SiC Nanoparticles Strengthened Alumina Ceramics Prepared by Extrusion Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Ceramic Slurry

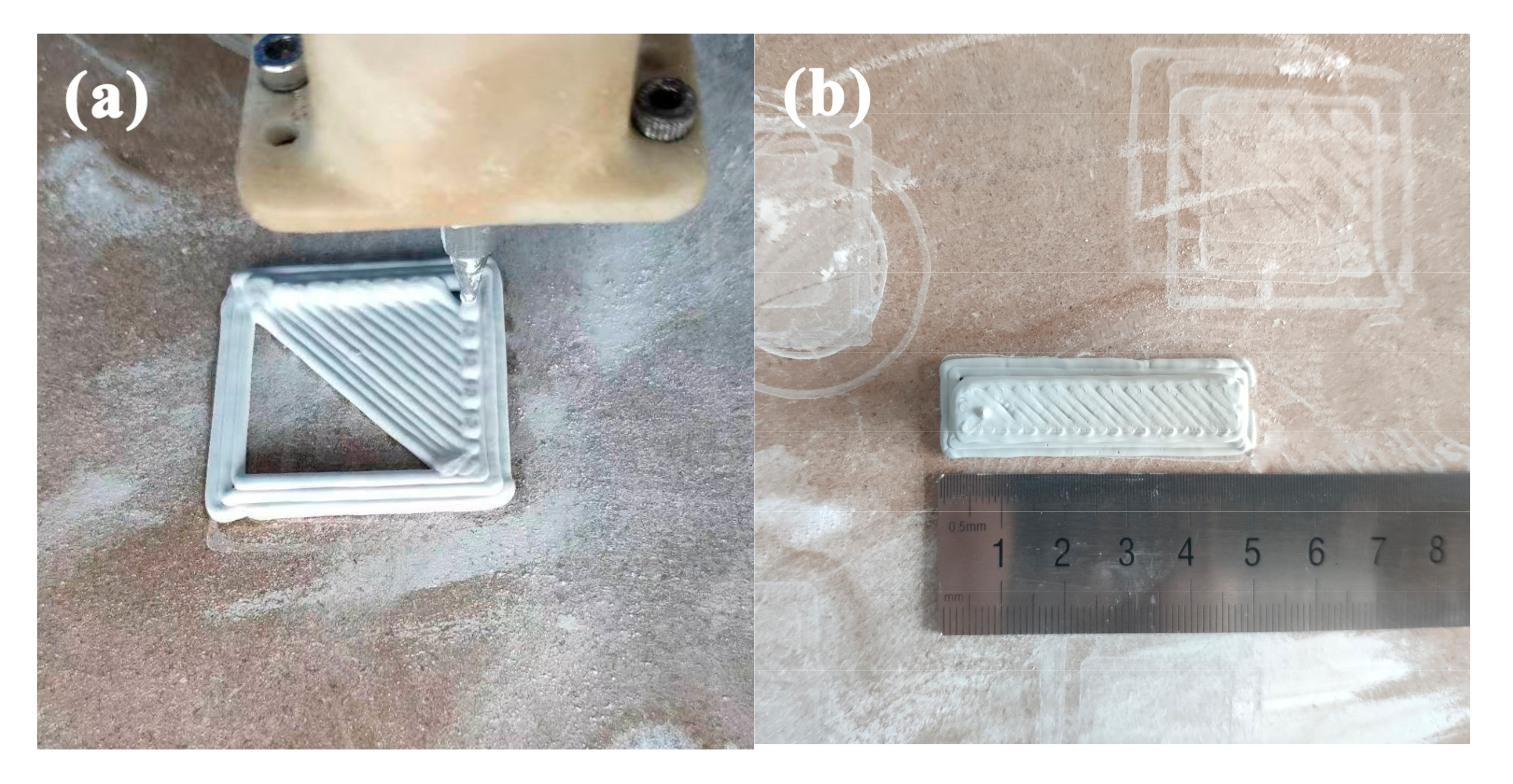

2.3. 3D printing of the Ceramic Green Body

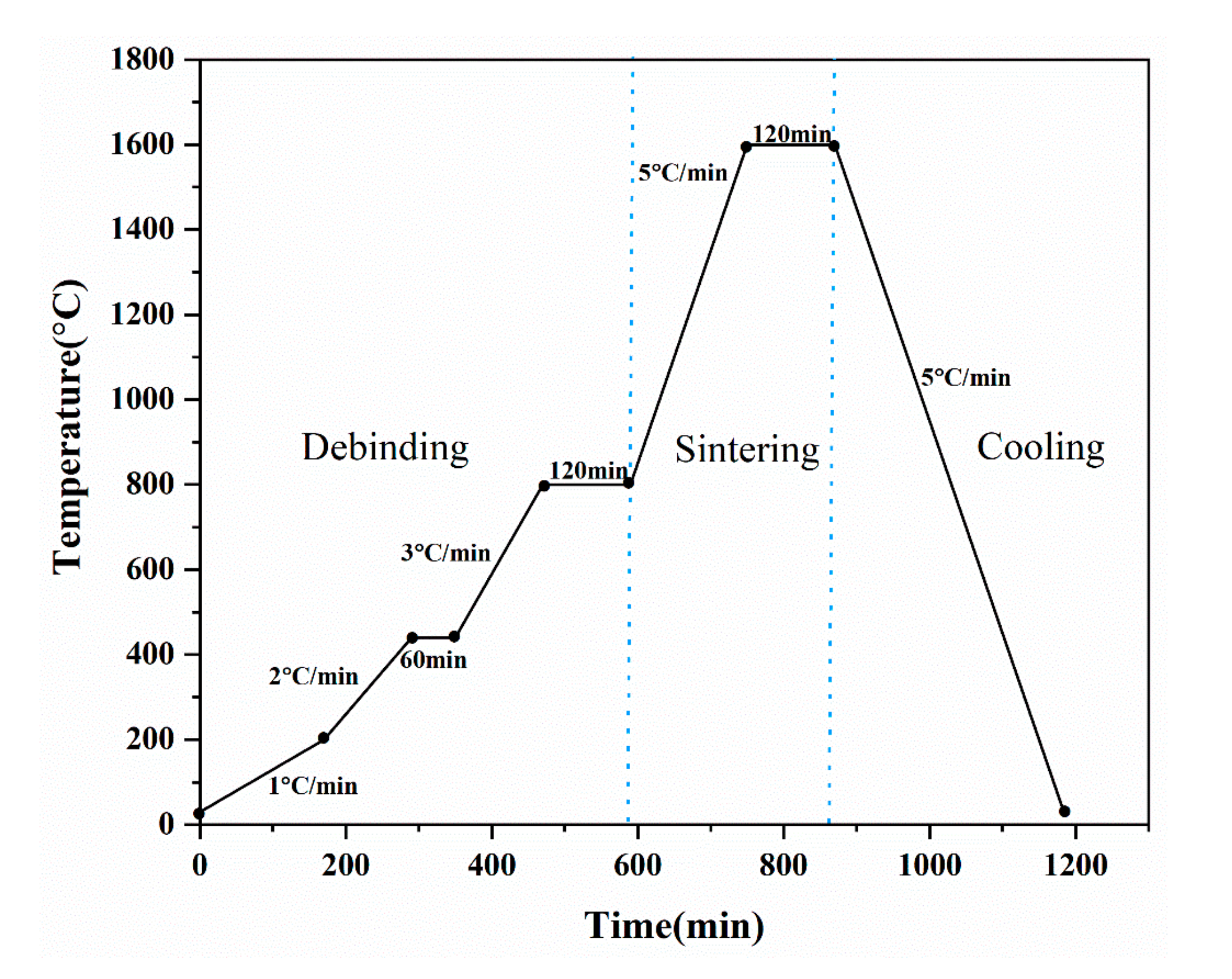

2.4. Debinding and Sintering

2.5. Characterization

3. Results and Discussion

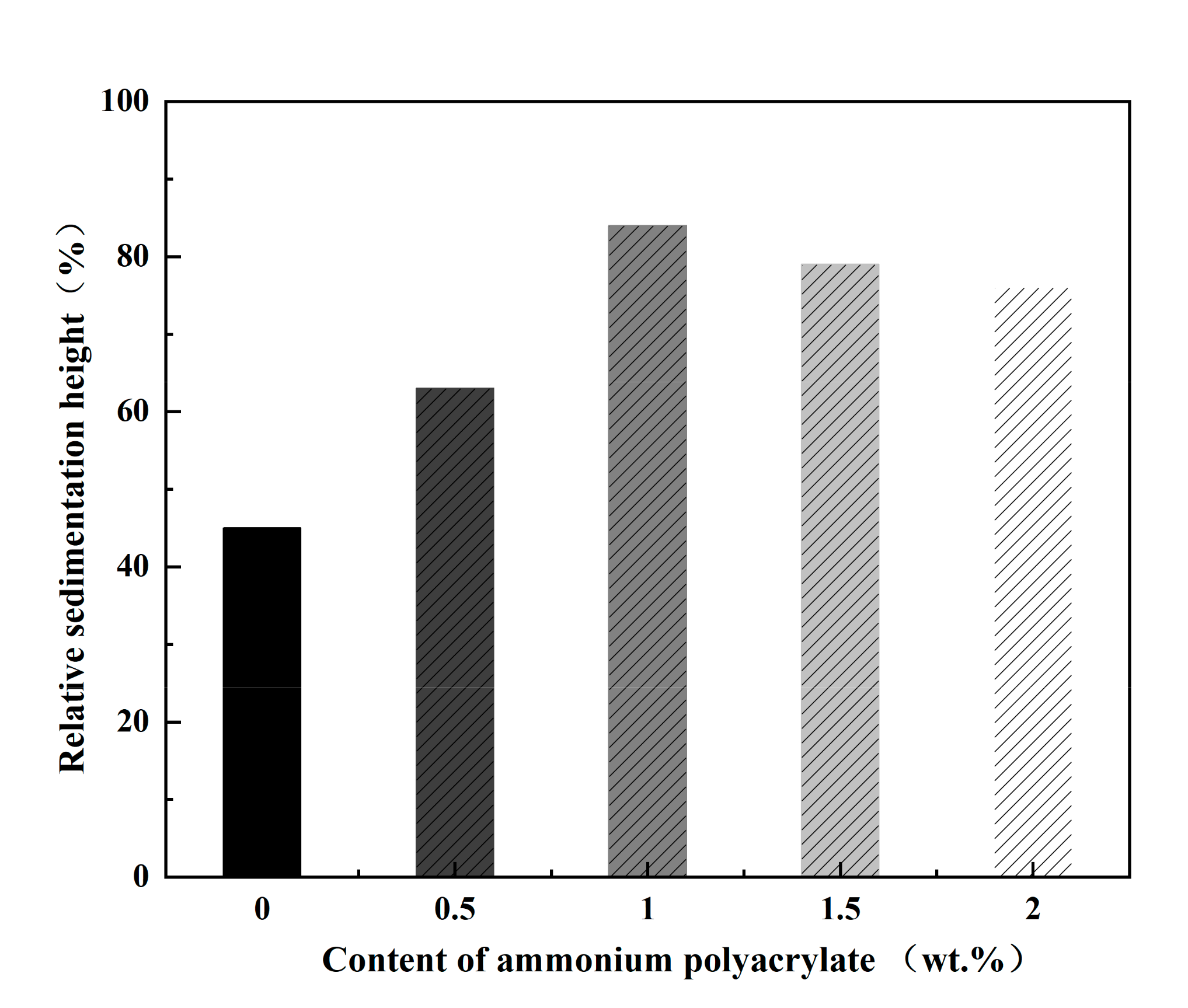

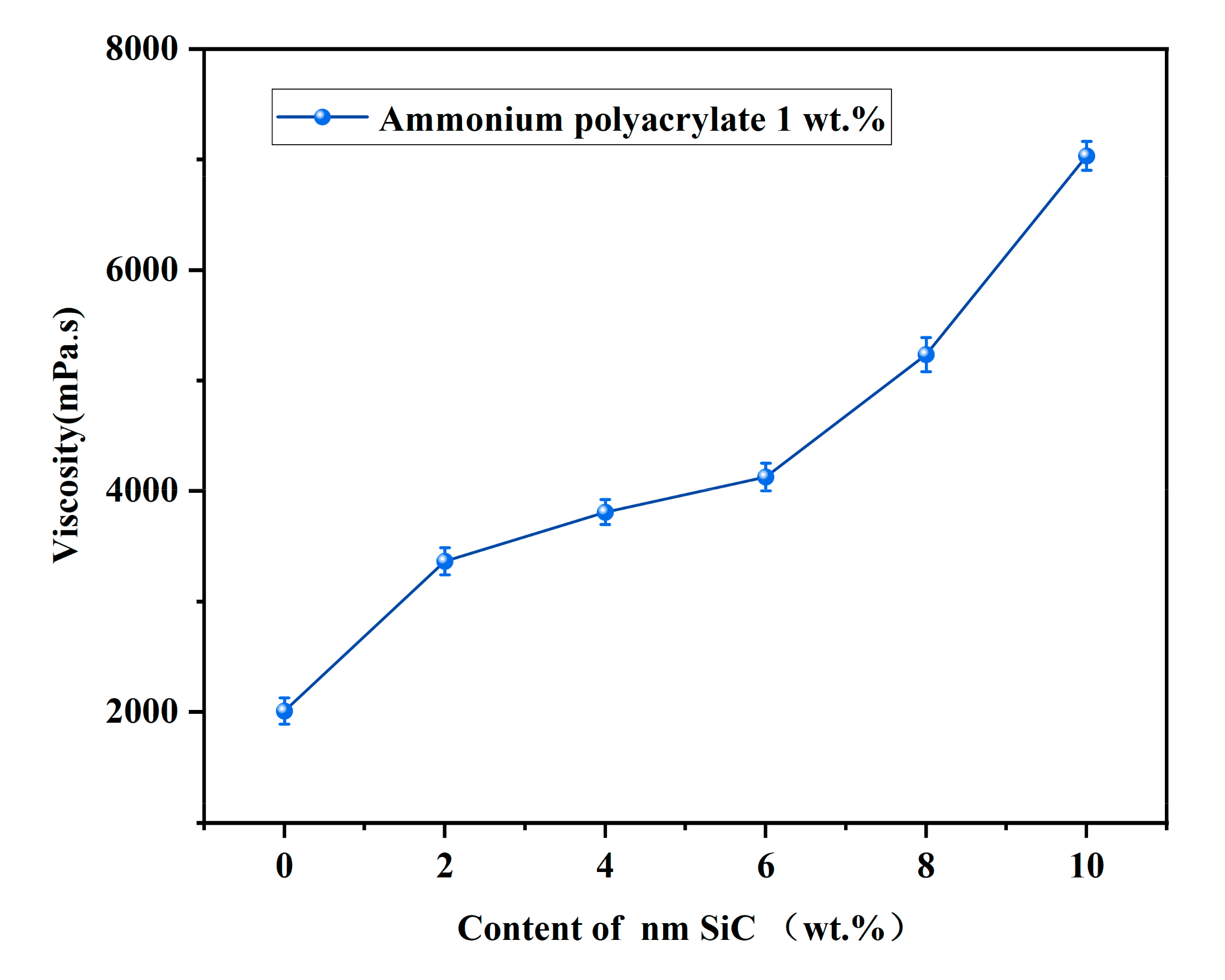

3.1. Rheological Properties of Ceramic Slurry

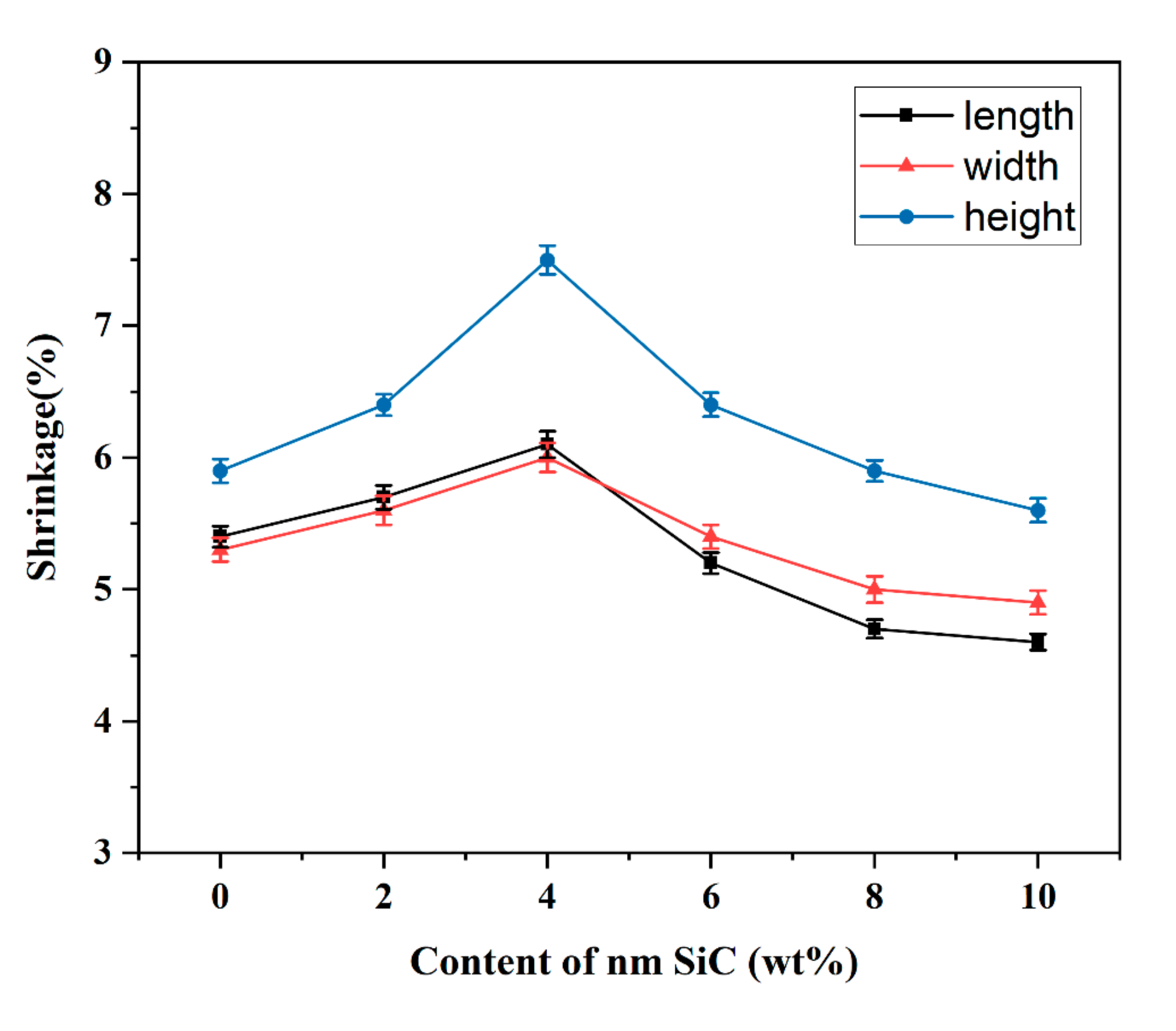

3.2. Physical Properties

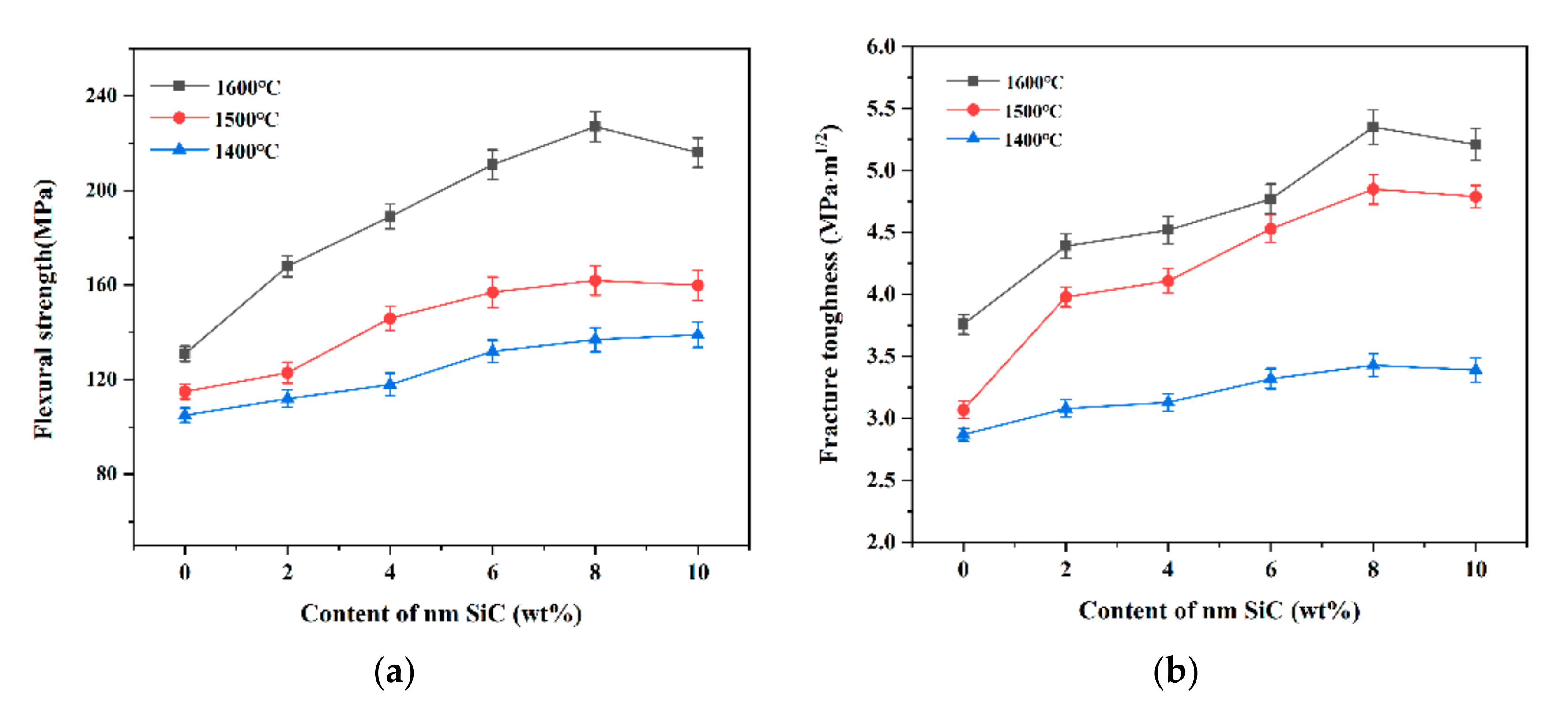

3.3. Effect of Temperature Regime on Mechanical Properties of Ceramics

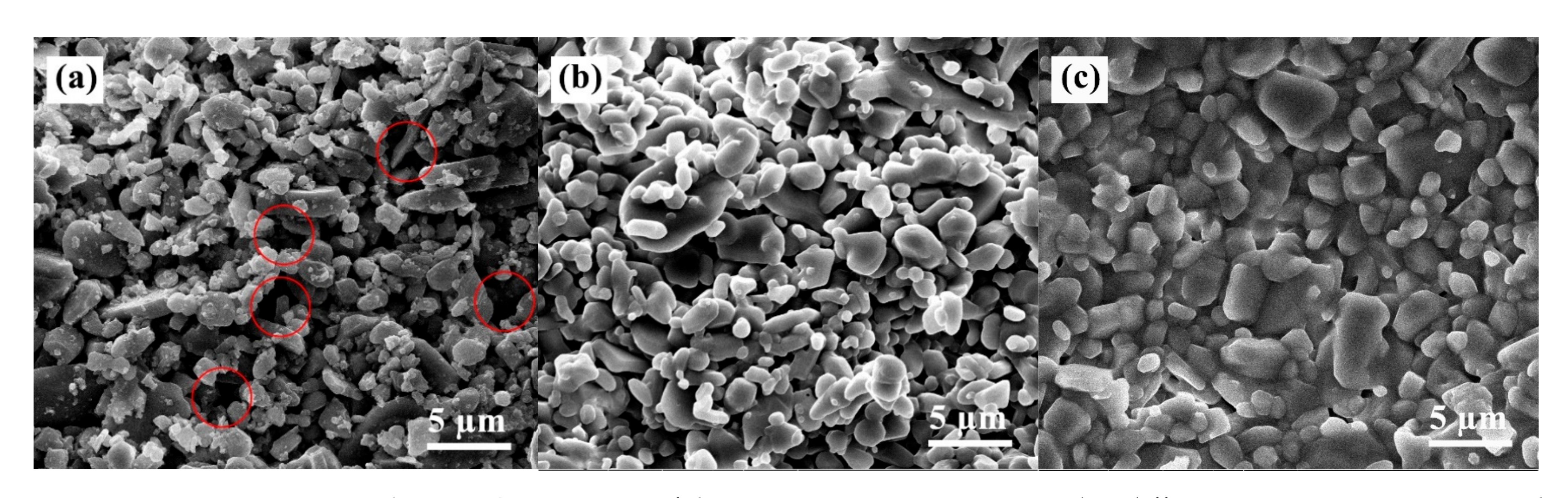

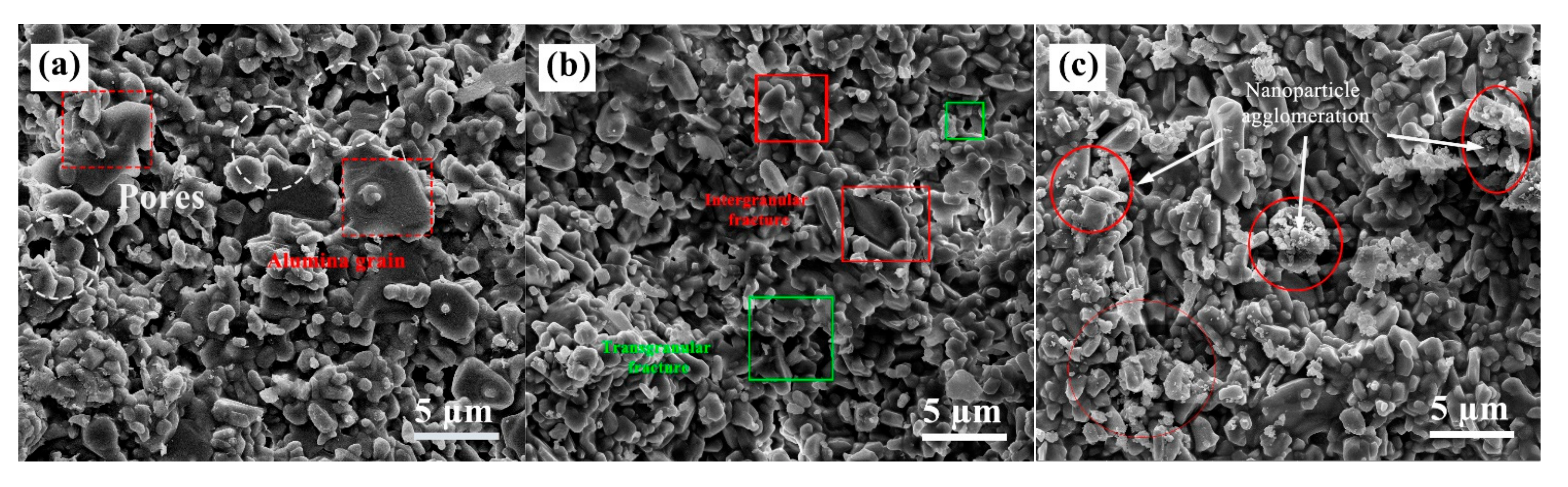

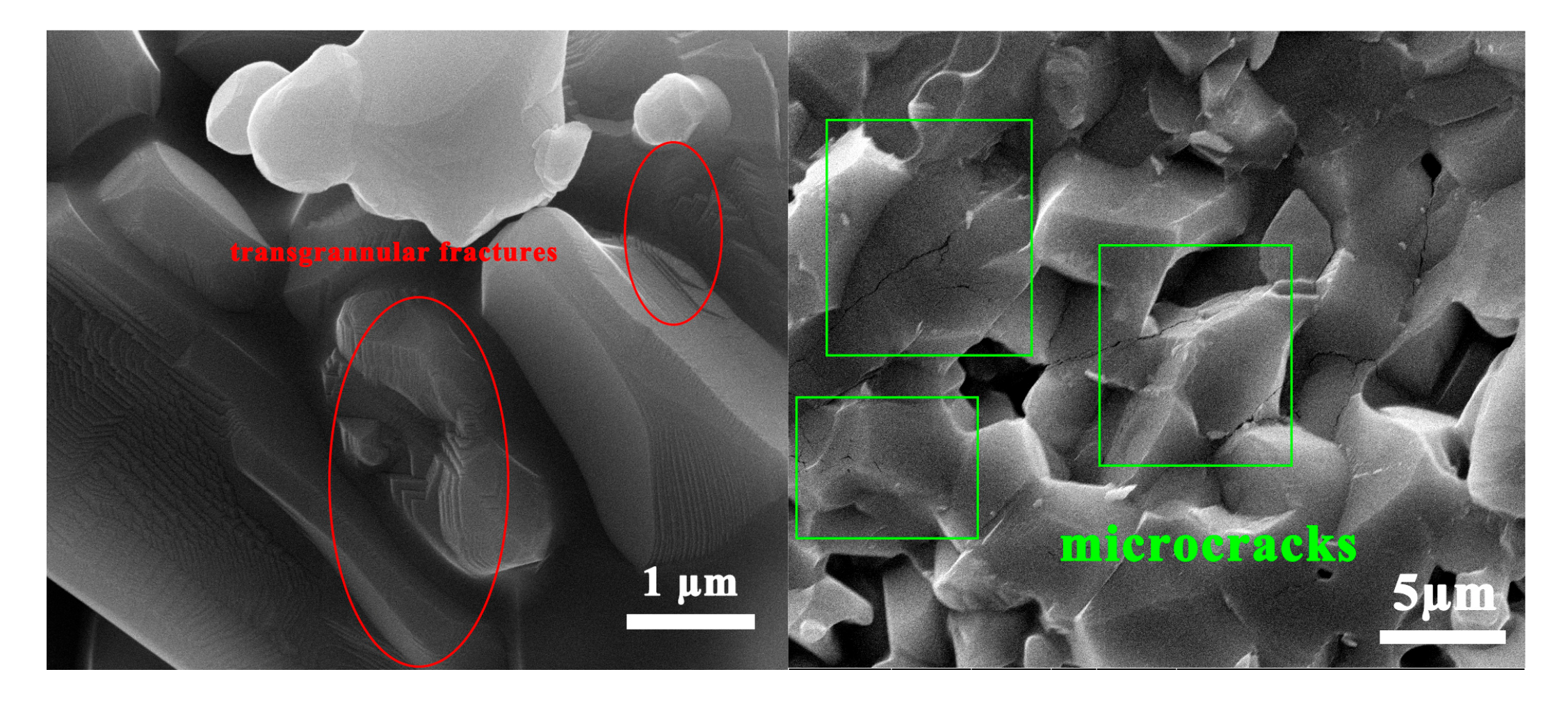

3.4. Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Maeda, K.; Onda, T.; Chen, Z.-C. Microstructure and improved mechanical properties of Al2O3/Ba-β-Al2O3/ZrO2 composites with YSZ addition. J. Eur. Ceram. Soc. 2018, 38, 5113–5121. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Liang, J. Silica strengthened alumina ceramic cores prepared by 3D printing. J. Eur. Ceram. Soc. 2021, 41, 2938–2947. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, W.; Wu, H.; Song, X.; Chen, Y.; Cheng, L.; He, F.; Chen, S.; Wu, S. Preparation of a defect-free alumina cutting tool via additive manufacturing based on stereolithography—Optimization of the drying and debinding processes. Ceram. Int. 2016, 42, 11598–11602. [Google Scholar] [CrossRef]

- Walter, W.L.; Insley, G.M.; Walter, W.K.; Tuke, M.A. Edge loading in third generation alumina ceramic-on-ceramicbearings: Stripe wear. J. Arthroplast. 2004, 19, 402–413. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Chen, N.; Du, G.; Zhang, M.; Zhao, X.; Wu, J. Effect of Y2O3-stabilized ZrO2 whiskers on the microstructure, mechanical and wear resistance properties of Al2O3 based ceramic composites. Ceram. Int. 2019, 45, 16504–16511. [Google Scholar] [CrossRef]

- Lv, L.; Lu, Y.; Zhang, X.; Chen, Y.; Huo, W.; Liu, W.; Yang, J. Preparation of low-shrinkage and high-performancealumina ceramics via incorporation of pre-sintered alumina powder based on Isobam gelcasting. Ceram. Int. 2019, 45, 11654–11659. [Google Scholar] [CrossRef]

- Boldin, M.S.; Popov, A.A.; Lantsev, E.A.; Nokhrin, A.V.; Chuvil’deev, V.N. Investigation of the Densification Behaviorof Alumina during Spark Plasma Sintering. Materials 2022, 15, 2167. [Google Scholar] [CrossRef] [PubMed]

- Hnatkova, E.; Hausnerova, B.; Filip, P. Evaluation of powder loading and flow properties of Al2O3 ceramic injectionmolding feedstocks treated with stearic acid. Ceram. Int. 2019, 45, 20084–20090. [Google Scholar] [CrossRef]

- Fu, Y.; Tao, Z.; Hou, X. Weibull distribution of the fracture strength of 99% alumina ceramic reshaped by cold isostatic pressing. Ceram. Int. 2014, 40, 7661–7667. [Google Scholar] [CrossRef]

- Echeberria, J.; Ollo, J.; Bocanegra-Bernal, M.H.; Garcia-Reyes, A.; Domínguez-Rios, C.; Aguilar-Elguezabal, A.; Reyes-Rojas, A. Sinter and hot isostatic pressing (HIP) of multi-wall carbon nanotubes (MWCNTs) reinforced ZTA nanocomposite: Microstructure and fracture toughness. Int. J. Refract. Met. Hard Mater. 2010, 28, 399–406. [Google Scholar] [CrossRef]

- Schlacher, J.; Lube, T.; Harrer, W.; Mitteramskogler, G.; Schwentenwein, M.; Danzer, R.; Bermejo, R. Strength of additive manufactured alumina. J. Eur. Ceram. Soc. 2020, 40, 4737–4745. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, H.; Huang, C.; Wang, J.; Cheng, M. Fabrication and mechanical properties of Al2O3-SiCw-TiCnp ceramictool material. Ceram. Int. 2017, 43, 10224–10230. [Google Scholar] [CrossRef]

- Tamura, Y.; Moshtaghioun, B.M.; Gomez-Garcia, D.; Rodríguez, A.D. Spark plasma sintering of fine-grained alumina ceramics reinforced with alumina whiskers. Ceram. Int. 2017, 43, 658–663. [Google Scholar] [CrossRef]

- Senthil Kumar, A.; Raja Durai, A.; Sornakumar, T. Wear behaviour of alumina based ceramic cutting tools on machining steels. Tribol. Int. 2006, 39, 191–197. [Google Scholar] [CrossRef]

- Yin, Z.; Huang, C.; Zou, B.; Liu, H.; Zhu, H.; Wang, J. Preparation and characterization of Al2O3/TiC micro–nano- composite ceramic tool materials. Ceram. Int. 2013, 39, 4253–4262. [Google Scholar] [CrossRef]

- Dong, Y.L.; Xu, F.M.; Shi, X.L.; Zhang, C.; Zhang, Z.J.; Yang, J.M.; Tan, Y. Fabrication and mechanical properties ofnano-/micro-sized Al2O3/SiC composites. Mater. Sci. Eng. A 2009, 504, 49–54. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturingof Ceramic-Based Materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Maleksaeedi, S.; Eng, H.; Wiria, F.E.; Ha, T.M.H.; He, Z. Property enhancement of 3D-printed alumina ceramics using vacuum infiltration. J. Mater. Process. Technol. 2014, 214, 1301–1306. [Google Scholar] [CrossRef]

- Notzel, D.; Eickhoff, R.; Pfeifer, C.; Hanemann, T. Printing of Zirconia Parts via Fused Filament Fabrication. Materials 2021, 14, 5467. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-curable ZrO2 slurries for additive manufacturing (LCM-DLP) technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Chen, A.-N.; Wu, J.-M.; Liu, K.; Chen, J.-Y.; Xiao, H.; Chen, P.; Li, C.-H.; Shi, Y.-S. High-performance ceramic parts with complex shape prepared by selective laser sintering: A review. Adv. Appl. Ceram. 2017, 117, 100–117. [Google Scholar] [CrossRef]

- Powell, J.; Assabumrungrat, S.; Blackburn, S. Design of ceramic paste formulations for co-extrusion. Powder Technol. 2013, 245, 21–27. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, W.; Sun, J.; Liu, J.; Bai, J. Development and evaluation of Al2O3–ZrO2 composite processed by digitallight 3D printing. Ceram. Int. 2020, 46, 8682–8688. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Liang, J. Thermal Treatment of γ-Al2O3 for the Preparation of Stereolithography 3D Printing Ceramic Slurries. Front. Mater. 2019, 6, 295. [Google Scholar] [CrossRef]

- Yun, J.S.; Park, T.-W.; Jeong, Y.H.; Cho, J.H. Development of ceramic-reinforced photopolymers for SLA 3D printing technology. Appl. Phys. A 2016, 122, 629. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.-P.; Vleugels, J. Preparation and indirect selective laser sinteringof alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Anya, C.C.; Roberts, S.G. Pressureless sintering and elastic constants of Al2O3-SiC ’nanocomposites’. J. Eur. Ceram. Soc. 1997, 17, 565–573. [Google Scholar] [CrossRef]

- Bae, S.I.; Baik, S.G. Sintering and grain-growth of ultrapure alumina. J. Mater. Sci. 1993, 28, 4197–4204. [Google Scholar] [CrossRef]

- Wang, H.Z.; Gao, L.; Guo, J.K. The effect of nanoscale SiC particles on the microstructure of Al2O3 ceramics. Ceram. Int. 2000, 26, 391–396. [Google Scholar] [CrossRef]

| Printing Parameter | Value |

|---|---|

| Screw rotating speed | 30 r/min |

| Printing speed | 20 mm/s |

| Layer height | 0.7 mm |

| Nozzle diameter | 1 mm |

| SiC Content | Vickers Hardness (%)GPa | Flexural Strength (MPa) | Fracture Toughness(%) MPa·m1/2 | Total Porosity (%) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|

| 0% | 15.58 ± 0.49 | 131 ± 4.26 | 3.76 ± 0.16 | 28 | 3.36 |

| 2% | 16.21 ± 0.46 | 168 ± 5.37 | 4.39 ± 0.23 | 24 | 3.41 |

| 4% | 16.74 ± 0.51 | 189 ± 6.23 | 4.52 ± 0.28 | 20 | 3.42 |

| 6% | 15.67 ± 0.48 | 211 ± 7.15 | 4.77 ± 0.36 | 19 | 3.42 |

| 8% | 15.53 ± 0.45 | 227 ± 7.33 | 5.35 ± 0.46 | 16 | 3.47 |

| 10% | 15.45 ± 0.46 | 216 ± 7.21 | 5.21 ± 0.34 | 17 | 3.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zheng, H.; Tang, M.; Yu, Z.; Pan, Z. SiC Nanoparticles Strengthened Alumina Ceramics Prepared by Extrusion Printing. Materials 2023, 16, 2483. https://doi.org/10.3390/ma16062483

Wu J, Zheng H, Tang M, Yu Z, Pan Z. SiC Nanoparticles Strengthened Alumina Ceramics Prepared by Extrusion Printing. Materials. 2023; 16(6):2483. https://doi.org/10.3390/ma16062483

Chicago/Turabian StyleWu, Jian, Hai Zheng, Mingliang Tang, Zhuqing Yu, and Zhigang Pan. 2023. "SiC Nanoparticles Strengthened Alumina Ceramics Prepared by Extrusion Printing" Materials 16, no. 6: 2483. https://doi.org/10.3390/ma16062483

APA StyleWu, J., Zheng, H., Tang, M., Yu, Z., & Pan, Z. (2023). SiC Nanoparticles Strengthened Alumina Ceramics Prepared by Extrusion Printing. Materials, 16(6), 2483. https://doi.org/10.3390/ma16062483