Dry Etching Characteristics of InGaZnO Thin Films Under Inductively Coupled Plasma–Reactive-Ion Etching with Hydrochloride and Argon Gas Mixture

Abstract

1. Introduction

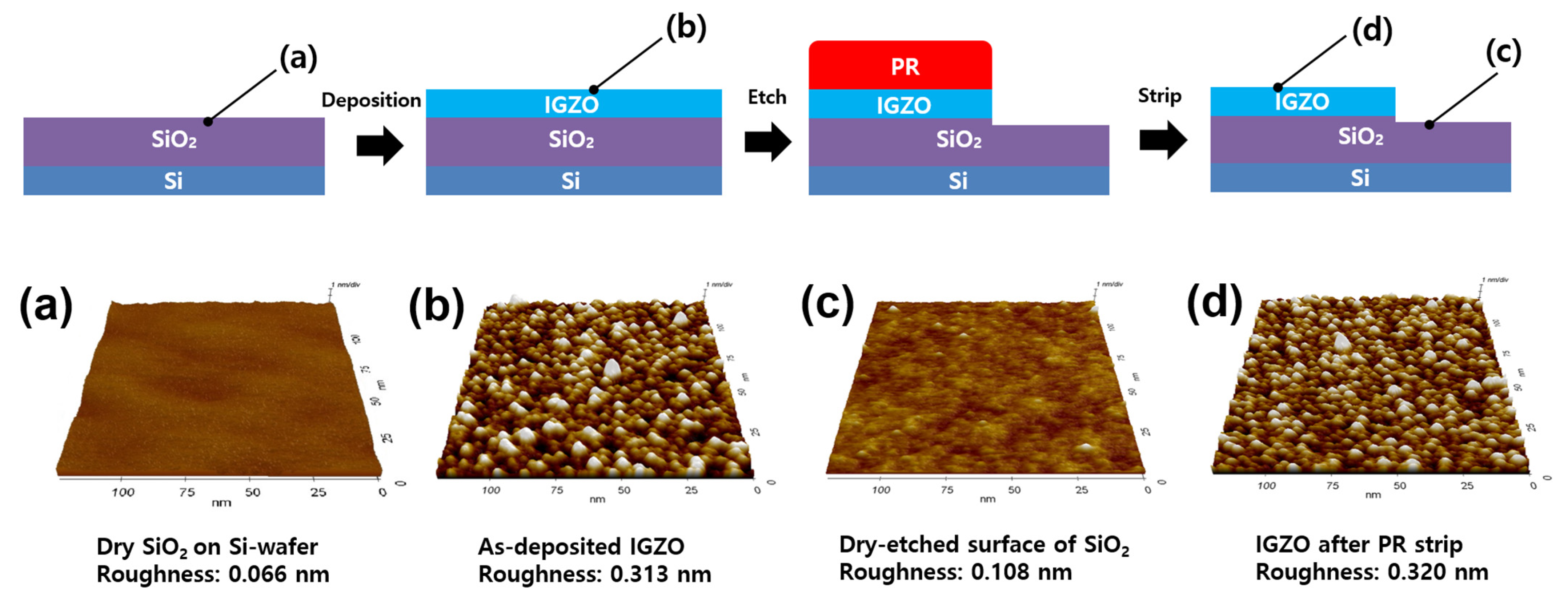

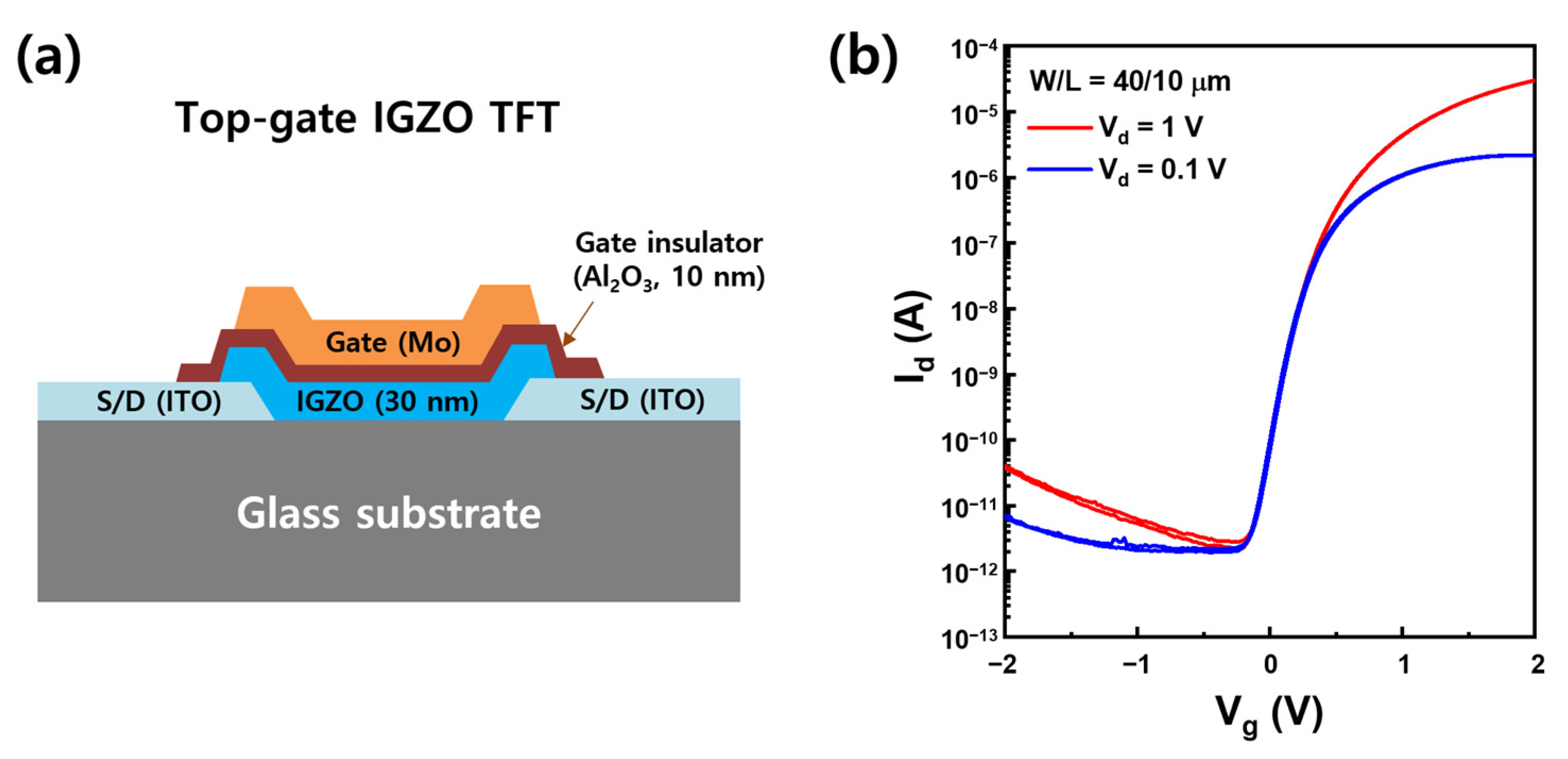

2. Materials and Methods

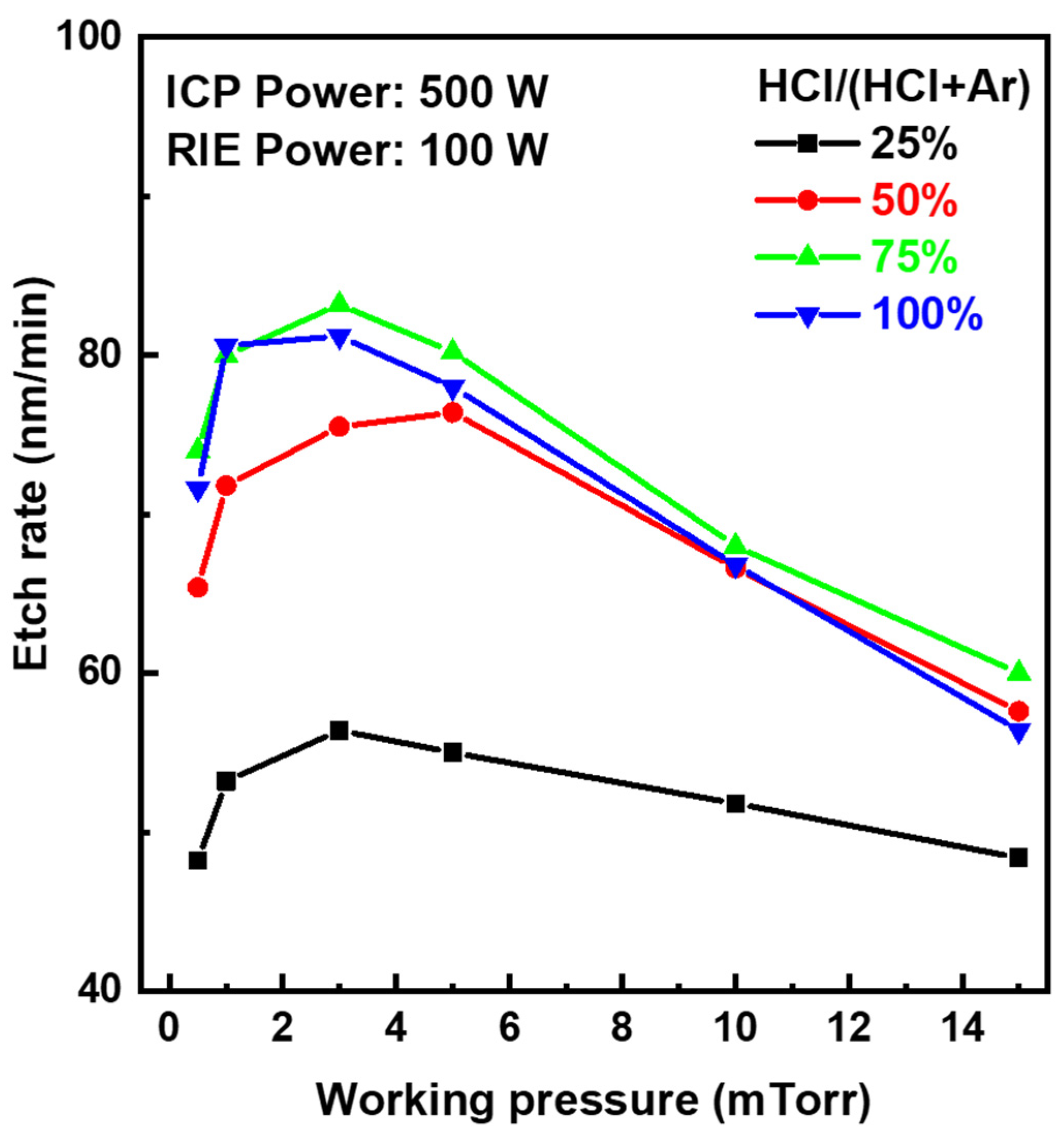

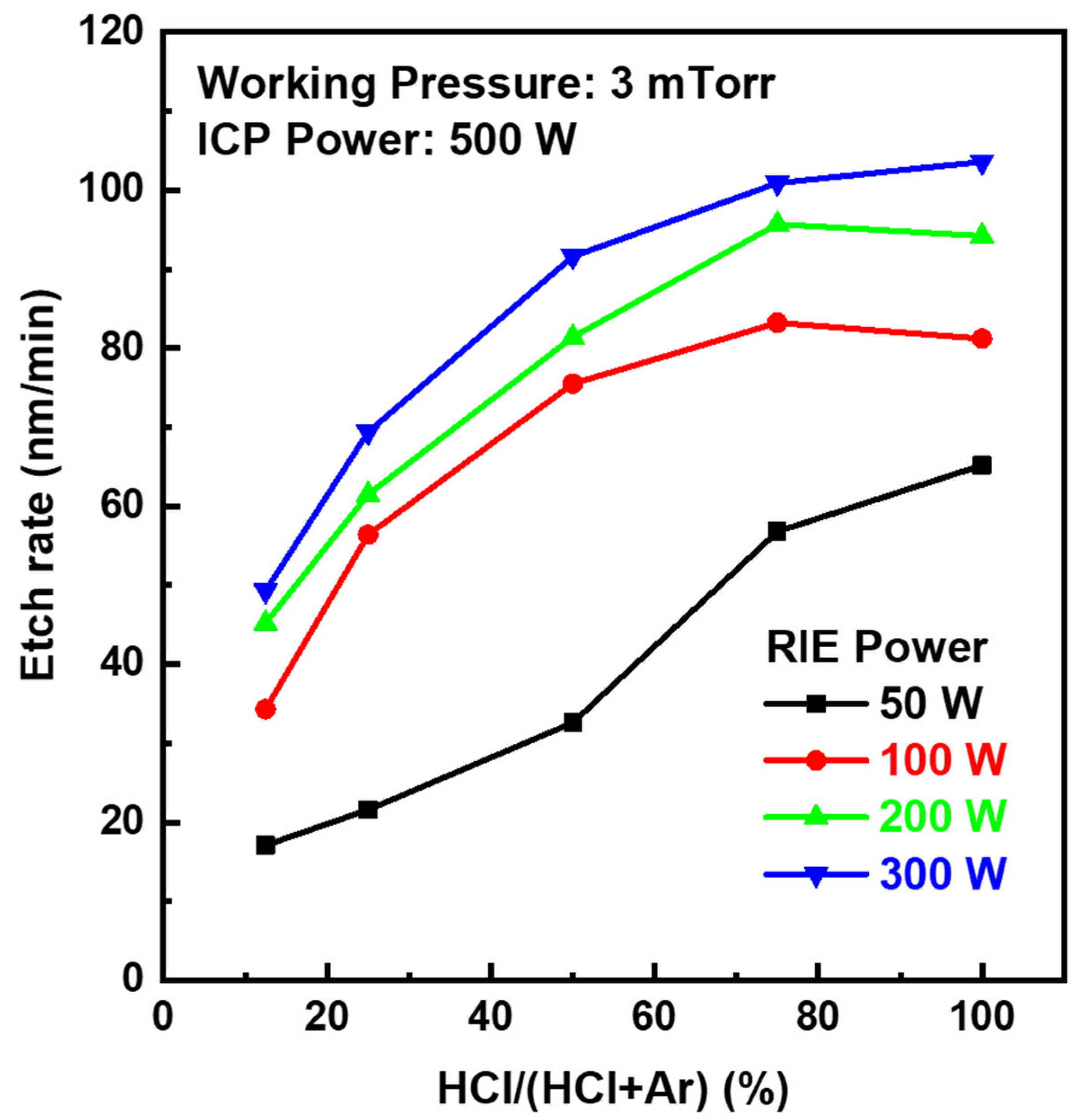

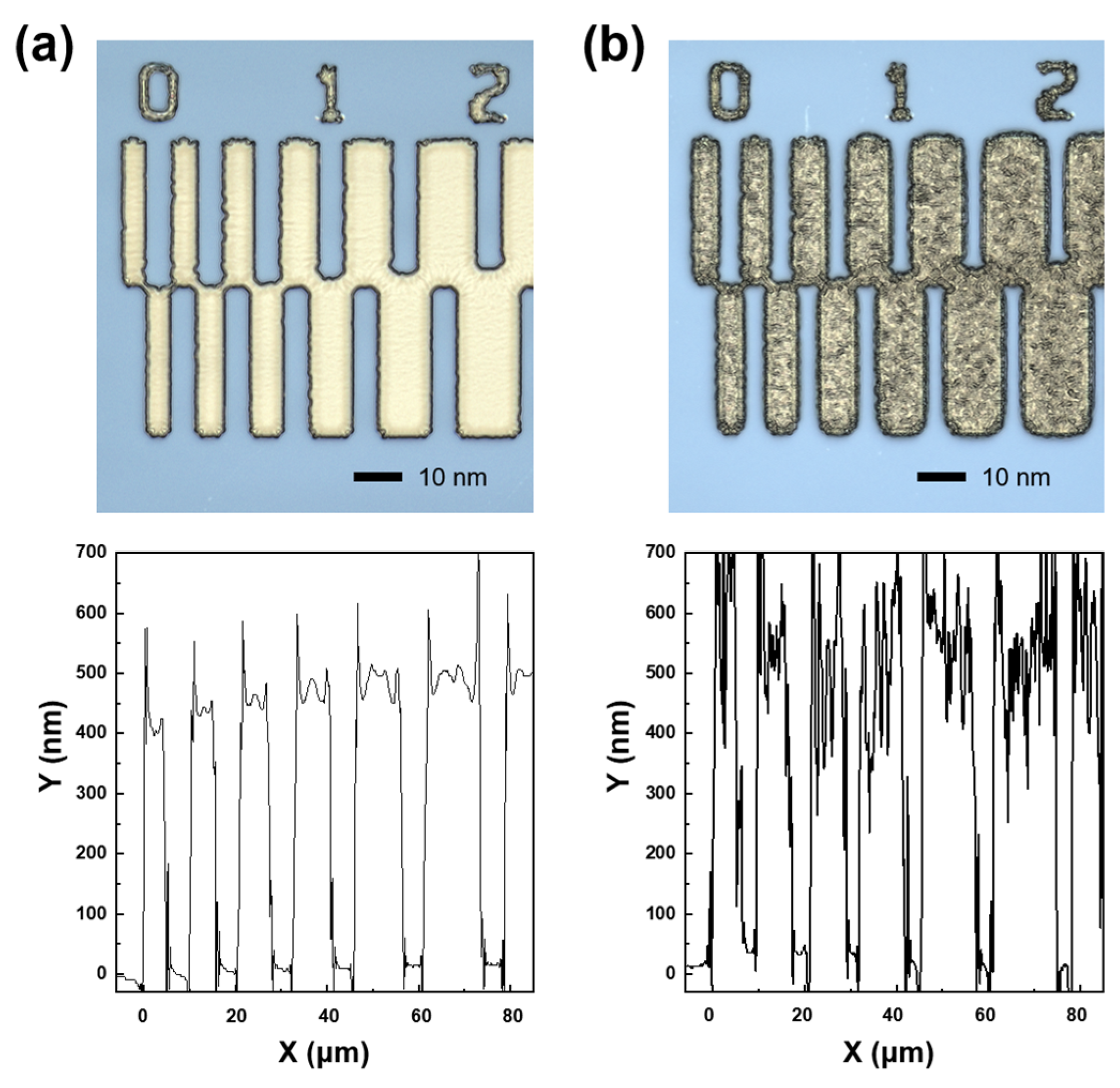

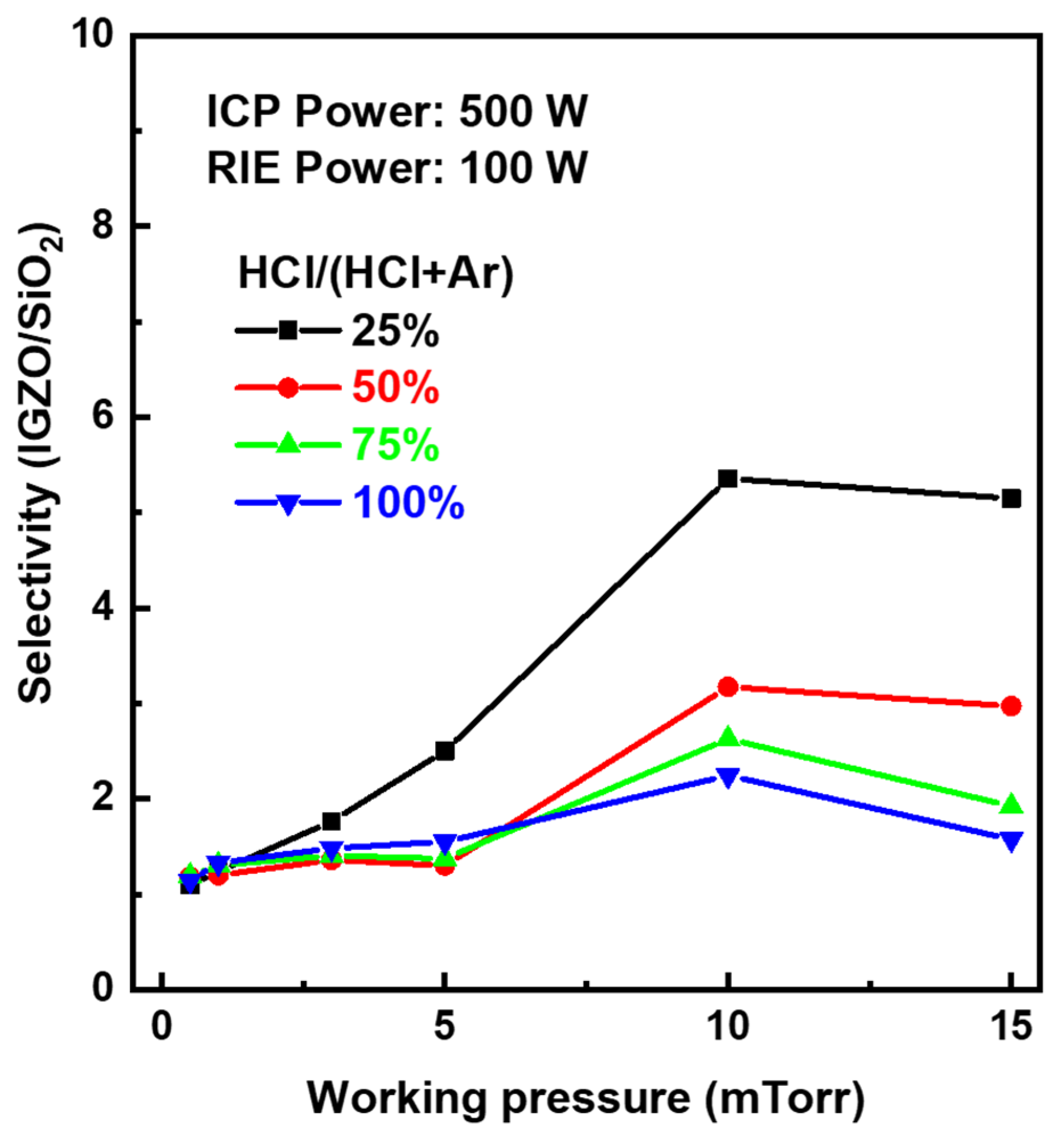

3. Experimental Section

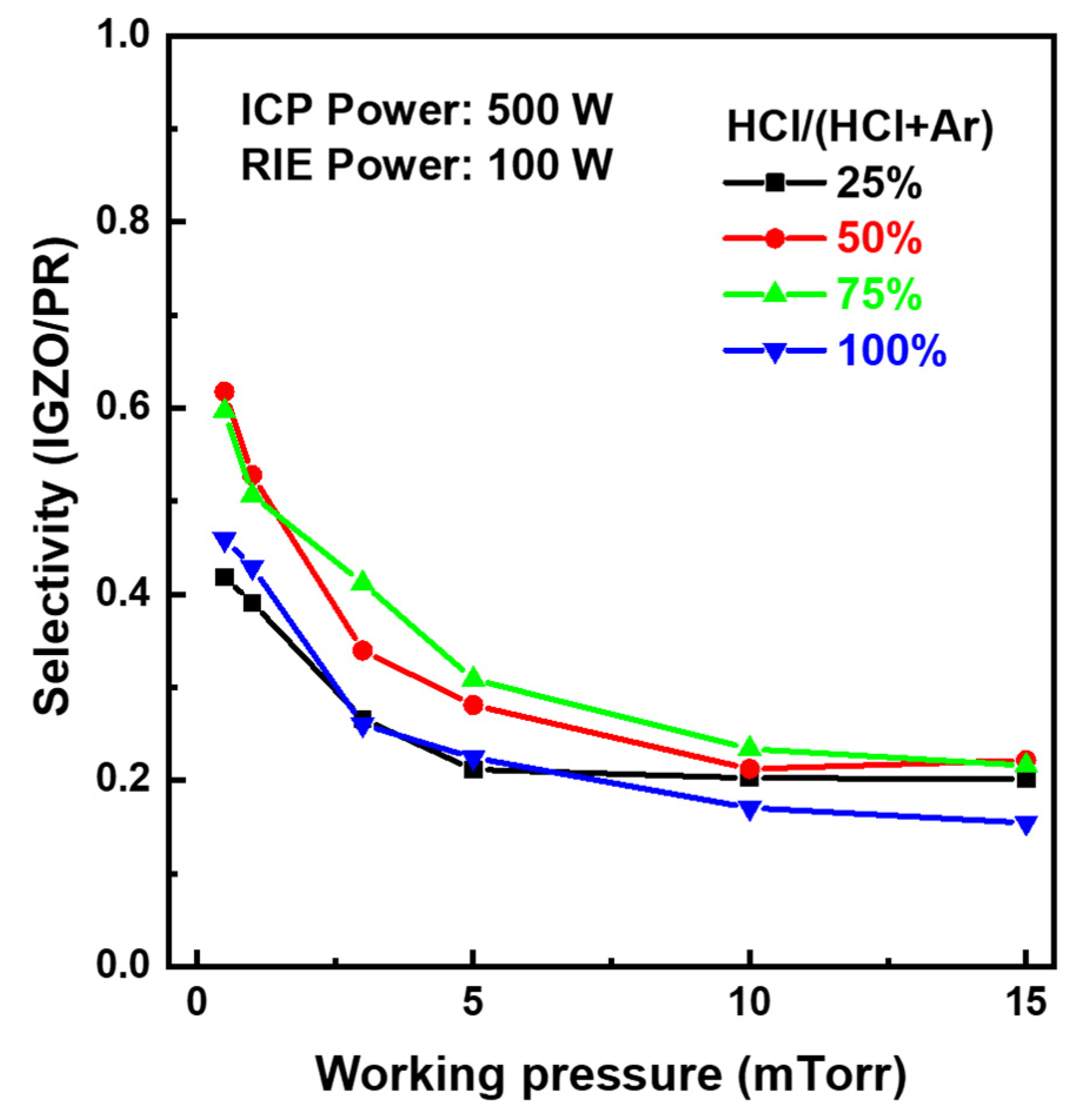

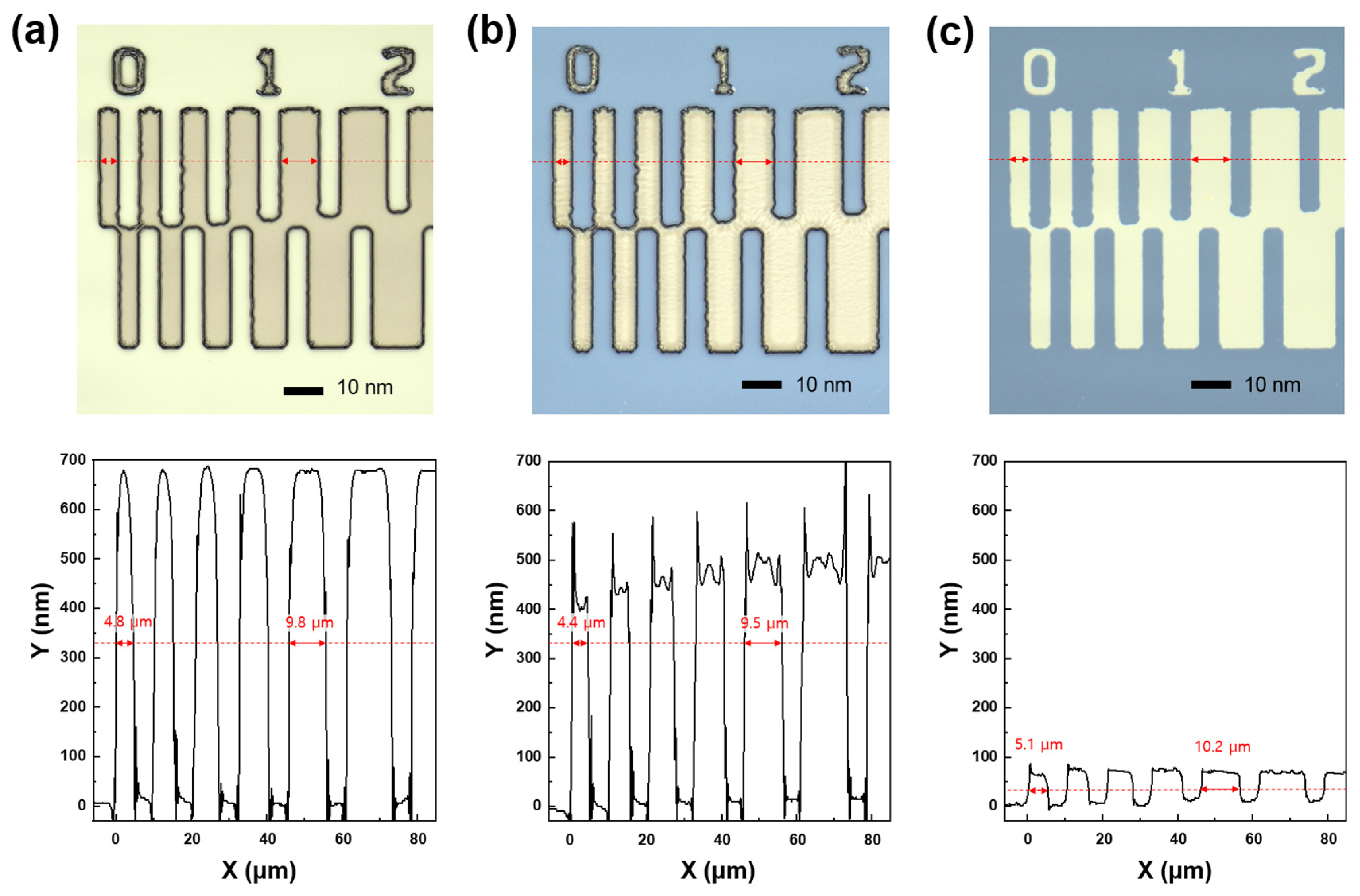

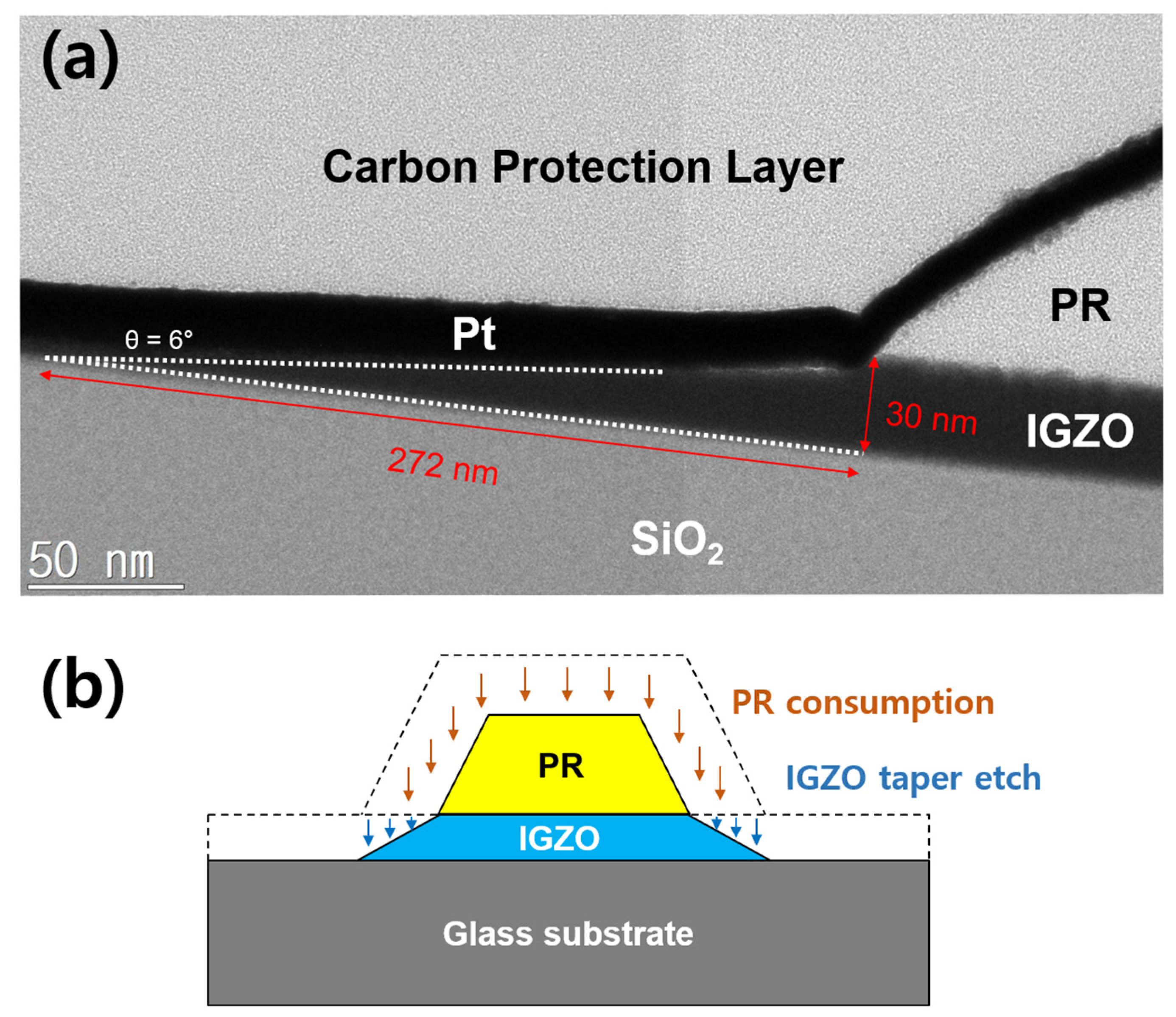

4. Analysis and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nomura, K. Recent progress of oxide-TFT-based inverter technology. J. Inf. Disp. 2021, 22, 211–229. [Google Scholar] [CrossRef]

- Pi, T.; Xiao, D.; Yang, H.; He, G.; Wu, X.; Liu, W.; Zhang, D.W.; Ding, S.-J. High-performance a-IGZO TFT fabricated with ultralow thermal budget via microwave annealing. IEEE Trans. Electron Devices 2021, 69, 156–159. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Niu, G.; Wei, Q.; Wu, S.; Yu, C.; Wang, H.-X. The clarification of leakage conduction mechanism of HfO2/SiNx stacked a-IGZO TFT and its variation at high temperature. Appl. Phys. Lett. 2022, 121, 233504. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Jeong, H.-J.; Park, J.-S. Low subthreshold swing and high performance of ultrathin PEALD InGaZnO thin-film transistors. IEEE Trans. Electron Devices 2021, 68, 1670–1675. [Google Scholar] [CrossRef]

- Mativenga, M.; An, S.; Jang, J. Bulk accumulation a-IGZO TFT for high current and turn-on voltage uniformity. IEEE Electron Device Lett. 2013, 34, 1533–1535. [Google Scholar] [CrossRef]

- Jang, H.J.; Lee, J.Y.; Kwak, J.; Lee, D.; Park, J.-H.; Lee, B.; Noh, Y.Y. Progress of display performances: AR, VR, QLED, OLED, and TFT. J. Inf. Disp. 2019, 20, 1–8. [Google Scholar] [CrossRef]

- Hara, Y.; Kikuchi, T.; Kitagawa, H.; Morinaga, J.; Ohgami, H.; Imai, H.; Daitoh, T.; Matsuo, T. IGZO-TFT technology for large-screen 8K display. J. Soc. Inf. Disp. 2018, 26, 169–177. [Google Scholar] [CrossRef]

- Wang, J.; Bi, J.; Xu, B.; Liu, M. Characteristics Analysis of IGZO TFT and Logic Unit in the Temperature Range of 8–475 K. Electronics 2024, 13, 1427. [Google Scholar] [CrossRef]

- Chung, J.; Tak, Y.J.; Kim, W.-G.; Kang, B.H.; Kim, H.J. Artificially Fabricated Subgap States for Visible-Light Absorption in Indium−Gallium−Zinc Oxide Phototransistor with Solution-Processed Oxide Absorption Layer. ACS Appl. Mater. Interfaces 2019, 11, 38964–38972. [Google Scholar] [CrossRef]

- Kim, M.Y.; Kim, H.Y.; Oh, C.; Park, S.H.; Kim, B.S. Stretchable oxide thin-film transistors with a mechanically and electrically reliable wavy structure for skin electronics. ACS Appl. Electron. Mater. 2024, 6, 435–446. [Google Scholar] [CrossRef]

- Choi, J.H.; Yang, J.-H.; Pi, J.-E.; Hwang, C.-Y.; Choi, K.; Kim, H.-O.; Kwon, O.-S.; Hwang, C.-S. 1-μm Short-channel oxide thin-film transistors with triangular gate spacer. IEEE Electron Device Lett. 2017, 38, 1398–1400. [Google Scholar] [CrossRef]

- Oh, C.-E.; Kwon, Y.-H.; Seong, N.-J.; Choi, K.-J.; Yoon, S.-M. Impact of Al2O3 spacers on the improvement in short-channel effects for the mesa-shaped vertical-channel In-Ga-Zn-O thin-film transistors with a channel length below 100 nm. Mater. Sci. Semicond. Process. 2024, 171, 108025. [Google Scholar] [CrossRef]

- Nakata, M.; Ochi, M.; Tsuji, H.; Takei, T.; Miyakawa, M.; Yamamoto, T.; Goto, H.; Kugimiya, T.; Fujisaki, Y. A method for shortening effective channel length in oxide TFT by partial formation of conductive region. Jpn. J. Appl. Phys. 2019, 58, 090602. [Google Scholar] [CrossRef]

- Baek, Y.J.; Kang, I.H.; Hwang, S.H.; Han, Y.L.; Kang, M.S.; Kang, S.J.; Kim, S.G.; Woo, J.G.; Yu, E.S.; Bae, B.S. Vertical oxide thin-film transistor with interfacial oxidation. Sci. Rep. 2022, 12, 3094. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, E.S.; Park, J.S.; Lim, J.H.; Kim, B.S. Influence of effective channel length in self-aligned coplanar amorphous indium-gallium-zinc-oxide thin-film transistors with different annealing temperatures. Appl. Phys. Lett. 2018, 113, 022104. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Joo, Y.-H.; Kim, M.P.; Um, D.-S.; Kim, C.-I. Etching characteristics and changes in surface properties of IGZO thin films by O2 addition in CF4/Ar plasma. Coatings 2021, 11, 906. [Google Scholar] [CrossRef]

- Park, J.C.; Jeong, O.G.; Kim, J.K.; Yun, Y.-H.; Pearton, S.J.; Cho, H. Comparison of chlorine- and fluorine-based inductively coupled plasmas for dry etching of InGaZnO4 films. Thin Solid Film. 2013, 546, 136–140. [Google Scholar] [CrossRef]

- Joo, Y.-H.; Woo, J.-C.; Kim, C.-I. Surface reaction effects on dry etching of IGZO thin films in N2/BCl3/Ar plasma. Microelectron. Eng. 2013, 112, 74–79. [Google Scholar] [CrossRef]

- Park, W.; Whang, K.-W.; Yoon, W.G.; Kim, J.H.; Rha, S.-H.; Hwang, C.S. High rate dry etching of InGaZnO by BCl3/O2 plasma. Appl. Phys. Lett. 2011, 99, 062110. [Google Scholar] [CrossRef]

- Xiao, Y.B.; Kim, E.H.; Kong, S.M.; Chung, C.W. Inductively coupled plasma reactive ion etching of gallium indium zinc oxide thin films using Cl2/Ar gas mix. Jpn. J. Appl. Phys. 2010, 49, 08JB01. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Chang, C.; Shih, W.-P.; Cai, C.-L. Wet etching rates of InGaZnO for the fabrication of transparent thin-film transistors on plastic substrates. Thin Solid Film. 2010, 518, 3992–3998. [Google Scholar] [CrossRef]

- Oh, S.; Jung, H.; Kim, Y.-H.; Kim, M.; Yoo, E.; Choi, Y.J.; Yoon, T.-S.; Lee, H. Characterization of ITO etching by spontaneously evaporated fume of hydrogen chloride. Microelectron. Eng. 2013, 103, 173–176. [Google Scholar] [CrossRef]

- Oh, C.; Kim, H.W.; Ju, M.W.; Song, J.H.; Kim, B.S. Study on effective dry etching of InGaZnO thin films under capacitively coupled plasma-reactive ion etching with a nonfluorine-based etching gas. J. Vac. Sci. Technol. A 2023, 41, 053007. [Google Scholar] [CrossRef]

- Perry, D.L.; Phillips, S.L. Handbook of Inorganic Compounds; CRC: Boca Raton, FL, USA, 1995; pp. 184, 186, 208, 209, 464, 468. [Google Scholar]

- Hirata, A.; Fukasawa, M.; Shigetoshi, T.; Okamoto, M.; Nagahata, K.; Li, H.; Karahashi, K.; Hamaguchi, S.; Tatsumi, T. Effects of hydrogen-damaged layer on tin-doped indium oxide etching by H2/Ar plasma. Jpn. J. Appl. Phys. 2017, 56, 06HD02. [Google Scholar] [CrossRef]

- Hirata, A.; Fukasawa, M.; Nagahata, K.; Li, H.; Karahashi, K.; Hamaguchi, S.; Tatsumi, T. Cyclic etching of tin-doped indium oxide using hydrogen-induced modified layer. Jpn. J. Appl. Phys. 2018, 57, 06JB02. [Google Scholar] [CrossRef]

- Hirata, A.; Fukasawa, M.; Kugimiya, K.; Karahashi, K.; Hamaguchi, S.; Nagaoka, K. Damage recovery and low-damage etching of ITO in H2/CO plasma: Effects of hydrogen or oxygen. Plasma Process. Polym. 2019, 16, 1900029. [Google Scholar] [CrossRef]

- Dai, C.-L.; Xiao, F.-Y.; Juang, Y.-Z.; Chiu, C.-F. An approach to fabricating microstructures that incorporate circuits using a post-CMOS process. J. Micromech. Microeng. 2005, 15, 98–103. [Google Scholar] [CrossRef]

- Fu, J.; Li, J.; He, X.; Yu, J.; Zhou, N.; Jiang, Q.; Li, J.; Wang, W.; Zhao, C. Fabricating metal structures with taper angles and smooth sidewalls. J. Micromech. Microeng. 2017, 27, 125011. [Google Scholar] [CrossRef]

- Kim, H.W.; Oh, C.; Jang, H.; Kim, M.Y.; Kim, B.S. Influence of oxygen-related defects on In-Ga-Sn-O semiconductor due to plasma-enhanced atomic layer deposition of Al2O3 for low-temperature thin-film transistor in terms of electrical properties. J. Alloys Compd. 2022, 918, 165649. [Google Scholar] [CrossRef]

- Oh, C.; Jang, H.; Kim, H.W.; Jung, H.; Park, H.; Cho, J.; Kim, B.S. Influence of oxygen partial pressure in In-Sn-Ga-O thin-film transistors at a low temperature. J. Alloys Compd. 2019, 805, 211–217. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, C.; Ju, M.W.; Jeong, H.; Song, J.H.; Kim, B.S.; Lee, D.G.; Cho, C. Dry Etching Characteristics of InGaZnO Thin Films Under Inductively Coupled Plasma–Reactive-Ion Etching with Hydrochloride and Argon Gas Mixture. Materials 2024, 17, 6241. https://doi.org/10.3390/ma17246241

Oh C, Ju MW, Jeong H, Song JH, Kim BS, Lee DG, Cho C. Dry Etching Characteristics of InGaZnO Thin Films Under Inductively Coupled Plasma–Reactive-Ion Etching with Hydrochloride and Argon Gas Mixture. Materials. 2024; 17(24):6241. https://doi.org/10.3390/ma17246241

Chicago/Turabian StyleOh, Changyong, Myeong Woo Ju, Hojun Jeong, Jun Ho Song, Bo Sung Kim, Dae Gyu Lee, and ChoongHo Cho. 2024. "Dry Etching Characteristics of InGaZnO Thin Films Under Inductively Coupled Plasma–Reactive-Ion Etching with Hydrochloride and Argon Gas Mixture" Materials 17, no. 24: 6241. https://doi.org/10.3390/ma17246241

APA StyleOh, C., Ju, M. W., Jeong, H., Song, J. H., Kim, B. S., Lee, D. G., & Cho, C. (2024). Dry Etching Characteristics of InGaZnO Thin Films Under Inductively Coupled Plasma–Reactive-Ion Etching with Hydrochloride and Argon Gas Mixture. Materials, 17(24), 6241. https://doi.org/10.3390/ma17246241