Experimental Research and Numerical Simulation of Laser Welding of 303Cu/440C-Nb Stainless-Steel Thin-Walled Natural-Gas Injector for Vehicles

Abstract

1. Introduction

2. Experiment and Simulation Methods

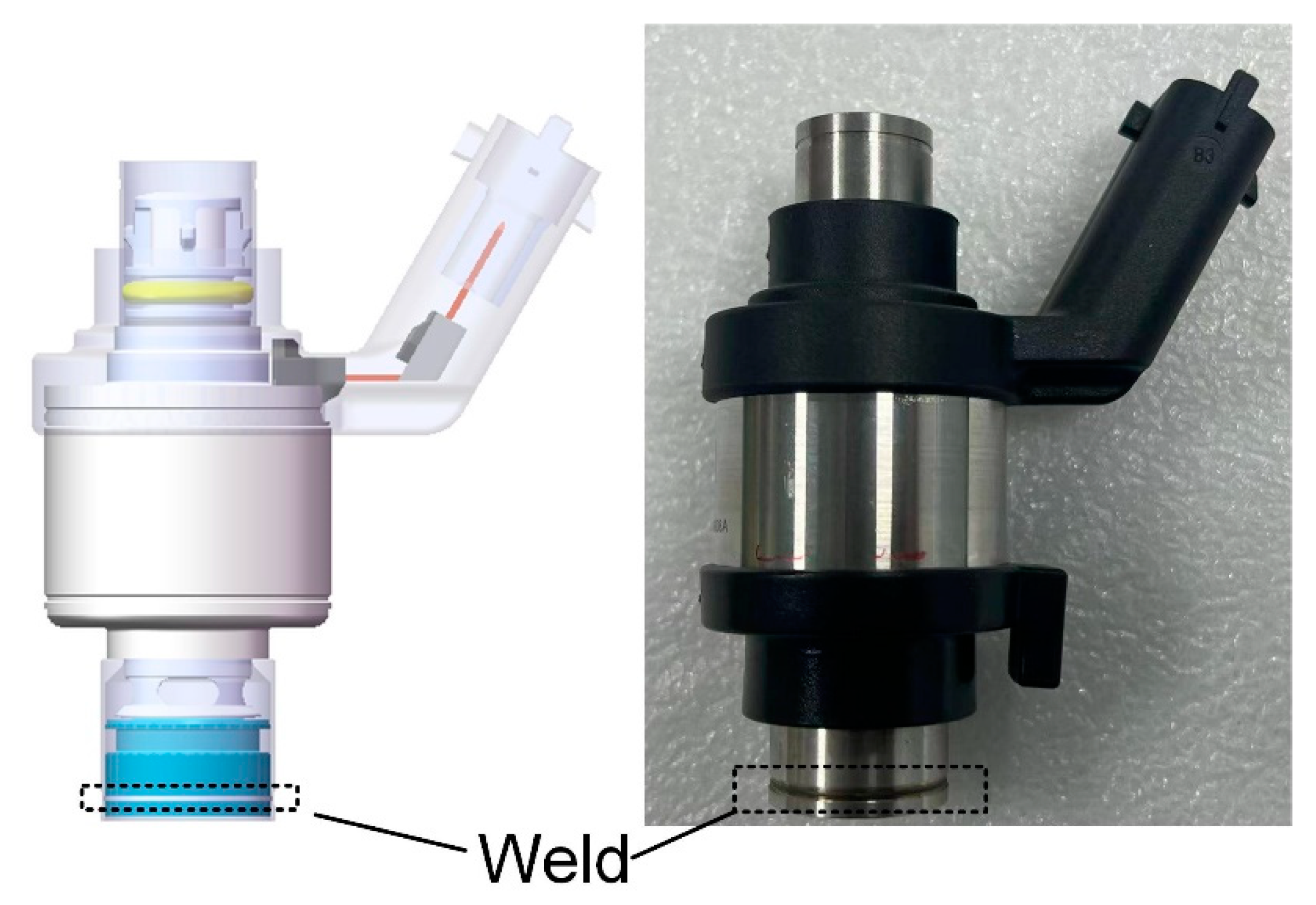

2.1. Sample and Materials

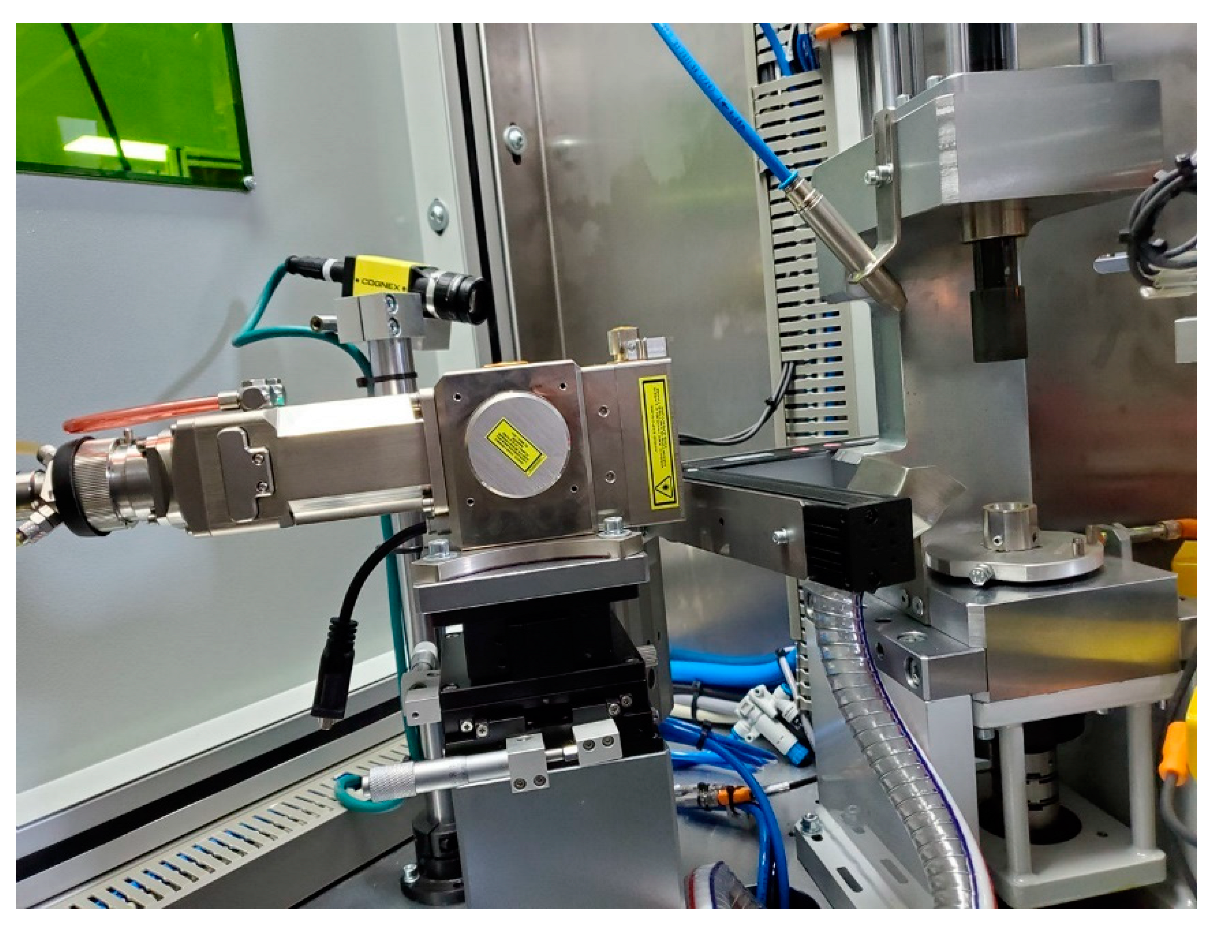

2.2. Experimental Equipment

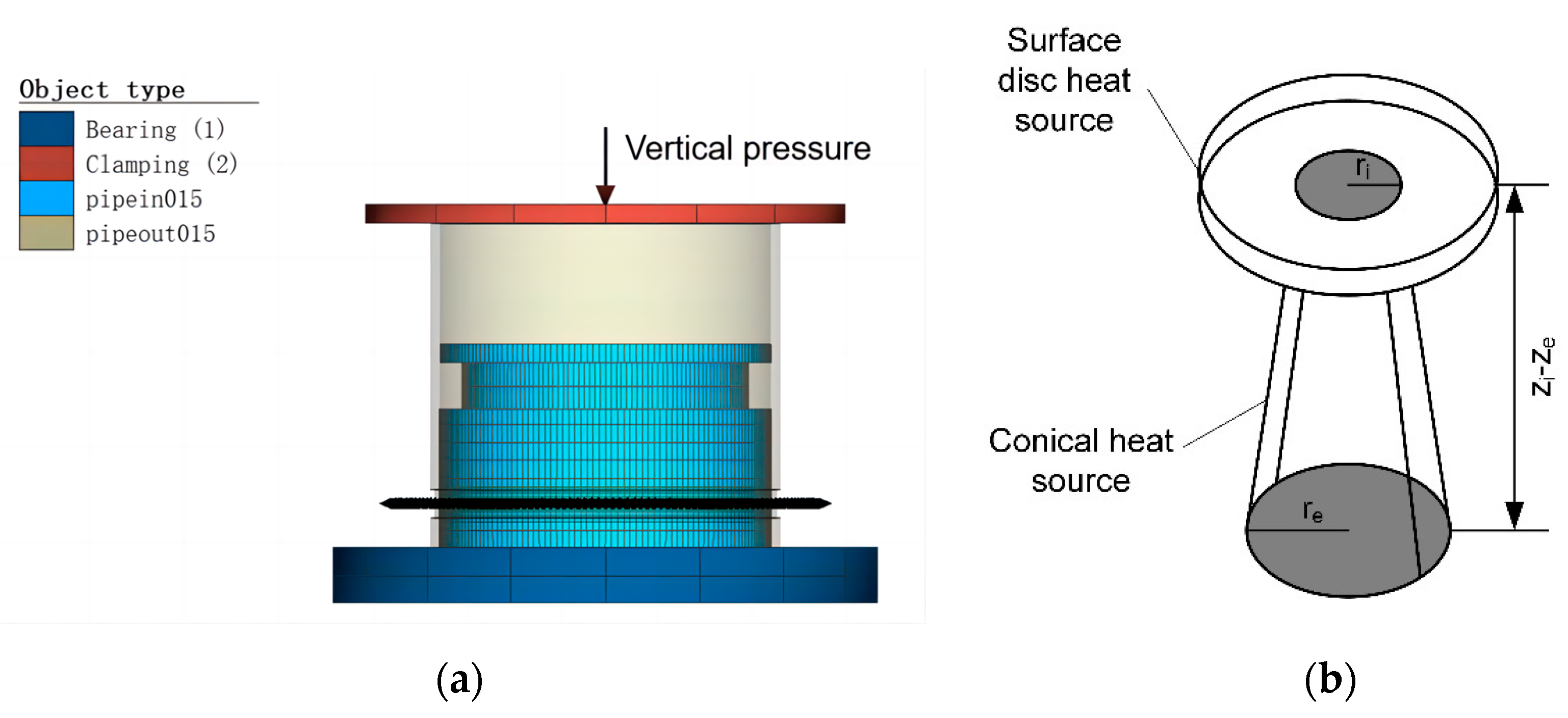

2.3. Numerical Simulation

3. Results and Discussion

3.1. Principle Analysis of Fixed Power Laser Welding

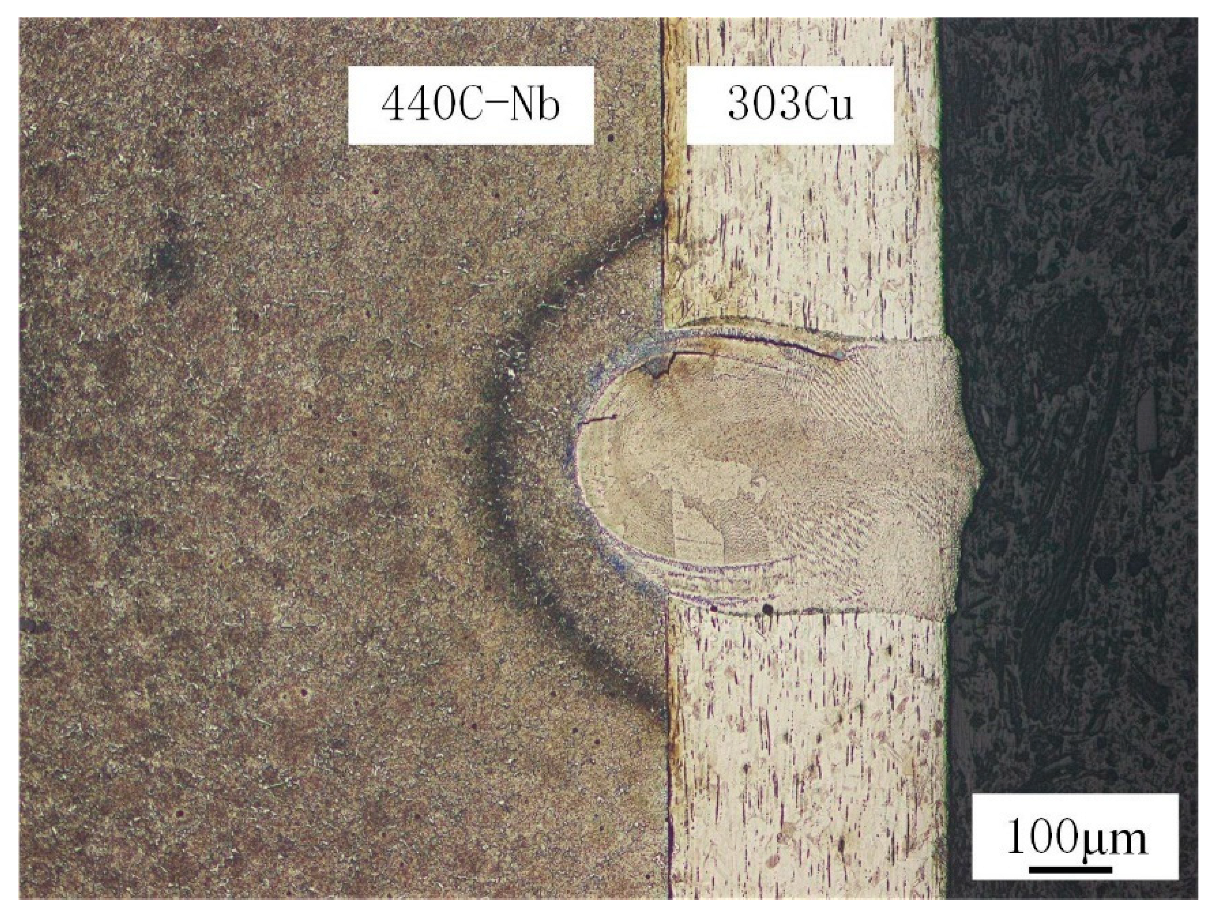

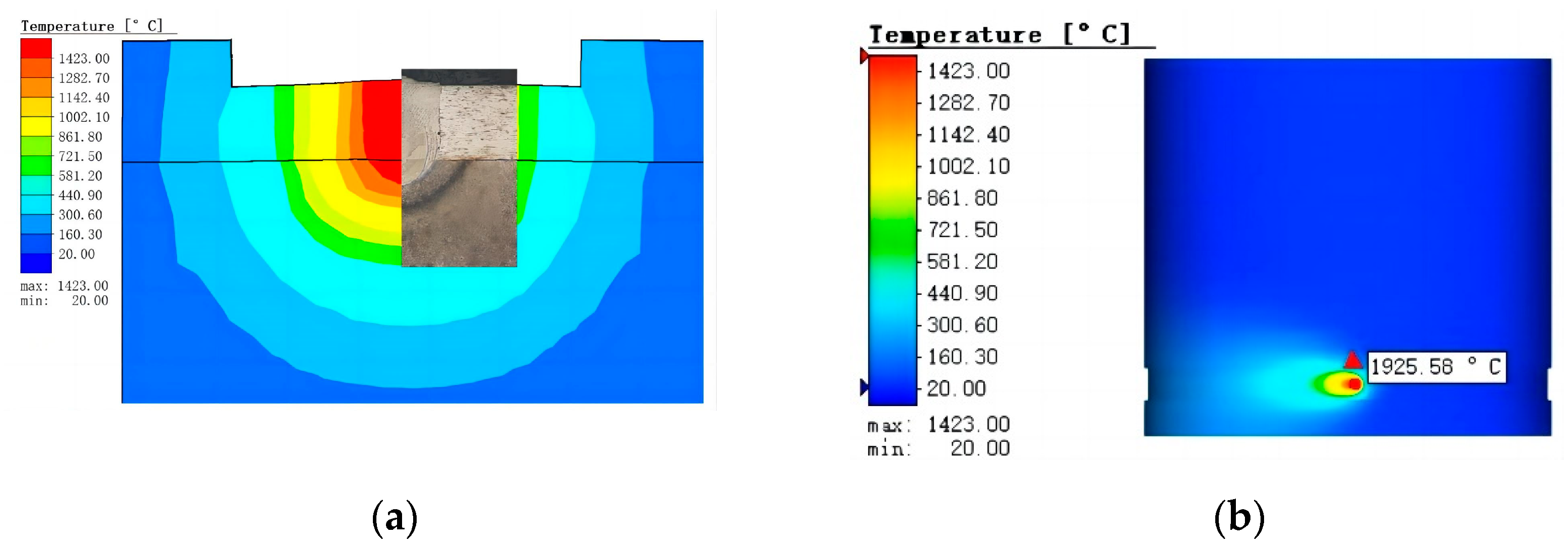

3.1.1. Verification and Discussion of Numerical Simulation

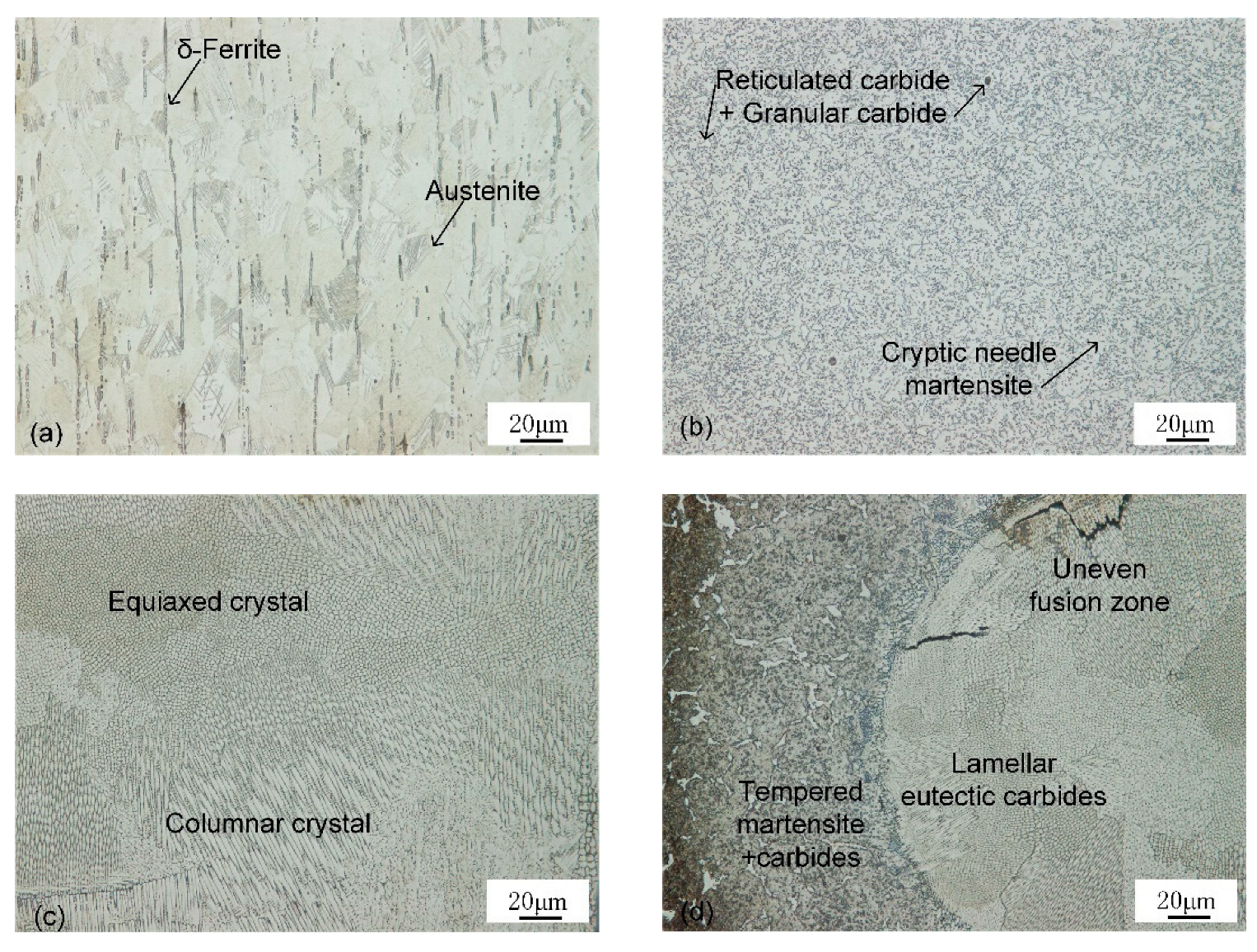

3.1.2. Microstructure Analysis

3.1.3. Microhardness Analysis

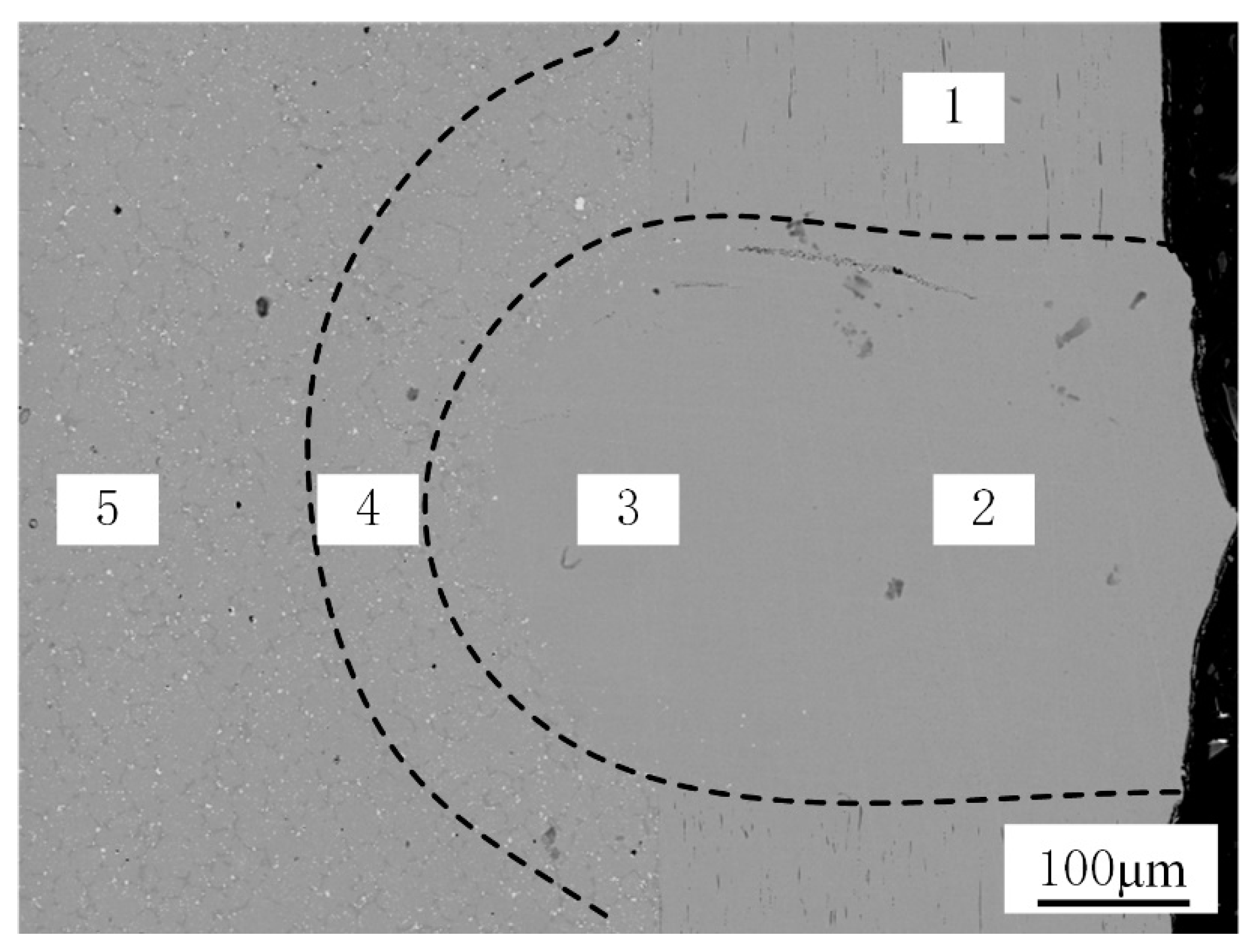

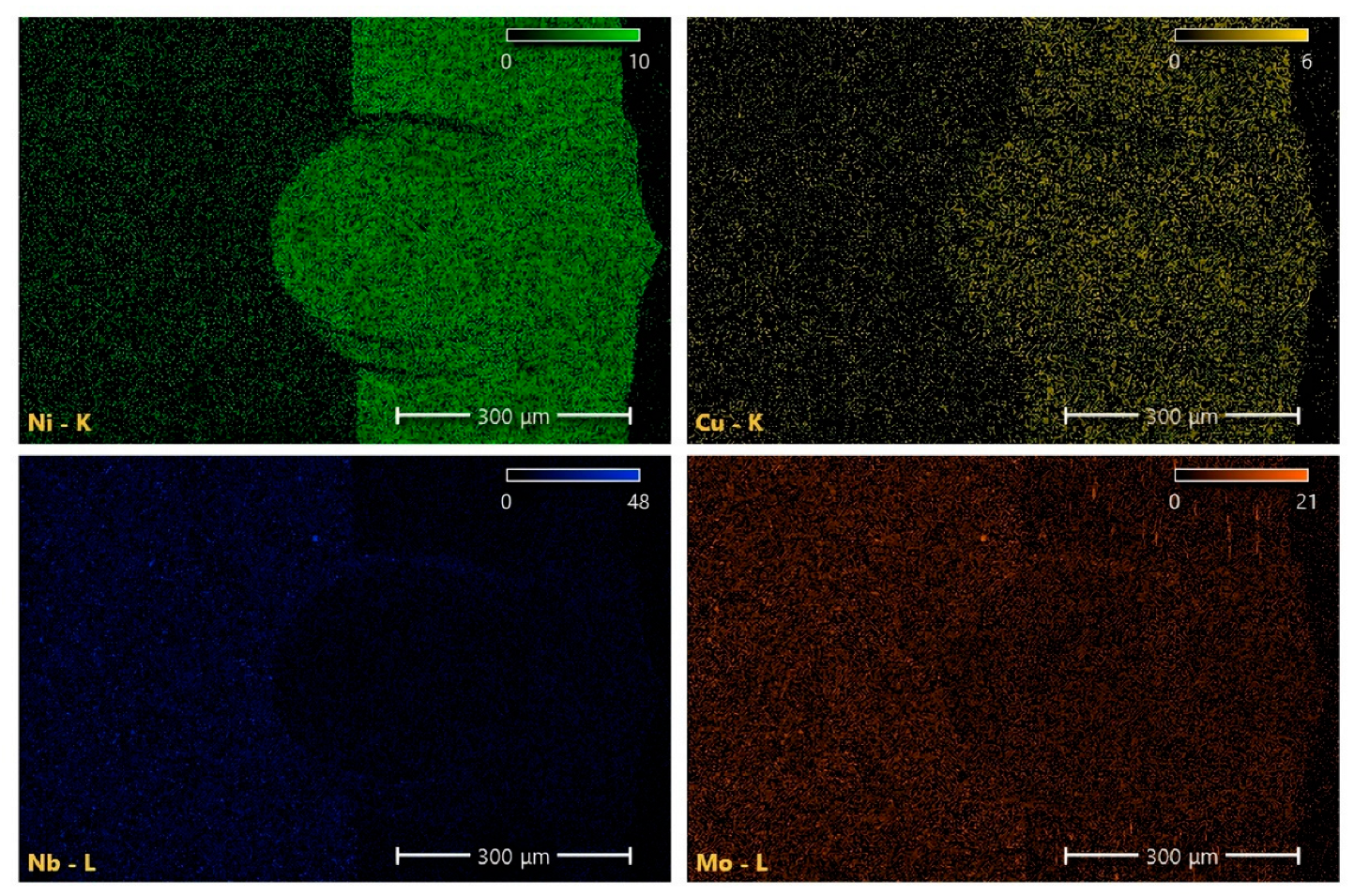

3.1.4. EDS Analysis

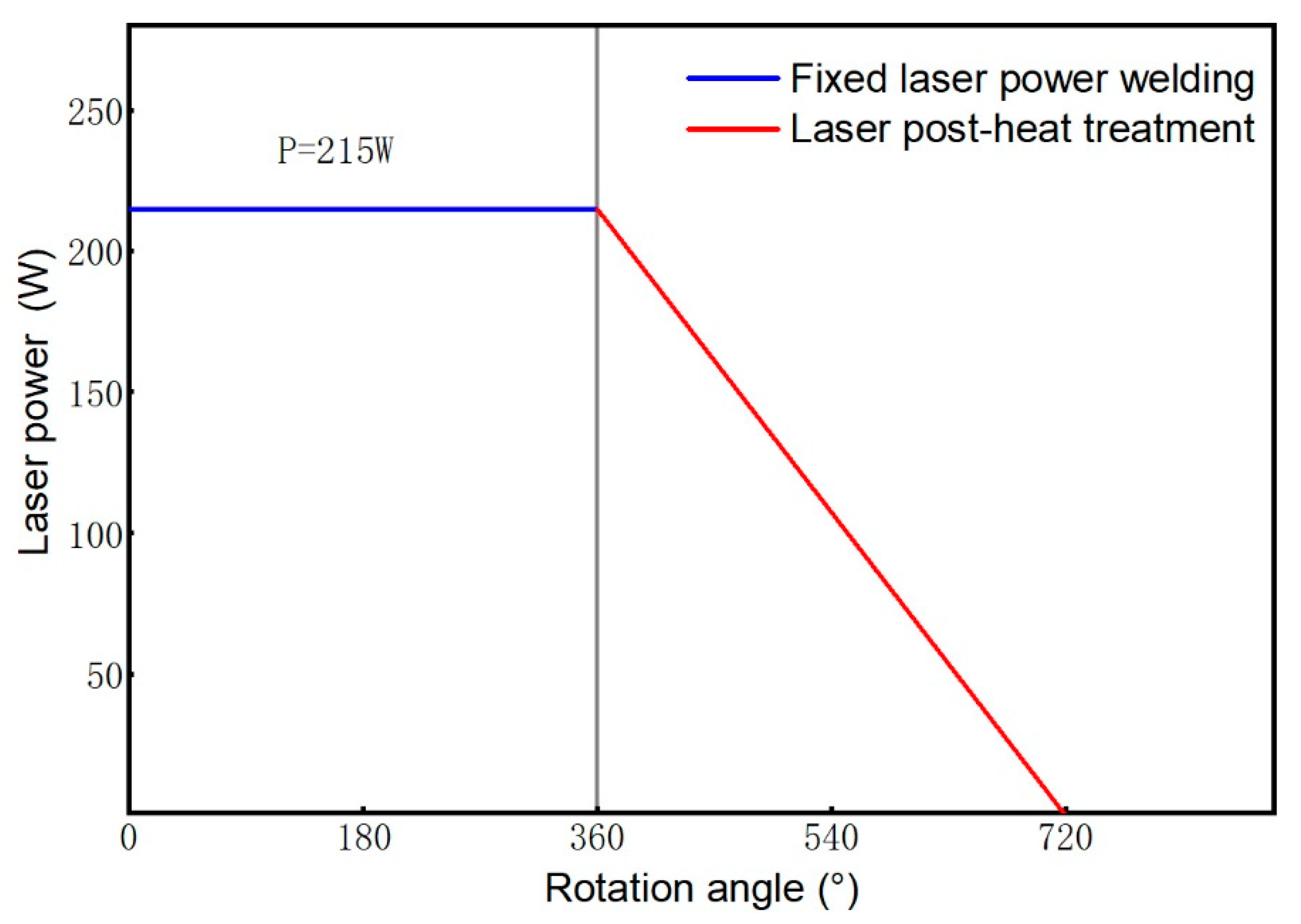

3.2. Comparative Analysis of Laser Post-Heat Treatment

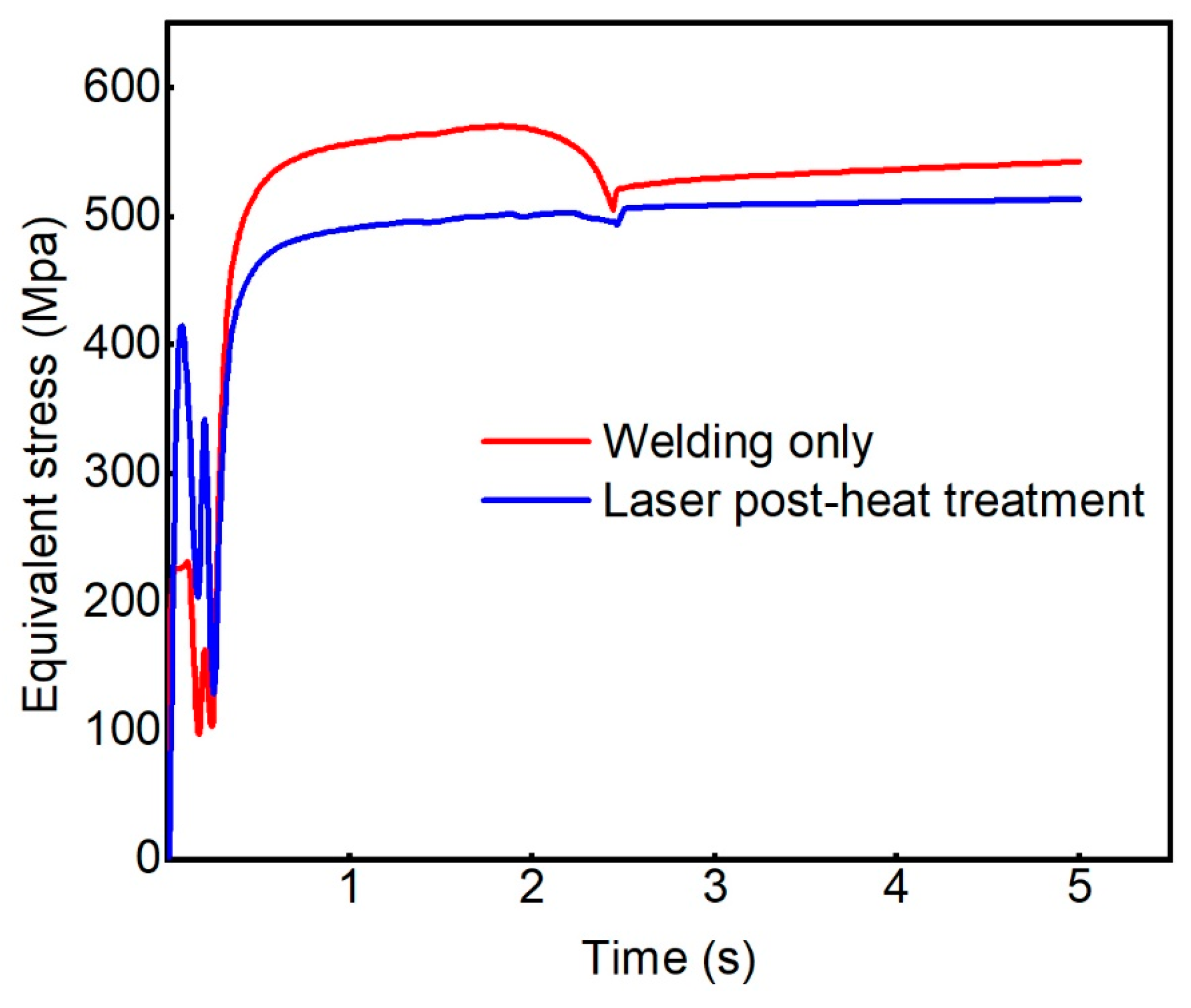

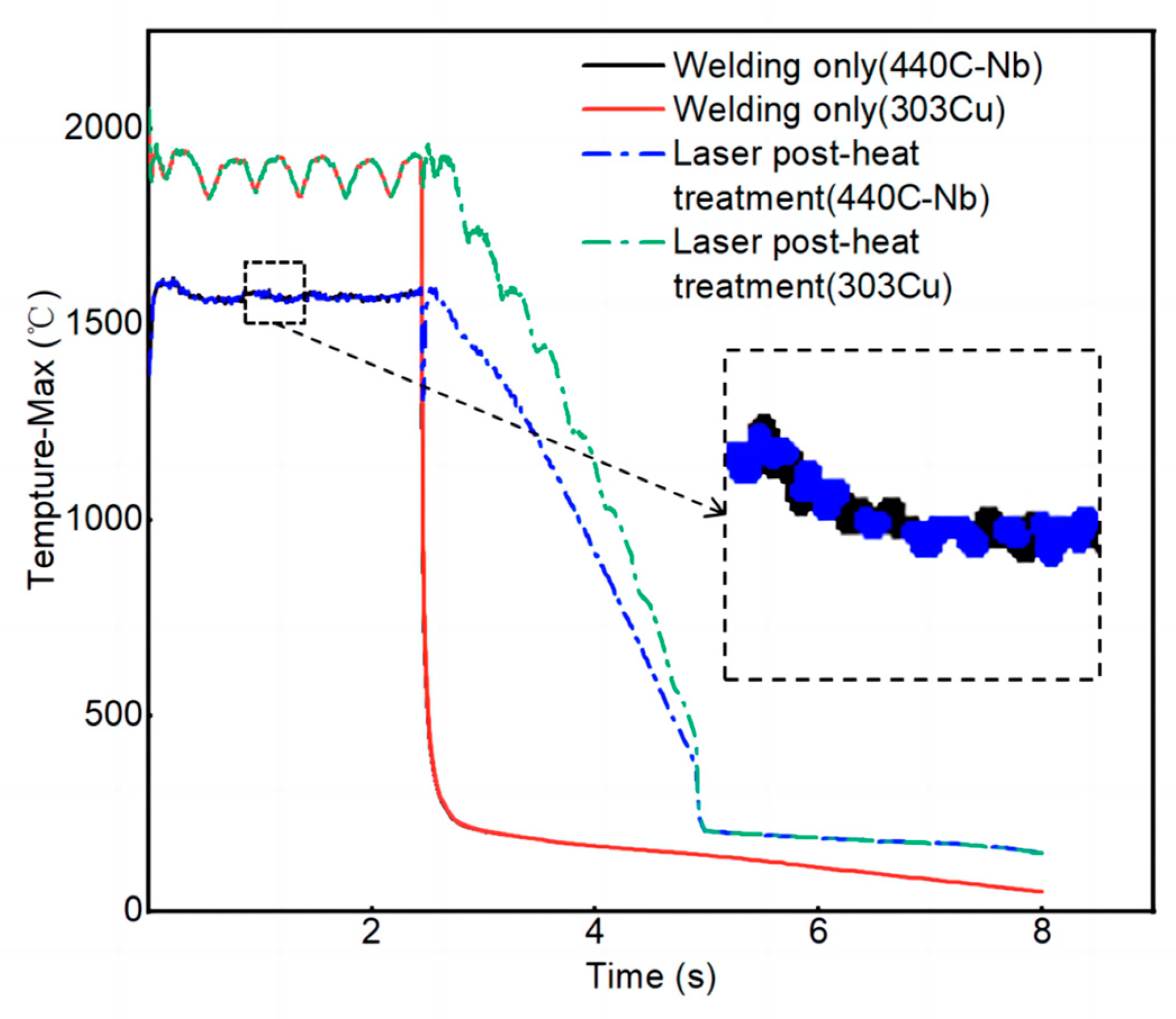

3.2.1. Comparison of Stress and Temperature Simulation

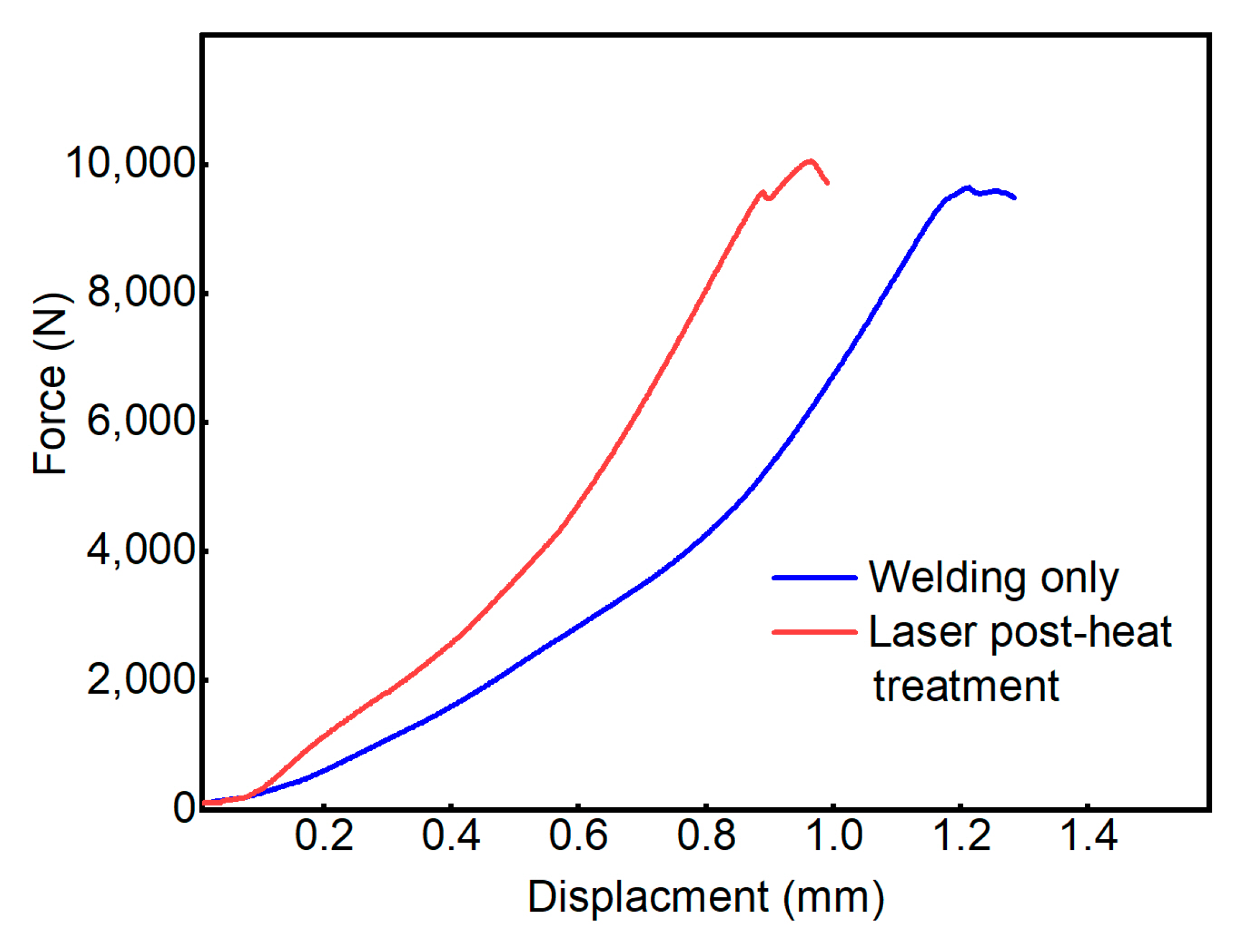

3.2.2. Comparison of Mechanical Properties

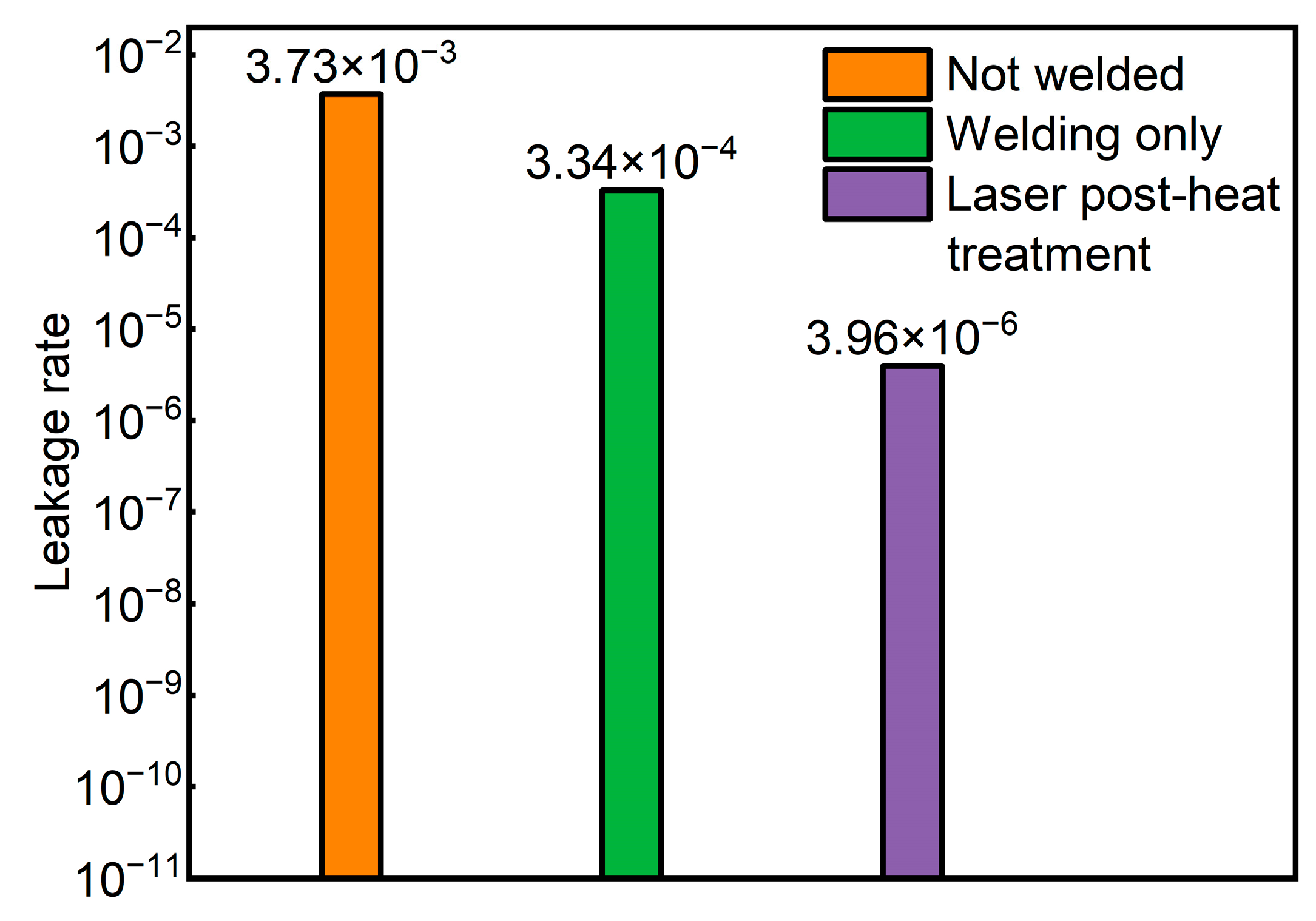

3.2.3. Comparison of Sealing Properties

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baratta, M.; Misul, D.; Xu, J.J.; Fuerhapter, A.; Heindl, R.; Peletto, C.; Preuhs, J.; Salemi, P. Development of a High Performance Natural Gas Engine with Direct Gas Injection and Variable Valve Actuation. SAE Int. J. Engines 2017, 10, 2535–2551. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Wu, S.; Lu, H. Optimization of butt welding of zinc-coated thin sheets with oscillating fiber laser beams: Weld formation, microstructure, and mechanical properties. Weld. World 2021, 65, 1711–1723. [Google Scholar] [CrossRef]

- Wen, X.; Wu, D.; Zhang, P.; Liu, S.; Luo, Z.; Jia, Z.; Ye, X.; Shi, H.; Yu, Z. Influence mechanism of the keyhole behavior on penetration depth by in-situ monitoring in pulsed laser welding of aluminum alloy. Optik 2021, 246, 167812. [Google Scholar] [CrossRef]

- Liavoli, R.P.; Gorji, H.; Bakhshi-Jooybari, M.; Mirnia, M.J. Investigation on Formability of Tailor-Welded Blanks in Incremental Forming. Int. J. Eng. 2020, 33, 906–915. [Google Scholar] [CrossRef]

- Grabmann, S.; Kriegler, J.; Harst, F.; Günter, F.J.; Zaeh, M.F. Laser welding of current collector foil stacks in battery production–mechanical properties of joints welded with a green high-power disk laser. Int. J. Adv. Manuf. Technol. 2021, 118, 2571–2586. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Fang, H.; Ma, N. Characteristics of welding distortion and residual stresses in thin-walled pipes by solid-shell hybrid modelling and experimental verification. J. Manuf. Process. 2021, 69, 532–544. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Liverani, E.; Fortunato, A. Experimental investigation on the effect of spot diameter on continuous-wave laser welding of copper and aluminum thin sheets for battery manufacturing. Opt. Laser Technol. 2022, 145, 107495. [Google Scholar] [CrossRef]

- Stanciu, E.M.; Pascu, A.; Tierean, M.H.; Roata, I.C.; Voiculescu, I.; Hulka, I.; Croitoru, C. Dissimilar Laser Welding of AISI 321 and AISI 1010. Teh. Vjesn. Tech. Gaz. 2018, 25, 344–349. [Google Scholar] [CrossRef]

- Babu, S.S. Thermodynamic and kinetic models for describing microstructure evolution during joining of metals and alloys. Int. Mater. Rev. 2013, 54, 333–367. [Google Scholar] [CrossRef]

- Mao, K.S.; Sun, C.; Shiau, C.-H.; Yano, K.H.; Freyer, P.D.; El-Azab, A.A.; Garner, F.A.; French, A.; Shao, L.; Wharry, J.P. Role of cavities on deformation-induced martensitic transformation pathways in a laser-welded, neutron irradiated austenitic stainless steel. Scr. Mater. 2019, 178, 1–6. [Google Scholar] [CrossRef]

- Andersson, O.; Budak, N.; Melander, A.; Palmquist, N. Experimental measurements and numerical simulations of distortions of overlap laser-welded thin sheet steel beam structures. Weld. World 2017, 61, 927–934. [Google Scholar] [CrossRef]

- Dak, G.; Pandey, C. A critical review on dissimilar welds joint between martensitic and austenitic steel for power plant application. J. Manuf. Process. 2020, 58, 377–406. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Halvaee, A. Resistance upset butt welding of austenitic to martensitic stainless steels. Mater. Des. 2010, 31, 3044–3050. [Google Scholar] [CrossRef]

- Casalino, G.; Angelastro, A.; Perulli, P.; Casavola, C.; Moramarco, V. Study on the fiber laser/TIG weldability of AISI 304 and AISI 410 dissimilar weld. J. Manuf. Process. 2018, 35, 216–225. [Google Scholar] [CrossRef]

- Dak, G.; Sirohi, S.; Pandey, C. Study on microstructure and mechanical behavior relationship for laser-welded dissimilar joint of P92 martensitic and 304L austenitic steel. Int. J. Press. Vessel. Pip. 2022, 196, 104629. [Google Scholar] [CrossRef]

- Varbai, B.; Bolyhos, P.; Kemény, D.M.; Májlinger, K. Microstructure and Corrosion Properties of Austenitic and Duplex Stainless Steel Dissimilar Joints. Period. Polytech. Mech. Eng. 2022, 66, 344–349. [Google Scholar] [CrossRef]

- Tuz, L.; Sokołowski, Ł.; Stano, S. Effect of Post-Weld Heat Treatment on Microstructure and Hardness of Laser Beam Welded 17-4 PH Stainless Steel. Materials 2023, 16, 1334. [Google Scholar] [CrossRef]

- Hietala, M.; Jaskari, M.; Ali, M.; Jarvenpaa, A.; Hamada, A. Dissimilar Laser Welding of Austenitic Stainless Steel and Abrasion-Resistant Steel: Microstructural Evolution and Mechanical Properties Enhanced by Post-Weld Heat Treatment. Materials 2021, 14, 5580. [Google Scholar] [CrossRef]

- Pancikiewicz, K.; Swierczynska, A.; Hucko, P.; Tumidajewicz, M. Laser Dissimilar Welding of AISI 430F and AISI 304 Stainless Steels. Materials 2020, 13, 4540. [Google Scholar] [CrossRef]

- Zhang, W.W.; Cong, S. Process optimization and performance evaluation on laser beam welding of austenitic/martensitic dissimilar materials. Int. J. Adv. Manuf. Technol. 2017, 92, 4161–4168. [Google Scholar] [CrossRef]

- Pańcikiewicz, K.; Radomski, W. Lack of tightness analysis of concealed welded radiators. Eng. Fail. Anal. 2020, 114, 104579. [Google Scholar] [CrossRef]

- Perulli, P.; Dassisti, M.; Casalino, G. Thermo-Mechanical Simulation of Hybrid Welding of DP/AISI 316 and TWIP/AISI 316 Dissimilar Weld. Materials 2020, 13, 2088. [Google Scholar] [CrossRef] [PubMed]

- Danielewski, H.; Skrzypczyk, A.; Tofil, S.; Witkowski, G.; Rutkowski, S. Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint. Open Eng. 2020, 10, 491–498. [Google Scholar] [CrossRef]

- Danielewski, H.; Skrzypczyk, A. Steel Sheets Laser Lap Joint Welding-Process Analysis. Materials 2020, 13, 2258. [Google Scholar] [CrossRef]

- Kik, T. Heat Source Models in Numerical Simulations of Laser Welding. Materials 2020, 13, 2653. [Google Scholar] [CrossRef]

- Morawiec, M.; Kik, T.; Stano, S.; Rozanski, M.; Grajcar, A. Numerical Simulation and Experimental Analysis of Thermal Cycles and Phase Transformation Behavior of Laser-Welded Advanced Multiphase Steel. Symmetry 2022, 14, 477. [Google Scholar] [CrossRef]

- Omoniyi, P.; Mahamood, R.; Arthur, N.; Pityana, S.; Skhosane, S.; Okamoto, Y.; Shinonaga, T.; Maina, M.; Jen, T.-C.; Akinlabi, E. Laser Butt Welding of Thin Ti6Al4V Sheets: Effects of Welding Parameters. J. Compos. Sci. 2021, 5, 246. [Google Scholar] [CrossRef]

- Dak, G.; Pandey, C. Microstructure anomaly during welding and its influence on the mechanical properties of dissimilar weldments of P92 martensitic steel and AISI 304L austenitic stainless steel. J. Manuf. Process. 2022, 80, 829–851. [Google Scholar] [CrossRef]

- Başyiğit, A.; Murat, M. The Effects of TIG Welding Rod Compositions on Microstructural and Mechanical Properties of Dissimilar AISI 304L and 420 Stainless Steel Welds. Metals 2018, 8, 972. [Google Scholar] [CrossRef]

- Tigga, S.S.; Verma, D.K.; Panneerselvam, K. Microstructure & mechanical properties of dissimilar material joints between T91 martensitic & S304H austenitic steels using different filler wires. Mater. Today Proc. 2021, 46, 9397–9404. [Google Scholar] [CrossRef]

- Hong, K.-M.; Shin, Y.C. The effects of interface gap on weld strength during overlapping fiber laser welding of AISI 304 stainless steel and AZ31 magnesium alloys. Int. J. Adv. Manuf. Technol. 2016, 90, 3685–3696. [Google Scholar] [CrossRef]

- Jiang, M.; Tao, W.; Chen, Y. Laser Welding under Vacuum: A Review. Appl. Sci. 2017, 7, 909. [Google Scholar] [CrossRef]

- Kik, T.; Moravec, J.; Svec, M. Experiments and Numerical Simulations of the Annealing Temperature Influence on the Residual Stresses Level in S700MC Steel Welded Elements. Materials 2020, 13, 5289. [Google Scholar] [CrossRef]

| Weight (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Materials | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Nb |

| 303Cu | 0.05 | 0.09 | 2.37 | 0.026 | 0.272 | 17.41 | 8.54 | - | 2.03 | - |

| 440C-Nb | 1.20 | 0.60 | 0.80 | - | - | 17.00 | 0.15 | 0.50 | - | 3.00 |

| Laser Power (W) | Welding Speed v/(mm/s) | Defocus Amount (Δf/mm) | Rotation Angle (°) |

|---|---|---|---|

| 215 | 23.88 | +1.5 | 360 |

| Weight (%) | |||||

|---|---|---|---|---|---|

| Elements | Area 1 | Area 2 | Area 3 | Area 4 | Area 5 |

| Ni | 7.7 | 7.2 | 7.4 | 2.3 | 0.3 |

| Cu | 2.0 | 1.7 | 1.5 | 0.0 | 0.0 |

| Nb | 0.0 | 0.0 | 0.0 | 2.6 | 3.8 |

| Mo | 0.0 | 0.0 | 0.0 | 0.6 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Li, D.; Xu, C.; Zheng, Z.; Liu, Y. Experimental Research and Numerical Simulation of Laser Welding of 303Cu/440C-Nb Stainless-Steel Thin-Walled Natural-Gas Injector for Vehicles. Materials 2023, 16, 2109. https://doi.org/10.3390/ma16052109

Zhou L, Li D, Xu C, Zheng Z, Liu Y. Experimental Research and Numerical Simulation of Laser Welding of 303Cu/440C-Nb Stainless-Steel Thin-Walled Natural-Gas Injector for Vehicles. Materials. 2023; 16(5):2109. https://doi.org/10.3390/ma16052109

Chicago/Turabian StyleZhou, Lisen, Dongya Li, Chonghai Xu, Zhaoxing Zheng, and Yu Liu. 2023. "Experimental Research and Numerical Simulation of Laser Welding of 303Cu/440C-Nb Stainless-Steel Thin-Walled Natural-Gas Injector for Vehicles" Materials 16, no. 5: 2109. https://doi.org/10.3390/ma16052109

APA StyleZhou, L., Li, D., Xu, C., Zheng, Z., & Liu, Y. (2023). Experimental Research and Numerical Simulation of Laser Welding of 303Cu/440C-Nb Stainless-Steel Thin-Walled Natural-Gas Injector for Vehicles. Materials, 16(5), 2109. https://doi.org/10.3390/ma16052109