1. Introduction

Due to the increasing concentration of urban populations and the limited availability of land, modern structures are becoming taller, larger, and more space-efficient. Consequently, the demand for construction materials, such as rebar and cement, continues to rise. Over the past five years, global crude steel production, a primary material for rebar, has increased by an average of 2.3% annually [

1]. Future steel demand is projected to grow between 1.4% and 3.3% per year [

2,

3,

4]. However, steel production incurs significant environmental costs, particularly through greenhouse gas (GHG) emissions. On average, the production of crude steel generates 1.91 tonnes of CO

2 per tonne of steel, accounting for approximately 7–9% of global fossil fuel emissions [

5]. As a result, the construction industry is actively seeking ways to reduce CO

2 emissions.

While many studies have focused on reducing the carbon footprint of concrete (particularly cement) through material substitution or admixtures [

6,

7], comparatively fewer studies have explored the sustainability potential of reinforcement optimization [

8]. Since steel reinforcement also accounts for a substantial portion of embodied energy in reinforced concrete structures, improving the efficiency and mechanical performance of rebar can lead to meaningful reductions in total material use and environmental impact. Therefore, this study focuses on the sustainability of reinforcement rather than concrete as a strategic approach to material reduction.

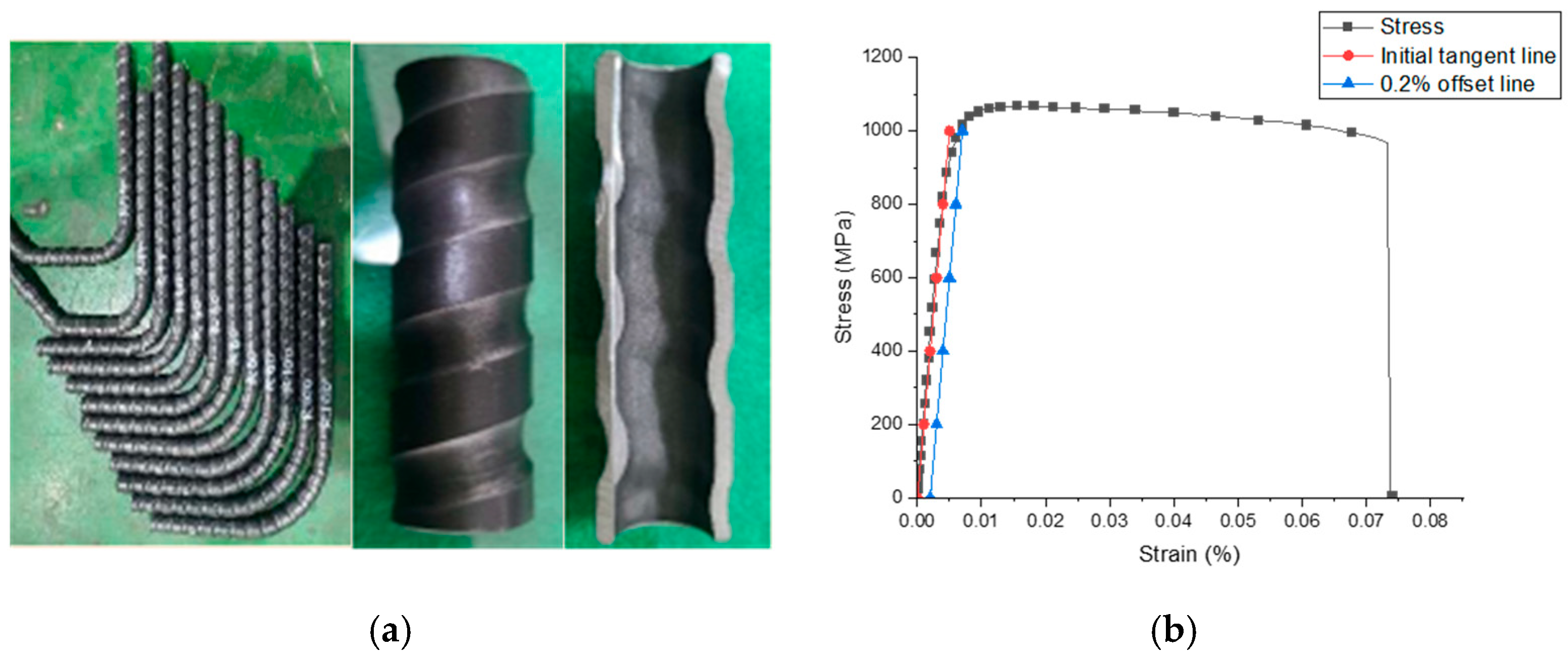

One proposed solution in Korea involves replacing traditional deformed rebar with tubular rebar. The newly developed STG800 tubular rebar is a high-strength material that requires less raw material than conventional deformed rebar, thereby reducing GHG emissions. This tubular rebar has a hollow section, a yield strength of 800 MPa, and the same diameter as deformed rebar. It is also approximately 5–10% cheaper and 50% lighter per meter than conventional deformed rebar. An et al. evaluated the use of a tubular rebar net in a landslide protection wall, demonstrating a 20% improvement in bending performance, confirming its applicability to real structures [

9].

High-strength rebars, including tubular rebars, reduce the overall amount of reinforcement needed in structures. Rautenberg et al. confirmed that using rebars with a strength exceeding 80 ksi (550 MPa) allows for a reduction in the quantity of main reinforcement [

10]. However, while high-strength rebars offer durability and enhanced mechanical properties, they often exhibit reduced ductility [

11]. Since reinforced concrete (RC) members require adequate ductility in addition to strength, design standards in various countries impose limitations on the maximum yield strength of rebar [

12,

13,

14,

15]. Shahrooz et al. suggested modifying strain limits and restricting service load stress to 60% of the yield strength to ensure comparable curvature behavior in bending members using high-strength rebars [

16]. Thus, securing adequate ductility is essential for the effective application of high-strength rebars.

Tubular rebars, in particular, are expected to exhibit lower ductility than conventional deformed rebars. While deformed rebars resist deflection across their entire cross-section, tubular rebars cannot fully resist deflection due to their hollow geometry. Therefore, structural deflection control is crucial for their application [

17,

18]. Although previous studies have explored the mechanical properties of tubular rebar, including bond behavior and fire resistance, research on its practical application in real-world structures remains limited.

Therefore, this study aims to investigate the structural performance of reinforced concrete members using tubular rebars through both experimental and numerical approaches. The research gap lies in the lack of data on the application of tubular reinforcement in full-scale elements under realistic conditions, particularly regarding flexural behavior and ductility. The remainder of this paper is organized as follows:

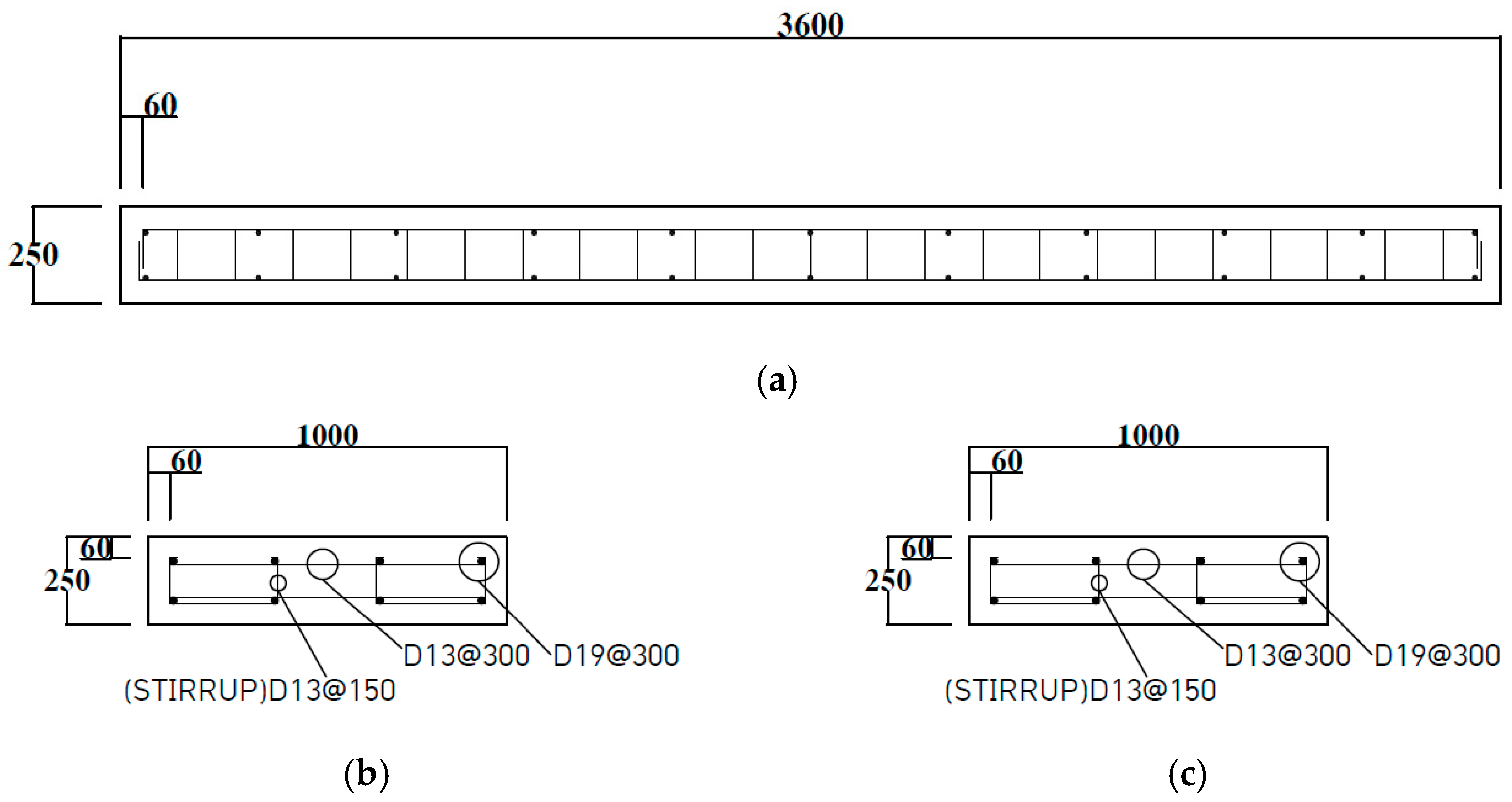

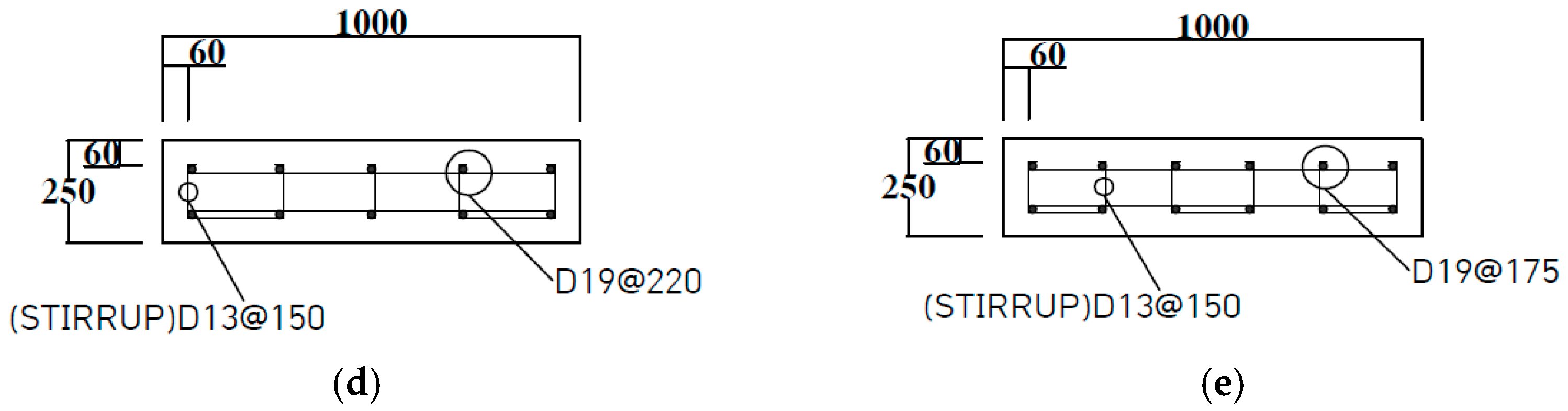

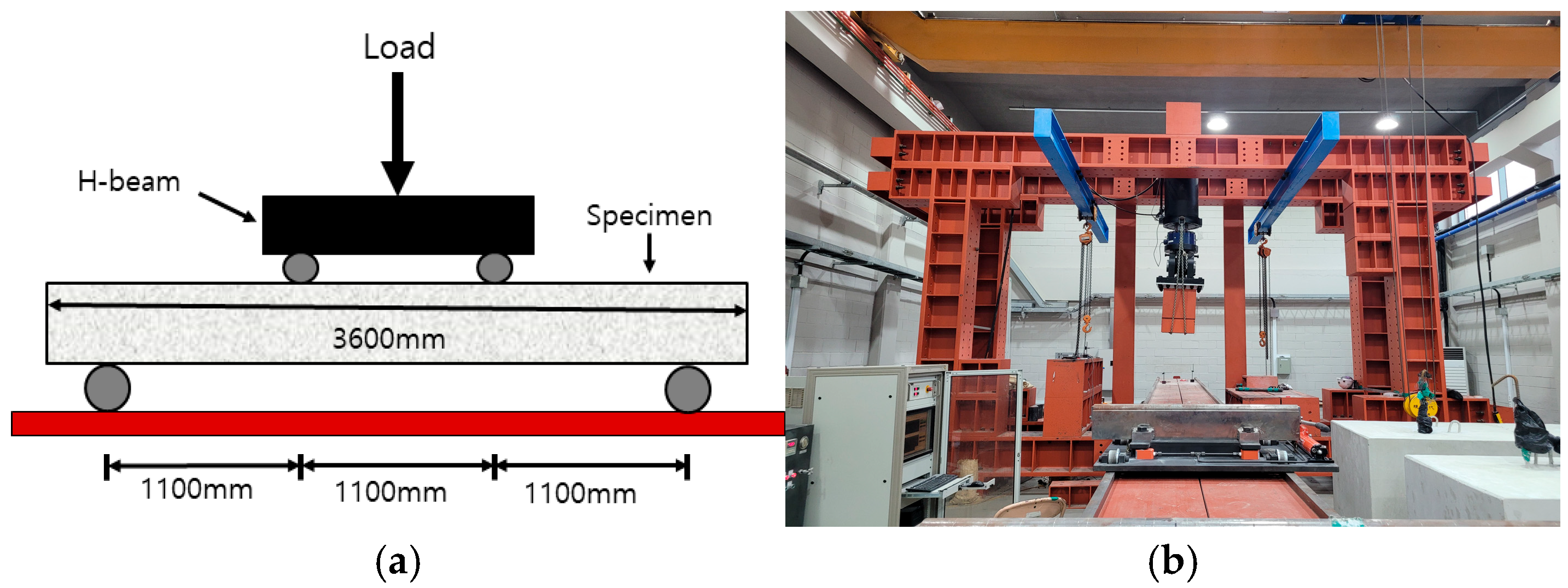

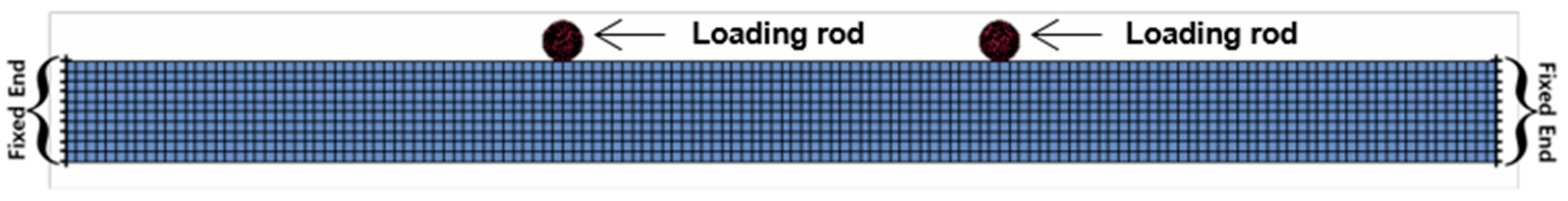

Section 2 presents the experimental program,

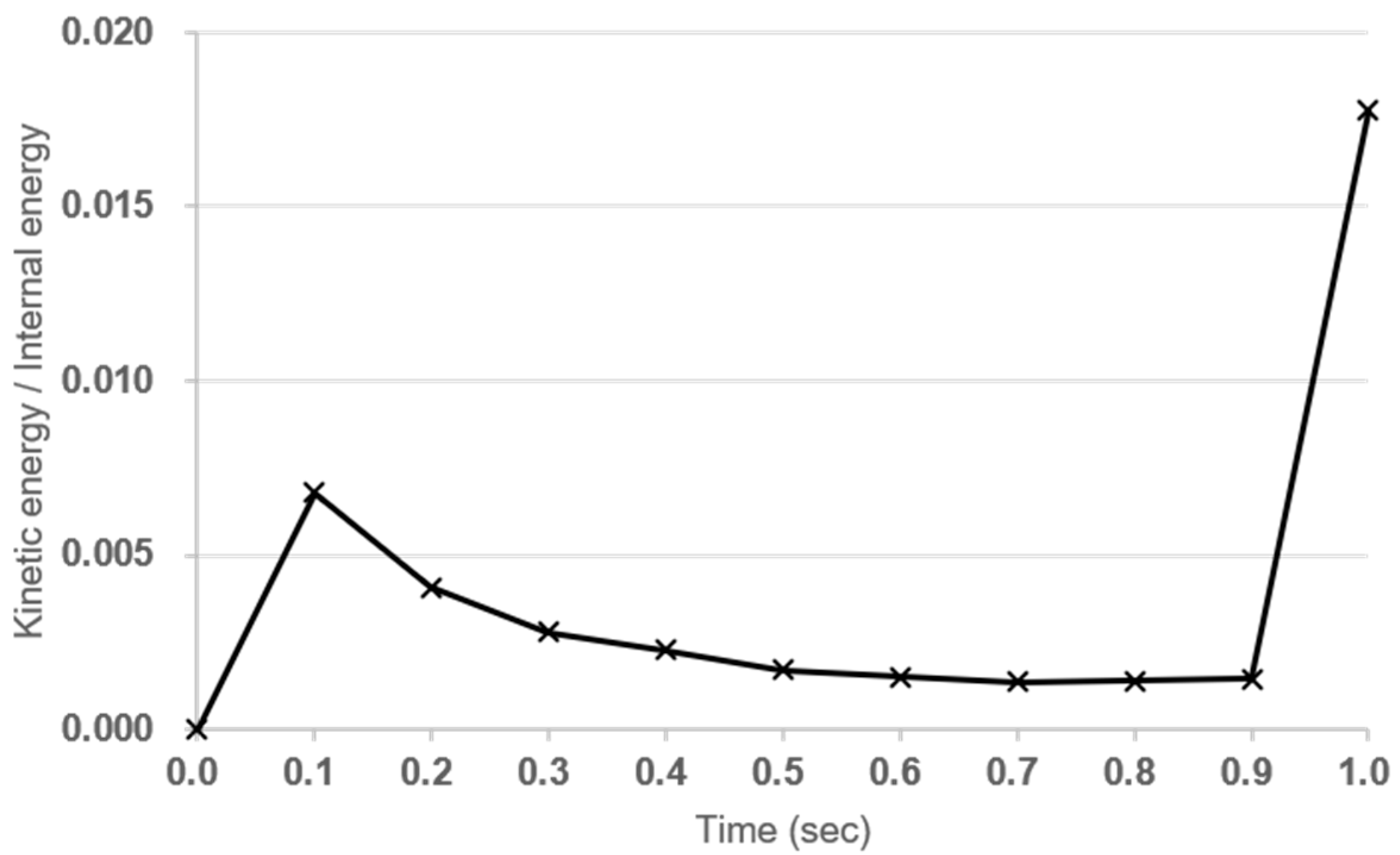

Section 3 describes the numerical simulation and comparison with the experimental results,

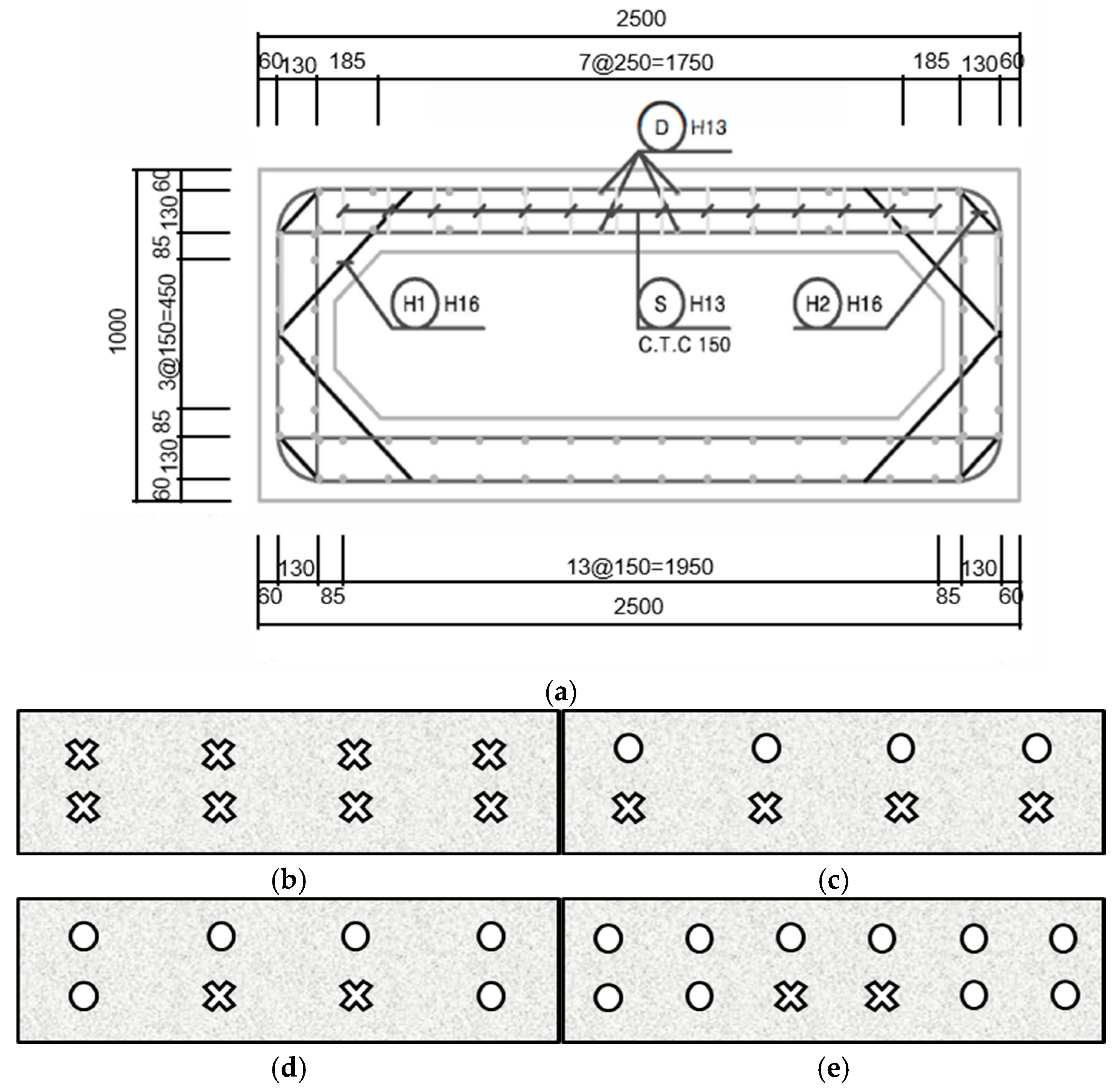

Section 4 provides additional experimental verification through a bending test on a box culvert, a representative statically indeterminate structure,

Section 5 discusses the implications and contributions of the findings, and

Section 6 concludes the paper.

5. Discussion

5.1. Demands for Statically Indeterminate States

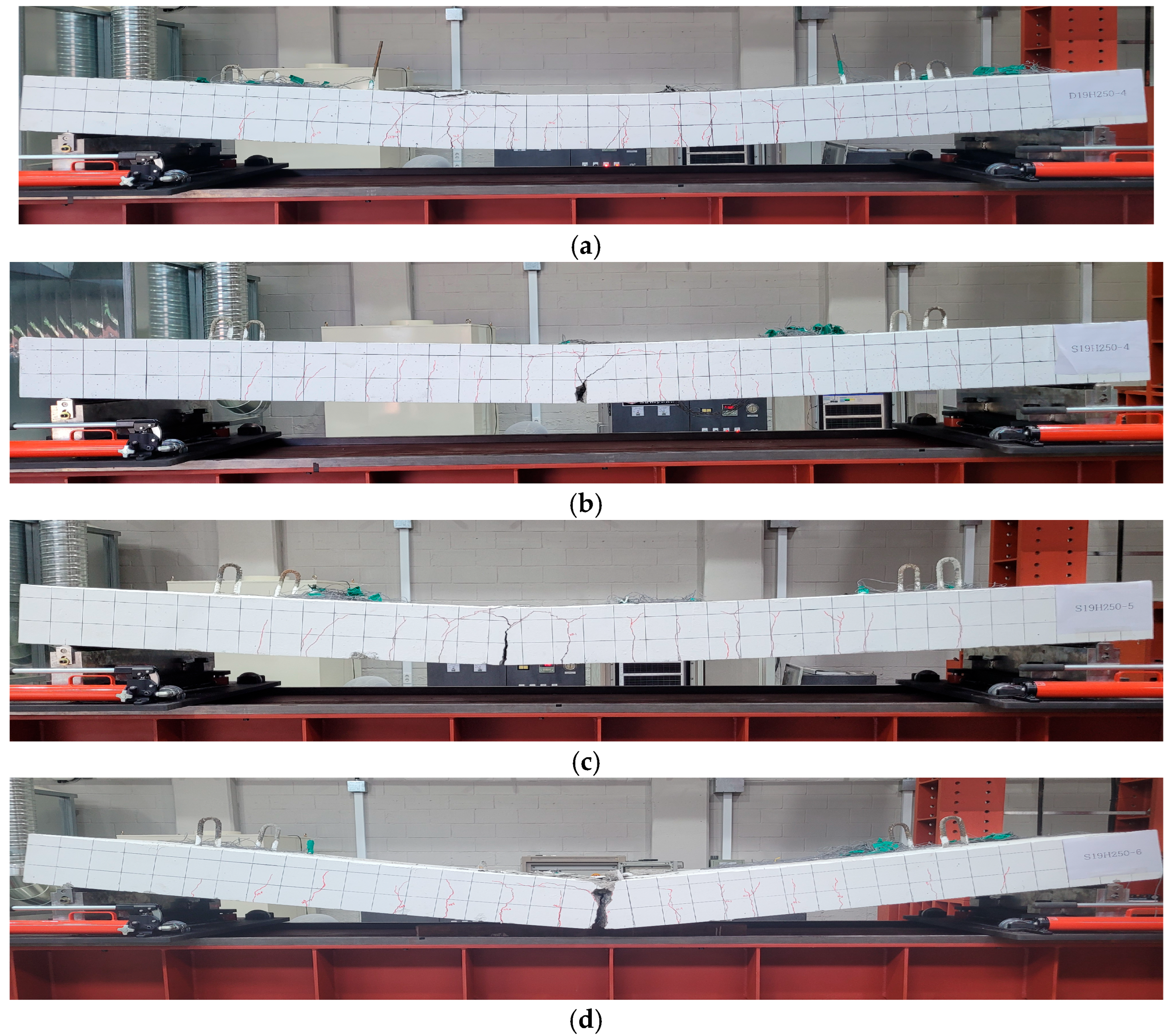

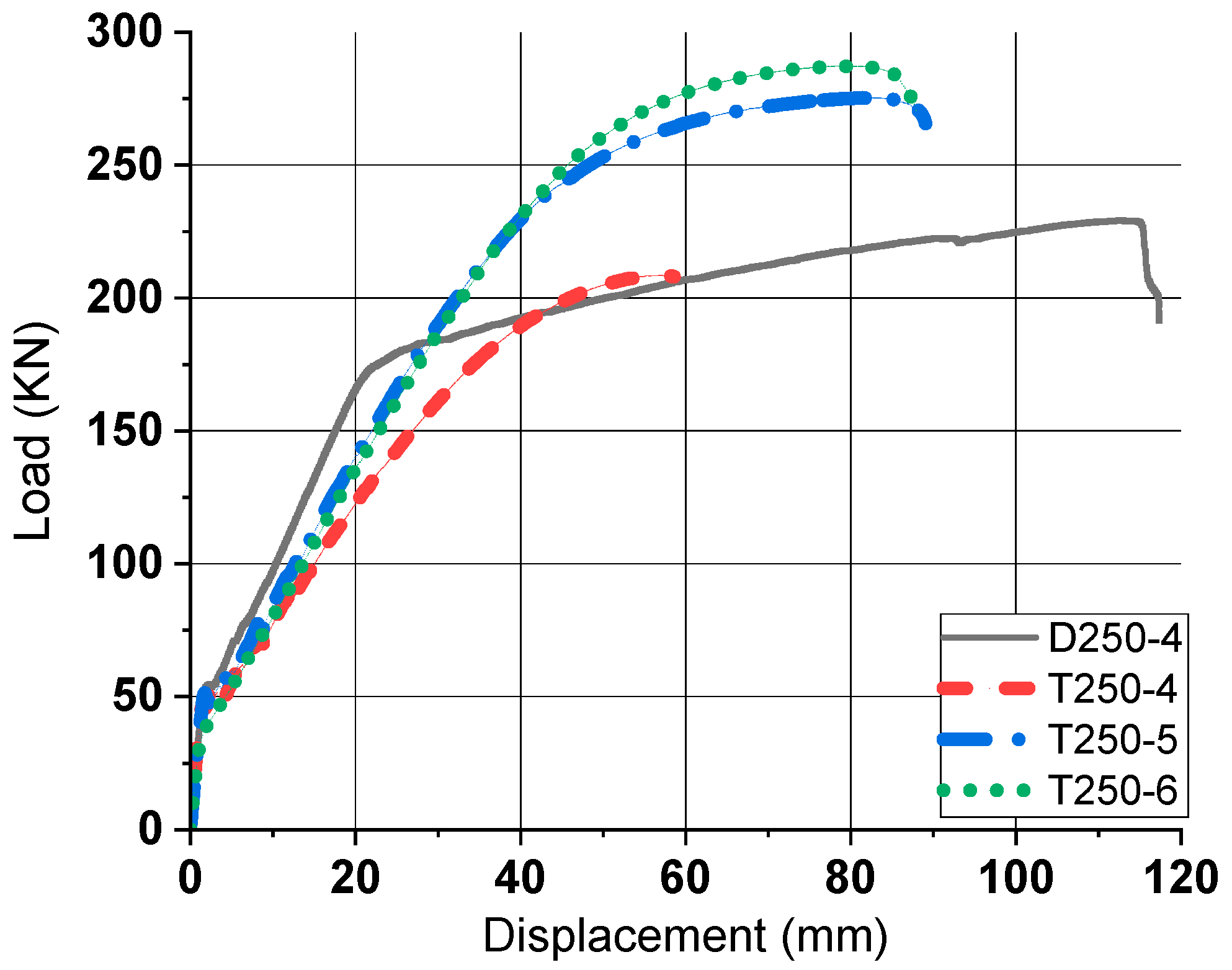

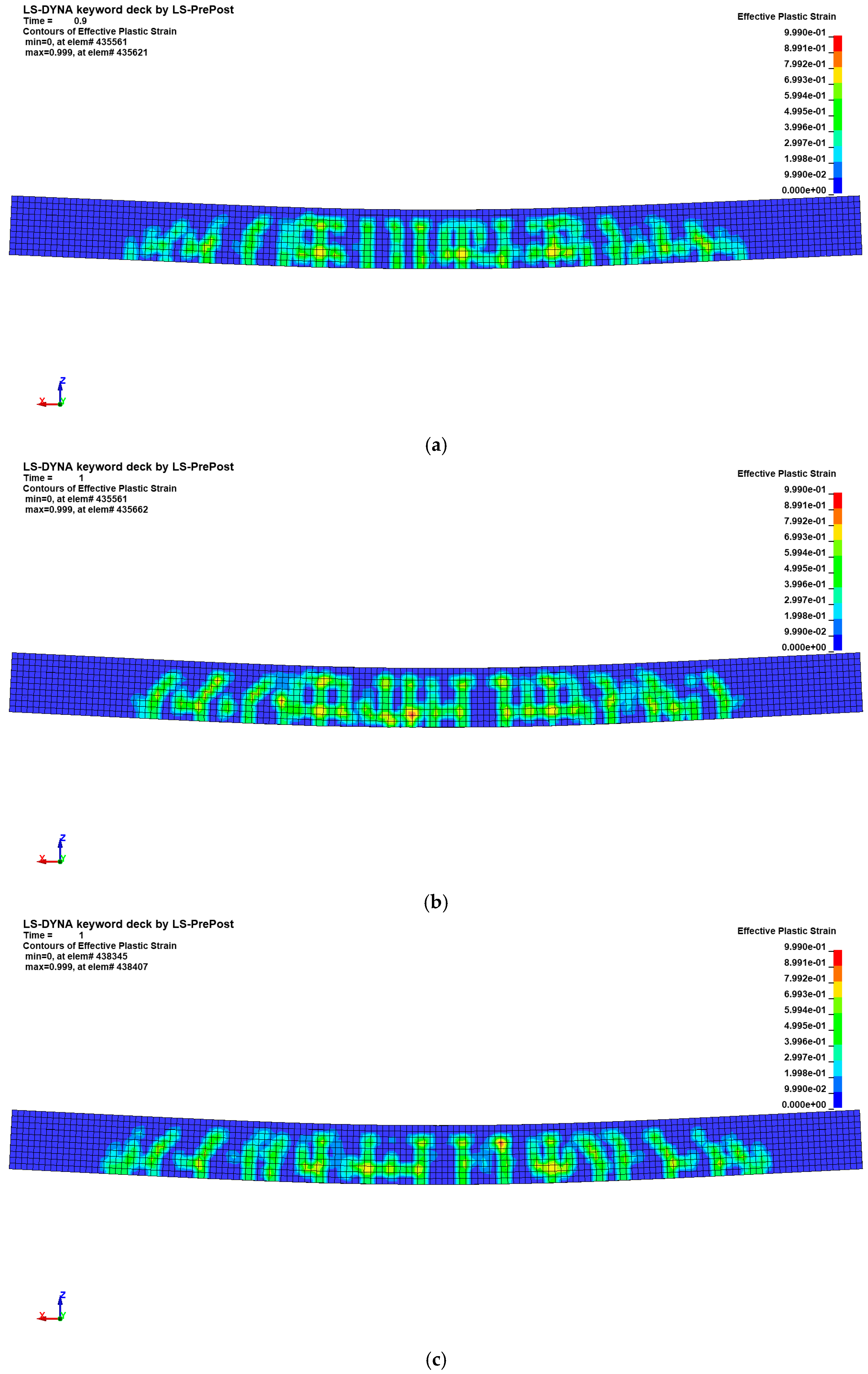

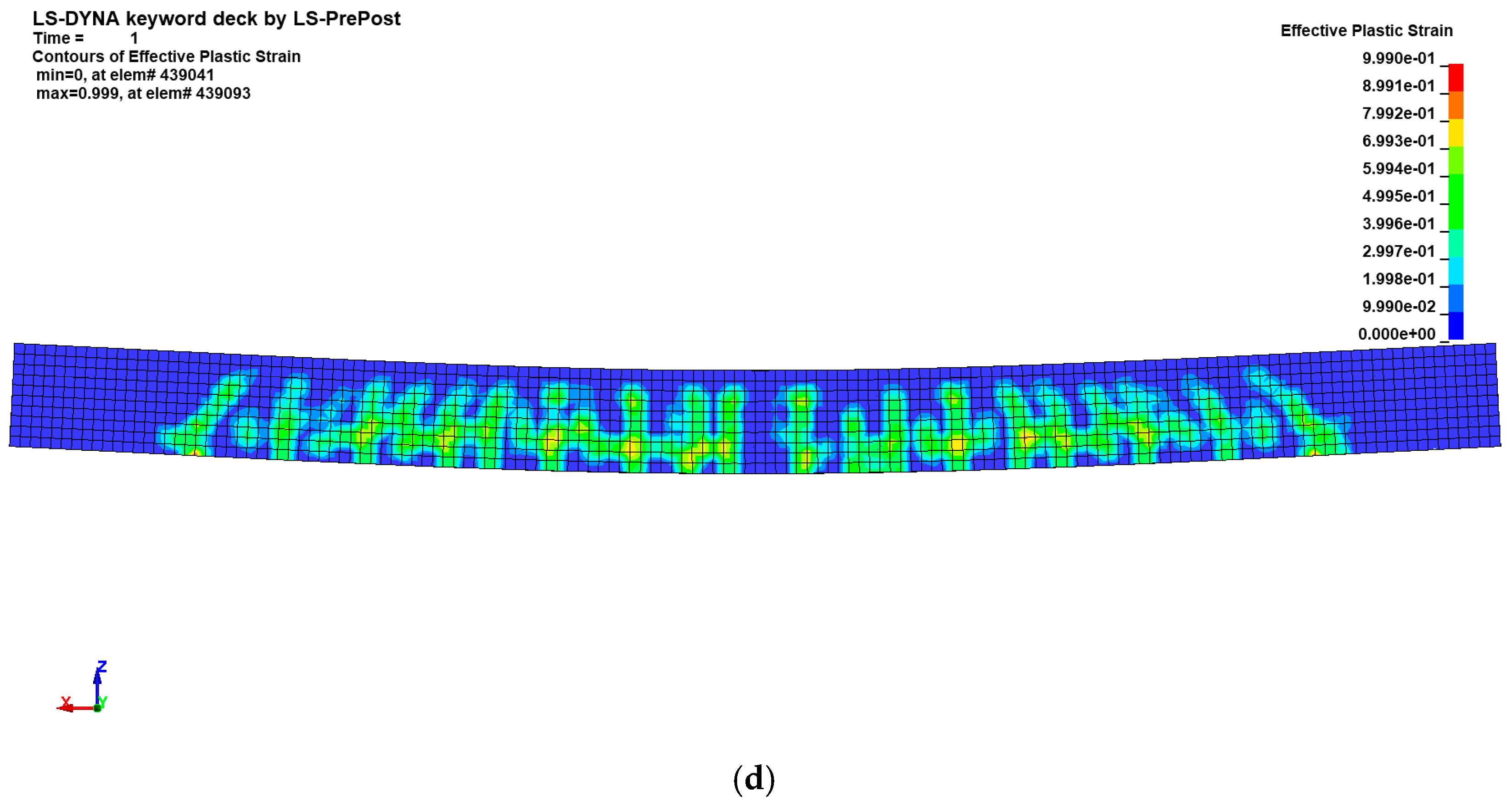

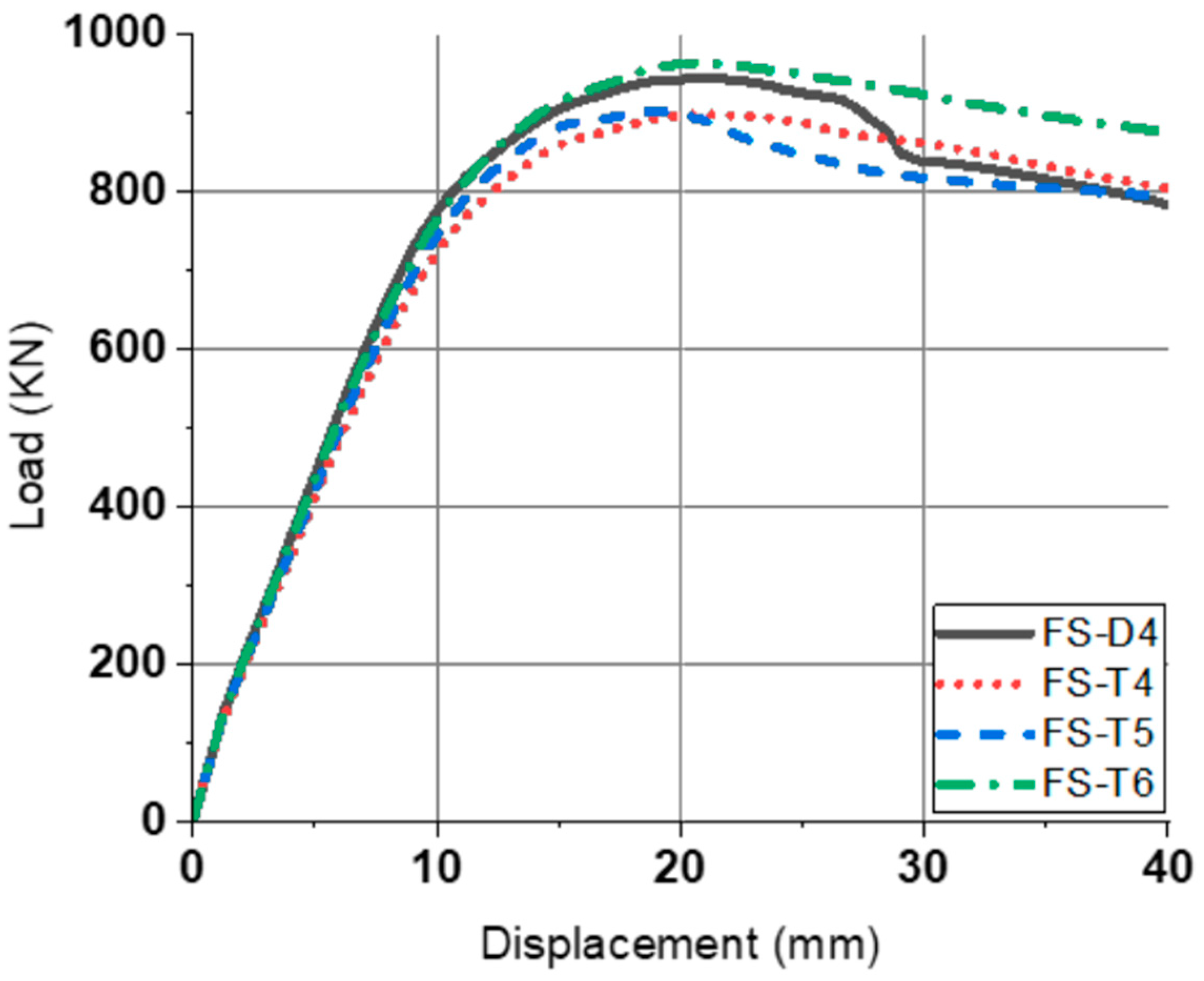

Through the previous experiment and FEA, the bending performance of pinned slab, fixed slab, and box culvert using tubular rebar was reviewed. In the case of pinned slab, tubular rebars, like general high strength rebars, had high yield strength and extreme strength, but showed excessive displacement of members due to low ductility. Therefore, it was confirmed that the displacement of members should be limited in the use of tubular rebars. FS-T5, which had a reinforcing ratio of 62.5% compared to FS-D4, had almost the same ductility before the yield of the member, but has a low ultimate load, and FS-T6, which has a reinforcing ratio of 75% shows a similar ductility and a higher ultimate load. Through this, it was verified that tubular rebars can have improved bending performance at a lower reinforcing ratio in a statically indeterminate state.

The experimental observations provide valuable insights into how the geometry of reinforcement influences failure mechanisms. This also validates the need for accurate material modeling to capture such effects, as demonstrated in the numerical simulation.

5.2. Effect of Replacing Reinforcement

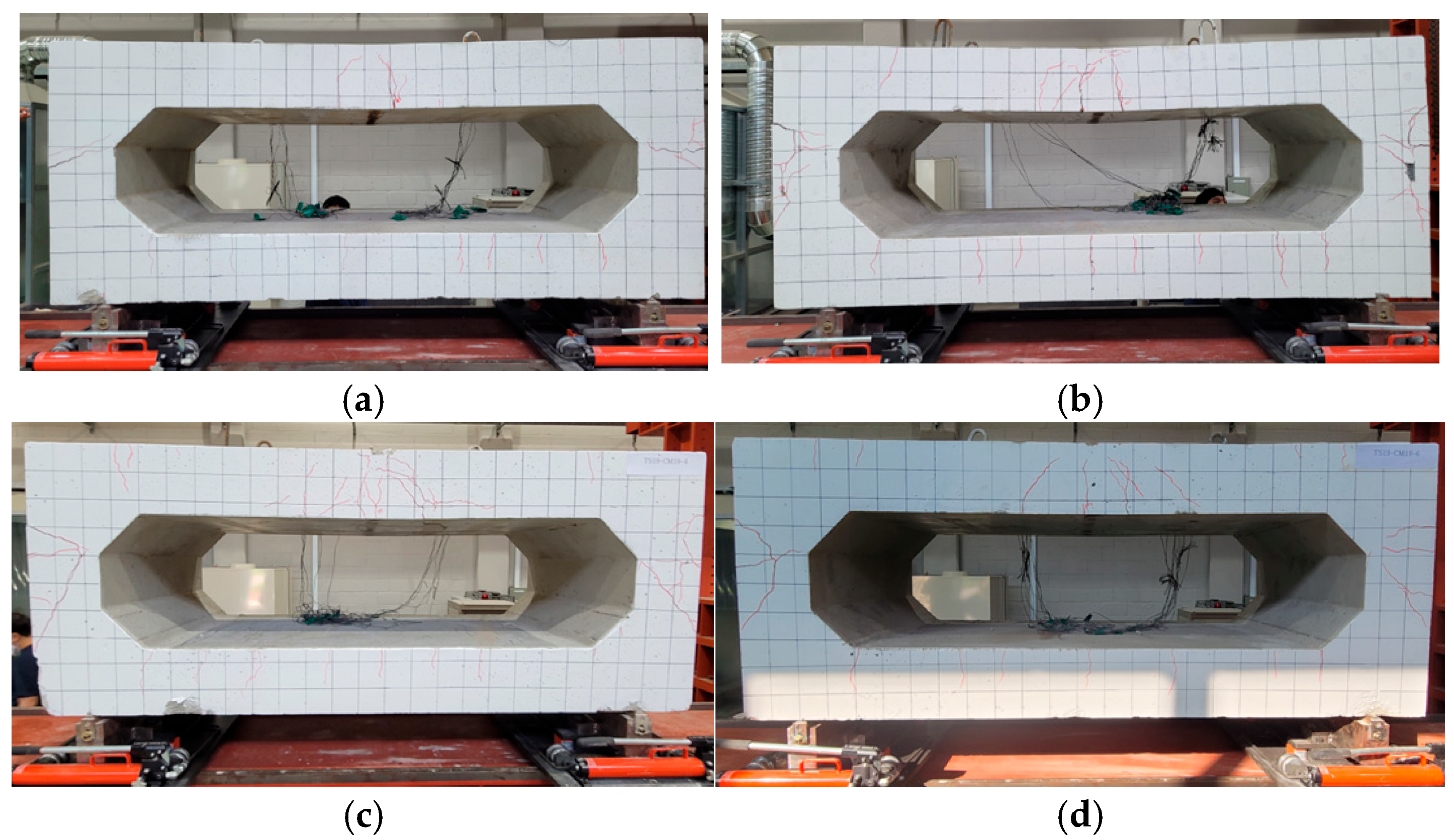

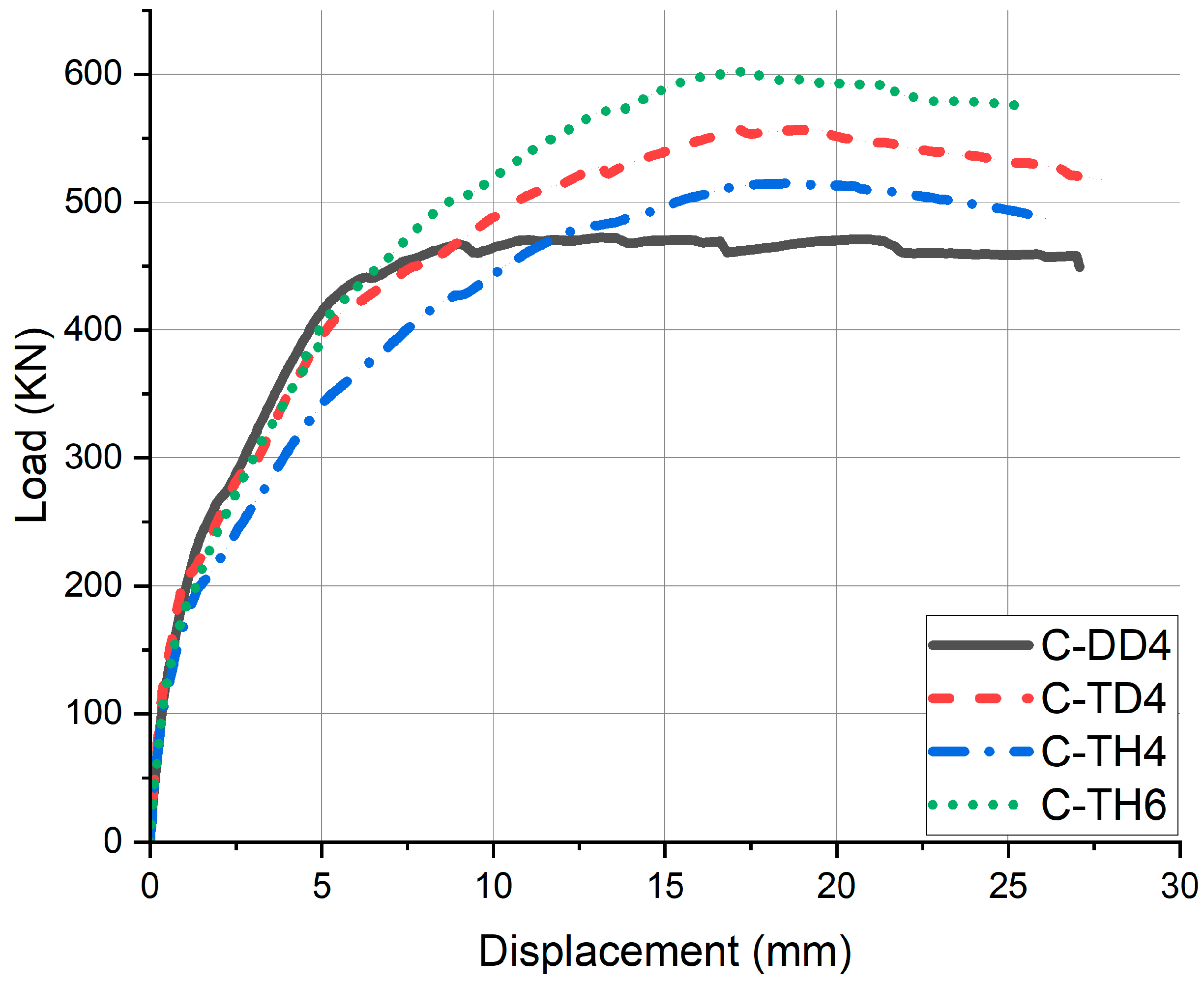

In order for tubular rebars to be effectively used as bending members by replacing deformed rebars, the structure should be in a statistically indeterminate state with restrictions on displacement. In that state, as shown in results of the fixed slab and box culverts, it should have a reinforcement ratio of 75% or more compared to deformed rebar members. As can be seen in the case of C-TD4, in the case of replacing the compression part, a very effective bending rebar replacement performance was confirmed. In the case of the tensile part, as observed in the case of C-TH4, it may have a high bending strength, but the amount of displacement increases. Therefore, like C-TH6, when tubular rebars and deformed rebars are fabricated as hybrid and the rebar ratio is 87.5% or higher, similar ductility can be observed as well as higher bending strength.

The experimental results also revealed that tubular rebar specimens tended to fail in a brittle manner, particularly in statically determinate conditions. This behavior was attributed to stress concentration at the hollow section, which accelerated localized fractures. These observations emphasize that while tubular rebars may limit ductility, they can be advantageous in statically indeterminate systems where internal force redistribution is allowed. The experimental insights thus reinforce the importance of structural configuration when considering tubular reinforcement.

While this study focuses primarily on the structural performance and material efficiency of tubular rebars, it is important to note that a complete sustainability assessment should also consider energy consumption in the manufacturing process, transport, and construction, as well as life-cycle environmental impacts. Future research is planned to evaluate the embodied energy and carbon footprint associated with tubular reinforcement to provide a more comprehensive understanding of its sustainability potential.