Parameters of Concrete Modified with Micronized Chalcedonite

Abstract

:1. Introduction

- The coefficient k concept;

- The equivalent performance concept;

- The equivalent performance combination concept.

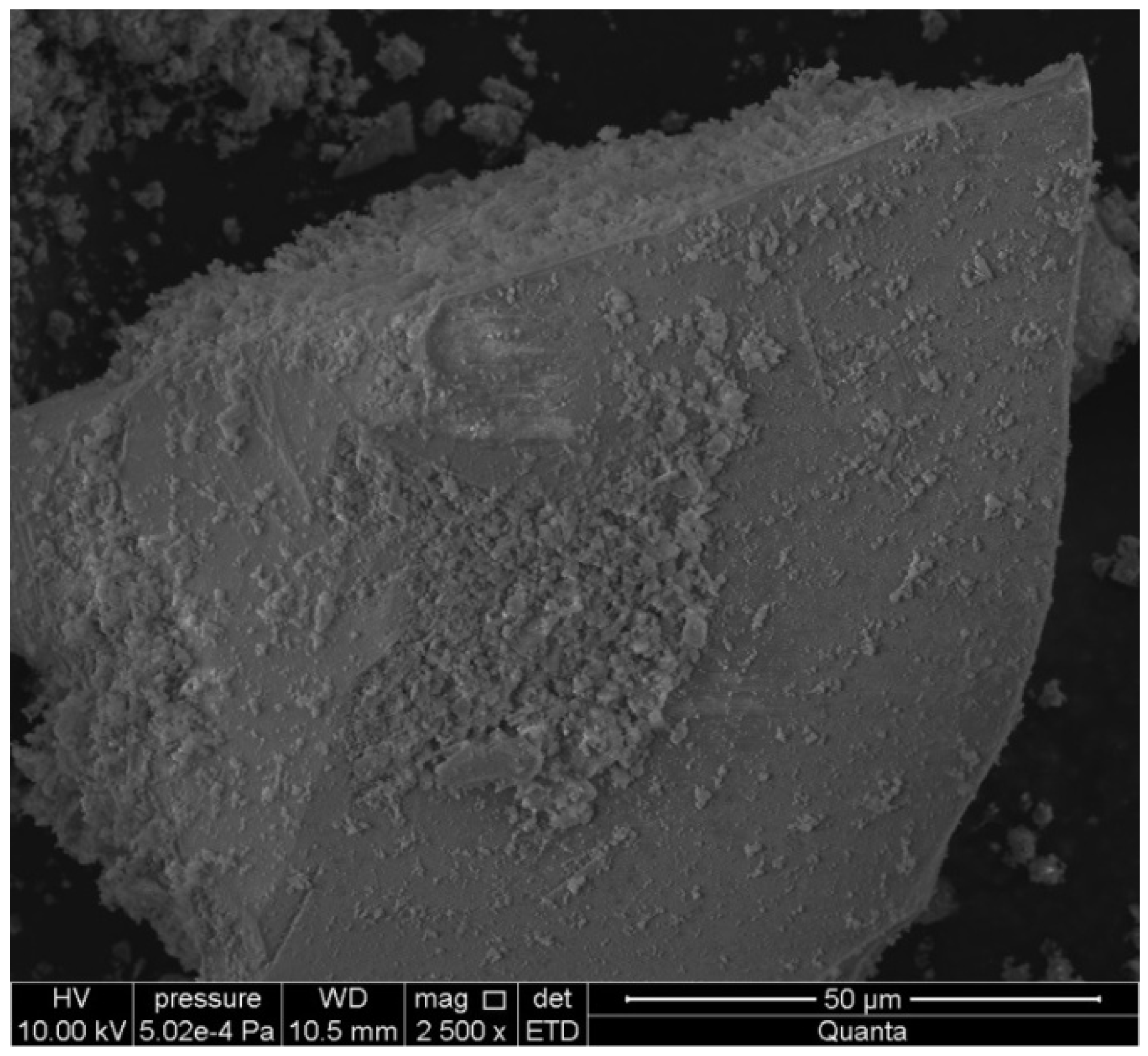

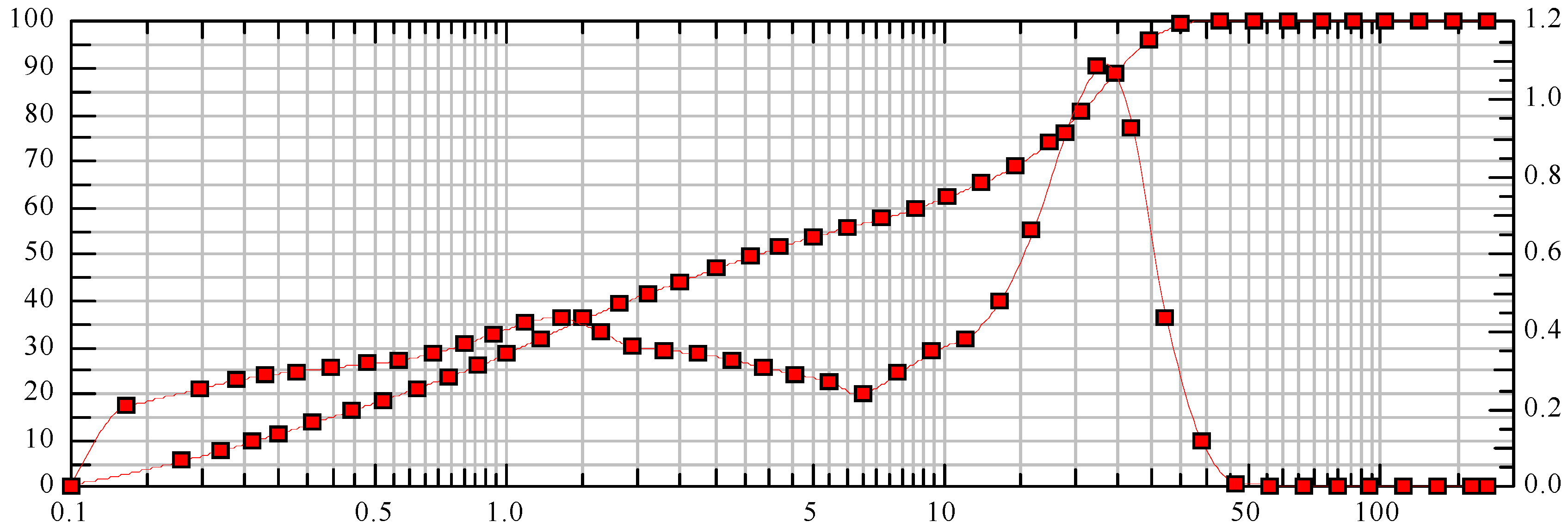

2. Materials and Methods

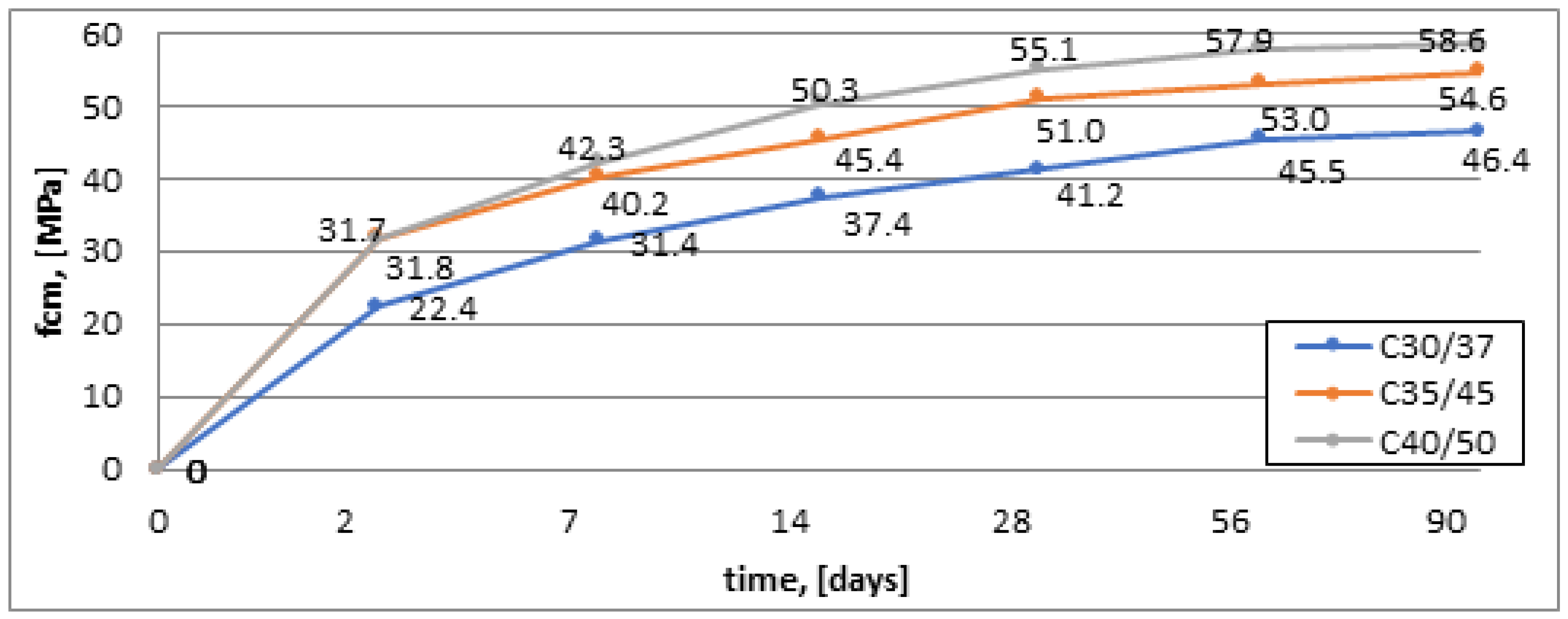

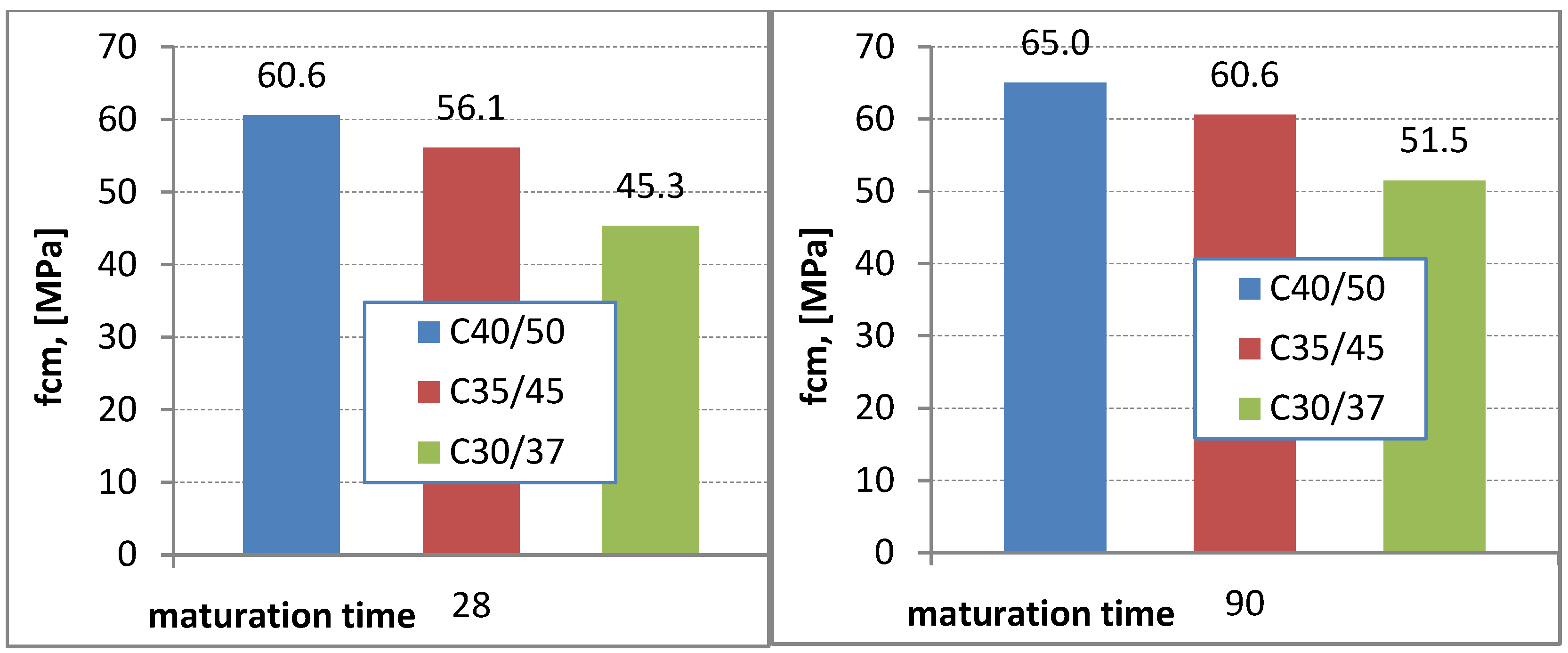

3. Results

4. Discussion

5. Conclusions

- Compressive strength: after 28 days of maturation, all three tested series of C30/37 (labeled as 1SW), C35/45 (labeled as 2SW), and C40/50 (labeled as 3SW) with the addition of chalcedonite dust achieved the assumed strength classes. The components of concrete mixtures were correctly designed. The addition of chalcedonite dust to the concrete mixture did not result in a decrease in compressive strength to such an extent that the analyzed series did not meet the normative requirements regarding concrete classes according to PN-EN 206+A1:2014, [11]. Comparing the compressive strength of the series with the addition of chalcedonite dust to those without it resulted in an average strength reduction of 10%.

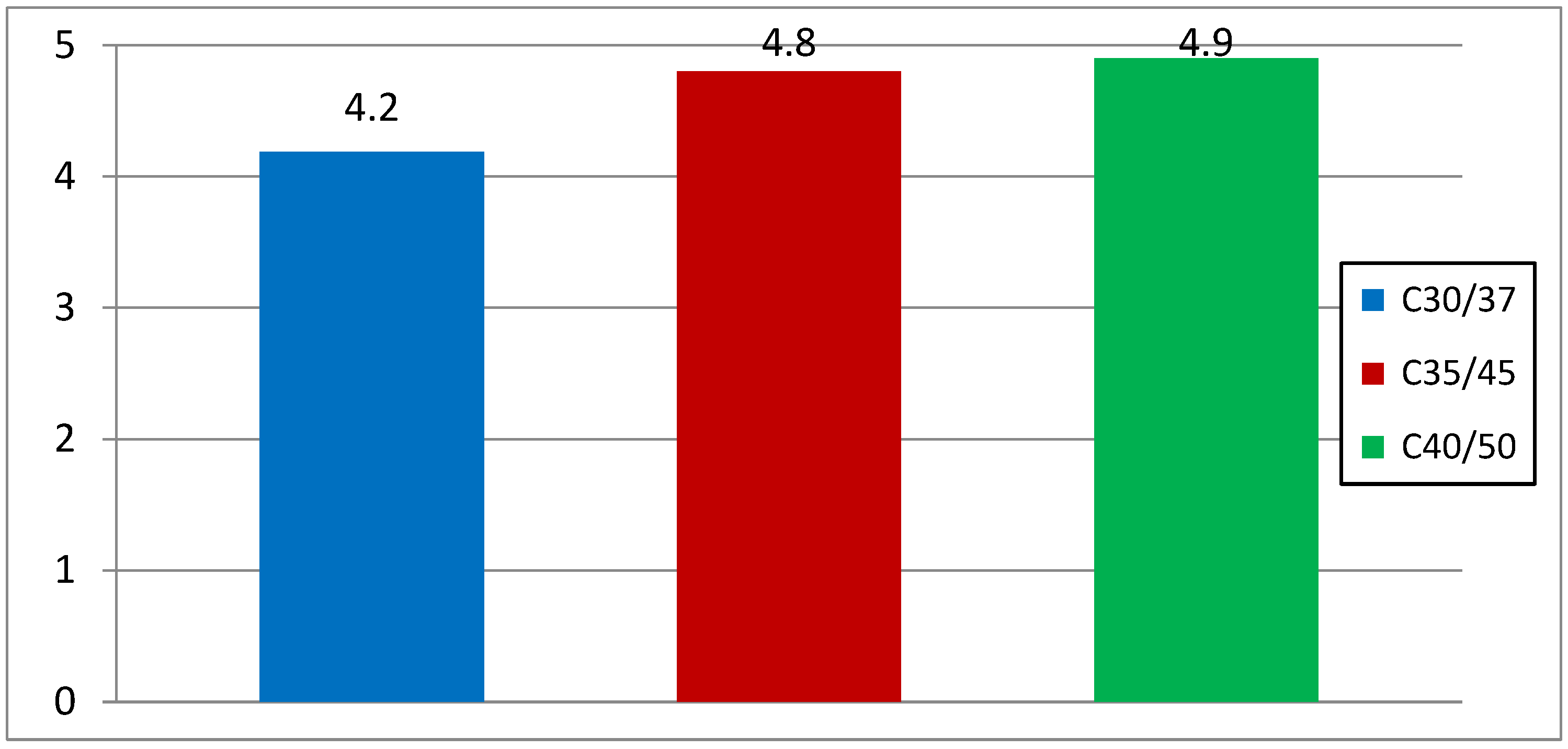

- Water absorption: the obtained results indicate water absorption below 5%. This means that the concretes made in laboratory conditions (precise dosing of components, known quality and strength parameters) are characterized by water absorption not exceeding 5% for series C30/37 (1SW), C35/45 (2SW), C40/50 (3SW) with the addition of chalcedonite dust.

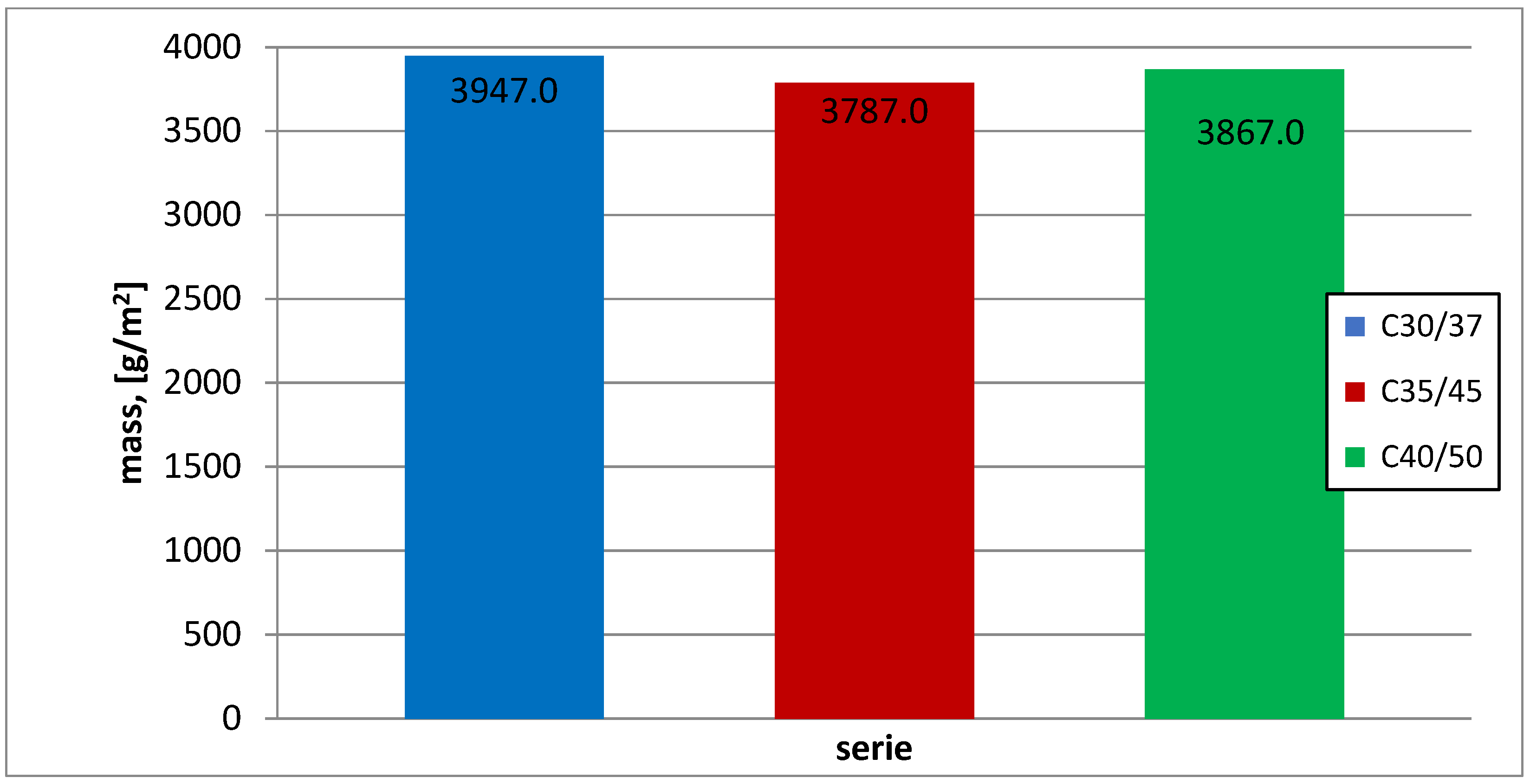

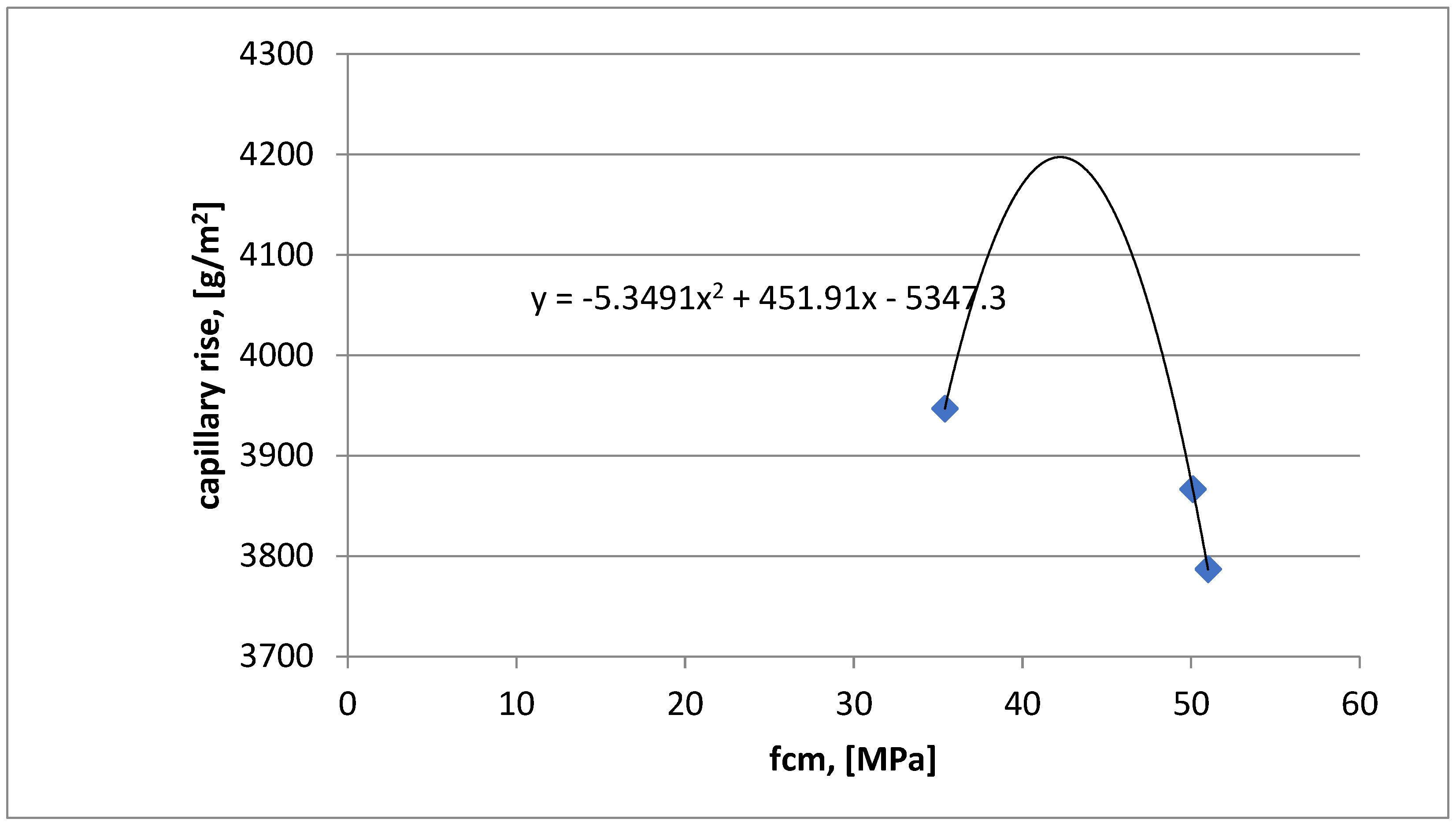

- Capillary absorption: the C30/35 (1SW), C35/37 (2SW), and C40/50 (3SW) concrete classes, with the addition of chalcedonite dust, achieved similar values.

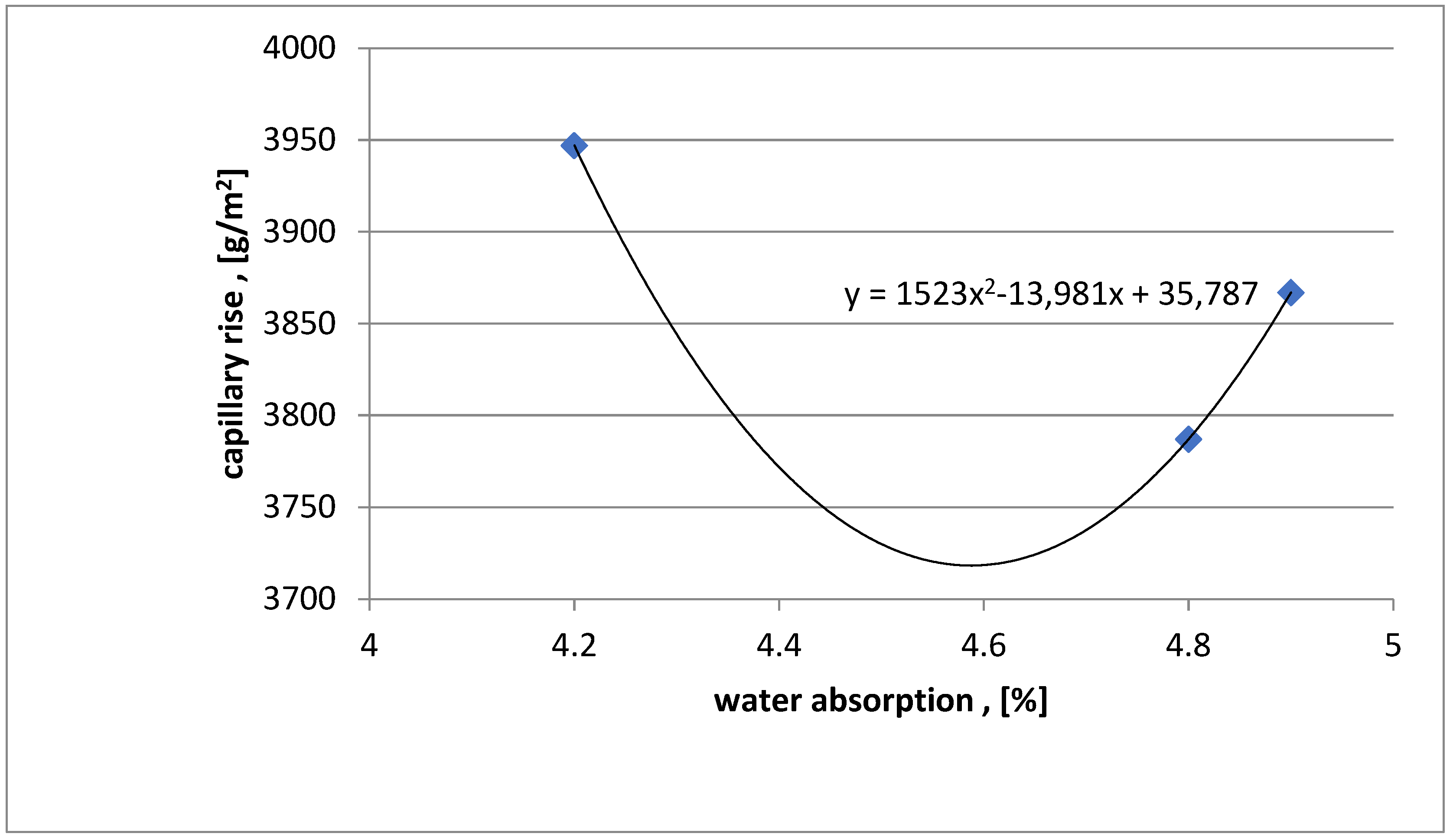

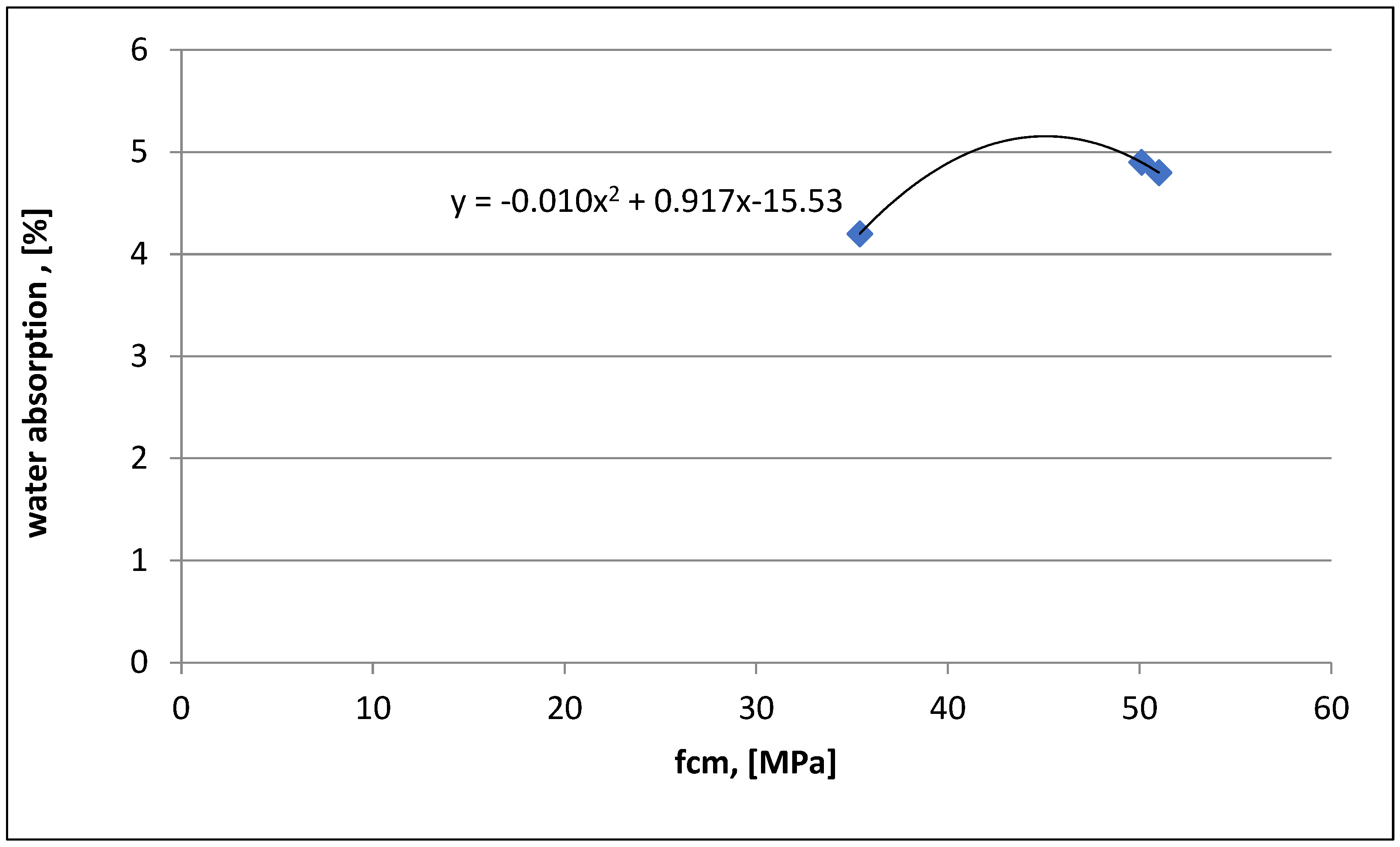

- Dependencies of compressive strength on water absorption or capillary absorption, as well as water absorption on capillary absorption, were developed for the three tested concrete classes C30/37 (1SW), C35/45 (2SW), C40/50 (3SW) with the addition of chalcedonite dust after 28 days of maturation.

- Based on the obtained laboratory test results, chalcedonite dust can be used as an additive to concrete in an amount of 15% of the cement mass. The use of chalcedonite dust as an additive to concrete could help solve the problem of storing and managing waste from chalcedonite aggregate production in Poland.

- Consideration should be given to attempting to develop general guidelines for the use of this additive in concrete mixtures in order to manage billions of tons of waste from broken chalcedonite aggregate mines. Disposing of waste in this way could help people protect their health from the adverse effects of inhaling airborne dust.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PN-EN 206+A1:2016; Beton. Wymagania Właściwości, Produkcja i Zgodność. Polski Komitet Normalizacyjny: Warsaw, Poland, 2016.

- Bajorek, G.; Gruszczyński, M. O potrzebie opracowania krajowych regulacji do normy PN-EN206:2014-04”. Mater. Bud. 2015, 8, 71. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M. Nowe dodatki mineralne do betonu. Civ. Environ. Eng. 2011, 2, 47–55. [Google Scholar]

- Wolska-Kotańska, C. Dodatki do betonu według normy europejskiej EN-206 Beton. Build. Res. Inst. Q. 2000, 4, 116. [Google Scholar]

- Neville, A. Właściwości Betonu; Wydawnictwo Polski Cement: Kraków, Poland, 2012. [Google Scholar]

- Wolska-Kotańska, C. Dodatki i domieszki do betonów wysokowartościowych. Cement–Wapno–Beton 1996, 12, 216–220. [Google Scholar]

- Ściślewski, Z.; Wojtowicz, M. The Influence of Silića Fume on Durability of Concrete and Reinforced Concrete. In Proceedings of the 7th Conference on Durability of Building Materials and Components, Stockholm, Sweden, 19–23 May 1996. [Google Scholar]

- Wolska-Kotańska, C. Zwiększenie szczelności betonu przez zastosowanie pyłów krzemionkowych. In Proceedings of the XVI Konferencja Naukowo—Techniczna, Jadwisin, Poland, 20–24 April 1998. [Google Scholar]

- Available online: www.dyckerhoff.pl (accessed on 15 September 2022).

- Mansour, M.S.M.; Abadlia, T.; Afalfi, A.; Ladaoui, W. Rhéologie du mortier et du béton contenant des ajouts minéraux. Cem. Wapno Beton 2013, 5, 264–270. [Google Scholar]

- Bobrowicz, J. Influence of reduced temperature and admixtures on hydration of cements. Cem. Wapno Beton 2016, 3, 177–190. [Google Scholar]

- Chatterjee, A.; Sui, T. Alternative fuels—Effects on clinker process and properties. Cem. Conr. Res. 2019, 123, 105777. [Google Scholar] [CrossRef]

- Łukawski, P. Domieszki Do Zapraw I Betonów, Polski Cement; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2008. [Google Scholar]

- Giergiczny, Z.; Synowiec, K.; Batog, M. Stosowanie dodatków typu II w składzie betonu wg normy PN-EN206: 2014. Mater. Bud. 2015, 10, 112–113. [Google Scholar] [CrossRef]

- PN-EN 450-1:2009; Popiół Lotny do Betonu—Część 1: Definicje, Specyfikacje i Kryteria Zgodności. Polski Komitet Normalizacyjny: Warsaw, Poland, 2009.

- Broszura Informacyjna “Beton wg Normy PN-EN206” Górażdże Cement; Wydawnictwo Polski Cement: Kraków, Poland, 2014.

- Małolepszy, J. Zastosowanie Dodatków Mineralnych w Produkcji Betonu Towarowego; Kwartalnik Polski Cement–Budownictwo-Technologie-Architektura; Wydawnictwo SPBT: Warsaw, Poland, 2022. [Google Scholar]

- Giergiczny, Z. Wymagania Graniczne Dotyczące Składu Betonu wg PN-EN 206-1 a Jego Trwałość, Materiały Szkoleniowe SPBT: Norma PN-EN 206-1 „Beton …”–Bez Tajemnic; Wydawnictwo Diecezjalne i Drukarnia w Sandomierzu: Sandomierz, Poland, 2006. [Google Scholar]

- Łukowski, P. Modyfikacja Materiałowa Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2016. [Google Scholar]

- Jaworska, B.; Sokołowska, J.; Łukowski, P.; Jaworski, J. Waste mineral powders as components of polymer—Cement composites. Arch. Civ. Eng. 2015, 61, 199–210. [Google Scholar] [CrossRef]

- EN197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- Wolska-Kotańska, C. Instrukcja ITB nr362/99 Stosowanie Pyłów Krzemionkowych do Wykonywania Betonów Narażonych na Działanie Wybranych Warunków Środowiskowych; ITB: Warsaw, Poland, 1999. [Google Scholar]

- Łukowski, P. Modyfikacja Materiałowa i jej Rola w Technologii Betonu—Spojrzenie z Perspektywy Dziesięciu Konferencji „Dni Betonu” “Dni Betonu” 2000–2018 Oraz Materiały Stowarzyszenia Producentów Chemii Budowlanej; Budownictwo Technologie Architektura: Kraków, Poland, 2019. [Google Scholar]

- Bjegovic, D.; Stirmer, N.; Serdar, M. Ecological aspects of concrete production. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2008. [Google Scholar]

- Kosior-Kazberuk, M.; Karwowska, J. Wybrane problemy zagospodarowania popiołów pochodzących ze spalania osadów ściekowych w technologii materiałów cementowych. Inżynieria Ekol. 2011, 25, 110–123. [Google Scholar]

- Giergiczny, E. Popiół lotny ze współspalania jako dodatek do cementu i betonu w aspekcie wymagań normowych i środowiskowych. In Proceedings of the W: Materiały XIV Międzynarodowej Konferencji “Popioły z energetyki”, Międzyzdroje, Poland, 24–25 May 2007. [Google Scholar]

- Karta Charakterystyki. Chalcednit Mikronizowany. Sekcja 1: Identyfikacja Substancji/Mieszaniny i Identyfikacja Spółk; Przedsiębiorstwa, Crusil: Warsaw, Poland, 2019.

- Bajorek, G. Pielęgnacja Betonu w Okresie Dojrzewania; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2017. [Google Scholar]

- PN-EN 197-1:2012; Cement—Część 1: Skład, Wymagania i Kryteria Zgodności Dotyczące Cementów Powszechnego Użytku. Polski Komitet Normalizacyjny: Warsaw, Poland, 2012.

- Spychał, E.; Kotwa, A. Evaluation of the possibility of using chalcedonite powder asa component of mortars. Struct. Environ. 2022, 14, 119–125. [Google Scholar] [CrossRef]

- Kotwa, A.; Spychał, E. Influence of mineral additives on concrete properties. Struct. Environ. 2016, 8, 15–20. [Google Scholar]

- Dachowski, R.; Komisarczyk, K. Study of physical and chemical properties of lime—Sand products modified with diabase aggregate and chalcedonite powder. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 1–8. [Google Scholar] [CrossRef]

- Vyšvařil, M.; Krebs, M.; Bayer, P. The use of chalcedonite powder as an additive in lime mortars. In Proceedings of the REHABEND 2022, Building Pathology, Rehabilitation Technology and Heritage Management, Granada, Spain, 13–16 September 2022; pp. 1314–1320. [Google Scholar]

- Kamiński, M.; Bywalski, C.; Kaźmierowski, M. Badania wytrzymałości na ściskanie betonów wysokowartościowych z dodatkiem włókien stalowych. Mater. Bud. 2015, 6, 72–73. [Google Scholar] [CrossRef]

- Aitcin, P.C. High—Performance Concrete; E&FNSpon: London, UK, 1998. [Google Scholar]

- Kaszyńska, M. Kinetyka Wydzielania Ciepła a Zmiany Wytrzymałości Twardniejącego Betonu z Popiołem Lotnym w Konstrukcjach Masywnych. Ph.D. Thesis, UAM, Szczecin, Poland, 1989. [Google Scholar]

- Nowak-Michta, A. Modele wytrzymałościowe betonu z dodatkiem popiołu lotnego. In Proceedings of the 20 Konferencja Naukowo—Techniczna Beton i Prefabrykacja, Jadwisin, Poland, 17–19 May 2006. [Google Scholar]

- Oner, M.; Erdogu, K.; Gunulu, A. Effect of components fineness on strength of blast furnace slag cement. Cem. Concr. Res. 2003, 33, 463–469. [Google Scholar] [CrossRef]

- PN-EN 12350-2:2011; Badanie Mieszanki Betonowej—Część 2: Badanie Konsystencji Metodą Opadu Stożka. Polski Komitet Normalizacyjny: Warsaw, Poland, 2011.

- PN-EN88/B-06259; Beton Zwykły. Polski Komitet Normalizacyjny: Warsaw, Poland, 1988.

- PN-EN 12390-3:2011; Badania Betonu—Część 3: Wytrzymałość Naściskanie Próbek do Badań. Polski Komitet Normalizacyjny: Warsaw, Poland, 2012.

| Chemical Compound | Elemental Content, [%] |

|---|---|

| F | 0.06 |

| NA2O | 0.09 |

| MgO | 0.15 |

| Al2O3 | 3.04 |

| SiO2 | 91.8 |

| P2O5 | 0.04 |

| SO3 | 0.05 |

| K2O | 0.42 |

| CaO | 0.45 |

| TiO2 | 0.11 |

| Fe2O3 | 1.28 |

| ZrO2 | 0.01 |

| BaO | 0.04 |

| Component, (kg/m3) | Serie 1 | Serie 2 | Serie 3 | Serie 1SW | Serie 2SW | Serie 3SW |

|---|---|---|---|---|---|---|

| Cement CEM I 42.5R | 420 | 440 | 460 | 483 | 506 | 529 |

| Chalcedonite dust | 63 | 66 | 69 | --- | --- | --- |

| Water | 156 | 164 | 173 | 156 | 164 | 173 |

| Chalcedonite sand 0/2 mm | 680 | 600 | 600 | 680 | 600 | 600 |

| Dolomit 2/8 mm | 600 | 500 | 530 | 600 | 500 | 530 |

| Dolomit 8/16 mm | 650 | 700 | 680 | 650 | 700 | 680 |

| Plasticizing admixture | 1.82 | 1.82 | 1.82 | 1.79 | 1.79 | 1.79 |

| Sealing admixture | 4.1 | 4.1 | 4.1 | 4.0 | 4.0 | 4.0 |

| Aerating admixture | 2.72 | 2.72 | 2.72 | 2.7 | 2.7 | 2.7 |

| No. | Cement Type | Chemical Composition, % | Blaine | Resistance, MPa | |||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | MgO | Fe2O3 | Al2O3 | cm2/g | R2 | R28 | ||

| 1 | CEM I 42.5R | 19.49 | 62.3 | 2.08 | 3.25 | 4.75 | 4053 | 32.0 | 53.0 |

| Series Name | Volumetric Density, (kg/m3) |

|---|---|

| series 1 | 2374 |

| series 2 | 2392 |

| series 3 | 2408 |

| series 1SW | 2414 |

| series 2SW | 2437 |

| series 3SW | 2493 |

| Series Name | Air Content, (%) |

|---|---|

| series 1 | 7.0 |

| series 2 | 7.2 |

| series 3 | 7.3 |

| series 1SW | 6.9 |

| series 2SW | 7.0 |

| series 3SW | 7.4 |

| Series | Conditions | Value | Criterion fulfilled |

| Criterion 1 | fcm ≥ fck + 4 | 41.2 | YES |

| Criterion 2 | fci ≥ fck−4 | 41.1 | YES |

| Conclusions: The tested concrete meets the compressive strength requirements for class C30/37 according to PN-EN 206-A1:2016 | |||

| Value | Criterion fulfilled | ||

| Criterion 1 | fcm ≥ fck + 4 | 51.0 | YES |

| Criterion 2 | fci ≥ fck − 4 | 50.2 | YES |

| Conclusions: The tested concrete meets the compressive strength requirements for class C35/45 according to PN-EN 206-A1:2016 | |||

| Value | Criterion fulfilled | ||

| Criterion 1 | fcm ≥ fck + 4 | 55.1 | YES |

| Criterion 2 | fci ≥ fck − 4 | 54.7 | YES |

| Conclusions: The tested concrete meets the compressive strength requirements for class C40/50 according to PN-EN 206-A1:2016 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotwa, A.; Ramiączek, P.; Bąk-Patyna, P.; Kowalik, R. Parameters of Concrete Modified with Micronized Chalcedonite. Materials 2023, 16, 3602. https://doi.org/10.3390/ma16093602

Kotwa A, Ramiączek P, Bąk-Patyna P, Kowalik R. Parameters of Concrete Modified with Micronized Chalcedonite. Materials. 2023; 16(9):3602. https://doi.org/10.3390/ma16093602

Chicago/Turabian StyleKotwa, Anna, Piotr Ramiączek, Paulina Bąk-Patyna, and Robert Kowalik. 2023. "Parameters of Concrete Modified with Micronized Chalcedonite" Materials 16, no. 9: 3602. https://doi.org/10.3390/ma16093602

APA StyleKotwa, A., Ramiączek, P., Bąk-Patyna, P., & Kowalik, R. (2023). Parameters of Concrete Modified with Micronized Chalcedonite. Materials, 16(9), 3602. https://doi.org/10.3390/ma16093602