Investigation of the Properties of High-Viscosity Modified Asphalt Binder under Hygrothermal Environments

Abstract

1. Introduction

2. Materials and Methods

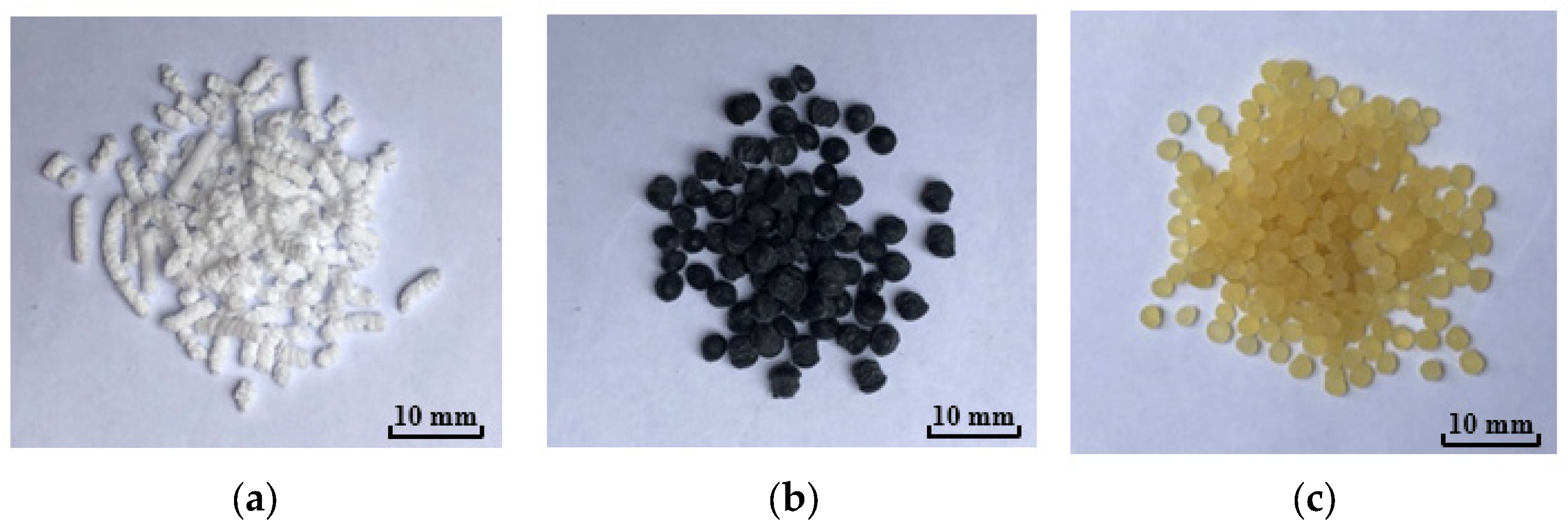

2.1. Materials

2.1.1. Bitumen

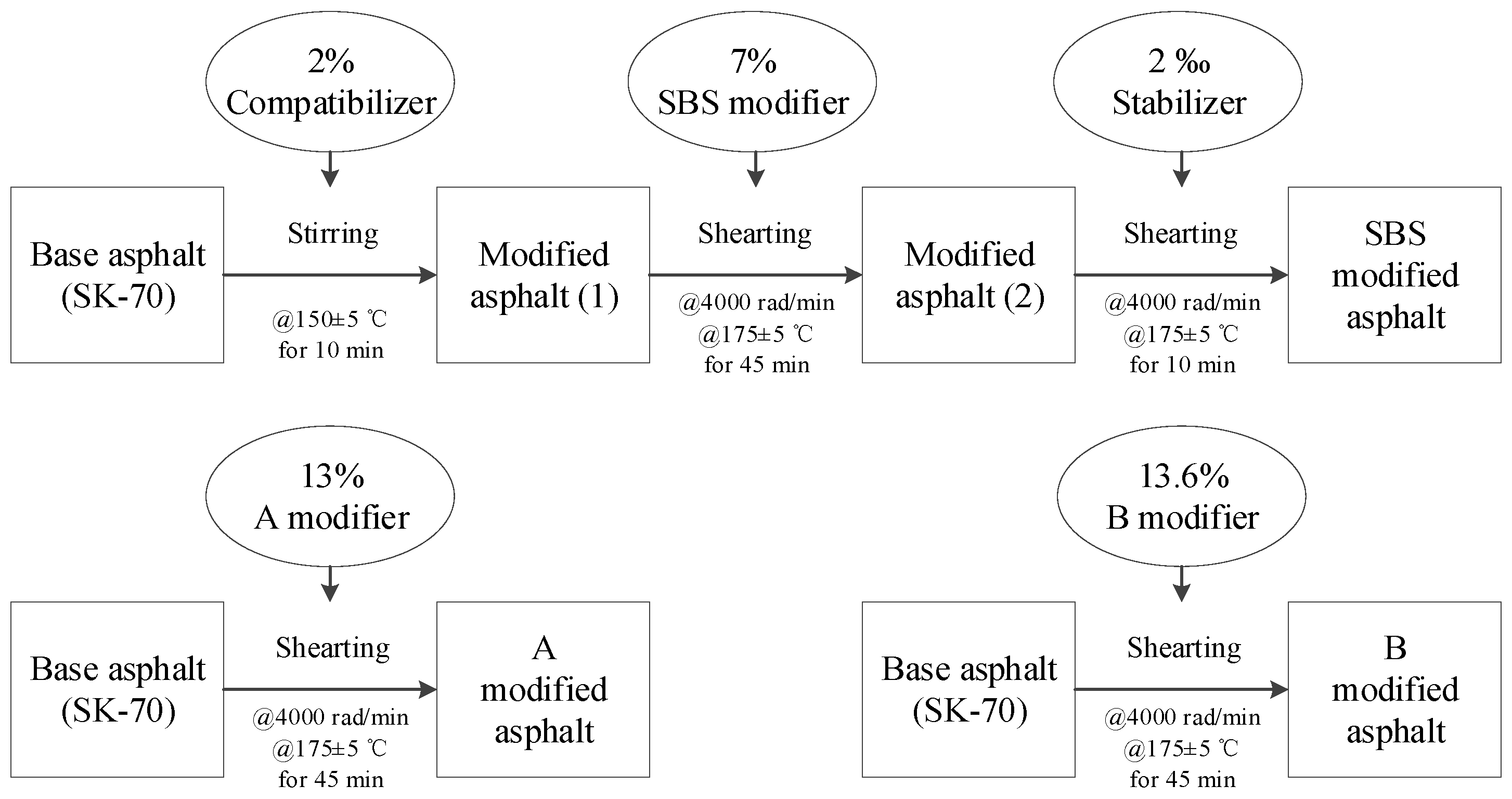

2.1.2. Preparation of Modified Asphalt Binder

2.2. Aging Test

2.2.1. Heat Aging Test

2.2.2. Hygrothermal Cycling Aging Test

2.3. FTIR

2.4. Thermal Analysis

2.5. Rheological Study

2.5.1. Temperature Scanning in DSR

2.5.2. Frequency Scanning in DSR

2.5.3. MSCR

3. Results and Discussion

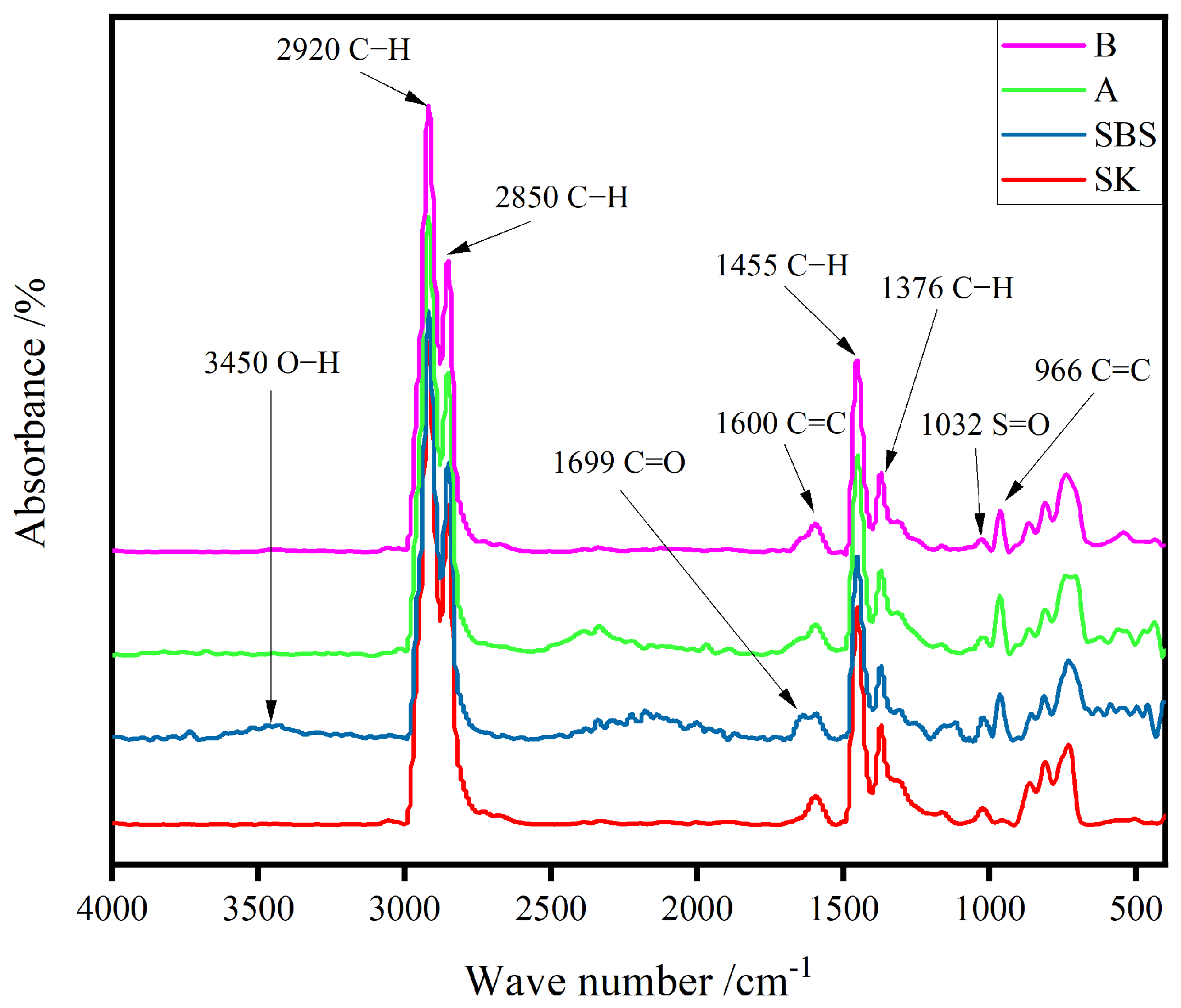

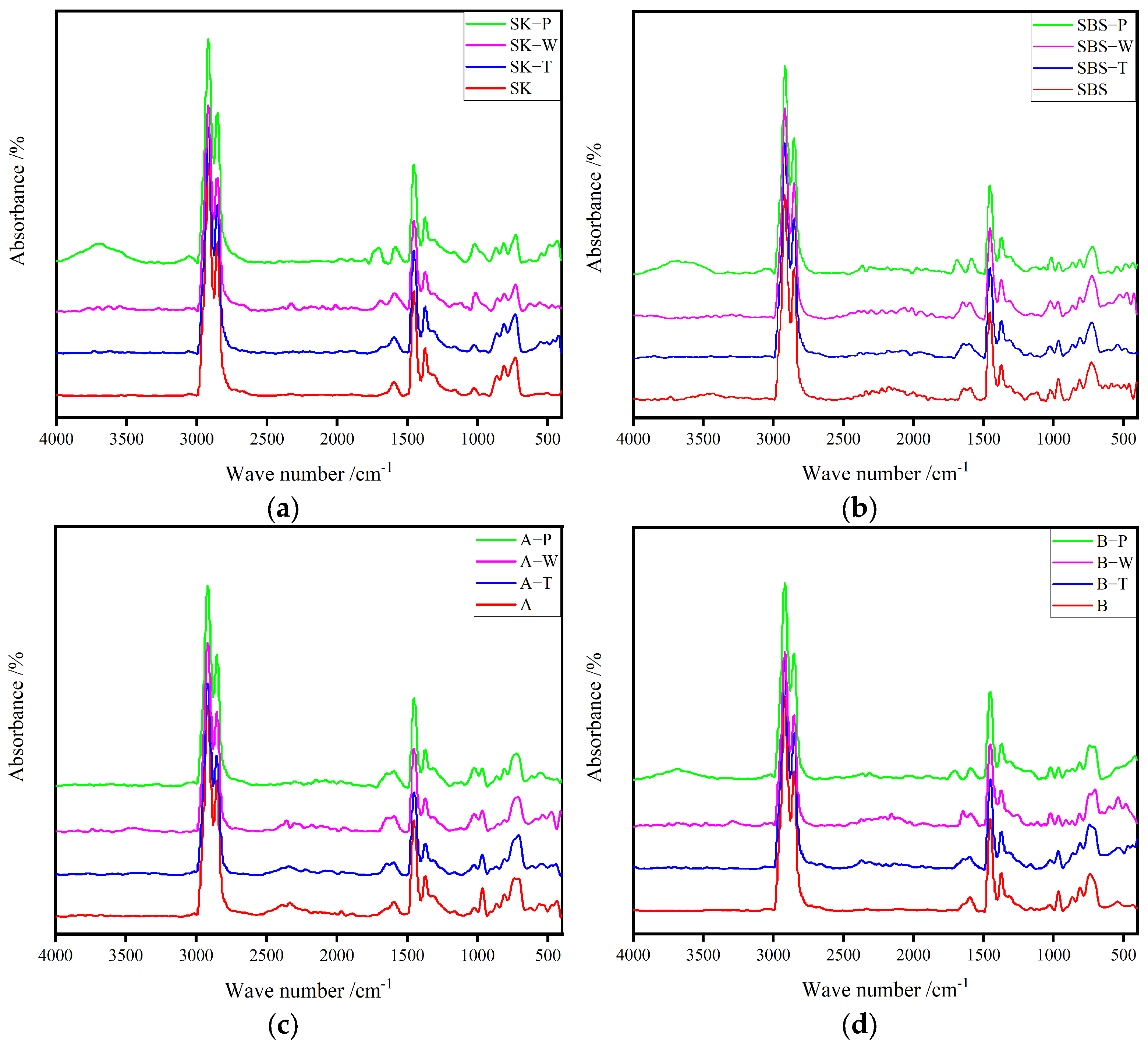

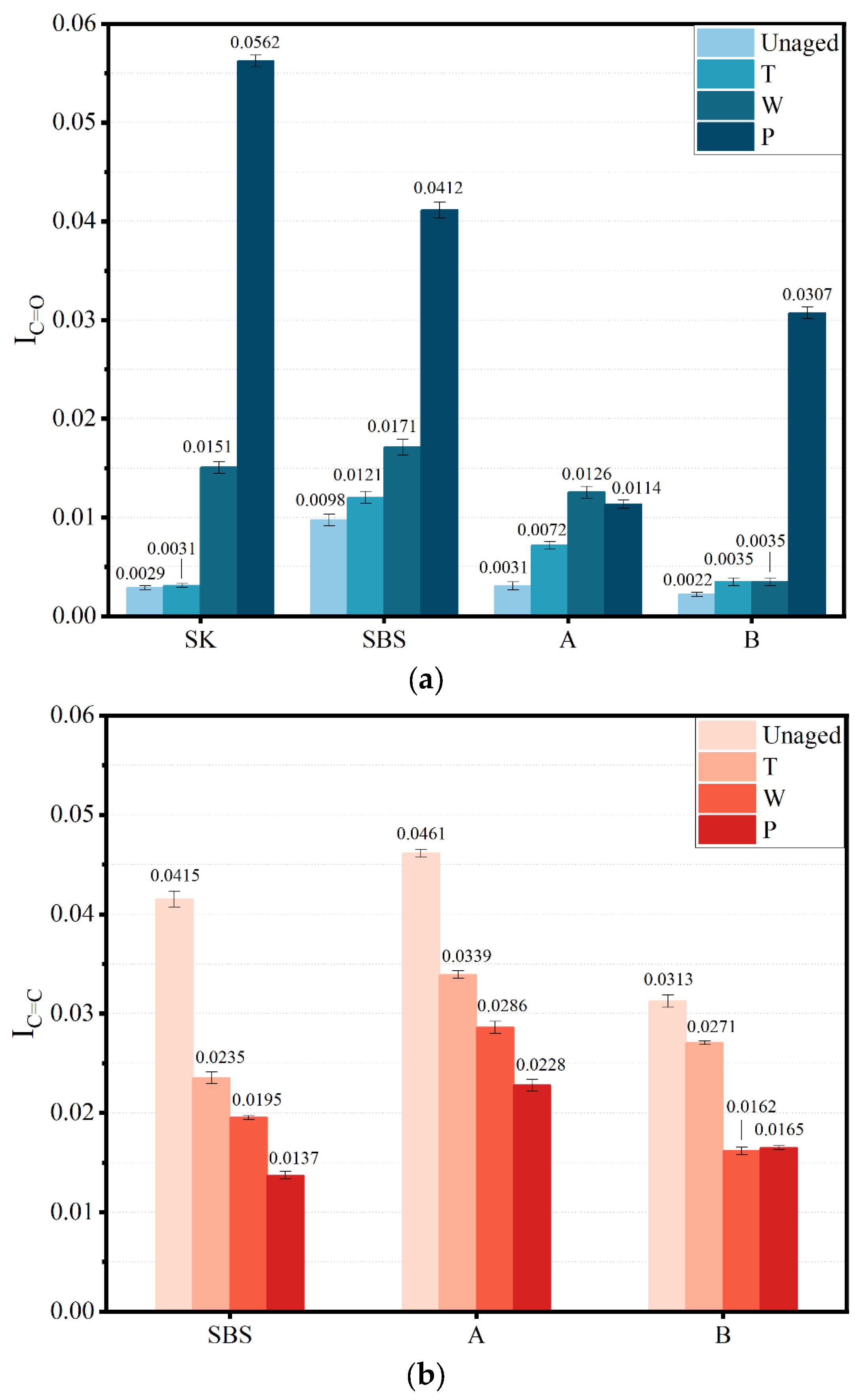

3.1. FTIR Analysis

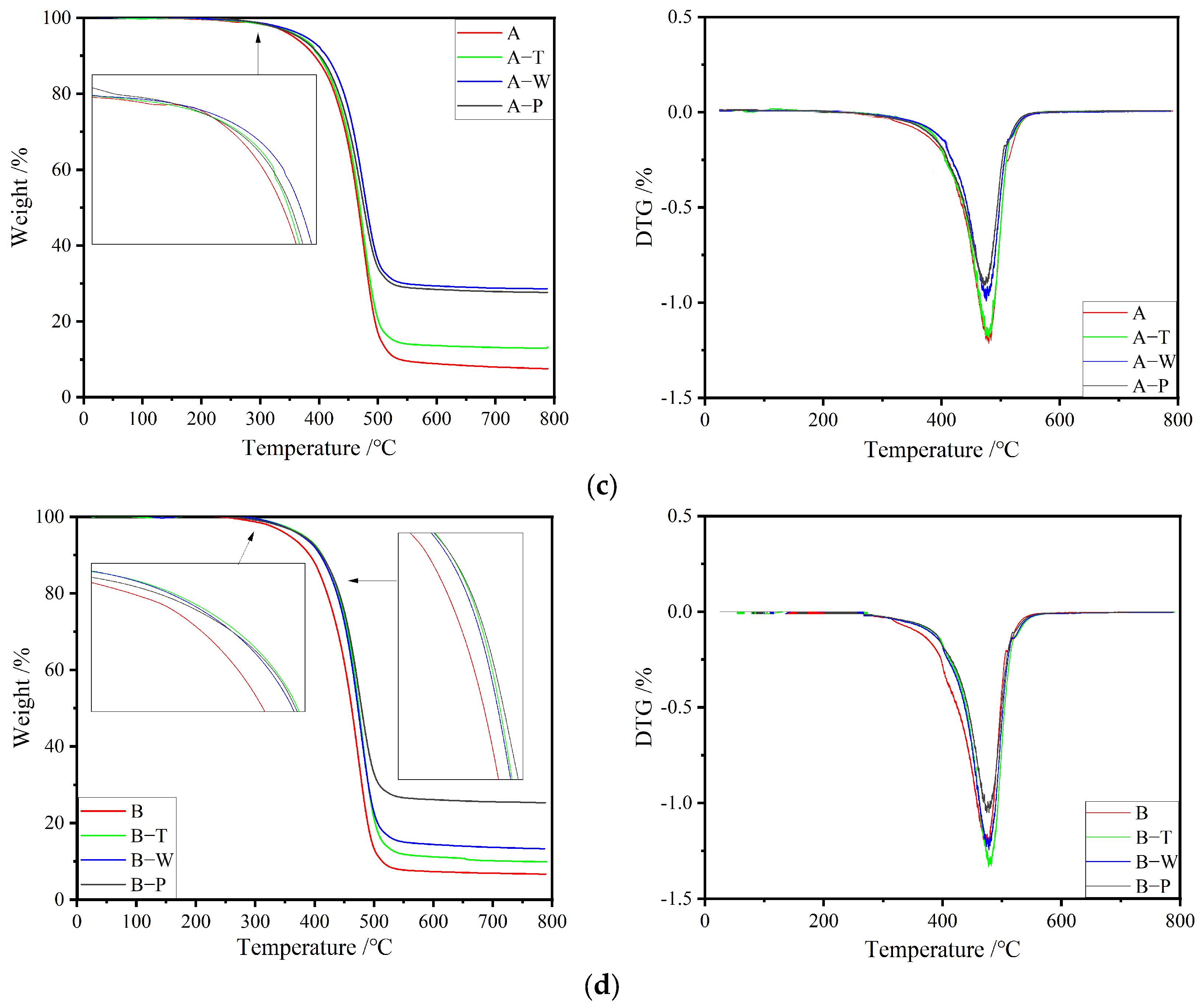

3.2. Thermal Analysis

3.3. Rheological Analysis

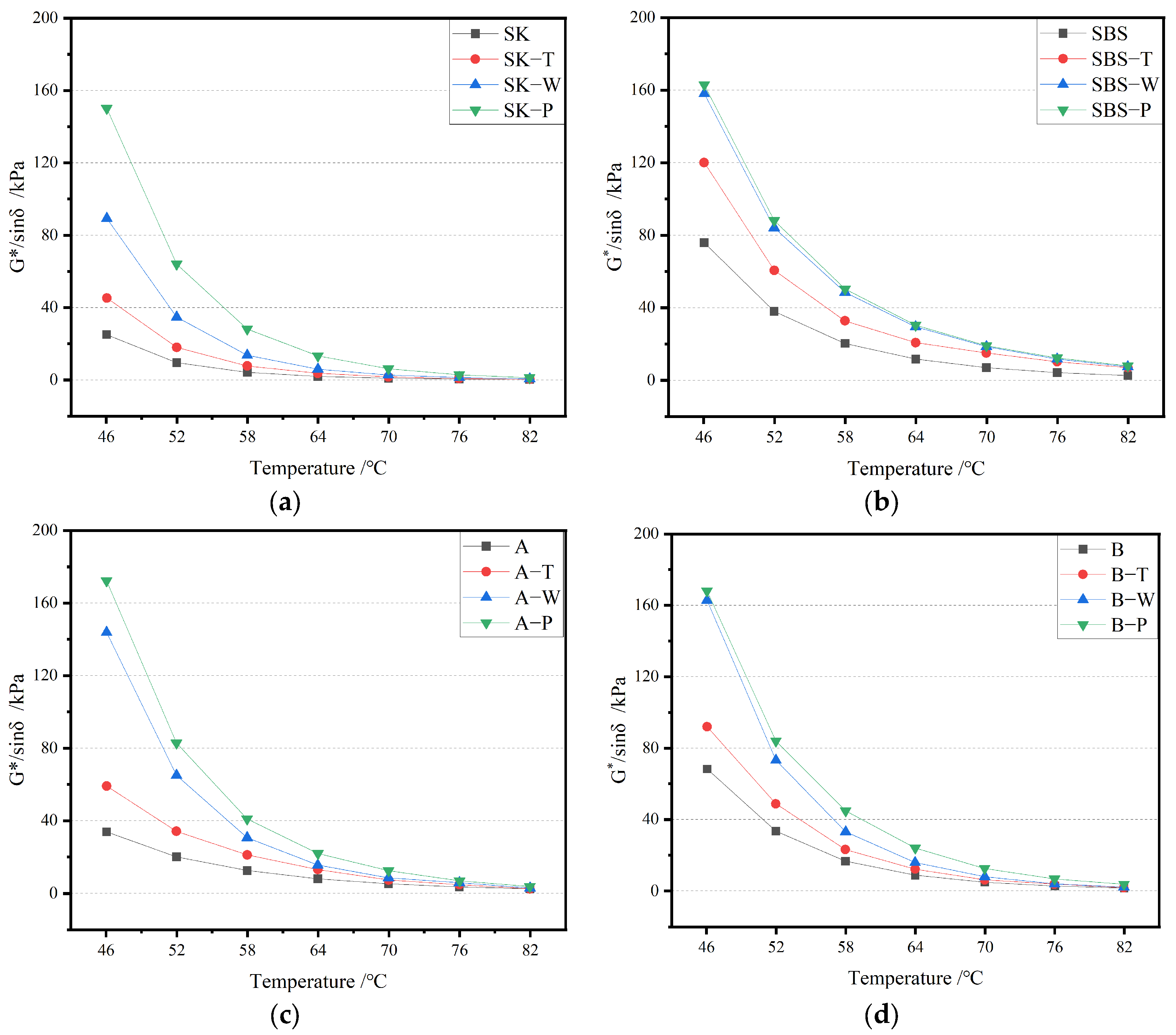

3.3.1. DSR Analysis

Rutting Factor Analysis

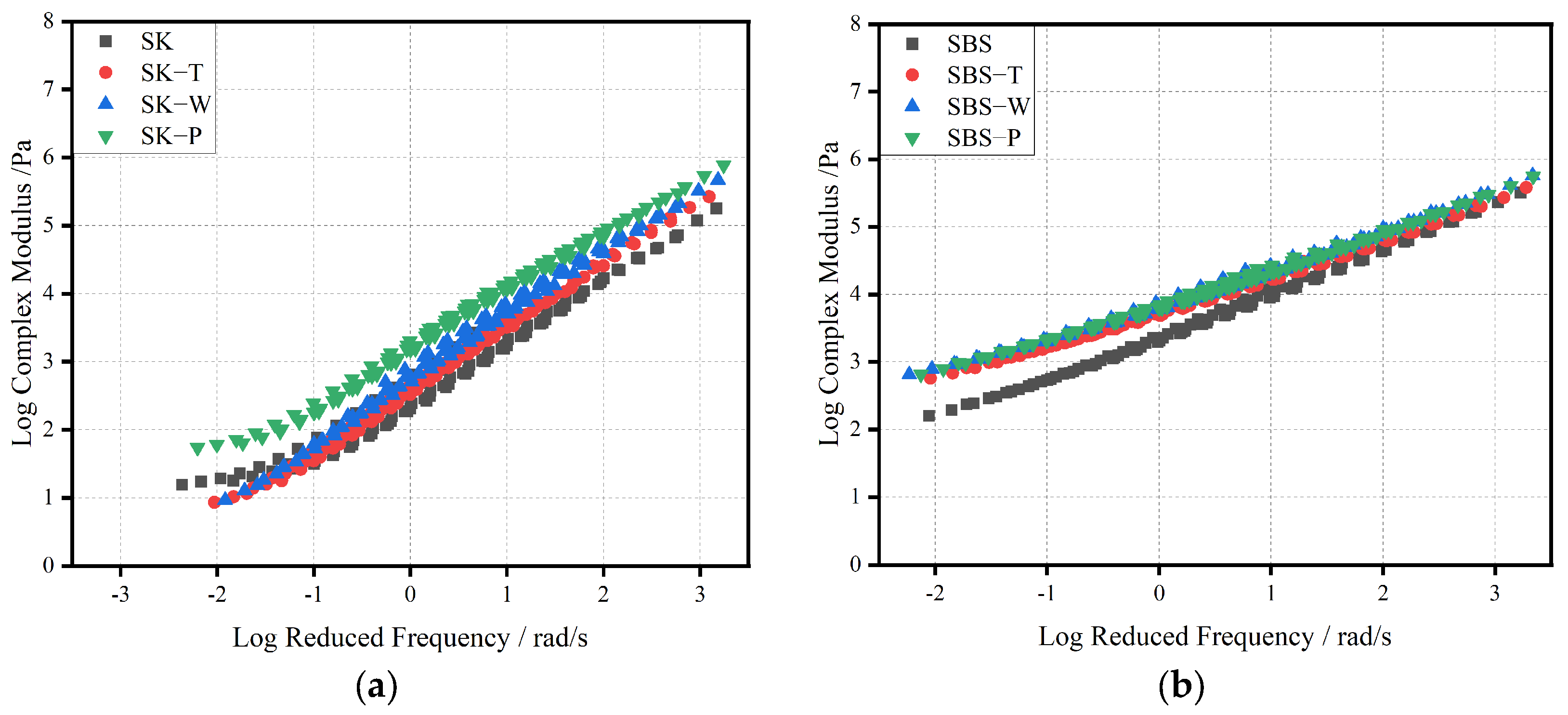

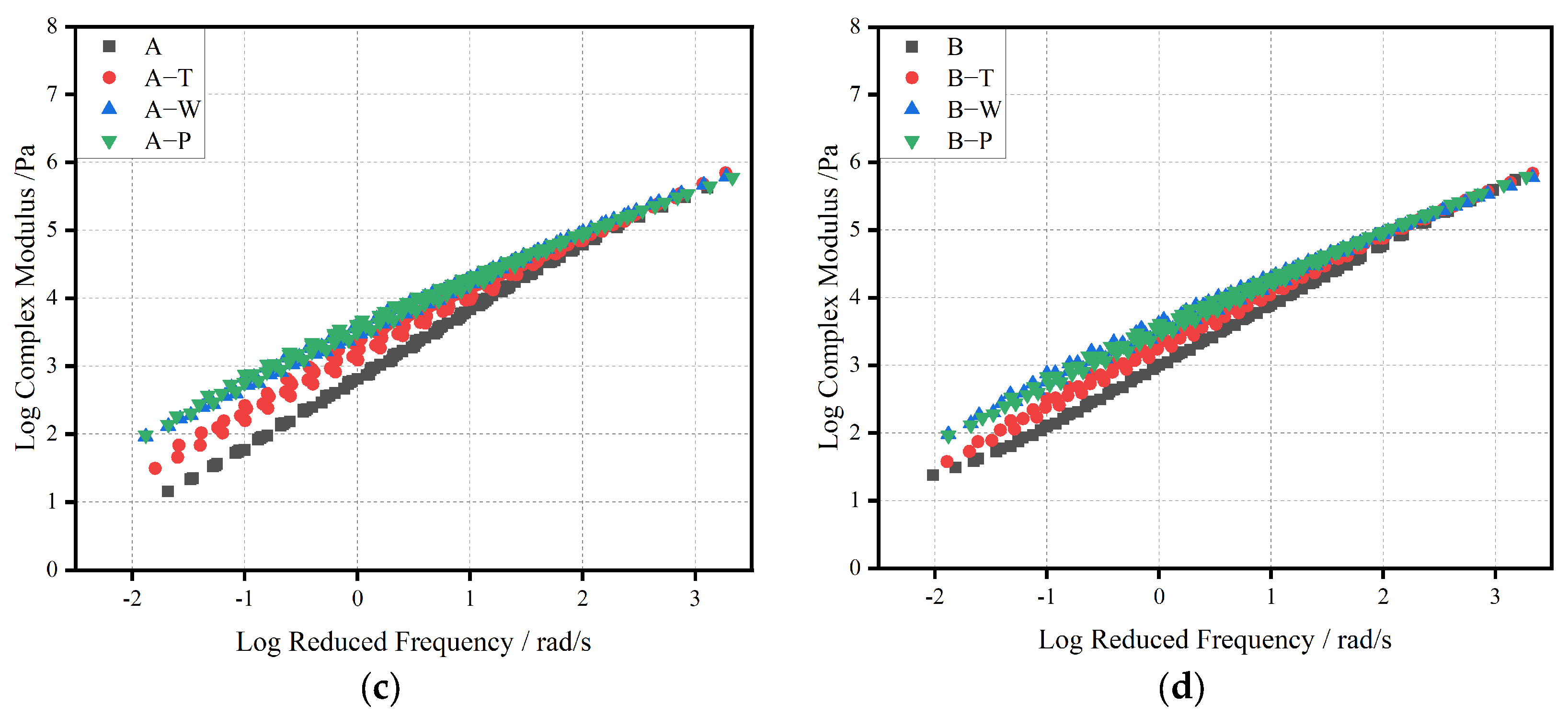

Analysis of Complex Modulus Master Curve

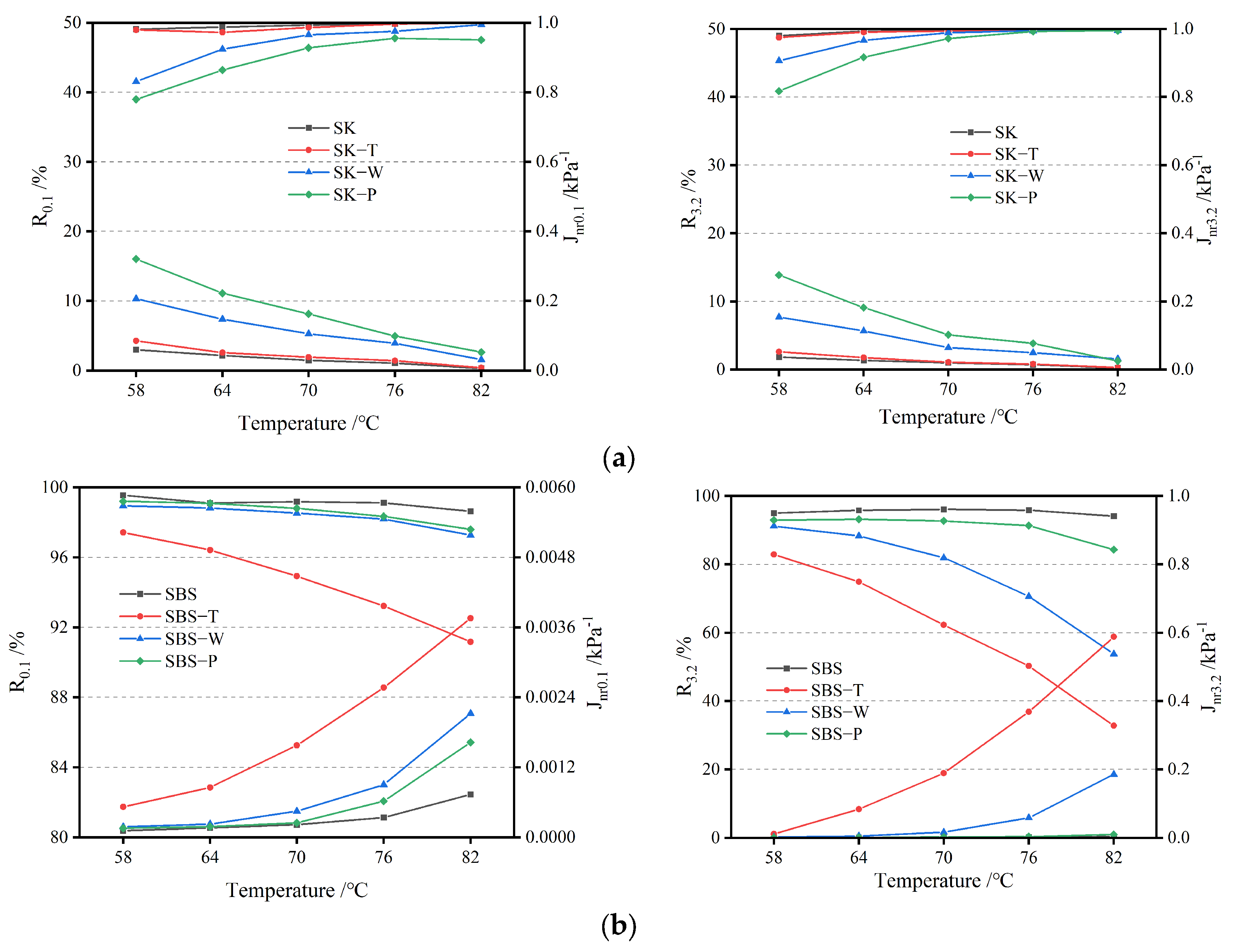

3.3.2. MSCR Analysis

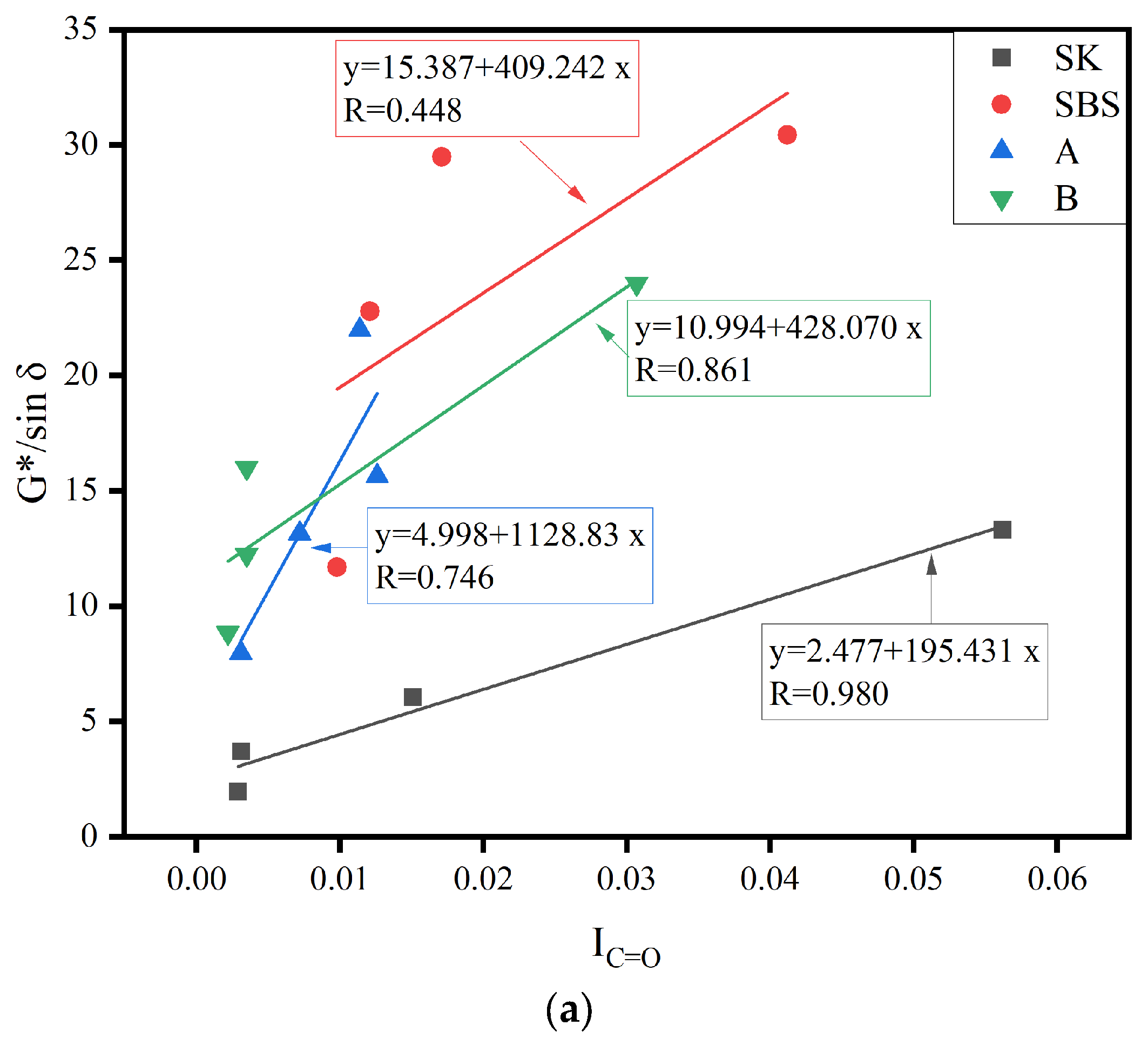

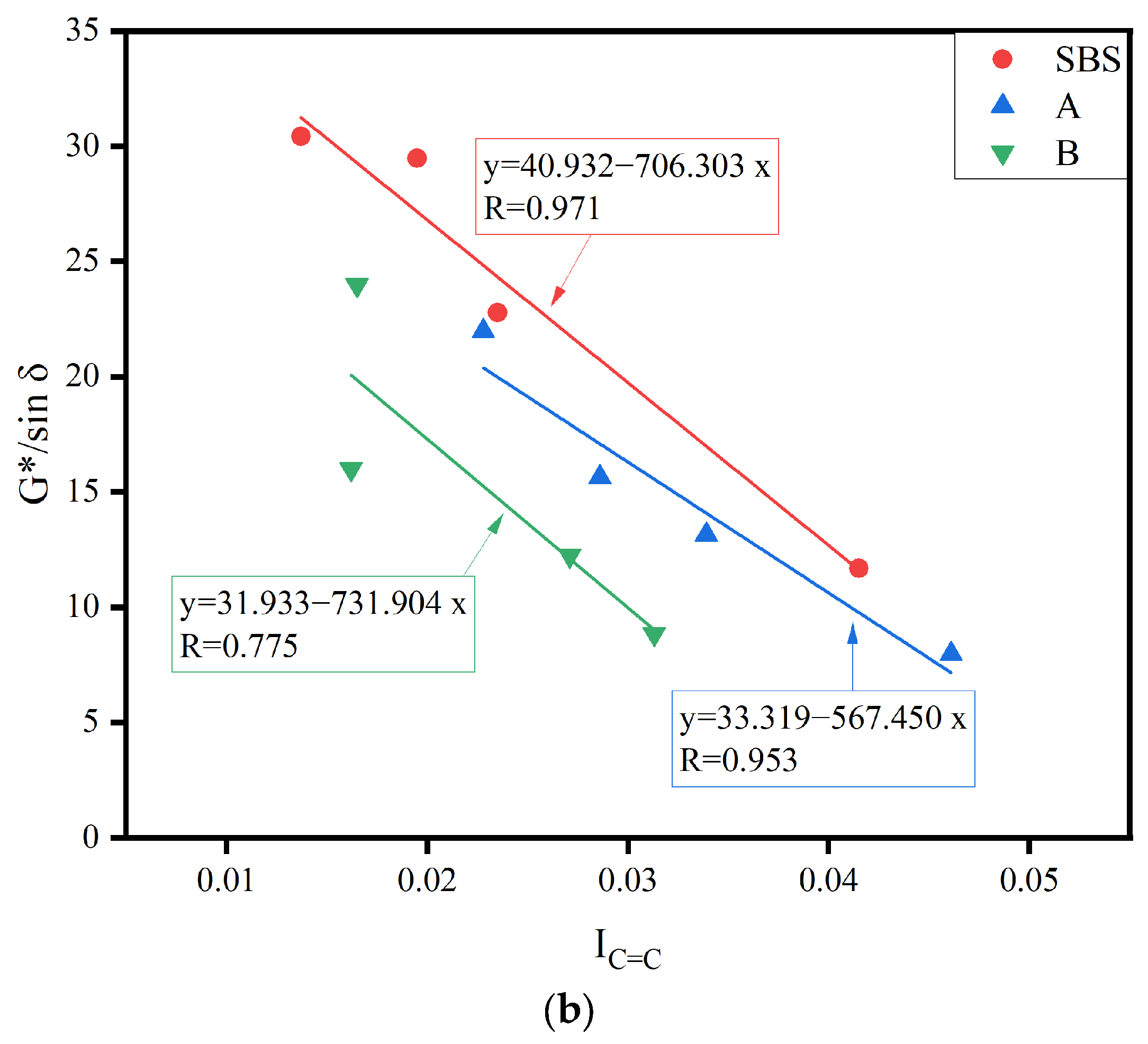

3.4. Correlation Analysis

4. Conclusions and Future Work

- (1)

- In FTIR analysis, after aging, the decrease in the butadiene index indicated polymer degradation, while the increase in the molecular weight of asphalt binder led to an increase in the carbonyl index. The effects of the hygrothermal environment expedited the decomposition of the polymer and the formation of carbonyl groups compared with the TFOT and PAV test.

- (2)

- TGA showed that there was only one single mass loss process in all samples, which mainly occurred between 200 and 550 °C. The process involved primarily the decomposition of the residual polymer and hard asphalt binder components. There was a positive correlation between the residual mass at 780 °C and the aging degree of asphalt binder, which corresponded to the change in the carbonyl group in FTIR. The thermal stability of asphalt binder was improved after HCAT. In the hygrothermal environment, the presence of water accelerated asphalt binder aging.

- (3)

- The results of DSR tests showed that the rutting factor increased obviously after HCAT. This indicated that the rutting factor of asphalt binder was significantly affected by the hygrothermal environment, and its anti-rutting performance was elevated. The master curves also verified this point. The results of MSCR tests showed that the elasticity of base bitumen increased with aging, while high-viscosity modified asphalt exhibited a different elastic response to different aging methods. Under the hygrothermal environment, A and B aged further, and there was an elastic response to different aging methods. Under the hygrothermal environment, A and B aged dramatically.

- (4)

- In general, the hygrothermal environment aggravated the aging of asphalt binder and significantly promoted the thermal oxidative aging reaction. Therefore, the service life of high-viscosity modified asphalt in long-term hot and rainy climate areas would be shortened. It is necessary to further improve the performance of the resistance of this material to hygrothermal factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Cao, D. Research on Material Composition and Performance of Porous Asphalt Pavement. J. Mater. Civ. Eng. 2009, 21, 135–140. [Google Scholar] [CrossRef]

- Tang, T.; Anupam, K.; Kasbergen, C.; Scarpas, A.; Erkens, S. A Finite Element Study of Rain Intensity on Skid Resistance for Permeable Asphalt Concrete Mixes. Constr. Build. Mater. 2019, 220, 464–475. [Google Scholar] [CrossRef]

- Zhao, K.; Song, S.; Wei, Y.; Li, G.; Guo, F. Adhesion Properties of Recycled High-Viscosity Asphalt-Aggregate Interface under Dynamic Water Erosion. Materials 2023, 16, 6203. [Google Scholar] [CrossRef] [PubMed]

- Xing, M.L.; Chen, H.X.; Li, Z.Z.; Ma, X.Y.; Sun, Y.; Liang, Z.H. Rheological Properties of Asphalt Mortar with High Viscosity. IOP Conf. Ser. Mater. Sci. Eng. 2018, 359, 012048. [Google Scholar] [CrossRef]

- Xiao, N. Asphalt Mixture Viscoelasticity Mechanics and Material Science Principle; China Communications Press: Beijing, China, 2006. [Google Scholar]

- Ma, T.; Huang, X.; Mahmoud, E.; Garibaldy, E. Effect of Moisture on the Aging Behavior of Asphalt Binder. Int. J. Miner. Metall. Mater. 2011, 18, 460–466. [Google Scholar] [CrossRef]

- Geng, J.; Li, H.; Li, W. Aging Characteristic of Styrene-Butadiene-Styrene Modified Asphalt under Thermal-Humidity Conditions. Int. J. Pavement Res. Technol. 2014, 7, 376–380. [Google Scholar]

- Qian, G.; Yu, H.; Jin, D.; Bai, X.; Gong, X. Different Water Environment Coupled with Ultraviolet Radiation on Ageing of Asphalt Binder. Road Mater. Pavement Des. 2021, 22, 2410–2423. [Google Scholar] [CrossRef]

- Dong, Z.; Yang, C.; Luan, H.; Zhou, T.; Wang, P. Chemical Characteristics of Bio-Asphalt and Its Rheological Properties after CR/SBS Composite Modification. Constr. Build. Mater. 2019, 200, 46–54. [Google Scholar] [CrossRef]

- Zeng, M.; Bahia, H.U.; Zhai, H.; Anderson, M.R.; Turner, P. Rheological Modeling of Modified Asphalt Binders and Mixtures. J. Assoc. Asph. Paving Technol. 2001, 70, 403–441. [Google Scholar]

- Dan, H.; Yang, P.; Cao, W.; Shan, H.; Zhang, Z. The Stiffness Behavior of Asphalt Mixtures with Different Compactness under Variable Confinement. Materials 2023, 16, 771. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-Forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Shirodkar, P.; Mehta, Y.; Nolan, A.; Dahm, K.; Dusseau, R.; McCarthy, L. Characterization of Creep and Recovery Curve of Polymer Modified Binder. Constr. Build. Mater. 2012, 34, 504–511. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, J.; Kim, K.W.; Xiao, F. Chemical, Thermal and Rheological Characteristics of Composite Polymerized Asphalts. Fuel 2018, 227, 289–299. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, W. Aging Resistance of Silica Fume/Styrene-Butadiene-Styrene Composite-Modified Asphalt. Materials 2021, 14, 6536. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yu, J.; Han, J. Effects of Thermal Oxidative Ageing on Dynamic Viscosity, TG/DTG, DTA and FTIR of SBS- and SBS/Sulfur-Modified Asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Geng, J.; Wang, Q.; Li, W. Aging Behavior of SBS Modified Asphalt in Coupled Water–Heat Condition. Adv. Mater. Res. 2013, 723, 575–579. [Google Scholar] [CrossRef]

- Yan, C.; Xiao, F.; Huang, W.; Lv, Q. Critical Matters in Using Attenuated Total Reflectance Fourier Transform Infrared to Characterize the Polymer Degradation in Styrene–Butadiene–Styrene-Modified Asphalt Binders. Polym. Test. 2018, 70, 289–296. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Fa, C.; Zhang, Y.; Xiong, J.; Chen, H. Investigation on Characteristics and Properties of Bagasse Fibers: Performances of Asphalt Mixtures with Bagasse Fibers. Constr. Build. Mater. 2020, 248, 118648. [Google Scholar] [CrossRef]

- Radhakrishnan, C.K.; Sujith, A.; Unnikrishnan, G. Thermal Behaviour of Styrene Butadiene Rubber/Poly(Ethylene-Co-Vinyl Acetate) Blends: TG and DSC Analysis. J. Therm. Anal. Calorim. 2007, 90, 191–199. [Google Scholar] [CrossRef]

- Jiménez-Mateos, J.M.; Quintero, L.C.; Rial, C. Characterization of Petroleum Bitumens and Their Fractions by Thermogravimetric Analysis and Differential Scanning Calorimetry. Fuel 1996, 75, 1691–1700. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.B.; Peng, A.; Xuan, W.; Li, W. Analysis of the Performance and Mechanism of Desulfurized Rubber and Low-Density Polyethylene Compound-Modified Asphalt. J. Appl. Polym. Sci. 2019, 136, 48194. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.; Zhang, Y. The Effect of PPA on Performances and Structures of High-Viscosity Modified Asphalt. J. Therm. Anal. Calorim. 2018, 134, 1729–1738. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The Research for Thermal Behaviour, Creep Properties and Morphology of SBS-Modified Asphalt. J. Therm. Anal. Calorim. 2015, 121, 651–661. [Google Scholar] [CrossRef]

- de Fátima Amazonas de Sá Araujo, M.; de Freitas Cunha Lins, V.; Pasa, V.M.D.; Leite, L.F.M. Weathering Aging of Modified Asphalt Binders. Fuel Process. Technol. 2013, 115, 19–25. [Google Scholar] [CrossRef]

- Liu, G.; Yang, T.; Li, J.; Jia, Y.; Zhao, Y.; Zhang, J. Effects of Aging on Rheological Properties of Asphalt Materials and Asphalt-Filler Interaction Ability. Constr. Build. Mater. 2018, 168, 501–511. [Google Scholar] [CrossRef]

- Kang, A.; Zhang, W. Study on Performance and Microstructure of SBS Modified Asphalt During Shearing Process. Appl. Polym. Sci. 2012, 178–181, 1442–1447. [Google Scholar] [CrossRef]

- Shan, L.; Qi, X.; Duan, X.; Liu, S.; Chen, J. Effect of Styrene-Butadiene-Styrene (SBS) on the Rheological Behavior of Asphalt Binders. Constr. Build. Mater. 2020, 231, 117076. [Google Scholar] [CrossRef]

- Sun, G.; Li, B.; Sun, D.; Yu, F.; Hu, M. Chemo-Rheological and Morphology Evolution of Polymer Modified Bitumen under Thermal Oxidative and All-Weather Aging. Fuel 2021, 285, 118989. [Google Scholar] [CrossRef]

- Xu, X.; Yu, J.; Xue, L.; Zhang, C.; Zha, Y.; Gu, Y. Investigation of Molecular Structure and Thermal Properties of Thermo-Oxidative Aged SBS in Blends and Their Relations. Materials 2017, 10, 768. [Google Scholar] [CrossRef]

- Yan, J. Research on Development and Evaluation Method of High Viscosity Modified Asphalt; Chang’an University: Xi’an, China, 2020. [Google Scholar]

- Yan, C.; Huang, W.; Lin, P.; Zhang, Y.; Lv, Q. Chemical and Rheological Evaluation of Aging Properties of High Content SBS Polymer Modified Asphalt. Fuel 2019, 252, 417–426. [Google Scholar] [CrossRef]

- Shao, L.; Wang, H.; Zhang, R.; Zheng, W.; Hossiney, N.; Wu, C. Analysis of the Chemical Properties and High-Temperature Rheological Properties of MDI Modified Bio-Asphalt. Constr. Build. Mater. 2021, 267, 121044. [Google Scholar] [CrossRef]

- Li, Z.; Fa, C.; Zhao, H.; Zhang, Y.; Chen, H.; Xie, H. Investigation on Evolution of Bitumen Composition and Micro-Structure during Aging. Constr. Build. Mater. 2020, 244, 118322. [Google Scholar] [CrossRef]

| Indices | Test Results | Specification Requirement |

|---|---|---|

| Softening point/°C | 48.5 | ≥45 |

| Penetration at 25 °C/0.1 mm | 66 | 60–80 |

| Ductility (15 °C)/cm | 141 | ≥100 |

| Dynamic viscosity at 60 °C/Pa·s | 213 | ≥160 |

| Indices | Softening Point /°C | Penetration (25 °C)/0.1 mm | Ductility (5 °C) /cm | Dynamic Viscosity (60 °C)/Pa·s | Rotational Viscosity (135 °C)/Pa·s |

|---|---|---|---|---|---|

| SBS | 118.0 | 33 | 33.3 | 172,676 | 2.83 |

| Specification Requirement | ≥55 | 30–60 | ≥30 | ≥20,000 | ≤3 |

| A | 81.0 | 46 | 58.2 | 140,987 | 2.43 |

| B | 83.0 | 48 | 49.7 | 184,771 | 2.95 |

| Specification Requirement | ≥70 | 40–80 | ≥20 | ≥20,000 | ≤3 |

| Peak Position/cm−1 | Functional Groups | Details |

|---|---|---|

| 3450 | O-H | Stretching vibration |

| 2920 | C-H | Asymmetric stretching vibration |

| 2850 | C-H | Symmetric stretching vibration |

| 1699 | C=O | Stretching vibration |

| 1600 | -C=C- | Vibration of Conjugate Ring |

| 1455 | CH3&CH2 | Asymmetric deformation |

| 1376 | CH3 | Symmetrical deformation |

| 1032 | S=O | Stretching vibration |

| 966 | -C=C- | Bending vibration |

| Indices | ∆T, IC=O/% | ∆H, IC=O/% | ∆P, IC=O/% | ∆T, IC=C/% | ∆H, IC=C/% | ∆P, IC=C/% |

|---|---|---|---|---|---|---|

| SK | 7 | 416 | 1824 | / | / | / |

| SBS | 24 | 76 | 322 | −43 | −53 | −67 |

| A | 132 | 308 | 269 | −26 | −38 | −51 |

| B | 57 | 741 | 1269 | −13 | −48 | −47 |

| Samples | T10 wt%/°C | Mass Loss/% | Residue at 780 °C/wt.% |

|---|---|---|---|

| SK | 384.0 | 84.95 | 12.46 |

| SK-T | 391.6 | 82.55 | 15.61 |

| SK-W | 395.9 | 76.82 | 21.69 |

| SK-P | 382.8 | 69.12 | 29.23 |

| SBS | 402.3 | 87.53 | 10.45 |

| SBS-T | 418.3 | 82.31 | 16.17 |

| SBS-W | 411.6 | 82.67 | 15.04 |

| SBS-P | 416.1 | 75.21 | 23.37 |

| A | 392.1 | 90.08 | 7.53 |

| A-T | 399.5 | 85.72 | 13.22 |

| A-W | 412.3 | 69.93 | 28.58 |

| A-P | 401.6 | 71.07 | 27.62 |

| B | 391.6 | 92.26 | 6.66 |

| B-T | 412.7 | 88.14 | 9.86 |

| B-W | 409.4 | 84.95 | 13.28 |

| B-P | 412.0 | 73.38 | 25.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, M.; Li, G.; Zhou, X.; Liu, H.; Cao, Z.; Li, Z.; Chen, H. Investigation of the Properties of High-Viscosity Modified Asphalt Binder under Hygrothermal Environments. Materials 2024, 17, 2869. https://doi.org/10.3390/ma17122869

Xing M, Li G, Zhou X, Liu H, Cao Z, Li Z, Chen H. Investigation of the Properties of High-Viscosity Modified Asphalt Binder under Hygrothermal Environments. Materials. 2024; 17(12):2869. https://doi.org/10.3390/ma17122869

Chicago/Turabian StyleXing, Mingliang, Guimin Li, Xiaowei Zhou, Huan Liu, Zhulin Cao, Zuzhong Li, and Huaxin Chen. 2024. "Investigation of the Properties of High-Viscosity Modified Asphalt Binder under Hygrothermal Environments" Materials 17, no. 12: 2869. https://doi.org/10.3390/ma17122869

APA StyleXing, M., Li, G., Zhou, X., Liu, H., Cao, Z., Li, Z., & Chen, H. (2024). Investigation of the Properties of High-Viscosity Modified Asphalt Binder under Hygrothermal Environments. Materials, 17(12), 2869. https://doi.org/10.3390/ma17122869