Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt

Abstract

1. Introduction

2. Raw Materials and Test Methods

2.1. Raw Materials

2.2. Sample Preparation

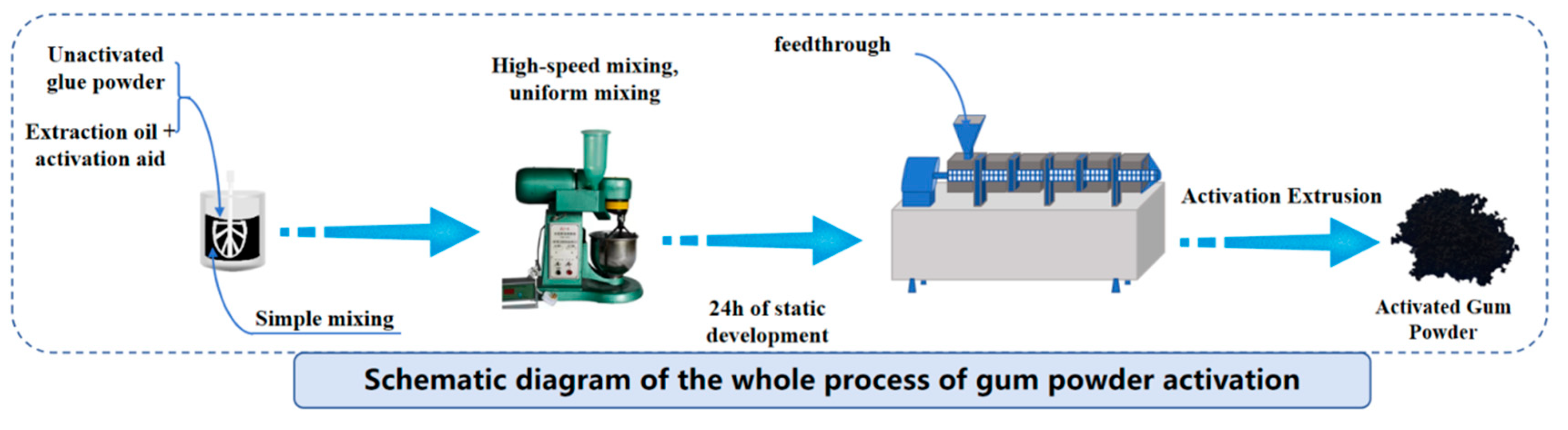

- (1)

- Activated Rubber Powder Preparation

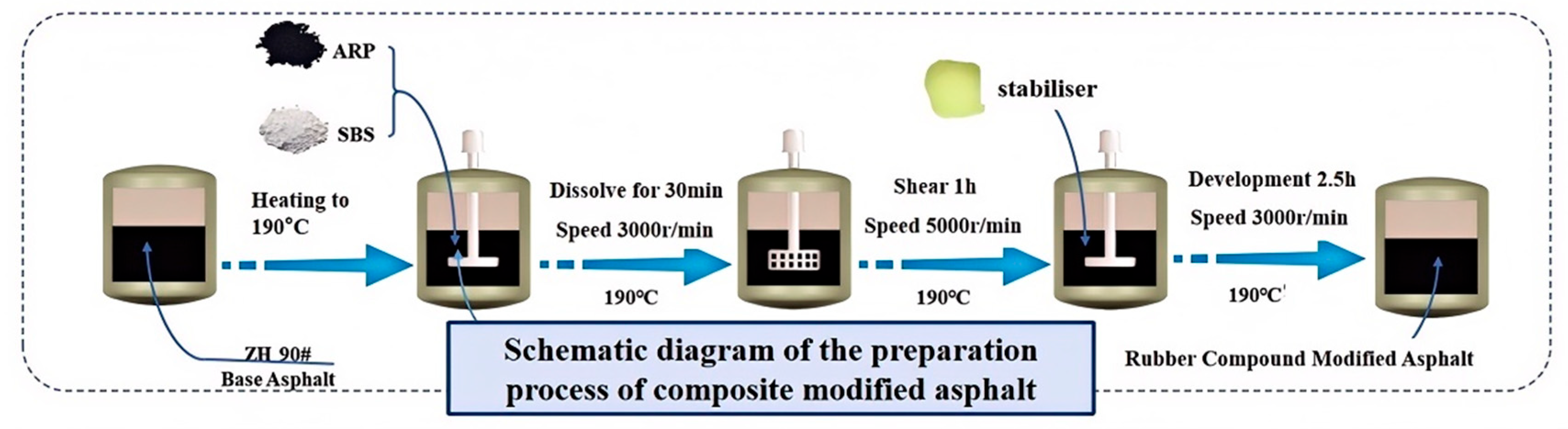

- (2)

- Preparation of Activated Rubber Powder Composite SBS-Modified Asphalt

2.3. Test Method

- (1)

- Routine Performance Test

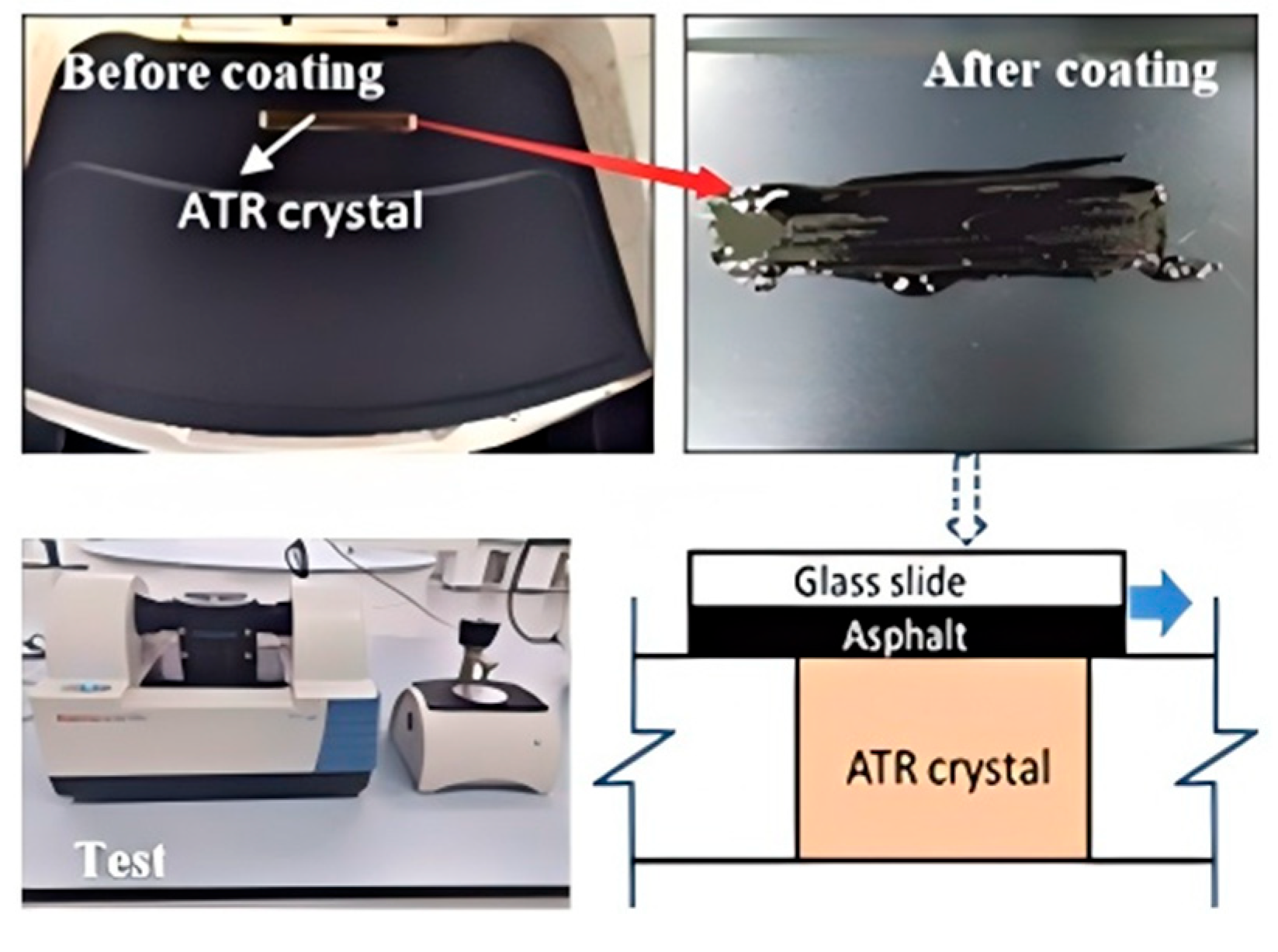

- (2)

- Infrared Spectroscopy Testing

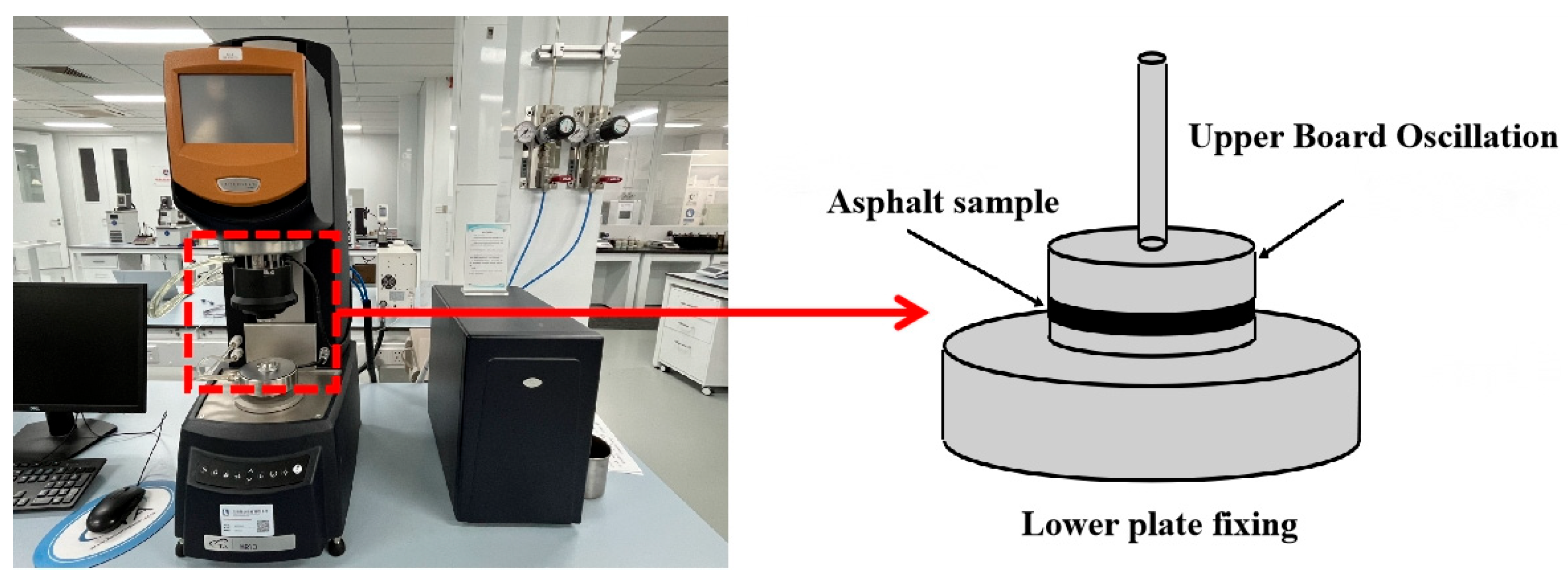

- (3)

- Dynamic Shear Rheological Test

- (4)

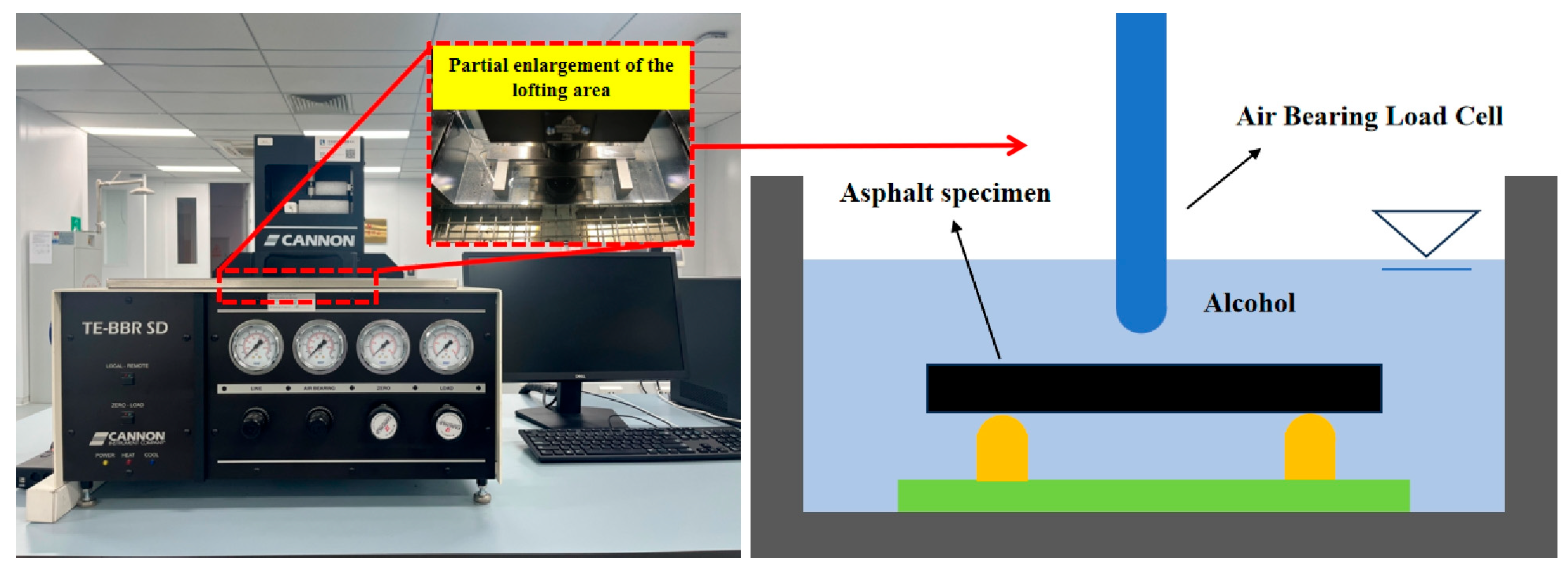

- Bending Beam Rheological Test

- (5)

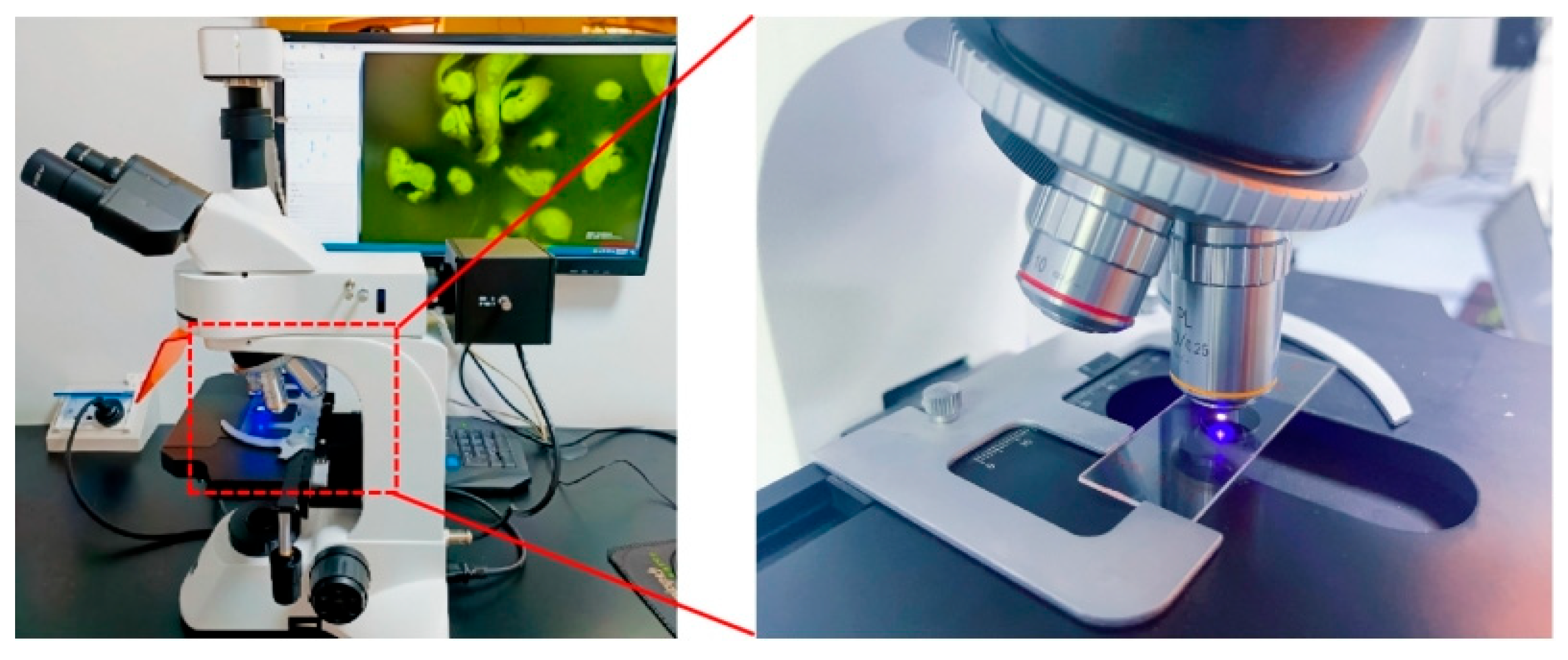

- Fluorescence microscope experiment

3. Experimental Results and Analysis

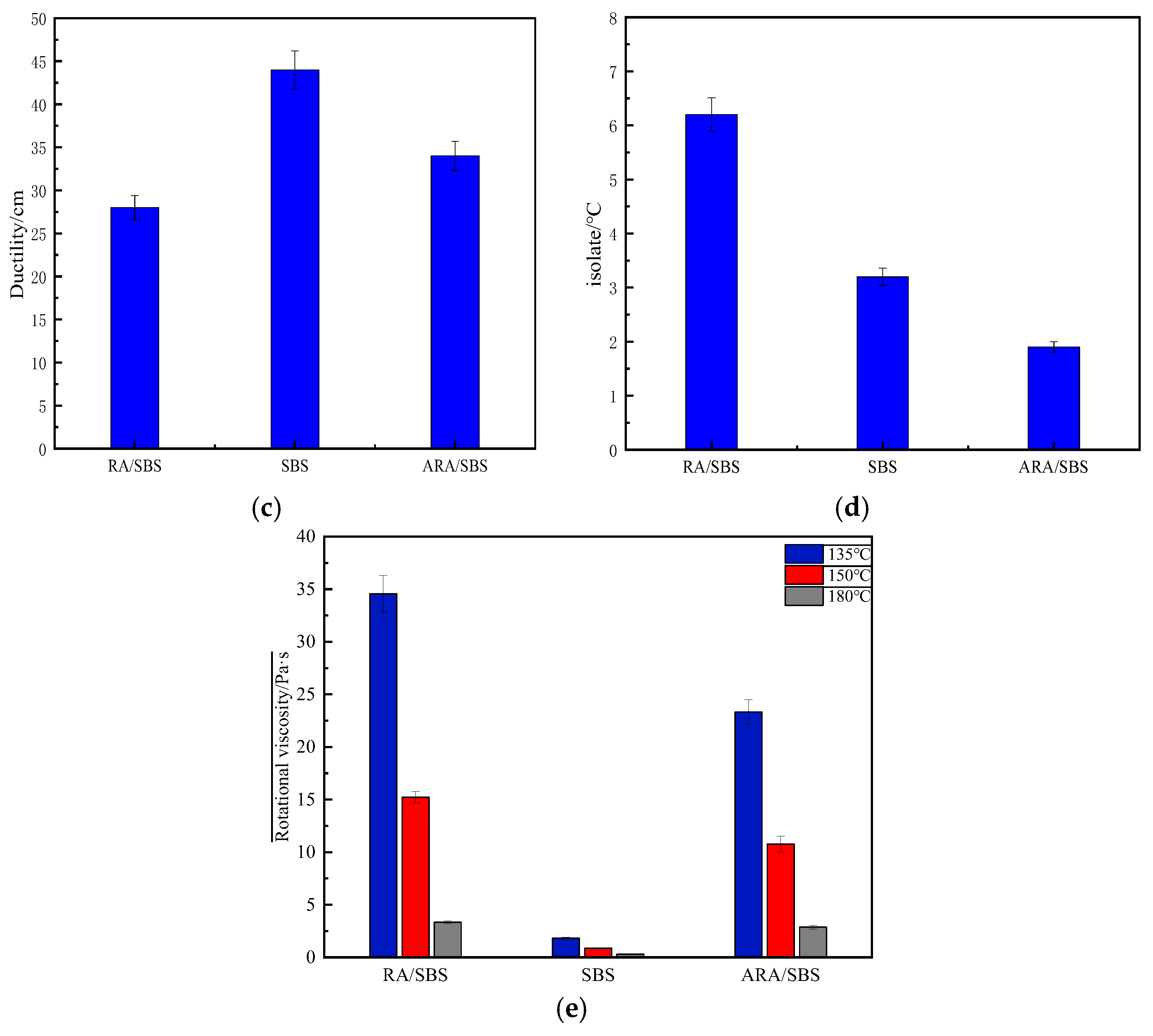

3.1. Conventional Performance Testing Analysis

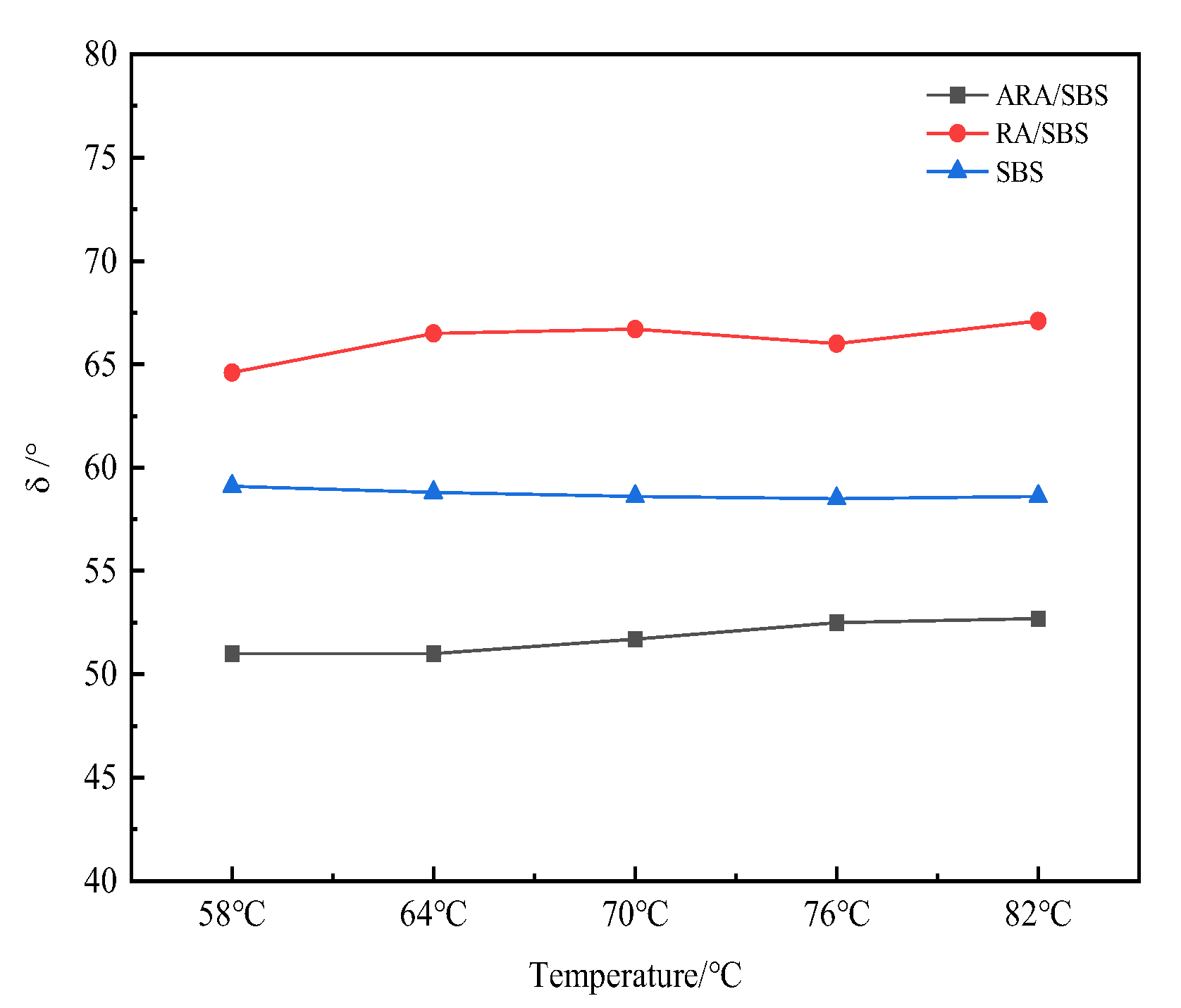

3.2. Dynamic Shear Rheological Test Analysis

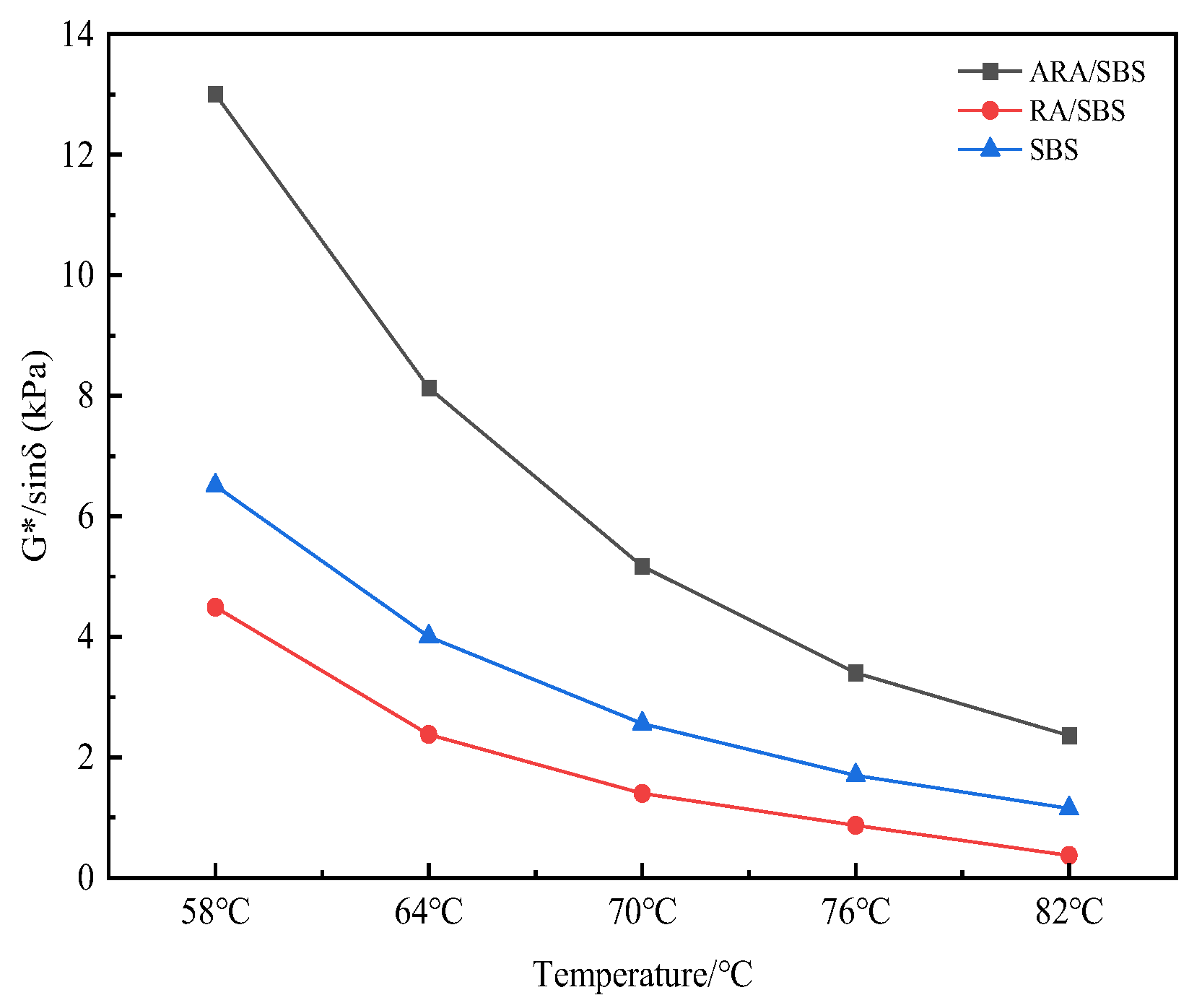

- (1)

- Temperature Sweep Test

- (2)

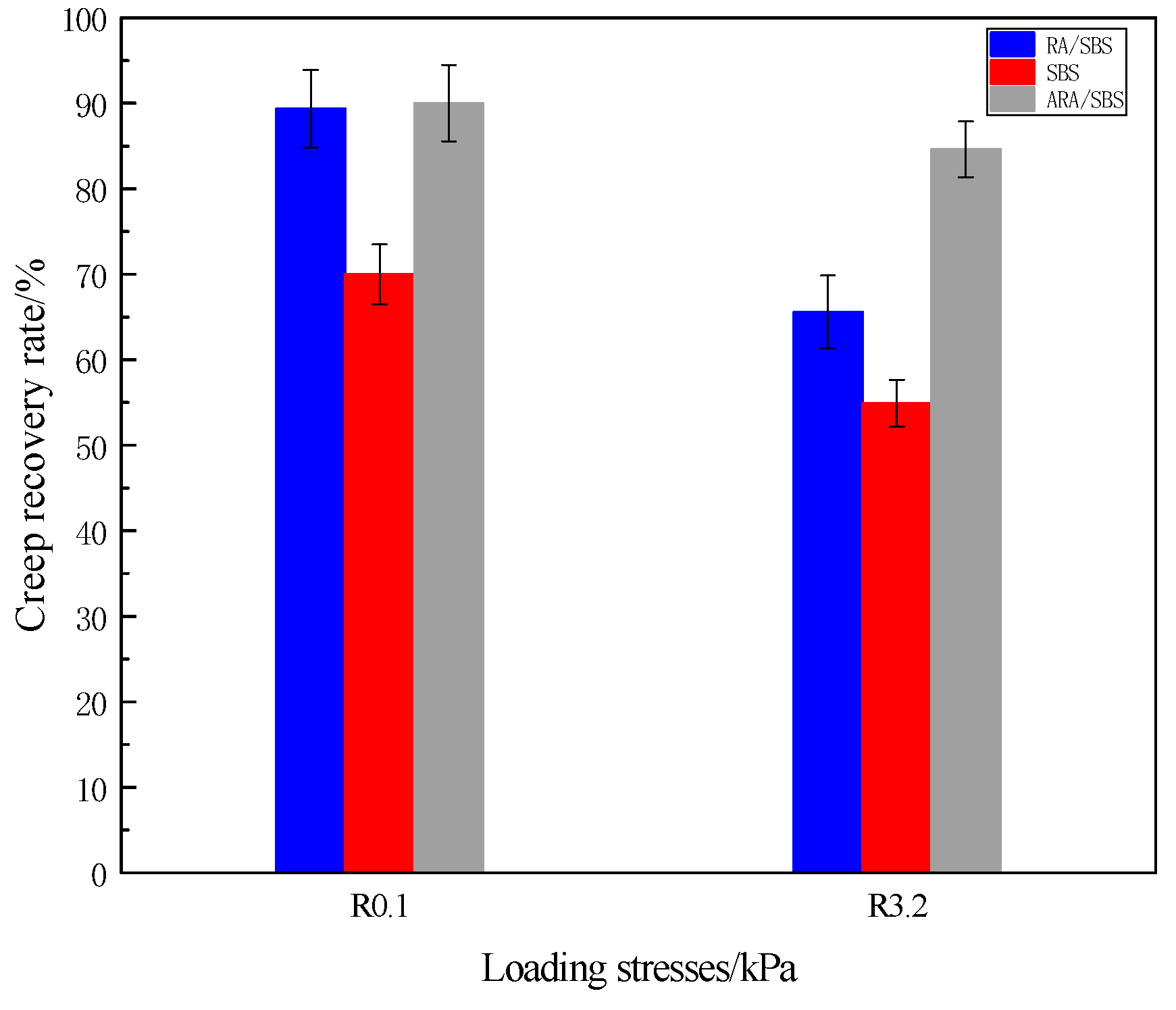

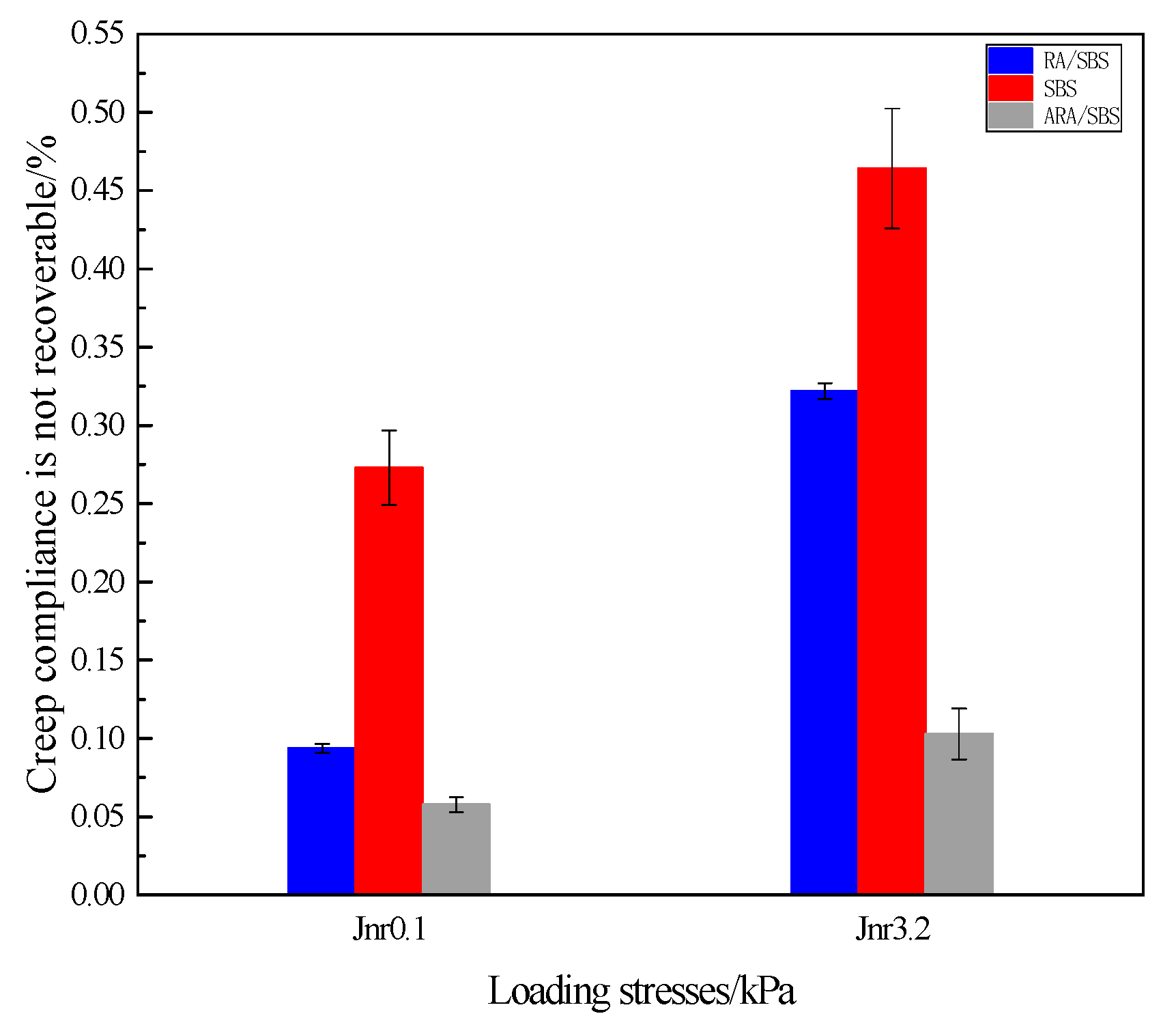

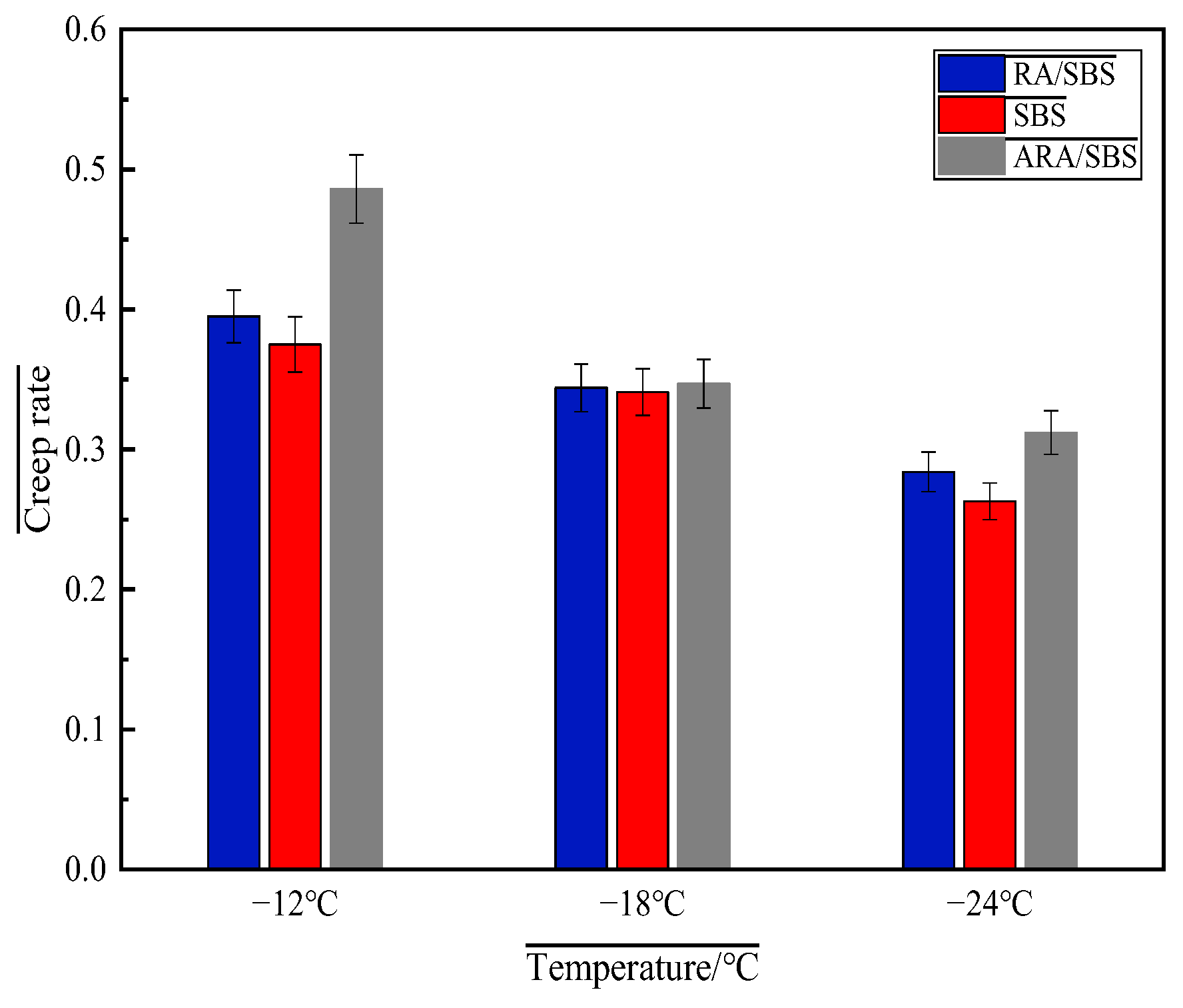

- Multi-Stress Creep Recovery Test

- (3)

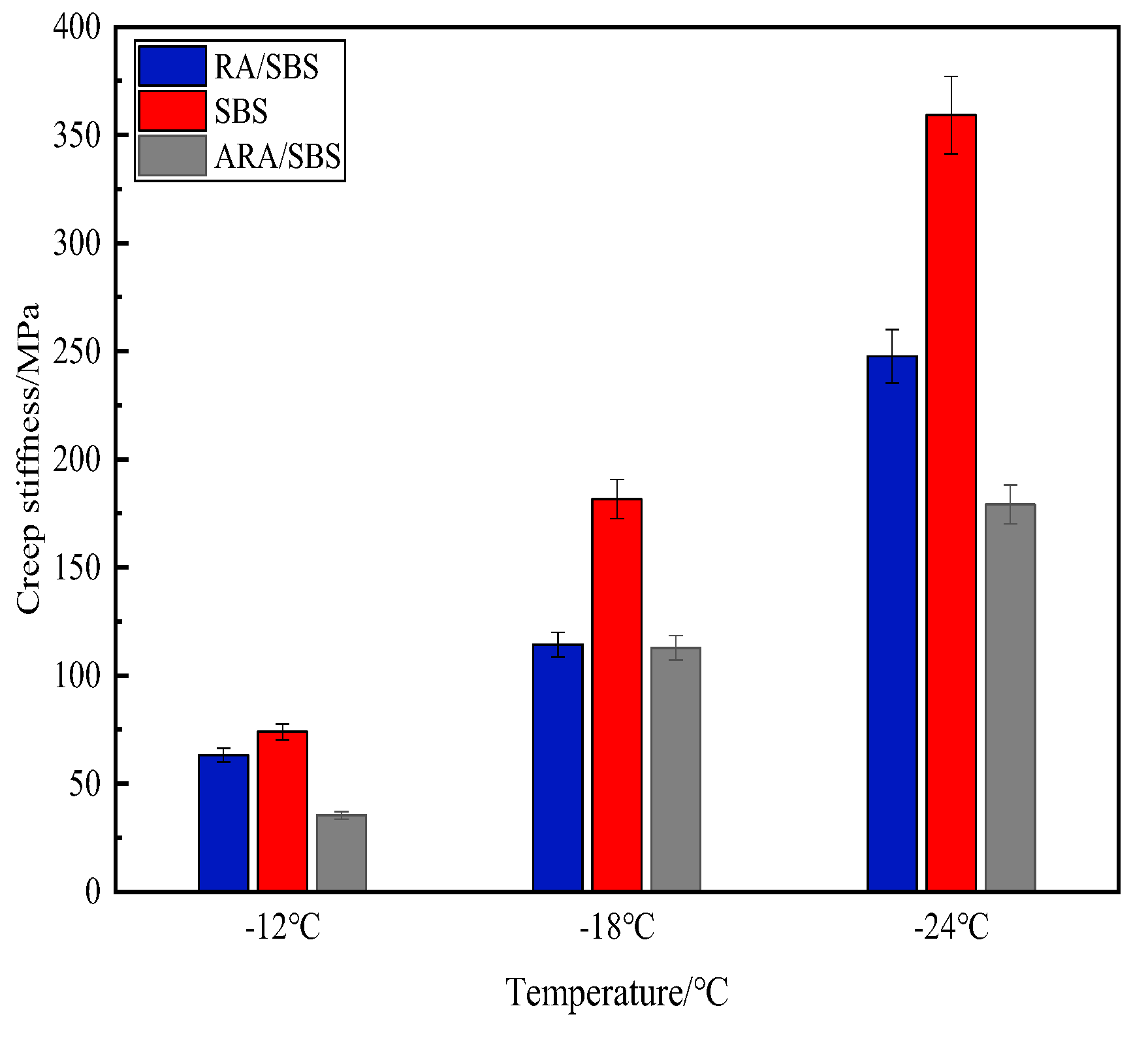

- BBR Test Results Analysis

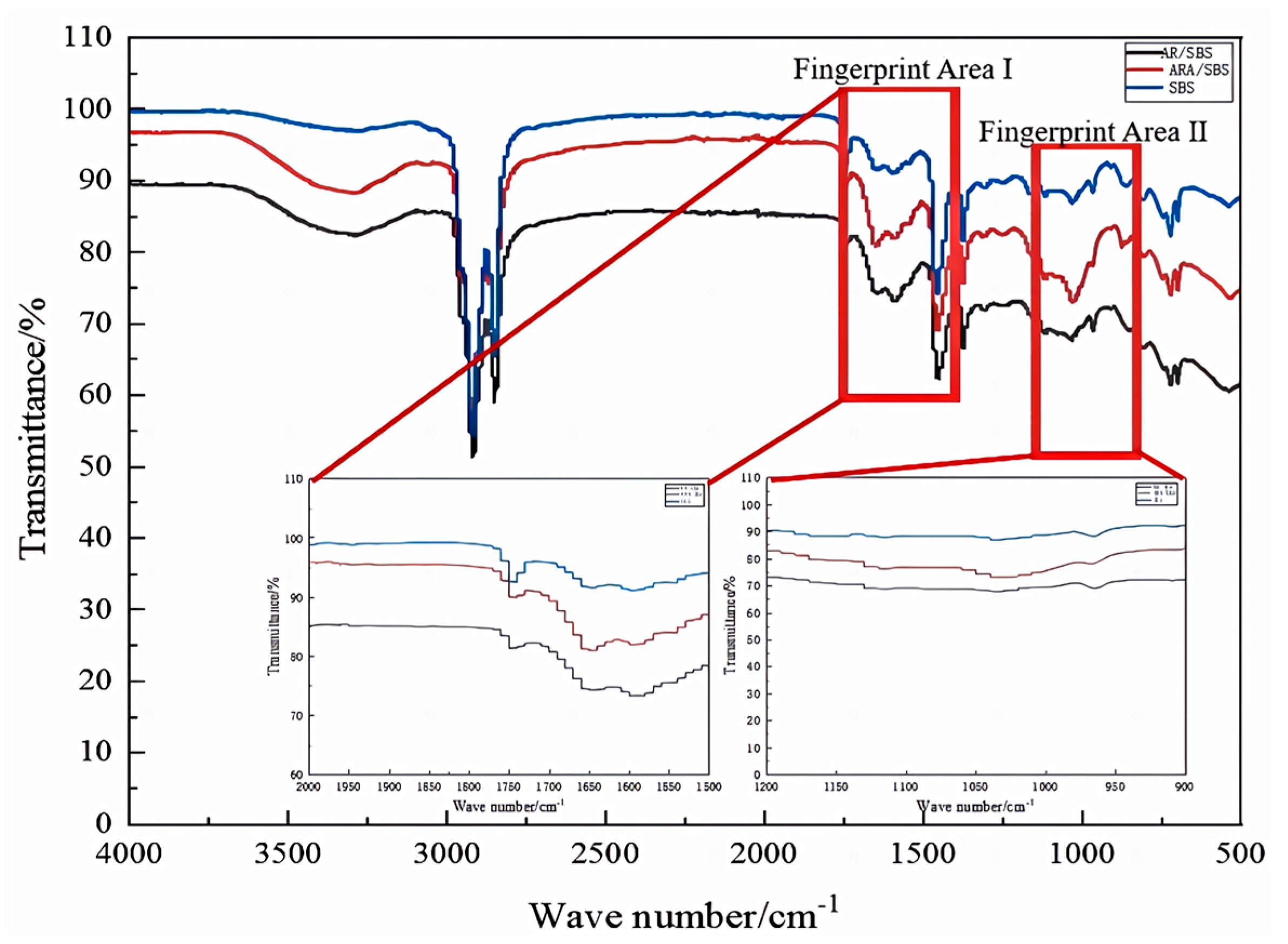

3.3. FTIR Test Analysis

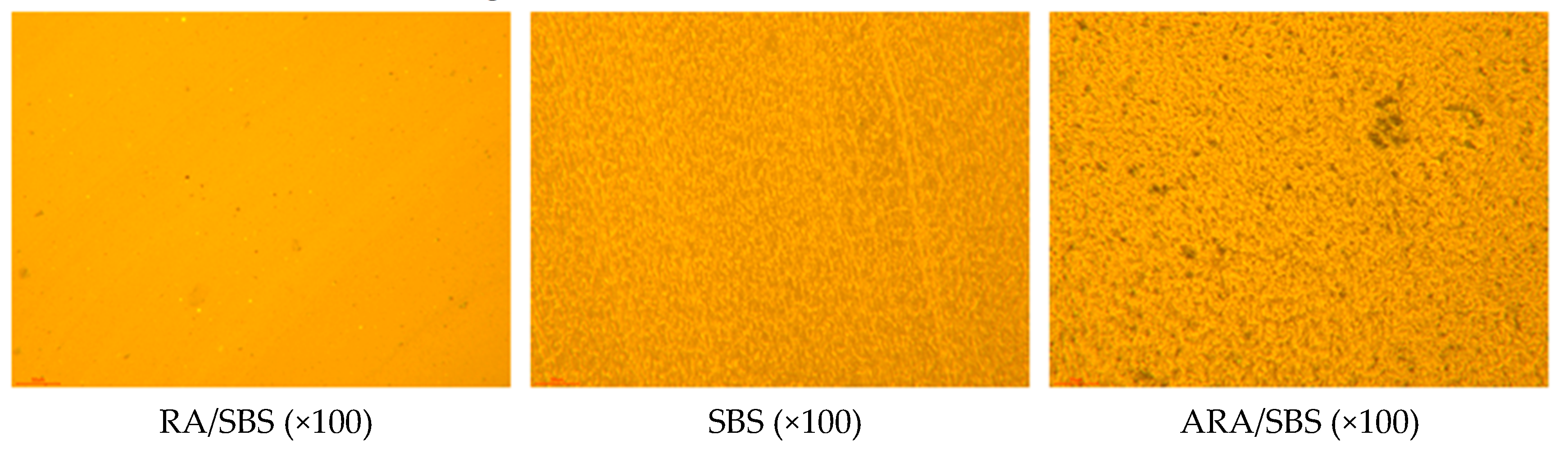

3.4. Fluorescent Microscope Test Analysis

4. Conclusions

- (1)

- Through the above experimental characterization, it can be seen that ARA/SBS composite-modified asphalt shows a significant multidimensional performance synergistic effect, which confirms that the activated rubber powder can give the material excellent viscoelastic properties, improve the storage stability, and also show good high temperature performance.

- (2)

- High activation degree of rubber particles on the asphalt system modification presents two-sided effect: on the one hand, the interface compatibility enhancement can inhibit the tendency for phase separation, but excessive activation will trigger local agglomeration due to insufficient participation in the matrix asphalt cross-linking reaction in the dynamic load, evolving into a crack-sprouting point, resulting in a decrease in ductility; on the other hand, the higher the activation degree, the better the compatibility of rubber and asphalt, so the softening point and the degree of needle entry increase; thus, the dosage of activated rubber particles must be strictly controlled.

- (3)

- RA/SBS will trigger the stress concentration effect due to surface inertia, making the asphalt performance enhancement limited; twin-screw shear activation technology can be realized to enhance the phase dispersion effect by increasing the surface of the rubber powder polar functional groups, while encouraging coupling between the carboxyl and hydroxyl groups in the ARA/SBS and asphalt gel, causing the chemical formation of a three-dimensional cross-linked network structure. The constructed structure greatly improved the high- and low-temperature capability of asphalt.

- (4)

- ARA/SBS showed the emergence of obvious functional groups at 1750 cm−1 and 1075 cm−1 due to the surface oxidation of functional groups and asphalt components in the polar aromatic structure of the reaction. This shows that the activation of the rubber particles and matrix asphalt matches the degree of enhancement, prompting the composite-modified asphalt system to show enhanced interfacial compatibility, and ultimately showing the synergistic optimization of the performance indexes.

- (5)

- The twin-screw extruder activation significantly improves the reaction activity of the rubber powder, activated rubber powder, and asphalt/SBS combination; in detail, the asphalt rutting factor increases and both the high-temperature rutting and low-temperature cracking resistance show optimization, compared with the traditional process used to enhance the mixing of the rubber powder. The process also promotes the use of waste tires resources, providing a comprehensive cost reduction.

- (6)

- The industrialization of the twin-screw activation process can significantly reduce energy consumption, enhance the efficiency of waste rubber regeneration through continuous production, and reduce the accumulation of solid waste and carbon emissions. In terms of economic benefits, the integration of equipment can improve the production capacity, promote growth in the product interface bonding strength, and is applicable to high-value areas such as highway engineering, airport runways, etc. Additionally, green recycling, profitability, and efficiency metrics are all improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Z.; Wu, S.; Xie, J.; Yang, C.; Yang, X.; Chen, S.; Liu, Q. Recycle of waste tire rubber powder in a novel asphalt rubber pellets for asphalt performance enhancement. Constr. Build. Mater. 2023, 399, 132572. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Hao, G.; Zhao, Q.; Hu, Y.; Zou, X.; Li, Z. Effect of styrene butadiene styrene and desulfurized rubber powder on asphalt modification: Preparation, performance enhancement, mechanism analysis. Sci. Total Environ. 2023, 912, 169077. [Google Scholar] [CrossRef] [PubMed]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Kong, P.; Xu, G.; Yang, J.; Chen, X.; Zhu, Y. Study on Storage Stability of Activated Reclaimed Rubber Powder Modified Asphalt. Materials 2021, 14, 4684. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Xiao, F.; Amirkhanian, S.N. Surface activation of scrap tire crumb rubber to improve compatibility of rubberized asphalt. Resour. Conserv. Recycl. 2021, 169, 105518. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Y.; Yang, Y.; Ma, Y.; Li, J.; Huang, M. The effect of activation method of rubber on the performance of modified asphalt binder. Materials 2020, 13, 3679. [Google Scholar] [CrossRef]

- Mousavi, M.; Hosseinnezhad, S.; Kabir, S.F.; Burnett, D.J.; Fini, E.H. Reaction pathways for surface activated rubber particles. Resour. Conserv. Recycl. 2019, 149, 292–300. [Google Scholar] [CrossRef]

- Li, B.; Li, Q.; Zhu, X.; Wei, Y.; Li, Z.; Wei, D. Effect of sodium hypochlorite-activated crumb rubber on rheological properties of rubber-modified asphalt. J. Mater. Civ. Eng. 2020, 32, 04020326. [Google Scholar] [CrossRef]

- Shatanawi, K.M.; Biro, S.; Geiger, A.; Amirkhanian, S.N. Effects of furfural activated crumb rubber on the properties of rubberized asphalt. Constr. Build. Mater. 2012, 28, 96–103. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, J.; Li, Q.; Li, B. Aging Properties and Mechanism of Microwave-Activated Crumb Rubber Modified Asphalt Binder. Front. Mater. 2020, 7, 603938. [Google Scholar] [CrossRef]

- Sousa, J.B.; Vorobiev, A.; Rowe, G.M.; Ishai, I. Reacted and activated rubber: Elastomeric asphalt extender. Transp. Res. Rec. 2013, 2371, 32–40. [Google Scholar] [CrossRef]

- Chen, S.; Ge, D.; Gong, F.; You, Z.; Diab, A.; Ye, M. Rheological properties and chemical characterisation of reacted and activated rubber modified asphalt binder. Road Mater. Pavement Des. 2020, 21 (Suppl. 1), S140–S154. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.; Zhang, K.; Li, Z. Rheological Property Evaluation and Microreaction Mechanism of Rubber Asphalt, Desulfurized Rubber Asphalt, and Their Composites. J. Mater. Civ. Eng. 2021, 33, 04021100. [Google Scholar] [CrossRef]

- Sheng, Y.; Li, H.; Geng, J.; Tian, Y.; Li, Z.; Xiong, R. Production and performance of desulfurized rubber asphalt binder. Int. J. Pavement Res. Technol. 2017, 10, 262–273. [Google Scholar] [CrossRef]

- Hosseinnezhad, S.; Kabir, S.F.; Oldham, D.; Mousavi, M.; Fini, E.H. Surface functionalization of rubber particles to reduce phase separation in rubberized asphalt for sustainable construction. J. Clean. Prod. 2019, 225, 82–89. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, M.; Li, Y.; Zou, Y.; Chen, A.; Wang, F.; Liu, L.; Gu, D.; Zhou, S. Swelled mechanism of crumb rubber and technical properties of crumb rubber modified bitumen. Materials 2022, 15, 7987. [Google Scholar] [CrossRef]

- Highway Research Institute of the Ministry of Communications. Highway Engineering Asphalt and Asphalt Mixture Test Specification; People’s Traffic Press: Beijing, China, 1984. [Google Scholar]

- Yin, L.; Yang, X.; Shen, A.; Wu, H.; Lyu, Z.; Li, B. Mechanical properties and reaction mechanism of microwave-activated crumb rubber-modified asphalt before and after thermal aging. Constr. Build. Mater. 2021, 267, 120773. [Google Scholar] [CrossRef]

- Tang, N.; Luo, M.; Xue, C.; Liu, S.; Li, R.; Zhu, H.; Cheng, H. Performance evaluation and mechanism investigation of aged SBS/chemically activated rubberized asphalt. Constr. Build. Mater. 2025, 458, 139497. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, H.; Sun, J.; Yu, T. Comparative analysis on rheological characteristics of different modified asphalt based on DSR and BBR evaluation. J. Eng. Des. Technol. 2023, 21, 1568–1587. [Google Scholar] [CrossRef]

- Kabir, S.F.; Mousavi, M.; Fini, E.H. Selective adsorption of bio-oils’ molecules onto rubber surface and its effects on stability of rubberized asphalt. J. Clean. Prod. 2020, 252, 119856. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.; Lv, S.; Zhang, Y.; Zhu, X.; Zheng, C. Investigation on rheological properties and storage stability of modified asphalt based on the grafting activation of crumb rubber. Polymers 2019, 11, 1563. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.; Zhang, M.; Cao, D.; Su, Q.; Zhang, H. Development of Activated Waste Tire Rubber Composite-Modified Asphalt and Its Performance. J. Test. Eval. 2025, 53. [Google Scholar] [CrossRef]

- Mirwald, J.; Hofko, B.; Pipintakos, G.; Blom, J.; Soenen, H. Comparison of microscopic techniques to study the diversity of the bitumen microstructure. Micron 2022, 159, 103294. [Google Scholar] [CrossRef]

- Kedarisetty, S.; Biligiri, K.P.; Sousa, J.B. Advanced rheological characterization of Reacted and Activated Rubber (RAR) modified asphalt binders. Constr. Build. Mater. 2016, 122, 12–22. [Google Scholar] [CrossRef]

| Performance Indicators | Zhenhai 90# |

|---|---|

| Penetration of a needle (25 °C, 100 g, 5 s)/0.1 mm | 89.2 |

| Softening point (International Law)/°C | 44.0 |

| Ductility (5 cm/min, 10 °C)/cm | 150.19 |

| 135 °C Rotational viscosity/pa·s | 0.503 |

| 25 °C Elastic recovery/% | 12 |

| Residues after aging in rotary film ovens (163 °C, 85 min) | |

| Mass loss/% | 0.1301 |

| Needle penetration ratio/% | 62 |

| Ductility (5 cm/min, 10 °C)/cm | 44.9 |

| Sports Event | Sieve Residue (%) | Relative Density (g/cm3) | Moisture Content (%) | Metal Content (%) | Fiber Content (%) |

|---|---|---|---|---|---|

| Technical indicators | <10 | 1.10~1.30 | <1 | <0.03 | <1 |

| Sports Event | Ash (%) | Acetone Extract (%) | Carbon Black Content (%) | Rubber Hydrocarbon Content (%) | |

| Technical indicators | ≤8 | ≤16 | ≥28 | ≥48 | |

| Sports Event | Numbers |

|---|---|

| Densities (20 °C)/(g·cm3) | 0.9895 |

| Index of refraction | 1.5610 |

| Flash point (open)/°C | 270 |

| Relative average molecular weight | 357 |

| Quality Indicators | Numbers |

|---|---|

| Apparent density/g·cm3 | 0.8 |

| Melting point | ≥110 °C |

| Fineness (80 mesh sieve residue) | ≤2% |

| Hydration | ≤0.5% |

| Type of Asphalt | ||||||

|---|---|---|---|---|---|---|

| SBS | 2167.7 | 108 | 376.7 | 0.050 | 0.174 | 0.674 |

| RA/SBS | 2771.6 | 702 | 678 | 0.253 | 0.245 | 0.498 |

| ARA/SBS | 3630.6 | 968 | 1150.9 | 0.267 | 0.317 | 0.584 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Dong, R.; Zhao, J.; Wang, Y.; Guo, F.; Wei, X.; Li, B.; Huang, Y. Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt. Materials 2025, 18, 2359. https://doi.org/10.3390/ma18102359

Zhao Y, Dong R, Zhao J, Wang Y, Guo F, Wei X, Li B, Huang Y. Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt. Materials. 2025; 18(10):2359. https://doi.org/10.3390/ma18102359

Chicago/Turabian StyleZhao, Yicai, Rui Dong, Jingzhuo Zhao, Yongning Wang, Fucheng Guo, Xiaolong Wei, Bo Li, and Yong Huang. 2025. "Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt" Materials 18, no. 10: 2359. https://doi.org/10.3390/ma18102359

APA StyleZhao, Y., Dong, R., Zhao, J., Wang, Y., Guo, F., Wei, X., Li, B., & Huang, Y. (2025). Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt. Materials, 18(10), 2359. https://doi.org/10.3390/ma18102359