Investigation of the Damage Phenomenology with Dependence on the Macroporosity and Microporosity of Porous Freeze Foams

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

3. Results

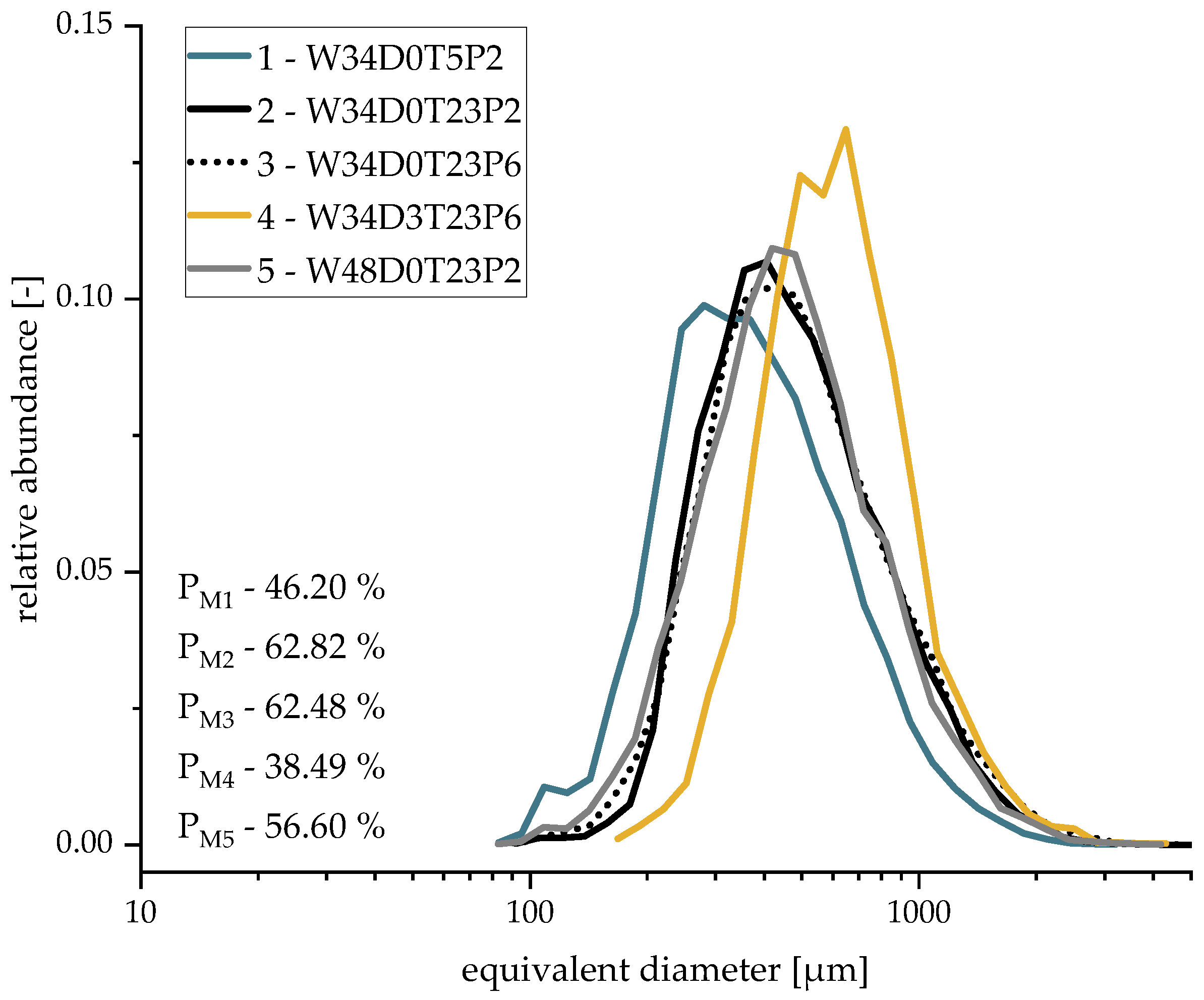

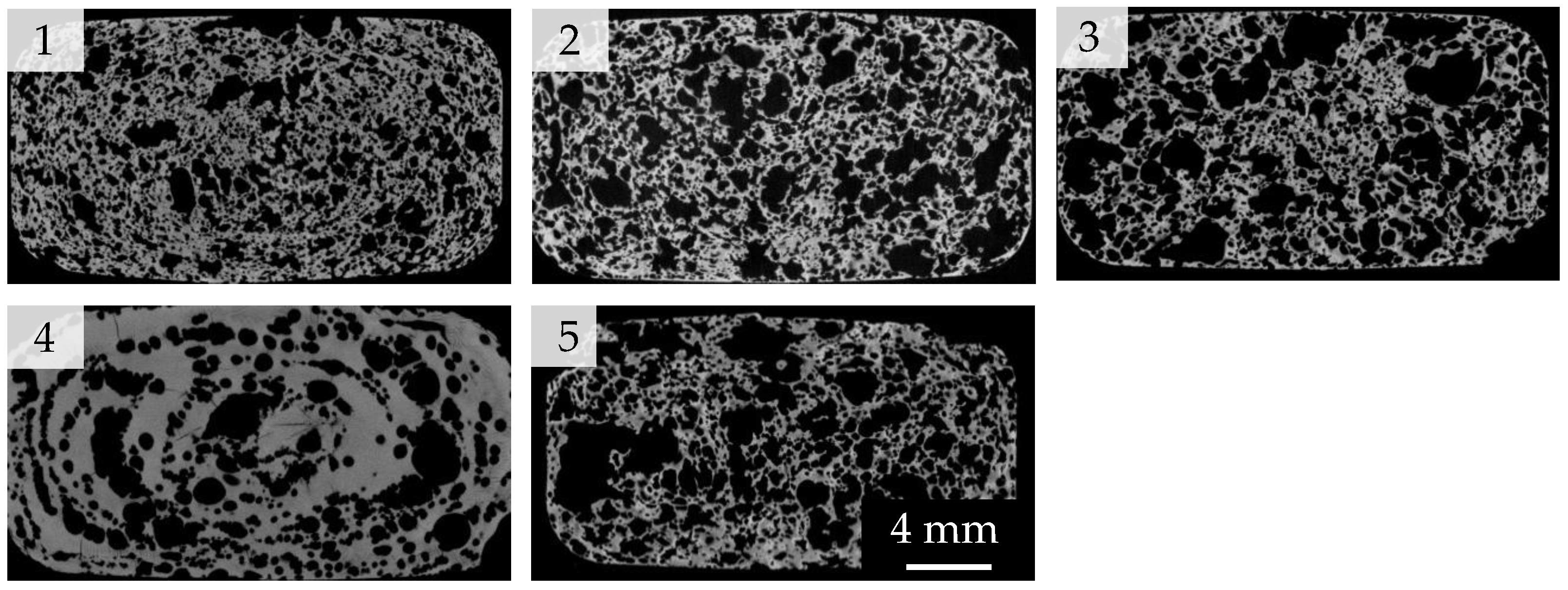

3.1. Macrostructure—Foam Cells

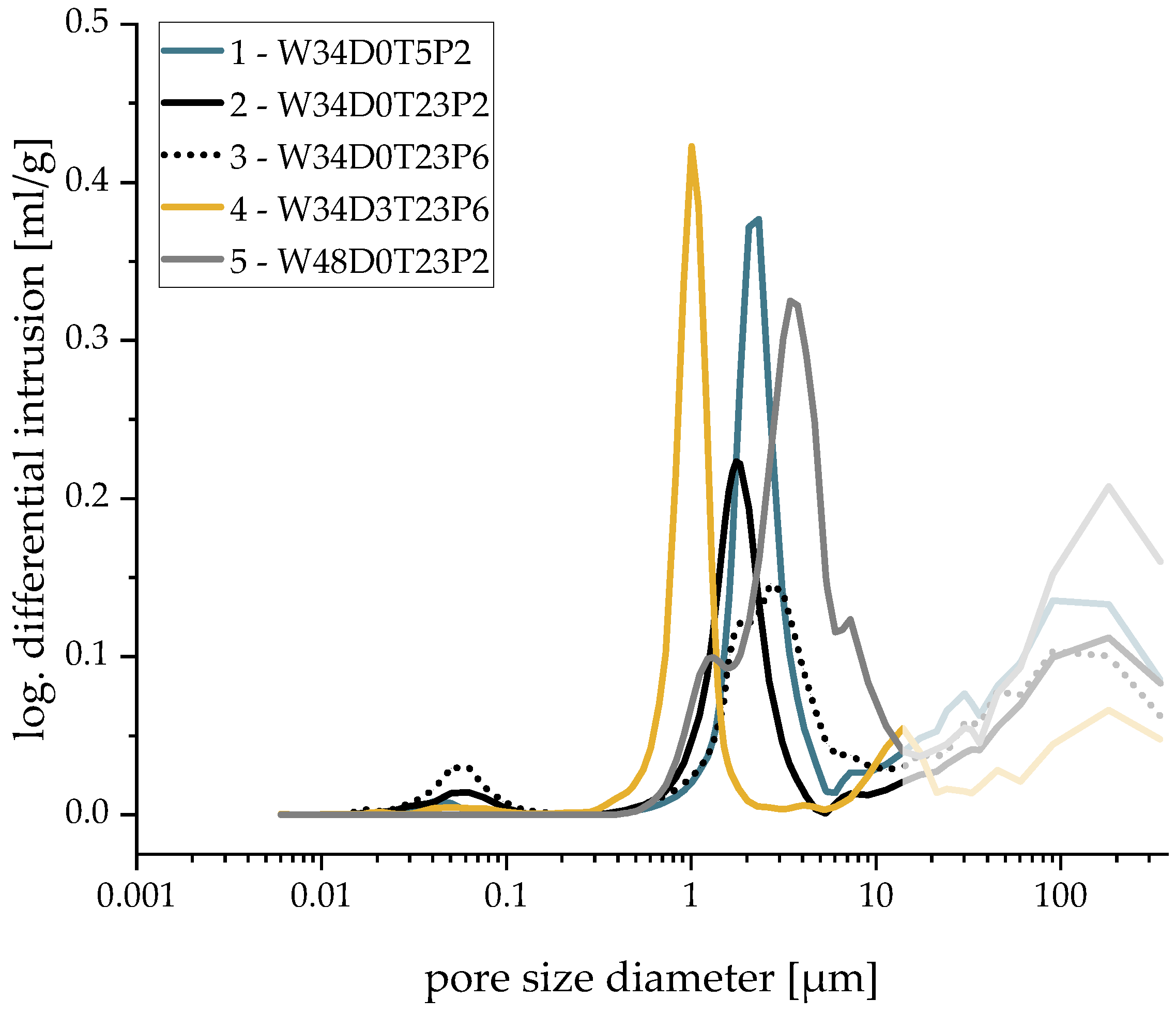

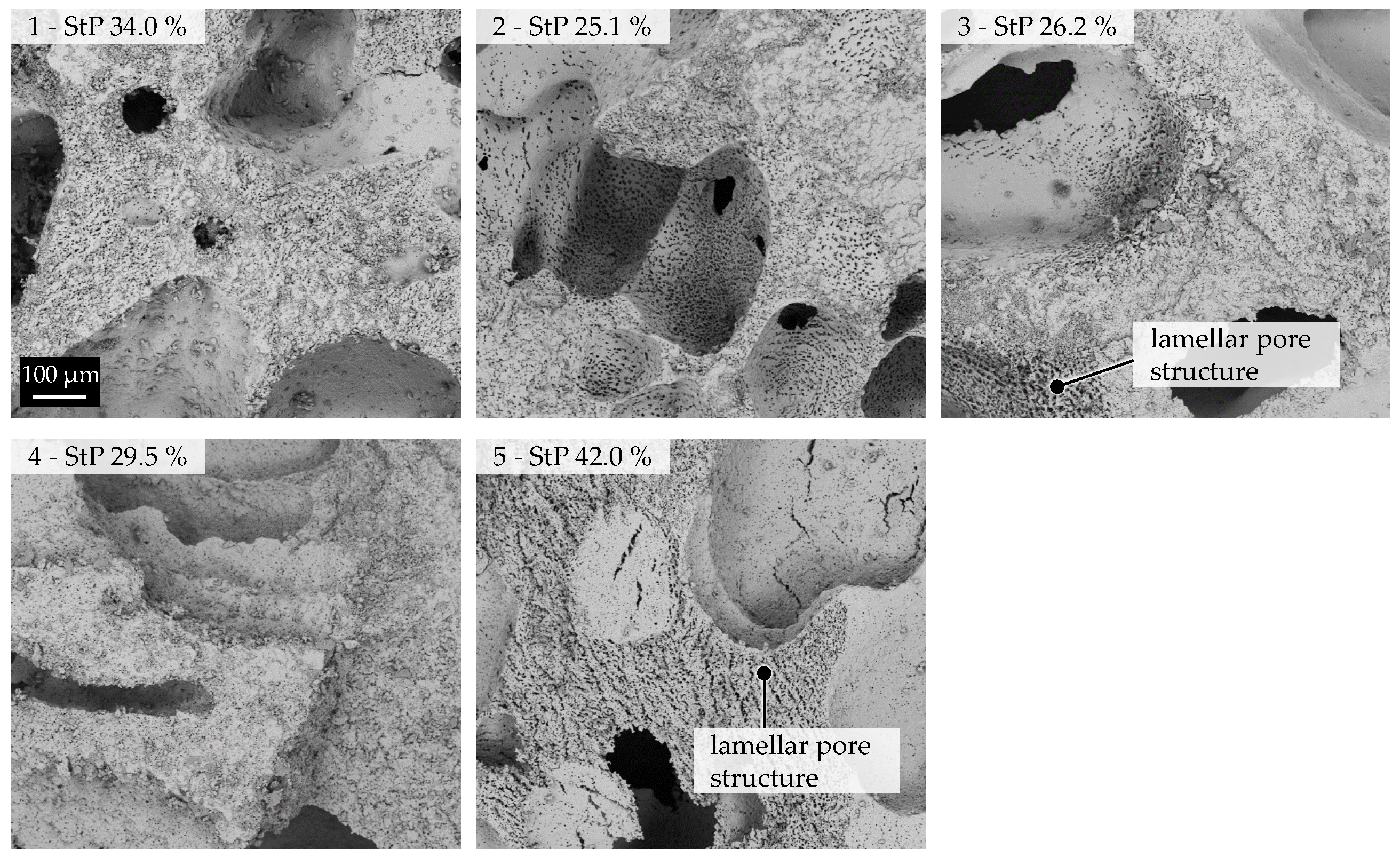

3.2. Microstructure—Strut Pores

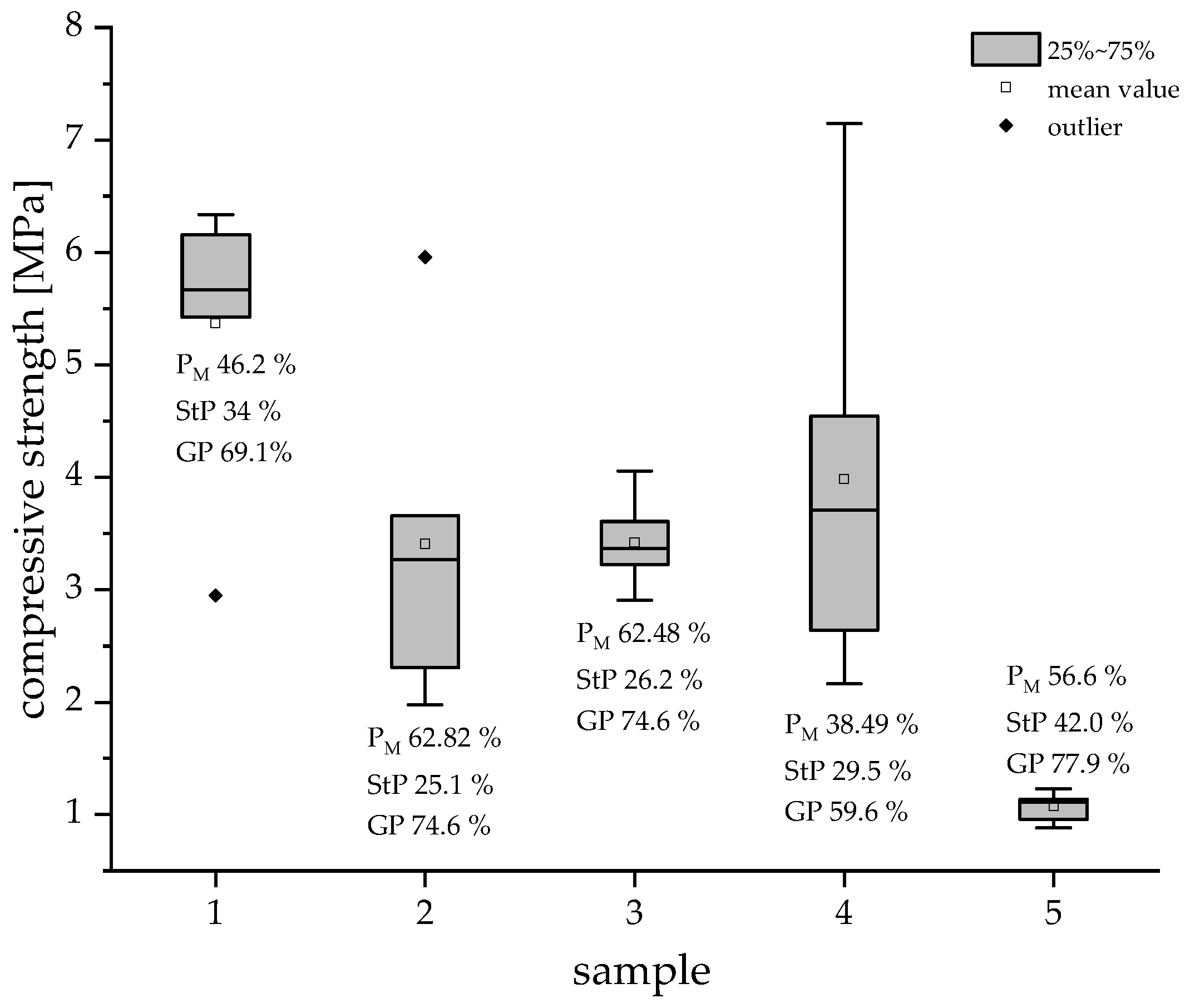

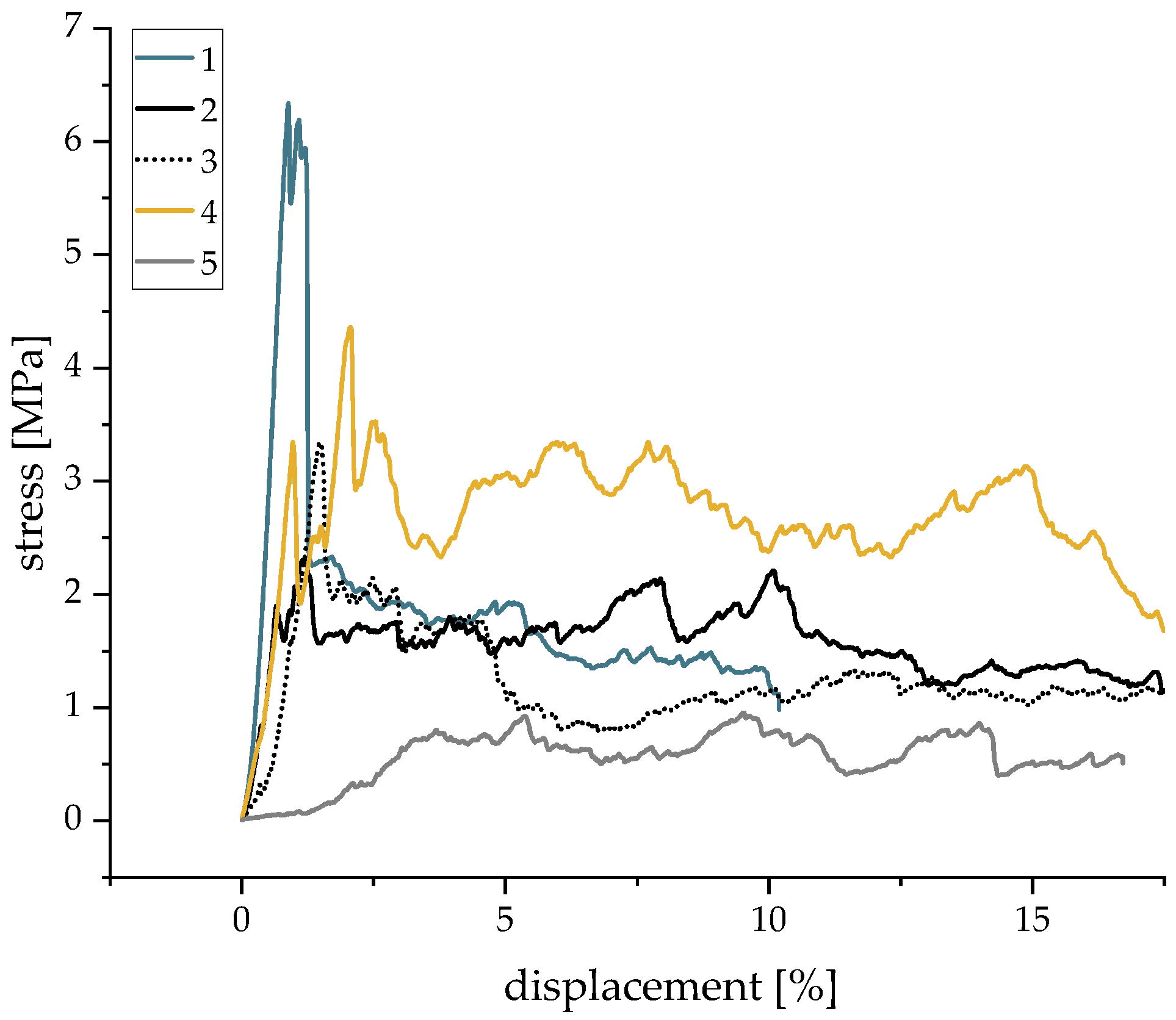

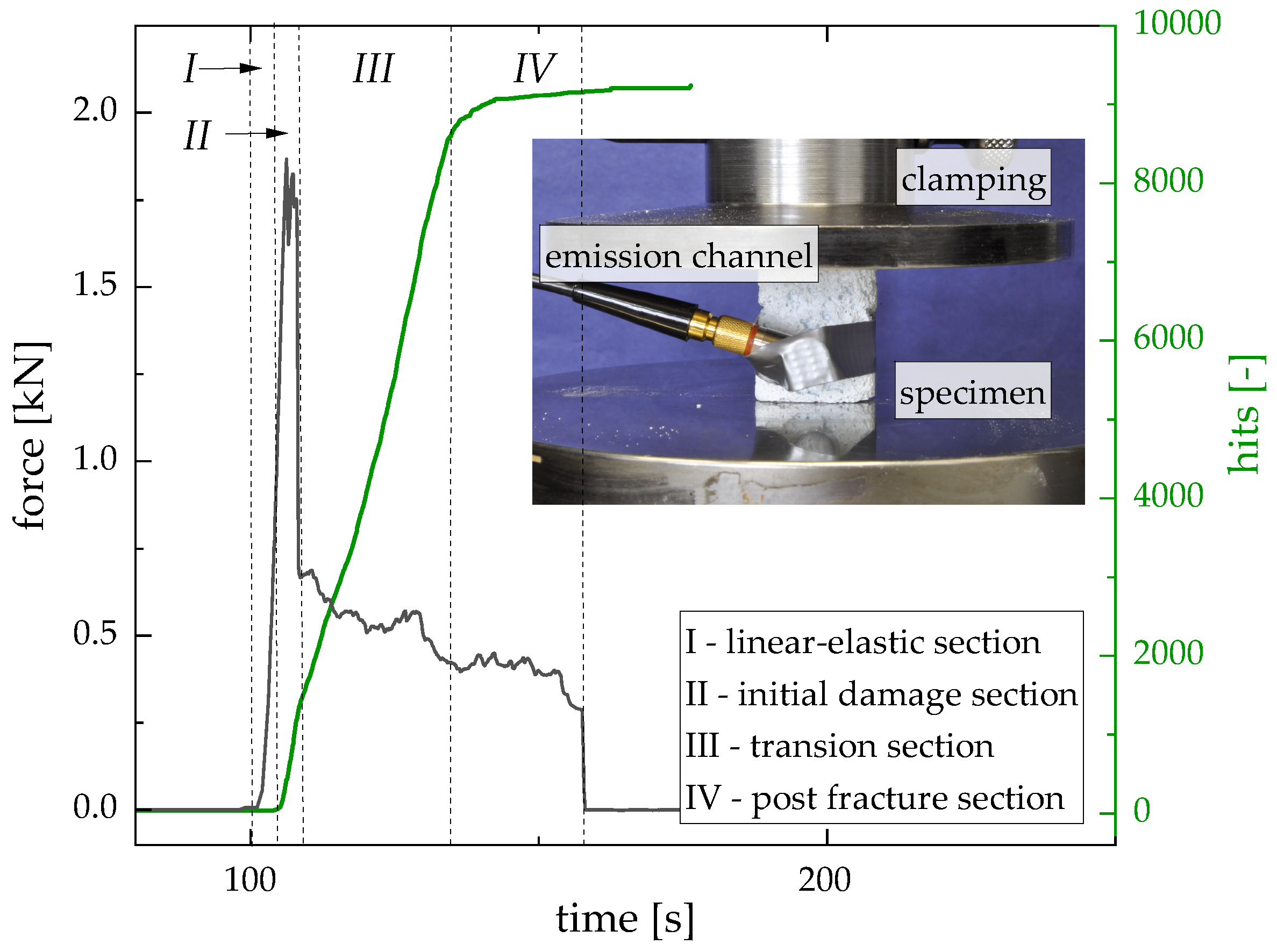

3.3. Compressive Strength and Damage Phenomenology

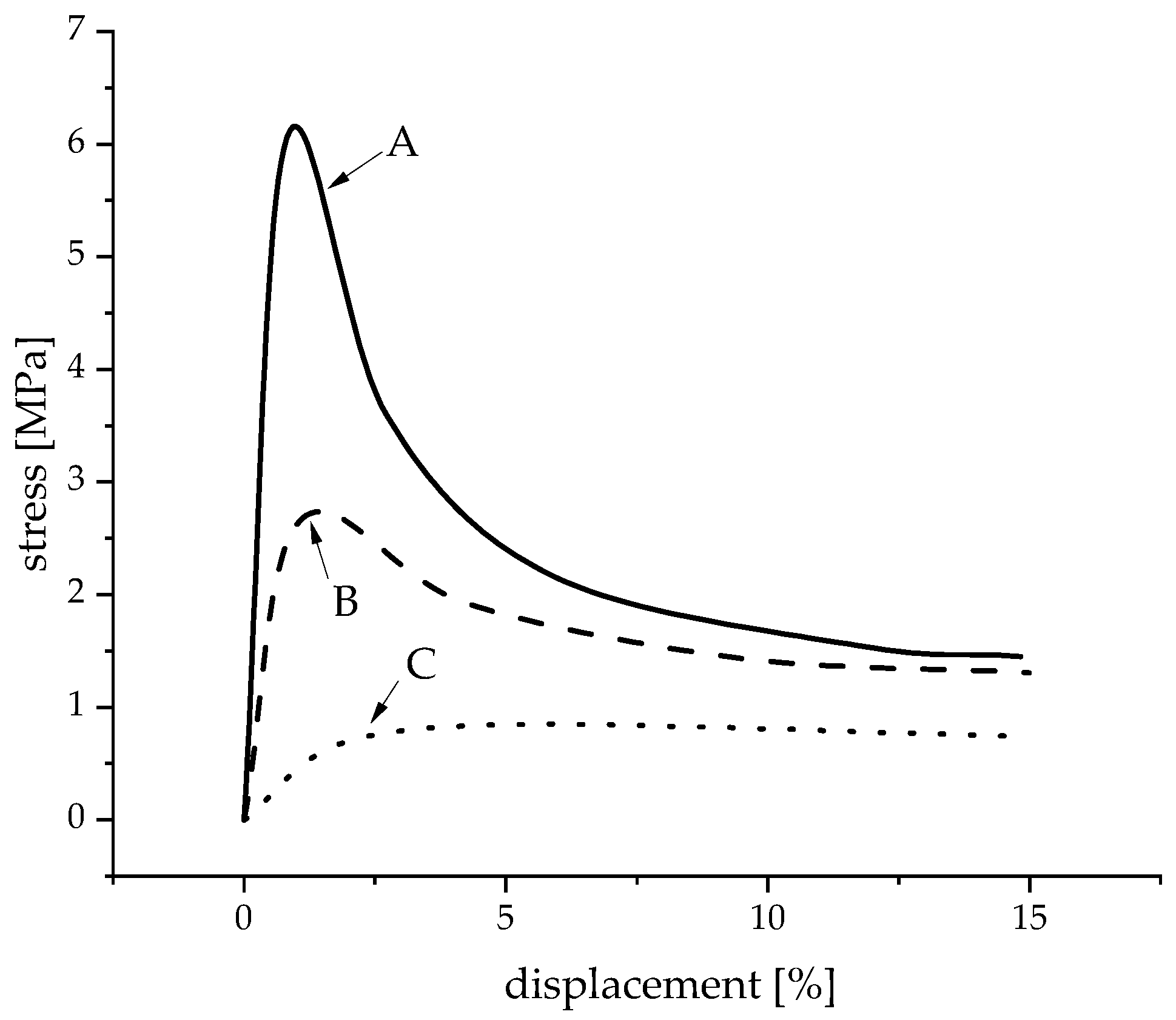

4. Discussion

- A—High and well-defined force maximum due to partly closed macroscopic pores with low porosity and closed microscopic pores, which was observed mostly in samples with W34 and T5.

- B—Medium force maximum because of interconnected macroscopic porosity with a high total porosity and closed and a low number of micropores that was the result of elevated temperatures (T23) and low water content.

- C—Almost constant, low resistance to deformation due to interconnected macroscopic and microscopic pores and high porosities that was caused by high water content (W48) and the resulting lamellar pores due to freezing.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, H.; Cheng, Y.; Liu, W.; He, R.; Zhou, M.; Wu, S.; Song, X.; Chen, Y. Effect of the particle size and the debinding process on the density of alumina ceramics fabricated by 3D printing based on stereolithography. Ceram. Int. 2016, 42, 17290–17294. [Google Scholar] [CrossRef]

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing routes to macroporous ceramics: A review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Ohji, T.; Fukushima, M. Macro-porous ceramics: Processing and properties. Int. Mater. Rev. 2012, 57, 115–131. [Google Scholar] [CrossRef]

- Scheffler, M.; Colombo, P. Cellular Ceramics: Structure, Manufacturing, Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ahlhelm, M.; Latorre, S.H.; Mayr, H.O.; Storch, C.; Freytag, C.; Werner, D.; Schwarzer-Fischer, E.; Seidenstücker, M. Mechanically Stable β-TCP Structural Hybrid Scaffolds for Potential Bone Replacement. J. Compos. Sci. 2021, 5, 281. [Google Scholar] [CrossRef]

- Fey, T.; Betke, U.; Rannabauer, S.; Scheffler, M. Reticulated replica ceramic foams: Processing, functionalization, and characterization. Adv. Eng. Mater. 2017, 19, 1700369. [Google Scholar] [CrossRef]

- Twigg, M.V.; Richardson, J.T. Fundamentals and applications of structured ceramic foam catalysts. Ind. Eng. Chem. Res. 2007, 46, 4166–4177. [Google Scholar] [CrossRef]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D printing of emulsions and foams into hierarchical porous ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef] [PubMed]

- Karl, S.; Somers, A.V. Method of Making Porous Ceramic Articles. US Patent 3,090,094, 21 May 1963. [Google Scholar]

- Zhou, J.; Fan, J.P.; Sun, G.L.; Zhang, J.Y.; Liu, X.M.; Zhang, D.H.; Wang, H.J. Preparation and properties of porous silicon nitride ceramics with uniform spherical pores by improved pore-forming agent method. J. Alloys Compd. 2015, 632, 655–660. [Google Scholar] [CrossRef]

- Gonzenbach, U.T.; Studart, A.R.; Steinlin, D.; Tervoort, E.; Gauckler, L.J. Processing of particle-stabilized wet foams into porous ceramics. J. Am. Ceram. Soc. 2007, 90, 3407–3414. [Google Scholar] [CrossRef]

- Li, W.; Lu, K.; Walz, J. Freeze casting of porous materials: Review of critical factors in microstructure evolution. Int. Mater. Rev. 2012, 57, 37–60. [Google Scholar] [CrossRef]

- Hwa, L.C.; Rajoo, S.; Noor, A.M.; Ahmad, N.; Uday, M. Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 2017, 21, 323–347. [Google Scholar] [CrossRef]

- Ahlhelm, M. Gefrierschäume—Entwicklung von Zellularen Strukturen für vielfältige Anwendungen/Freeze Foams—Development of Cellular Structures for Various Applications. In Schriftenreihe Kompetenzen in Keramik; Fraunhofer, I.K.T.S: Dresden, Germany, 2016; Band 32. [Google Scholar]

- Werner, D.; Maier, J.; Kaube, N.; Geske, V.; Behnisch, T.; Ahlhelm, M.; Moritz, T.; Michaelis, A.; Gude, M. Tailoring of hierarchical porous freeze foam structures. Materials 2022, 15, 836. [Google Scholar] [CrossRef] [PubMed]

- Maier, J.; Geske, V.; Werner, D.; Behnisch, T.; Ahlhelm, M.; Moritz, T.; Michaelis, A.; Gude, M. Investigation of Targeted Process Control for Adjusting the Macrostructure of Freeze Foams Using In Situ Computed Tomography. Ceramics 2022, 5, 269–280. [Google Scholar] [CrossRef]

- Dammler, K.; Schelm, K.; Kniep, D.; Hasemann, G.; Scheffler, M. Preceramic polymer-derived ceramic foams with lamellar strut porosity. IOP Conf. Ser. Mater. Sci. Eng. 2020, 882, 012005. [Google Scholar] [CrossRef]

- Schelm, K.; Fey, T.; Dammler, K.; Betke, U.; Scheffler, M. Hierarchical-Porous Ceramic Foams by a Combination of Replica and Freeze Technique. Adv. Eng. Mater. 2019, 21, 1801362. [Google Scholar] [CrossRef]

- Li, T.; Zhai, D.; Ma, B.; Xue, J.; Zhao, P.; Chang, J.; Gelinsky, M.; Wu, C. 3D printing of hot dog-like biomaterials with hierarchical architecture and distinct bioactivity. Adv. Sci. 2019, 6, 1901146. [Google Scholar] [CrossRef] [PubMed]

| Sample | W (m.-%) | D (min) | T (°C) | P (min) |

|---|---|---|---|---|

| 1-W34D0T5P2 | 34 | 0 | 5 | 2 |

| 2-W34D0T23P2 | 34 | 0 | 23 | 2 |

| 3-W34D0T23P6 | 34 | 0 | 23 | 6 |

| 4-W34D3T23P6 | 34 | 3 | 23 | 6 |

| 5-W48D0T23P2 | 48 | 0 | 23 | 2 |

| Sample | Peak 1 (µm) | Peak 2.1 (µm) | Peak 2.2 (µm) | Peak 3 (µm) |

|---|---|---|---|---|

| 1 | micro-cracks | 2.0 | - | 280 |

| 2 | micro-cracks | 1.8 | - | 406 |

| 3 | micro-cracks | 1.8 | 3.1 | 418 |

| 4 | micro-cracks | 1.0 | - | 648 |

| 5 | - | 1.2 | 3.4 | 479 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maier, J.; Werner, D.; Geske, V.; Behnisch, T.; Ahlhelm, M.; Moritz, T.; Michaelis, A.; Gude, M. Investigation of the Damage Phenomenology with Dependence on the Macroporosity and Microporosity of Porous Freeze Foams. Materials 2023, 16, 2484. https://doi.org/10.3390/ma16062484

Maier J, Werner D, Geske V, Behnisch T, Ahlhelm M, Moritz T, Michaelis A, Gude M. Investigation of the Damage Phenomenology with Dependence on the Macroporosity and Microporosity of Porous Freeze Foams. Materials. 2023; 16(6):2484. https://doi.org/10.3390/ma16062484

Chicago/Turabian StyleMaier, Johanna, David Werner, Vinzenz Geske, Thomas Behnisch, Mathias Ahlhelm, Tassilo Moritz, Alexander Michaelis, and Maik Gude. 2023. "Investigation of the Damage Phenomenology with Dependence on the Macroporosity and Microporosity of Porous Freeze Foams" Materials 16, no. 6: 2484. https://doi.org/10.3390/ma16062484

APA StyleMaier, J., Werner, D., Geske, V., Behnisch, T., Ahlhelm, M., Moritz, T., Michaelis, A., & Gude, M. (2023). Investigation of the Damage Phenomenology with Dependence on the Macroporosity and Microporosity of Porous Freeze Foams. Materials, 16(6), 2484. https://doi.org/10.3390/ma16062484