New Polymer–Carbon Lustrous Carbon Precursor in Synthetic Molding Sands—Part I: Studies on the Properties of Sands

Abstract

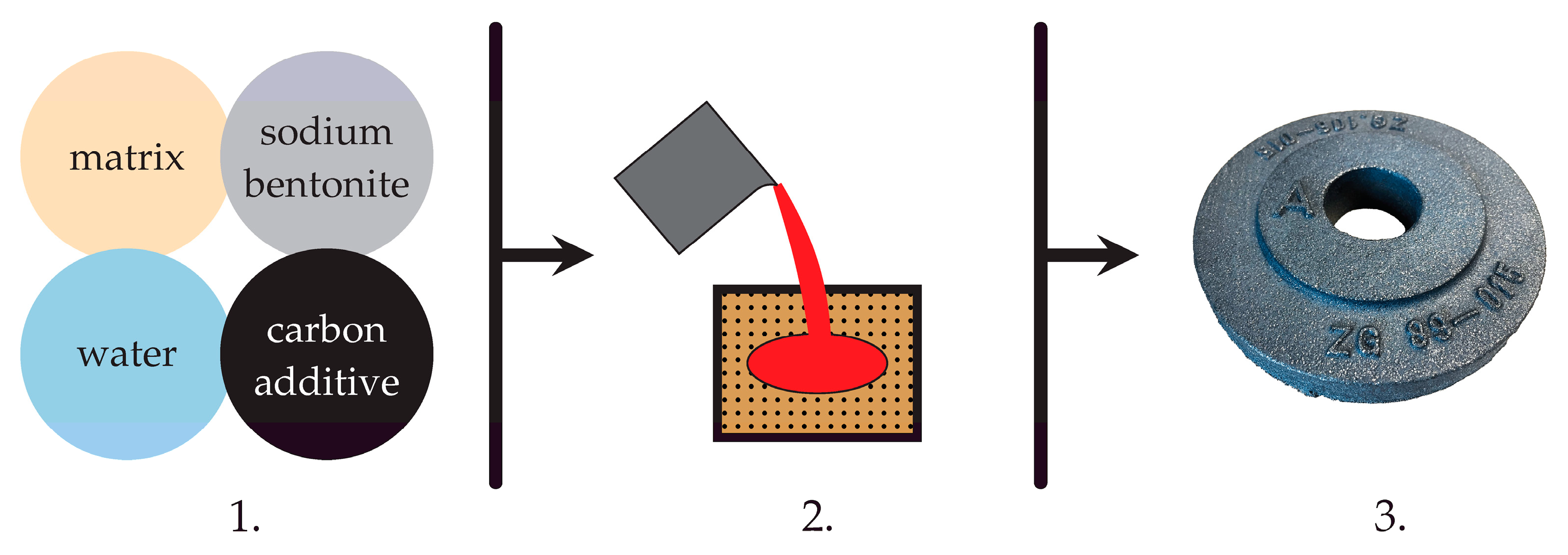

1. Introduction

2. Materials and Methods

2.1. Basic Materials

2.2. Preparation of Molding Sand

2.3. Preparation of Laboratory Samples

2.4. Investigations of Green Sands

3. Results

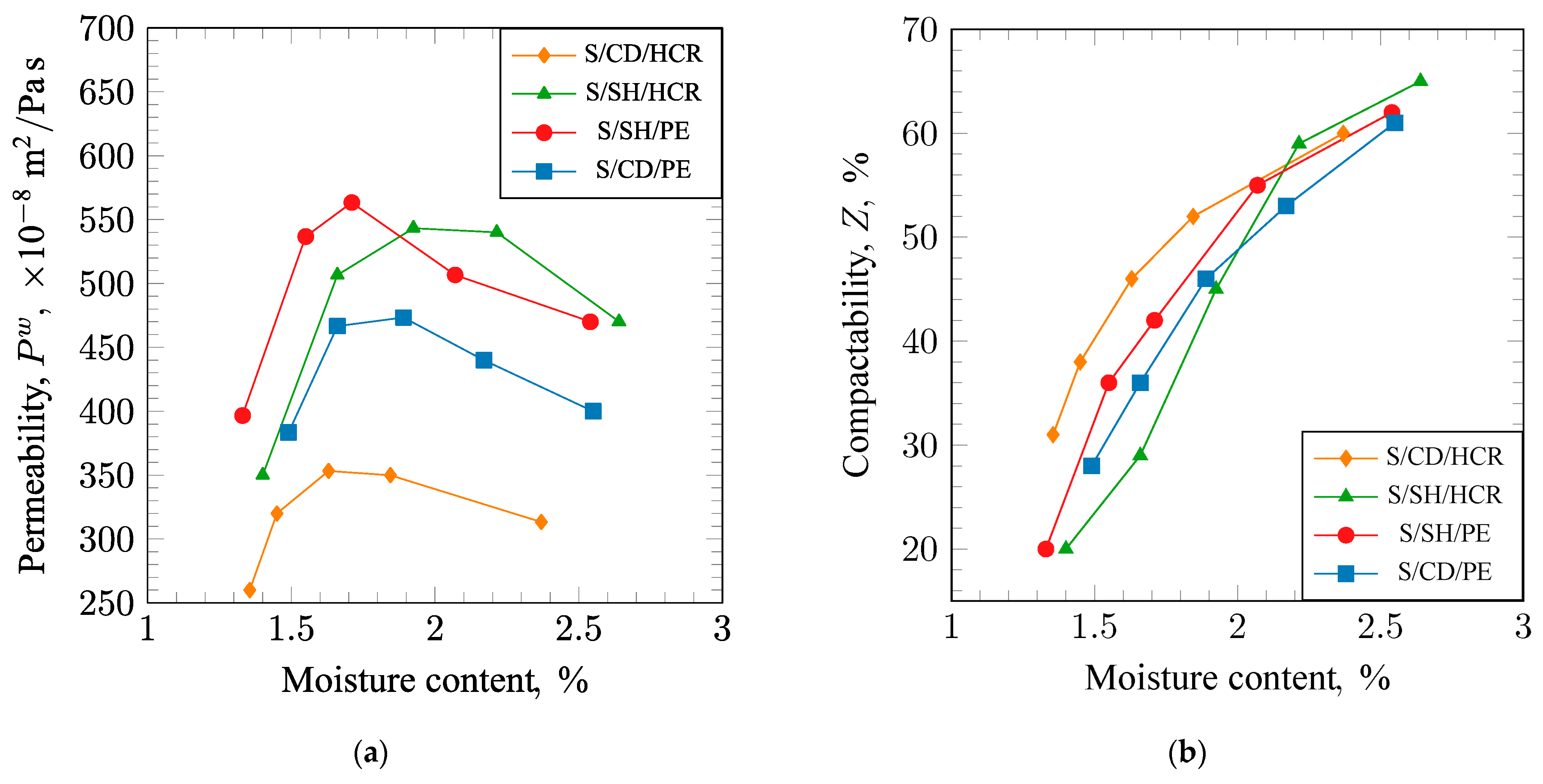

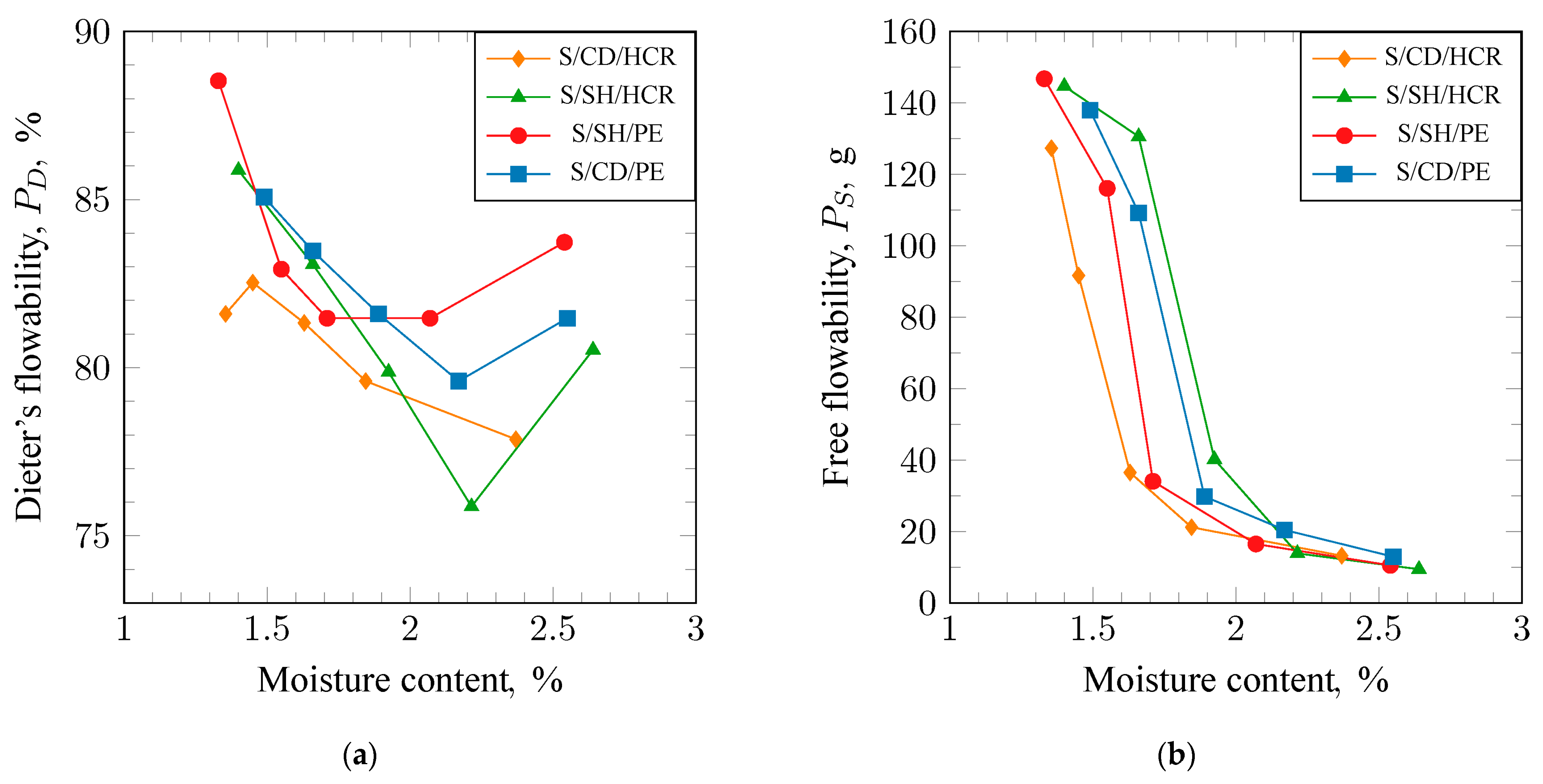

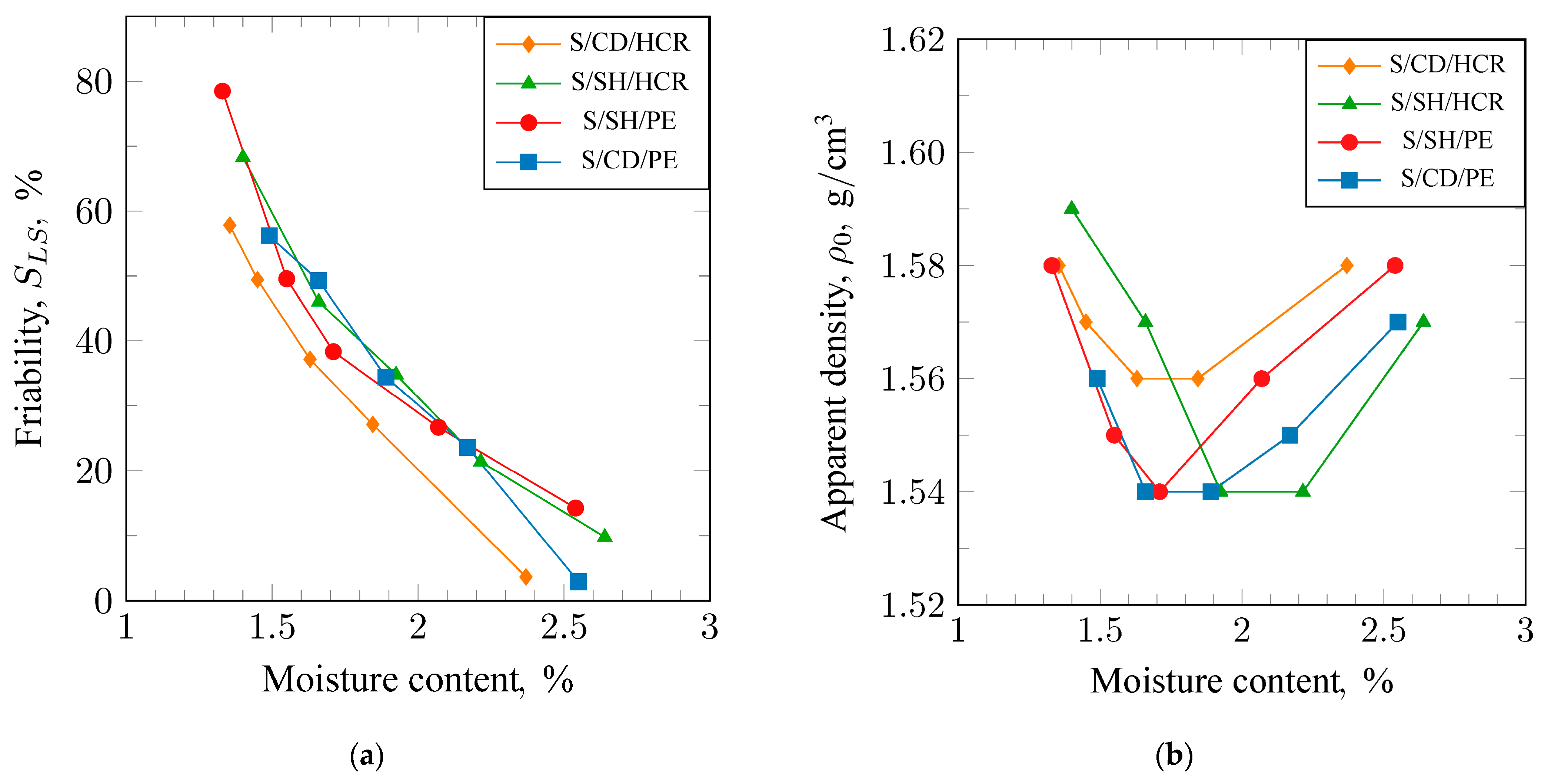

Results of the Research and Their Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lewandowski, J.L. Tworzywa na Formy Odlewnicze; Akapit: Kraków, Poland, 1997. [Google Scholar]

- Kadir, S.; Ülah, T.; Önalgil, N.; Erkoyun, H.; Elliott, W.C. Mineralogy, Geochemistry, and Genesis of Bentonites in Miocene Volcanic-Sedimentary Units of the Ankara-Çankiri Basin, Central Anatolia, Turkey. Clays Clay Min. 2017, 65, 64–91. [Google Scholar] [CrossRef]

- Modabberi, S.; Namayandeh, A.; Setti, M.; López-Galindo, A. Genesis of the Eastern Iranian Bentonite Deposits. Appl. Clay Sci. 2019, 168, 56–67. [Google Scholar] [CrossRef]

- Ayari, A.; Srasra, E.; Ayadi, M.T. Characterization of bentonitic clays and their use as adsorbent. Desalination 2005, 185, 391–397. [Google Scholar] [CrossRef]

- Paź, S.; Drożynski, D.; Gorny, M.; Cukrowicz, S. Properties of Bentonites and Bentonite Mixtures used in Casting Processes. Arch. Foundry Eng. 2019, 19, 127113. [Google Scholar] [CrossRef]

- Kamińska, J.; Puzio, S.; Angrecki, M.; Stachowicz, M. The Effect of the Addition of Bentonite Clay to Traditional Sand Mixtures on the Surface Quality of Iron Castings. J. Ecol. Eng. 2020, 21, 160–167. [Google Scholar] [CrossRef]

- Kahn, M.M.; Mahajani, S.M.; Jadhav, G.N. Transformation of bentonite used in green sand molds during metal casting process and its relevance in sand reclamation. Appl. Clay Sci. 2021, 206, 106072. [Google Scholar] [CrossRef]

- Saikaew, C.; Wiengwiset, S. Optimization of molding sand composition for quality improvement of iron castings. Appl. Clay Sci. 2012, 67, 26–31. [Google Scholar] [CrossRef]

- Żymankowska-Kumon, S.; Holtzer, M.; Olejnik, E.; Bobrowski, A. Influence of the Changes of the Structure of Foundry Bentonites on Their Binding Properties. Medziagotyra 2012, 18, 57–61. [Google Scholar] [CrossRef]

- Naro, R.L. An Update on the Formation and Control of Lustrous Carbon Surface Defects in Iron Castings. Ductile Iron News 2002, 3. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=ecca0e4ef776c99913af664e5a9fe3f8a436b0e9 (accessed on 4 December 2024).

- Jelinek, P.; Beno, J. Morphological forms of carbon and their utilizations at formation of iron casting surfaces. Arch. Foundry Eng. 2008, 8, 67–70. [Google Scholar]

- Kwaśniewska-Królikowska, D.; Holtzer, M. Selection criteria of lustrous carbon carriers in the aspect of properties of greensand system. Metalurgija 2013, 52, 62–64. [Google Scholar]

- Kamińska, A.; Stachowicz, M.; Kubecki, M. Research on Selected Types of Lustrous Carbon Carriers After the High- Temperature Pyrolysis. Arch. Foundry Eng. 2021, 21, 56–62. [Google Scholar] [CrossRef]

- Naro, R.L. Formation and control of lustrous carbon surface defects in iron and steel castings. Trans. Am. Foundrymens Soc. 2002, 1, 815–834. [Google Scholar]

- Chakherlou, T.N.; Mahdinia, Y.V.; Akbari, A. Influence of Lustrous Carbon Defects on the Fatigue Life of Ductile Iron Castings Using Lost Foam Process. Mater. Des. 2011, 32, 162–169. [Google Scholar] [CrossRef]

- Romanus, A. Additivated Coal Dust with Water Soluble Carbohydrates for Use in the Green Sand Composition for Casting Molding. U.S. Patent 7785412B2, 31 August 2010. [Google Scholar]

- Seidu, S.O.; Kutelu, B.J. Effects of Additives on Some Selected Properties of Base Sand. J. Miner. Mater. Charact. Eng. 2014, 2, 507–512. [Google Scholar] [CrossRef]

- Kumara, P.; Bhat, V.; Banagara, A. Effect of Wood Flours on Molding Sand Properties. IJRDO J. Mech. Civ. Eng. 2016, 2, 01–06. [Google Scholar]

- Major-Gabryś, K. Environmentally Friendly Foundry Molding and Core Sands. J. Mater. Eng. Perform. 2019, 28, 3905–3911. [Google Scholar] [CrossRef]

- Holtzer, M.; Bobrowski, A.; Grabowska, B.; Holtzer, M.; Bobrowski, A.; Grabowska, B.; Eichholz, S.; Hodor, K.; Manager, A. Investigation of Carriers of Lustrous Carbon at High Temperatures by Infrared Spectroscopy (FTIR). Arch. Foundry Eng. 2010, 10, 61–68. [Google Scholar]

- Holtzer, M.; Grabowska, B.; Żymankowska-Kumon, S.; Kwaśniewska-Królikowska, D.; Dańko, R.; Solarski, W.; Bobrowski, A. Harmfulness of Molding Sands with Bentonite and Lustrous Carbon Carriers. Metalurgija 2012, 51, 437–440. [Google Scholar]

- Hespers, W. Substitute for Coal Dust in Casting Molds as Lustrous Carbon-Forming Additive. U.S. Patent 3666706, 30 May 1972. [Google Scholar]

- Charles, R.L. Activated Carbon Foundry Sand Additives and Method of Casting Metal for Reduced VOC Emissions. U.S. Patent 5688313A, 18 November 1997. [Google Scholar]

- Grefhorst, C.; Senden, W.; Ilman, R.; Podobed, O.; Lafay, V.; Tilch, W. Reduction of Greensand Emissions by Minimum 25%—Case Study. China Foundry 2010, 7, 419–424. [Google Scholar]

- Miller, L.; Vakili, R.; Onge, J.; Wang, Z. Green Sand Emissions and the Concentration of Carbonaceous Additives|Modern Casting. Mod. Cast. Mag. 2019, 12, 26–28. [Google Scholar]

- Grefhorst, C.; Podobed, O. Reduzierung von Grunsandemissionen um mindestens 25%—Fallstudie. Giess. Rundsch. 2011, 58, 14–19. [Google Scholar]

- Cukrowicz, S.; Sitarz, M.; Kornaus, K.; Kaczmarska, K.; Bobrowski, A.; Gubernat, A.; Grabowska, B. Organobentonites Modified with Poly(Acrylic Acid) and Its Sodium Salt for Foundry Applications. Materials 2021, 14, 1947. [Google Scholar] [CrossRef]

- Bobrowski, A.; Grabowska, B.; Żymankowska-Kumon, S.; Kurleto-Kozioł, Z. Physico-Chemical and Environmental Characterisation of the Dust from Dry Dedusting of the Green Sand. Arch. Foundry Eng. 2016, 16, 33–36. [Google Scholar] [CrossRef]

- Grabowska, B.; Cukrowicz, S.; Kaczmarska, K.; Żymankowska-Kumon, S.; Bobrowski, A.; Tyliszczak, B.; Mrówka, N.M. Thermostability of organobentonite modified with poly(acrylic acid). Materials 2023, 16, 3626. [Google Scholar] [CrossRef]

- Grabowska, B.; Cukrowicz, S.; Bobrowski, A.; Drożyński, D.; Żymankowska-Kumon, S.; Kaczmarska, K.; Tyliszczak, B.; Pribulová, A. Organobentonite Binder for Binding Sand Grains in Foundry Molding Sands. Materials 2023, 16, 1585. [Google Scholar] [CrossRef]

- Grabowska, B.; Bobrowski, A.; Kaczmarska, K.; Drożyński, D.; Żymankowska-Kumon, S.; Cukrowicz, S.; Kwaśniewska-Królikowska, D. Masa Formierska Wiązana Bentonitem z Dodatkiem Węglowym. PL. 439688 A1, 1 February 2024. [Google Scholar]

- Melezhik, V.A.; Filippov, M.M.; Romashkin, A.E. A Giant Palaeoproterozoic Deposit of Shungite in NW Russia: Genesis and Practical Applications. Ore Geol. Rev. 2004, 24, 135–154. [Google Scholar] [CrossRef]

- Kovalevski, V.v.; Buseck, P.R.; Cowley, J.M. Comparison of Carbon in Shungite Rocks to Other Natural Carbons: An X-Ray and TEM Study. Carbon N Y 2001, 39, 243–256. [Google Scholar] [CrossRef]

- Shalimov, A.S.; Kovalevskii, V.V.; Obrezkov, O.N.; Yaroslavtsev, A.B. Sorptive Properties of Shungite. Inorg. Mater. 2004, 40, 364–367. [Google Scholar] [CrossRef]

- Sheka, E.F.; Rozhkova, N.N. Shungite as the Natural Pantry of Nanoscale Reduced Graphene Oxide. Int. J. Smart Nano Mater. 2014, 5, 885913. [Google Scholar] [CrossRef]

- BN-88 4024-9; Norma Branżowa Zgłoszona Przez Instytut Odlewnictwa w Krakowie. Pył Węglowy Odlewniczy i Jego Zamienniki. Pomiar Zawartości Węgla Błyszczącego. Instytut Odlewnictwa w Krakowie: Kraków, Poland, 1989.

- PN-83/H-11073/EN; Foundry Moulding Materials—Measurement of Resistance. Instytut Odlewnictwa w Krakowie: Kraków, Poland, 1983.

- PN-80/H-11072; Odlewnicze Materiały Formierskie—Pomiar Przepuszczalności. Instytut Odlewnictwa w Krakowie: Kraków, Poland, 1980.

- BN-77/4024-02; Norma Branżowa Zgłoszona Przez Instytut Odlewnictwa w Krakowie. Odlewnicze Masy Formierskie i Rdzeniowe—Badanie Osypliwości. Instytut Odlewnictwa w Krakowie: Kraków, Poland, 1977.

| Chemical Composition | Montmorillonite (MMT) Content, % | Cation Exchange CapacityCEC, mmol/100 g | Swelling Index Wp, cm3/2 g | Carbonate Content, % | Humidity, % | pH (10% r-r) | |

|---|---|---|---|---|---|---|---|

| Oxide Composition | Content, % | ||||||

| SiO2 | 79.6 | 79.6 | 75.1 | 35.4 | 5.0 | 9.3 | 10.1 |

| Al2O3 | 18.50 | ||||||

| MgO | 3.54 | ||||||

| CaO | 3.06 | ||||||

| Fe2O3 | 5.22 | ||||||

| Na2O | 3.37 | ||||||

| K2O | 1.32 | ||||||

| Sum | 98.90 | ||||||

| Material | Role in the Molding Sand | Supplier | Technical Data/Properties |

|---|---|---|---|

| Silica sand | Sand grains (matrix) | Sibelco, Bukowno, Poland | Main fraction 0.16–0.32 mm |

| Hydrocarbon resin (HCR) | Carbon additive | ZGM Zębiec S.A, Starachowice, Poland | Carbon content (C): 98.5%; LC content *: min. 55%; Moisture content: max. 0.4%; Ash content: max. 0.5%; Softening temperature: 95–115 °C; volatile fraction content: 95.4%. |

| Coal dust (CD) | Carbon additive | ZGM Zębiec S.A, Starachowice, Poland | Carbon content (C): 97.5%; LC content *: min. 9%; Moisture content: max. 0.5%; Ash content: max. 5.6%; Volatile fraction content: max. 36.0%. |

| Shungite (SH) | Carbon additive | Wessper, Rzezawa, Poland | Carbon content (C) based on XRF: 77.1%; LC content *: 25%; Other elemental composition based on XRF: 11.7% O; 8.9% Si; 0.7% Al; 0.6% Fe; 0.4% K; 0.3% S; 0.1% Mg. |

| Polyethylene (PE) | Carbon additive | Hostalen, Bassel Orlen, Płock, Poland | Manufacturer’s proprietary data: High density; Density: 0.958 g/cm3; LC content *: 38%. |

| Green Sand—Labelling at Work | Sand Grains (Matrix), pbw | Sodium Bentonite, pbw | HCR Resin, pbw | Coal Dust, pbw | Shungite, pbw | Polyolefin, pbw | Sum of Carbon Additives, pbw |

|---|---|---|---|---|---|---|---|

| S/CD/HCR * | 100 | 4.5 | 0.56 | 2.79 | - | - | 3.35 |

| S/SH/HCR | 100 | 4.5 | 0.56 | - | 2.79 | - | 3.35 |

| S/SH/PE | 100 | 4.5 | - | - | 2.79 | 0.56 | 3.35 |

| S/CD/PE | 100 | 4.5 | - | 2.79 | - | 0.56 | 3.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabowska, B.; Bobrowski, A.; Drożyński, D.; Kwaśniewska-Królikowska, D.; Pilch-Pitera, B.; Pojnar, K.; Nowak, D. New Polymer–Carbon Lustrous Carbon Precursor in Synthetic Molding Sands—Part I: Studies on the Properties of Sands. Materials 2024, 17, 6054. https://doi.org/10.3390/ma17246054

Grabowska B, Bobrowski A, Drożyński D, Kwaśniewska-Królikowska D, Pilch-Pitera B, Pojnar K, Nowak D. New Polymer–Carbon Lustrous Carbon Precursor in Synthetic Molding Sands—Part I: Studies on the Properties of Sands. Materials. 2024; 17(24):6054. https://doi.org/10.3390/ma17246054

Chicago/Turabian StyleGrabowska, Beata, Artur Bobrowski, Dariusz Drożyński, Dominika Kwaśniewska-Królikowska, Barbara Pilch-Pitera, Katarzyna Pojnar, and Daniel Nowak. 2024. "New Polymer–Carbon Lustrous Carbon Precursor in Synthetic Molding Sands—Part I: Studies on the Properties of Sands" Materials 17, no. 24: 6054. https://doi.org/10.3390/ma17246054

APA StyleGrabowska, B., Bobrowski, A., Drożyński, D., Kwaśniewska-Królikowska, D., Pilch-Pitera, B., Pojnar, K., & Nowak, D. (2024). New Polymer–Carbon Lustrous Carbon Precursor in Synthetic Molding Sands—Part I: Studies on the Properties of Sands. Materials, 17(24), 6054. https://doi.org/10.3390/ma17246054