Auto-Combustion of Corn Straw: Production and Characterization of Corn Straw Ash (CSA) for Its Use in Portland Cement Mortars

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

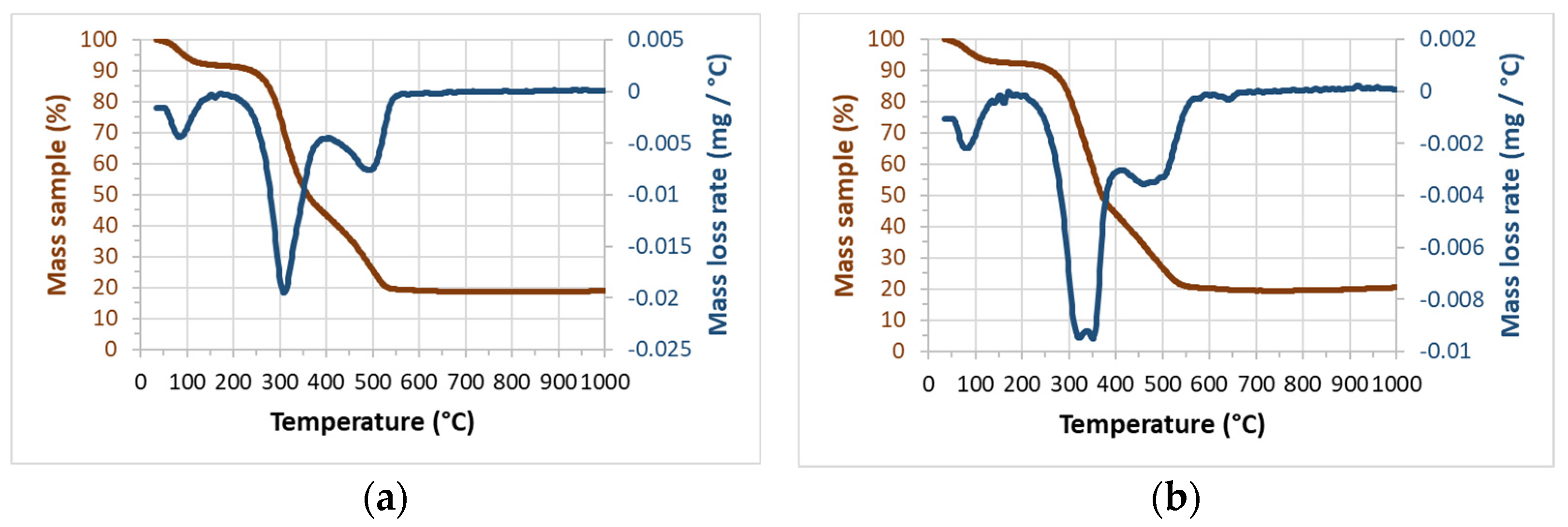

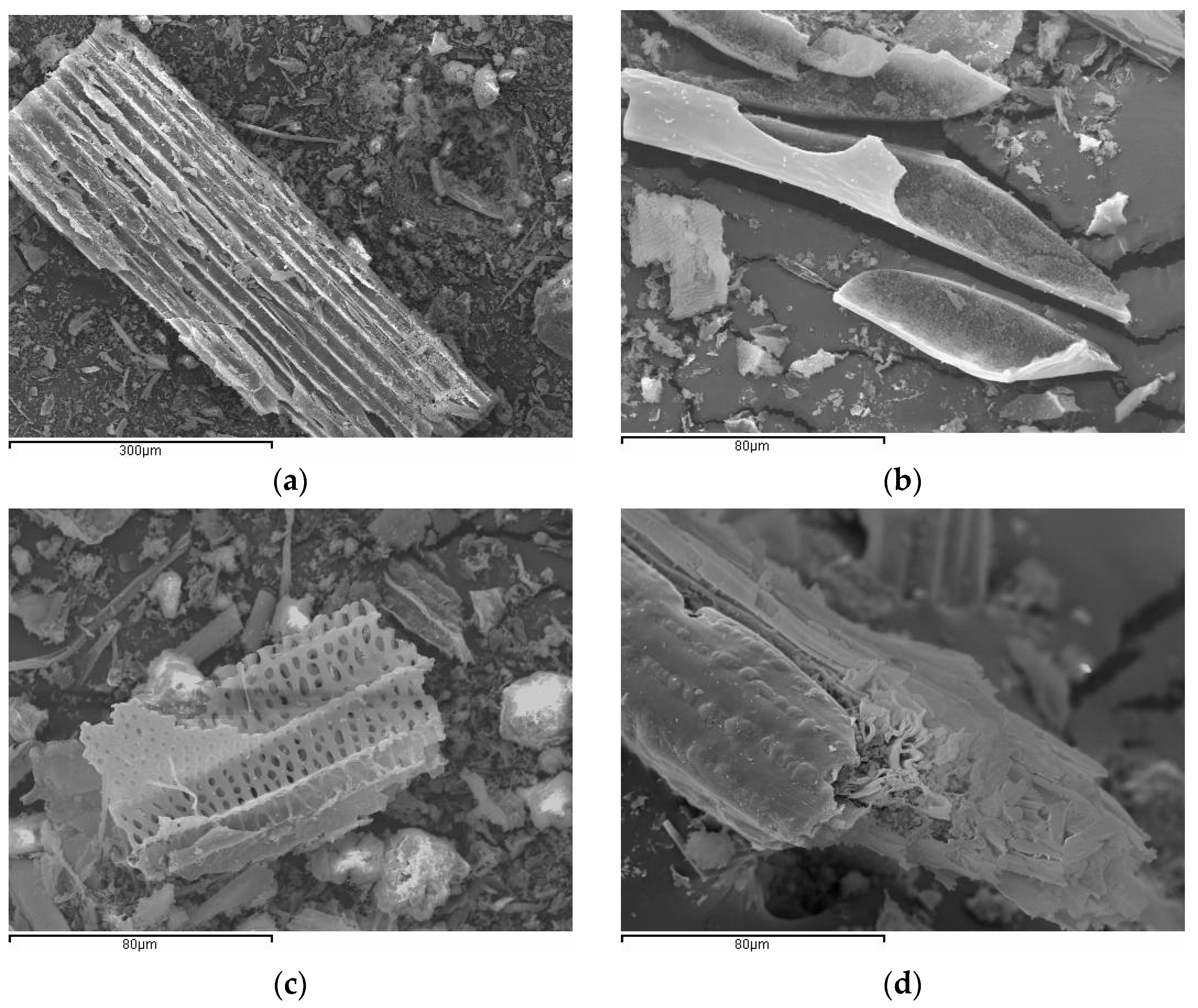

3.1. Characterization of Corn Straws

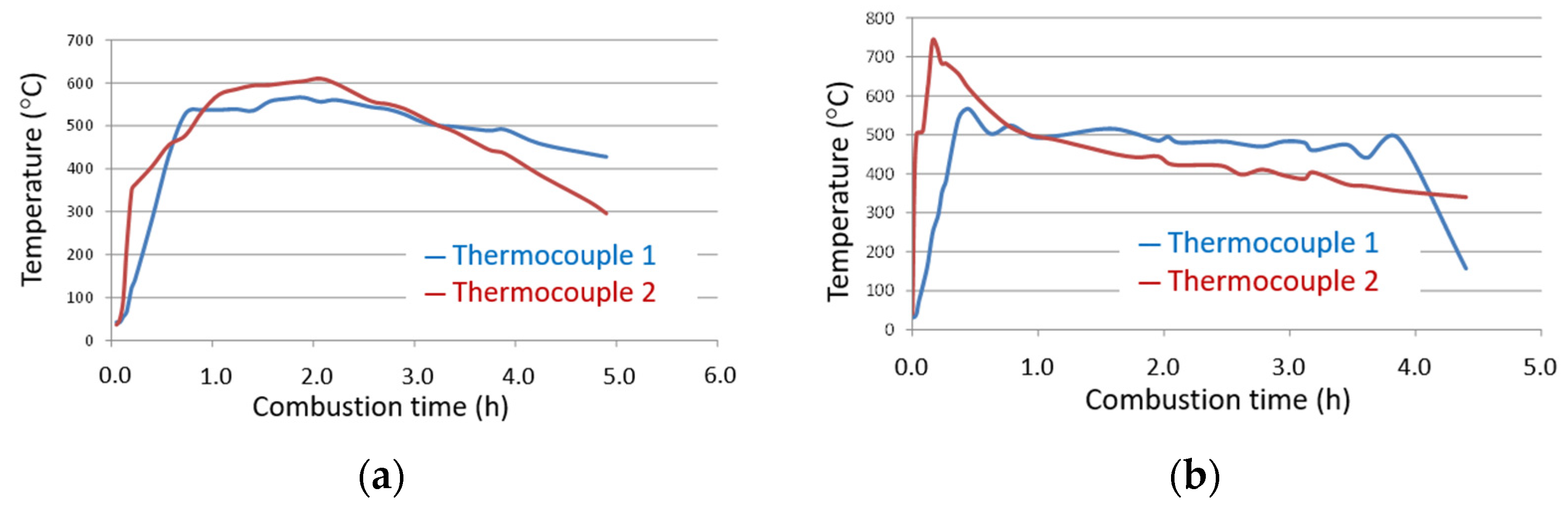

3.2. Auto-Combustion of Corn Straws

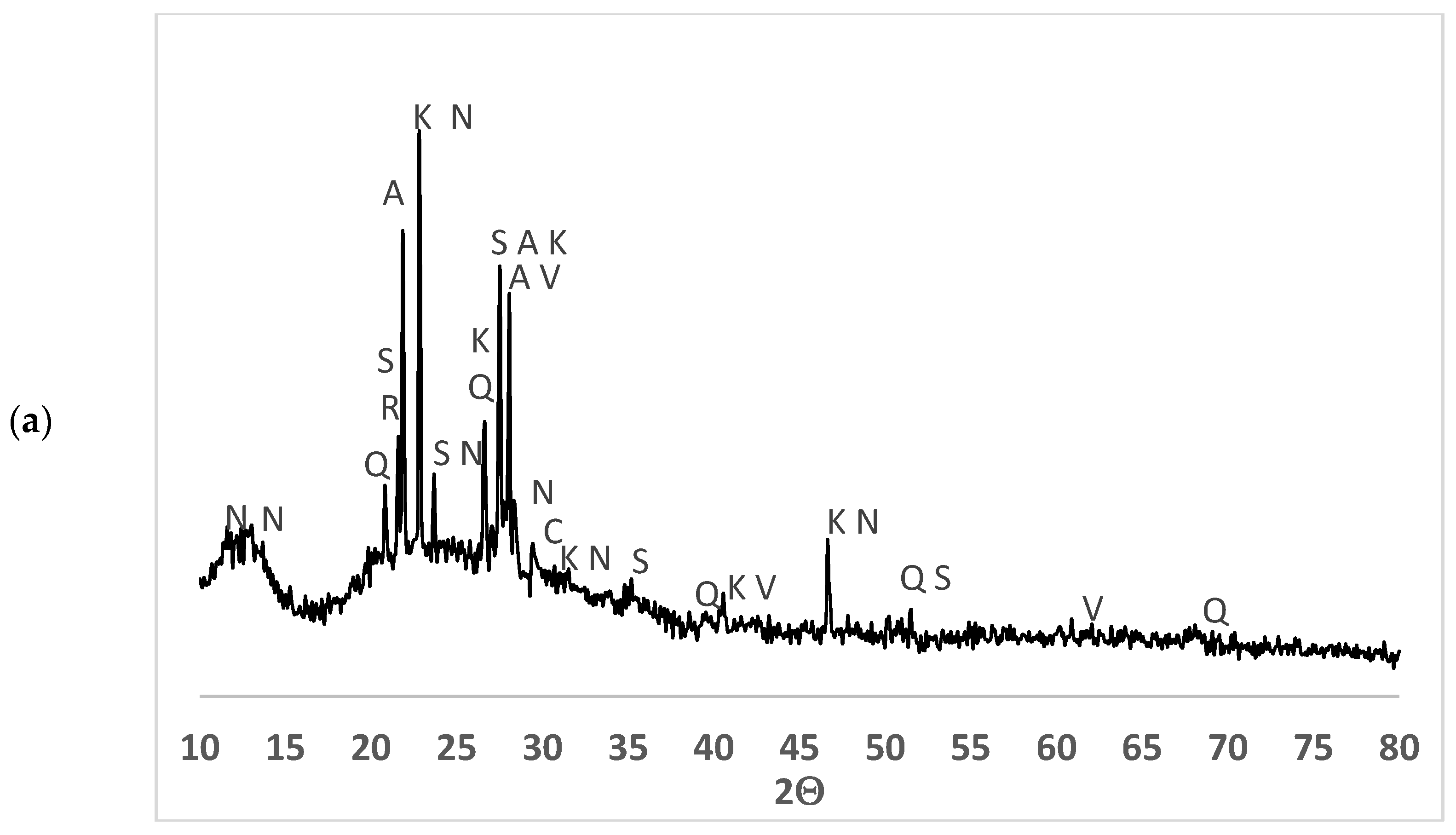

3.3. Characterization of Corn Straw Ashes (CSA)

3.4. Portland Cement Systems with CSA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbhuiya, S.; Das, B.B.; Adak, D. Roadmap to a net-zero carbon cement sector: Strategies, innovations and policy imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiya, B.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Statista. Available online: https://www.statista.com/statistics/1087115/global-cement-production-volume (accessed on 21 June 2024).

- Bronk & Company. Available online: https://bronk-company.com/en/2023/01/forecast-steel-demand-2030/ (accessed on 21 June 2024).

- ChemAnalyst. Available online: https://www.chemanalyst.com/industry-report/granulated-ground-blast-furnace-slag-ggbfs-market-713#:~:text=The%20global%20Granulated%20Ground%20Blast,the%20iron%20blast%20furnace%20process (accessed on 21 June 2024).

- HAS Silica Fume. Available online: https://microsilica-fume.com/silica-fume-market.html (accessed on 21 June 2024).

- Statista. Available online: https://www.statista.com/statistics/268108/world-silicon-production-by-country/#:~:text=China%20is%20the%20world’s%20largest,million%20metric%20tons%20in%202023 (accessed on 21 June 2024).

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Erenstein, O.; Jaleta, M.; Sonder, K.; Mottaleb, K.; Prasanna, B.M. Global maize production, consumption and trade: Trends and R&D implications. Food Sec. 2022, 14, 1295–1319. [Google Scholar] [CrossRef]

- Ahmad, J.; Arbili, M.M.; Alabduljabbar, H.; Deifalla, A.F. Concrete made with partially substitution corn cob ash: A review. Case Stud. Constr. Mater. 2023, 18, e02100. [Google Scholar] [CrossRef]

- ASTM C618-23; Standard Specification for Coal Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- Aliu, A.O.; Olalusi, O.B.; Awoyera, P.O.; Kiliswa, M. Evaluation of pozzolanic reactivity of maize straw ash as a binder supplement in concrete. Case Stud. Constr. Mater. 2023, 18, e01790. [Google Scholar] [CrossRef]

- de Lima, C.P.F.; Cordeiro, G.C. Evaluation of corn straw ash as supplementary cementitious material: Effect of acid leaching on its pozzolanic activity. Cement 2021, 4, 100007. [Google Scholar] [CrossRef]

- Qi, T.; Wang, H.; Feng, G.; Zhang, Y.; Bai, J.; Han, Y. Effect of calcination temperature on the pozzolanic activity of maize straw stem ash treated with portlandite solution. Int. J. Miner. Metall. Mater. 2022, 29, 1161–1169. [Google Scholar] [CrossRef]

- Raheem, A.A.; Adedokun, S.I.; Adeyinka, E.A.; Adewole, B.V. Application of corn stalk ash as partial replacement for cement in the production of interlocking paving stones. Int. J. Eng. Res. Afr. 2017, 30, 85–93. [Google Scholar] [CrossRef]

- Qi, T.; Feng, G.; Wang, H. Pozzolanic activity of corn straw leaf ash produced at different temperatures and treated with portlandite solution. BioResources 2020, 15, 8708–8727. [Google Scholar] [CrossRef]

- Awata, L.A.O.; Tongoona, P.; Danquah, E.; Ifie, B.E.; Suresh, L.M.; Jumbo, M.B.; Marchelo-Dragga, P.W.; Sitonik, C. Understanding tropical maize (Zea mays L.): The major monocot in modernization and sustainability of agriculture in sub-Saharan Africa. Int. J. Adv. Agric. Res. 2019, 7, 32–77. [Google Scholar] [CrossRef]

- UNE-EN 196-1; Methods of Testing Cement–Part 1: Determination of Strength. European Committee for Standardisation: Madrid, Spain, 2018.

- UNE-EN 413-2; Masonry Cement-Part 2: Test Methods. European Committee for Standardisation: Madrid, Spain, 2017.

- Andrade, F.A.; Andrade, O., Jr.; Andrade, C.G.T.J.; Miglioranza, E. Accumulation of silicon and arrangement and shapes of silica bodies in corn leaves. Genet. Mol. Res. 2014, 13, 1690–1696. [Google Scholar] [CrossRef] [PubMed]

- Prychid, C.J.; Rudall, P.J.; Gregory, M. Systematics and biology of silica bodies in monocotyledons. Bot. Rev. 2003, 69, 377–440. [Google Scholar] [CrossRef]

- Roselló, J.; Soriano, L.; Santamarina, M.P.; Akasaki, J.L.; Melges, J.L.; Payá, J. Microscopy Characterization of Silica-Rich Agrowastes to be used in Cement Binders: Bamboo and Sugarcane Leaves. Microsc. Microanal. 2015, 21, 1314–1326. [Google Scholar] [CrossRef] [PubMed]

- Roselló, J.; Soriano, L.; Savastano, H.; Borrachero, M.V.; Santamarina, P.; Payá, J. Microscopic Chemical Characterization and Reactivity in Cementing Systems of Elephant Grass Leaf Ashes. Microsc. Microanal. 2018, 24, 593–603. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, M.A.; Zakharenko, A.M.; Zemchenko, I.V.; Haider, M.S.; Ali, M.A.; Imtiaz, M.; Chung, G.; Tsatsakis, A.; Sun, S.; Golokhvast, K.S. Phytolith Formation in Plants: From Soil to Cell. Plants 2019, 8, 249. [Google Scholar] [CrossRef] [PubMed]

- Witzleben, S.T. Acceleration of Portland cement with lithium, sodium and potassium silicates and hydroxides. Mater. Chem. Phys. 2020, 243, 122608. [Google Scholar] [CrossRef]

| Crop | World Production of the Food (Mt/Year) | Biomass Name | Waste Biomass Proportion per Food Unit (%) | Ashes in the Biomass (%) | Theoretically Produced Ashes (Mt/Year) |

|---|---|---|---|---|---|

| Rice | 500 | Rice husk | 20 | 22 | 22 |

| Rice straw | 115 | 15 | 86 | ||

| Wheat | 780 | Wheat straw | 67 | 10 | 52 |

| Corn | 1200 | Corn cob | 15 | 2.2 | 4 |

| Maize straw | 107 | 12 | 154 | ||

| Sugarcane | 1860 | Sugarcane bagasse | 20 | 2.5 | 9 |

| Sugarcane straw | 150 | 5 | 140 |

| Sample | 35–200 °C | 200–400 °C | 400–600 °C | Total Mass Loss |

|---|---|---|---|---|

| R1 | 8.77 | 49.92 | 22.26 | 81.09 |

| R2 | 7.95 | 49.50 | 22.40 | 79.52 |

| Sample | 35–200 °C | 200–600 °C | 600–1000 °C |

|---|---|---|---|

| CSA-R1 | 2.74 | 4.83 | 10.93 |

| CSA-R2 | 2.63 | 4.96 | 11.13 |

| CSA-R1 | CSA-R2 | CSA-MX-L | CSA-MX-S | |

|---|---|---|---|---|

| Oxide | % | % | % | % |

| Na2O | 0.68 | 0.63 | 0.00 | 0.55 |

| MgO | 2.83 | 2.49 | 3.67 | 3.48 |

| Al2O3 | 5.50 | 7.60 | 1.33 | 2.26 |

| SiO2 | 58.68 | 69.62 | 52.92 | 26.54 |

| P2O5 | 2.10 | 2.52 | 8.06 | 9.43 |

| SO3 | 1.74 | 0.89 | 1.83 | 1.88 |

| Cl | 4.28 | 0.63 | 2.52 | 0.68 |

| K2O | 15.41 | 7.83 | 21.47 | 40.14 |

| CaO | 4.96 | 4.81 | 7.61 | 12.25 |

| Fe2O3 | 2.94 | 2.34 | 0.34 | 1.47 |

| Reference | [13] a | [14] b | [15] c | [16] d |

|---|---|---|---|---|

| Plant Part | Straw (Stem + Leaf) | Stem | Stem | Leaf |

| Oxide | % | % | % | % |

| Na2O | nd | 0.3 | 1.59 | 0.4 |

| MgO | nd | 5.73 | 3.89 | 3.68 |

| Al2O3 | nd | 1.15 | 5.28 | 2.15 |

| SiO2 | 62.5 | 31.34 | 64.26 | 67.02 |

| P2O5 | 3 | 1.97 | nd | 0.94 |

| SO3 | 2.6 | 0 | 3.43 | 2.42 |

| Cl | nd | 5.22 | nd | 0.39 |

| K2O | 17.2 | 21.44 | 9.45 | 5.24 |

| CaO | 8.7 | 4.27 | 6.23 | 6.78 |

| Fe2O3 | 0.9 | 0.49 | 2.33 | 1.01 |

| Curing Age (Days) | Flexural Strength (MPa) | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| Control | 10%-CSA-RM | 10%-Filler | Control | 10%-CSA-RM | 10%-Filler | |

| 28 | 6.75 ± 0.52 | 5.87 ± 0.32 | 6.51 ± 0.20 | 56.5 ± 1.6 | 52.1 ± 1.6 | 49.8 ± 2.4 |

| 56 | 6.65 ± 0.05 | 5.98 ± 0.41 | 6.35 ± 0.43 | 61.3 ± 1.7 | 56.4 ± 1.9 | 54.3 ± 2.4 |

| 90 | 7.70 ± 0.50 | 6.16 ± 0.28 | 7.16 ± 0.22 | 59.2 ± 2.1 | 57.8 ± 2.9 | 53.1 ±1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Payá, J.; Escalera, A.; Borrachero, M.V.; Roselló, J.; Monzó, J.; Soriano, L. Auto-Combustion of Corn Straw: Production and Characterization of Corn Straw Ash (CSA) for Its Use in Portland Cement Mortars. Materials 2024, 17, 4374. https://doi.org/10.3390/ma17174374

Payá J, Escalera A, Borrachero MV, Roselló J, Monzó J, Soriano L. Auto-Combustion of Corn Straw: Production and Characterization of Corn Straw Ash (CSA) for Its Use in Portland Cement Mortars. Materials. 2024; 17(17):4374. https://doi.org/10.3390/ma17174374

Chicago/Turabian StylePayá, Jordi, Alejandro Escalera, María Victoria Borrachero, Josefa Roselló, José Monzó, and Lourdes Soriano. 2024. "Auto-Combustion of Corn Straw: Production and Characterization of Corn Straw Ash (CSA) for Its Use in Portland Cement Mortars" Materials 17, no. 17: 4374. https://doi.org/10.3390/ma17174374

APA StylePayá, J., Escalera, A., Borrachero, M. V., Roselló, J., Monzó, J., & Soriano, L. (2024). Auto-Combustion of Corn Straw: Production and Characterization of Corn Straw Ash (CSA) for Its Use in Portland Cement Mortars. Materials, 17(17), 4374. https://doi.org/10.3390/ma17174374