Recent Progress in Laser Powder Bed Fusions Processes of Advanced High-Strength Steels

Abstract

1. Introduction

2. Insight into the Steels Manufactured by Laser Powder Bed Fusion

2.1. Short Overview of the Steels Commonly Produced by LPBF Not Covering the AHSS Group

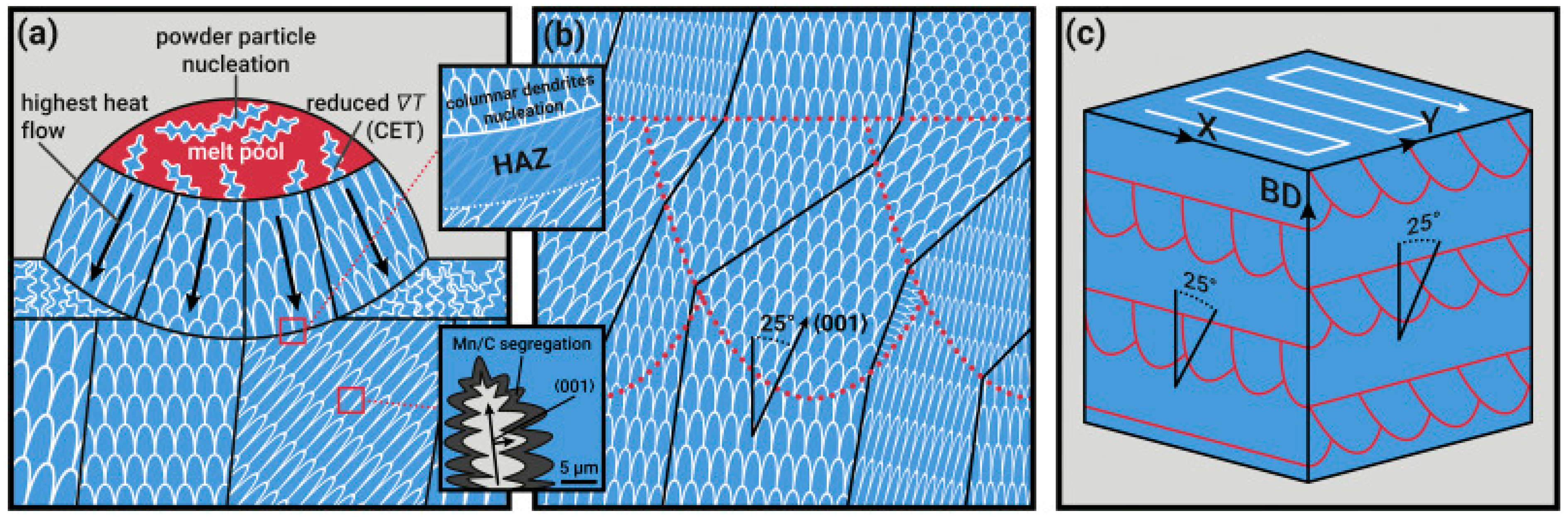

2.1.1. Austenitic Stainless Steels (ASS)

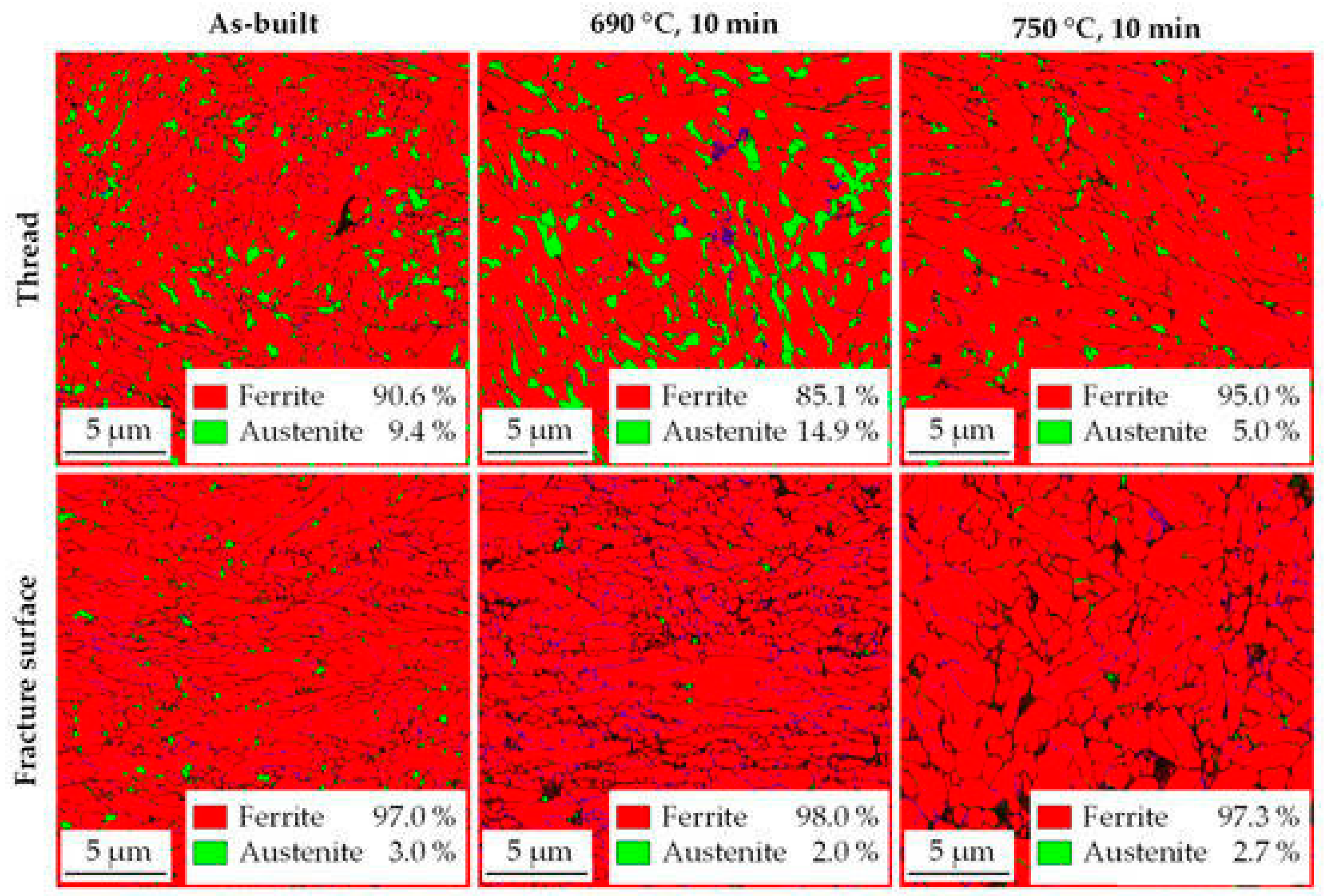

2.1.2. Duplex Stainless Steels (DSS)

2.1.3. Oxide Dispersion Strengthened (ODS) Steels

2.1.4. Precipitation-Hardened (PH) Stainless Steels

2.2. Advanced High-Strength Steels Produced by LPBF

2.2.1. Medium- and High-Mn TWIP and TRIP Steels

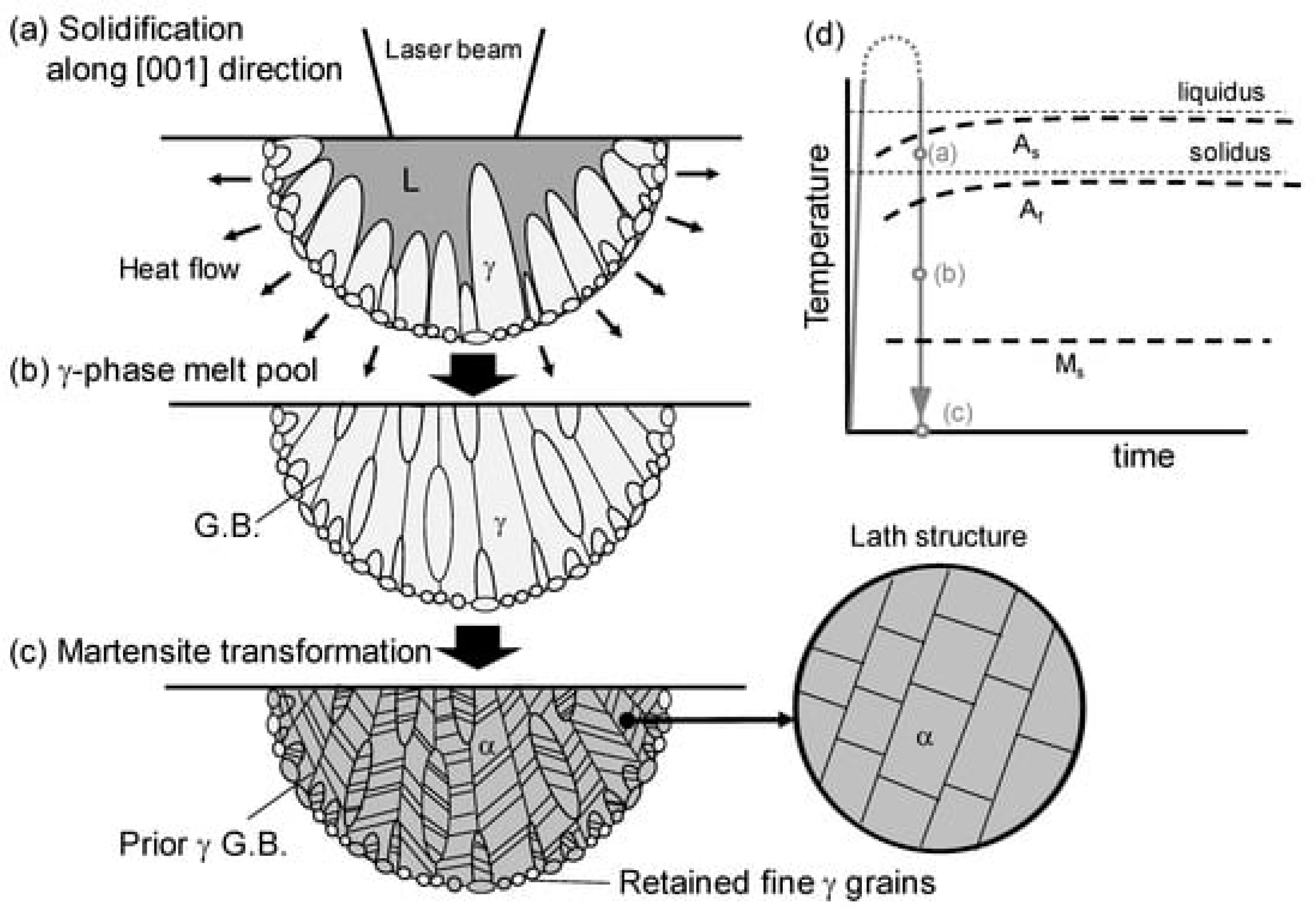

2.2.2. Maraging Steels

- precipitation of intermetallic phases;

- reversion of martensite into austenite.

| Powder | Parameters | Comments | Ref. | |

|---|---|---|---|---|

| X3NiCoMoTi18-9-5 steel (in wt %) | Gas atomized, particle size: 15 to 45 μm | Energy density: 60–70 J/mm3, Laser powder: 300 W, Scanning speed: 1 cm/s, Layer thickness: 50 μm, Argon gas atmosphere | In as-built state: elongated grains with nano-scale cellular dendritic structure. This microstructure transformed into a martensitic lath microstructure after heat treatment. The retained austenite completely transformed into martensite after solution annealing heat treatment. The aging process produced reverted austenite. | [85] |

| M789 (0.02C-12.2Cr-10Ni-1Mo0.06Al-1Ti-Fe) | Gas atomized, Particle size: 15–45 μm | Energy density: 75–85 J/mm3 Argon gas atmosphere | In as-built structures: melt pool boundaries with nano-scale columnar dendritic structures were present. The elongated grains transformed into martensitic needle-like structures after annealing and aging treatments. | [93] |

| 18Ni-350 (18.44Ni-11.91Co-4.88Mo-1.45Ti-0.12Al-0.01C) | Gas-atomization under nitrogen environment, average particle size: 30 μm | Laser power: 175 W, Hatch spacing: 100 μm, Scan speed: 300 mm/s, Layer thickness: 30 μm, Scan rotation: 67°, Energy density: 194.4 J/mm3, Relative density: 99.6–99.8 % | After direct aging, austenite reversion occurred, increasing the overall austenite fraction (21.8%). Austenitizing–aging, and solutionizing–austenitizing–aging treatments eliminated the austenite and a fully martensitic microstructure was achieved. A high density of dislocations was found in the martensitic laths in all the conditions examined. | [83] |

| 18Ni-300 0.025Mn-0.01Cr-4.5Mo-18Ni-0.07Al-9.2Co-0.91Ti | Atomized in an inert argon medium using electrode induction melting gas atomization, average particle size: 40 um | Laser power: 300 W, Focus diameter: 70 μm, Scan speed: 1300 mm/s, Hatch space: 70 μm, Layer thickness: 30 μm, Rotation angle: 33° | Absence of nano-precipitate in the as-built state, while precipitations of Ni-Ti-based and Mo-based precipitates were confirmed in both the aged and solution-aged states. | [94] |

| 18Ni-300 | Gas atomized, particle size: 15 to 53 μm | Laser power: 285 W, Scanning speed: 960 mm/s, Hatching space: 110 μm, Layer thickness: 40 μm, Scanning strategy: Orthogonal, Relative density: >99.5% | Significant anisotropies in the thermal expansion and CTE were observed between the OX (parallel) direction and OZ (perpendicular) direction in the LPBFed samples. The solution-treated and solution+ageing-treated samples showed differences in the coefficient of thermal expansion CTE compared to direct aging-treated samples. | [95] |

| 18Ni-300 | Gas atomized, average particle size: 88.8 μm | Laser power: 2000 W, Scanning speed: 1000–2000 mm/s, Hatch distance: 0.06–0.1 mm, Layer thickness: 0.1–0.2 mm, Hatch angle: 90°, Energy density: 50–180 J/mm3, Build rate: 6–40 mm3/s | High power (2000 W) contributed to typical HP-LPBF dendritic microstructure inside columnar prior-austenite grains (PAGs) growing along the building direction. The original cellular and columnar dendrites were replaced by parallel lath martensite and nanoprecipitates could be observed in the sample with solution-aging treatment. | [96] |

- Maraging steels constitute a steel group that may be effectively fabricated using LPBF/SLM processes after adjusting the process parameters to achieve high-density samples and reduced fraction of defects;

- The mechanical properties of LPBF-fabricated maraging steels are generally comparable to the conventional manufacturing routes;

- The LPBF-fabricated maraging steels to achieve expected mechanical properties are subjected to heat treatment (quenching + aging; solutionizing+austenitizing) or direct aging;

- During aging, the intermetallic precipitation growth is similar to the conventional manufacturing routes;

- During aging, the martensite is prone to transformation into reverted austenite;

- In the as-built conditions, the retained austenite is preserved. The retained austenite is formed especially at the melting pool boundaries due to occurred micro-segregation of local chemical composition.

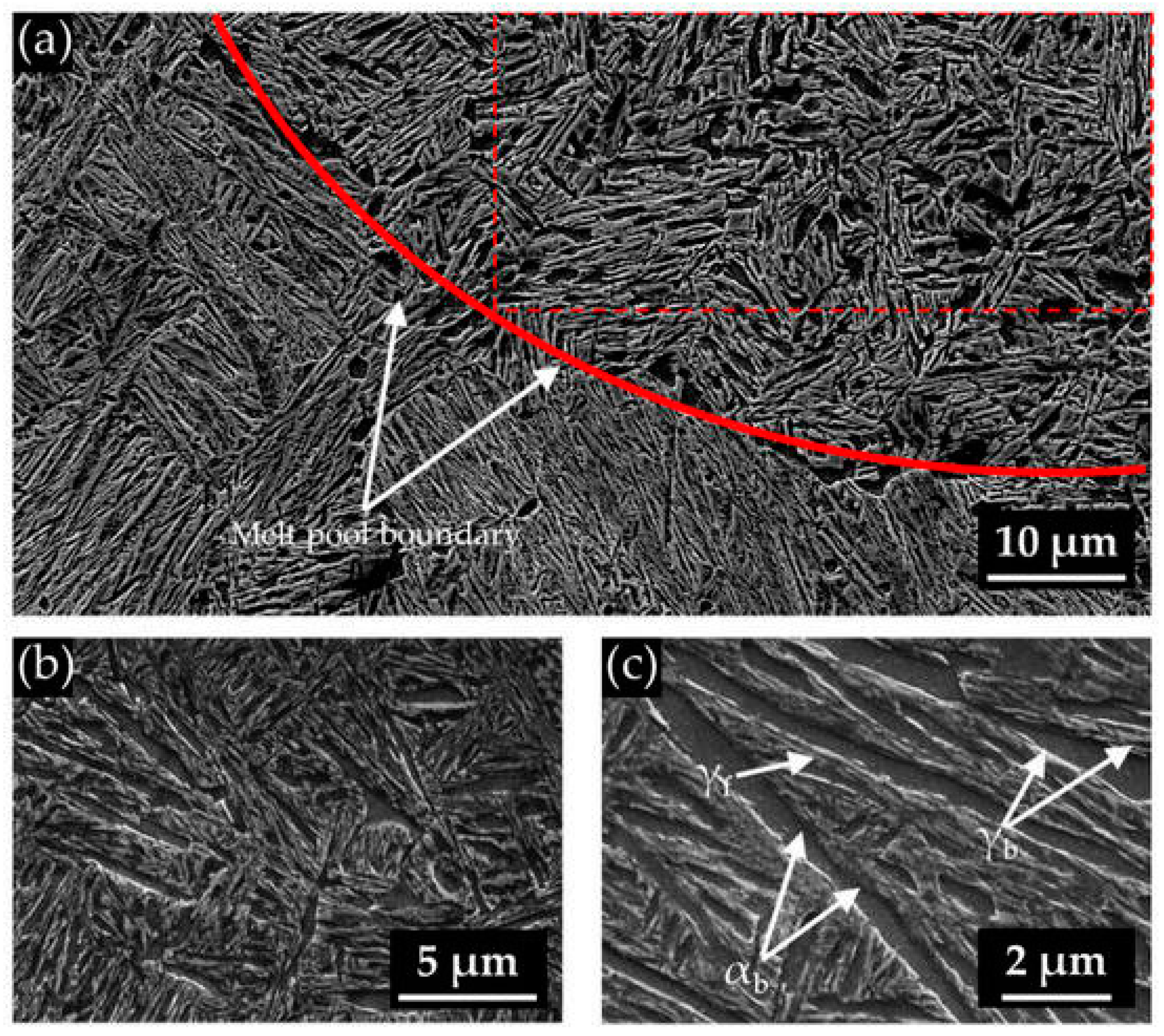

2.2.3. Bainitic Steels

- The ultra-fine bainitic steels are characterized by medium or high carbon content. The bainitic structure is achieved during prolonged isothermal heat treatment. Thus, during fast cooling after the process, the cold cracks related to martensite transformation are prone to be formed, similar to welding processes [116]. The solution for avoiding the cold crack is the usage of heated support with the temperature above martensite start (Ms) temperature.

- The LPBF is connected with formation layer-by-layer. The metastable bainitic structure together with the limited thermal stability of retained austenite tend to the decomposition process [106] and the deposition of subsequent layers. This process is similar to the tempering process.

- It seems that LPBF-fabricated bainitic steel should be subjected to a complete post-treatment process similar to conventional heat treatment (quenching and isothermal heat treatment). However, the processing of bainitic steels with lower carbon content and faster bainitic transformation may be produced using heated support at the temperature of bainitic transformation during the whole LPBF process. However, due to the segregation of chemical elements, the distribution of retained austenite may be not homogeneous in the fusion zone and heat-affected zone [115].

2.2.4. Novel Concepts of Advanced Steels—Low-Density High-Strength Steels

3. Conclusions

- Maraging steels: Adjusting process parameters enabled the fabrication of the parts with high density and a limited fraction of defects. After heat treatment or direct aging, strengthening by intermetallic phases is achieved similarly to conventional manufacturing processes. After the LBPF processes, the structure retains austenite located mainly at the melting pool boundaries, which is related to the micro-segregation of the chemical composition. During aging, the transformation of the martensite into reverted austenite occurs.

- High-Mn steels with TWIP/TRIP effect: Mechanical properties after LPBF are comparable to the conventional processing. The fully austenitic matrix is achieved. Additional post-printing heat treatment is not necessary to introduce TWIP and TRIP effects. The design strategy to reduce the segregation of chemical elements is favorable for AM processes. Both ε- and α´-martensite are formed during deformation. The contribution of TRIP and TWIP effects is related to the Al content.

- Medium-Mn steels with TRIP effect: A martensitic or martensitic–bainitic matrix with a controlled content of retained austenite is formed during the LPBF. Martensite is also subjected to the tempering process during printing. In as-built conditions, the content of retained austenite is lower compared to conventional manufacturing routes. The post-process heat treatment (intercritical annealing) significantly enhances the austenite susceptibility to the TRIP effect and increases the fraction of retained austenite compared to the as-built condition. Preheating at 200 °C is used to avoid cold cracking. The conducted research indicates that post-process heat treatment (intercritical annealing) is necessary to enhance mechanical behavior up to the level of conventional manufacturing processes of medium-Mn steels.

- Bainitic steels: They still constitute a research gap. After the LPBF process, a complete heat treatment allows for the formation of the expected carbide-free bainitic microstructure, which is, however, still characterized by heterogeneity. In terms of bainitic steels, a new chemical composition design strategy is required to achieve a bainitic structure during printing characterized by a combination of strength and ductility. Process parameters also require further investigation to prevent cold and hot cracking.

- Low-Density, High-Strength Steels: Although the low-density still attracts huge attention of researchers, the AM processes constitute a large research gap and require further investigations focused on eliminating cracks, micro- and macro-segregation, controlling the morphology of the microstructure and carbide precipitation (especially Kappa carbide), and tailoring the structure–property relationship. A crucial role is also played by process parameters and the development of effective post-treatment processes aimed at enhancing the mechanical properties and enabling the producing larger parts. Only TRIPLEX steel and Fe-30Mn-9Al-1Si-0.5Mo-9C were subjected to LPBF processes, which is a promising premise for further research.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raabe, D.; Sun, B.; Kwiatkowski Da Silva, A.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Thoudden Sukumar, P.; Souza Filho, I.R.; Katnagallu, S.; Jägle, E.; et al. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Metall. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Kalhor, A.; Soleimani, M.; Mirzadeh, H.; Uthaisangsuk, V. A review of recent progress in mechanical and corrosion properties of dual phase steels. Arch. Civ. Mech. Eng. 2020, 20, 85. [Google Scholar] [CrossRef]

- Heibel, S.; Dettinger, T.; Nester, W.; Clausmeyer, T.; Tekkaya, A.E. Damage Mechanisms and Mechanical Properties of High-Strength Multiphase Steels. Materials 2018, 11, 761. [Google Scholar] [CrossRef]

- Grajcar, A.; Skowronek, A.; Radwański, K. Mechanical behavior and stability of dispersed retained austenite in thermomechanically rolled and isothermally-treated TRIP-aided multiphase steel. Mater. Sci. Eng. A 2022, 830, 142300. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Kozlowska, A. Microstructure–Property Relationships in Thermomechanically Processed Medium-Mn Steels with High Al Content. Metals 2018, 8, 929. [Google Scholar] [CrossRef]

- Jacob, R.; Raman Sankaranarayanan, S.; Kumaresh Babu, S.P. Recent advancements in manganese steels—A review. Mater. Today Proc. 2020, 27, 2852–2858. [Google Scholar] [CrossRef]

- Grajcar, A.; Borek, W. Thermo-mechanical processing of high-manganese austenitic TWIP-type steels. Arch. Civ. Mech. Eng. 2008, 8, 29–38. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Soleimani, M.; Kalhor, A.; Mirzadeh, H. Transformation-induced plasticity (TRIP) in advanced steels: A review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 1. Mater. Sci. Technol. 2001, 17, 512–516. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 2. Mater. Sci. Technol. 2001, 17, 517–522. [Google Scholar] [CrossRef]

- Caballero, F.G.; Garcia-Mateo, C.; Miller, M.K. Design of novel bainitic steels: Moving from ultrafine to nanoscale structures. Jom 2014, 66, 747–755. [Google Scholar] [CrossRef]

- da Fonseca, D.P.M.; Feitosa, A.L.M.; de Carvalho, L.G.; Plaut, R.L.; Padilha, A.F. A Short Review on Ultra-High-Strength Maraging Steels and Future Perspectives. Mater. Res. 2021, 24, e20200470. [Google Scholar] [CrossRef]

- Rana, R.; Cordova-Tapia, E.; Jimenez, J.A.; Morales-Rivas, L.; Garcia-Mateo, C. Design of carbide free bainitic steels for hot rolling practices. Philos. Mag. Lett. 2024, 104, 2322552. [Google Scholar] [CrossRef]

- Morales-Rivas, L. Viewpoints on Technological Aspects of Advanced High-Strength Bainitic Steels. Metals 2022, 12, 195. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Sourmail, T.; Caballero, F.G.; Smanio, V.; Kuntz, M.; Ziegler, C.; Leiro, A.; Vuorinen, E.; Elvira, R.; Teeri, T. Nanostructured steel industrialisation: Plausible reality. Mater. Sci. Technol. 2014, 30, 1071–1078. [Google Scholar] [CrossRef]

- Sun, L.; Simm, T.H.; Martin, T.L.; McAdam, S.; Galvin, D.R.; Perkins, K.M.; Bagot, P.A.J.; Moody, M.P.; Ooi, S.W.; Hill, P.; et al. A novel ultra-high strength maraging steel with balanced ductility and creep resistance achieved by nanoscale β-NiAl and Laves phase precipitates. Acta Mater. 2018, 149, 285–301. [Google Scholar] [CrossRef]

- Li, J.; Zhan, D.; Jiang, Z.; Zhang, H.; Yang, Y.; Zhang, Y. Progress on improving strength-toughness of ultra-high strength martensitic steels for aerospace applications: A review. J. Mater. Res. Technol. 2023, 23, 172–190. [Google Scholar] [CrossRef]

- Pereira, R.; Peixinho, N.; Costa, S.L. A Review of Sheet Metal Forming Evaluation of Advanced High-Strength Steels (AHSS). Metals 2024, 14, 394. [Google Scholar] [CrossRef]

- Kvackaj, T.; Bidulská, J.; Bidulský, R. Overview of HSS Steel Grades Development and Study of Reheating Condition Effects on Austenite Grain Size Changes. Materials 2021, 14, 1988. [Google Scholar] [CrossRef] [PubMed]

- Grajcar, A.; Kuziak, R.; Zalecki, W. Third generation of AHSS with increased fraction of retained austenite for the automotive industry. Arch. Civ. Mech. Eng. 2012, 12, 334–341. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Lesch, C.; Kwiaton, N.; Klose, F.B. Advanced High Strength Steels (AHSS) for Automotive Applications − Tailored Properties by Smart Microstructural Adjustments. Steel Res. Int. 2017, 88, 1700210. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Gruber, K.; Smolina, I.; Stopyra, W. Assessing metal powder quality for additive manufacturing using diffuse light spectroscopy. Powder Technol. 2024, 434, 119366. [Google Scholar] [CrossRef]

- Romano-Acosta, L.F.; García-Rincon, O.; Pedraza, J.P.; Palmiere, E.J. Influence of thermomechanical processing parameters on critical temperatures to develop an Advanced High-Strength Steel microstructure. J. Mater. Sci. 2021, 56, 18710–18721. [Google Scholar] [CrossRef]

- Krbata, M.; Krizan, D.; Eckert, M.; Kaar, S.; Dubec, A.; Ciger, R. Austenite Decomposition of a Lean Medium Mn Steel Suitable for Quenching and Partitioning Process: Comparison of CCT and DCCT Diagram and Their Microstructural Changes. Materials 2022, 15, 1753. [Google Scholar] [CrossRef]

- Krbaťa, M.; Barényi, I.; Eckert, M.; Križan, D.; Kaar, S.; Breznická, A. Hot deformation analysis of lean medium-manganese 0.2C3Mn1.5Si steel suitable for quenching et partitioning process. Met. Mater. 2021, 59, 379–390. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Mai, S.; Wang, D.; Song, C. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater. Des. 2015, 87, 797–806. [Google Scholar] [CrossRef]

- Köhnen, P.; Létang, M.; Voshage, M.; Schleifenbaum, J.H.; Haase, C. Understanding the process-microstructure correlations for tailoring the mechanical properties of L-PBF produced austenitic advanced high strength steel. Addit. Manuf. 2019, 30, 100914. [Google Scholar] [CrossRef]

- Funch, C.V.; Somlo, K.; Christiansen, T.L.; Somers, M.A.J. Thermochemical post-processing of additively manufactured austenitic stainless steel. Surf. Coatings Technol. 2022, 441, 128495. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Dong, P.; Vecchiato, F.; Yang, Z.; Hooper, P.A.; Wenman, M.R. The effect of build direction and heat treatment on atmospheric stress corrosion cracking of laser powder bed fusion 316L austenitic stainless steel. Addit. Manuf. 2021, 40, 101902. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Köhler, M.L.; Kunz, J.; Herzog, S.; Kaletsch, A.; Broeckmann, C. Microstructure analysis of novel LPBF-processed duplex stainless steels correlated to their mechanical and corrosion properties. Mater. Sci. Eng. A 2021, 801, 140432. [Google Scholar] [CrossRef]

- Nigon, G.N.; Burkan Isgor, O.; Pasebani, S. The effect of annealing on the selective laser melting of 2205 duplex stainless steel: Microstructure, grain orientation, and manufacturing challenges. Opt. Laser Technol. 2021, 134, 106643. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Chen, H.; Chen, Z.; Ledermueller, C.; Liao, X.; Ringer, S.; Primig, S. On the pitting corrosion of 2205 duplex stainless steel produced by laser powder bed fusion additive manufacturing in the as-built and post-processed conditions. Mater. Des. 2021, 212, 110260. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, A.; Yin, B.; Wen, P. Additive manufacturing of duplex stainless steels—A critical review. J. Manuf. Process. 2022, 73, 496–517. [Google Scholar] [CrossRef]

- Paul, B.K.; Lee, K.; He, Y.; Ghayoor, M.; Chang, C.; Pasebani, S. Oxide dispersion strengthened 304 L stainless steel produced by ink jetting and laser powder bed fusion. CIRP Ann. 2020, 69, 193–196. [Google Scholar] [CrossRef]

- Wilms, M.B.; Streubel, R.; Frömel, F.; Weisheit, A.; Tenkamp, J.; Walther, F.; Barcikowski, S.; Schleifenbaum, J.H.; Gökce, B. Laser additive manufacturing of oxide dispersion strengthened steels using laser-generated nanoparticle-metal composite powders. Procedia CIRP 2018, 74, 196–200. [Google Scholar] [CrossRef]

- Horn, T.; Rock, C.; Kaoumi, D.; Anderson, I.; White, E.; Prost, T.; Rieken, J.; Saptarshi, S.; Schoell, R.; DeJong, M.; et al. Laser powder bed fusion additive manufacturing of oxide dispersion strengthened steel using gas atomized reaction synthesis powder. Mater. Des. 2022, 216, 110574. [Google Scholar] [CrossRef]

- Wilms, M.B.; Rittinghaus, S.-K.; Goßling, M.; Gökce, B. Additive manufacturing of oxide-dispersion strengthened alloys: Materials, synthesis and manufacturing. Prog. Mater. Sci. 2023, 133, 101049. [Google Scholar] [CrossRef]

- Sabooni, S.; Chabok, A.; Feng, S.C.; Blaauw, H.; Pijper, T.C.; Yang, H.J.; Pei, Y.T. Laser powder bed fusion of 17–4 PH stainless steel: A comparative study on the effect of heat treatment on the microstructure evolution and mechanical properties. Addit. Manuf. 2021, 46, 102176. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Lim, S.-H.; Della Crociata, D.; Castellote-Alvarez, R.; Simonelli, M.; San-Martín, D.; Hao, X.; Choi, P.-P.; Rivera-Díaz-del-Castillo, P.E.J. Genetic design of precipitation-hardening stainless steels for additive manufacturing. Acta Mater. 2024, 274, 120018. [Google Scholar] [CrossRef]

- Roberts, D.; Zhang, Y.; Charit, I.; Zhang, J. A comparative study of microstructure and high-temperature mechanical properties of 15-5 PH stainless steel processed via additive manufacturing and traditional manufacturing. Prog. Addit. Manuf. 2018, 3, 183–190. [Google Scholar] [CrossRef]

- Fields, B.; Amiri, M.; Lim, J.; Pürstl, J.T.; Begley, M.R.; Apelian, D.; Valdevit, L. Microstructural Control of a Multi-Phase PH Steel Printed with Laser Powder Bed Fusion. Adv. Mater. Technol. 2024, 9, 2301037. [Google Scholar] [CrossRef]

- Singh, K.K.; Moridi, A. Metastability mediated grain size control in PH 17-4 stainless steel fabricated using Laser-Powder Bed Fusion (LPBF). Materialia 2023, 30, 101857. [Google Scholar] [CrossRef]

- Vunnam, S.; Saboo, A.; Sudbrack, C.; Starr, T.L. Effect of powder chemical composition on the as-built microstructure of 17-4 PH stainless steel processed by selective laser melting. Addit. Manuf. 2019, 30, 100876. [Google Scholar] [CrossRef]

- Ko, G.; Kim, W.; Kwon, K.; Lee, T.-K. The Corrosion of Stainless Steel Made by Additive Manufacturing: A Review. Metals 2021, 11, 516. [Google Scholar] [CrossRef]

- Zadi-Maad, A.; Rohib, R.; Irawan, A. Additive manufacturing for steels: A review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 285, 012028. [Google Scholar] [CrossRef]

- Sun, B.; Kwiatkowski da Silva, A.; Wu, Y.; Ma, Y.; Chen, H.; Scott, C.; Ponge, D.; Raabe, D. Physical metallurgy of medium-Mn advanced high-strength steels. Int. Mater. Rev. 2023, 68, 786–824. [Google Scholar] [CrossRef]

- Miller, R.L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Trans. 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Grain size effect on strain hardening in twinning-induced plasticity steels. Scr. Mater. 2012, 66, 992–996. [Google Scholar] [CrossRef]

- Zambrano, O.A. A general perspective of Fe–Mn–Al–C steels. J. Mater. Sci. 2018, 53, 14003–14062. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.X. Abnormal TRIP effect on the work hardening behavior of a quenching and partitioning steel at high strain rate. Acta Mater. 2020, 188, 551–559. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, D.; Sung, H. Reviews on factors affecting fatigue behavior of high-Mn steels. Met. Mater. Int. 2018, 24, 1–14. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Lee, Y.-K.; Raabe, D.; Tsuzaki, K. Overview of hydrogen embrittlement in high-Mn steels. Int. J. Hydrogen Energy 2017, 42, 12706–12723. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F. Steel showing twinning-induced plasticity processed by selective laser melting—An additively manufactured high performance material. Mater. Charact. 2013, 85, 57–63. [Google Scholar] [CrossRef]

- Haase, C.; Bültmann, J.; Hof, J.; Ziegler, S.; Bremen, S.; Hinke, C.; Schwedt, A.; Prahl, U.; Bleck, W. Exploiting Process-Related Advantages of Selective Laser Melting for the Production of High-Manganese Steel. Materials 2017, 10, 56. [Google Scholar] [CrossRef] [PubMed]

- Kies, F.; Köhnen, P.; Wilms, M.B.; Brasche, F.; Pradeep, K.G.; Schwedt, A.; Richter, S.; Weisheit, A.; Schleifenbaum, J.H.; Haase, C. Design of high-manganese steels for additive manufacturing applications with energy-absorption functionality. Mater. Des. 2018, 160, 1250–1264. [Google Scholar] [CrossRef]

- Ewald, S.; Schaukellis, M.; Koehnen, P.; Schleifenbaum, J.H. Laser Powder Bed Fusion of Advanced High-Strength Steels—Modification of Deformation Mechanisms by Increasing Stacking Fault Energy. BHM Berg Hüttenmännische Monatshefte 2019, 164, 127–132. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F.; Hoyer, P.; Schwarze, D.; Schaper, M.; Grothe, R.; Wiesener, M.; Grundmeier, G.; Maier, H.J. Processing of New Materials by Additive Manufacturing: Iron-Based Alloys Containing Silver for Biomedical Applications. Metall. Mater. Trans. A 2015, 46, 2829–2833. [Google Scholar] [CrossRef]

- Köhnen, P.; Ewald, S.; Schleifenbaum, J.H.; Belyakov, A.; Haase, C. Controlling microstructure and mechanical properties of additively manufactured high-strength steels by tailored solidification. Addit. Manuf. 2020, 35, 101389. [Google Scholar] [CrossRef]

- Pawlak, A.; Dziedzic, R.; Kasprowicz, M.; Stopyra, W.; Kuźnicka, B.; Chlebus, E.; Schob, B.; Zopp, C.; Kroll, L.; Kordass, R.; et al. Properties of medium-manganese steel processed by laser powder bed fusion: The effect of microstructure in as-built and intercritically annealed state on energy absorption during tensile and impact tests. Mater. Sci. Eng. A 2023, 870, 144859. [Google Scholar] [CrossRef]

- Heemann, L.; Mostaghimi, F.; Schob, B.; Schubert, F.; Kroll, L.; Uhlenwinkel, V.; Steinbacher, M.; Toenjes, A.; von Hehl, A. Adjustment of Mechanical Properties of Medium Manganese Steel Produced by Laser Powder Bed Fusion with a Subsequent Heat Treatment. Materials 2021, 14, 3081. [Google Scholar] [CrossRef]

- Wang, W.; Yan, W.; Duan, Q.; Shan, Y.; Zhang, Z.; Yang, K. Study on fatigue property of a new 2.8GPa grade maraging steel. Mater. Sci. Eng. A 2010, 527, 3057–3063. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rainforth, W.M.; Rivera-Díaz-del-Castillo, P.E.J. Predicting microstructure and strength of maraging steels: Elemental optimisation. Acta Mater. 2016, 117, 270–285. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shahriari, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Additive manufacturing of an Fe–Cr–Ni–Al maraging stainless steel: Microstructure evolution, heat treatment, and strengthening mechanisms. Mater. Sci. Eng. A 2020, 787, 139470. [Google Scholar] [CrossRef]

- Bagchi, A.; Gope, D.K.; Chattopadhyaya, S.; Wuriti, G. A critical review on susceptibility of stress corrosion cracking in maraging steel weldments. Mater. Today Proc. 2020, 27, 2303–2307. [Google Scholar] [CrossRef]

- Rohit, B.; Muktinutalapati, N.R. Fatigue Behavior of 18% Ni Maraging Steels: A Review. J. Mater. Eng. Perform. 2021, 30, 2341–2354. [Google Scholar] [CrossRef]

- Nageswara Rao, M.; Narayana Murty, S.V.S. Hot Deformation of 18% Ni Maraging Steels: A Review. Mater. Perform. Charact. 2019, 8, 742–765. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, L.; Andersson, J.; Ojo, O. Additive manufacturing of 18% nickel maraging steels: Defect, structure and mechanical properties: A review. J. Mater. Sci. Technol. 2022, 120, 227–252. [Google Scholar] [CrossRef]

- Mooney, B.; Kourousis, K. A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals 2020, 10, 1273. [Google Scholar] [CrossRef]

- Kizhakkinan, U.; Seetharaman, S.; Raghavan, N.; Rosen, D.W. Laser Powder Bed Fusion Additive Manufacturing of Maraging Steel: A Review. J. Manuf. Sci. Eng. 2023, 145, 110801. [Google Scholar] [CrossRef]

- Rao, B.S.; Rao, T.B. Effect of Process Parameters on Powder Bed Fusion Maraging Steel 300: A Review. Lasers Manuf. Mater. Process. 2022, 9, 338–375. [Google Scholar] [CrossRef]

- Simson, T.; Koch, J.; Rosenthal, J.; Kepka, M.; Zetek, M.; Zetková, I.; Wolf, G.; Tomčík, P.; Kulhánek, J. Mechanical Properties of 18Ni-300 maraging steel manufactured by LPBF. Procedia Struct. Integr. 2019, 17, 843–849. [Google Scholar] [CrossRef]

- Jägle, E.; Sheng, Z.; Kürnsteiner, P.; Ocylok, S.; Weisheit, A.; Raabe, D. Comparison of Maraging Steel Micro- and Nanostructure Produced Conventionally and by Laser Additive Manufacturing. Materials 2016, 10, 8. [Google Scholar] [CrossRef] [PubMed]

- Takata, N.; Nishida, R.; Suzuki, A.; Kobashi, M.; Kato, M. Crystallographic Features of Microstructure in Maraging Steel Fabricated by Selective Laser Melting. Metals 2018, 8, 440. [Google Scholar] [CrossRef]

- Wei, S.; Kumar, P.; Lau, K.B.; Wuu, D.; Liew, L.-L.; Wei, F.; Teo, S.L.; Cheong, A.; Ng, C.K.; Zhang, B.; et al. Effect of heat treatment on the microstructure and mechanical properties of 2.4 GPa grade maraging steel fabricated by laser powder bed fusion. Addit. Manuf. 2022, 59, 103190. [Google Scholar] [CrossRef]

- Karlapudy, S.P.; Nancharaiah, T.; Subba Rao, V.V. Influence of post-heat treatment on microstructure, texture, and mechanical properties of 18Ni-300 maraging steel fabricated by using LPBF technique. Prog. Addit. Manuf. 2023, 1–16. [Google Scholar] [CrossRef]

- Chadha, K.; Tian, Y.; Bocher, P.; Spray, J.G.; Aranas, C. Microstructure Evolution, Mechanical Properties and Deformation Behavior of an Additively Manufactured Maraging Steel. Materials 2020, 13, 2380. [Google Scholar] [CrossRef]

- Król, M.; Snopiński, P.; Czech, A. The phase transitions in selective laser-melted 18-NI (300-grade) maraging steel. J. Therm. Anal. Calorim. 2020, 142, 1011–1018. [Google Scholar] [CrossRef]

- Eres-Castellanos, A.; Santana, A.; De-Castro, D.; Jimenez, J.A.; Rementeria, R.; Capdevila, C.; Caballero, F.G. Effect of processing parameters on texture and variant selection of as-built 300 maraging steel processed by laser powder bed fusion. Sci. Rep. 2022, 12, 16168. [Google Scholar] [CrossRef]

- Santana, A.; Eres-Castellanos, A.; Jimenez, J.A.; Rementeria, R.; Capdevila, C.; Caballero, F.G. Effect of layer thickness and laser emission mode on the microstructure of an additive manufactured maraging steel. J. Mater. Res. Technol. 2023, 25, 6898–6912. [Google Scholar] [CrossRef]

- Kannan, R.; Leonard, D.N.; Nandwana, P. Optimization of direct aging temperature of Ti free grade 300 maraging steel manufactured using laser powder bed fusion (LPBF). Mater. Sci. Eng. A 2021, 817, 141266. [Google Scholar] [CrossRef]

- Piekło, J.; Garbacz-Klempka, A.; Myszka, D.; Figurski, K. Numerical and Experimental Analysis of Strength Loss of 1.2709 Maraging Steel Produced by Selective Laser Melting (SLM) under Thermo-Mechanical Fatigue Conditions. Materials 2023, 16, 7682. [Google Scholar] [CrossRef]

- Zhao, Z.; Dong, C.; Kong, D.; Wang, L.; Ni, X.; Zhang, L.; Wu, W.; Zhu, L.; Li, X. Influence of pore defects on the mechanical property and corrosion behavior of SLM 18Ni300 maraging steel. Mater. Charact. 2021, 182, 111514. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Investigation of remelting and preheating in SLM of 18Ni300 maraging steel as corrective and preventive measures for porosity reduction. Int. J. Adv. Manuf. Technol. 2017, 93, 2697–2709. [Google Scholar] [CrossRef]

- Palad, R.; Tian, Y.; Chadha, K.; Rodrigues, S.; Aranas, C. Microstructural features of novel corrosion-resistant maraging steel manufactured by laser powder bed fusion. Mater. Lett. 2020, 275, 128026. [Google Scholar] [CrossRef]

- Allam, T.; Pradeep, K.G.; Köhnen, P.; Marshal, A.; Schleifenbaum, J.H.; Haase, C. Tailoring the nanostructure of laser powder bed fusion additively manufactured maraging steel. Addit. Manuf. 2020, 36, 101561. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Zhang, J.; Wang, H. Abnormal thermal expansion behaviour and phase transition of laser powder bed fusion maraging steel with different thermal histories during continuous heating. Addit. Manuf. 2022, 53, 102712. [Google Scholar] [CrossRef]

- Huang, G.; Wei, K.; Deng, J.; Zeng, X. High power laser powder bed fusion of 18Ni300 maraging steel: Processing optimization, microstructure and mechanical properties. Mater. Sci. Eng. A 2022, 856, 143983. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Nanostructured bainite. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 3–18. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef]

- Królicka, A.; Caballero, F.G.; Jimenez, J.A.; Zalecki, W.; Kuziak, R. Development of advanced cementite-free bainitic steel using Ni, Al and Cu additions—Design concept and phase transformations study. J. Mater. Res. Technol. 2023, 27, 1265–1280. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. The bainite transformation in a silicon steel. Metall. Trans. A 1979, 10, 895–907. [Google Scholar] [CrossRef]

- Huang, H.; Sherif, M.Y.; Rivera-Díaz-del-Castillo, P.E.J. Combinatorial optimization of carbide-free bainitic nanostructures. Acta Mater. 2013, 61, 1639–1647. [Google Scholar] [CrossRef]

- Caballero, F.G. Carbide-free bainite in steels. In Phase Transformations in Steels; Elsevier: Amsterdam, The Netherlands, 2012; pp. 436–467. [Google Scholar]

- Garcia-Mateo, C.; Paul, G.; Somani, M.; Porter, D.; Bracke, L.; Latz, A.; Garcia De Andres, C.; Caballero, F. Transferring Nanoscale Bainite Concept to Lower C Contents: A Perspective. Metals 2017, 7, 159. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, Z. Development of and Perspective on High-Performance Nanostructured Bainitic Bearing Steel. Engineering 2019, 5, 319–328. [Google Scholar] [CrossRef]

- Królicka, A.; Żak, A.M.; Caballero, F.G. Enhancing technological prospect of nanostructured bainitic steels by the control of thermal stability of austenite. Mater. Des. 2021, 211, 110143. [Google Scholar] [CrossRef]

- Benrabah, I.-E.; Deboer, A.; Geandier, G.; Van Landeghem, H.; Hutchinson, C.; Brechet, Y.; Zurob, H. Effect of deformation on the bainitic transformation. Acta Mater. 2024, 277, 120195. [Google Scholar] [CrossRef]

- Caballero, F.G.; Allain, S.; Cornide, J.; Puerta Velásquez, J.D.; Garcia-Mateo, C.; Miller, M.K. Design of cold rolled and continuous annealed carbide-free bainitic steels for automotive application. Mater. Des. 2013, 49, 667–680. [Google Scholar] [CrossRef]

- Youheng, F.; Guilan, W.; Haiou, Z.; Liye, L. Optimization of surface appearance for wire and arc additive manufacturing of Bainite steel. Int. J. Adv. Manuf. Technol. 2017, 91, 301–313. [Google Scholar] [CrossRef]

- Mu, S.; Li, Y.; Song, D.; Xu, B.; Chen, X. Low Cycle Fatigue Behavior and Failure Mechanism of Wire Arc Additive Manufacturing 16MND5 Bainitic Steel. J. Mater. Eng. Perform. 2021, 30, 4911–4924. [Google Scholar] [CrossRef]

- Xing, X.; Qin, G.; Zhou, Y.; Yu, H.; Liu, L.; Zhang, L.; Yang, Q. Microstructure Optimization and Cracking Control of Additive Manufactured Bainite Steel by Gas Metal Arc Welding Technology. J. Mater. Eng. Perform. 2019, 28, 5138–5145. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, H.; Wang, G.; Wang, H. Investigation of mechanical properties for hybrid deposition and micro-rolling of bainite steel. J. Mater. Process. Technol. 2017, 250, 220–227. [Google Scholar] [CrossRef]

- Panicker, S.; Nagarajan, H.P.N.; Tuominen, J.; Patnamsetty, M.; Coatanéa, E.; Haapala, K.R. Investigation of thermal influence on weld microstructure and mechanical properties in wire and arc additive manufacturing of steels. Mater. Sci. Eng. A 2022, 853, 143690. [Google Scholar] [CrossRef]

- Bartels, D.; Novotny, T.; Mohr, A.; van Soest, F.; Hentschel, O.; Merklein, C.; Schmidt, M. PBF-LB/M of Low-Alloyed Steels: Bainite-like Microstructures despite High Cooling Rates. Materials 2022, 15, 6171. [Google Scholar] [CrossRef]

- Franceschi, M.; Yazdanpanah, A.; Leone, D.; Pezzato, L.; Dabalà, M. Laser Powder Bed Fusion Fabrication of a Novel Carbide-Free Bainitic Steel: The Possibilities and a Comparative Study with the Conventional Alloy. Metals 2024, 14, 113. [Google Scholar] [CrossRef]

- Królicka, A.; Ambroziak, A.; Żak, A. Welding Capabilities of Nanostructured Carbide-Free Bainite: Review of Welding Methods, Materials, Problems, and Perspectives. Appl. Sci. 2019, 9, 3798. [Google Scholar] [CrossRef]

- Kuntz, M.; Wicks, G.; Sourmail, T.; Garcia-Mateo, C. Fatigue Properties at Elevated Temperatures of Secondary Tempered Nanostructured Bainite: A Study of Deformation Mechanisms. Steel Res. Int. 2024, 95, 2400105. [Google Scholar] [CrossRef]

- Królicka, A.; Caballero, F.G.; Zalecki, W.; Kuziak, R.; Rozmus, R. Controlling the Thermal Stability of a Bainitic Structure by Alloy Design and Isothermal Heat Treatment. Materials 2023, 16, 2963. [Google Scholar] [CrossRef]

- Huang, B.M.; Yang, J.R.; Yen, H.W.; Hsu, C.H.; Huang, C.Y.; Mohrbacher, H. Secondary hardened bainite. Mater. Sci. Technol. 2014, 30, 1014–1023. [Google Scholar] [CrossRef]

- Shahriari, B.; Vafaei, R.; Sharifi, E.M.; Farmanesh, K. Continuous cooling transformation behavior and the kinetics of bainite formation in a bainitic–martensitic steel. Int. J. Mater. Res. 2017, 108, 715–724. [Google Scholar] [CrossRef]

- Królicka, A.; Lesiuk, G.; Kuziak, R.; Radwański, K.; Janik, A. The role of microstructure morphology on fracture mechanisms of continuously cooled bainitic steel designed for rails application. Metall. Mater. Trans. A 2023, 54, 487–504. [Google Scholar] [CrossRef]

- Zheng, Y.-F.; Wu, R.-M.; Li, X.-C.; Wu, X.-C. Continuous cooling transformation behaviour and bainite formation kinetics of new bainitic steel. Mater. Sci. Technol. 2017, 33, 454–463. [Google Scholar] [CrossRef]

- Hulme-Smith, C.N.; Ooi, S.W.; Bhadeshia, H.K.D.H. Intermetallic-strengthened nanocrystalline bainitic steel. Mater. Sci. Technol. 2018, 34, 1976–1979. [Google Scholar] [CrossRef]

- Królicka, A.; Żak, A.M.; Caballero, F.G. Revealing intermetallic strengthening in bainitic steel designed for nickel aluminide formation. Scr. Mater. 2024, 249, 116153. [Google Scholar] [CrossRef]

- Królicka, A.; Caballero, F.G.; Kuziak, R.; Radwański, K.; Sozańska-Jędrasik, L.; Stawarczyk, P. Two design strategies for enhancing the thermal stability of bainitic structures. J. Mater. Res. Technol. 2023, 24, 7004–7020. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, Z.; Yang, W.; Yang, H. Fe–Mn–C–Al Low-Density Steel for Structural Materials: A Review of Alloying, Heat Treatment, Microstructure, and Mechanical Properties. Steel Res. Int. 2022, 93, 2200191. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.-W.; Kim, N.J. Fe–Al–Mn–C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar] [CrossRef] [PubMed]

- Sutou, Y.; Kamiya, N.; Umino, R.; Ohnuma, I.; Ishida, K. High-strength Fe-20Mn-Al-C-based Alloys with Low Density. ISIJ Int. 2010, 50, 893–899. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Daamen, M.; Haase, C.; Dierdorf, J.; Molodov, D.A.; Hirt, G. Twin-roll strip casting: A competitive alternative for the production of high-manganese steels with advanced mechanical properties. Mater. Sci. Eng. A 2015, 627, 72–81. [Google Scholar] [CrossRef]

- Akhlaghi, S.; Yue, S. Effect of Thermomechanical Processing on the Hot Ductility of a Nb-Ti Microalloyed Steel. ISIJ Int. 2001, 41, 1350–1356. [Google Scholar] [CrossRef]

- Steenken, B.; Rezende, J.L.L.; Senk, D. Hot ductility behaviour of high manganese steels with varying aluminium contents. Mater. Sci. Technol. 2017, 33, 567–573. [Google Scholar] [CrossRef]

- Wietbrock, B.; Bambach, M.; Seuren, S.; Hirt, G. Homogenization Strategy and Material Characterization of High-Manganese TRIP and TWIP Steels. Mater. Sci. Forum 2010, 638–642, 3134–3139. [Google Scholar] [CrossRef]

- Seede, R.; Whitt, A.; Ye, J.; Gibbons, S.; Flater, P.; Gaskey, B.; Elwany, A.; Arroyave, R.; Karaman, I. A lightweight Fe–Mn–Al–C austenitic steel with ultra-high strength and ductility fabricated via laser powder bed fusion. Mater. Sci. Eng. A 2023, 874, 145007. [Google Scholar] [CrossRef]

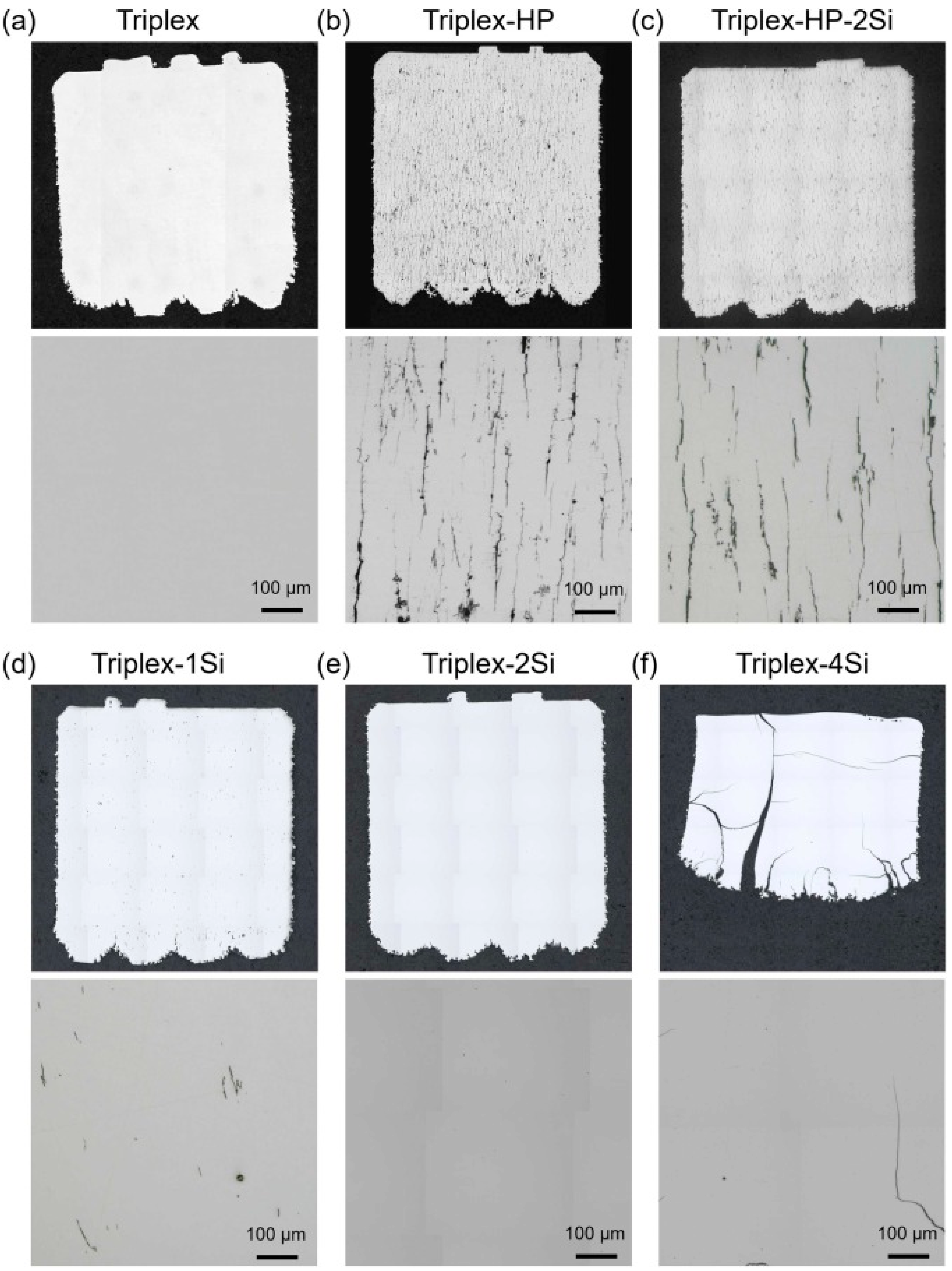

- Sanchez-Poncela, M.; Jin, Q.; Hebert, R.; Aindow, M.; Amigó-Borrás, V.; Rementeria, R. Triplex steel powder design to avoid hot cracking in laser-powder bed fusion using computational thermodynamics. Addit. Manuf. 2024, 86, 104196. [Google Scholar] [CrossRef]

| Powder | Parameters | Comments | Ref. | |

|---|---|---|---|---|

| Fe-0.15C-0.46Si-7.21Mn-1.81Mn (wt.%) Medium-Mn steel | Argon atomization, particle size: 20–65 μm | Layer thickness: 30–60 μm, Laser power: 250–350 W, Scanning speed: 700–1000 mm/s, Linear energy: 0.25–0.50 J/mm, Preheatment: 200 °C, Relative density: 99.76–99.87% | Intercritical annealing at 670 °C (0.5–6 h). The as-built microstructure: lath martensite and retained austenite (~8%). Microstructure after intercritical annealing: tempered martensite and retained austenite (~40%). Increased strength properties, elongation, and impact toughness. TRIP effect. | [68] |

| Fe-0.23C-3.93Mn-2.01Al-0.51Si (wt.%) Medium-Mn steel | Atomized using a Close-Coupled-Atomizer, particle size: 20–63 µm | Layer thickness: 60 μm, Laser power: 300 W, Scanning speed: 500 mm/s, Preheatment: 200 °C, Energy input: 111.1 J/mm3, Relative density: 99.9% | Intercritical annealing at 630–770 °C (3, 10 and 60 min). The as-built microstructure: bainitic–martensitic matrix and retained austenite. Microstructure after intercritical annealing: martensite/bainite, M/A constituents, and retained austenite. After post-treatment mechanical behavior was comparable to conventional production routes. TRIP effect. | [69] |

| Fe-0.60C-22.36Mn-0.25V-0.2Cr-0.25Si (wt.%) High-Mn steel | Spray aeration in an argon inert gas, particle size: 40 μm | Laser power: Up to 400 W | An anisotropic structure covering elongated grains, texture, and process-related defects (inclusions and pores). Mechanical properties after LPBF are comparable to the conventional processing. Dynamic Hall–Petch effect was revealed. TWIP effect. | [62] |

| Fe-0.27C-20.15Mn-0.05Si-0.01Al (wt.%) High-Mn steel | Electrode induction melting gas atomization with argon, particle size: below 45 μm | Scan line spacing: 100 μm, Scanning speed: 571 mm/s, Relative density: 99.9% | Due to the reduced chemical elements segregation compared to strip-cast material the additional post-treatment may be avoided. Revealed crystallographic texture related to the solidification affected the mechanical behavior. The austenite matrix contained ε- and α′-martensite. TRIP and TWIP effect. | [63] |

| Fe-0.33C-21.9Mn-0.01Al-0.03Si (wt.%) High-Mn steel | Gas-atomized, particle size: 15–50 μm | Layer thickness: 30 μm, Laser power: 120 W, Scanning speed: 700 mm/s | SLM lattice structure manufacturing. Reduced segregation after LPBF processes. TRIP and TWIP effects. Formation of ε- and α′-martensite during deformation. | [64] |

| Fe-(21-22)Mn-(0-5)Al-0.3C (wt.%) High-Mn steel | - | Layer thickness: 30 μm, Laser power: 90–120 W, Scanning speed: 200–700 mm/s, Relative density: 99.85–99.95% | TRIP and TWIP effects were revealed after the LPBF process. The Al content influenced the contribution of TRIP and TWIP effects. | [65] |

| X30Mn21 steel and controlled content of aluminum powder (0.03–5.39 wt.%) High-Mn steel | Argon gas atomized, particle size: 10–45 μm | Layer thickness: 30 μm, Laser power: 120 W, Scanning speed: 750 mm/s, Relative density: 99.9% | TRIP and TWIP effects were revealed after the LPBF process. Fully austenite matrix below 4 wt.% of Al. Above 4 wt.% of Al the dual phase structure occurs (ferrite and austenite). | [67] |

| Powder | Parameters | Comments | Ref. | |

|---|---|---|---|---|

| Fe-0.22C-0.7Si-1.2Mn-1.0Cr-0.9Mo-(wt.%) Low-carbon bainite | Particle size: 15–45 μm | Layer thickness: 60 μm, Laser power: 225–275 W, Scanning speed: 550–850 mm/s, Relative density: above 99.7% | Post-treatment: tempering (150–600 °C), quenching, and tempering. Various bainite morphologies in the fusion zone and heat-affected zone. Post-treatment reduced the retained austenite. | [114] |

| Fe-0.4C-3.2Si-2.6Mn-0.1Al Medium-carbon carbide-free bainite | Argon atomization particle size: 15–53 µm | Layer thickness: 60 μm, Laser power: 170–295 W, Scanning speed: 500–750 mm/s, Energy density: 22–89 J/mm3, Pore density: from 2.15% | Post-treatment: austenitization at 900 °C and isothermal annealing at 325 °C for 3 h. A refined carbide-free bainitic structure due to the smaller prior austenite grains formed during the LPBF process. Non-homogeneous bainite morphology. The cracks were observed. | [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Królicka, A.; Malawska, J. Recent Progress in Laser Powder Bed Fusions Processes of Advanced High-Strength Steels. Materials 2024, 17, 4699. https://doi.org/10.3390/ma17194699

Królicka A, Malawska J. Recent Progress in Laser Powder Bed Fusions Processes of Advanced High-Strength Steels. Materials. 2024; 17(19):4699. https://doi.org/10.3390/ma17194699

Chicago/Turabian StyleKrólicka, Aleksandra, and Julia Malawska. 2024. "Recent Progress in Laser Powder Bed Fusions Processes of Advanced High-Strength Steels" Materials 17, no. 19: 4699. https://doi.org/10.3390/ma17194699

APA StyleKrólicka, A., & Malawska, J. (2024). Recent Progress in Laser Powder Bed Fusions Processes of Advanced High-Strength Steels. Materials, 17(19), 4699. https://doi.org/10.3390/ma17194699