Evaluation of Adhesive Seams of High-Density Polyethylene Geomembrane Subjected to Wetting and Freeze-Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Test Methods

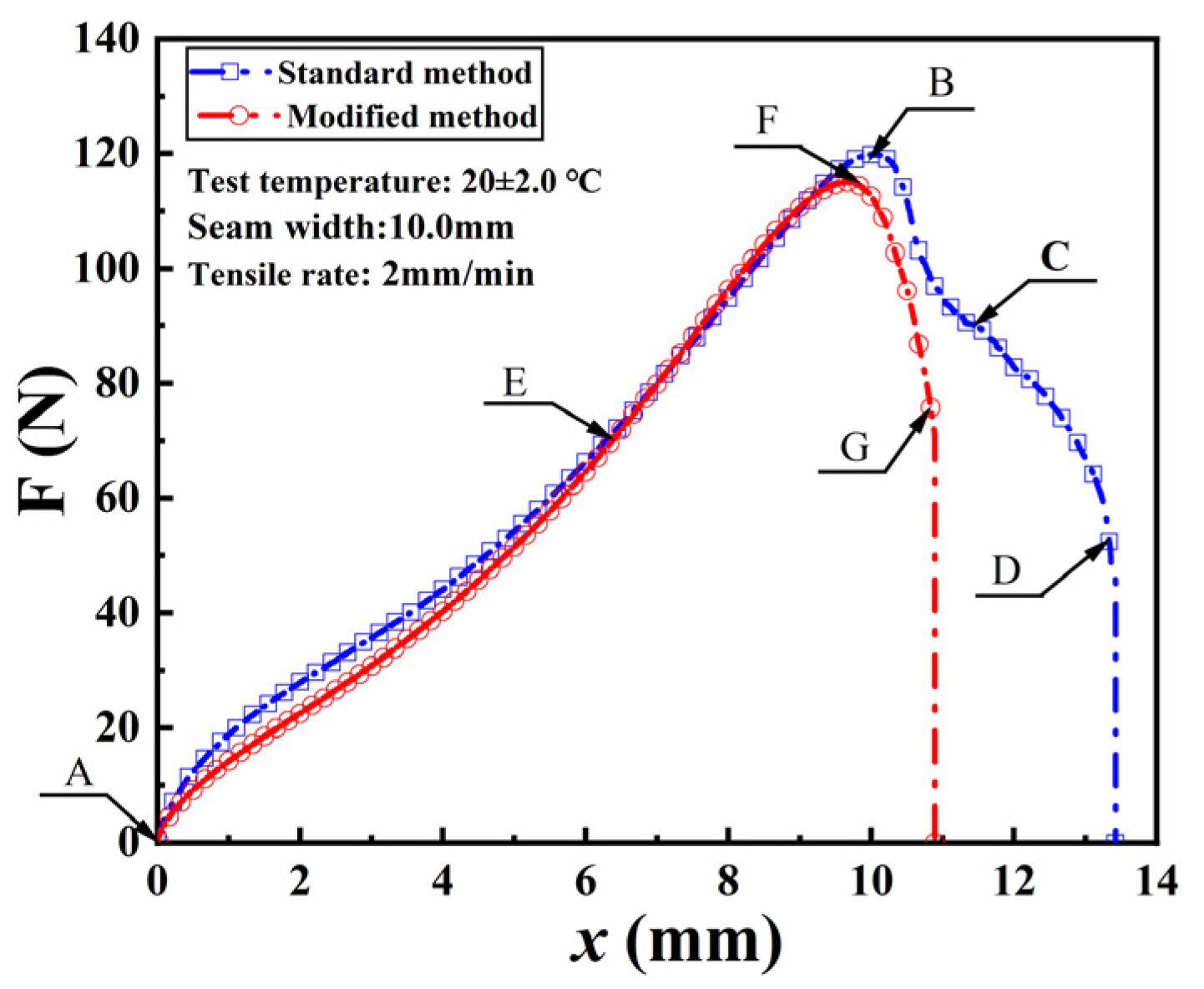

2.2.1. Standard Method

2.2.2. Modified Method

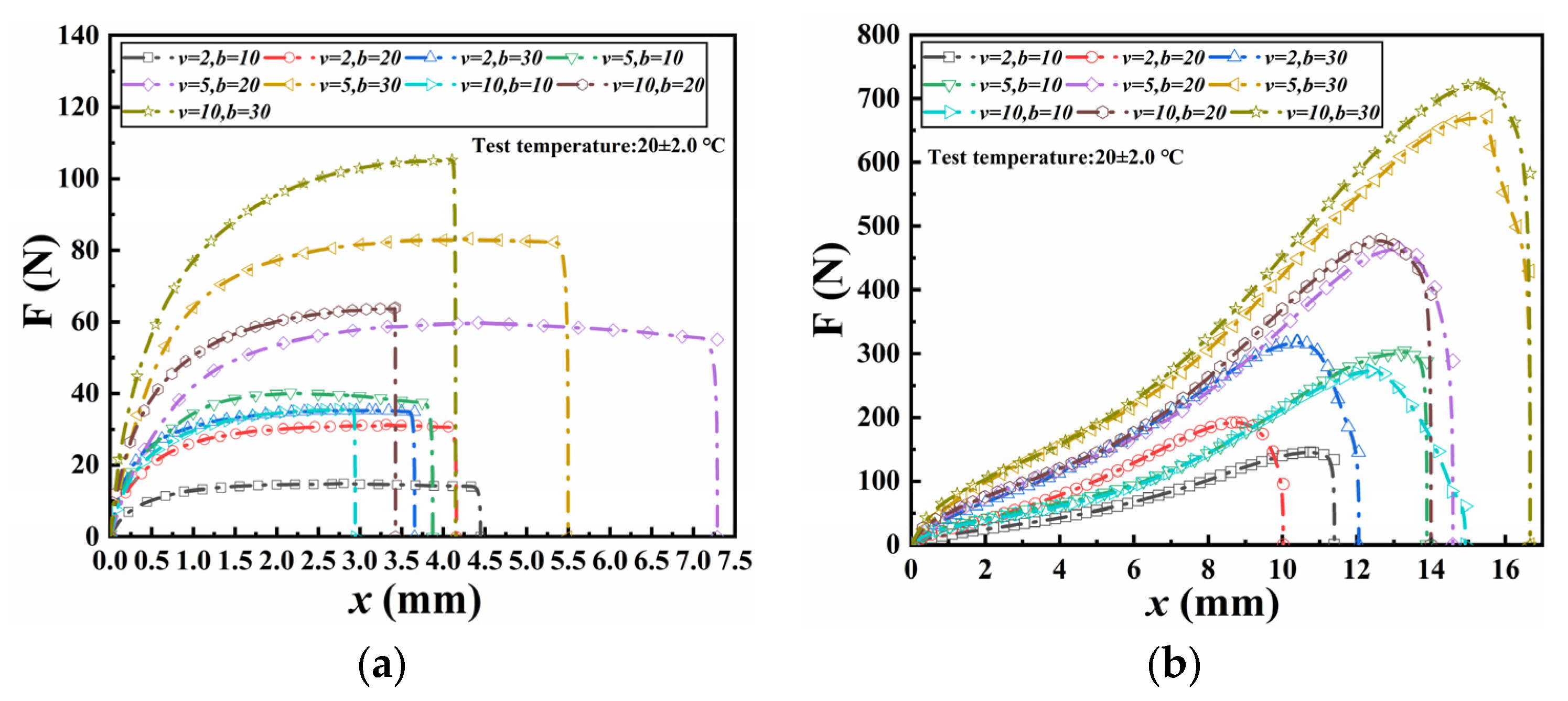

2.3. Selection of Tensile Rate and Seam Width

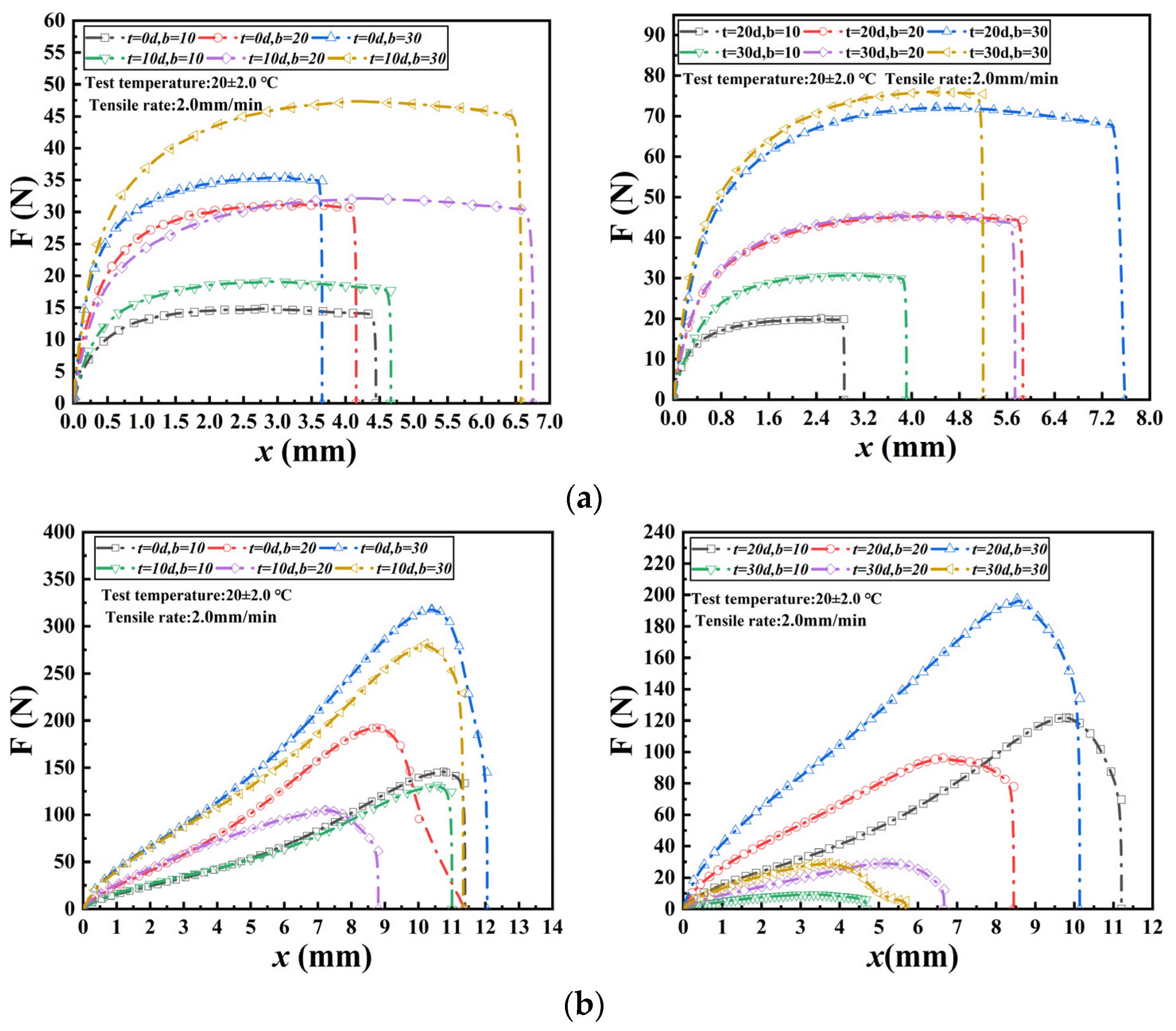

2.4. Seam Tensile Test Under Wetting Conditions

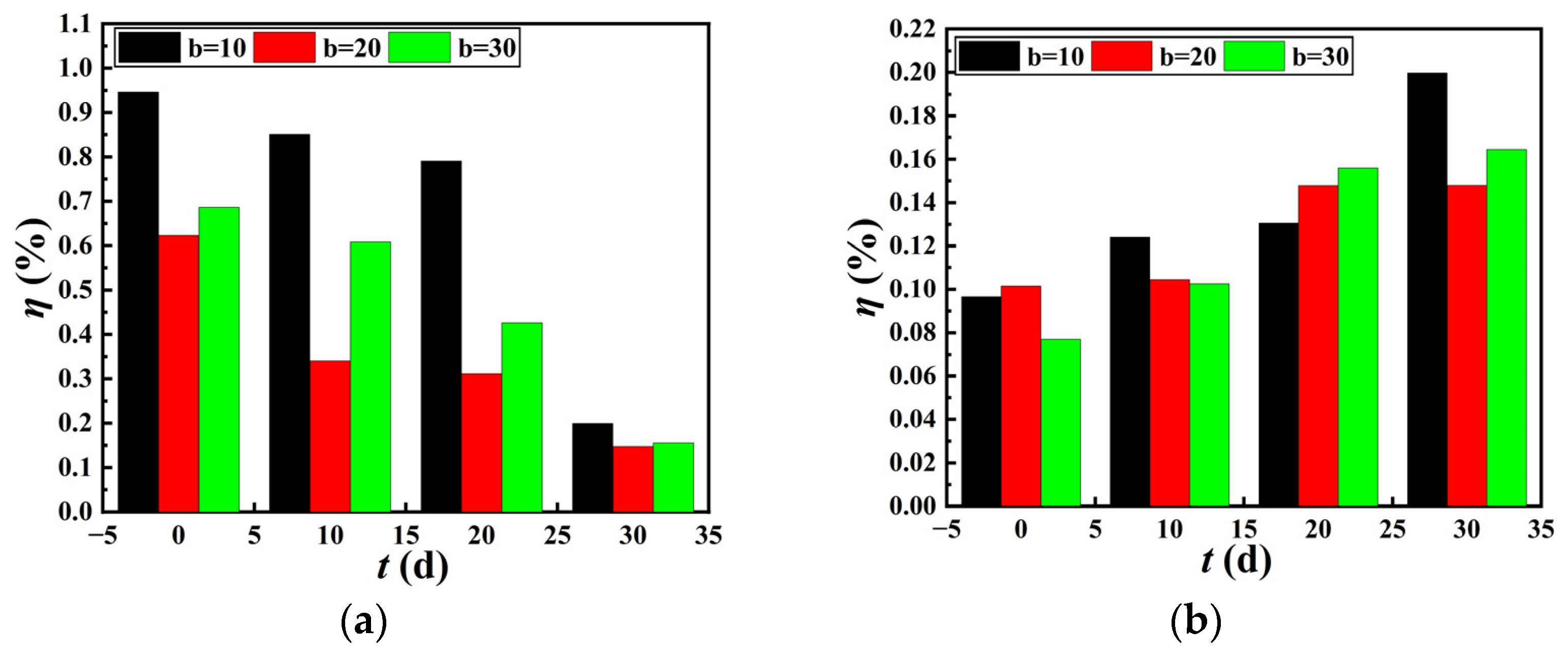

2.5. Seam Tensile Test Under FTCs Conditions

2.6. Analysis Method in Specification

3. Results

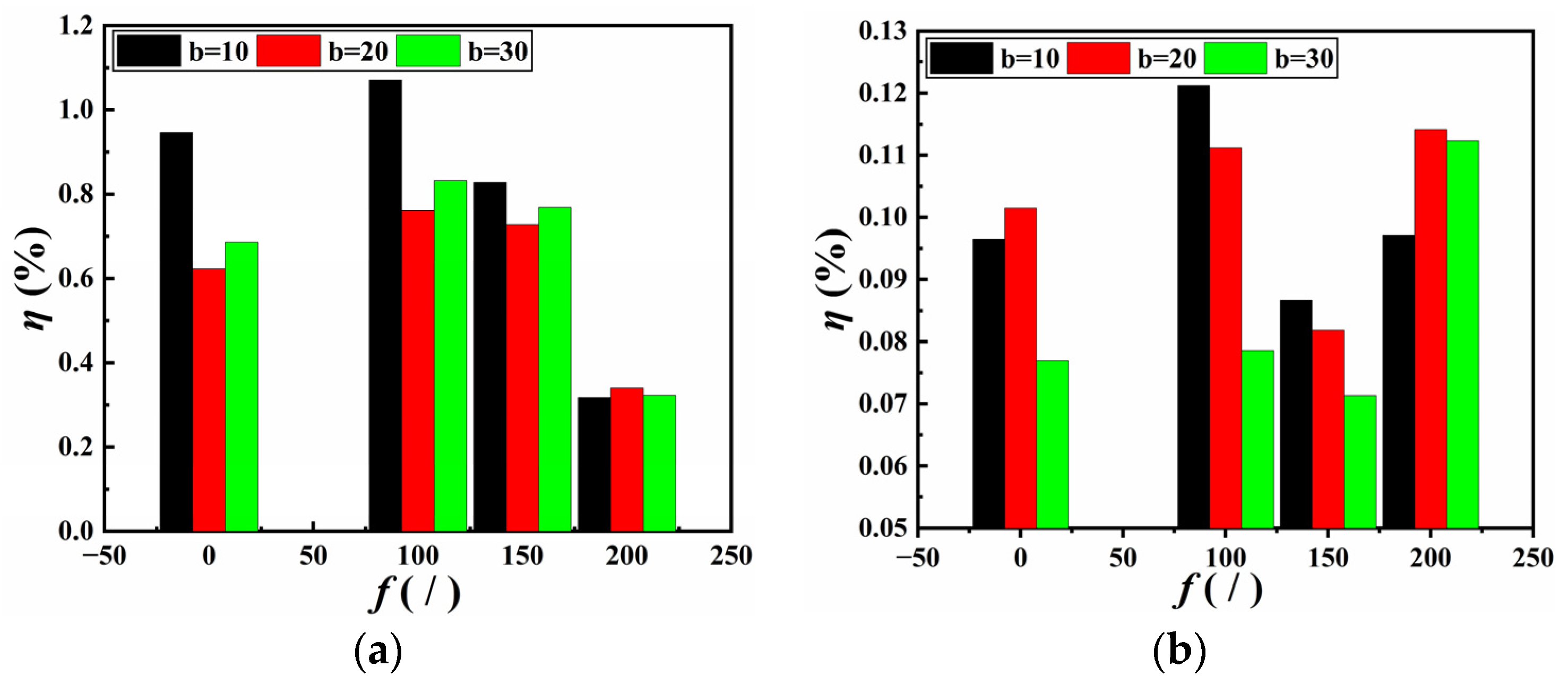

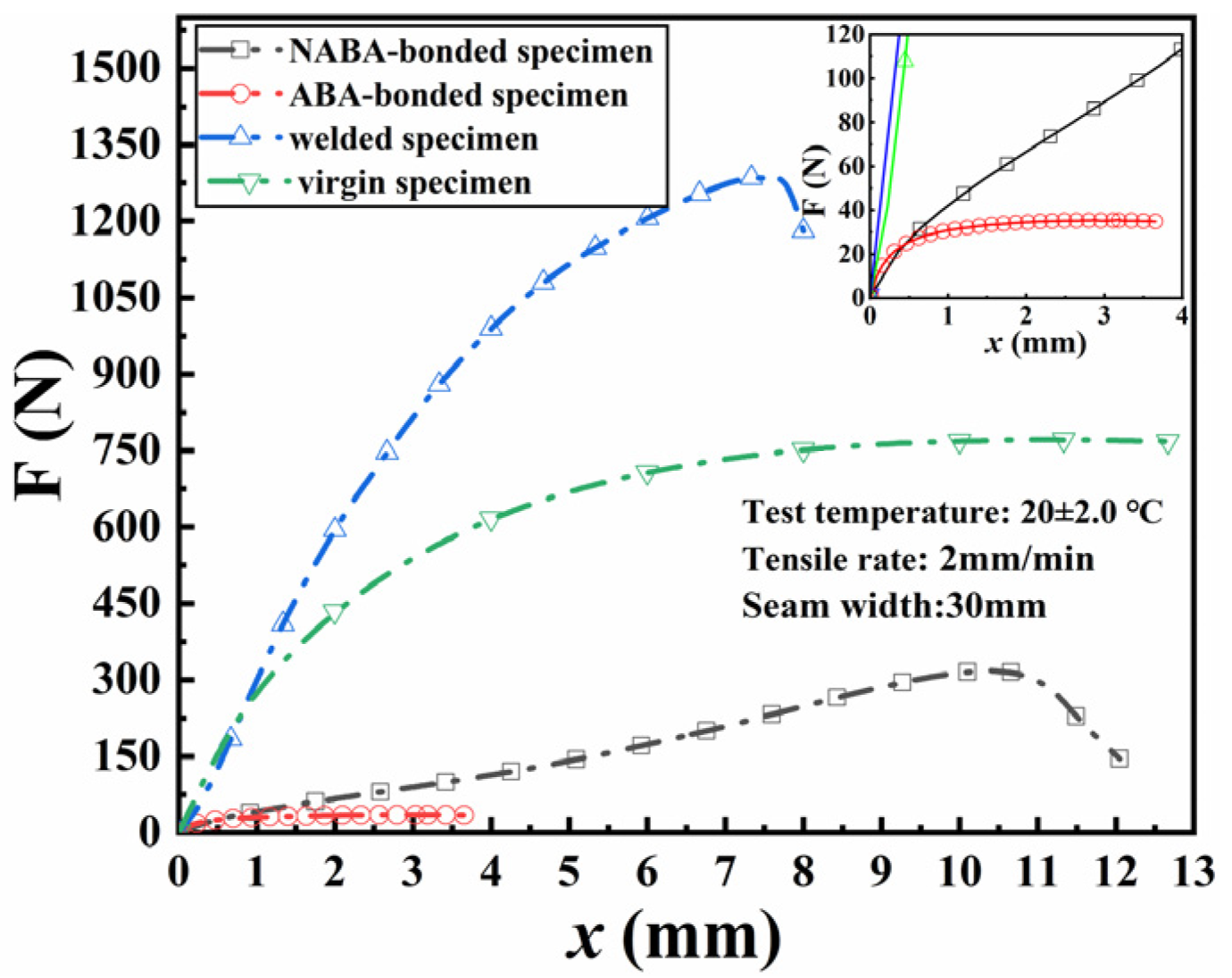

3.1. Effect of Wetting Time and Seam Width on Seam Strength

3.2. Effect of FTCs and Seam Width on Seam Strength

4. Discussion

5. Conclusions

- (1)

- The results measured by the modified specimens can accurately represent the real seam strength, and the seam efficiency stipulated in the specification is updated.

- (2)

- Under wetting conditions, the seam strength of specimens bonded with ABA increased as wetting time increased (with a maximum increase of 113.8%). Conversely, for specimens bonded with NABA, the seam strength decreased with increasing wetting time (with a maximum decrease of 93.4%). The seam strength of both specimens exhibited an increase with seam width. Prolonged wetting resulted in the seam strength of NABA-bonded specimens becoming lower than that of ABA-bonded specimens over time, indicating superior seam quality for ABA-bonded specimens under wetting conditions.

- (3)

- The FTCs led to a reduction in seam strength for specimens bonded with NABA with a maximum decrease of 58.5%, whereas they resulted in an increase in seam strength for specimens bonded with ABA with a maximum increase of 80.6%. After 200 FTCs, the seam strength of NABA-bonded specimens remained higher than that of ABA-bonded specimens.

- (4)

- The specimens bonded with NABA exhibited a reduction in seam efficiency due to wetting and FTCs, whereas those bonded with ABA showed a slight improvement. However, the improved seam efficiency remained below 1.2%, an extremely small value. Consequently, the mechanical properties of ABA-bonded specimens were superior to those of NABA-bonded specimens.

- (5)

- The seam width had minimal effect on seam efficiency under wetting and FTCs conditions. Therefore, it can be reasonably selected based on engineering practice, provided that seam quality is ensured.

- (6)

- Given that the axial tensile strength of bonded specimens was significantly lower than that of seamless specimens, bonding method in critical engineering locations was not recommended. However, the bonding method can be used with caution for non-essential structural components where welding implementation was challenging but repair and replacement were relatively straightforward.

- (1)

- To examine whether the impermeability of bonded seams satisfies the requirements for safe engineering operation, and to identify the influencing factors and underlying mechanisms.

- (2)

- To identify the physical and mechanical properties as well as the hydraulic characteristics of specialized adhesives used for GMBs.

- (3)

- To investigate the aging resistance of GMBs at seams and predict their service life using a numerical model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ICOLD. Geomembrane Sealing Systems for Dams-Design Principles and Review of Experience; Bulletin 135; International Commission on Large Dams: Paris, France, 2010. [Google Scholar]

- Touze-Foltz, N.; Bannour, H.; Barral, C.; Stoltz, G. A review of the performance of geosynthetics for environmental protection. Geotext. Geomembr. 2016, 44, 656–672. [Google Scholar] [CrossRef]

- Scuero, A.; Vaschetti, G. Geomembrane sealing systems for dams: ICOLD bulletin 135. Innov. Infrastruct. Solut. 2017, 2, 29. [Google Scholar] [CrossRef]

- Touze, N. Healing the world: A geosynthetics solution. Geosynth. Int. 2021, 28, 1–31. [Google Scholar] [CrossRef]

- Morsy, M.S.; Rowe, R.K.; Abdelaal, F.B. Longevity of 12 geomembranes in chlorinated water. Can. Geotech. J. 2021, 58, 479–495. [Google Scholar] [CrossRef]

- Tuomela, A.; Ronkanen, A.K.; Rossi, P.M.; Rauhala, A.; Haapasalo, H.; Kujala, K. Using geomembrane liners to reduce seepage through the base of tailings ponds—A review and a framework for design guidelines. Geosciences 2021, 11, 93. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, Z.; Gedela, R.; Tang, C.; Feng, Y.; Liu, J.; Yao, H. Performance and geocell-soil interaction of sand subgrade reinforced with high-density polyethylene, polyester, and polymer-blend geocells: 3d numerical studies. Comput. Geotech. 2025, 178, 106949. [Google Scholar] [CrossRef]

- Peggs, I.D.; Gassner, F.; Scheirs, J.; Tan, D.; Arango, A.M.N.; Burkard, B. Is there a resurgence of stress cracking in HDPE geomembranes? In Proceedings of the 10th International Geosynthetics Conference, Berlin, Germany, 21–25 September 2014; DGGT: Essen, Germany, 2014. [Google Scholar]

- Rollin, A.L.; Marcotte, M.; Jacqueline, T.; Chaput, L. Leak location in exposed geomembrane liners using an electrical leak detection technique. In Proceedings of the Geosynthetic’99; IFAI: Boston, MA, USA; Roseville, MI, USA, 1999; Volume 2, pp. 615–626. [Google Scholar]

- Gassner, F.; Fairhead, G. Field leakage rates of geosynthetic lined facilities. In Proceedings of the 10th International Geosynthetics Conference, Berlin, Germany, 21–25 September 2014; DGGT: Essen, Germany, 2014. [Google Scholar]

- Fan, J.Y.; Rowe, R.K. Creep rupture behaviour of elastomeric bituminous geomembrane seams. Geotext. Geomembr. 2024, 52, 1134–1144. [Google Scholar] [CrossRef]

- Koerner, R.M.; Lord, A.E., Jr. Nondestructive evaluation of geomembrane seams: Methods in development. Geotext. Geomembr. 1990, 9, 431–443. [Google Scholar] [CrossRef]

- Giroud, J.P. Quantification of geosynthetic behavior. Geosynth. Int. 2005, 12, 2–27. [Google Scholar] [CrossRef]

- Giroud, J.P.; Tisseau, B.; Soderman, K.L.; Beech, J.F. Analysis of strain concentration next to geomembrane seams. Geosynth. Int. 1995, 2, 1049–1097. [Google Scholar] [CrossRef]

- Kavazanjian, E.; Andresen, J.; Gutierrez, A. Experimental evaluation of HDPE geomembrane seam strain concentrations. Geosynth. Int. 2017, 24, 333–342. [Google Scholar] [CrossRef]

- Stark, T.D.; Hernandez, M.A.; Rohe, D.S. Geomembrane factory and field thermally welded seams comparison. Geotext. Geomembr. 2020, 48, 454–467. [Google Scholar] [CrossRef]

- Rowe, R.K.; Shoaib, M. Long-term performance of high-density polyethylene (HDPE) geomembrane seams in municipal solid waste (MSW) leachate. Can. Geotech. J. 2017, 54, 1623–1636. [Google Scholar] [CrossRef]

- Shoaib, M.; Rowe, R.K. Durability and long-term strength of seams in HDPE geomembranes. In Proceedings of the 66th Canadian Geotechnical Conference, Montreal, QC, Canada, 29 September–3 October 2013; CGS: Richmond, BC, Canada, 2013. paper 342. [Google Scholar]

- Zhang, L.; Bouazza, A.; Rowe, R.K.; Scheirs, J. Effect of welding parameters on properties of HDPE geomembrane seams. Geosynth. Int. 2017, 24, 408–418. [Google Scholar] [CrossRef]

- Rowe, R.K.; Shoaib, M. Durability of HDPE geomembrane seams immersed in brine for three years. J. Geotech. Geoenviron. Eng. 2018, 144, 04017114. [Google Scholar] [CrossRef]

- Francey, W.; Rowe, R.K. Importance of thickness reduction and squeeze-out Std-OIT loss for HDPE geomembrane fusion seams. Geotext. Geomembr. 2023, 51, 30–42. [Google Scholar] [CrossRef]

- Peggs, I.D.; Fairhead, G. Impact of Microstructure on HDPE Geomembrane Seaming and Vice Versa. In Proceedings of the Geosynthetics 2019 Conference, Houston, TX, USA, 10–13 February 2019; IFAI: Houston, TX, USA, 2019. [Google Scholar]

- Francey, W.; Rowe, R.K. Stress crack resistance of unaged high-density polyethylene geomembrane fusion seams. Geosynth. Int. 2023, 30, 154–168. [Google Scholar] [CrossRef]

- Francey, W.; Rowe, R.K. Factors affecting the tensile strength of bituminous geomembrane seams. Geosynth. Int. 2024, 32, 219–229. [Google Scholar] [CrossRef]

- Thomas, R.W.; Stark, T.D.; Choi, H. Air channel testing of thermally bonded PVC geomembrane seams. Geosynth. Int. 2003, 10, 56–69. [Google Scholar] [CrossRef]

- Stark, T.D.; Choi, H.; Thomas, R.W. Low-temperature air channel testing of thermally bonded PVC geomembrane seams. Geosynth. Int. 2004, 11, 481–490. [Google Scholar] [CrossRef]

- Stark, T.D.; Pazmino, L.F. High-temperature air channel testing of thermally bonded PVC geomembrane seams. Geosynth. Int. 2011, 18, 84–89. [Google Scholar] [CrossRef]

- ASTM D5261-10; Standard Test Method for Measuring Mass per Unit Area of Geotextiles. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D5199-12; Standard Test Method for Measuring the Nominal Thickness of Geosynthetics. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D4885-01; Standards Test Method for Determining Performance Strength of Geomembranes by the Wide Strip Tensile Method. ASTM International: West Conshohocken, PA, USA, 2023.

- GB/T 13760-2009; Geosynthetics—Sampling and preparation of test specimens. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2009.

- SL 235-2012; Specification for test and measurement of geosynthetics. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2012.

- Zhao, Y.; Chen, J.; Lu, Z.; Liu, J.; Tabaroei, A.; Tang, C.; Wang, Y.; Wu, L.; Wang, B.; Yao, H. Elastic-viscoplastic behaviors of polymer-blend geocell sheets: Numerical and experimental investigations. J. Rock. Mech. Geotech. 2024, 16, 11. [Google Scholar] [CrossRef]

- GB/T 16989-2013; Geosynthetics—Tensile Test for Joints/Seams by Wide-Width Strip Method. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2013.

- ASTM D7408-12; Standard Specification for Non-reinforced PVC (Polyvinyl Chloride) Geomembrane Seams. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D638-22; Standard test method for tensile properties of plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D6693/D6693M-20; Standard Test Method for Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible Polypropylene Geomembranes. ASTM International: West Conshohocken, PA, USA, 2020.

| Name | Mass per Unit Area | Thickness | Tensile Strength at Yield | Tensile Strength at Break | Tensile Strain at Yield |

|---|---|---|---|---|---|

| g/m2 | mm | N/mm | N/mm | % | |

| HDPE GMB | 2400.00 | 0.5 | 7.320 | 20.00 | 146.99 |

| ABA | 9296.66 | 1.0 | 4.796 | — | — |

| NABA | 4187.77 | 0.8 | 5.294 | — | — |

| Methods | SL 235-2012 [32] | GB/T 16989-2013 [34] | ASTM D7408-12 [35] | ASTM D4885-01 [30] | ASTM D638-22 [36] | ASTM D6693 [37] |

|---|---|---|---|---|---|---|

| Tensile rate (mm/min) | 20 | 20 | 50.8 | 10.0 | 5.0 | 50 |

| Seam Width (mm) | Wetting Time ti/d | △t1 (t1–t0) | △t2 (t2–t0) | △t3 (t3–t0) | △t4 (t2–t1) | △t5 (t3–t2) | Unit | |||

|---|---|---|---|---|---|---|---|---|---|---|

| t0 = 0 | t1 = 10 | t2 = 20 | t3 = 30 | |||||||

| 10 (ABA) | 0.0993 | 0.1275 | 0.1343 | 0.1855 | 0.0282 | 0.035 | 0.0862 | 0.0068 | 0.0512 | kN/m |

| 20 (ABA) | 0.2088 | 0.2148 | 0.3039 | 0.4041 | 0.0060 | 0.0951 | 0.1953 | 0.0891 | 0.1002 | kN/m |

| 30 (ABA) | 0.2374 | 0.3164 | 0.4814 | 0.5076 | 0.0790 | 0.244 | 0.2702 | 0.1650 | 0.0262 | kN/m |

| 10 (NABA) | 0.9733 | 0.8753 | 0.8132 | 0.0615 | −0.098 | −0.1601 | −0.9118 | −0.0621 | −0.7517 | kN/m |

| 20 (NABA) | 1.2825 | 0.7033 | 0.6416 | 0.1952 | −0.5792 | −0.6409 | −1.0873 | −0.0617 | −0.4464 | kN/m |

| 30 (NABA) | 2.1185 | 1.8780 | 1.3153 | 0.1943 | −0.2405 | −0.8032 | −1.9242 | −0.5627 | −1.121 | kN/m |

| Seam Width (mm) | FTCs Ni/Number | △N1 (N1–N0) | △N2 (N2–N0) | △N3 (N3–N0) | △N4 (N2–N1) | △N5 (N3–N2) | Unit | |||

|---|---|---|---|---|---|---|---|---|---|---|

| N0 = 0 | N1 = 100 | N2 = 150 | N3 = 200 | |||||||

| 10 (ABA) | 0.0993 | 0.1569 | 0.1206 | 0.1236 | 0.0576 | 0.0214 | 0.0244 | −0.0362 | 0.003 | kN/m |

| 20 (ABA) | 0.2088 | 0.2287 | 0.2117 | 0.2905 | 0.0199 | 0.0029 | 0.0817 | −0.017 | 0.0788 | kN/m |

| 30 (ABA) | 0.2374 | 0.328 | 0.277 | 0.4287 | 0.0906 | 0.0396 | 0.1913 | −0.051 | 0.1517 | kN/m |

| 10 (NABA) | 0.9733 | 1.4896 | 1.0715 | 0.4044 | 0.5163 | 0.0982 | −0.5689 | −0.4181 | −0.6671 | kN/m |

| 20 (NABA) | 1.2825 | 2.1205 | 1.8842 | 0.8655 | 0.8380 | 0.6017 | −0.4170 | −0.2363 | −1.0187 | kN/m |

| 30 (NABA) | 2.1185 | 3.4754 | 2.9862 | 1.2324 | 1.3570 | 0.8677 | −0.8861 | −0.4892 | −1.7538 | kN/m |

| Seam Width (mm) | Wetting Time (d) | Unit | |||

|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | ||

| 10 (ABA) | 0.0099 | 0.0128 | 0.0134 | 0.0205 | MPa |

| 20 (ABA) | 0.0104 | 0.0107 | 0.0152 | 0.0152 | MPa |

| 30 (ABA) | 0.0079 | 0.0105 | 0.0169 | 0.016 | MPa |

| 10 (NABA) | 0.0973 | 0.0813 | 0.0875 | 0.0061 | MPa |

| 20 (NABA) | 0.0641 | 0.0321 | 0.035 | 0.0098 | MPa |

| 30 (NABA) | 0.0706 | 0.0438 | 0.0626 | 0.0065 | MPa |

| 0 (SS) | 10.2839 | 10.2123 | 10.2678 | 10.2864 | MPa |

| Seam Width (mm) | FTCs/Number | Unit | ||

|---|---|---|---|---|

| 100 | 150 | 200 | ||

| 10 (ABA) | 0.0121 | 0.0157 | 0.0124 | MPa |

| 20 (ABA) | 0.0114 | 0.0106 | 0.0145 | MPa |

| 30 (ABA) | 0.0109 | 0.0092 | 0.0143 | MPa |

| 10 (NABA) | 0.149 | 0.1072 | 0.0404 | MPa |

| 20 (NABA) | 0.106 | 0.0942 | 0.0433 | MPa |

| 30 (NABA) | 0.1158 | 0.0995 | 0.0411 | MPa |

| 0 (SS) | 13.914 | 12.9374 | 12.7203 | MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhai, J.; Tang, Y.; Wu, Y. Evaluation of Adhesive Seams of High-Density Polyethylene Geomembrane Subjected to Wetting and Freeze-Thaw Cycles. Materials 2025, 18, 2368. https://doi.org/10.3390/ma18102368

Zhang X, Zhai J, Tang Y, Wu Y. Evaluation of Adhesive Seams of High-Density Polyethylene Geomembrane Subjected to Wetting and Freeze-Thaw Cycles. Materials. 2025; 18(10):2368. https://doi.org/10.3390/ma18102368

Chicago/Turabian StyleZhang, Xianlei, Jialong Zhai, Yuan Tang, and Yunyun Wu. 2025. "Evaluation of Adhesive Seams of High-Density Polyethylene Geomembrane Subjected to Wetting and Freeze-Thaw Cycles" Materials 18, no. 10: 2368. https://doi.org/10.3390/ma18102368

APA StyleZhang, X., Zhai, J., Tang, Y., & Wu, Y. (2025). Evaluation of Adhesive Seams of High-Density Polyethylene Geomembrane Subjected to Wetting and Freeze-Thaw Cycles. Materials, 18(10), 2368. https://doi.org/10.3390/ma18102368