Conversion of Oil-Containing Residue from Waste Oil Recycling Plant into Porous Carbon Materials Through Activation Method with Phosphoric Acid

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermochemical Properties of Oil-Containing Sludge

2.3. Phosphoric Acid Activation Experiments

2.4. Characterization of Carbon Products

3. Results

3.1. Thermochemical Characterization of Oil-Containing Sludge

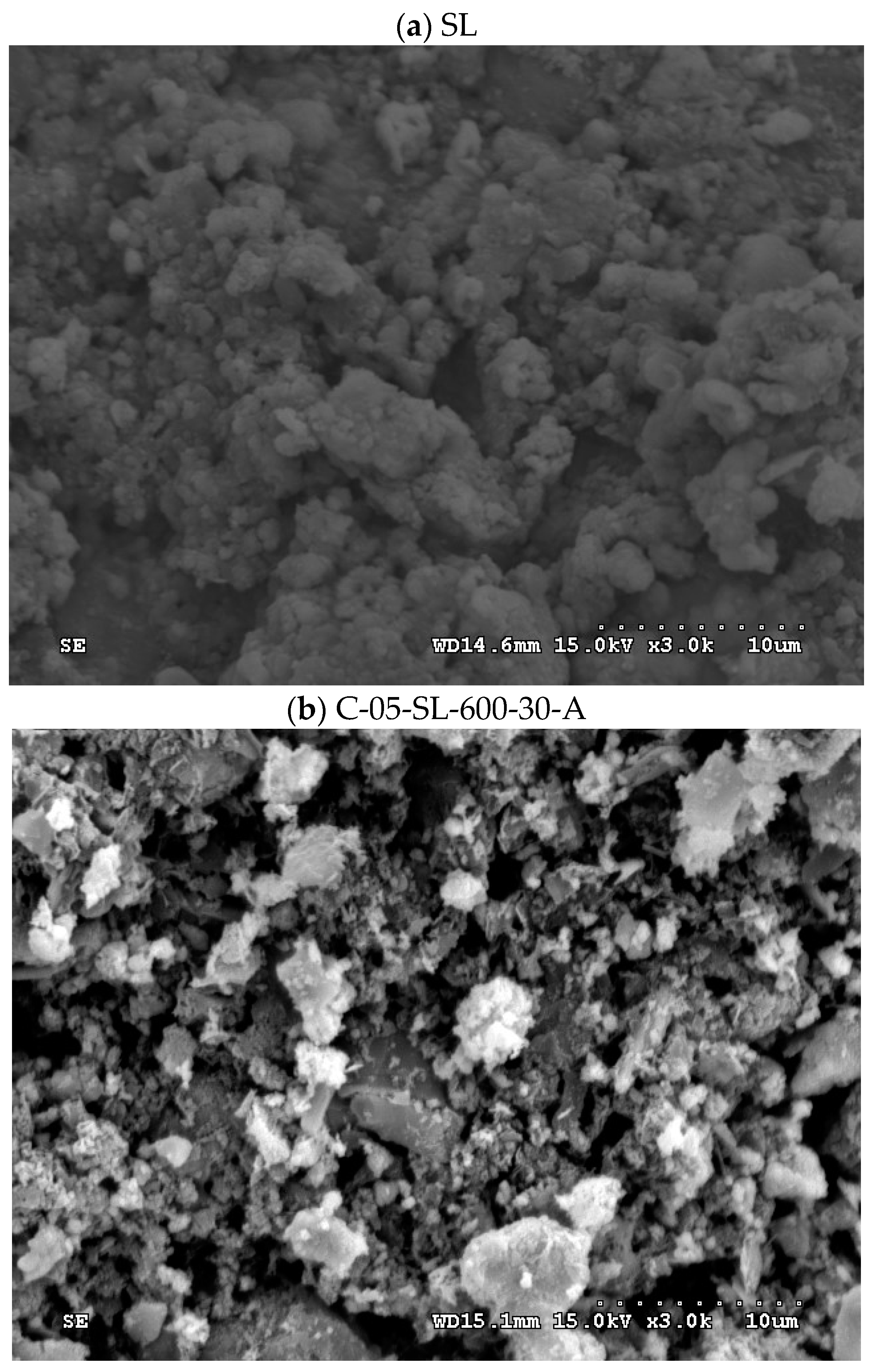

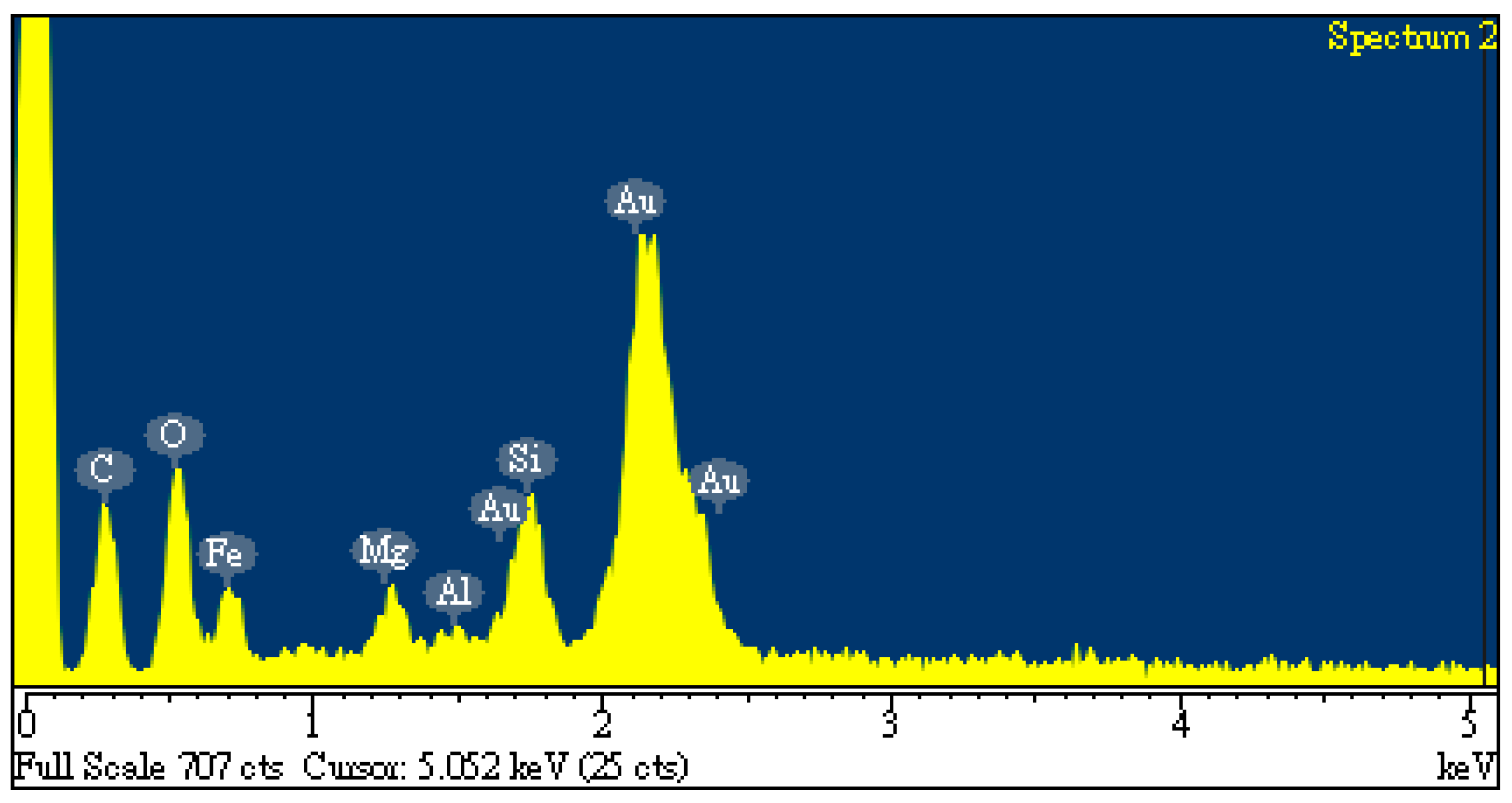

3.2. Characterization of Resulting Carbon Products

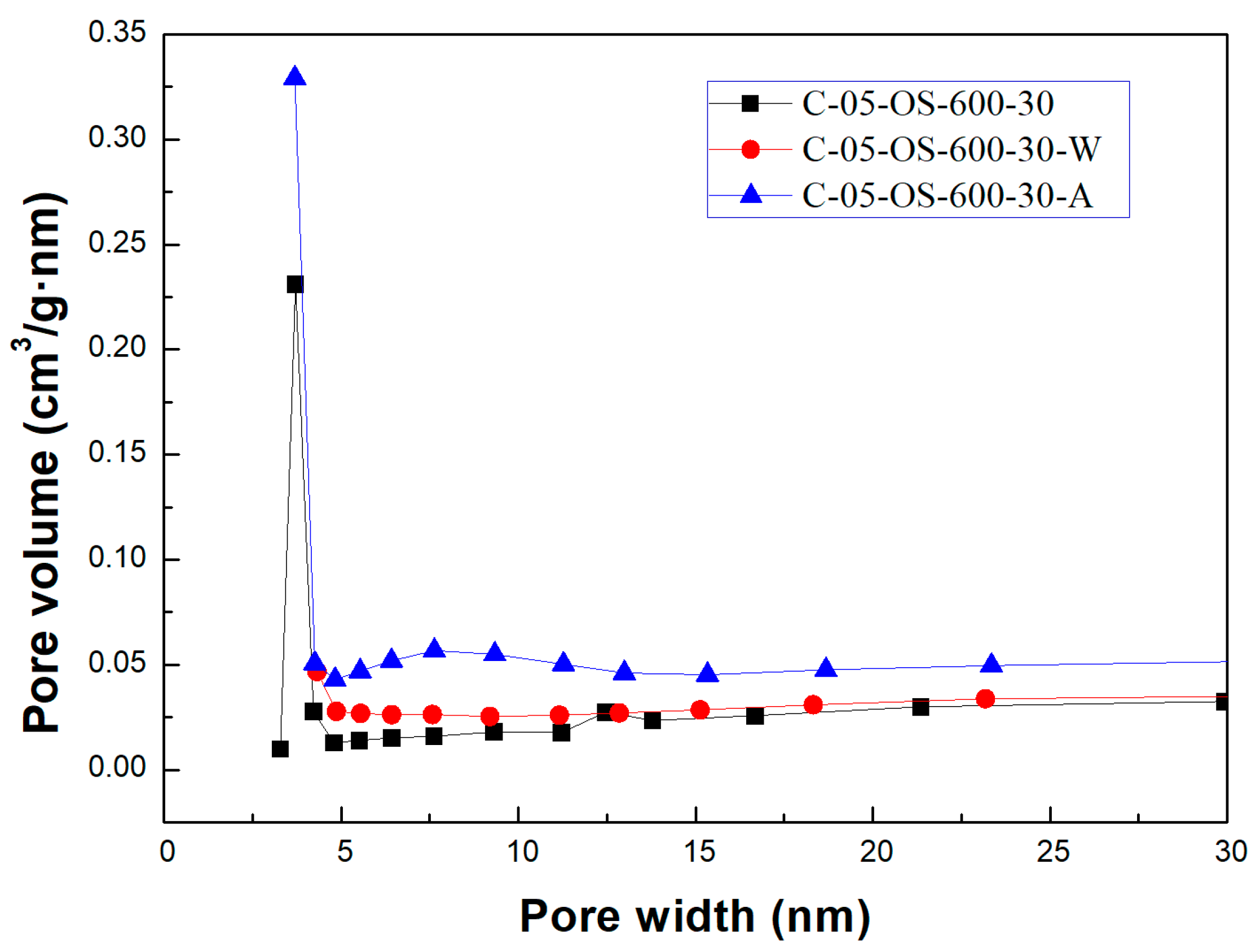

- The H3PO4 impregnation ratio had a positive impact on the pore properties of the resulting carbon products. The BET surface area indicated a slight increasing trend as the impregnation ratio increased. As compared to the carbon product without impregnation by H3PO4 (i.e., C-0-SL-600-30), the enhancement in pore development with impregnation seemed be insignificant, thus showing that its BET surface area was slightly higher than that of the other carbon product (i.e., C-05-SL-600-30).

- The pore properties of carbon products can be enhanced by post-washing with water and dilute acid solution; that is, the following specific surface areas were obtained: 50.799 and 49.462 m2/g (C-0-SL-600-30 and C-05-SL-600-30, respectively), 58.980 and 57.832 m2/g (C-0-SL-600-30-W and C-05-SL-600-30-W, respectively), and 63.132 and 69.132 m2/g (C-0-SL-600-30-A and C-05-SL-600-30-A, respectively). On the other hand, acid-washing resulted in better pore properties than those obtained by water-washing, possibly due to more dissolution (leaching-off) of inorganic minerals and more pores being developed and formed [30,31,34].

4. Discussion

4.1. Thermochemical Characterization of Oil-Containing Sludge

4.2. Characterization of Resulting Carbon Products

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maceiras, R.; Alfonsín, V.; Morales, F.J. Recycling of waste engine oil for diesel production. Waste Manag. 2017, 60, 351–356. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef]

- Mishra, A.; Siddiqi, H.; Kumari, U.; Behera, I.D.; Mukherjee, S.; Meikap, B.C. Pyrolysis of waste lubricating oil/waste motor oil to generate high-grade fuel oil: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 150, 111446. [Google Scholar] [CrossRef]

- Hui, K.; Tang, J.; Lu, H.; Xi, B.; Qu, C.; Li, J. Status and prospect of oil recovery from oily sludge: A review. Arab. J. Chem. 2020, 13, 6523–6543. [Google Scholar] [CrossRef]

- Di, X.; Pan, H.; Li, D.; Hu, H.; Hu, Z.; Yan, Y. Thermochemical recycling of oily sludge by catalytic pyrolysis: A review. Scanning 2021, 2021, 1131858. [Google Scholar] [CrossRef] [PubMed]

- Teng, Q.; Zhang, D.; Yang, C. A review of the application of different treatment processes for oily sludge. Environ. Sci. Pollut. Res. 2021, 28, 121–132. [Google Scholar] [CrossRef]

- Niu, A.; Sun, X.; Lin, C. Trend in research on characterization, environmental impacts and treatment of oily sludge: A systematic review. Molecules 2022, 27, 7795. [Google Scholar] [CrossRef] [PubMed]

- Chu, Z.; Li, Y.; Zhang, C.; Fang, Y.; Zhao, J. A review on resource utilization of oil sludge based on pyrolysis and gasification. J. Environ. Chem. Eng. 2023, 11, 109692. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Liang, H.; Chen, B.; Liu, Y.; Ma, Z.; Wang, Z. Characterization and treatment of oily sludge: A systematic review. Environ. Pollut. 2024, 344, 123245. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lin, Y.Q. Preparation and characterization of porous carbon composites from oil-containing sludge by a pyrolysis-activation process. Processes 2022, 10, 834. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lin, Y.Q.; Tsai, C.H.; Shen, Y.H. Production of mesoporous magnetic carbon materials from oily sludge by combining thermal activation and post-washing. Materials 2022, 15, 5794. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, S.; Mirghaffari, N. A preliminary study of the preparation of porous carbon from oil sludge for water treatment by simple pyrolysis or KOH activation. New Carbon Mater. 2015, 30, 310–318. [Google Scholar] [CrossRef]

- Mohammadi, S.; Mirghaffari, N. Optimization and comparison of Cd removal from aqueous solutions using activated and non-activated carbonaceous adsorbents prepared by pyrolysis of oily sludge. Water Air Soil Pollut. 2015, 226, 2237. [Google Scholar] [CrossRef]

- Li, X.; Liu, K.; Liu, Z.; Wang, Z.; Li, B.; Zhang, D. Hierarchical porous carbon from hazardous waste oily sludge for all-solid-state flexible supercapacitor. Electrochim. Acta 2017, 240, 43–52. [Google Scholar] [CrossRef]

- Wang, J.; Liu, T.L.; Huang, Q.X.; Ma, Z.Y.; Chi, Y.; Yan, J.H. Production and characterization of high quality activated carbon from oily sludge. Fuel Process. Technol. 2017, 162, 13–19. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Guo, L.; Han, D.; Li, B.; Gong, Z. Manganese oxide/hierarchical porous carbon nanocomposite from oily sludge for high-performance asymmetric supercapacitors. Electrochim. Acta 2018, 265, 71–77. [Google Scholar] [CrossRef]

- Gong, Z.; Meng, F.; Wang, Z.; Fang, P.; Li, X.; Liu, L.; Zhang, H. Study on preparation of an oil sludge-based carbon material and its adsorption of CO2: Effect of the blending ratio of oil sludge pyrolysis char to KOH and urea. Energy Fuels 2019, 33, 10056–10065. [Google Scholar] [CrossRef]

- Li, X.; Han, D.; Zhang, M.; Li, B.; Wang, Z.; Gong, Z.; Liu, P.; Zhang, Y.; Yang, X. Removal of toxic dyes from aqueous solution using new activated carbon materials developed from oil sludge waste. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123505. [Google Scholar] [CrossRef]

- Meng, F.; Gong, Z.; Wang, Z.; Fang, P.; Li, X. Study on a nitrogen-doped porous carbon from oil sludge for CO2 adsorption. Fuel 2019, 251, 562–571. [Google Scholar] [CrossRef]

- Mojoudi, N.; Mirghaffari, N.; Soleimani, M.; Shariatmadari, H.; Belver, C.; Bedia, J. Phenol adsorption on high microporous activated carbons prepared from oily sludge: Equilibrium, kinetic and thermodynamic studies. Sci. Rep. 2019, 9, 19352. [Google Scholar] [CrossRef]

- Mojoudi, N.; Soleimani, M.; Mirghaffari, N.; Belver, C.; Bedia, J. Removal of phenol and phosphate from aqueous solutions using activated carbons prepared from oily sludge through physical and chemical activation. Water Sci. Technol. 2019, 80, 275–286. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Han, D.; Gong, Z.; Wang, Z. Nest-Like MnO2 nanowire/hierarchical porous carbon composite for high-performance supercapacitor from oily sludge. Nanomaterials 2021, 11, 2715. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Li, J.; McGill, W.B.; Whitcombe, T.W. Impact of pyrolysis temperature and activation on oily sludge-derived char for Pb(II) and Cd(II) removal from aqueous solution. Environ. Sci. Pollut. Res. 2021, 28, 5532–5547. [Google Scholar] [CrossRef]

- Tian, S.; Zhang, B.; Han, D.; Gong, Z.; Li, X. Fe2O3/porous carbon composite derived from oily sludge waste as an advanced anode material for supercapacitor application. Nanomaterials 2022, 12, 3819. [Google Scholar] [CrossRef]

- Amari, A.; Noreen, A.; Osman, H.; Sammen, S.S.; Al-Ansari, N.; Salman, H.M. Investigation of the viable role of oil sludge-derived activated carbon for oily wastewater remediation. Front. Environ. Sci. 2023, 11, 1138308. [Google Scholar] [CrossRef]

- Cheng, H.; Peng, L.; Liu, J.; Ma, C.; Hao, F.; Zheng, B.; Yang, J. Adsorption separation of various polar dyes in water by oil sludge-based porous carbon. Appl. Sci. 2024, 14, 7283. [Google Scholar] [CrossRef]

- Jerez, S.; Pedersen, A.; Ventura, M.; Mazzoli, L.; Pariente, M.I.; Titirici, M.; Melero, J.A.; Barrio, J. Fe-N doped carbon materials from oily sludge as electrocatalysts for alkaline oxygen reduction reaction. Electrochim. Acta 2024, 483, 144045. [Google Scholar] [CrossRef]

- Long, J.; He, P.; Przystupa, K.; Wang, Y.; Kochan, O. Preparation of oily sludge-derived activated carbon and its adsorption performance for tetracycline hydrochloride. Molecules 2024, 29, 769. [Google Scholar] [CrossRef] [PubMed]

- Marsh, H.; Rodriguez-Reinoso, F. Activated Carbon; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Tsai, W.T.; Huang, P.C. Characterization of acid-leaching cocoa pod husk (CPH) and its resulting activated carbon. Biomass Convers. Biorefinery 2018, 8, 521–528. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lin, Y.Q.; Tsai, C.H.; Chen, W.S.; Chang, Y.T. Enhancing the pore properties and adsorption performance of cocoa pod husk (CPH)-derived biochars via post-acid treatment. Processes 2020, 8, 144. [Google Scholar] [CrossRef]

- Condon, J.B. Surface Area and Porosity Determinations by Physisorption: Measurements and Theory; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Tsai, C.H.; Tsai, W.T.; Kuo, L.A. Effect of post-washing on textural characteristics of carbon materials derived from pineapple peel biomass. Materials 2023, 16, 7529. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Academic Press: San Diego, CA, USA, 2013. [Google Scholar]

- Facts and Figures—Heat Values of Various Fuels. Available online: https://world-nuclear.org/information-library/facts-and-figures/heat-values-of-various-fuels (accessed on 14 November 2024).

- Yi, I.G.; Kang, J.K.; Lee, S.C.; Lee, C.G.; Kim, S.B. Synthesis of an oxidized mesoporous carbon-based magnetic composite and its application for heavy metal removal from aqueous solutions. Microporous Mesoporous Mater. 2019, 279, 45–52. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Z.; Fu, J.; Ao, W.; Siyal, A.A.; Zhou, C.; Liu, C.; Dai, J.; Yu, M.; Zhang, Y.; et al. Iron-biochar production from oily sludge pyrolysis and its application for organic dyes removal. Chemosphere 2022, 301, 134803. [Google Scholar] [CrossRef] [PubMed]

| Property a | Value |

|---|---|

| Proximate analysis b | |

| Moisture (wt%) | 65.44 ± 0.34 |

| Ash (wt%) | 24.98 ± 0.47 |

| Combustible fraction (wt%) | 9.58 ± 0.35 |

| Calorific value (MJ/kg) c | 13.06 ± 0.92 |

| Code of Carbon Product | SBET b (m2/g) | Smicro c (m2/g) | Sext d (m2/g) | Vt e (cm3/g) | Vmicro c (cm3/g) | Dav f (nm) |

|---|---|---|---|---|---|---|

| C-0-SL-600-30 | 50.799 | 24.947 | 25.852 | 0.0769 | 0.0130 | 6.053 |

| C-05-SL-600-30 | 49.462 | 29.524 | 19.938 | 0.0657 | 0.0148 | 5.314 |

| C-10-SL-600-30 | 51.610 | 31.352 | 20.258 | 0.0613 | 0.0163 | 4.751 |

| C-15-SL-600-30 | 54.563 | 39.245 | 15.318 | 0.0566 | 0.0197 | 4.147 |

| C-20-SL-600-30 | 58.611 | 38.529 | 20.082 | 0.0590 | 0.0195 | 4.028 |

| C-0-SL-600-30-W | 58.980 | 31.315 | 27.665 | 0.0796 | 0.0157 | 5.399 |

| C-05-SL-600-30-W | 57.832 | 29.589 | 25.243 | 0.0760 | 0.0598 | 5.256 |

| C-10-SL-600-30-W | 60.168 | 36.468 | 23.700 | 0.0674 | 0.0190 | 4.478 |

| C-15-SL-600-30-W | 57.255 | 37.268 | 19.987 | 0.0584 | 0.0187 | 4.083 |

| C-20-SL-600-30-W | 59.296 | 37.800 | 21.496 | 0.0686 | 0.0197 | 4.629 |

| C-0-SL-600-30-A | 63.132 | 26.641 | 36.6889 | 0.0979 | 0.0138 | 6.185 |

| C-05-SL-600-30-A | 69.132 | 31.152 | 37.980 | 0.1100 | 0.0155 | 6.365 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, L.-A.; Tsai, W.-T.; Pan, C.-C.; Ye, Y.-C.; Tsai, C.-H. Conversion of Oil-Containing Residue from Waste Oil Recycling Plant into Porous Carbon Materials Through Activation Method with Phosphoric Acid. Materials 2024, 17, 6161. https://doi.org/10.3390/ma17246161

Kuo L-A, Tsai W-T, Pan C-C, Ye Y-C, Tsai C-H. Conversion of Oil-Containing Residue from Waste Oil Recycling Plant into Porous Carbon Materials Through Activation Method with Phosphoric Acid. Materials. 2024; 17(24):6161. https://doi.org/10.3390/ma17246161

Chicago/Turabian StyleKuo, Li-An, Wen-Tien Tsai, Chien-Chen Pan, Ya-Chen Ye, and Chi-Hung Tsai. 2024. "Conversion of Oil-Containing Residue from Waste Oil Recycling Plant into Porous Carbon Materials Through Activation Method with Phosphoric Acid" Materials 17, no. 24: 6161. https://doi.org/10.3390/ma17246161

APA StyleKuo, L.-A., Tsai, W.-T., Pan, C.-C., Ye, Y.-C., & Tsai, C.-H. (2024). Conversion of Oil-Containing Residue from Waste Oil Recycling Plant into Porous Carbon Materials Through Activation Method with Phosphoric Acid. Materials, 17(24), 6161. https://doi.org/10.3390/ma17246161