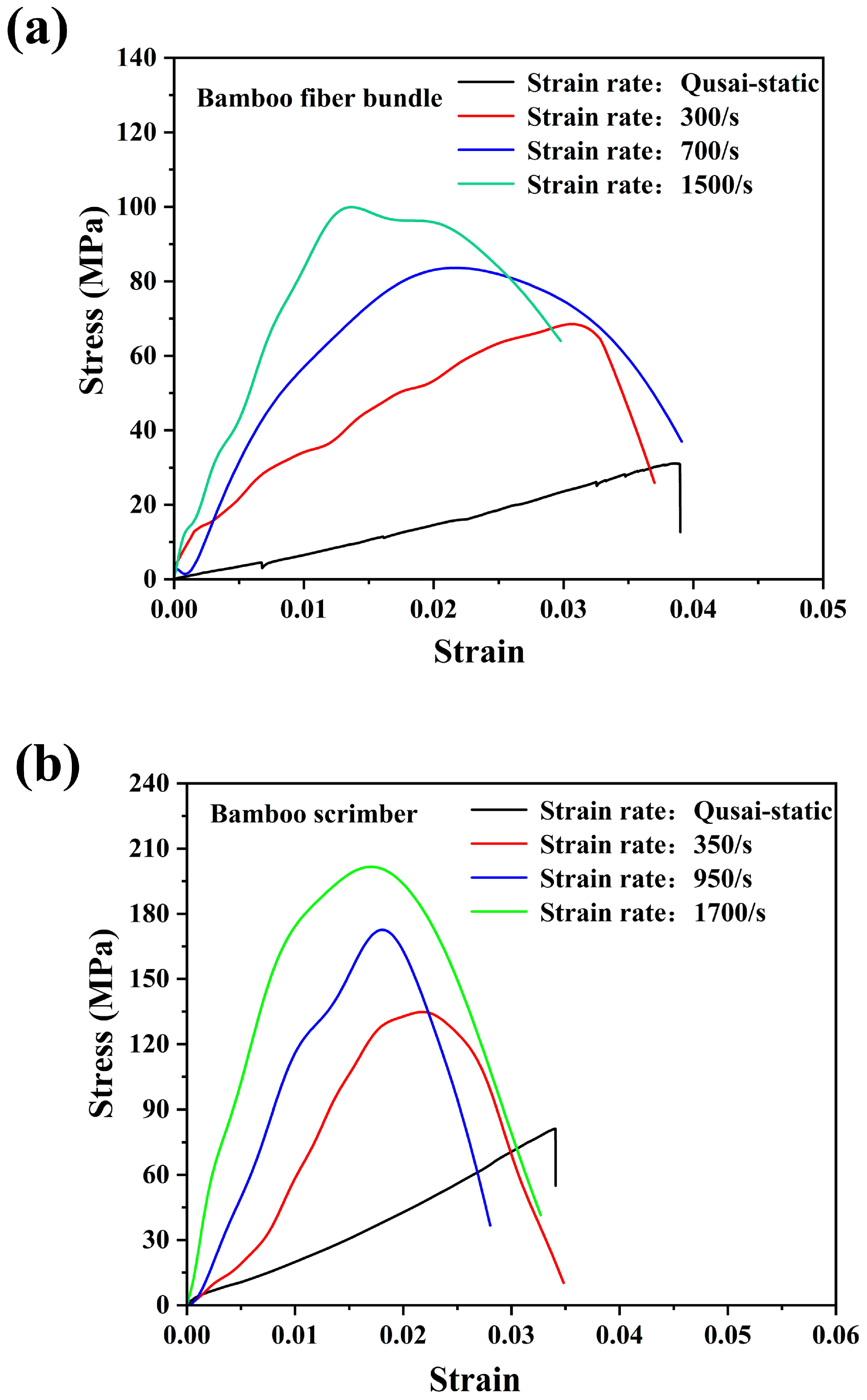

3.3. Rate Dependence of Tensile Properties of Bamboo Fiber Bundle and Its Bamboo Scrimber

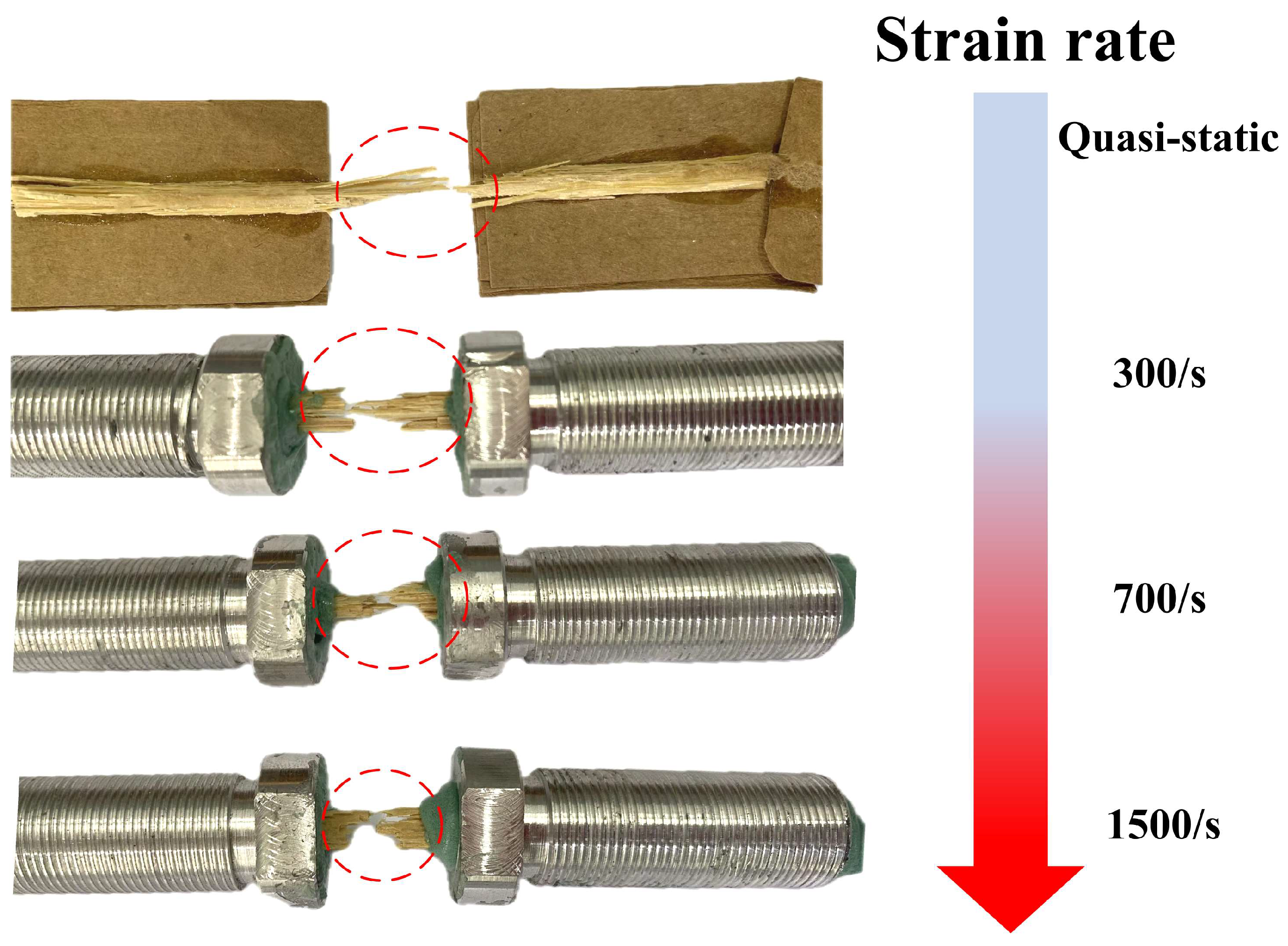

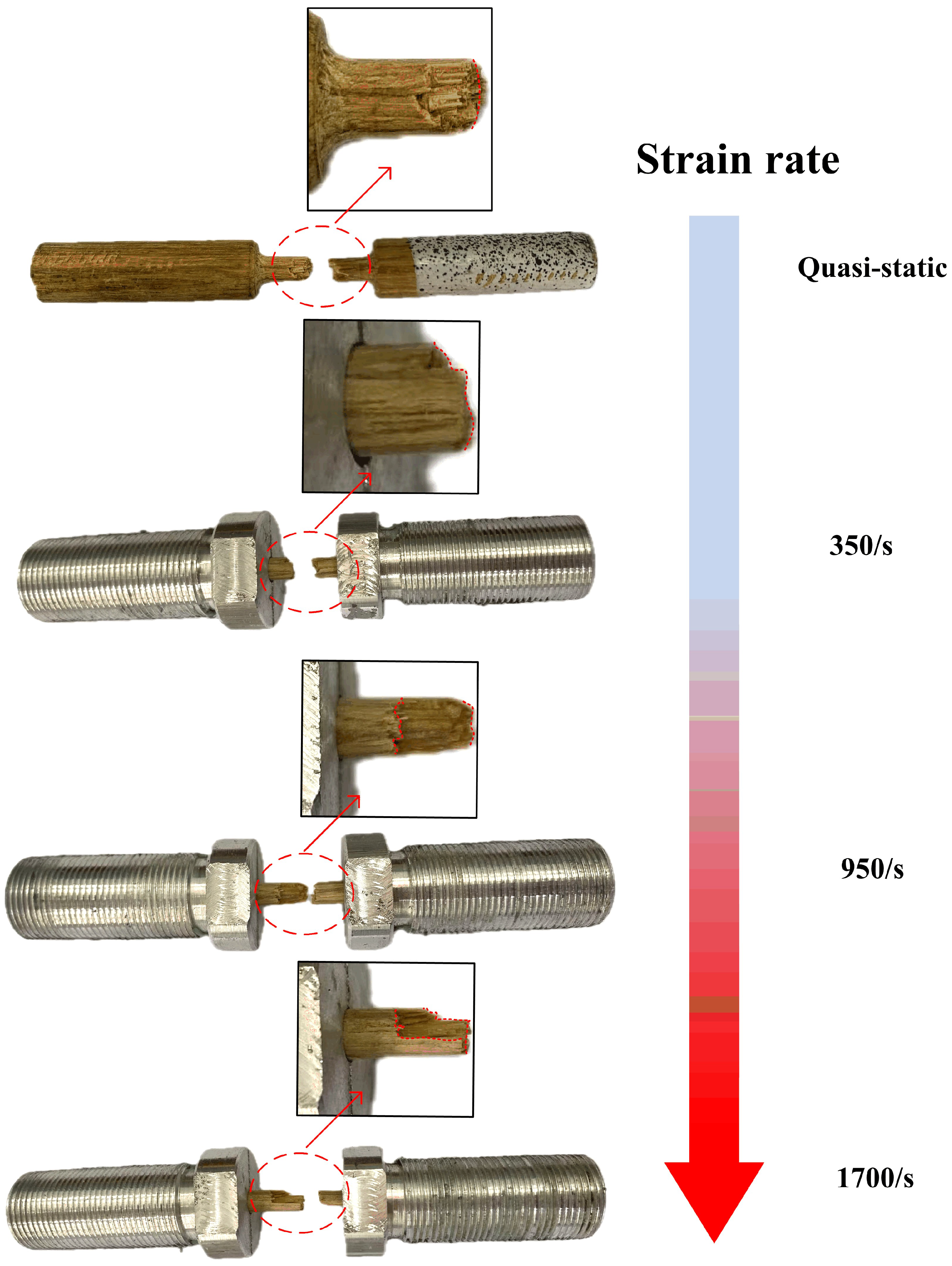

3.4. Failure Mechanisms

4. Conclusions

- The single bamboo fiber bundle exhibited typical linear elastic behavior under quasi-static tension, ultimately leading to brittle fracture with an ultimate tensile strength of approximately 32 MPa.

- The bamboo scrimber exhibited relatively smooth linear elastic behavior under quasi-static tension, with an ultimate tensile strength of approximately 82 MPa, which was lower than the values reported in the existing literature. This may be related to differences in sample size and the characteristics of the bamboo itself.

- Under dynamic stretching, the ultimate tensile strength of the bamboo fiber bundles significantly increased with the increase in strain rates, showing a significant positive effect of the strain rate. For example, at a strain rate of 300/s, the ultimate tensile strength was approximately 66 MPa. At a strain rate of 1500/s, the ultimate tensile strength reached approximately 100 MPa.

- The bamboo scrimber also exhibited a positive strain rate effect under dynamic stretching. For example, at a strain rate of 350/s, the ultimate tensile strength was about 131 MPa, which was about 60% higher than under quasi-static conditions. As the strain rate further increased to 950/s and 1700/s, the ultimate tensile strength of the reconstituted bamboo reached approximately 170 MPa and 206 MPa, respectively. The fracture strain of the recombinant bamboo at high strain rates was also smaller than that at low strain rates.

- At different strain rates, there was no significant difference in the fracture morphologies of the bamboo fiber bundles, and the fracture zone mainly occurred at the small fiber fracture inside the fiber bundle. The fracture morphologies of the recombinant bamboo exhibited two different failure modes: linear and folded. For the quasi-static condition and 350/s strain rate, the fracture surface was rough and approximately linear. At strain rates of 950/s and 1700/s, the fracture surface exhibited a discontinuous zigzag crack path.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 1–10. [Google Scholar] [CrossRef]

- Amjad, A.I. Bamboo fibre: A sustainable solution for textile manufacturing. Adv. Bamboo Sci. 2024, 7, 100088. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, F.; Liang, W.; Wang, Z.; Duan, Z.; Yang, B. Thermal and mechanical properties of bamboo fiber reinforced epoxy composites. Polymers 2018, 10, 608. [Google Scholar] [CrossRef]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Bala, A.; Gupta, S. Engineered bamboo and bamboo-reinforced concrete elements as sustainable building materials: A review. Constr. Build. Mater. 2023, 394, 132116. [Google Scholar] [CrossRef]

- Li, J.; Singh, A.; Sharma, R.; Yu, X.; Zhou, J.; Ge, P.; Yang, S. Size Influence of Laminated Bamboo on Tensile Mechanical Properties with the Consideration of Density. Materials 2025, 18, 238. [Google Scholar] [CrossRef]

- Liang, E.; Zhou, Q.; Lin, X.; Wang, X.; Li, X.; Ma, H.; Shi, L.; Hu, C.; Tu, D. Feasibility of one-time drying for manufacturing bamboo scrimber: Fresh bamboo bundle at high initial moisture content impregnated by PF. Ind. Crops Prod. 2023, 194, 116302. [Google Scholar] [CrossRef]

- Peng, R.; Yang, F.; Yin, W.; Du, C.; Liu, C.; Chen, S.; Shan, Y.; Shao, Y.; Wang, Y. Facile preparation, pyrolysis and pilot production a bamboo scrimber with halogen-free, flame-resistance and low-smoke. Ind. Crops Prod. 2023, 204, 117358. [Google Scholar] [CrossRef]

- Yuan, Z.; Wu, X.; Wang, X.; Zhang, X.; Yuan, T.; Liu, X.; Li, Y. Effects of one-step hot oil treatment on the physical, mechanical, and surface properties of bamboo scrimber. Molecules 2020, 25, 4488. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Qiu, Z.; Su, J.; Wei, D.; Lorenzo, R.; Yuan, C.; Liu, H.; Zhou, C. Mechanical properties and stress strain relationship models for bamboo scrimber. J. Renew. Mater. 2020, 8, 13–27. [Google Scholar] [CrossRef]

- Lei, W.; Huang, Y.; Yu, W.; Wang, X.; Wu, J.; Yang, Y.; Qi, Y.; Zhang, Y. Evolution of structural characteristics of bamboo scrimber under extreme weather. Ind. Crops Prod. 2023, 203, 117195. [Google Scholar] [CrossRef]

- Wang, M.; Cai, X.; Lu, Y.; Noori, A.; Chen, F.; Chen, L.; Jiang, X. Mechanical behavior and failure modes of bamboo scrimber under quasi-static and dynamic compressive loads. Eng. Fail. Anal. 2023, 146, 107006. [Google Scholar] [CrossRef]

- Guan, S.; Zhao, J.; Dai, L.; Zhang, S.; Zhao, H. Static and dynamic mechanical behaviors of bamboo scrimber under combined tension-bending. Compos. Sci. Technol. 2023, 242, 110191. [Google Scholar] [CrossRef]

- Liu, W.; Hui, C.; Wang, F.; Wang, M.; Liu, G. Review of the Resources and Utilization of Bamboo in China. Bamboo-Curr. Future Prospect. 2018, 16, 133–142. [Google Scholar]

- Yu, J.; Yang, D.; He, Q.; Zhu, X.; Hu, M.; Tao, Y. Flexural performance of innovative bamboo scrimber-concrete composite board. Ind. Crops Prod. 2024, 212, 118353. [Google Scholar] [CrossRef]

- Liu, F.; Li, F.; Li, X.; Tian, H.; Lei, X. Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading. Polymers 2024, 16, 804. [Google Scholar] [CrossRef]

- Schwenke, E.; Morin, D.; Clausen, A.H. Behaviour of two semi-crystalline polymers at a wide range of rates and temperatures. Int. J. Impact Eng. 2025, 202, 105292. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, X.; Guo, F.; Xiao, K.; Zheng, D.; Ma, Y.; Zhao, Q.; Wang, F.; Yang, B. Improved dynamic compressive and electro-thermal properties of hybrid nanocomposite visa physical modification. Nanomaterials 2022, 13, 52. [Google Scholar] [CrossRef]

- Xiao, X.; Ding, M.; Ge, Y.; Wang, X.; Shen, L.; Ran, C. Mechanical Properties and Stress–Strain Relationship of Grade 14.9 Superhigh-Tension Bolt (SHTB) Under Fire. Materials 2025, 18, 1780. [Google Scholar] [CrossRef]

- Kim, Y.B.; Kim, J. Redesign of Split-Hopkinson Tensile bar to eliminate spurious wave and verification of strain signal using FEM. Adv. Mech. Eng. 2023, 15, 16878132231199843. [Google Scholar] [CrossRef]

- Al-Fasih, M.Y.; Hamzah, S.; Ahmad, Y.; Ibrahim, I.S.; Mohd Ariffin, M.A. Tensile properties of bamboo strips and flexural behaviour of the bamboo reinforced concrete beams. Eur. J. Environ. Civ. Eng. 2022, 26, 6444–6460. [Google Scholar] [CrossRef]

- Wang, M.T.; Cai, X.F.; Lu, Y.B.; Noori, A.; Chen, F.M.; Chen, L.B.; Jiang, X.; Liu, J.Q. Tensile mechanical properties and failure mechanism of bamboo scrimber under different strain rates. Constr. Build. Mater. 2021, 299, 124258. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, D.; Fan, S.; Rahman, M.Z.; Guo, S.; Chen, F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: A review. J. Mater. Res. Technol. 2022, 19, 1162–1190. [Google Scholar] [CrossRef]

- Miao, Y.; Du, B.; Ma, C.; Hu, H.; Deng, Q. Some fundamental problems concerning the measurement accuracy of the Hopkinson tension bar technique. Meas. Sci. Technol. 2019, 30, 055009. [Google Scholar] [CrossRef]

- Al-Mousawi, M.M.; Reid, S.R.; Deans, W.F. The use of the split Hopkinson pressure bar techniques in high strain rate materials testing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1997, 211, 273–292. [Google Scholar] [CrossRef]

- Chen, Y.; Clausen, A.H.; Hopperstad, O.S.; Langseth, M. Application of a split-Hopkinson tension bar in a mutual assessment of experimental tests and numerical predictions. Int. J. Impact Eng. 2011, 38, 824–836. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. High-strain-rate tensile mechanical response of a polyurethane elastomeric material. Polymer 2015, 65, 72–80. [Google Scholar] [CrossRef]

- Heimbs, S.; Schmeer, S.; Middendorf, P.; Maier, M. Strain rate effects in phenolic composites and phenolic-impregnated honeycomb structures. Compos. Sci. Technol. 2007, 67, 2827–2837. [Google Scholar] [CrossRef]

- Kidane, A.; Gowtham, H.L.; Naik, N.K. Strain rate effects in polymer matrix composites under shear loading: A critical review. J. Dyn. Behav. Mater. 2017, 3, 110–132. [Google Scholar] [CrossRef]

- Osorio, L.; Trujillo, E.; Lens, F.; Ivens, J.; Verpoest, I.; Van Vuure, A.W. In-depth study of the microstructure of bamboo fibres and their relation to the mechanical properties. J. Reinf. Plast. Compos. 2018, 37, 1099–1113. [Google Scholar] [CrossRef]

- Chen, H.; Yu, Y.; Zhong, T.; Wu, Y.; Li, Y.; Wu, Z.; Fei, B. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers. Cellulose 2017, 24, 333–347. [Google Scholar] [CrossRef]

- Song, J.; Yan, J.; Yi, B.; Gong, W.; Du, Z.; Liu, T.; Liang, D.; Xie, C.; Pu, Z. Bamboo-inspired hierarchical microlattice structures (BHMSs) for high strength and energy absorption. Mech. Adv. Mater. Struct. 2024, 31, 7991–8003. [Google Scholar] [CrossRef]

- Wegst, U.G.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef]

- Talreja, R. Assessment of the fundamentals of failure theories for composite materials. Compos. Sci. Technol. 2014, 105, 190–201. [Google Scholar] [CrossRef]

| Bamboo Fiber Bundle | Ultimate Tensile Strength (MPa) | |||

|---|---|---|---|---|

| Strain rate | 0.002/s | 300/s | 700/s | 1500/s |

| 31.66 ± 1.74 | 65.67 ± 3.91 | 84.57 ± 4.53 | 99.71 ± 1.43 | |

| Bamboo Scrimber | Ultimate Tensile Strength (MPa) | |||

| Strain rate | 0.002/s | 350/s | 950/s | 1700/s |

| 131.33 ± 2.82 | 169.67 ± 3.11 | 206.16 ± 10.73 | 131.33 ± 2.82 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Xia, H.; Xu, L.; Zhou, S.; Gao, L.; Zuo, G.; Zhang, X.; Li, Q. Tensile Behavior and Failure Mechanism of Bamboo Fiber Bundle and Its Scrimber Under Different Strain Rates. Materials 2025, 18, 2550. https://doi.org/10.3390/ma18112550

Zhang K, Xia H, Xu L, Zhou S, Gao L, Zuo G, Zhang X, Li Q. Tensile Behavior and Failure Mechanism of Bamboo Fiber Bundle and Its Scrimber Under Different Strain Rates. Materials. 2025; 18(11):2550. https://doi.org/10.3390/ma18112550

Chicago/Turabian StyleZhang, Kai, Haoran Xia, Lizhi Xu, Shengbo Zhou, Li Gao, Gong Zuo, Xiaotao Zhang, and Quan Li. 2025. "Tensile Behavior and Failure Mechanism of Bamboo Fiber Bundle and Its Scrimber Under Different Strain Rates" Materials 18, no. 11: 2550. https://doi.org/10.3390/ma18112550

APA StyleZhang, K., Xia, H., Xu, L., Zhou, S., Gao, L., Zuo, G., Zhang, X., & Li, Q. (2025). Tensile Behavior and Failure Mechanism of Bamboo Fiber Bundle and Its Scrimber Under Different Strain Rates. Materials, 18(11), 2550. https://doi.org/10.3390/ma18112550