Effects of Process Parameters on Forming Quality and Microstructure of FeCrAl-ODS Alloy Fabricated by Selective Laser Melting

Abstract

1. Introduction

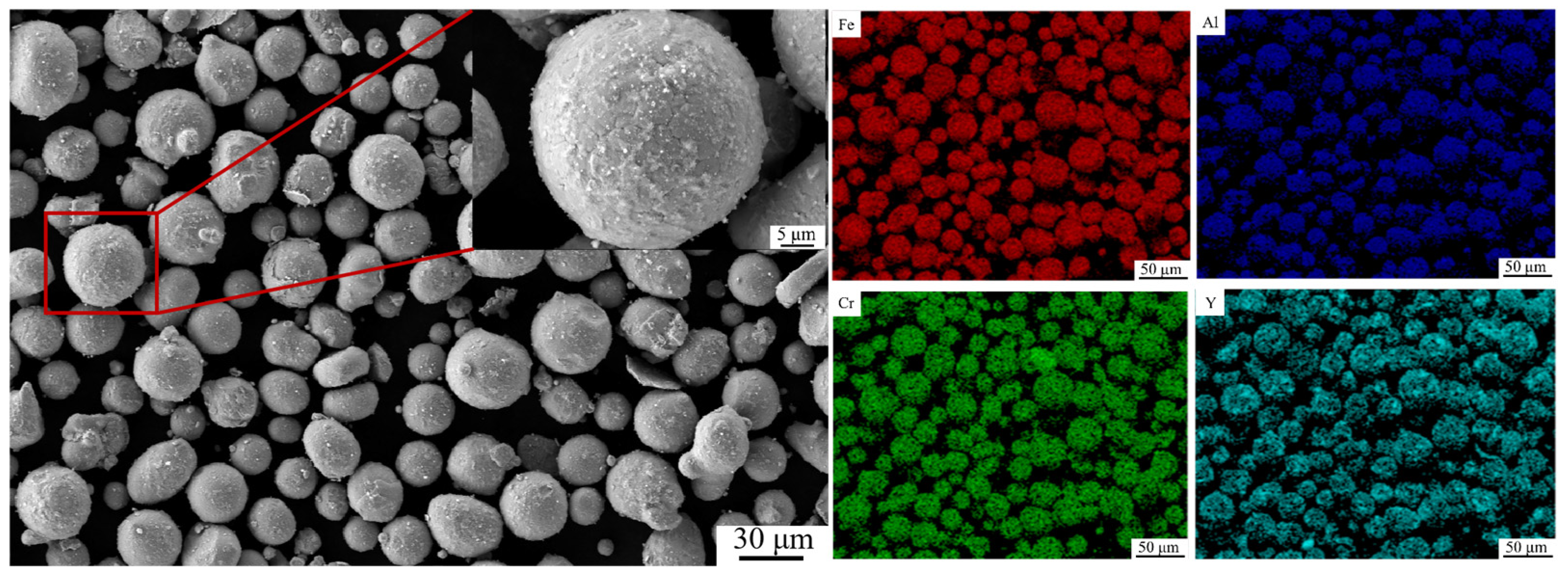

2. Experimental Methods

3. Results and Discussion

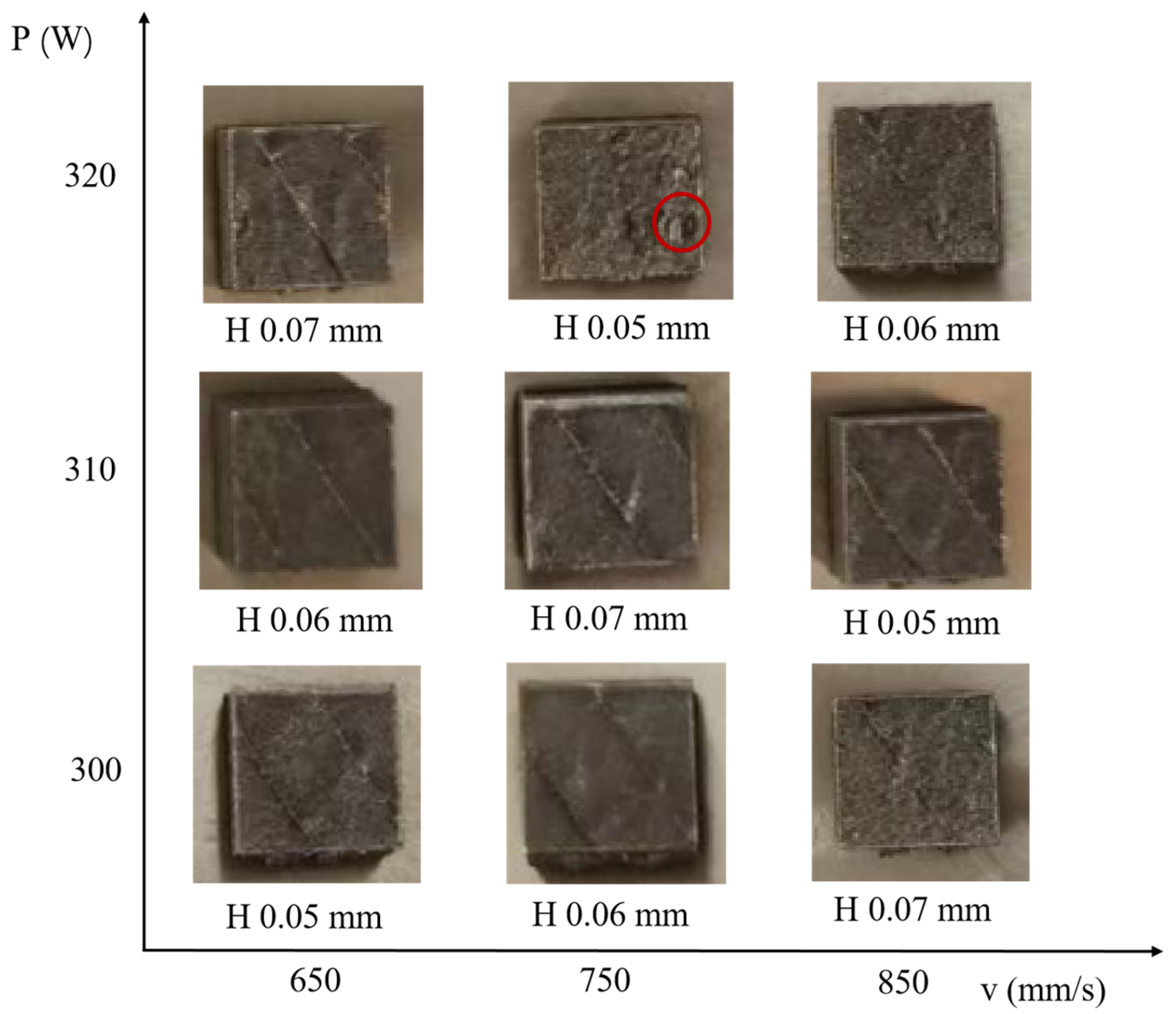

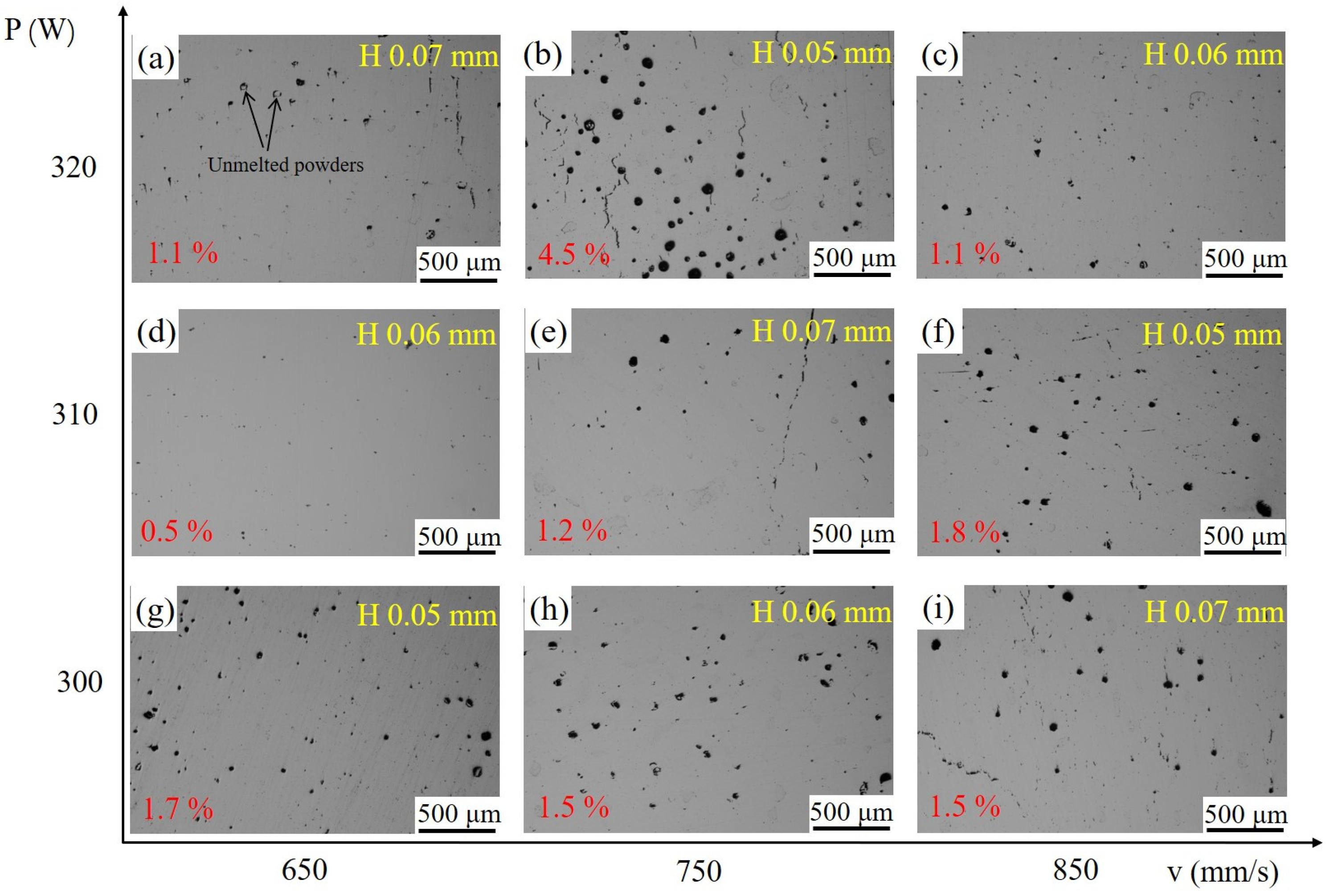

3.1. Effect of Process Parameters on the Forming Quality

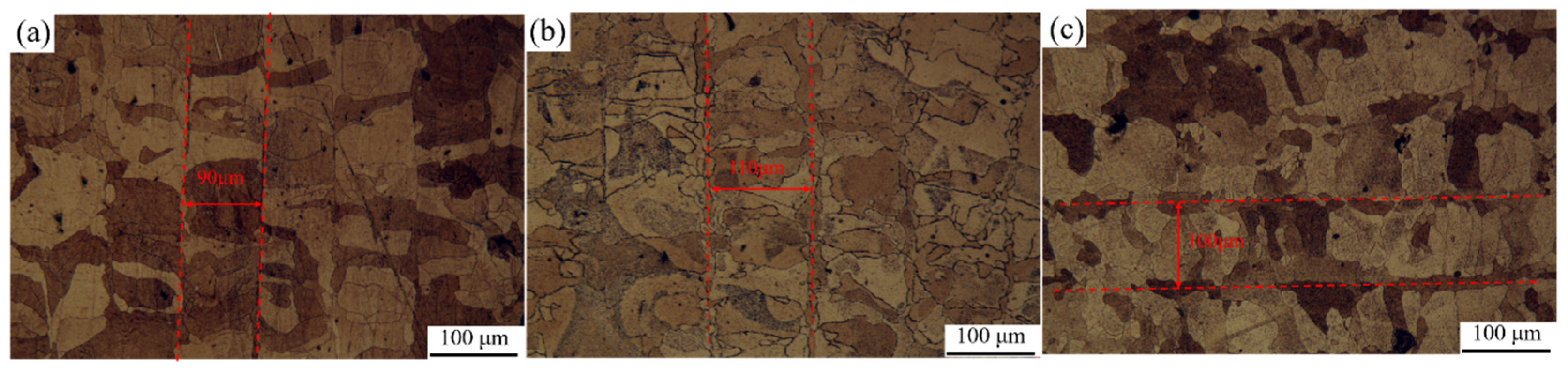

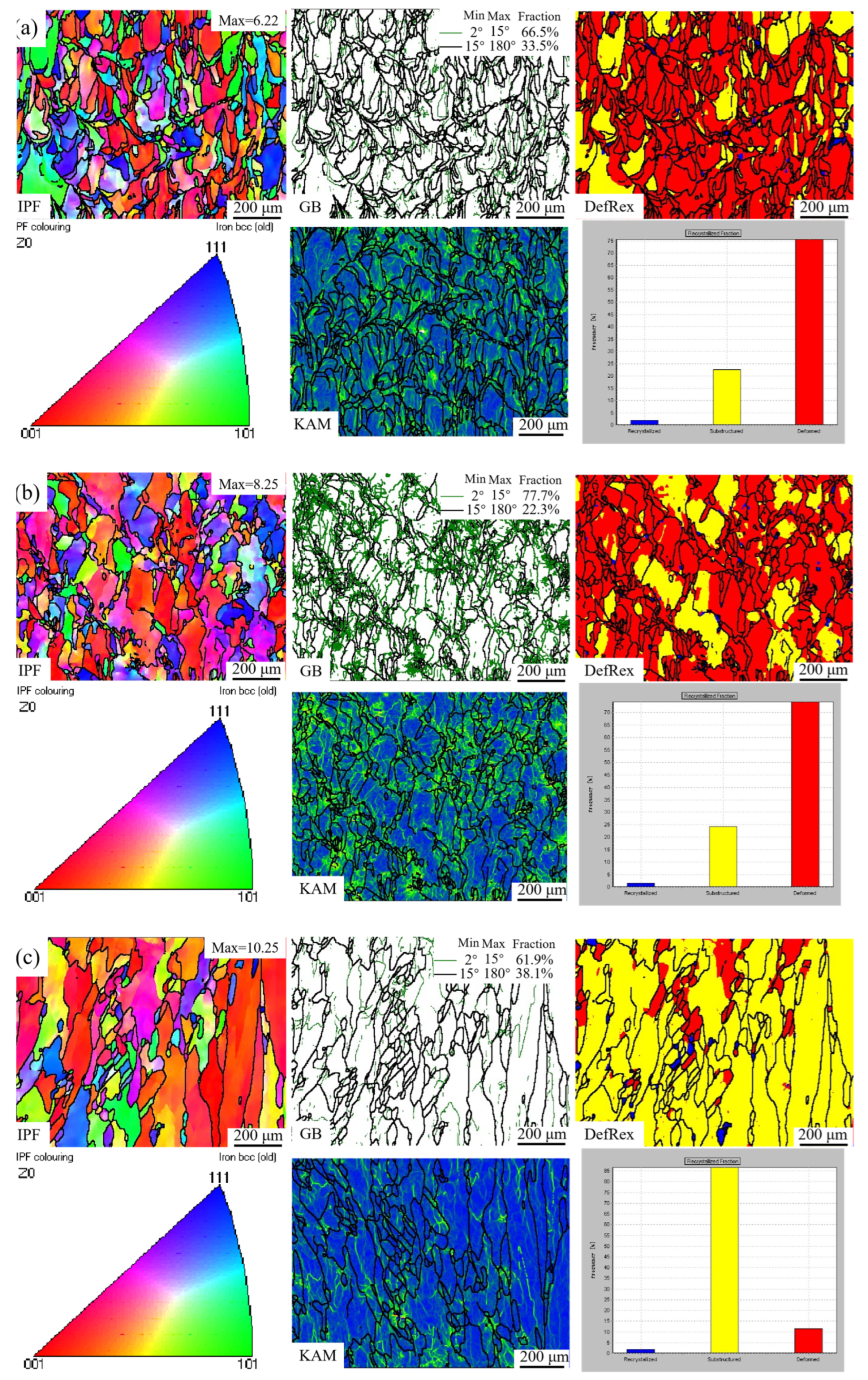

3.2. Effect of Process Parameters on the Evolution of Microstructure

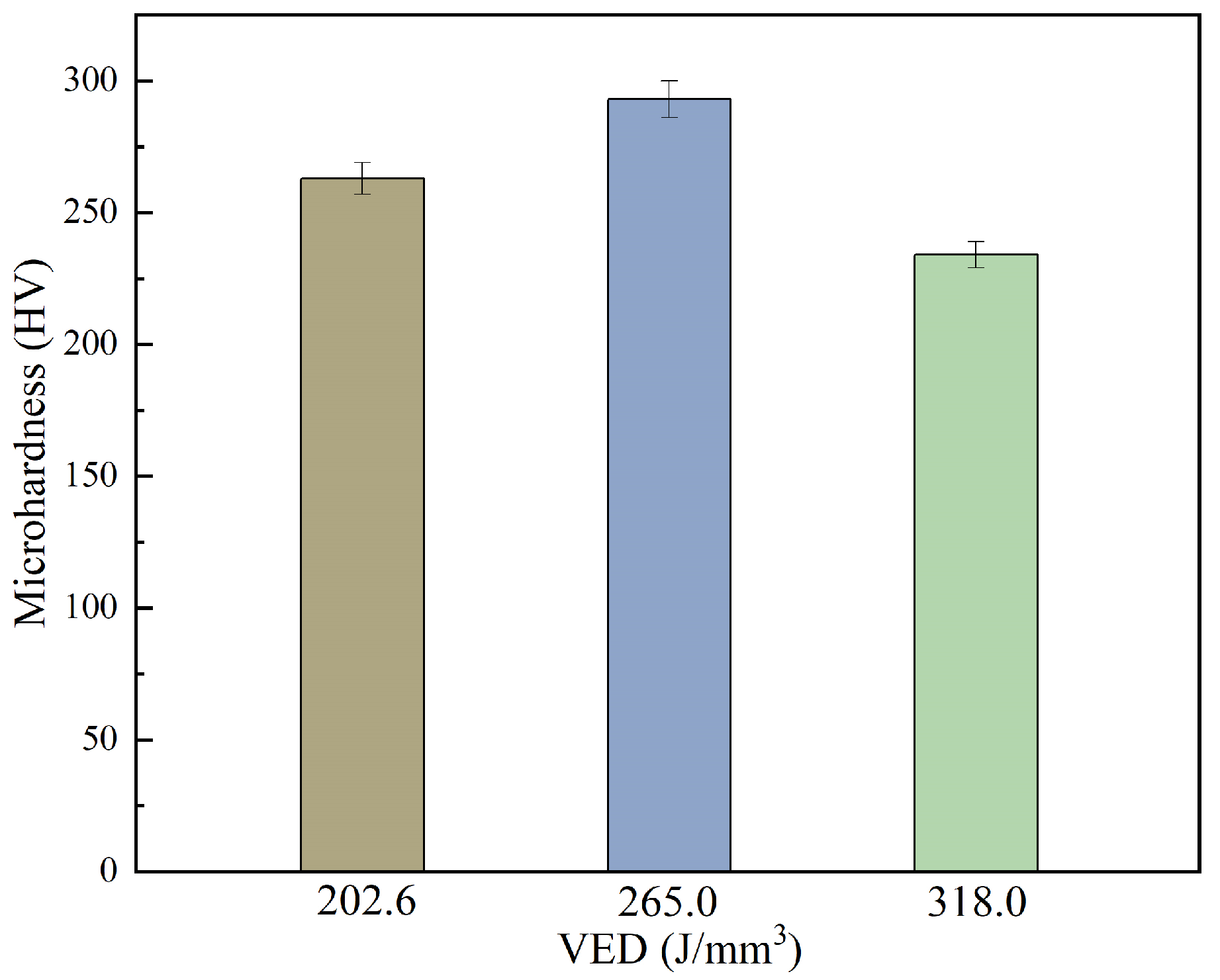

3.3. Effect of VED on the Hardness of FeCrAl-ODS Alloys

4. Conclusions

- (1)

- Optimization of forming quality—Hatch spacing critically influenced defect distribution. At 0.06 mm, overlapping melt tracks minimized cracks and pores, whereas excessive laser power (320 W) or VED (318.0 J/mm3) caused surface pits due to element evaporation from overheating. The scanning speed has a relatively minor impact on forming quality;

- (2)

- Microstructural regulation—VED significantly affected grain structure and texture. At 265.0 J/mm3, nano-sized Y2O3 particles inhibited grain coarsening via pinning effects, forming fine grains with a high fraction of LAGBs and achieving a peak hardness of 293 HV. Conversely, excessive VED (318.0 J/mm3) induced abnormal grain growth and released internal stress, reducing hardness to 230 HV. A moderate VED is conducive to control microstructure evolution;

- (3)

- Optimal parameters—The combination of 310 W laser power, 650 mm/s scanning speed, and 0.06 mm hatch spacing (VED 265.0 J/mm3) balanced forming quality and mechanical performance, laying a foundation for engineering applications of FeCrAl-ODS alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ukai, S.; Sakamoto, K.; Ohtsuka, S.; Yamashita, S.; Kimura, A. Alloy design and characterization of a recrystallized FeCrAl-ODS cladding for accident-tolerant BWR fuels: An overview of research activity in Japan. J. Nucl. Mater. 2023, 583, 154508. [Google Scholar] [CrossRef]

- Ukai, S.; Fujiwara, M. Perspective of ODS alloys application in nuclear environments. J. Nucl. Mater. 2002, 307, 749–757. [Google Scholar] [CrossRef]

- Chung, S.; Lee, T.; Jeong, W.; Kong, B.S.; Ryu, H.J. Additive manufacturing of oxide dispersion-strengthened CoCrNi medium-entropy alloy by in situ oxide synthesis. J. Alloys Compd. 2023, 965, 171340. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals: Physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Leng, B.; Ukai, S.; Sugino, Y.; Tang, Q.; Narita, T.; Hayashi, S.; Wan, F.; Ohtsuka, S.; Kaito, T. Recrystallization texture of cold-rolled oxide dispersion strengthened ferritic steel. ISIJ Int. 2011, 51, 951–957. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Xu, B.; Zhang, J.; Sun, M.; Li, D. Research progress on preparation technology of oxide dispersion strengthened steel for nuclear energy. Int. J. Extrem. Manuf. 2021, 3, 032001. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Zou, J.; Li, X.; Cui, D.; Shen, Z. Oxide dispersion strengthened stainless steel 316L with superior strength and ductility by selective laser melting. J. Mater. Sci. Technol. 2020, 42, 97–105. [Google Scholar] [CrossRef]

- Song, Q.S.; Zhang, Y.; Wei, Y.F.; Zhou, X.Y.; Shen, Y.F.; Zhou, Y.M.; Feng, X.M. Microstructure and mechanical performance of ODS superalloys manufactured by selective laser melting. Opt. Laser Technol. 2021, 144, 107423. [Google Scholar] [CrossRef]

- Doñate-Buendia, C.; Kürnsteiner, P.; Stern, F.; Wilms, M.B.; Streubel, R.; Kusoglu, I.M.; Tenkamp, J.; Bruder, E.; Pirch, N.; Barcikowski, S.; et al. Microstructure formation and mechanical properties of ODS steels built by laser additive manufacturing of nanoparticle coated iron-chromium powders. Acta Mater. 2021, 206, 116566. [Google Scholar] [CrossRef]

- Autones, L.; Aubry, P.; Ribis, J.; Leguy, H.; Legris, A.; de Carlan, Y. Assessment of ferritic ODS steels obtained by laser additive manufacturing. Materials 2023, 16, 2397. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, F.; Wang, Y.; Li, Z.; Zhang, S.; Kuo, Y.L.; Bai, P.; Liu, B. Study on forming process and microstructure of FeCrAl-ODS alloy by selective laser melting. J. Mater. Res. Technol. 2025, 35, 1369–1376. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.P.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Li, F.; Wang, Y.; Li, Z.; Chen, Y.; Wang, L.; Liu, B.; Bai, P. Study on defects of Zr-containing Al-Cu-Mn-Mg alloys manufactured by selective laser melting. J. Mater. Res. Technol. 2024, 29, 119–129. [Google Scholar] [CrossRef]

- Yang, W.; Gan, X.; He, J. Defect Identification of 316L Stainless Steel in Selective Laser Melting Process Based on Deep Learning. Processes 2024, 12, 1054. [Google Scholar] [CrossRef]

- Fardan, A.; Fazi, A.; Peng, R.L.; Mishurova, T.; Thuvander, M.; Bruno, G.; Brodin, H.; Hryha, E. Fine-Tuning Melt Pools and Microstructures: Taming Cracks in Powder Bed Fusion—Laser Beam of a non-weldable Ni-base Superalloy. Materialia 2024, 34, 102059. [Google Scholar] [CrossRef]

- Liu, S.; Lee, M.; Choi, C.; Shin, K. Effect of additive manufacturing of SUS316L using selective laser melting. J. Mater. Res. Technol. 2023, 24, 9824–9833. [Google Scholar] [CrossRef]

- Li, A.; Chen, Q.; Mao, J.; Wu, X.; Xin, H.; Fang, Z.; Teng, C.; Wu, L.; Tang, J. Laser powder bed fusion of oxide dispersion strengthened FeCrAl alloy: Processing and microstructural evolution. Mater. Charact. 2024, 208, 113590. [Google Scholar] [CrossRef]

- Greco, S.; Gutzeit, K.; Hotz, H.; Kirsch, B.; Aurich, J.C. Selective laser melting (SLM) of AISI 316L—Impact of laser power, layer thickness, and hatch spacing on roughness, density, and microhardness at constant input energy density. Int. J. Adv. Manuf. Technol. 2020, 108, 1551–1562. [Google Scholar] [CrossRef]

- Zhang, S.H.; Ukai, S.; Nishikawa, T.; Aghamiri, S.M.S.; Oono, N.; Hayashi, S. Development and characterization of g/a transformable FeCrAl-ODS alloys by cobalt addition. J. Alloys Compd. 2019, 797, 390–398. [Google Scholar] [CrossRef]

- Zhang, S.; Ukai, S.; Aghamiri, S.M.S.; Oono, N.; Hayashi, S. Tensile properties of Co-added FeCrAl oxide dispersion strengthened alloy. J. Alloys Compd. 2021, 852, 156956. [Google Scholar] [CrossRef]

| Sample ID | P (W) | v (mm/s) | H (mm) | VED (J/mm3) |

|---|---|---|---|---|

| 1 | 300 | 650 | 0.05 | 307.7 |

| 2 | 300 | 750 | 0.06 | 222.2 |

| 3 | 300 | 850 | 0.07 | 168.1 |

| 4 | 310 | 650 | 0.06 | 265.0 |

| 5 | 310 | 750 | 0.07 | 196.8 |

| 6 | 310 | 850 | 0.05 | 243.1 |

| 7 | 320 | 650 | 0.07 | 234.4 |

| 8 | 320 | 750 | 0.05 | 284.4 |

| 9 | 320 | 850 | 0.06 | 209.2 |

| Sample ID | P (W) | v (mm/s) | H (mm) | VED (J/mm3) |

|---|---|---|---|---|

| 1 | 310 | 850 | 0.06 | 202.6 |

| 2 | 310 | 650 | 0.06 | 265.0 |

| 3 | 310 | 650 | 0.05 | 318.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Li, F.; Wang, Y.; Su, H.; Li, J. Effects of Process Parameters on Forming Quality and Microstructure of FeCrAl-ODS Alloy Fabricated by Selective Laser Melting. Materials 2025, 18, 2462. https://doi.org/10.3390/ma18112462

Zhang S, Li F, Wang Y, Su H, Li J. Effects of Process Parameters on Forming Quality and Microstructure of FeCrAl-ODS Alloy Fabricated by Selective Laser Melting. Materials. 2025; 18(11):2462. https://doi.org/10.3390/ma18112462

Chicago/Turabian StyleZhang, Shenghua, Fudong Li, Yu Wang, Hongwen Su, and Jun Li. 2025. "Effects of Process Parameters on Forming Quality and Microstructure of FeCrAl-ODS Alloy Fabricated by Selective Laser Melting" Materials 18, no. 11: 2462. https://doi.org/10.3390/ma18112462

APA StyleZhang, S., Li, F., Wang, Y., Su, H., & Li, J. (2025). Effects of Process Parameters on Forming Quality and Microstructure of FeCrAl-ODS Alloy Fabricated by Selective Laser Melting. Materials, 18(11), 2462. https://doi.org/10.3390/ma18112462