Wear Mechanisms, Composition and Thickness of Antiwear Tribofilms Formed from Multi-Component Lubricants

Abstract

1. Introduction

2. Experimental Methods

2.1. Specimens and Wear Experiments

2.2. Blend Formulations

2.3. Surface Profilometry

2.4. Wear Analysis

2.5. Microanalytical Techniques

3. Results and Discussion

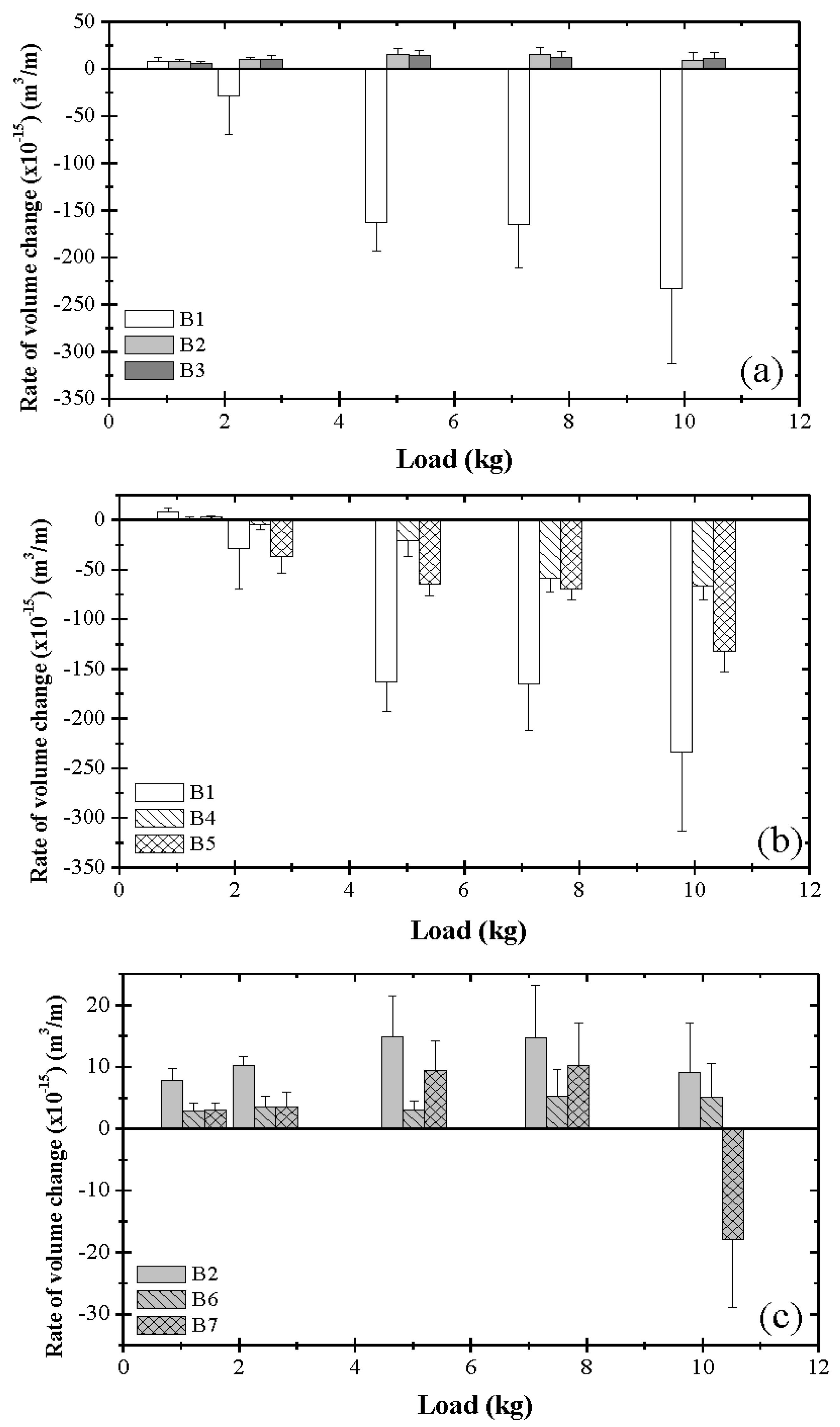

3.1. Wear Rate

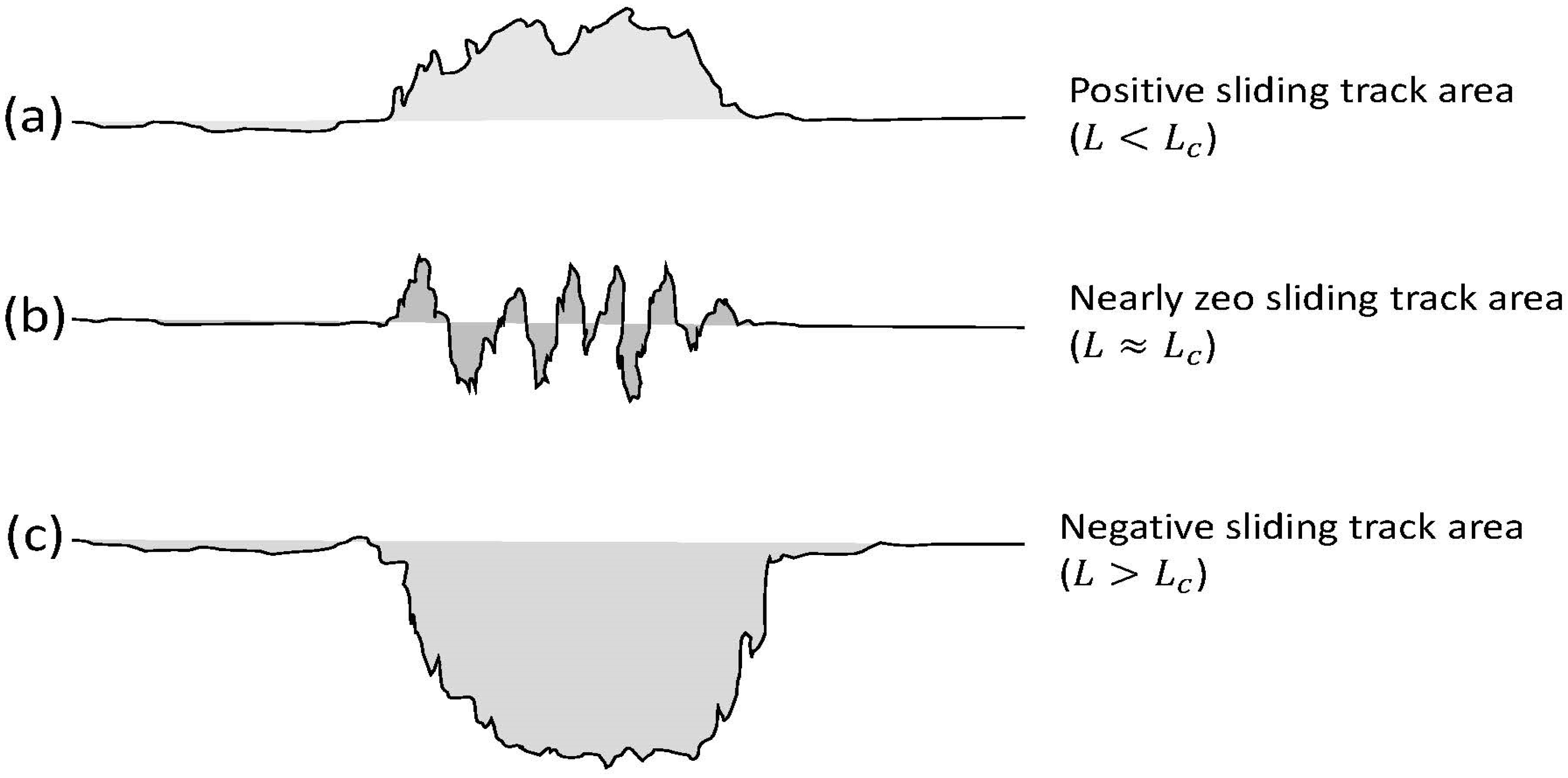

3.2. Critical Load

3.3. Wear Mechanisms

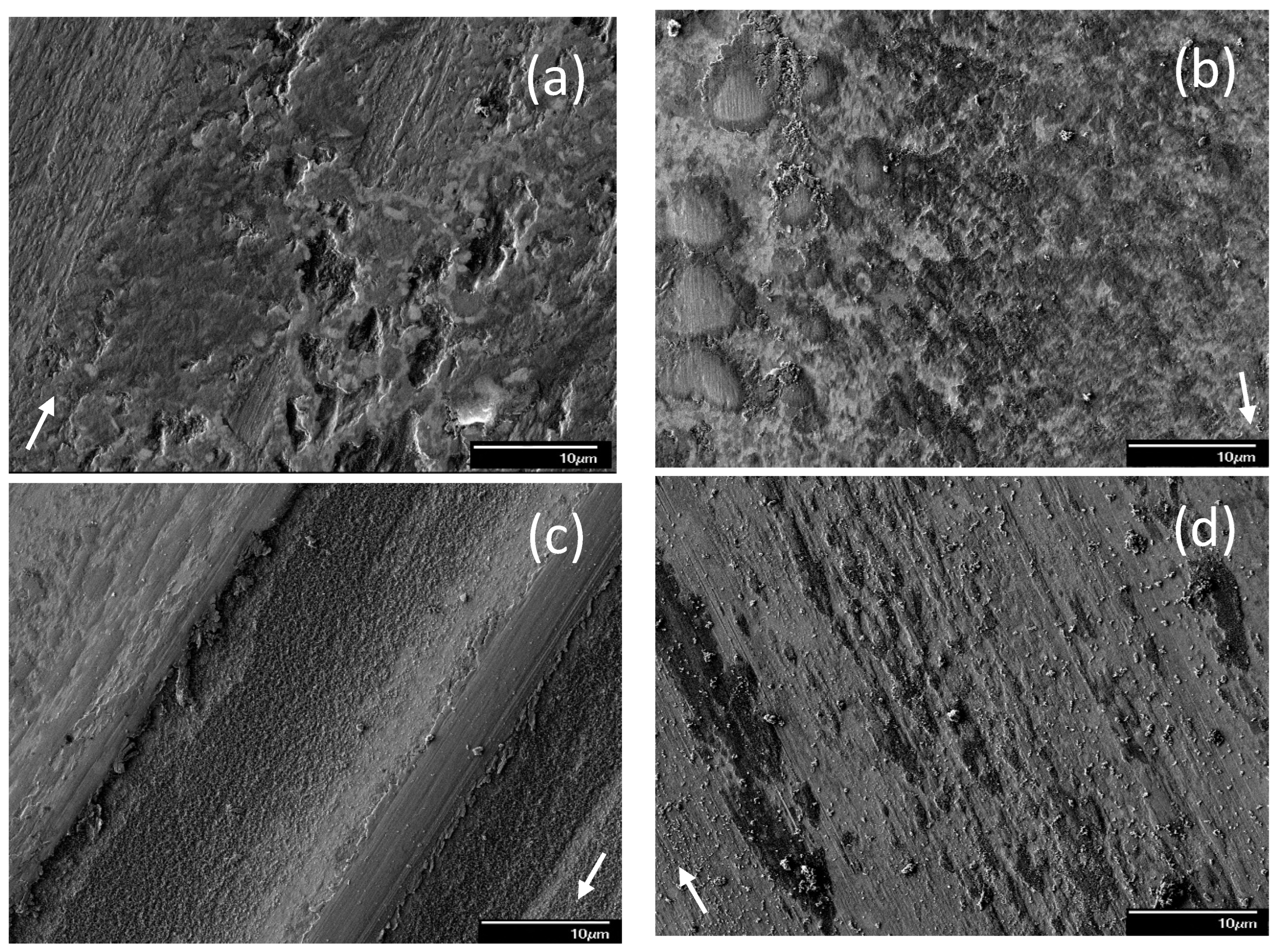

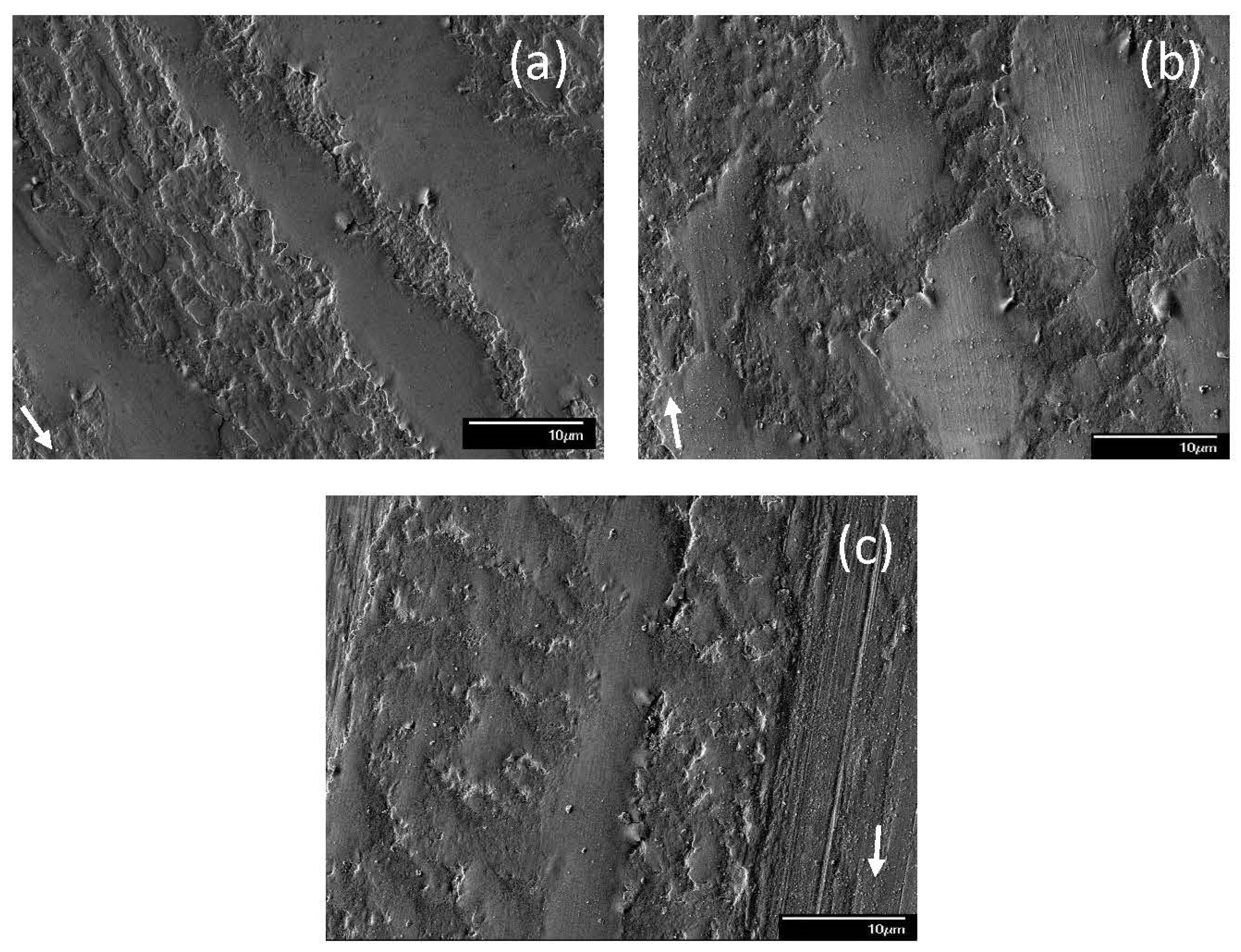

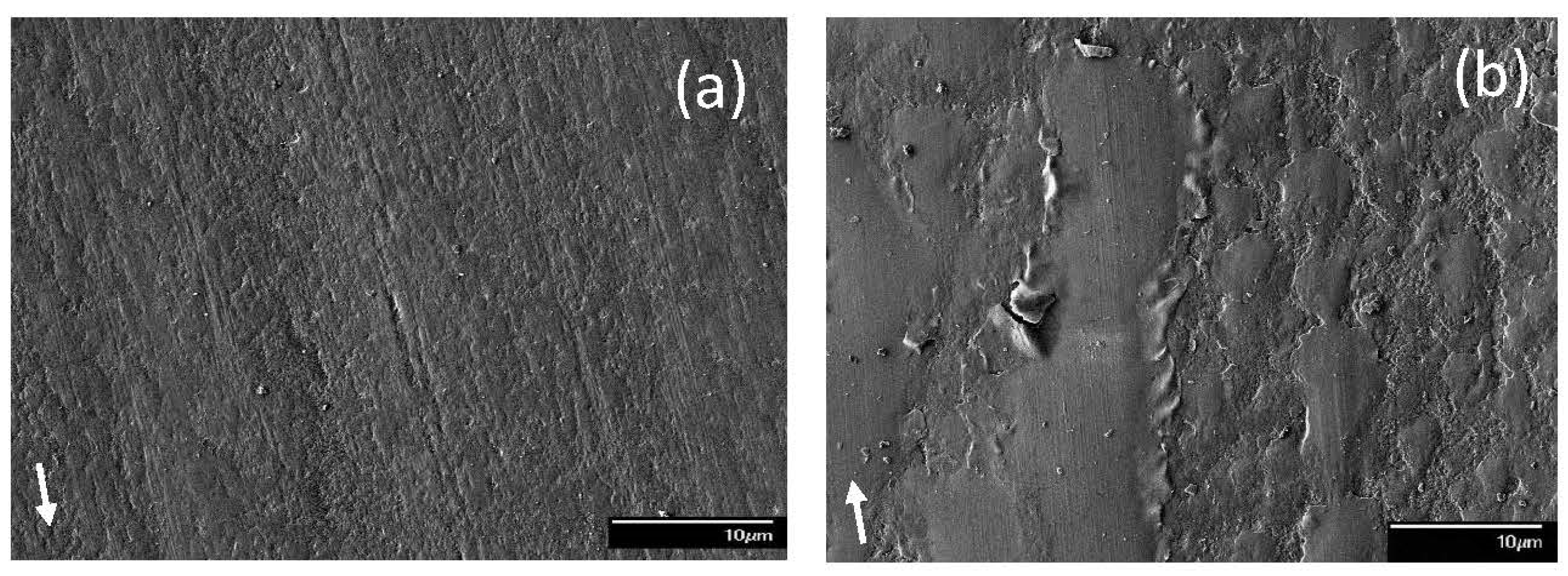

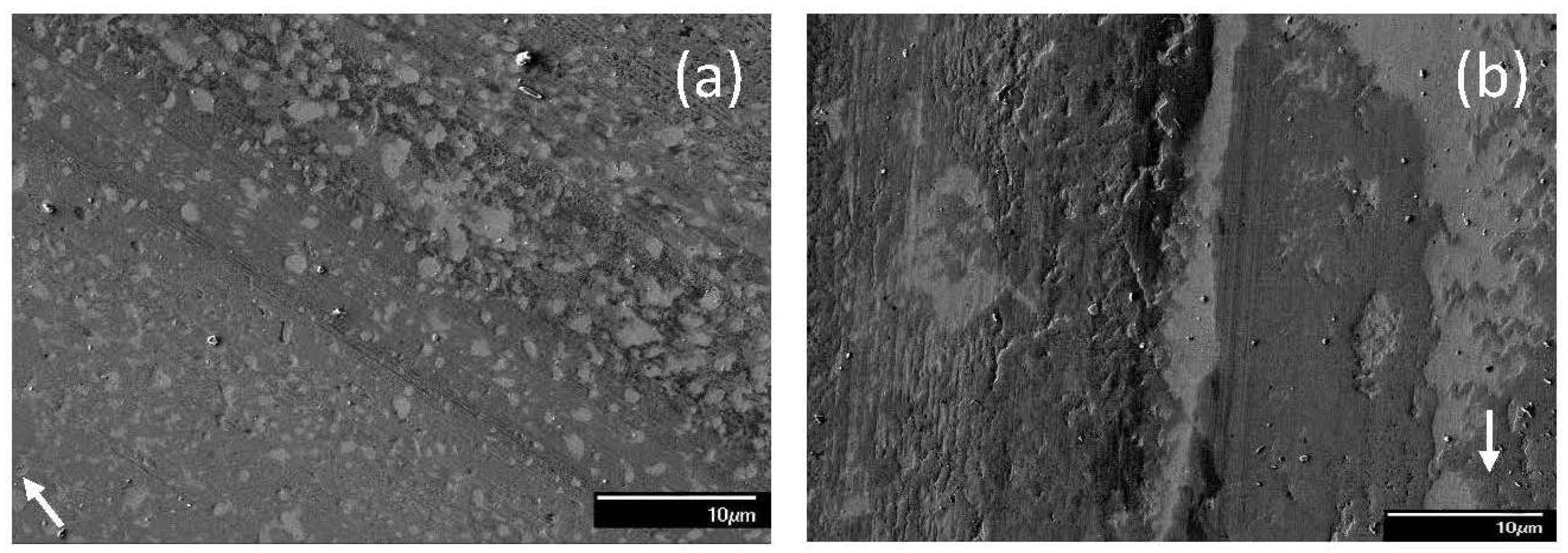

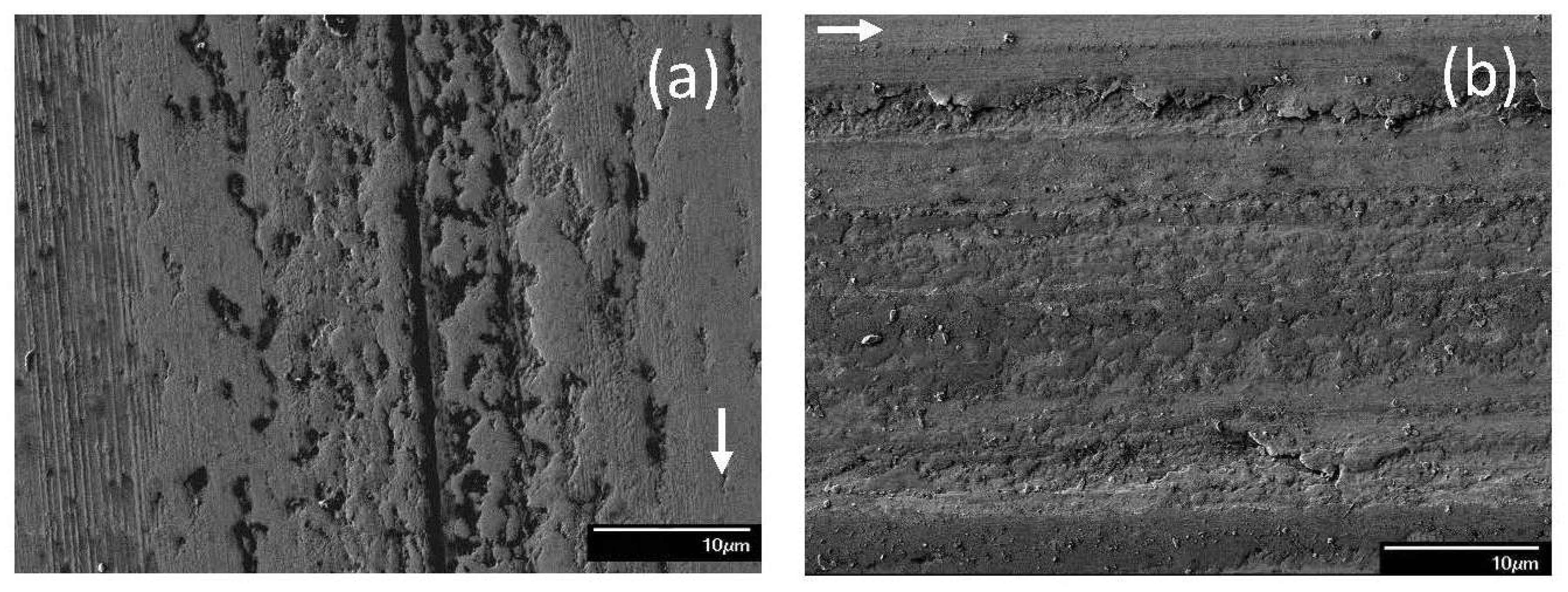

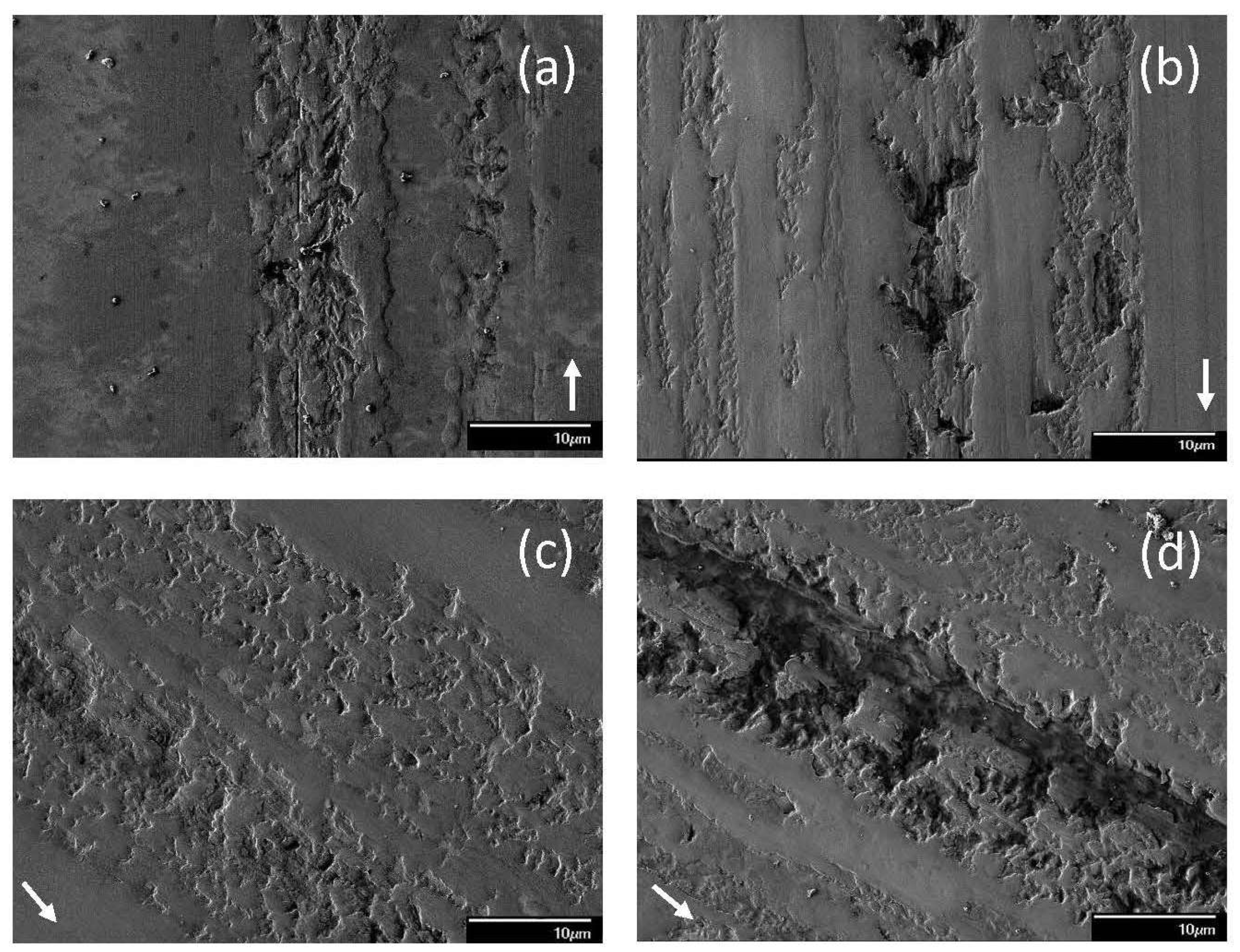

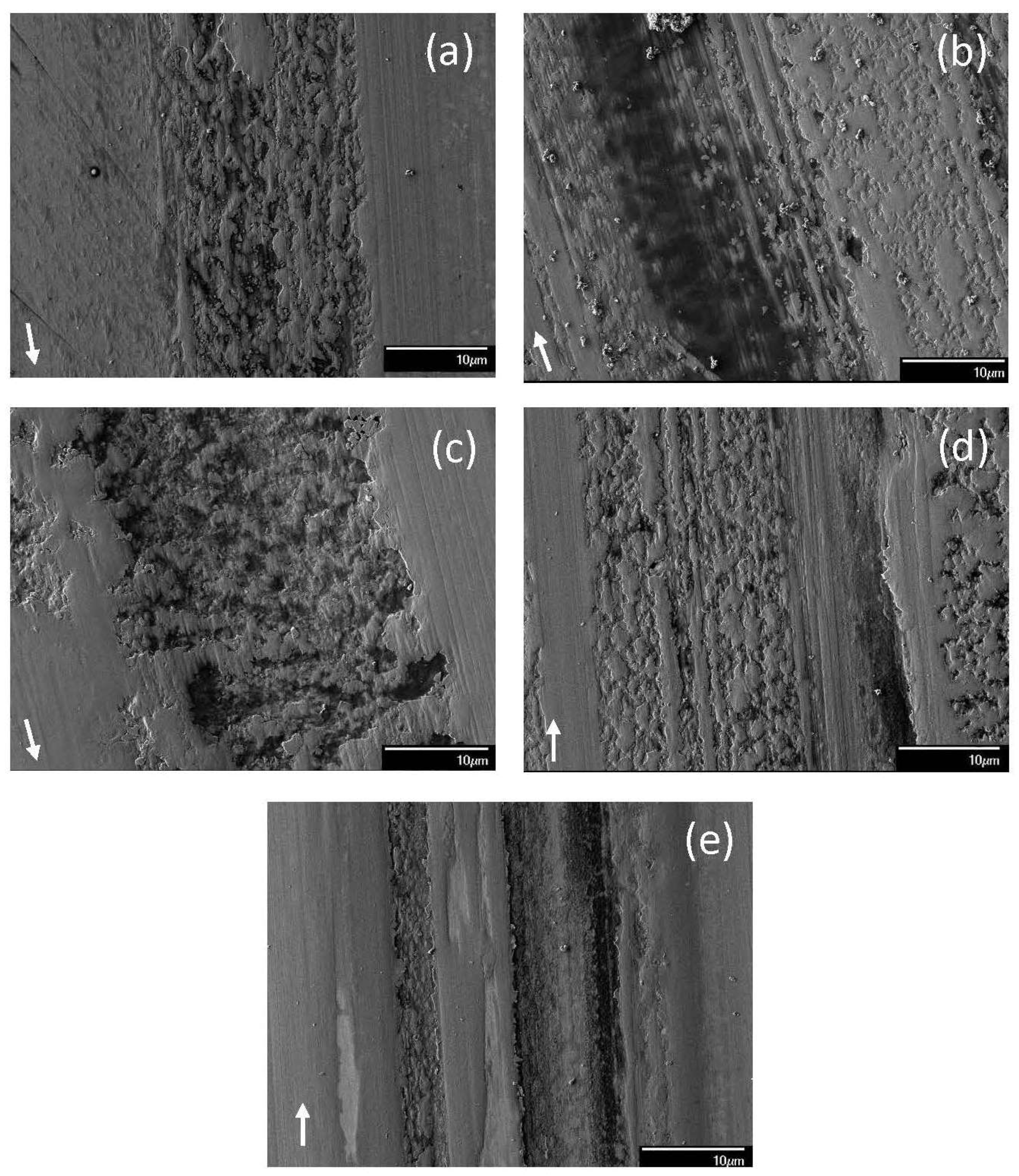

3.4. Tribofilm Chemical Composition

3.5. Tribofilm Thickness

4. Conclusions

- (1)

- In the case of lubrication by pure gear base oil, the surface oxide film deteriorated under high-load sliding conditions.

- (2)

- ZDDP suppressed wear even for sliding under the highest load used in this study. Nevertheless, the activation energy required for the formation of an iron oxide tribofilm was much lower than that of a ZDDP-derived tribofilm.

- (3)

- Although the coexistence of dispersant and ZDDP in base oil, i.e., blend 6 (base oil + 0.05 wt% ZDDP + dispersant B), resulted in the formation of a tribofilm exhibiting lower wear resistance than the tribofilms produced from blends consisting of base oil and ZDDP, material loss did not occur throughout the entire load range.

- (4)

- The tribofilm produced from blend 7 (base oil + 0.05 wt% ZDDP + dispersant B) demonstrated better wear behavior under low- and intermediate-load sliding conditions; however, the critical load of this tribofilm was lower than that of the tribofilm produced from blend 6.

- (5)

- Among all the blends, the tribofilms due to blends 2 and 6 demonstrated overall better wear characteristics.

- (6)

- Tribochemical wear of the tribofilms was characterized by the dominance of one or more wear mechanisms. The most frequently encountered wear mechanism was adhesive wear, resulting in tribofilm cohesive failure. Different types of abrasive wear were demonstrated by some of the tribofilms. Tribofilm replenishment was generally characterized by the formation of patch-like patterns on the sliding track.

- (7)

- Tribofilms of iron oxide possessed an average thickness of ~80 nm, whereas ZDDP-derived tribofilms were characterized by a larger thickness of ~200 nm.

- (8)

- The findings of this study provide impetus for further investigations aimed at replacing environmentally harmful additives with other substances that are not harmful to the environment and can form antiwear tribofilms.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konicek, A.R.; Jacobs, P.W.; Webster, M.N.; Schilowitz, A.M. Role of Tribofilms in Wear Protection. Tribol. Int. 2016, 94, 14–19. [Google Scholar] [CrossRef]

- Totolin, V.; Ripoll, M.R.; Jech, M.; Podgornik, B. Enhanced tribological performance of tungsten carbide functionalized surfaces via in-situ formation of low-friction tribofilms. Tribol. Int. 2016, 94, 269–278. [Google Scholar] [CrossRef]

- Ernens, D.; Langedijk, G.; Smit, P.; de Rooij, M.B.; Pasaribu, H.R.; Schipper, D.J. Characterization of the Adsorption Mechanism of Manganese Phosphate Conversion Coating Derived Tribofilms. Tribol. Lett. 2018, 66, 131. [Google Scholar] [CrossRef]

- Garcia, C.E.; Ueda, M.; Spikes, H.; Wong, J.S.S. Temperature Dependence of Molybdenum Dialkyl Dithiocarbamate (MoDTC) Tribofilms via Time-resolved Raman Spectroscopy. Sci. Rep. 2021, 11, 3621. [Google Scholar] [CrossRef] [PubMed]

- Willermet, P.A.; Dailey, D.P.; Carter, R.O., III.; Schmitz, P.J.; Zhu, W. Mechanism of Formation of Antiwear Films from Zinc Dialkyldithiophosphates. Tribol. Int. 1995, 28, 177–187. [Google Scholar] [CrossRef]

- Martin, J.M. Antiwear Mechanisms of Zinc Dithiophospahte: A Chemical Hardness Approach. Tribol. Lett. 1999, 6, 1–8. [Google Scholar] [CrossRef]

- Spikes, H.A. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Spikes, H.A. The Formation of Zinc Dithiophosphate Antiwear Films. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2004, 218, 265–278. [Google Scholar]

- Zhang, J.; Ueda, M.; Campen, S.; Spikes, H. Boundary Friction of ZDDP Tribofilms. Tribol. Lett. 2021, 69, 8. [Google Scholar] [CrossRef]

- Kumar, D.; Jain, J.; Gosvami, N.N. In Situ Study of Role of Microstructure on Antiwear Tribofilm Formation on AZ91 Magnesium Alloy under Zinc Dialkyldithiophosphate Containing Lubricant. Adv. Eng. Mater. 2020, 22, 2000335. [Google Scholar] [CrossRef]

- Equey, S.; Roos, S.; Mueller, U.; Hauert, R.; Spencer, N.D.; Crockett, R. Tribofilm Formation from ZnDTP on Diamond-like Carbon. Wear 2008, 264, 316–321. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Mathia, T.G.; Bigerelle, M. Influence of roughness on ZDDP tribofilm formation in boundary lubricated fretting. Tribology 2012, 6, 182–188. [Google Scholar] [CrossRef]

- Nehme, G.; Mourhatch, R.; Aswath, P.B. Effect of Contact Load and Lubricant Volume on the Properties of Tribofilms Formed under Boundary Lubrication in a Fully Formulated Oil under Extreme Load Conditions. Wear 2010, 268, 1129–1147. [Google Scholar] [CrossRef]

- Tasdemir, H.A.; Tokoroyama, T.; Kousaka, H.; Umehara, N.; Mabuchi, Y. Influence of Zinc Dialkyldithiophosphate Tribofilm Formation on the Tribological Performance of Self-mated Diamond-like Carbon Contacts under Boundary Lubrication. Thin Solid Films 2014, 562, 389–397. [Google Scholar] [CrossRef]

- Dawczyk, J.; Morgan, N.; Russo, J.; Spikes, H. Film Thickness and Friction of ZDDP Tribofilms. Tribol. Lett. 2019, 67, 34. [Google Scholar] [CrossRef]

- Dias, L.C.; Pintaude, G.; Vittorino, A.A.O.F.; Costa, H.L. ZDDP Tribofilm Formation from a Formulated Oil on Textured Cylinder Liners. Lubricants 2022, 10, 118. [Google Scholar] [CrossRef]

- McQueen, J.S.; Gao, H.; Black, E.D.; Gangopadhyay, A.K.; Jensen, P.K. Friction and Wear of Tribofilms Formed by Zinc Dialkyl Dithiophosphate Antiwear Additive in Low Viscosity Engine Oils. Tribol. Int. 2005, 38, 289–297. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A. Understanding the Composition and Low Friction Tribofilm Formation/Removal in Boundary Lubrication. Tribol. Int. 2007, 40, 1696–1704. [Google Scholar] [CrossRef]

- Huynh, K.K.; Tieu, K.A.; Pham, S.T. Synergistic and Competitive Effects between Zinc Dialkyldithiophosphates and Modern Generation of Additives in Engine Oil. Lubricants 2021, 9, 35. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z. Experimental Investigation of ZnO Nanoparticles Effects on Thermophysical and Tribological Properties of Diesel Oil. Int. J. Hydrogen Energy 2020, 45, 23603–23614. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Righi, M.C.; Sumant, A.V.; Anasori, B.; Mochalin, V.N. Perspectives of 2D MXene Tribology. Adv. Mater. 2023, 35, 2207757. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Zhou, Y.; Sang, X.; Leonard, D.N.; Qu, J.; Poplawsky, J.D. Atom Probe Tomography Unveils Formation Mechanisms of Wear-Protective Tribofilms by ZDDP, Ionic Liquid, and Their Combination. ACS Appl. Mater. Interfaces 2017, 9, 23152–23163. [Google Scholar] [CrossRef]

- Zhou, Y.; Leonard, D.N.; Guo, W.; Qu, J. Understanding Tribofilm Formation Mechanisms in Ionic Liquid Lubrication. Sci. Rep. 2017, 7, 8426. [Google Scholar] [CrossRef] [PubMed]

- Minami, I.; Ichihashi, T.; Kubo, T.; Nanao, H.; Mori, S. Tribochemical Approach Toward Mechanism for Synergism of Lubricant Additives on Antiwear and Friction Reducing Properties. In Tribology and Interface Engineering Series; Dowson, D., Priest, M., Dalmaz, G., Lubrecht, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 48, pp. 259–268. [Google Scholar]

- Komvopoulos, K.; Do, V.; Yamaguchi, E.S.; Yeh, S.W.; Ryason, P.R. X-ray Photoelectron Spectroscopy Analysis of Antiwear Tribofilms Produced on Boundary-Lubricated Steel Surfaces from Sulfur- and Phosphorus-Containing Additives and Metal Deactivator Additive. Tribol. Trans. 2004, 47, 321–327. [Google Scholar] [CrossRef]

- Bovington, C. Friction, Wear and the Role of Additives in Controlling Them. In Chemistry and Technology of Lubricants; Mortier, R., Fox, M., Orszulik, S., Eds.; Springer: Dordrecht, Germany, 2010. [Google Scholar]

- Komvopoulos, K.; Pernama, S.A.; Yamaguchi, E.S.; Ryason, P.R. Friction Reduction and Antiwear Capacity of Oil Blends Containing Zinc Dialkyl Dithiophosphate and Molybdenum-Complex Additives. Tribol. Trans. 2006, 49, 151–165. [Google Scholar] [CrossRef]

- Minfray, C.; Martin, J.M.; Esnouf, C.; Le Mogne, T.; Kersting, R.; Hagenhoff, B. A Multi-technique Approach of Tribofilm Characterisation. Thin Solid Films 2004, 447–448, 272–277. [Google Scholar] [CrossRef]

- Costa, H.L.; Evangelista, K.S.; Cousseau, T.; Acero, J.S.R.; Kessler, F. Use of XANES and XPS to Investigate the Effects of Ethanol Contamination on Anti-wear ZDDP Tribofilms. Tribol. Int. 2021, 159, 106997. [Google Scholar] [CrossRef]

- Feng, W.; Song, H.; Lu, Z.; Yang, Z.; Hu, X. On the Mechanical and Tribological Performances of the Tribofilm Formed by Zinc Dialkyl Dithiophosphate. J. Ind. Eng. Chem. 2023, 122, 152–160. [Google Scholar] [CrossRef]

- Mourhatch, R.; Aswath, P.B. Nanoscale Properties of Tribofilms Formed with Zinc Dialkyl Dithiophosphate (ZDDP) under Extreme Pressure Condition. J. Nanosci. Nanotechnol. 2009, 9, 2682–2691. [Google Scholar] [CrossRef]

- Willermet, P.A. Some Engine Oil Additives and Their Effects on Antiwear Film Formation. Tribol. Lett. 1998, 5, 41–47. [Google Scholar] [CrossRef]

- Guerret-Piécourt, C.; Grossiord, C.; Le Mogne, T.; Martin, J.-M.; Palermo, T. Role of Complexation in the Interaction between Antiwear and Dispersant Additives in Lubricants. Lubr. Sci. 2001, 13, 201–218. [Google Scholar] [CrossRef]

- Kontou, A.; Taylor, R.I.; Spikes, H.A. Effects of Dispersant and ZDDP Additives on Fretting Wear. Tribol. Lett. 2021, 69, 6. [Google Scholar] [CrossRef]

- Benmansour, M.; Afanasie, P.; Galipaud, J.; Vacher, B.; Trillaud, V.; Joly-Pottuz, L.; Dassenoy, F. Influence of a Succinimide Dispersant on the Tribological Performance of MoS2 Nanoparticles. Tribol. Lett. 2024, 72, 15. [Google Scholar] [CrossRef]

- Wan, Y.; Suominen Fuller, M.L.; Kasrai, M.; Bancroft, G.M.; Fyfe, K.; Torkelson, J.R.; Hu, Y.F.; Tan, K.H. Effects of Detergent on the Chemistry of Tribofilms from ZDDP: Studied by X-ray Absorption Spectroscopy and XPS. Tribol. Ser. 2002, 40, 155–166. [Google Scholar]

- Gong, Y.; Morina, A.; Wang, C.; Wang, Y.; Tamura, Y.; Ishihara, A.; Ghanbarzadeh, A.; Neville, A. Experimental and Numerical Study on Wear Characteristics of Steel Surfaces Involving the Tribochemistry of a Fully Formulated Oil. Part I: Experiments. Tribol. Int. 2022, 176, 107888. [Google Scholar] [CrossRef]

- Tsai, A.E.; Komvopoulos, K. Dynamics of Tribofilm Formation in Boundary Lubrication Investigated Using In Situ Measurements of the Friction Force and Contact Voltage. Materials 2024, 17, 1335. [Google Scholar] [CrossRef]

- Umer, J.; Morris, N.J.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S.; Balakrishnan, S. Effect of Dispersant Concentration with Friction Modifiers and Anti-wear Additives on the Tribofilm Composition and Boundary Friction. ASME. J. Tribol. 2021, 143, 111901. [Google Scholar] [CrossRef]

- Zhang, J.; Yamaguchi, E.; Spikes, H. The Antagonism between Succinimide Dispersants and a Secondary Zinc Dialkyl Dithiophosphate. Tribol. Trans. 2014, 57, 57–65. [Google Scholar] [CrossRef]

- Masuko, M.; Ohkido, T.; Suzuki, A.; Ueno, T.; Okuda, S.; Sagawa, T. Effect of Ashless Dispersant on Deterioration of Antiwear Characteristics of ZnDTP due to Decomposition during the Oxidation Inhibition Process. Tribol. Trans. 2007, 50, 310–318. [Google Scholar] [CrossRef]

- Wollenberg, R.H.; Plavac, F.; Erdman, T.R. Modified Succinimides. U.S. Patent 4,612,132, 16 September 1986. [Google Scholar]

- Ruhe, W.R., Jr.; Stokes, C.D. Lubricating Oil Additive Composition and Method of Making the Same. U.S. Patent 0247386 A1, 2 November 2006. [Google Scholar]

- Kontou, A.; Southby, M.; Morgan, N.; Spikes, H.A. Influence of Dispersant and ZDDP on Soot Wear. Tribol. Lett. 2018, 66, 157. [Google Scholar] [CrossRef]

| Composition | Content (wt%) |

|---|---|

| Aromatics | 24.8 |

| Polars | 1.4 |

| Saturates | 73.8 |

| Insolubles | 0.0 |

| Analytical Data | |

| Element | Amount (ppm) |

| B | <1.8 |

| Ca | <0.9 |

| K | <2.6 |

| P | <6.1 |

| S | 4040 |

| Zn | <0.9 |

| N | 76.88 |

| Blend | Composition | Concentration (ppm) | |||

|---|---|---|---|---|---|

| N | P | Zn | S | ||

| 1 | base oil | – | – | – | 19 |

| 2 | base oil + 0.05 wt% ZDDP | 1.7 | 513 | 545 | 1042 |

| 3 | base oil + 0.08 wt% ZDDP | – | 803 | 868 | 1615 |

| 4 | base oil + 0.1 wt% dispersant A | 894 | – | – | 57 |

| 5 | base oil + 0.1 wt% dispersant B | 175 | – | – | 26.7 |

| 6 | base oil + 0.05 wt% ZDDP + 0.1 wt% dispersant A | 888 | 516 | 552 | 1102 |

| 7 | base oil + 0.05 wt% ZDDP + 0.1 wt% dispersant B | 175 | 519 | 551 | 1081 |

| Blend | Load (kg) | ||||

|---|---|---|---|---|---|

| 1.22 | 2.45 | 5.02 | 7.49 | 10.15 | |

| 1 | 7.86 ± 4.43 | −28.41 ± 41.46 | −163.05 ± 29.63 | −165.23 ± 46.17 | −233.53 ± 79.53 |

| 2 | 7.86 ± 1.87 | 10.28 ± 1.44 | 14.80 ± 6.63 | 14.77 ± 8.45 | 9.12 ± 8.01 |

| 3 | 5.72 ± 2.39 | 9.86 ± 4.20 | 14.04 ± 6.09 | 12.66 ± 6.31 | 11.72 ± 5.47 |

| 4 | 1.25 ± 1.57 | −4.63 ± 5.11 | −21.08 ± 15.59 | −58.61 ± 14.18 | −66.35 ± 13.82 |

| 5 | 2.71 ± 1.19 | −36.58 ± 16.65 | −64.76 ± 11.93 | −69.75 ± 10.33 | −132.32 ± 20.50 |

| 6 | 2.93 ± 1.23 | 3.58 ± 1.79 | 3.08 ± 1.38 | 5.35 ± 4.23 | 5.17 ± 5.33 |

| 7 | 3.02 ± 1.18 | 3.58 ± 2.32 | 9.38 ± 4.83 | 10.20 ± 6.87 | −17.88 ± 10.97 |

| Blend | Composition | Critical Load (kg) |

|---|---|---|

| 1 | base oil | ~2.45 |

| 2 | base oil + 0.05 wt% ZDDP | >10.15 |

| 3 | base oil + 0.08 wt% ZDDP | >10.15 |

| 4 | base oil + 0.1 wt% dispersant A | ~1.22 |

| 5 | base oil + 0.1 wt% dispersant B | ~1.22 |

| 6 | base oil + 0.05 wt% ZDDP + 0.1 wt% dispersant A | >10.15 |

| 7 | base oil + 0.05 wt% ZDDP + 0.1 wt% dispersant B | ~9.0 |

| Blend | Load (kg) (Mode) | Surface Location | Element Concentration (at%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Amine (N) | P | S | Sulfide | Sulfate | Fe | Zn | |||

| 1 | 1.22 | on-scar | 2.36 | 0.76 | 0.27 | − | 0.27 | 2.40 | − |

| off-scar | 2.94 | − | 0.62 | 0.15 | 0.47 | 4.74 | − | ||

| 2.45 (M1) | on-scar | 1.16 | 1.86 | 0.33 | 0.10 | 0.23 | 3.31 | 0.55 | |

| off-scar | 1.41 | − | 0.17 | 0.01 | 0.16 | 6.48 | 0.21 | ||

| 2.45 (M2) | on-scar | 0.47 | 0.63 | 0.10 | 0.01 | 0.09 | 7.60 | 0.15 | |

| off-scar | 0.58 | 0.15 | 0.10 | − | 0.10 | 9.27 | 0.13 | ||

| 2 | 1.22 | on-scar | 2.56 | 5.38 | 3.06 | 2.56 | 0.50 | 3.45 | 6.26 |

| off-scar | 1.00 | 0.87 | 0.93 | 0.36 | 0.57 | 6.96 | 4.31 | ||

| 10.15 (M1) | on-scar | 2.98 | 11.24 | 2.06 | 2.06 | − | − | 11.60 | |

| off-scar | 1.94 | 1.29 | 1.30 | 0.65 | 0.65 | 6.77 | 4.07 | ||

| 10.15 (M2) | on-scar | 2.85 | 10.07 | 2.56 | 2.51 | 0.05 | 0.82 | 9.66 | |

| off-scar | 1.39 | 0.77 | 1.07 | 0.48 | 0.59 | 6.66 | 2.50 | ||

| 3 | 1.22 | on-scar | 2.04 | 4.85 | 3.71 | 3.39 | 0.32 | 2.28 | 5.76 |

| off-scar | 1.67 | 0.40 | 0.93 | 0.46 | 0.47 | 4.37 | 1.91 | ||

| 10.15 | on-scar | 2.54 | 10.11 | 2.36 | 2.36 | 0.00 | 0.17 | 11.91 | |

| off-scar | 3.91 | 0.40 | 1.50 | 1.00 | 0.50 | 4.51 | 4.95 | ||

| 4 | 1.22 | on-scar | 2.84 | 0.94 | 0.46 | 0.07 | 0.39 | 6.96 | 0.16 |

| off-scar | 3.97 | − | 0.39 | 0.17 | 0.22 | 5.95 | − | ||

| 5 | 1.22 | on-scar | 1.38 | 0.99 | − | − | − | 3.56 | − |

| off-scar | 3.07 | 0.18 | − | − | − | 5.90 | − | ||

| 6 | 1.22 | on-scar | 2.68 | 2.30 | 2.40 | 2.27 | 0.13 | 3.69 | 5.51 |

| off-scar | 3.28 | 0.11 | 0.25 | − | 0.25 | 7.15 | 0.79 | ||

| 7.49 (M1) | on-scar | 4.87 | 11.40 | 6.39 | 6.19 | 0.20 | 0.58 | 0.47 | |

| off-scar | 5.17 | 0.41 | 0.56 | 0.12 | 0.44 | 2.62 | 0.14 | ||

| 7.49 (M2) | on-scar | 5.16 | 7.49 | 4.03 | 4.03 | − | 0.45 | 0.86 | |

| off-scar | 4.60 | 0.45 | 0.12 | 0.11 | 0.01 | 4.61 | 0.81 | ||

| 10.15 | on-scar | 4.44 | 8.41 | 3.96 | 3.84 | 0.12 | 0.92 | 2.40 | |

| off-scar | 5.37 | 0.31 | 1.01 | 0.64 | 0.37 | 4.06 | 0.64 | ||

| 7 | 1.22 | on-scar | 3.47 | 4.20 | 2.47 | 2.30 | 0.17 | 1.59 | 2.69 |

| off-scar | 2.24 | 0.43 | 0.32 | 0.12 | 0.20 | 4.77 | 0.91 | ||

| 7.49 (M1) | on-scar | 2.37 | 7.39 | 2.88 | 2.85 | 0.03 | 1.22 | 6.64 | |

| off-scar | 2.46 | 0.40 | 0.39 | 0.13 | 0.26 | 3.56 | 0.81 | ||

| 7.49 (M2) | on-scar | 1.50 | 8.34 | 2.98 | 2.77 | 0.21 | 1.36 | 12.53 | |

| off-scar | 1.38 | 0.16 | 0.15 | − | 0.15 | 8.83 | 1.79 | ||

| 10.15 (M1) | on-scar | 1.68 | 7.46 | 2.62 | 2.38 | 0.24 | 1.39 | 8.51 | |

| off-scar | 2.84 | 0.35 | 0.64 | 0.10 | 0.54 | 5.29 | 1.16 | ||

| 10.15 (M2) | on-scar | 1.58 | 7.94 | 2.62 | 2.48 | 0.14 | 2.15 | 8.48 | |

| off-scar | 2.69 | 0.44 | 0.95 | 0.31 | 0.64 | 3.99 | 1.56 | ||

| Blend | Load (kg) | Tribofilm Thickness (nm) |

|---|---|---|

| 1 | 1.22 | 80 |

| 2.45 (M1) | 240 | |

| 2.45 (M2) | 40 | |

| 2 | 1.22 | 160 |

| 10.15 (M1) | 230 | |

| 10.15 (M2) | 170 | |

| 3 | 1.22 | 110 |

| 10.15 | 230 | |

| 4 | 1.22 | 80 |

| 5 | 1.22 | 90 |

| 6 | 1.22 | 30 |

| 7.49 (M1) | 200 | |

| 7.49 (M2) | 220 | |

| 10.15 | 230 | |

| 7 | 1.22 | 80 |

| 7.49 (M1) | 240 | |

| 7.49 (M2) | 230 | |

| 10.15 (M1) | 140 | |

| 10.15 (M2) | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, A.E.; Komvopoulos, K. Wear Mechanisms, Composition and Thickness of Antiwear Tribofilms Formed from Multi-Component Lubricants. Materials 2024, 17, 2324. https://doi.org/10.3390/ma17102324

Tsai AE, Komvopoulos K. Wear Mechanisms, Composition and Thickness of Antiwear Tribofilms Formed from Multi-Component Lubricants. Materials. 2024; 17(10):2324. https://doi.org/10.3390/ma17102324

Chicago/Turabian StyleTsai, Anna E., and Kyriakos Komvopoulos. 2024. "Wear Mechanisms, Composition and Thickness of Antiwear Tribofilms Formed from Multi-Component Lubricants" Materials 17, no. 10: 2324. https://doi.org/10.3390/ma17102324

APA StyleTsai, A. E., & Komvopoulos, K. (2024). Wear Mechanisms, Composition and Thickness of Antiwear Tribofilms Formed from Multi-Component Lubricants. Materials, 17(10), 2324. https://doi.org/10.3390/ma17102324