Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

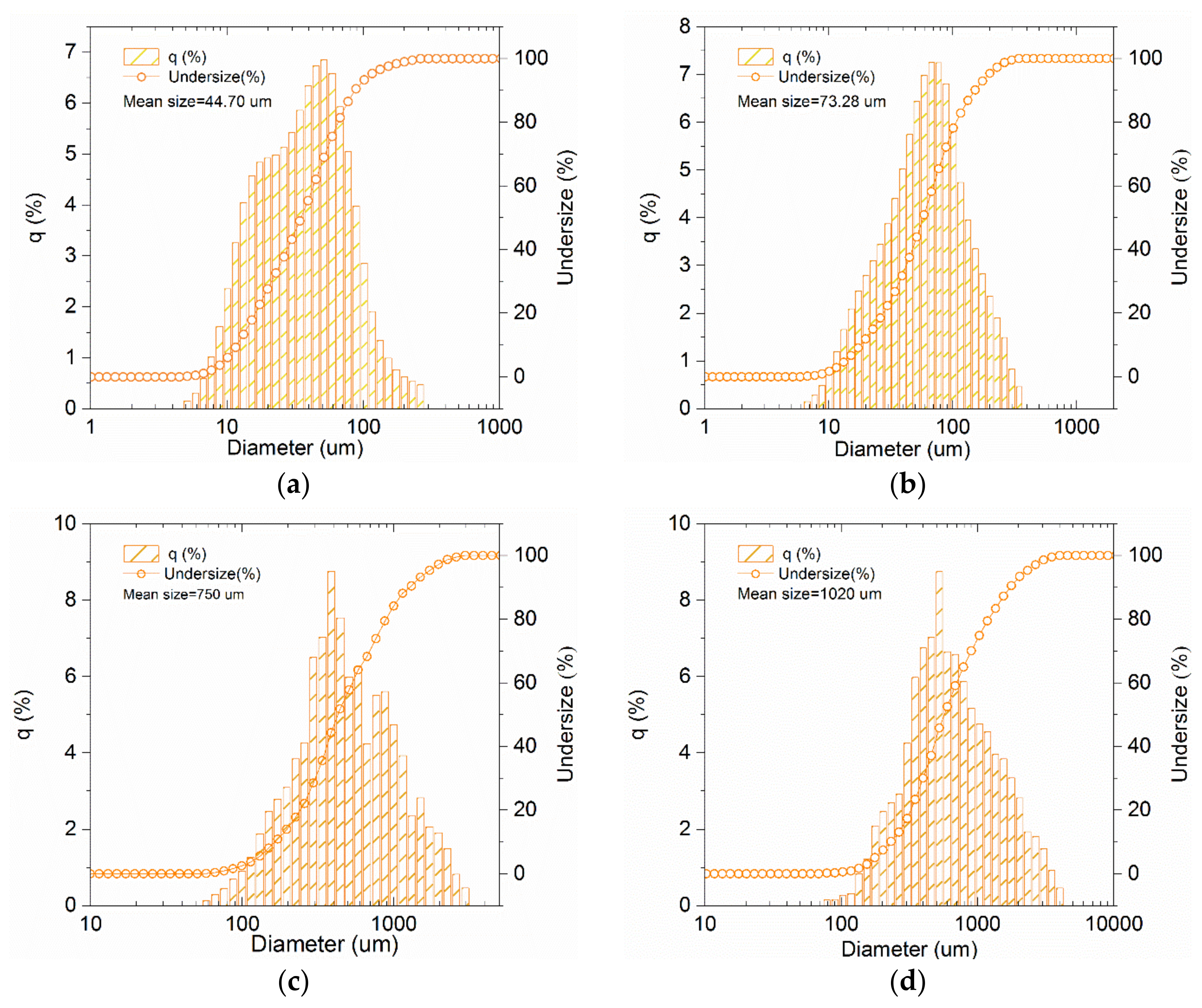

2.2. Preparation of Biochar

2.3. Design and Preparation of Specimens

2.4. Test Methods

3. Results and Discussion

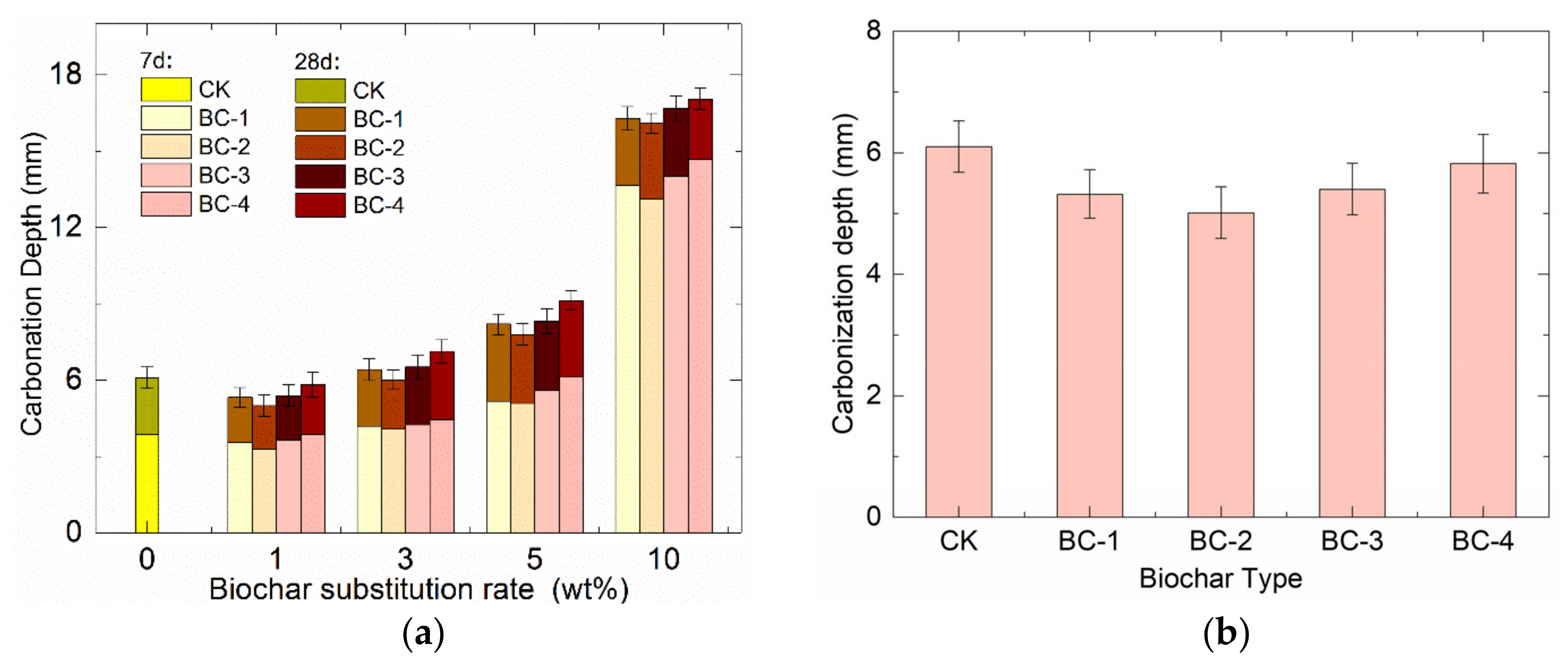

3.1. Effect on the Carbonation Depth of Concrete

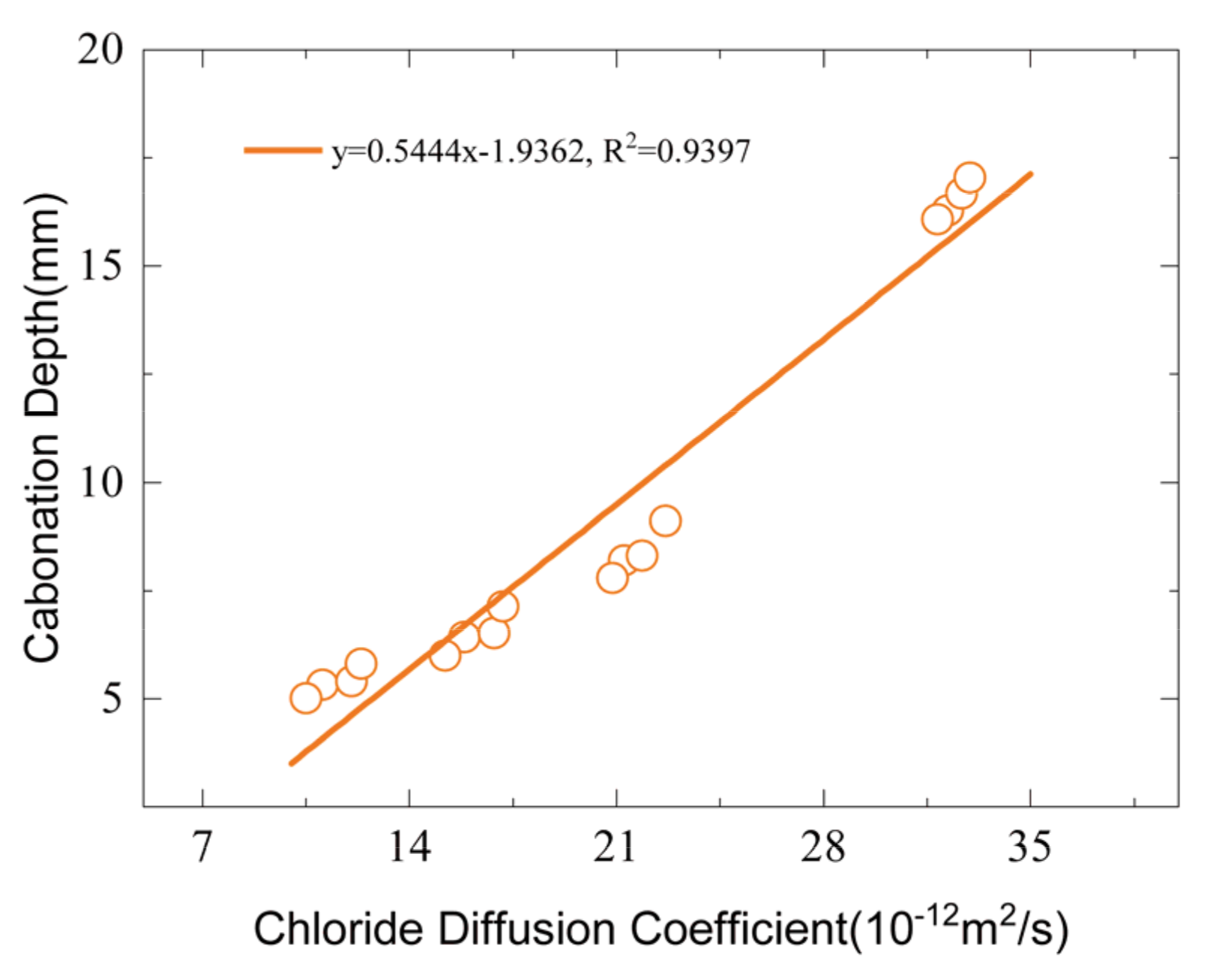

3.2. Effect on the Chloride Diffusion Coefficient of Concrete

3.3. Effect on Compressive and Flexural Strength of Concrete

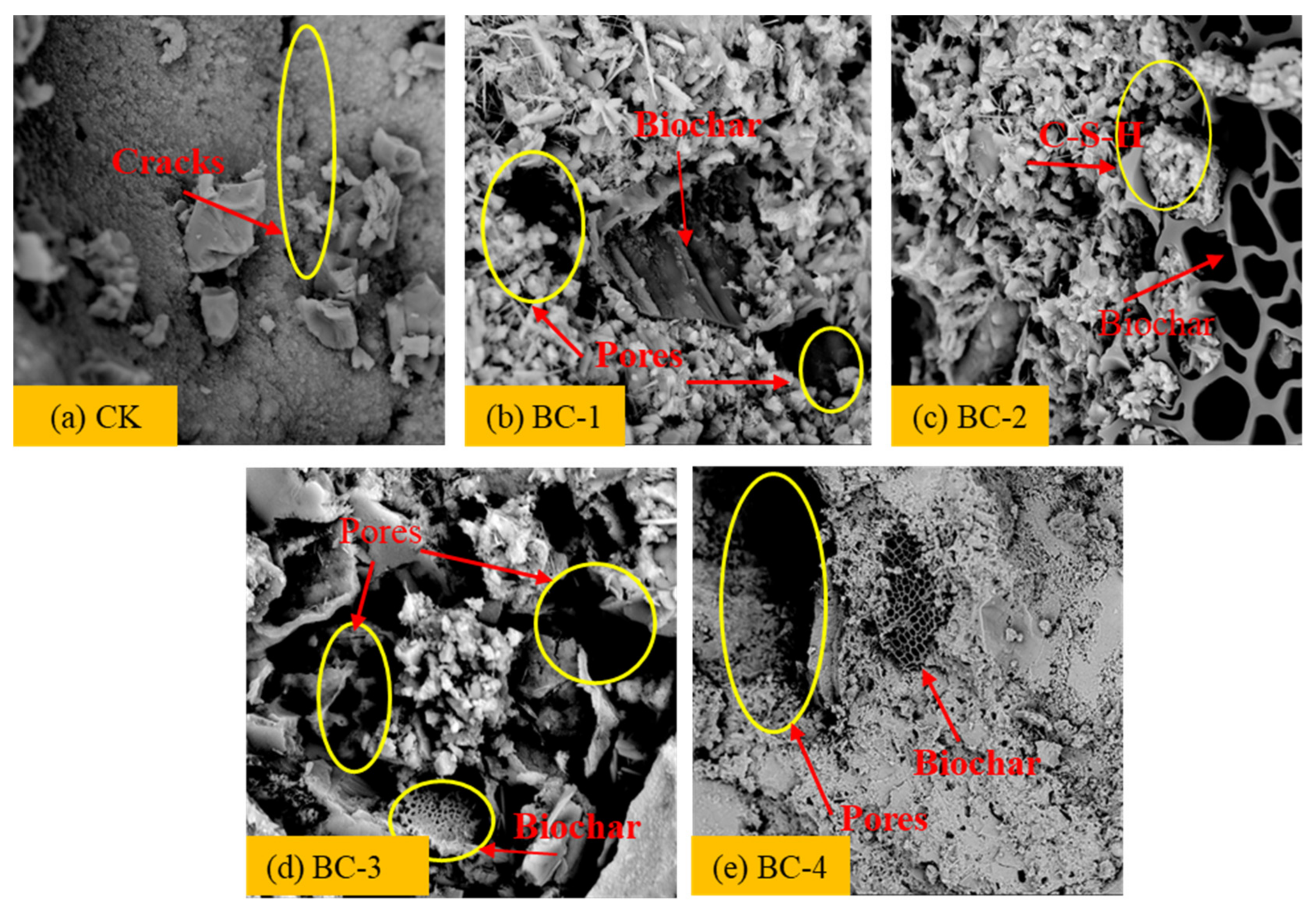

3.4. SEM Analysis

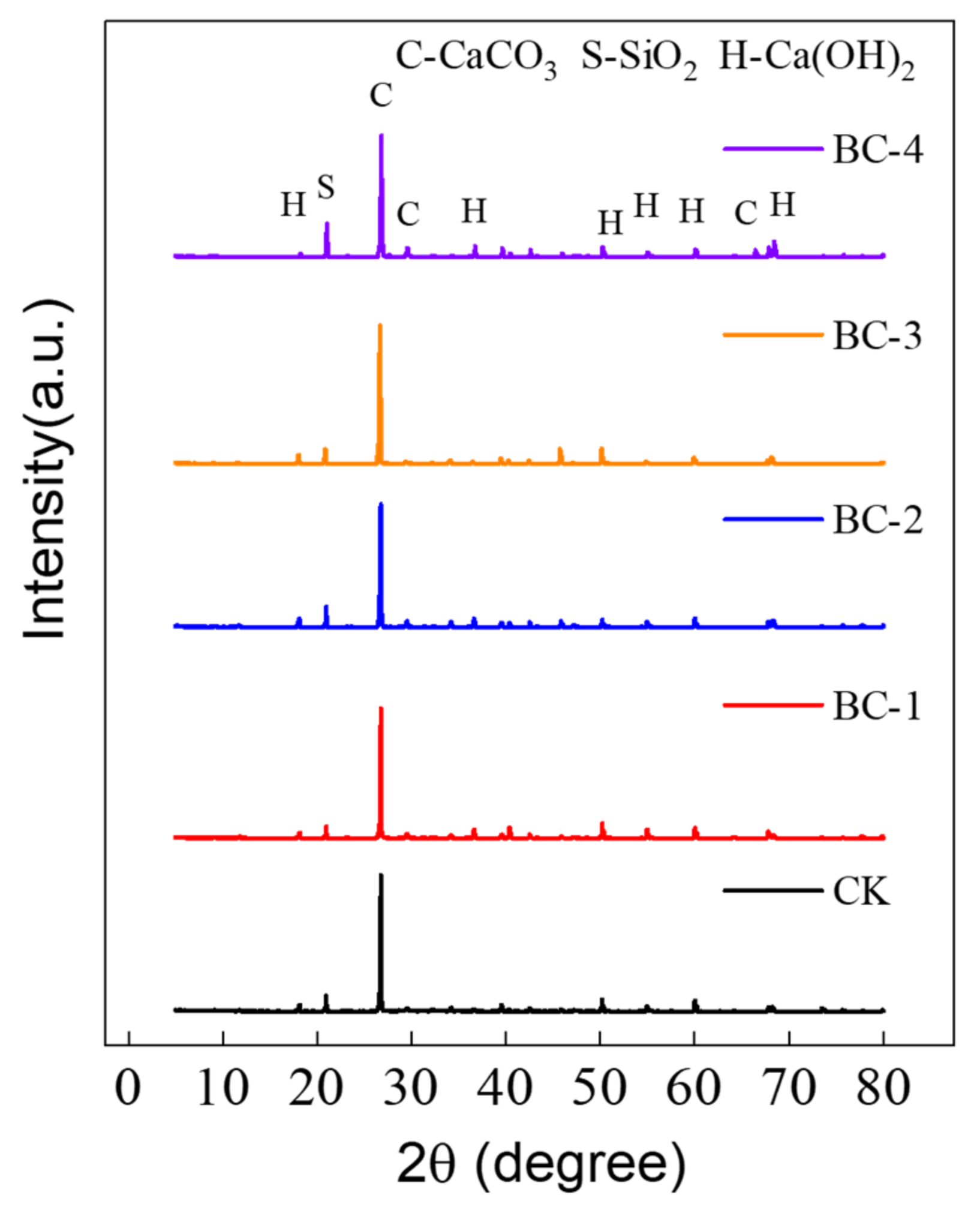

3.5. XRD Analysis

4. Conclusions

- Increasing biochar fineness initially led to a decrease in rapid carbonation depth and chloride diffusion coefficient, followed by an increase. Adding 1–3% biochar resulted in the rapid carbonation depth and chloride diffusion coefficient of concrete decreasing by a maximum of 17.9% and 32%, respectively.

- The compressive and flexural strength of concrete increased and then decreased as the replacement rate of BC increases. When the content was less than 5%, the strength of biochar concrete was not lower than that of the control group. Of all the biochar fineness levels tested, BC-2 exhibited the most significant improvement in the strength of concrete.

- SEM and XRD analyses demonstrated that the addition of biochar enhanced the microstructure of concrete by facilitating additional nucleation sites for cement hydration and filling internal pores, ultimately leading to a more uniform and dense composition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, T.; Ng, S.T.; Chen, J. Deciphering the CO2 emissions and emission intensity of cement sector in China through decomposition analysis. J. Clean. Prod. 2022, 352, 131627. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of biochars produced from pyrolysis of pelletized agricultural residues. Renew. Sustain. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.; Wang, L.; Yan, J.; Ma, B.; Zhu, X.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C. Biochar as construction materials for achieving carbon neutrality. BioChar 2022, 4, 59. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Wang, J. Evaluation of the properties and carbon sequestration potential of biochar-modified pervious concrete. Constr. Build. Mater. 2022, 314, 125648. [Google Scholar] [CrossRef]

- Javed, M.H.; Sikandar, M.A.; Ahmad, W.; Bashir, M.T.; Alrowais, R.; Wadud, M.B. Effect of various biochars on physical, mechanical, and microstructural characteristics of cement pastes and mortars. J. Build. Eng. 2022, 57, 104850. [Google Scholar]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A. Utilization of biochar from unwashed peanut shell in cementitious building materials—Effect on early age properties and environmental benefits. Fuel Process. Technol. 2021, 218, 106841. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.; Pang, S. Biochar-mortar composite: Manufacturing, evaluation of physical properties and economic viability. Constr. Build. Mater. 2018, 167, 874–889. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.; Koh, H. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kua, H.; Pang, S. Healing cement mortar by immobilization of bacteria in biochar: An integrated approach of self-healing and carbon sequestration. Cem. Concr. Compos. 2018, 86, 238–254. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Khushnood, R.A.; Ahmad, S.; Restuccia, L.; Spoto, C.; Jagdale, P.; Tulliani, J.M.; Ferro, G.A. Carbonized nano/microparticles for enhanced mechanical properties and electromagnetic interference shielding of cementitious materials. Front. Struct. Civ. Eng. 2016, 10, 209–213. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.; Lee, J. Mechanical properties of mortar containing bio-char from pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar]

- Tan, K.; Qin, Y.; Du, T.; Li, L.; Zhang, L.; Wang, J. Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr. Build. Mater. 2021, 287, 123078. [Google Scholar] [CrossRef]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Tan, K.H.; Wang, T.Y.; Zhou, Z.H.; Qin, Y.H. Biochar as a partial cement replacement material for developing sustainable concrete: An overview. J. Mater. Civ. Eng. 2021, 33, 03121001. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Dai Pang, S.; Kua, H.W. Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Tan, K.; Wang, J. Substrate modified with biochar improves the hydrothermal properties of green roofs. Environ. Res. 2023, 216, 114405. [Google Scholar] [CrossRef] [PubMed]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. General Administration of Quality Supervision, Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Guo, S.; Li, Y.; Wang, Y.; Wang, L.; Sun, Y.; Liu, L. Recent advances in biochar-based adsorbents for CO2 capture. Carbon Capture Sci. Technol. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Dissanayake, P.D.; You, S.; Igalavithana, A.D.; Xia, Y.; Bhatnagar, A.; Gupta, S.; Kua, H.W.; Kim, S.; Kwon, J.H.; Tsang, D.C.; et al. Biochar-based adsorbents for carbon dioxide capture: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109582. [Google Scholar] [CrossRef]

- Iu, J.; Liu, G.; Zhang, W.; Li, Z.; Xing, F.; Tang, L. Application potential analysis of biochar as a carbon capture material in cementitious composites: A review. Constr. Build. Mater. 2022, 350, 128715. [Google Scholar]

- Gupta, S. Carbon sequestration in cementitious matrix containing pyrogenic carbon from waste biomass: A comparison of external and internal carbonation approach. J. Build. Eng. 2021, 43, 102910. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.-Y. Hydration-strength-durability-workability of biochar-cement binary blends. J. Build. Eng. 2021, 42, 103064. [Google Scholar] [CrossRef]

- Gupta, S.; Muthukrishnan, S.; Kua, H.W. Comparing influence of inert biochar and silica rich biochar on cement mortar–Hydration kinetics and durability under chloride and sulfate environment. Constr. Build. Mater. 2021, 268, 121142. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, Q.; Chen, X.; Xing, F.; Han, N.; He, Y.; Ma, Y. Understanding the interacted mechanism between carbonation and chloride aerosol attack in ordinary Portland cement concrete. Cem. Concr. Res. 2017, 95, 217–225. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Hu, H.; He, C.; Song, L.; Huang, W. Pore structure and durability of green concrete containing recycled powder and recycled coarse aggregate. J. Build. Eng. 2022, 53, 104584. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Choren, J.A.; Heinrich, S.M.; Silver-Thorn, M.B. Young’s modulus and volume porosity relationships for additive manufacturing applications. J. Mater. Sci. 2013, 48, 5103–5112. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of biochar addition on long-term behavior of concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Zeng, S.; Kan, E. Sustainable use of Ca(OH)2 modified biochar for phosphorus recovery and tetracycline removal from water. Sci. Total Environ. 2022, 839, 156159. [Google Scholar] [CrossRef] [PubMed]

| Chemical Composition (%) | Physical Properties | ||

|---|---|---|---|

| CaO | 63.57 | Specify Gravity (g/cm3) | 3.16 |

| SiO2 | 20.03 | Blaine Specific Surface (cm2/g) | 4650 |

| Al2O3 | 6.26 | Initial Setting (min) | 165 |

| Fe2O3 | 2.59 | Final Setting (min) | 254 |

| MgO | 2.68 | Compressive Strength (MPa) | - |

| Na2O and K2O | 0.95 | 3 d | 20.8 |

| MnO | 0.33 | 28 d | 47.6 |

| SO3 | 2.01 | Flexural Strength (MPa) | - |

| P2O5 | - | 3 d | 4.4 |

| LOI | 1.80 | 28 d | 8.6 |

| Sample | Cement (kg/m3) | Sand (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Biochar (kg/m3) | Biochar Alternative Cement Ratio (wt%) |

|---|---|---|---|---|---|---|

| CK | 433 | 611.05 | 1134.82 | 195 | 0 | 0 |

| BC-1/2/3/4 | 428.67 | 611.05 | 1134.82 | 193.05 | 4.33 | 1 |

| 420.01 | 611.05 | 1134.82 | 189.15 | 12.99 | 3 | |

| 411.35 | 611.05 | 1134.82 | 185.25 | 21.65 | 5 | |

| 398.36 | 611.05 | 1134.82 | 179.4 | 34.64 | 8 |

| Property | Standard Followed | Remarks |

|---|---|---|

| Concrete carbonation depth | GB/t 50082-2009 [22] | The sample size was 150 × 150 × 150 mm3 |

| Concrete chloride diffusion coefficient | ||

| Compressive strength | GB/T 50081-2016 [23] | |

| Flexural strength | The flexural strength was tested using a four-point loading method on beam specimens with dimensions of 100 × 100 × 400 mm3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials 2023, 16, 2809. https://doi.org/10.3390/ma16072809

Ling Y, Wu X, Tan K, Zou Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials. 2023; 16(7):2809. https://doi.org/10.3390/ma16072809

Chicago/Turabian StyleLing, Yifu, Xionghua Wu, Kanghao Tan, and Zhenjie Zou. 2023. "Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete" Materials 16, no. 7: 2809. https://doi.org/10.3390/ma16072809

APA StyleLing, Y., Wu, X., Tan, K., & Zou, Z. (2023). Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials, 16(7), 2809. https://doi.org/10.3390/ma16072809