Hydrogen Embrittlement Detection Technology Using Nondestructive Testing for Realizing a Hydrogen Society

Abstract

1. Introduction

2. Experimental Procedure

2.1. Hydrogen Charging Method and Measurement of Hydrogen Ingress

2.2. Nondestructive Inspection System

2.3. Finite Element Method (FEM) Stress Analysis

Analysis of Changes in the Distance between Loading Points

3. Experimental Results

3.1. Results of Hydrogen Measurement

3.2. Crack Growth Property

3.3. Fracture Morphologies

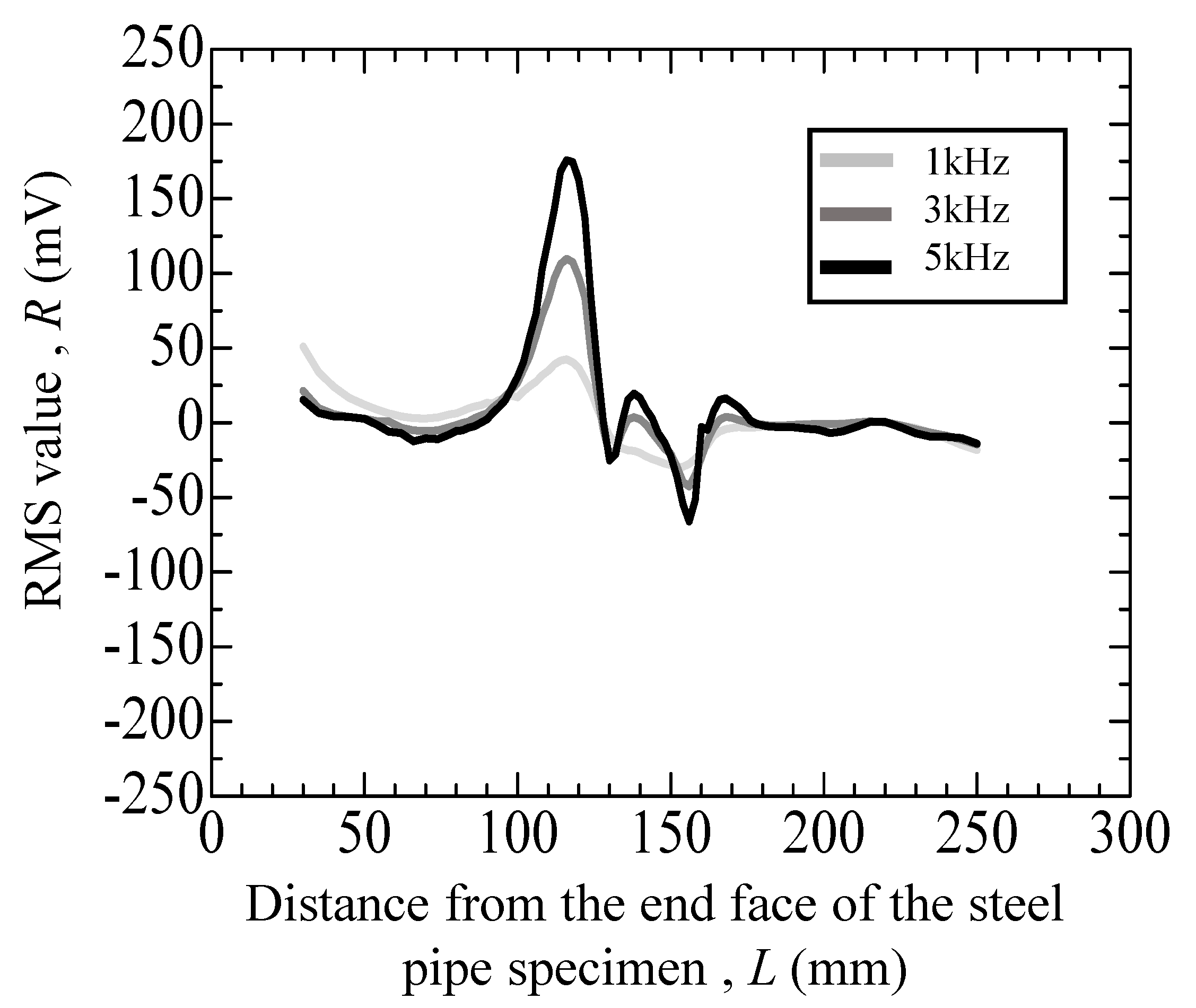

3.4. Nondestructive Flaw Detection

4. Hammering Test

5. Conclusions

- When the piping specimens were immersed in a 20 wt% ammonium thiocyanate solution at 40 °C, the hydrogen content reached the saturation value after 72 h. Thus, the optimal immersion time was set to 72 h.

- The crack growth rate of the hydrogen-precharged specimen was accelerated by hydrogen compared with that of the uncharged specimen, and the cracks that started from the inner surface of the pipe were accelerated by approximately 10 times until they reached the outer surface.

- The fracture surface morphology of the cracks exhibited a flat fracture surface in the hydrogen-precharged material, whereas the morphology was convex or concave in the uncharged material.

- The results of eddy current and hammering tests revealed differences in the presence and absence of large cracks in the uncharged and hydrogen-precharged materials. In the eddy current test, clear results were not obtained for the half-cracked material, whereas in the hammering test, the results were similar to those obtained for the fractured and half-cracked materials. No significant differences were observed between the uncharged and hydrogen-precharged materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Hassan, Q.; Azzawi, I.D.J.; Sameen, A.Z.; Salman, H.M. Hydrogen Fuel Cell Vehicles: Opportunities and Challenges. Sustainability 2023, 15, 11501. [Google Scholar] [CrossRef]

- Samsun, R.C.; Rex, M.; Antoni, L.; Stolten, D. Deployment of Fuel Cell Vehicles and Hydrogen Refueling Station Infrastructure: A Global Overview and Perspectives. Energies 2022, 15, 4975. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Trans. 1972, 3, 437–451. [Google Scholar] [CrossRef]

- Birnbaum, H.K.; Sofronis, P. Hydrogen-enhanced localized plasticity: A mechanism for hydrogen- related fracture. Mater. Sci. Eng. A 1994, 176, 191–202. [Google Scholar] [CrossRef]

- Eliezer, D.; Chakrapani, D.G.; Altstetter, C.J.; Pugh, E.N. The influence of austenite stability on the hydrogen embrittlement and stress-corrosion cracking of stainless steel. Metall. Mater. Trans. A 1979, 10, 935–941. [Google Scholar] [CrossRef]

- Gangloff, R.P. Hydrogen assisted cracking of high strength alloy. In Comprehensive Structural Integrity; Milne, I., Ritchie, R.O., Karihaloo, B., Petit, J., Scott, P., Eds.; Elsevier Science: New York, NY, USA, 2003; pp. 31–101. [Google Scholar]

- Hirth, J.P. Effects of hydrogen on the properties of iron and steel. Metall. Mater. Trans. A 1980, 11, 861–890. [Google Scholar] [CrossRef]

- Hwang, C.; Bernstein, I.M. Hydrogen induced slip and twinning in iron alloys. Scr. Metall. 1982, 16, 85–90. [Google Scholar] [CrossRef]

- Kanezaki, T.; Narazaki, C.; Mine, Y.; Matsuoka, S.; Murakami, Y. Effect of hydrogen on fatigue crack growth and martensitic transformation of stainless steels. Trans. J. SME Ser. A 2006, 72, 1717–1724. [Google Scholar] [CrossRef][Green Version]

- Kanezaki, T.; Narazaki, C.; Mine, Y.; Matsuoka, S.; Murakami, Y. Effect of hydrogen on fatigue crack growth behavior of austenitic stainless steels. Int. J. Hydrogen Energy 2008, 33, 2604–2619. [Google Scholar] [CrossRef]

- Kirchheim, R. Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation: II. Experimental evidence and consequences. Acta Mater. 2007, 55, 5139–5148. [Google Scholar] [CrossRef]

- Marchi, C.S.; Somerday, B.P. Technical Reference on Hydrogen Compatibility of Materials; Report No.: SAND2008-1163; Sandia National Laboratories: Livermore, CA, USA, 2008.

- Matsui, H.; Kimura, H.; Kimura, A. The effect of hydrogen on the mechanical properties of high-purity iron. III. e the dependence of softening on specimen size and charging current density. Mater. Sci. Eng. A 1979, 40, 227–234. [Google Scholar] [CrossRef]

- Matsunaga, H.; Yoshikawa, M.; Kondo, R.; Yamabe, J.; Matsuoka, S. Slow strain rate tensile and fatigue properties of Cr-Mo and carbon steels in a 115 MPa hydrogen gas atmosphere. Int. J. Hydrogen Energy 2015, 40, 5739–5748. [Google Scholar] [CrossRef]

- Matsuoka, S.; Matsunaga, H.; Yamabe, J.; Hamada, S.; Iijima, T. Various strength properties of SCM435 and SNCM439 low-alloy steels in 115 MPa hydrogen gas and proposal of design guideline. Trans. JSME Ser. A 2017, 83, 17–00264. [Google Scholar]

- Matsuoka, S.; Yamabe, J.; Matsunaga, H. Criteria for determining hydrogen compatibility and the mechanisms for hydrogen-assisted, surface crack growth in austenitic stainless steels. Eng. Fract. Mech. 2016, 153, 103–127. [Google Scholar] [CrossRef]

- Murakami, Y.; Matsuoka, S.; Kondo, Y.; Nishimura, S. Mechanism of Hydrogen Embrittlement and Guide for Fatigue Design; Yokendo: Tokyo, Japan, 2012; 361p. [Google Scholar]

- Murakami, Y.; Kanezaki, T.; Mine, Y. Hydrogen effect against hydrogen embrittlement. Metall. Mater. Trans. A 2010, 41, 2548–2562. [Google Scholar] [CrossRef]

- Murakami, Y.; Kanezaki, T.; Mine, Y.; Matsuoka, S. Hydrogen embrittlement mechanism in fatigue of austenitic stainless steel. Metall. Mater. Trans. A 2008, 39, 1327–1339. [Google Scholar] [CrossRef]

- Murakami, Y.; Matsunaga, H. The effect of hydrogen on fatigue properties of steels used for fuel cell system. Int. J. Fatigue 2006, 28, 1509–1520. [Google Scholar] [CrossRef]

- Nagumo, M.; Nakamura, M.; Takai, K. Hydrogen thermal desorption relevant to delayed-fracture susceptibility of high-strength steels. Metall. Mater. Trans. A 2001, 32, 339–347. [Google Scholar] [CrossRef]

- NASA. NSS 1740.16. In Safety Standard for Hydrogen and Hydrogen Systems; NASA: Washington, DC, USA, 1997. [Google Scholar]

- Oriani, O.A.; Josephic, P.H. Equilibrium aspects of hydrogeninduced cracking of steels. Acta Metall. 1974, 22, 1065–1074. [Google Scholar] [CrossRef]

- Robertson, I.M.; Birnbaum, H.K. An HVEM study of hydrogen effects on the deformation and fracture of nickel. Acta Metall. 1986, 34, 353–366. [Google Scholar] [CrossRef]

- San Marchi, C.; Michler, T.; Nibur, K.A.; Somerday, B.P. On the physical differences between tensile testing of type 304 and 316 austenitic stainless steels with internal hydrogen and in external hydrogen. Int. J. Hydrogen Energy 2010, 35, 9736–9745. [Google Scholar] [CrossRef]

- Shih, D.S.; Robertson, I.M.; Birnbaum, H.K. Hydrogen embrittlement of alpha titanium: In situ TEM studies. Acta Metall. 1988, 36, 111–124. [Google Scholar] [CrossRef]

- Sofronis, P.; Birnbaum, H.K. Mechanics of the hydrogendashdislocationdashimpurity interactions-I. Increasing shear modulus. J. Mech. Phys. Sol. 1995, 43, 49–90. [Google Scholar] [CrossRef]

- Sofronis, P.; McMeeking, R.M. Numerical analysis of hydrogen transport near a blunting crack tip. J. Mech. Phys. Solids 1989, 37, 317–350. [Google Scholar] [CrossRef]

- Tabata, T.; Birnbaum, H.K. Direct observations of the effect of hydrogen on the behavior of dislocations in iron. Scr. Metall. 1983, 17, 947–950. [Google Scholar] [CrossRef]

- Takai, K.; Watanuki, R. Hydrogen in trapping states innocuous to environmental degradation of high-strength steels. ISIJ Int. 2003, 43, 520–526. [Google Scholar] [CrossRef]

- Takeda, S.; Ohara, Y.; Uchimoto, T.; Enoki, H.d.; Iijima, T.; Tokuda, E.; Yamada, T.; Nagatomo, Y. Characterization of fatigue crack of hydrogen-charged austenitic stainless steel by electromagnetic and ultrasonic techniques. Int. J. Hydrogen Energy 2022, 47, 32223–32234. [Google Scholar] [CrossRef]

- Troiano, R. The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans. ASM 1960, 52, 54–80. [Google Scholar] [CrossRef]

- Yamabe, J.; Itoga, H.; Awane, T.; Matsuo, T.; Matsunaga, H.; Matsuoka, S. Pressure cycle testing of Cr-Mo steel pressure vessels subjected to gaseous hydrogen. ASME J. Press. Vessel Technol. 2016, 138, 13. [Google Scholar] [CrossRef]

- Yamabe, J.; Matsunaga, H.; Furuya, Y.; Hamada, S.; Itoga, H.; Yoshikawa, M.; Matsuoka, S. Qualification of chromiumemolybdenum steel based on the safety factor multiplier method in CHMC1-2014. Int. J. Hydrogen Energy 2015, 40, 719–728. [Google Scholar] [CrossRef]

- Yamabe, J.; Yoshikawa, M.; Matsunaga, H.; Matsuoka, S. Effects of hydrogen pressure, test frequency and test temperature on fatigue crack growth properties of low-carbon steel in gaseous hydrogen. Procedia Struct. Integr. 2016, 2, 525–532. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Matsuo, T.; Tsutsumi, N.; Matsunaga, H.; Matsuoka, S. Effects of hydrogen gas pressure and test frequency on fatigue crack growth properties of low carbon steel in a 0.1–90 MPa hydrogen gas. Trans. JSME 2014, 80, SMM0254. [Google Scholar] [CrossRef]

- Murakami, Y. Theory of Elasticity and Stress Concentration; Willy: Hoboken, NJ, USA, 2016. [Google Scholar]

- JARI. Technical Standard for Containers for Compressed-Hydrogen Vehicle Fuel Device; Japan Automobile Research Institute: Tsukuba, Japan, 2004; p. JARI-S001. [Google Scholar]

- Geľatko, M.; Hatala, M.; Botko, F.; Vandžura, R.; Hajnyš, J. Eddy Current Testing of Artificial Defects in 316L Stainless Steel Samples Made by Additive Manufacturing Technology. Materials 2022, 15, 6783. [Google Scholar] [CrossRef] [PubMed]

- Farag, H.E.; Toyserkani, E.; Khamesee, M.B. Non-Destructive Testing Using Eddy Current Sensors for Defect Detection in Additively Manufactured Titanium and Stainless-Steel Parts. Sensors 2022, 22, 5440. [Google Scholar] [CrossRef]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-Destructive Techniques Based on Eddy Current Testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef]

| Load P (kN) | Figure | Hydrogen Precharging | Number of Loading Cycles | Crack and Dent | Peaks of RMS Value for Crack Detection |

|---|---|---|---|---|---|

| - | Figure 11 | Uncharged | - | without crack and indent | No peak |

| 40 | Figure 12 | Uncharged | N = 6000 | without crack and with indent | No peak |

| 40 | Figure 13 | Uncharged | N = 20,498 | with crack and indent | +75 (mV) |

| 40 | Figure 15 | Hydrogen precharged after cyclic loading of uncharged N = 16,000 | N = 113 | with crack and indent | +25 (mV) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abiru, Y.; Nishiguchi, H.; Maekawa, M.; Nagata, T.; Itaya, T.; Koga, M.; Nishi, T. Hydrogen Embrittlement Detection Technology Using Nondestructive Testing for Realizing a Hydrogen Society. Materials 2024, 17, 4237. https://doi.org/10.3390/ma17174237

Abiru Y, Nishiguchi H, Maekawa M, Nagata T, Itaya T, Koga M, Nishi T. Hydrogen Embrittlement Detection Technology Using Nondestructive Testing for Realizing a Hydrogen Society. Materials. 2024; 17(17):4237. https://doi.org/10.3390/ma17174237

Chicago/Turabian StyleAbiru, Yamato, Hiroshi Nishiguchi, Masato Maekawa, Takara Nagata, Toshiya Itaya, Michie Koga, and Toshiomi Nishi. 2024. "Hydrogen Embrittlement Detection Technology Using Nondestructive Testing for Realizing a Hydrogen Society" Materials 17, no. 17: 4237. https://doi.org/10.3390/ma17174237

APA StyleAbiru, Y., Nishiguchi, H., Maekawa, M., Nagata, T., Itaya, T., Koga, M., & Nishi, T. (2024). Hydrogen Embrittlement Detection Technology Using Nondestructive Testing for Realizing a Hydrogen Society. Materials, 17(17), 4237. https://doi.org/10.3390/ma17174237