Evaluation of Wetting Behaviors of Liquid Sodium on Transition Metals: An Experimental and Molecular Dynamics Simulation Study

Abstract

1. Introduction

2. Experimental and Simulation Details

2.1. Materials and Methods

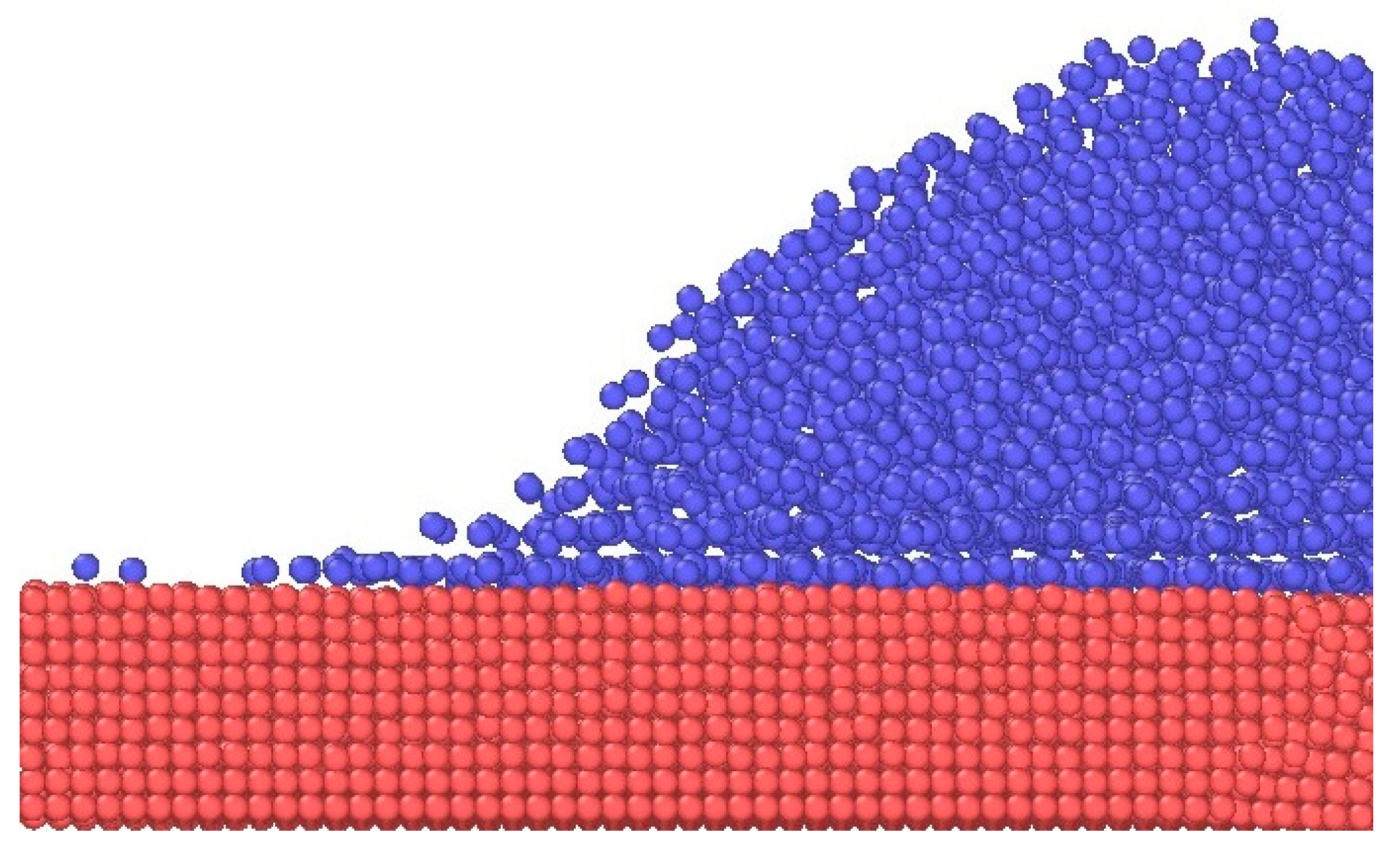

2.2. Simulation Model and Methodology

3. Results

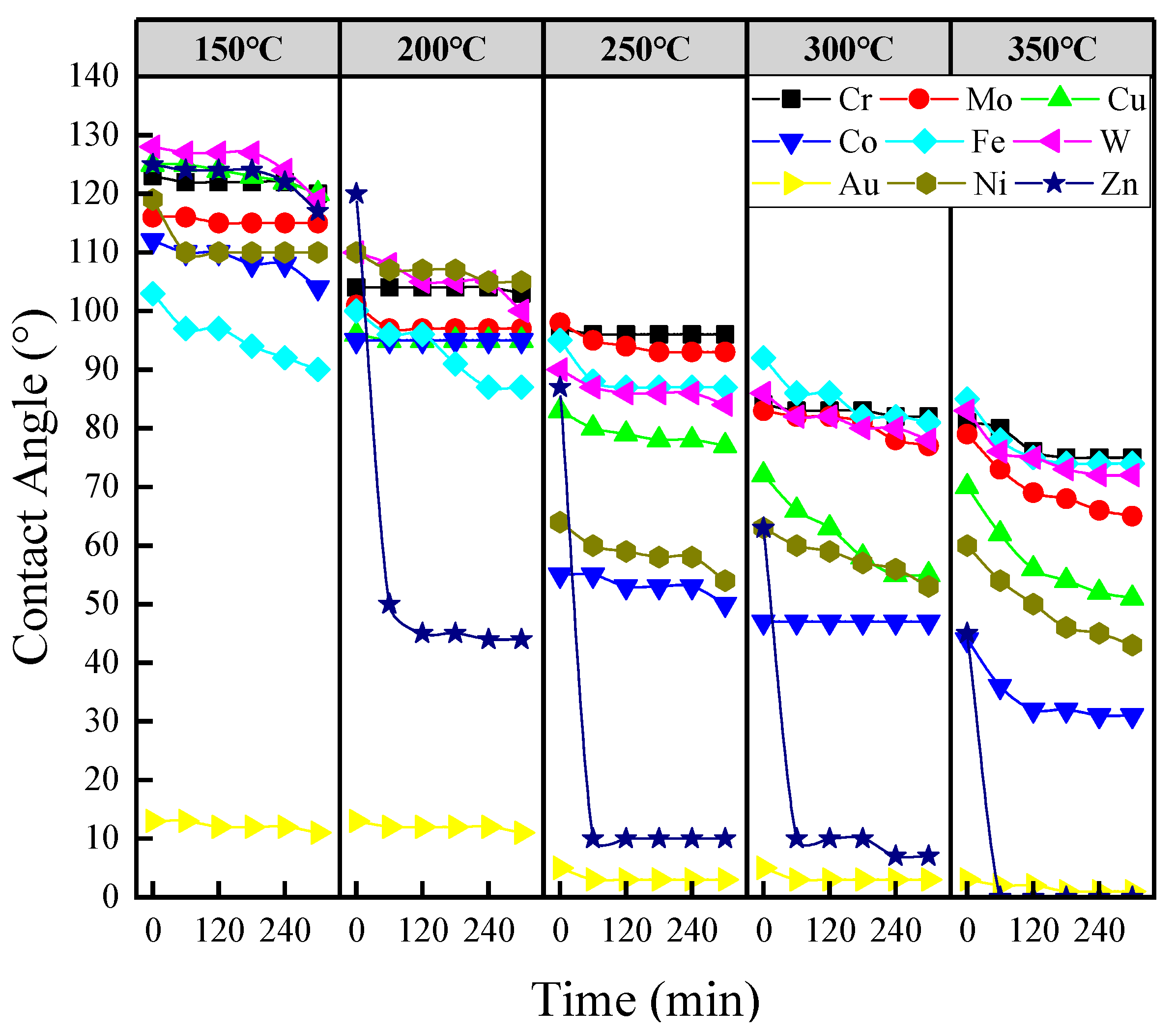

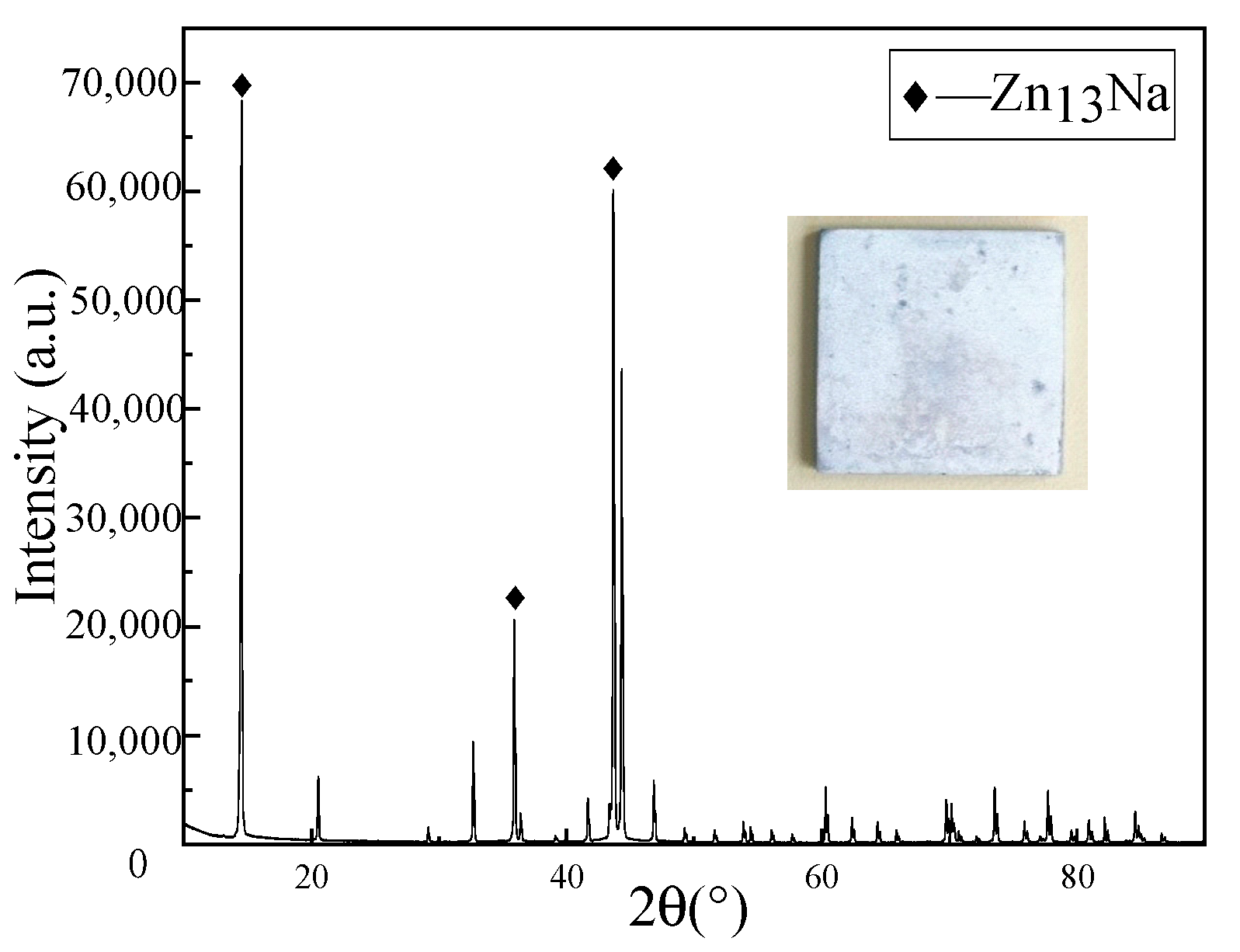

3.1. Contact Angle Measurement and Surface Composition Analysis

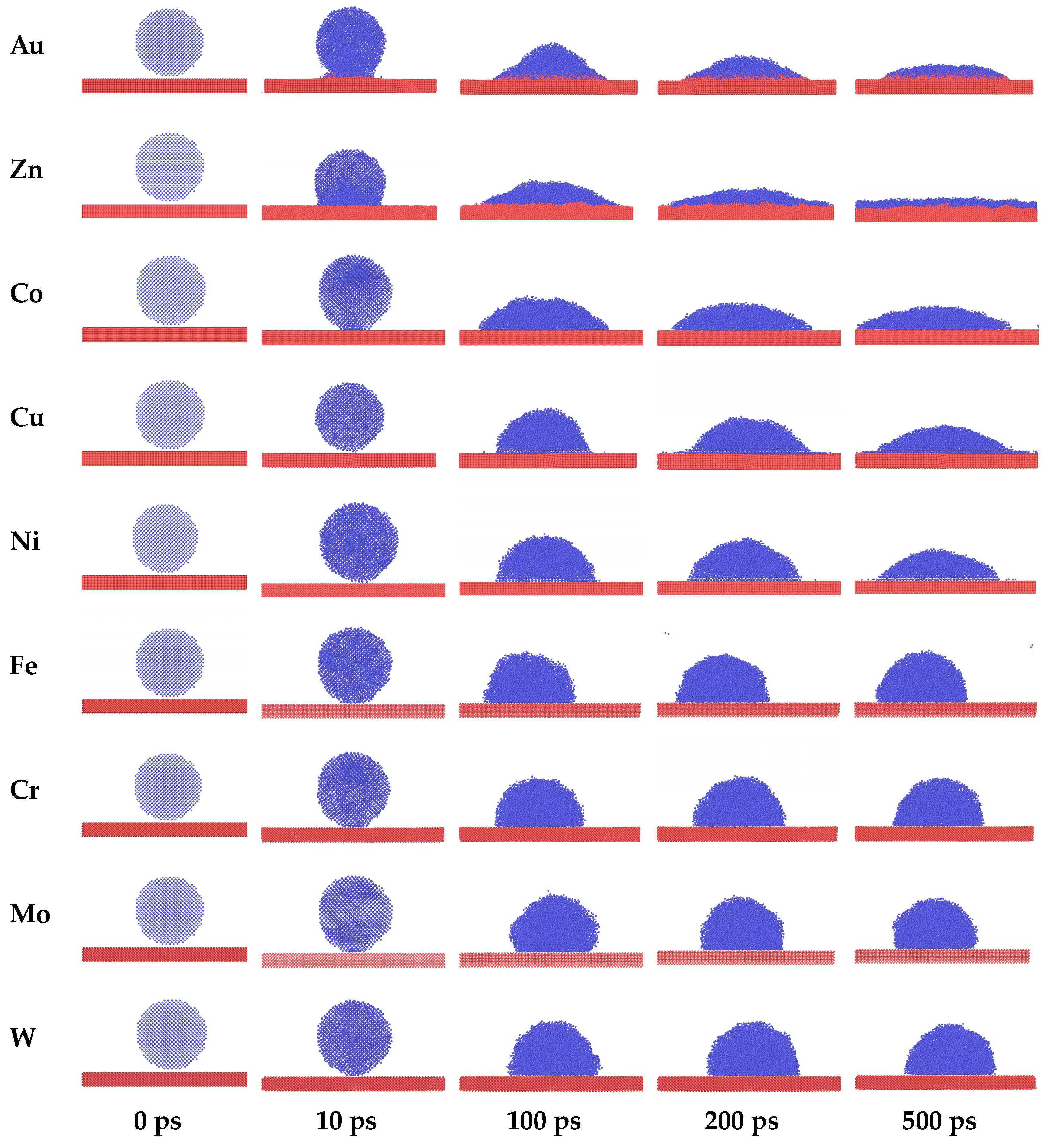

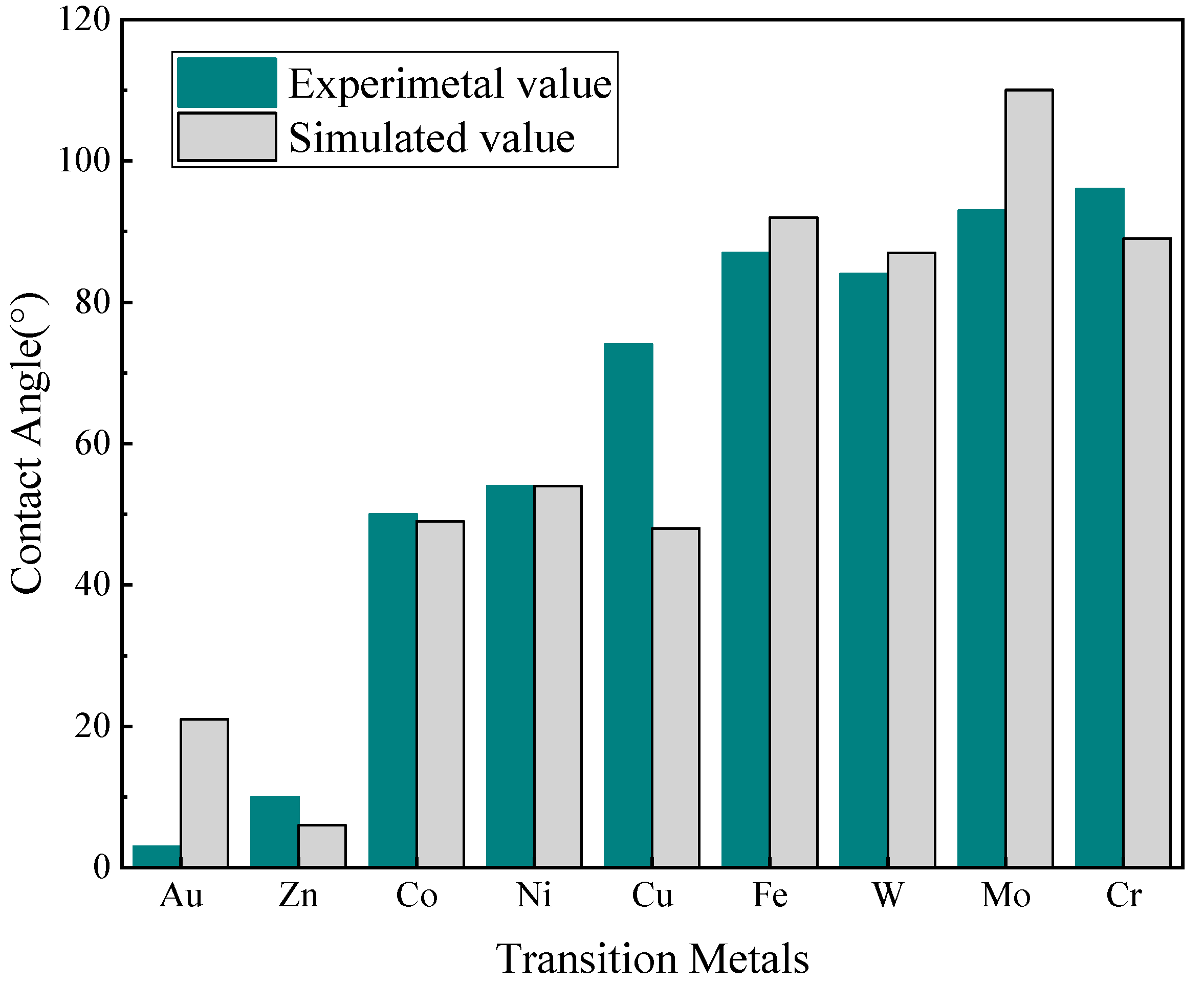

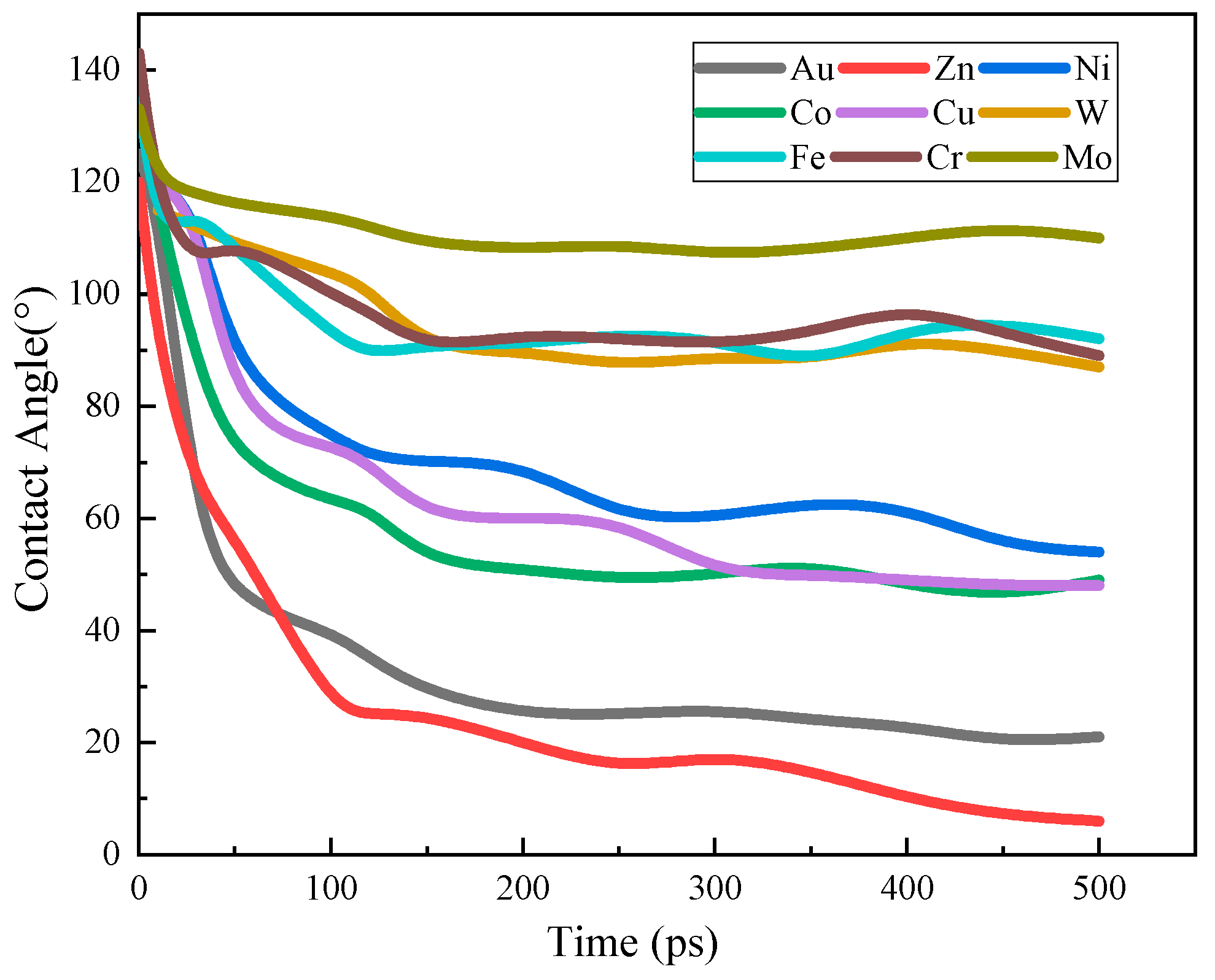

3.2. Spreading Behaviors of Na Droplets on Substrates

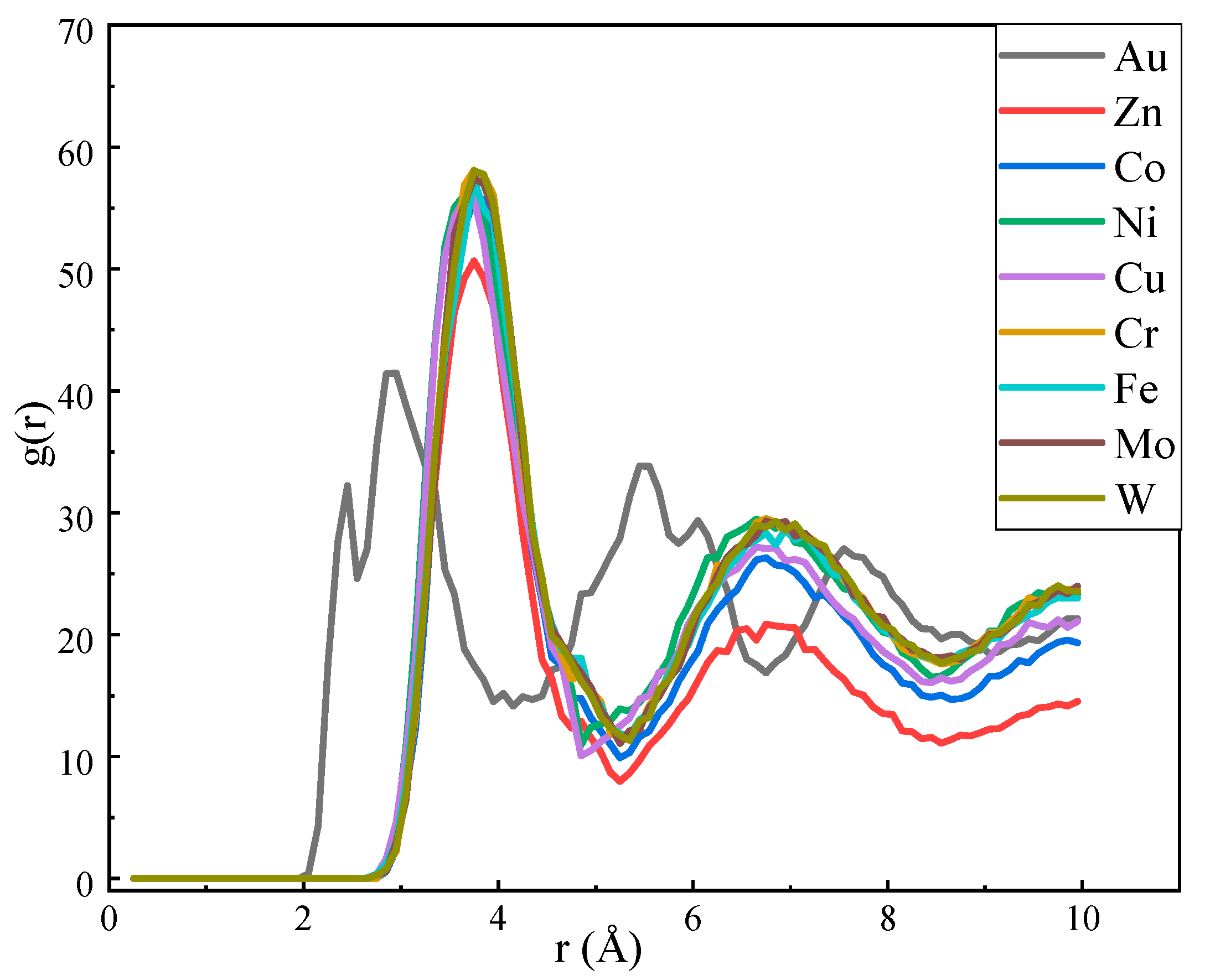

3.3. End-State Wetting of Na Droplets and Interfacial Atomic Behavior

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aoto, K.; Dufour, P. A summary of sodium-cooled fast reactor development. Prog. Nucl. Energy 2014, 77, 247–265. [Google Scholar] [CrossRef]

- Park, S.; Yang, J.; Heo, G. Dynamic data validation and reconciliation for improving the detection of sodium leakage in a sodium-cooled fast reactor. Nucl. Eng. Technol. 2023, 55, 1528–1539. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, J.; Lim, J.Y.; Cheon, J.S. Overall system description and safety characteristics of prototype Gen IV sodium cooled fast reactor in Korea. Nucl. Eng. Technol. 2016, 48, 1059–1070. [Google Scholar] [CrossRef]

- Ral, B.; Chellapandi, P.; Vasudeva, P.R. Sodium Fast Reactors with Closed Fuel Cycle; CRC Press: Boca Raton, FL, USA, 2015; pp. 27–77. [Google Scholar]

- Ichimiya, M. The status of generation IV Sodium-Cooled Fast Reactor technology development and its future Project. Energy Procedia 2011, 7, 79–87. [Google Scholar] [CrossRef][Green Version]

- Addison, C.C.; Iberson, E.; Manning, J.A. The role of oxide films in the wetting of Iron, Cobalt, and Nickel by liquid sodium, and by solutions of Barium and Calcium in liquid sodium. J. Chem. Soc. 1962, 2699–2705. [Google Scholar] [CrossRef]

- Addison, C.C.; Kerridge, D.H.; Lewis, J. The surface tension of liquid sodium: The Vertical-plate Technique. J. Chem. Soc. 1954, 2861–2866. [Google Scholar] [CrossRef]

- Addison, C.C.; Addison, W.E.; Kerridge, D.H.; Lewis, J. The surface tension of liquid sodium: The drop-volume technique. J. Chem. Soc. 1955, 2262–2264. [Google Scholar] [CrossRef]

- Griffin, J.W.; Bond, L.J.; Peters, T.J.; Denslow, K.M.; Posakony, G.J. Under-Sodium Viewing: A Review of Ultrasonic Imaging Technology for Liquid Metal Fast Reactors. Tech. Rep. 2009. [Google Scholar] [CrossRef]

- Ando, M.; Kubo, S.; Kamishima, Y.; Litsuka, T. Study on in-service inspection program and inspection technologies for commercialized Sodium-Cooled Fast Reactor. In Proceedings of the 14th International Conference on Nuclear Engineering, Miami, FL, USA, 17–20 July 2006; Volume 7, pp. 17–20. [Google Scholar]

- Baque, F. Review of in-service inspection and repair technique developments for french liquid metal fast reactors. Nucl. Technol. 2005, 150, 67–78. [Google Scholar] [CrossRef]

- Barrett, L.M.; Mchnight, J.A.; Fothergill, J.R. Ultrasonic viewing in fast reactors. Phys. Tech. 1984, 15, 308–314. [Google Scholar] [CrossRef]

- Boehmer, L.S.; Smith, R.W.; Day, C.D. An ultrasonic instrument for continuous measurement of sodium level. Ieee. T. Nul. Sci. 1976, 23, 359–362. [Google Scholar] [CrossRef]

- Addition, C.C.; Addison, W.E.; Kerridge, D.H.; Lewis, J. The wetting of zinc by liquid sodium: The significance of the critical wetting temperature. J. Chem. Soc. 1956, 1454–1461. [Google Scholar] [CrossRef]

- Addition, C.C.; Iberson, E. The wetting of chromium, molybdenum, and tungsten by liquid sodium. J. Chem. Soc. 1965, 1437–1440. [Google Scholar] [CrossRef]

- Addition, C.C.; Coldrey, J.M.; Halsteds, W.D. The surface tension of solutions of barium and calcium in liquid sodium. J. Chem. Soc. 1962, 3868–3873. [Google Scholar] [CrossRef]

- Jordan, D.O.; Lane, J.E. The wetting of some solid transition metals by liquid lithium, sodium, and potassium. Aust. J. Chem. 1966, 19, 1093–1102. [Google Scholar] [CrossRef]

- Kawaguchi, M.; Tagawa, A.; Miyahara, S. Reactive wetting of metallic plated steels by liquid sodium. J. Nucl. Sci. Technol. 2011, 4, 499–503. [Google Scholar] [CrossRef]

- Kawaguchi, M.; Hanada, H. Reactive wetting by liquid sodium on thin Au plating. J. Nucl. Sci. Technol. 2014, 51, 201–207. [Google Scholar] [CrossRef]

- Hsieh, J.Y.; Chen, J.L.; Chen, C.; Lin, C.H.; Yang, S.S.; Hwang, C.C. Reactive wetting behaviors of Sn/Cu systems: A molecular dynamics study. Nano-Micro. Lett. 2010, 2, 60–67. [Google Scholar] [CrossRef]

- Chen, X.; Sun, X.G.; Deng, H.Q.; Xiao, S.F.; Gan, X.L.; Li, X.F.; Hu, W.Y. The wetting properties of Li droplet on Cu surfaces: A molecular dynamics study. Com. Mater. Sci. 2016, 119, 114–119. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wang, S.L.; Yang, Y.R.; Wang, X.D.; Lee, D.J. High-temperature reactive wetting systems: Role of lattice constant. Chem. Eng. Sci. 2019, 209, 115206. [Google Scholar] [CrossRef]

- Lv, X.J.; Guan, C.H.; Han, Z.; Zhang, H.B.; Liu, Q.S. The wetting characteristics of copper droplets on tungsten surfaces on atomic scale: A molecular dynamics simulation. Com. Mater. Sci. 2020, 174, 109487. [Google Scholar] [CrossRef]

- Chlouk, Z.E.; Kassen, W.; Shehadeh, M.; Hamade, R.F. On the mechanical response and intermetallic compound formation in Al/Fe interface: Molecular dynamics analyses. Philos. Mag. 2020, 100, 3041–3060. [Google Scholar] [CrossRef]

- Wang, P.; Duan, Y.Y.; Zheng, H.P.; Chen, Z.; Wang, M.H.; Wang, X.P.; Li, H.S.; Hou, D.S. Molecular structure and dynamics of water on the surface of cement hydration products: Wetting behavior at nanoscale. Appl. Surf. Sci. 2023, 611, 155713. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Shinoda, W.; Devane, R.; Klein, M.L. Multi-property fitting and parameterization of a coarse grained model for aqueous surfactants. Mol. Simul. 2007, 33, 27–36. [Google Scholar] [CrossRef]

- Shinoda, W.; Devane, R. Coarse-grained molecular modeling of non-ionic surfactant self-assembly. Soft Matter. 2008, 4, 2454–2462. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, B.J. Second nearest-neighbor modified embedded atom method interatomic potentials for Na-M-Sn (M = Cu, Mn, Ni) ternary systems. Com. Mater. Sci. 2022, 206, 111305. [Google Scholar] [CrossRef]

- Elliott, R.S.; Akerson, A. Efficient “universal” shifted Lennard-Jones model for all KIM API supported species. OpenKIM Data 2015. [Google Scholar]

- Pappe, A.K.; Casewit, C.J.; Colwell, K.S.; Goddara, W.A.; Skiff, W.M. UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 1992, 114, 10024–10035. [Google Scholar]

- Halicioglu, T.; Pound, G.M. Calculation of potential energy parameters. Phys. Stat. Sol. 1975, 30, 619–623. [Google Scholar] [CrossRef]

- Mayo, S.L.; Olafson, B.D.; Goddard, W.A. A generic force field for molecular simulations. J. Phys. Chem. 1990, 94, 8897–8909. [Google Scholar] [CrossRef]

- Nichol, A.; Achland, G.J. Property trends in simple metals: An empirical potential approach. Phys. Rev. 2016, 93, 184101. [Google Scholar] [CrossRef]

- Marinica, M.C.; Ventelon, L.; Gilbert, M.R.; Tadmor, E.B. Finnis-Sinclair potential (LAMMPS cubic hermite tabulation) for W. OpenKIM Data 2015. [Google Scholar]

- Mendelev, M.I.; Han, S.; Srolovitz, D.J.; Ackland, G.J.; Sun, D.Y.; Asta, M. Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos. Mag. 2003, 83, 3977–3994. [Google Scholar] [CrossRef]

- Zhakhovskii, V.V.; Inogamov, N.A.; Petrov, Y.V.; Ashitkov, S.I.; Nishihara, K. Molecular dynamics simulation of femtosecond ablation and spallation with different interatomic potentials. Appl. Surf. Sci. 2009, 255, 9592–9596. [Google Scholar] [CrossRef]

- Jang, H.S.; Kim, K.M.; Lee, B.J. Modified embedded-atom method interatomic potentials for pure Zn and Mg-Zn binary system. Galphad 2018, 60, 200–207. [Google Scholar] [CrossRef]

- Kim, J.S.; Seol, D.; Ji, J.; Jang, H.S.; Kim, Y.; Lee, B.J. Second nearest-neighbor modified embedded-atom method interatomic potentials for the Pt-M (M = Al, Co, Cu, Mo, Ni, Ti, V) binary systems. Calphad 2017, 59, 131–141. [Google Scholar] [CrossRef]

- Choi, W.M.; Kim, Y.; Seol, D.; Lee, B.J. Modified embedded-atom method interatomic potentials for the Co-Cr, Co-Fe, Co-Mn, Cr-Mn and Mn-Ni binary systems. Comp. Mater. Sci. 2017, 130, 121–129. [Google Scholar] [CrossRef]

- Dong, W.P.; Kim, H.K.; Ko, W.S.; Lee, B.M.; Lee, B.J. Atomistic modeling of pure Co and Co–Al system. Calphad 2012, 38, 7–16. [Google Scholar] [CrossRef]

- Naidich, J.V. The wettability of solids by liquid metals. In Progress in Surface and Membrane Science; E-Publishing Inc.: New York, NY, USA, 1981; pp. 358–390. [Google Scholar]

- Aksay, I.A.; Hoge, C.E.; Pask, J.A. Wetting under chemical equilibrium and none quilibreium conditions. J Phys Chem. 1974, 78, 1178–1183. [Google Scholar] [CrossRef]

- Protsenko, P.; Terlain, A.; Traskine, V.; Eustathopoulos, N. The role of intermetallics in wetting in metallic systems. Scripta. Mater. 2001, 45, 1439–1445. [Google Scholar] [CrossRef]

- Cetin, H.; Ross, R.G. The phase diagram of Na-Zn alloys. J. Phase Equilibria 1991, 12, 6–9. [Google Scholar] [CrossRef]

- Pelton, A.D. The Au-Na (Gold-Sodium) system. Alloy Phase Diagrams 1986, 7, 136–138. [Google Scholar] [CrossRef]

| System | Na–Cr | Na–Fe | Na–Co | Na–Zn | Na–Mo | Na–W | Na–Au |

|---|---|---|---|---|---|---|---|

| Interaction Energy (eV) | −69 | −251 | −322 | −1432 | −42.63 | −45 | −40,515 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, N.; Fu, X.; Zhang, J.; Ruan, Z.; Qin, B.; Ma, T.; Long, B. Evaluation of Wetting Behaviors of Liquid Sodium on Transition Metals: An Experimental and Molecular Dynamics Simulation Study. Materials 2024, 17, 691. https://doi.org/10.3390/ma17030691

Liang N, Fu X, Zhang J, Ruan Z, Qin B, Ma T, Long B. Evaluation of Wetting Behaviors of Liquid Sodium on Transition Metals: An Experimental and Molecular Dynamics Simulation Study. Materials. 2024; 17(3):691. https://doi.org/10.3390/ma17030691

Chicago/Turabian StyleLiang, Na, Xiaogang Fu, Jinquan Zhang, Zhangshun Ruan, Bo Qin, Tengfei Ma, and Bin Long. 2024. "Evaluation of Wetting Behaviors of Liquid Sodium on Transition Metals: An Experimental and Molecular Dynamics Simulation Study" Materials 17, no. 3: 691. https://doi.org/10.3390/ma17030691

APA StyleLiang, N., Fu, X., Zhang, J., Ruan, Z., Qin, B., Ma, T., & Long, B. (2024). Evaluation of Wetting Behaviors of Liquid Sodium on Transition Metals: An Experimental and Molecular Dynamics Simulation Study. Materials, 17(3), 691. https://doi.org/10.3390/ma17030691