Influence of Grinding Parameters on Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystal

Abstract

1. Introduction

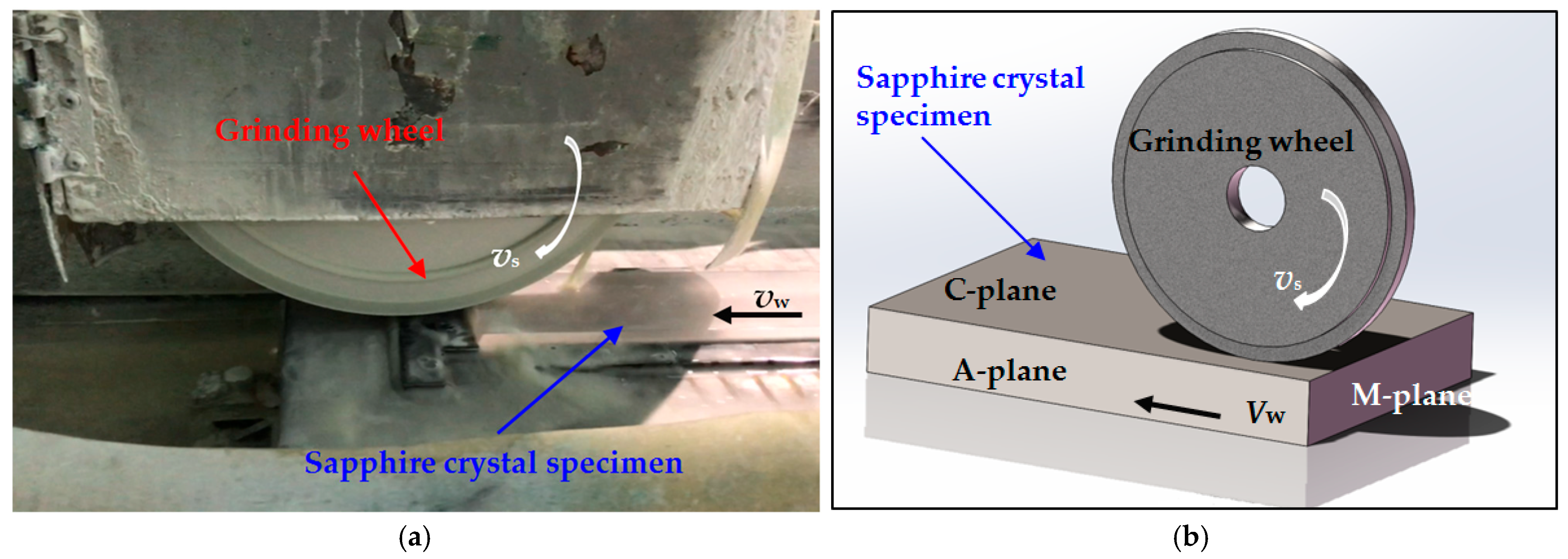

2. Materials and Methods

2.1. Experimental Material and Equipment

2.2. Experimental Design

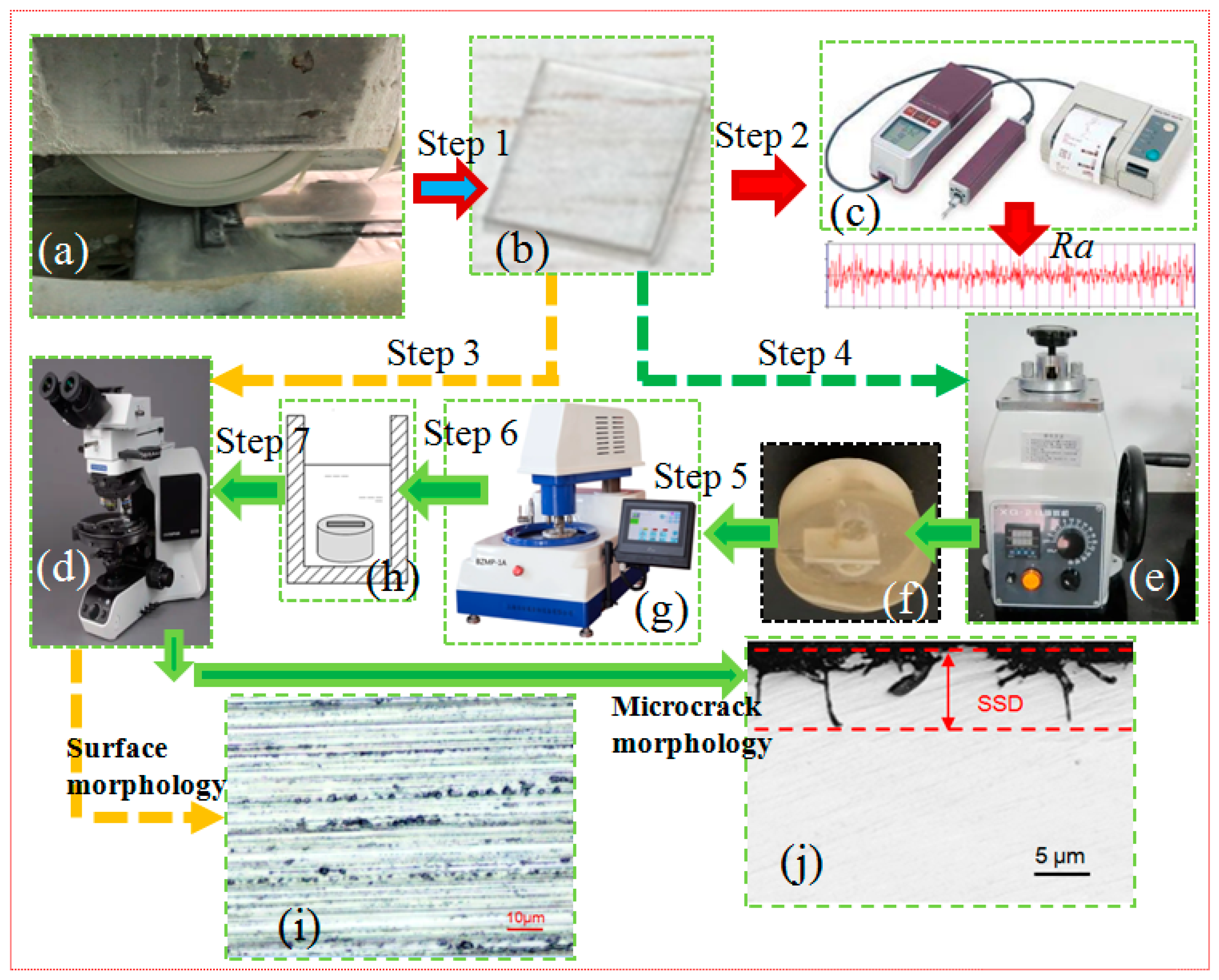

2.3. Evaluation of Ra and SSD of Ground Sapphire Crystal

3. Results and Discussion

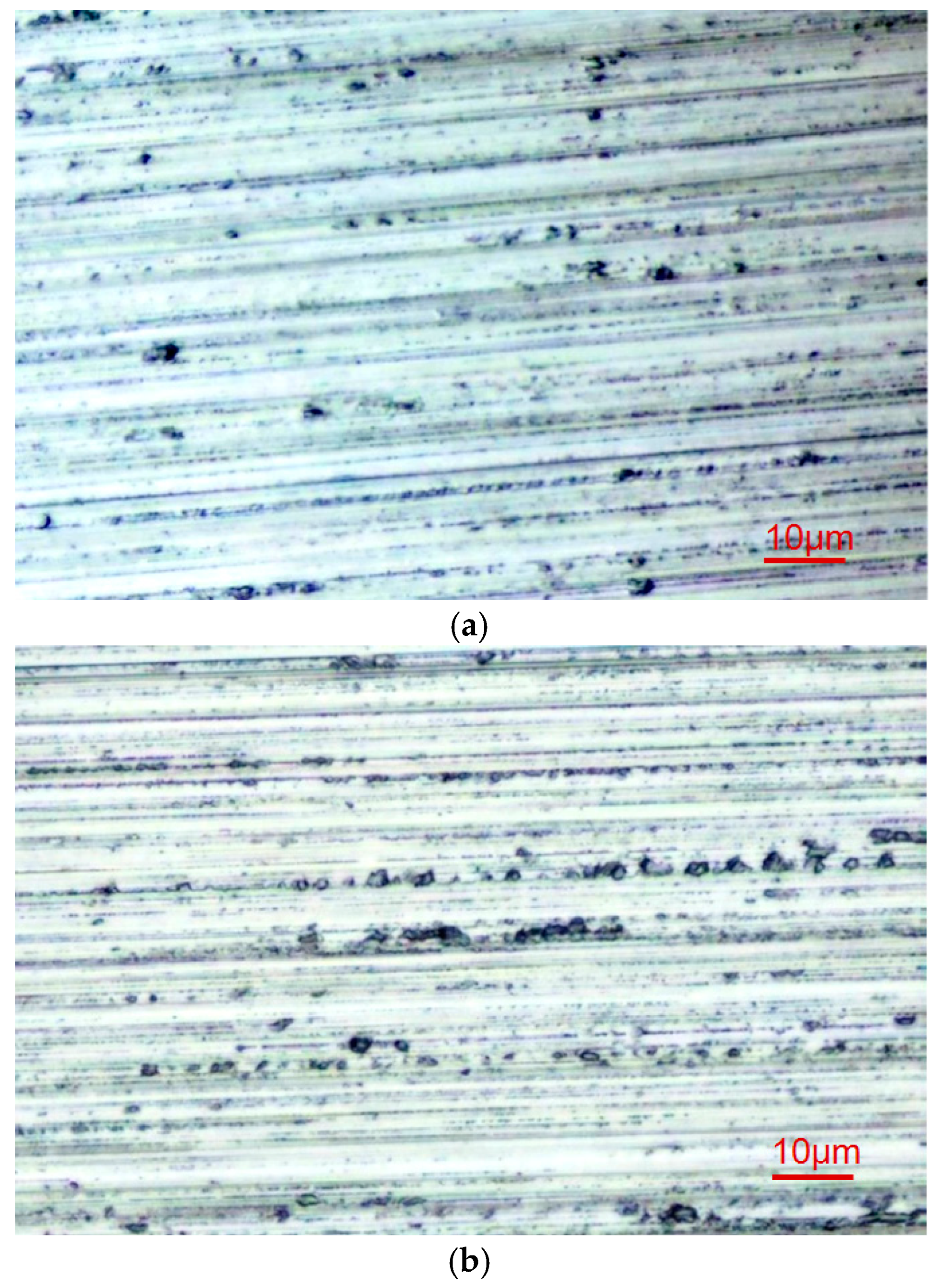

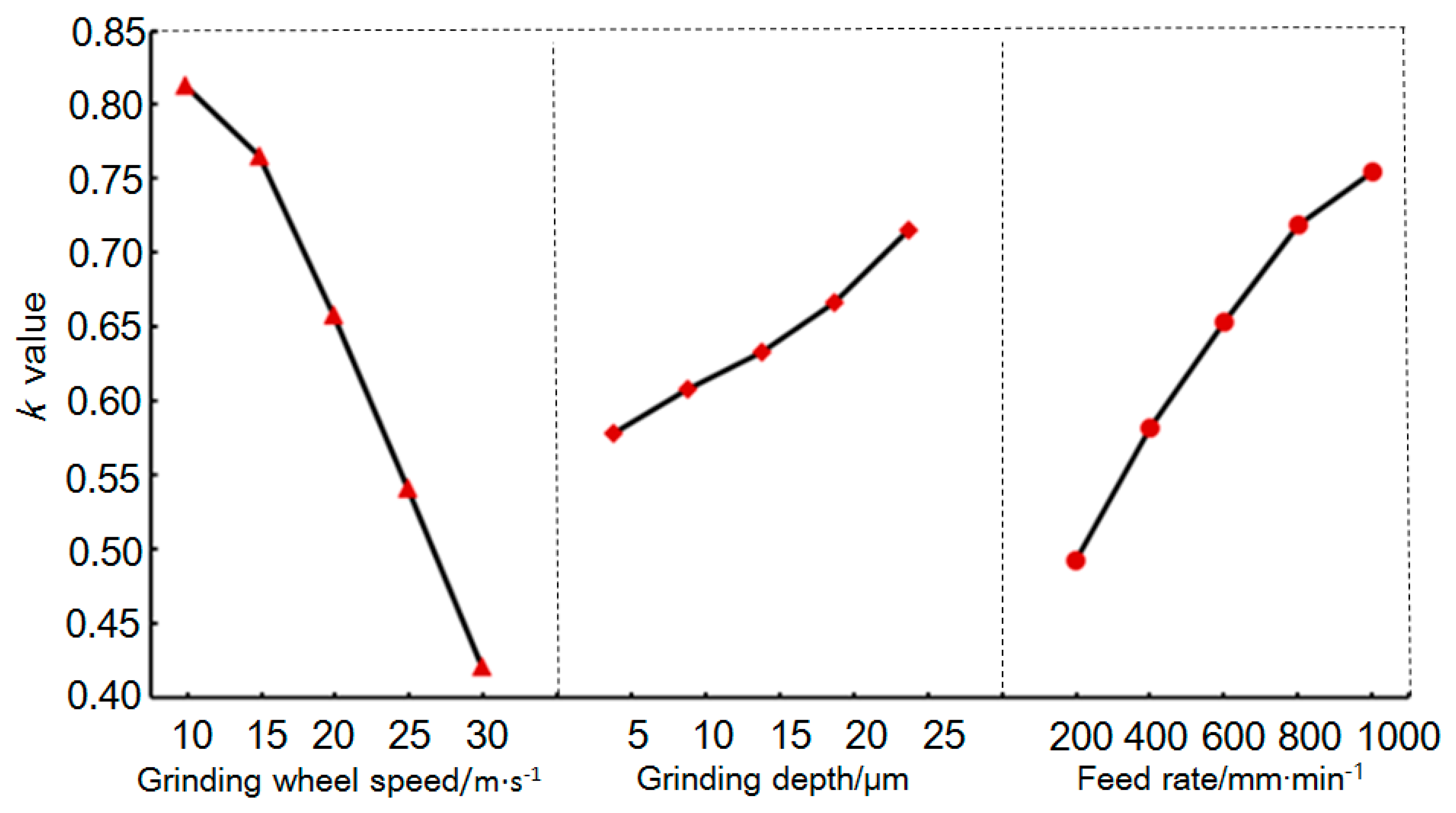

3.1. Effect of Grinding Parameters on Surface Roughness

3.2. Effect of Grinding Parameters on SSD

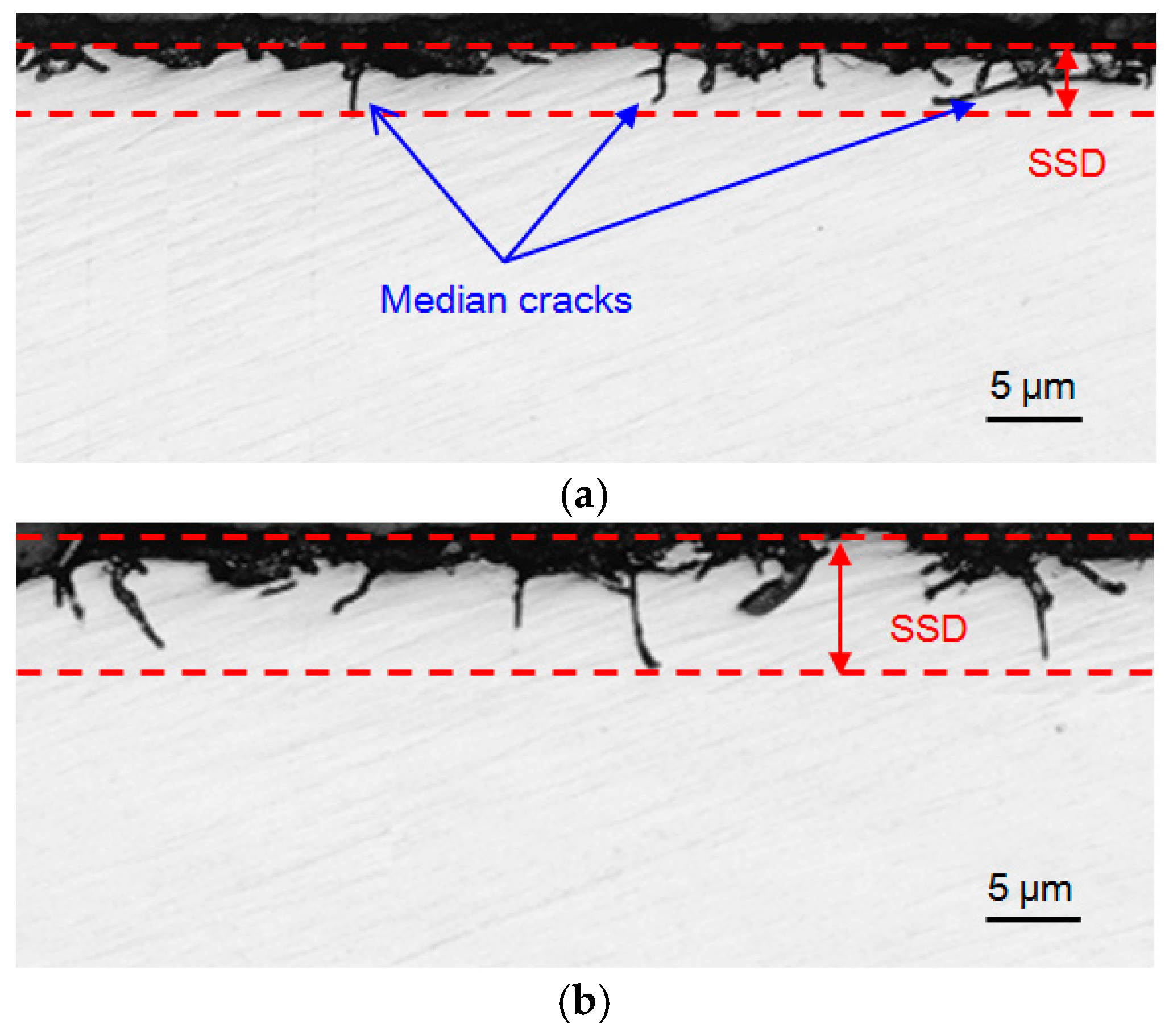

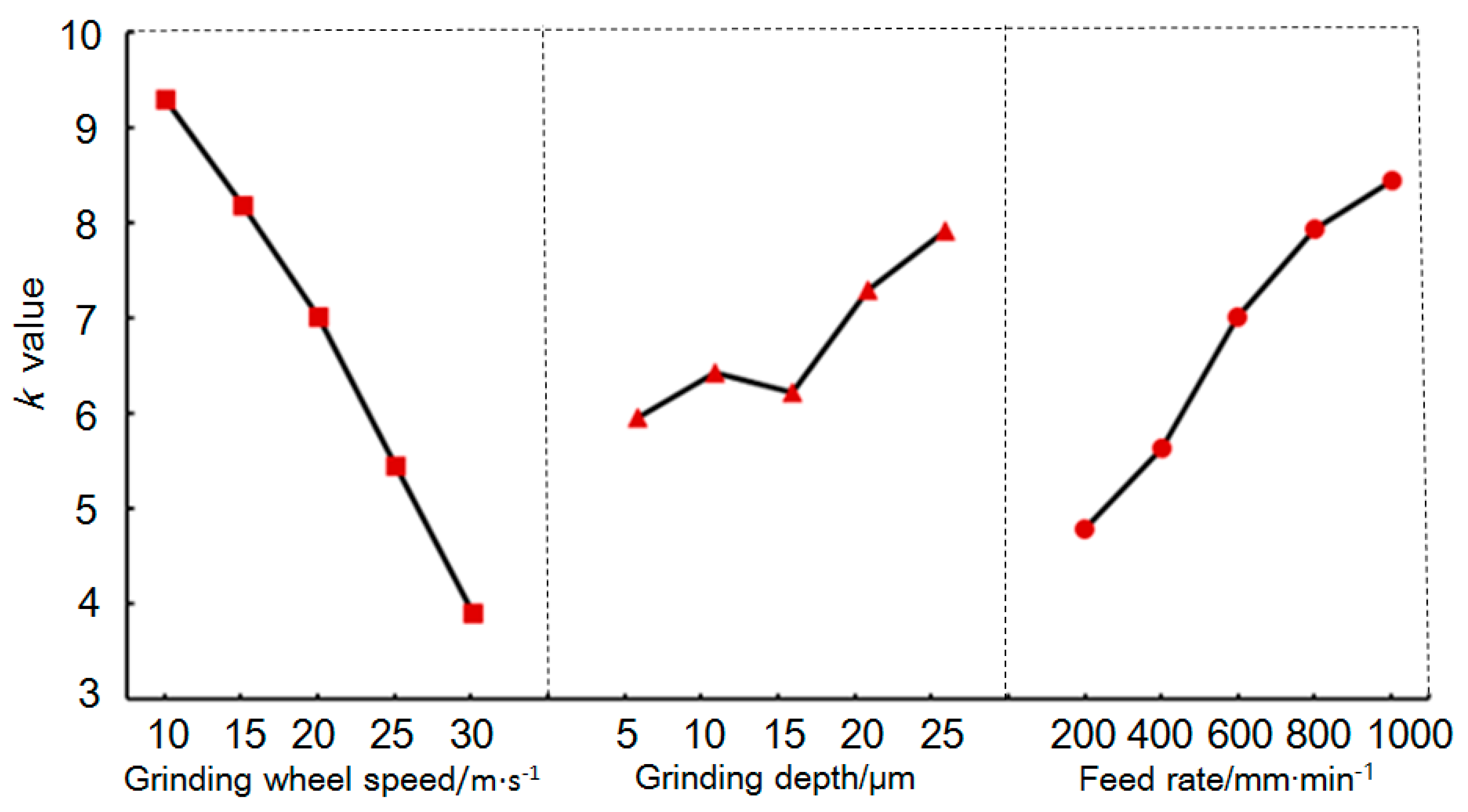

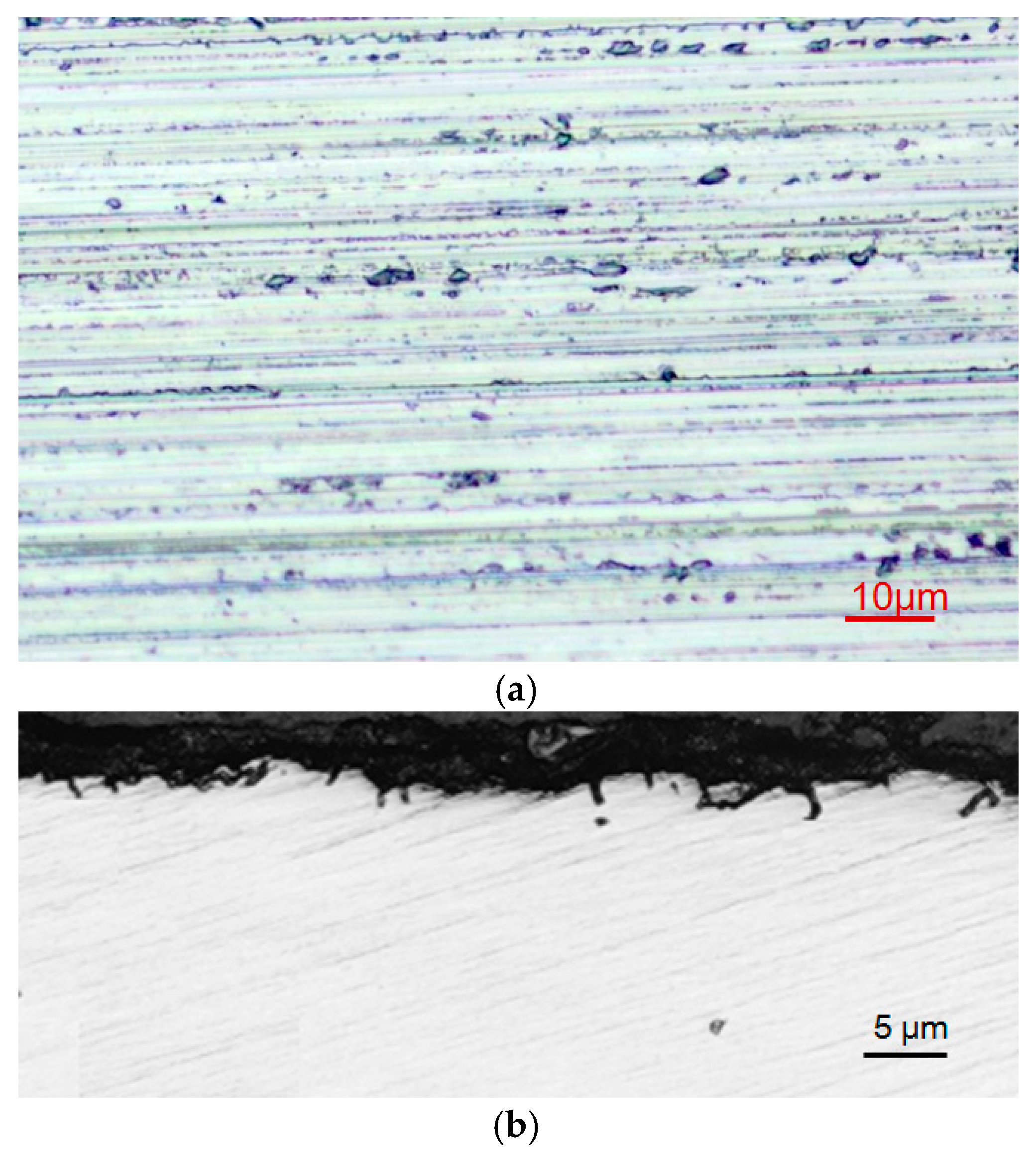

3.3. Results of Grinding Experiment Using Optimal Process Parameter Combination

4. Conclusions

- (1)

- Within the range of the process parameters used in this experiment, the grinding process did not achieve the full ductile removal of the material. Some material was removed in a brittle mode, forming fractured pits on the ground surface, and median crack propagation occurred in the subsurface, forming a subsurface microcrack damage layer. The grinding parameters showed a consistent trend regarding their impact on the surface roughness Ra and subsurface microcrack damage depth, which was that the parameter with the greatest impact was the grinding wheel speed, followed by the feed rate and grinding depth.

- (2)

- The values of the Ra and SSD improved with an increase in the grinding wheel speed and a decrease in the grinding depth and feed rate. The Ra and SSD obtained under the optimized grinding parameter combination were 0.326 μm and 2.86 μm, respectively.

- (3)

- The regression equations for the Ra and SSD values established based on the experimental data were Ra = 0457vs−0.582ap0.114vw0.272 and SSD = 3.808 vs−0.756ap0.148vw0.372, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tithy, F.; Hussain, S. Comprehensive Study of Group III-Nitride Light Emitting Diode Structures Based On Sapphire And Scalmgo4 (0001) Substrate For High Intensity Green Emission. Semicond. Phys. Quant. 2023, 26, 215–221. [Google Scholar] [CrossRef]

- Lang, L.; Saltarelli, F.; Lacaille, G.; Rowan, S.; Hough, J.; Graumann, I.; Phillips, C.; Keller, U. Silicate Bonding Of Sapphire to SESAMs: Adjustable Thermal Lensing for High-Power Lasers. Opt. Express 2021, 29, 18059–18069. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Mondal, A.; Sharma, S.; Bag, A. Unveiling Thermal Effects on Sn-Doped β-Ga2O3 Schottky Barrier Diodes on Sapphire for High-Temperature Power Electronics. IEEE Trans. Electron Devices 2024, 71, 1529–1534. [Google Scholar] [CrossRef]

- Zhao, N.; Lin, Q.; Zhu, L.; Li, C.; Zhang, Z.; Yao, K.; Chen, Y.; Tian, B.; Yang, P.; Jiang, Z. Development of Sapphire Optical Temperature Sensing System Used in Harsh Environment Sensing. IEEE Trans. Instrum. Meas. 2022, 71, 9506710. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, H.; Wang, L.; Liao, X. Experimental Study on Normal Force of Cutting Sapphire with Multi-Wire Swing Reciprocating Wire Saw. Diam. Abras. Eng. 2024, 44, 143–150. [Google Scholar] [CrossRef]

- Lai, Z.; Liao, X.; Yang, H.; Hu, Z.; Huang, H. Experimental Study on the Formation Mechanism of Saw Marks in Wire Sawing. Int. J. Mech. Sci. 2024, 265, 108894. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, Y.; Shi, Z.; Zhang, X. Study on Surface Characteristics Of As-Sawn Sapphire Crystal Wafer Considering Diamond Saw Wire Wear. Wear 2023, 530, 205037. [Google Scholar] [CrossRef]

- Gupta, A.; Chen, C.; Hsu, H. Study on Diamond Wire Wear, Surface Quality, and Subsurface Damage during Multi-Wire Slicing of C-Plane Sapphire Wafer. Int. J. Adv. Manuf. Technol. 2019, 100, 1801–1814. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, Y.; Zhang, X. Study on Subsurface Microcrack Damage Depth of Diamond Wire as-Sawn Sapphire Crystal Wafers. Eng. Fract. Mech. 2023, 28, 109347. [Google Scholar] [CrossRef]

- Wang, S.; Tie, G.; Shi, F.; Tian, Y.; Yang, X. Effect of Different Grinding Strategies on Subsequent Polishing Processes of Sapphire. J. Manuf. Process. 2024, 112, 339–357. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, J.; Zhan, H.; Fu, B.; Zhan, Y.; Zheng, T. Performance of Thermal Field-assisted Precision Lapping for Single Crystal Sapphire Wafers. Diam. Abras. Eng. 2023, 43, 649–656. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Liang, Z.; Su, Y.; Xu, Z.; Guo, R.; Wang, B. Research on Sapphire Surface MicroStructure Processed by Diamond Grinding Wheel. New Technol. New Process 2018, 3, 68–72. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.; Yang, X. Surface and Subsurface Microscopic Characteristics in Sapphire Ultra-precision Grinding. Tribol. Int. 2022, 174, 107710. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, W.; Bao, X.; Zhao, Q. Anisotropy Monitoring of Ultra-precision Grinding Force and Acoustic Emission Signal of Monocrystalline Sapphire. Measurement 2025, 247, 116835. [Google Scholar] [CrossRef]

- Hu, Z.; Shao, M.; Guo, J.; Huang, S.; Xu, X. Comparison of Grinding Characteristics of Different Crystal Surfaces for Sapphire. Opt. Precis. Eng. 2017, 25, 1250–1258. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, T.; Wu, J.; Jin, Y. Experimental Study on “Ductile-brittle” Transition in Micro-grinding of Single Crystal Sapphire. Int. J. Adv. Manuf. Technol. 2018, 98, 3229–3249. [Google Scholar] [CrossRef]

- Wang, Q.; Liang, Z.; Wang, X.; Zhao, W.; Wu, Y.; Zhou, T. Fractal Analysis of Surface Topography in Ground Monocrystal Sapphire. Appl. Surf. Sci. 2015, 327, 182–189. [Google Scholar] [CrossRef]

- Zhou, F.; Xu, J.; Zhang, W.; Yu, H. Research on Quality of Bottom Surface of Sapphire Micro-grooves Ground by Structured Grinding Wheels. J. Hunan Univ. Nat. Sci. 2024, 51, 20–26. [Google Scholar] [CrossRef]

- Zhou, F.; Xu, J.; Zhang, Y.; Zhang, W.; Zhao, B.; Yu, H. Numerical simulation and experimental study of micro-structured surface of sapphire ground by structured grinding wheel. Precis. Eng. 2024, 86, 82–100. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.; Zhao, Q.; Zhou, M. Investigate on Surface/Subsurface Damage Mechanisms and Manufacturability of Ultra-smooth Surface in Ultra-precision Ductile Grinding of Sapphire Optics. J. Mater. Res. Technol. 2025, 34, 1966–1989. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, W.; Wang, J.; Ding, J.; Wang, B.; Shi, F. Research on Subsurface Damage Mechanism and Suppression Method of Ultrasonic Vibration-assisted Grinding of Sapphire Components under Extreme Service Environment. Int. J. Adv. Manuf. Technol. 2024, 135, 2215–2242. [Google Scholar] [CrossRef]

- Xiao, H.; Yin, S.; Zhou, P.; Wu, H. Prediction of Grinding Parameters Based on Specific Surface Integrity of Hard-brittle Materials. J. Manual. Process. 2025, 134, 659–679. [Google Scholar] [CrossRef]

- Wasmer, K.; Pochon, P.; Sage, D.; Giovanola, J. Parametric Experimental Study and Design of Experiment Modelling of Sapphire Grinding. J. Clean. Prod. 2017, 141, 323–335. [Google Scholar] [CrossRef]

- Peng, C.; Li, G.; Zhang, X.; Gao, Y. Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet. Materials 2025, 18, 1173. [Google Scholar] [CrossRef]

- Hasçelik, A.; Aslantas, K.; Yalçın, B. Optimization of Cutting Parameters to Minimize Wall Deformation in Micro-Milling of Thin-Wall Geometries. Micromachines 2025, 16, 310. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Wang, T.; Hu, S.; Yao, T.; Miao, R.; Kang, Q.; Zhang, Y. Parameter Optimization of Laser Based on Orthogonal Experiment and Response Surface Method. Laser Optoelectron. Prog. 2022, 59, 1114004. [Google Scholar] [CrossRef]

- Li, S.; Wang, Z.; Wu, Y. Relationship between Subsurface Damage and Surface Roughness of Optical Materials in Grinding and Lapping Processes. J. Mater. Process. Technol. 2008, 205, 34–41. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, Y.; Shi, Z. Relationship between Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystals Cut by Diamond Wire Saw Based on Slicing Experiments. Int. J. Adv. Manuf. Technol. 2024, 134, 5907–5916. [Google Scholar] [CrossRef]

- Wang, K.; Gao, Y.; Yang, C. Prediction of Subsurface Microcrack Damage Depth Based on Surface Roughness in Diamond Wire Sawing of Monocrystalline Silicon. Materials 2024, 17, 553. [Google Scholar] [CrossRef]

| Levels | Factors | ||

|---|---|---|---|

| (A) Grinding Wheel Speed (vs) /m·s−1 | (B) Grinding Depth (ap) /μm | (C) Feed Rate (vw) /mm·min−1 | |

| 1 | 30 (A1) | 25 (B1) | 200 (C1) |

| 2 | 25 (A2) | 20 (B2) | 400 (C2) |

| 3 | 20 (A3) | 15 (B3) | 600 (C3) |

| 4 | 15 (A4) | 10 (B4) | 800 (C4) |

| 5 | 10 (A5) | 5 (B5) | 1000 (C5) |

| No. | Parameter Combinations | No. | Parameter Combinations | ||||

|---|---|---|---|---|---|---|---|

| 1 | A1 | B1 | C1 | 14 | A3 | B4 | C5 |

| 2 | A1 | B2 | C3 | 15 | A3 | B5 | C2 |

| 3 | A1 | B3 | C5 | 16 | A4 | B1 | C3 |

| 4 | A1 | B4 | C2 | 17 | A4 | B2 | C5 |

| 5 | A1 | B5 | C4 | 18 | A4 | B3 | C2 |

| 6 | A2 | B1 | C5 | 19 | A4 | B4 | C4 |

| 7 | A2 | B2 | C2 | 20 | A4 | B5 | C1 |

| 8 | A2 | B3 | C4 | 21 | A5 | B1 | C2 |

| 9 | A2 | B4 | C1 | 22 | A5 | B2 | C4 |

| 10 | A2 | B5 | C3 | 23 | A5 | B3 | C1 |

| 11 | A3 | B1 | C4 | 24 | A5 | B4 | C3 |

| 12 | A3 | B2 | C1 | 25 | A5 | B5 | C5 |

| 13 | A3 | B3 | C3 | ||||

| No. | Ra (μm) | No. | Ra (μm) | No. | Ra (μm) |

|---|---|---|---|---|---|

| 1 | 0.354 | 10 | 0.517 | 19 | 0.775 |

| 2 | 0.442 | 11 | 0.812 | 20 | 0.515 |

| 3 | 0.501 | 12 | 0.555 | 21 | 0.836 |

| 4 | 0.349 | 13 | 0.669 | 22 | 0.939 |

| 5 | 0.458 | 14 | 0.729 | 23 | 0.634 |

| 6 | 0.727 | 15 | 0.527 | 24 | 0.788 |

| 7 | 0.451 | 16 | 0.848 | 25 | 0.871 |

| 8 | 0.611 | 17 | 0.942 | ||

| 9 | 0.401 | 18 | 0.747 |

| Item | Adj MS | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| Grinding wheel speed (vs) | 0.520 | 4 | 0.130 | 99.139 | <0.001 |

| Grinding depth (ap) | 0.057 | 4 | 0.014 | 10.776 | <0.001 |

| Feed rate (vw) | 0.224 | 4 | 0.056 | 42.649 | <0.001 |

| Error | 0.016 | 12 | 0.001 | ||

| R2 = 0.981 | |||||

| Item | Grinding Wheel Speed (vs) | Grinding Depth (ap) | Feed Rate (vw) |

|---|---|---|---|

| K1 | 2.104 | 3.577 | 2.459 |

| K2 | 2.707 | 3.329 | 2.91 |

| K3 | 3.292 | 3.162 | 3.264 |

| K4 | 3.827 | 3.042 | 3.595 |

| K5 | 4.068 | 2.888 | 3.77 |

| k1 | 0.4208 | 0.7154 | 0.4918 |

| k2 | 0.5414 | 0.6658 | 0.582 |

| k3 | 0.6584 | 0.6324 | 0.6528 |

| k4 | 0.7654 | 0.6084 | 0.719 |

| k5 | 0.8136 | 0.5776 | 0.754 |

| R | 0.3928 | 0.1378 | 0.2622 |

| Order | 1 | 3 | 2 |

| No. | SSD (μm) | No. | SSD (μm) | No. | SSD (μm) |

|---|---|---|---|---|---|

| 1 | 3.05 | 10 | 5.05 | 19 | 8.67 |

| 2 | 4.21 | 11 | 9.19 | 20 | 5.03 |

| 3 | 4.85 | 12 | 5.55 | 21 | 9.59 |

| 4 | 3.01 | 13 | 7.13 | 22 | 11.21 |

| 5 | 4.30 | 14 | 7.99 | 23 | 6.63 |

| 6 | 7.96 | 15 | 5.18 | 24 | 8.86 |

| 7 | 4.21 | 16 | 9.77 | 25 | 10.13 |

| 8 | 6.31 | 17 | 11.25 | ||

| 9 | 3.61 | 18 | 6.17 |

| Item | Adj MS | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| Grinding wheel speed (vs) | 92.442 | 4 | 23.110 | 88.288 | <0.001 |

| Grinding depth (ap) | 13.417 | 4 | 3.354 | 12.814 | <0.001 |

| Feed rate (vw) | 47.340 | 4 | 11.835 | 45.213 | <0.001 |

| Error | 3.141 | 12 | 0.262 | ||

| R2 = 0.980 | |||||

| Item | Grinding Wheel Speed (vs) | Grinding Depth (ap) | Feed Rate (vw) |

|---|---|---|---|

| K1 | 19.42 | 39.56 | 23.87 |

| K2 | 27.14 | 36.43 | 28.16 |

| K3 | 35.04 | 31.09 | 35.02 |

| K4 | 40.89 | 32.14 | 39.68 |

| K5 | 46.42 | 29.69 | 42.18 |

| k1 | 3.884 | 7.912 | 4.774 |

| k2 | 5.428 | 7.286 | 5.632 |

| k3 | 7.008 | 6.218 | 7.004 |

| k4 | 8.178 | 6.428 | 7.936 |

| k5 | 9.284 | 5.938 | 8.436 |

| R | 5.4 | 1.974 | 3.662 |

| Order | 1 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Gao, Y.; Yang, C. Influence of Grinding Parameters on Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystal. Materials 2025, 18, 2461. https://doi.org/10.3390/ma18112461

Hou Y, Gao Y, Yang C. Influence of Grinding Parameters on Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystal. Materials. 2025; 18(11):2461. https://doi.org/10.3390/ma18112461

Chicago/Turabian StyleHou, Yingqi, Yufei Gao, and Chunfeng Yang. 2025. "Influence of Grinding Parameters on Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystal" Materials 18, no. 11: 2461. https://doi.org/10.3390/ma18112461

APA StyleHou, Y., Gao, Y., & Yang, C. (2025). Influence of Grinding Parameters on Surface Roughness and Subsurface Crack Damage Depth of Sapphire Crystal. Materials, 18(11), 2461. https://doi.org/10.3390/ma18112461