Investigation of the Failure Modes of Textile-Reinforced Concrete and Fiber/Textile-Reinforced Concrete under Uniaxial Tensile Tests

Abstract

1. Introduction

2. Research Method, Content and Significance

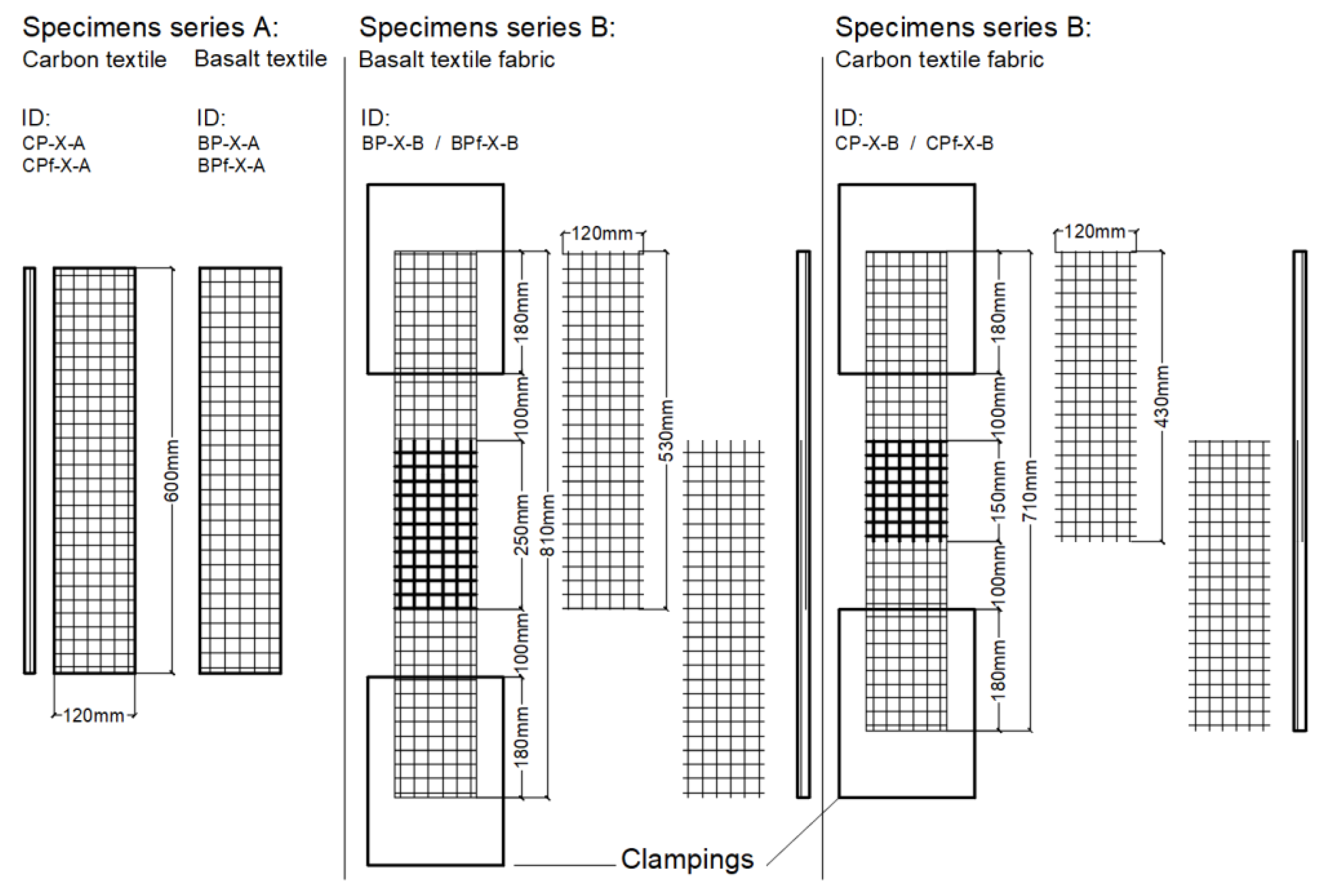

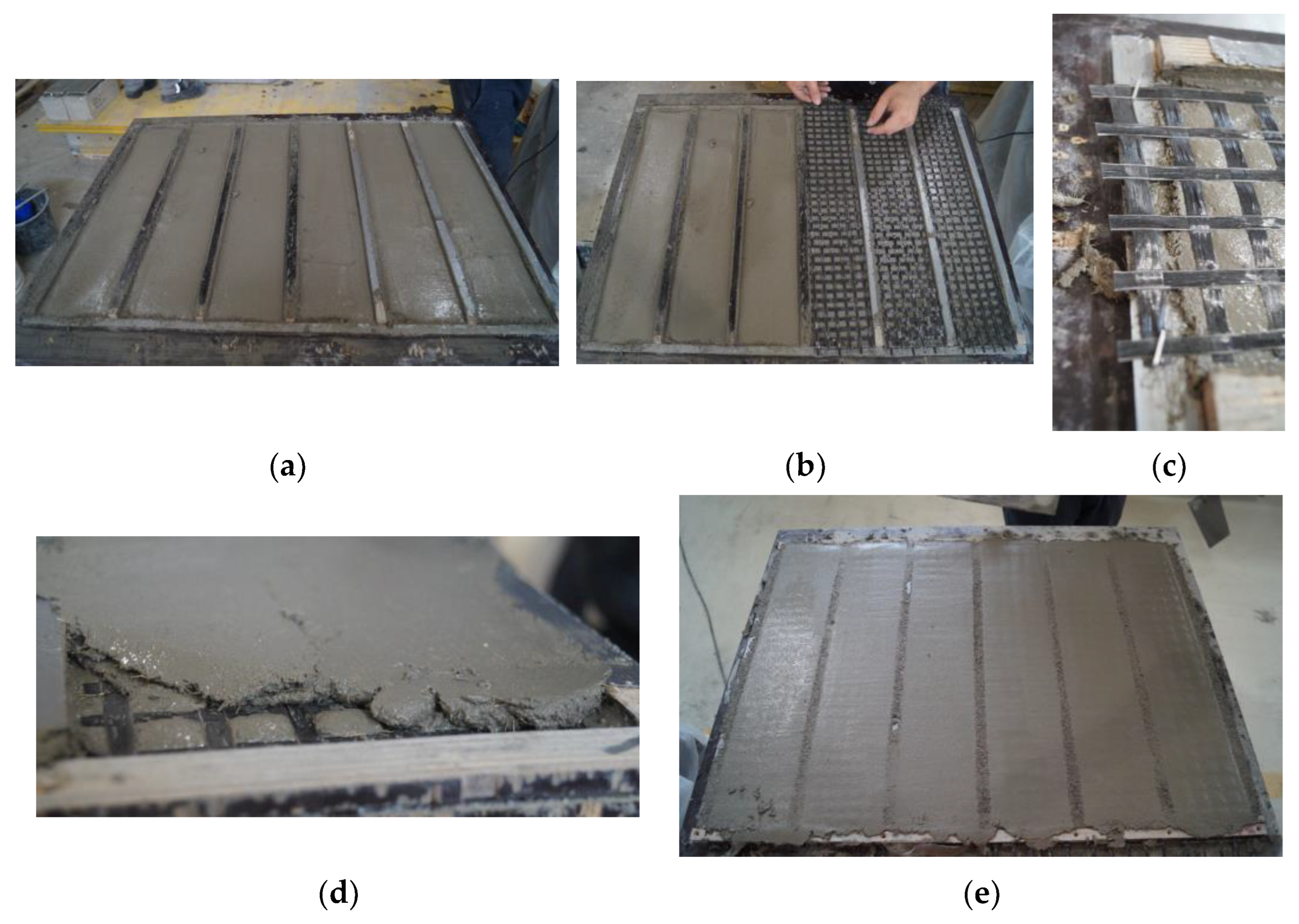

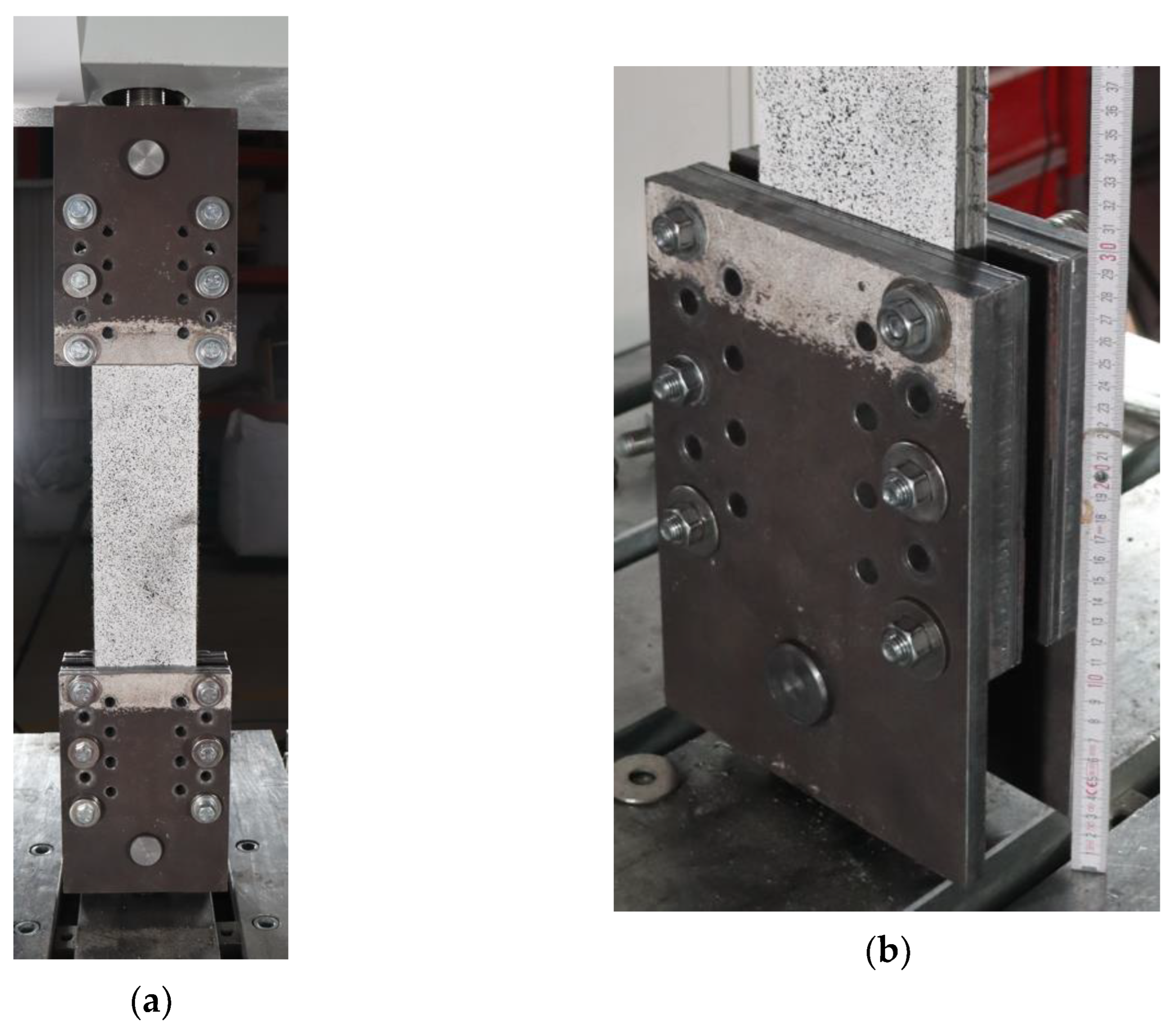

3. Materials and Methods

4. Results

4.1. Series A

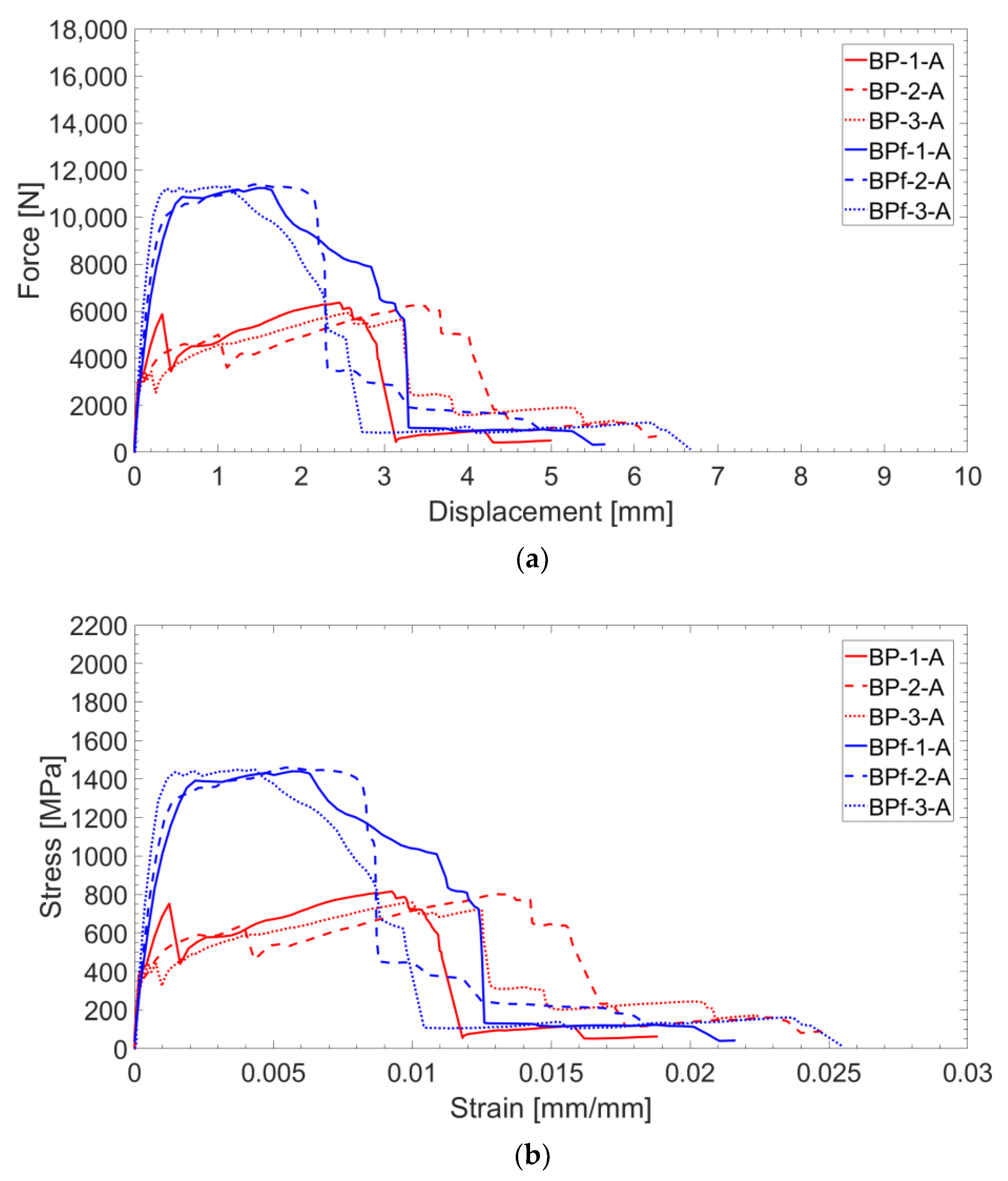

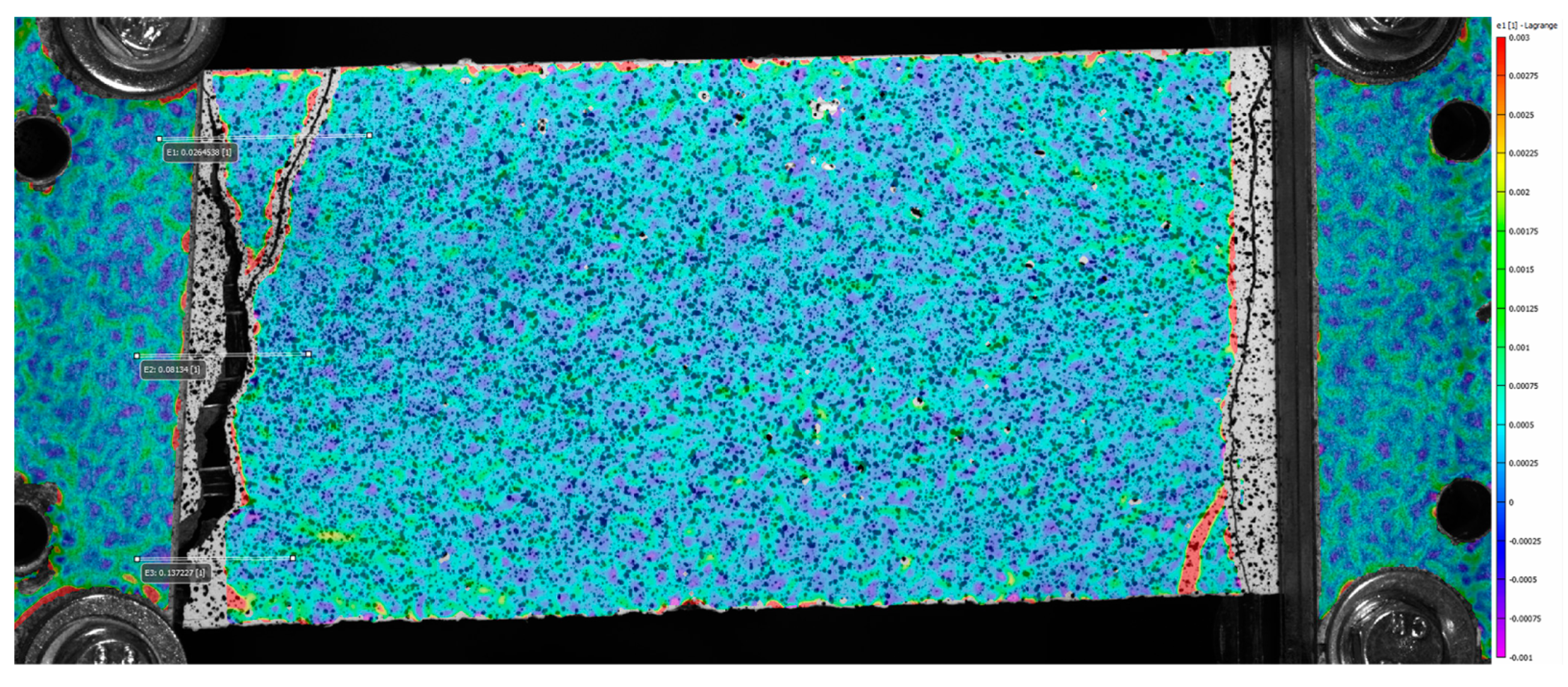

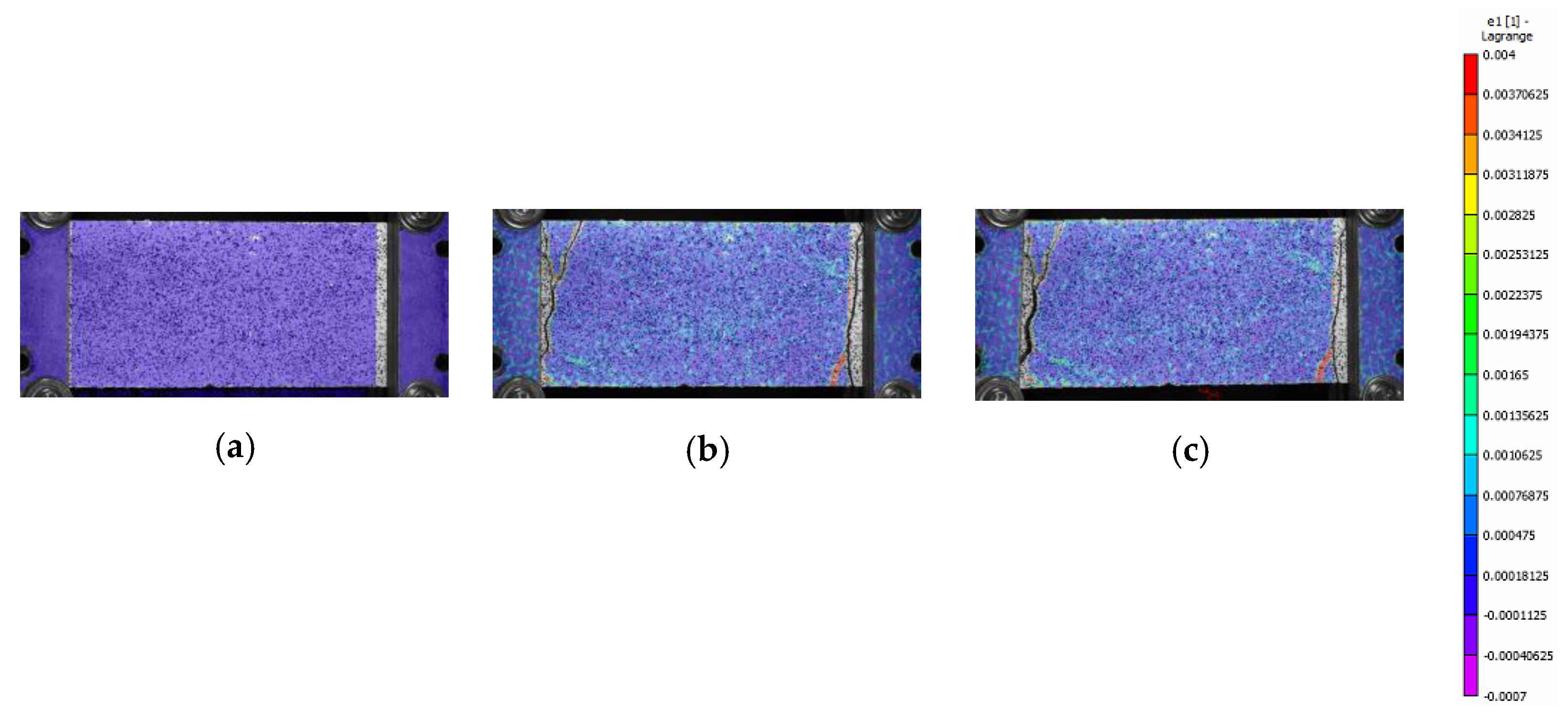

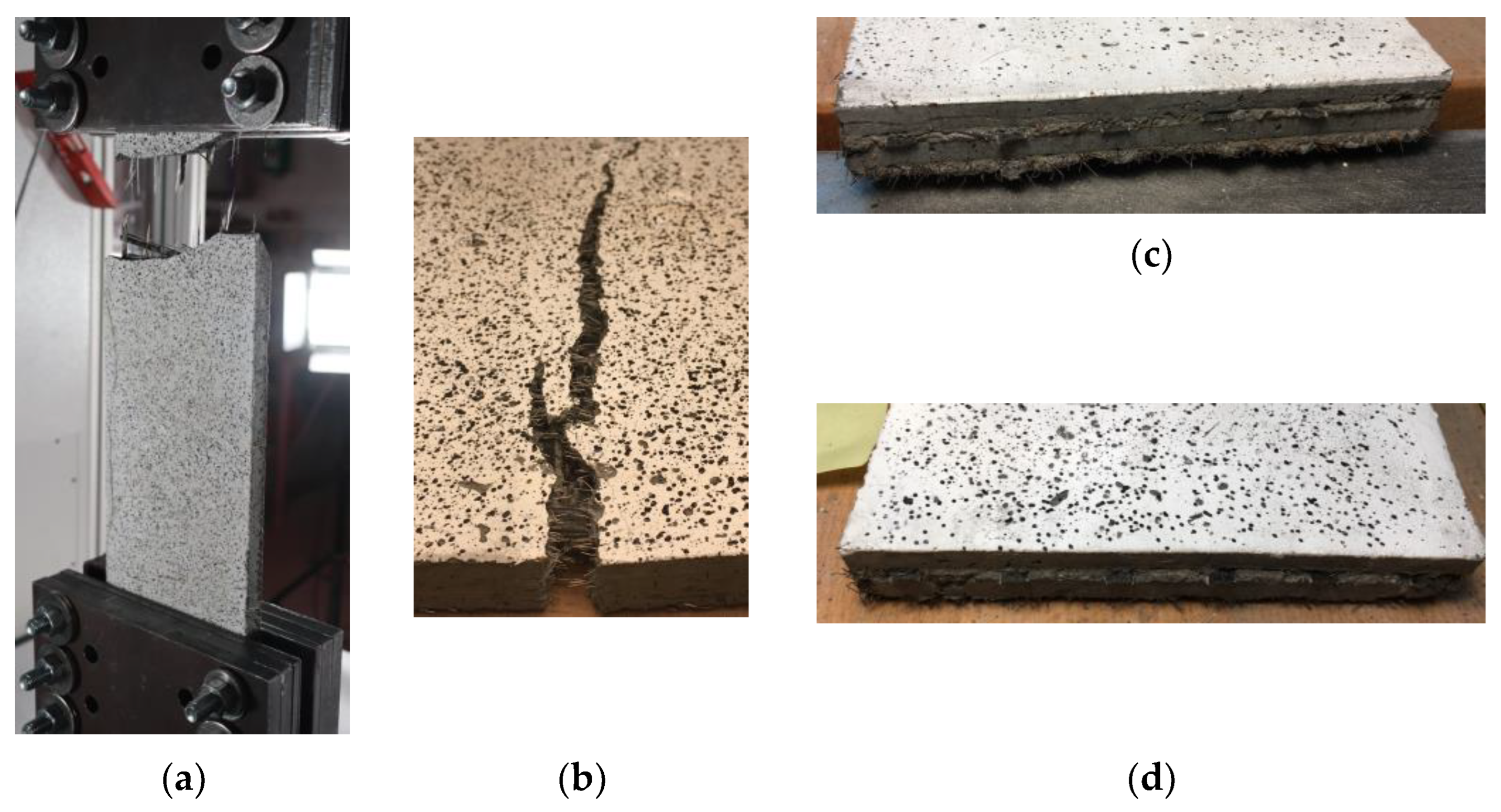

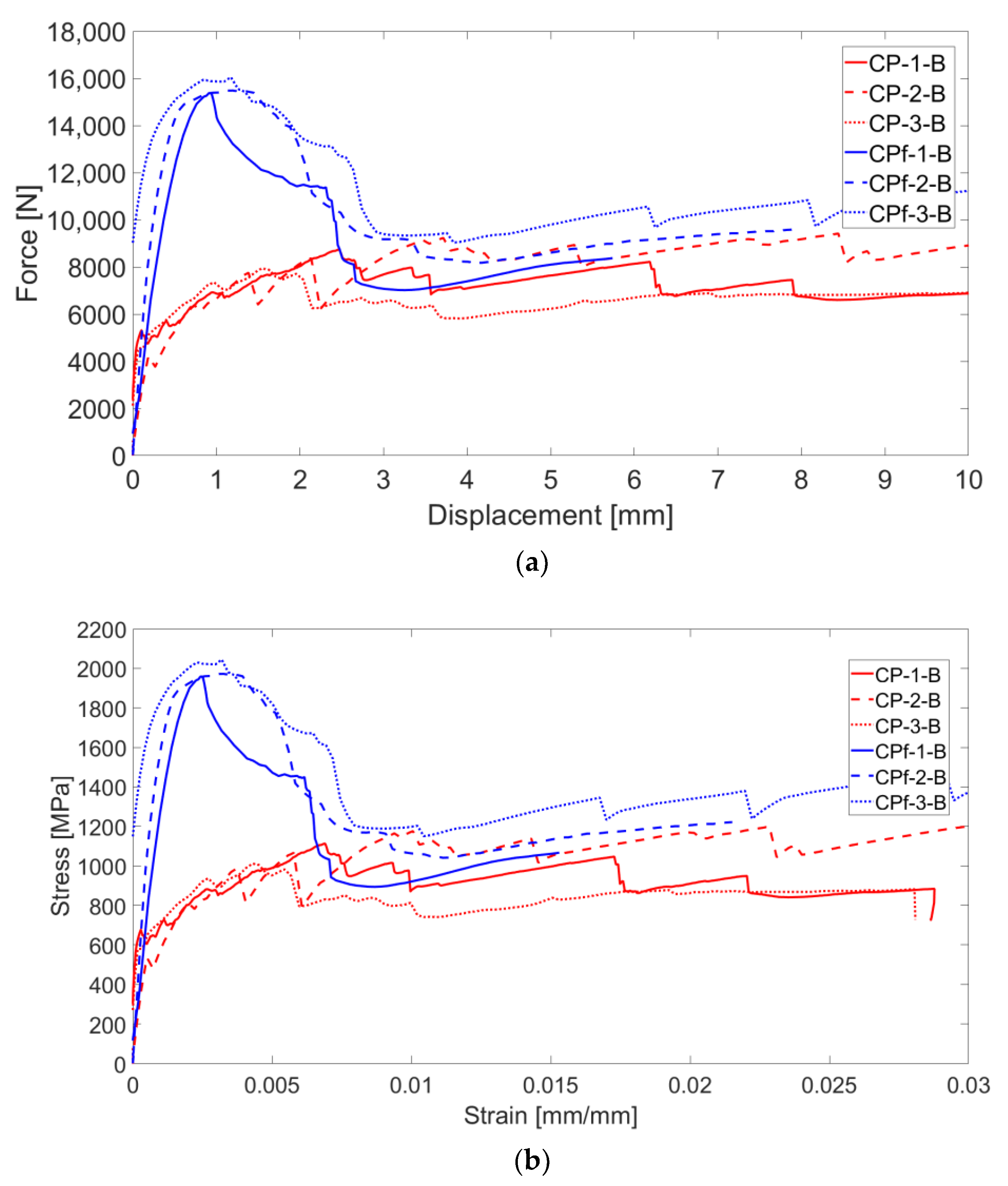

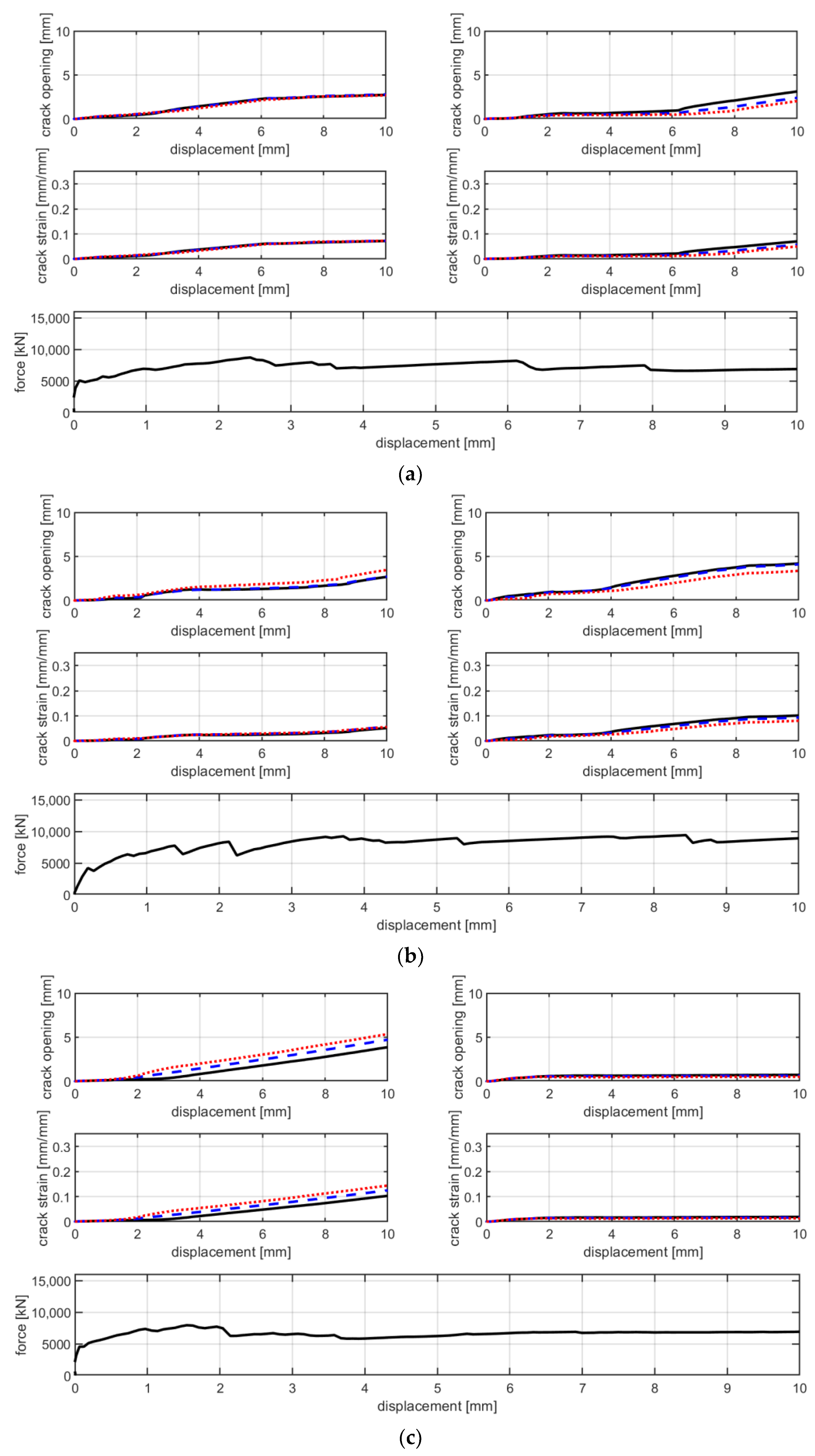

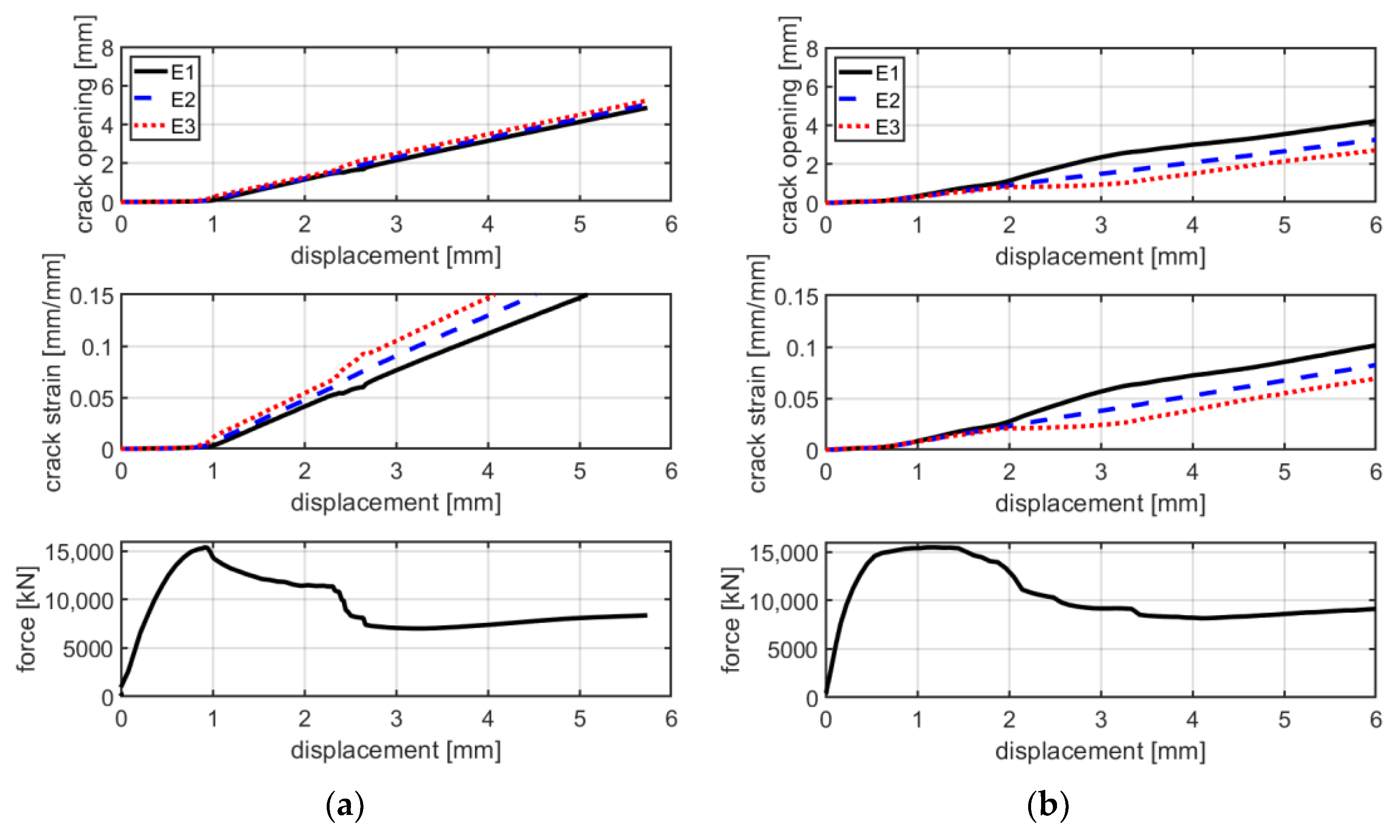

4.1.1. B-TRC vs. B-F/TRC

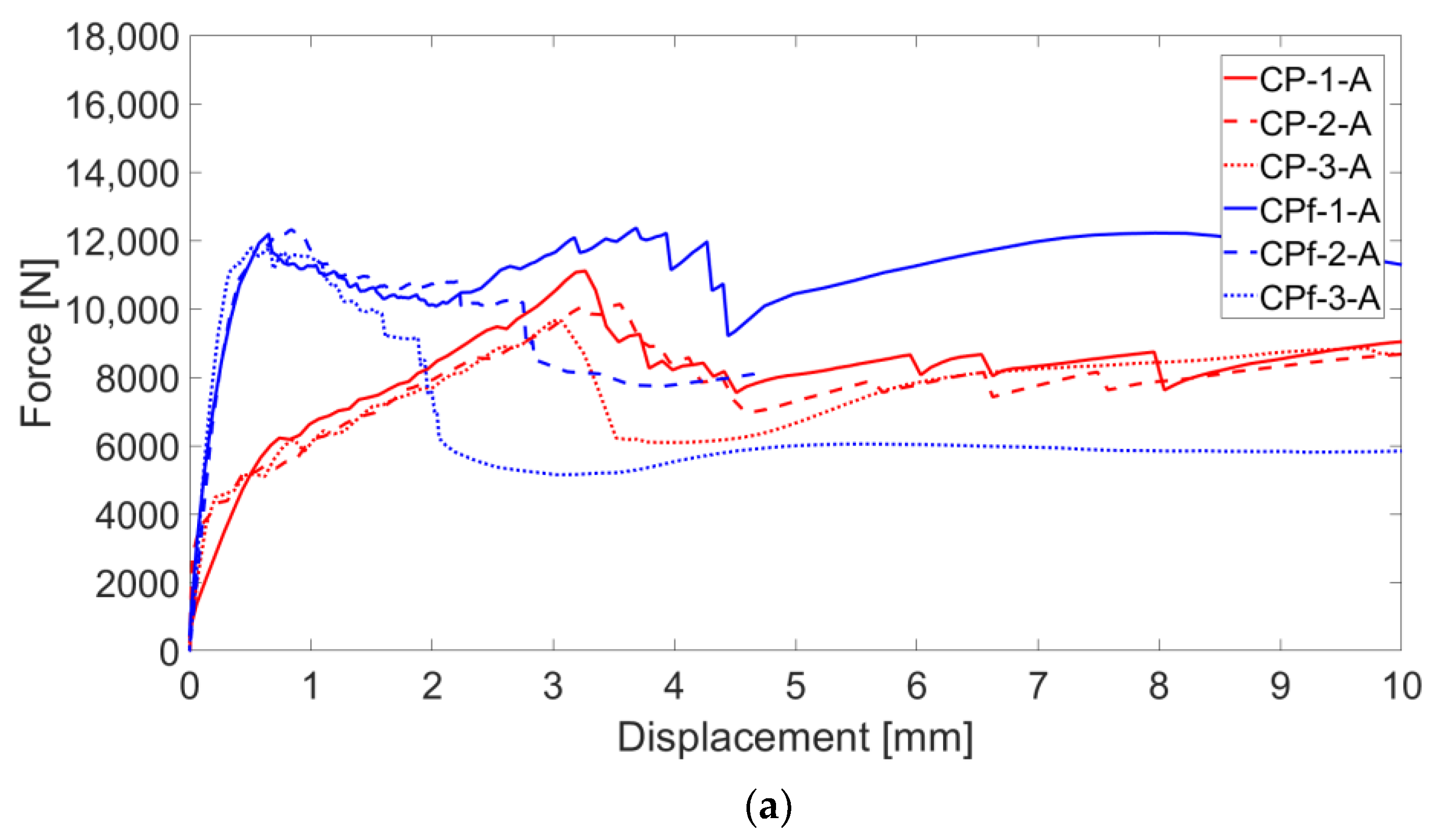

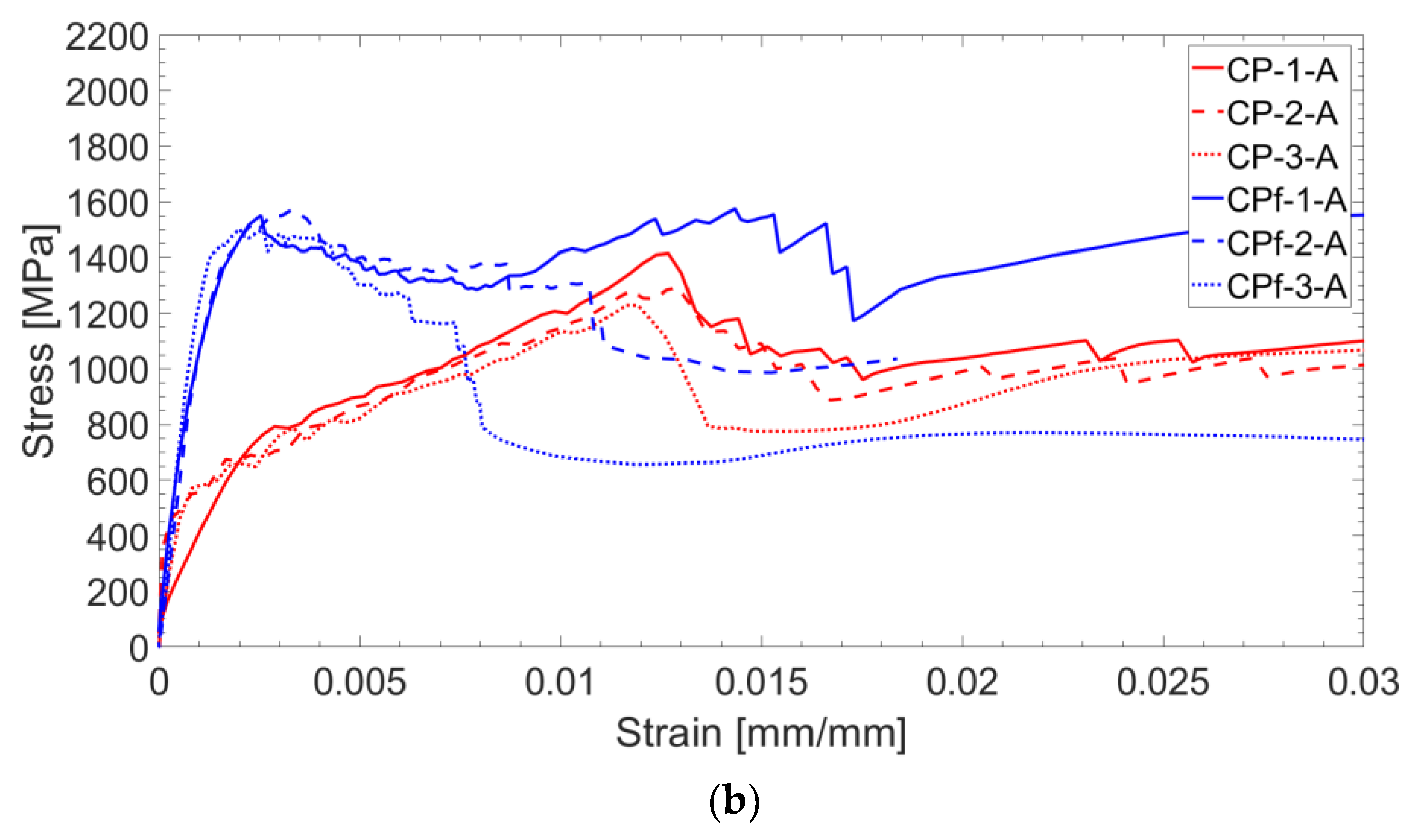

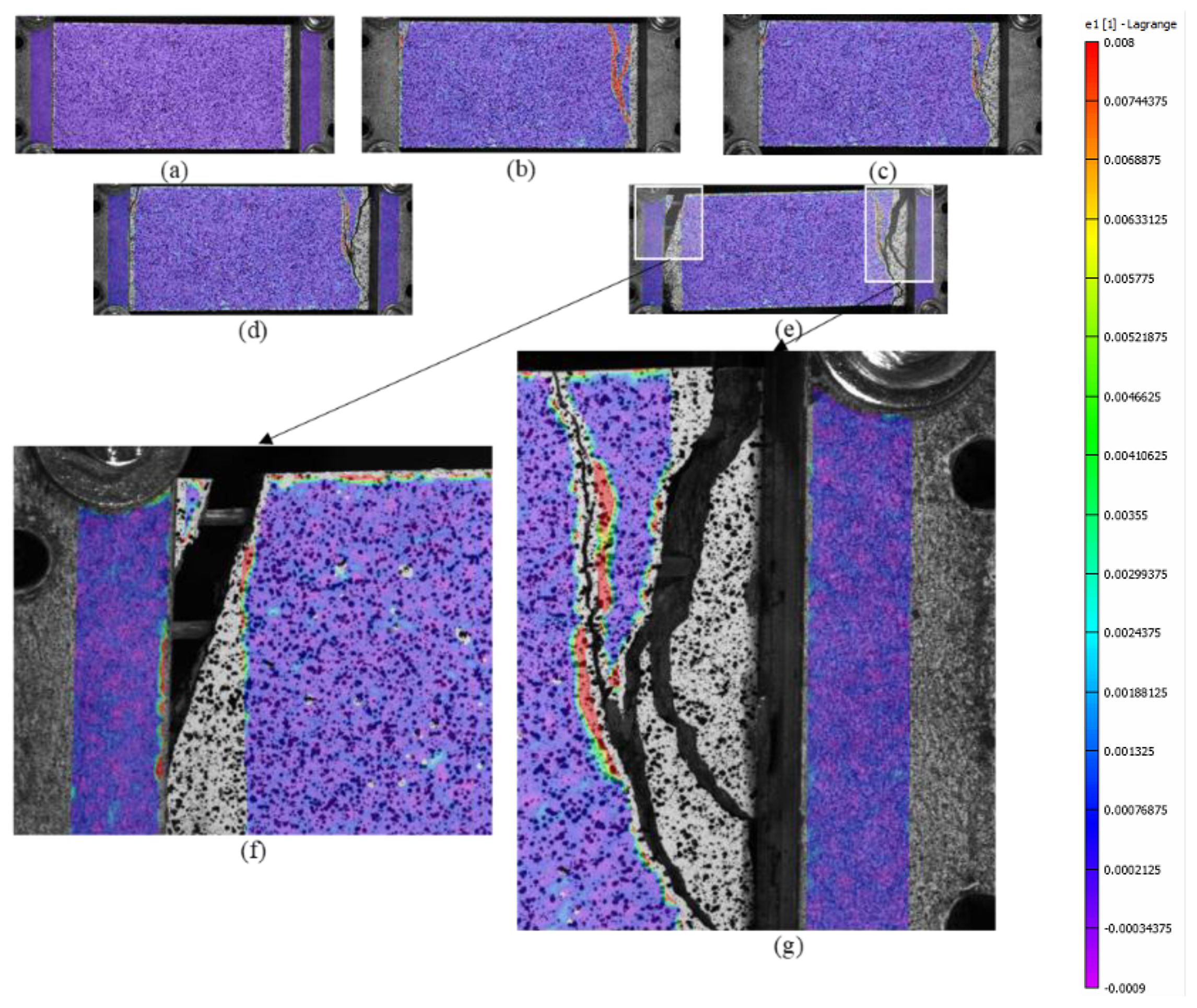

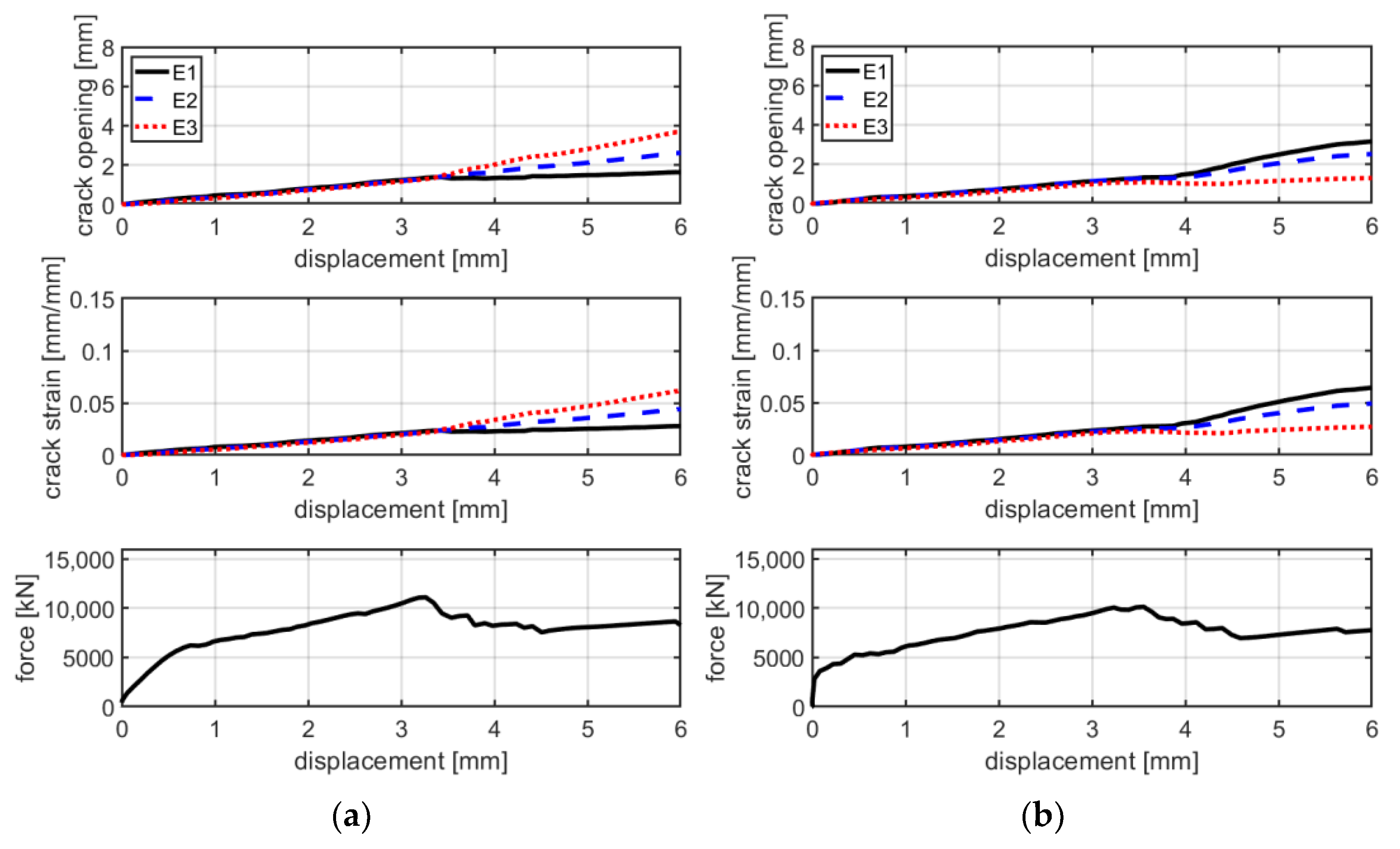

4.1.2. C-TRC vs. C-F/TRC

4.2. Series B

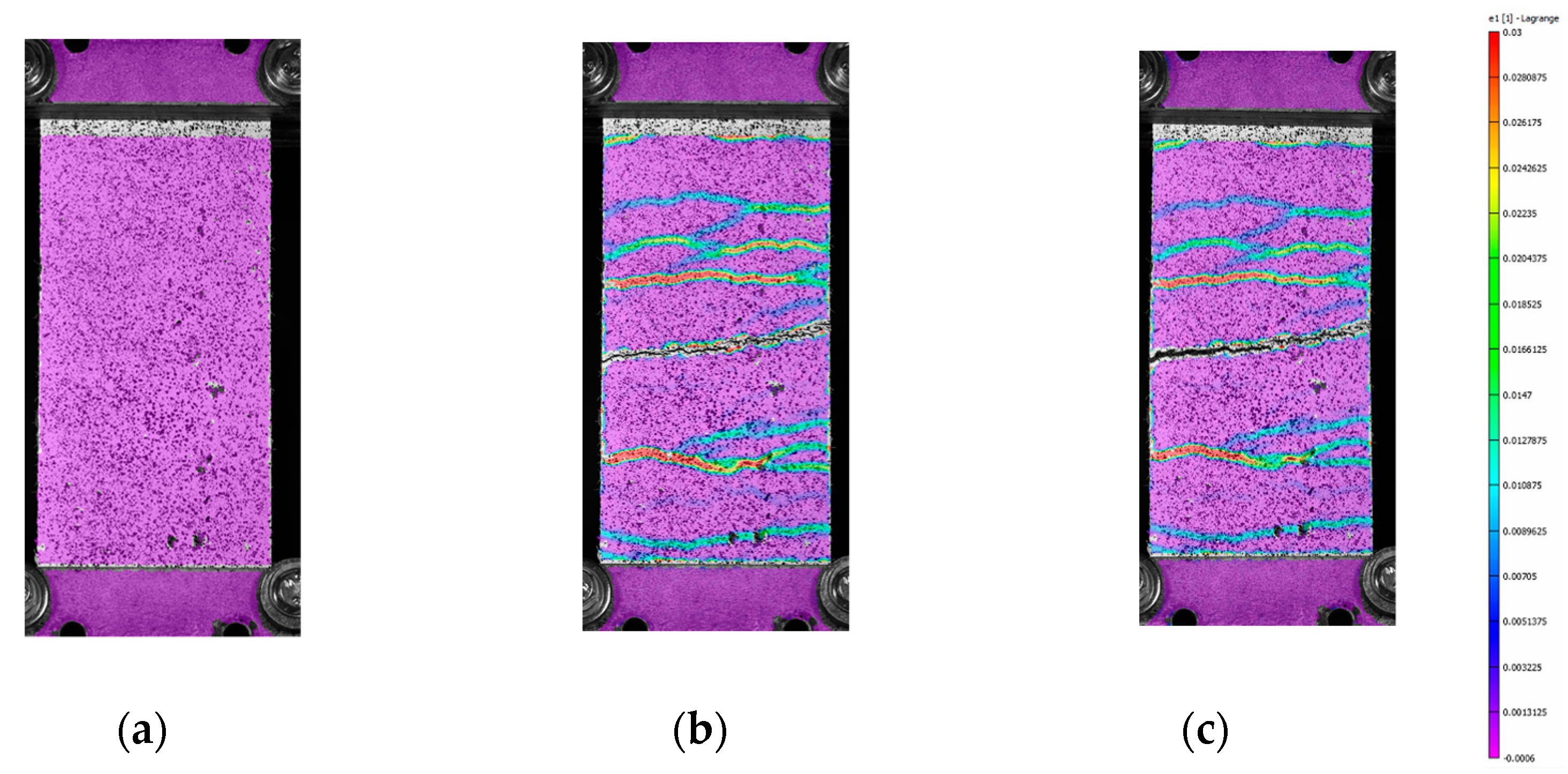

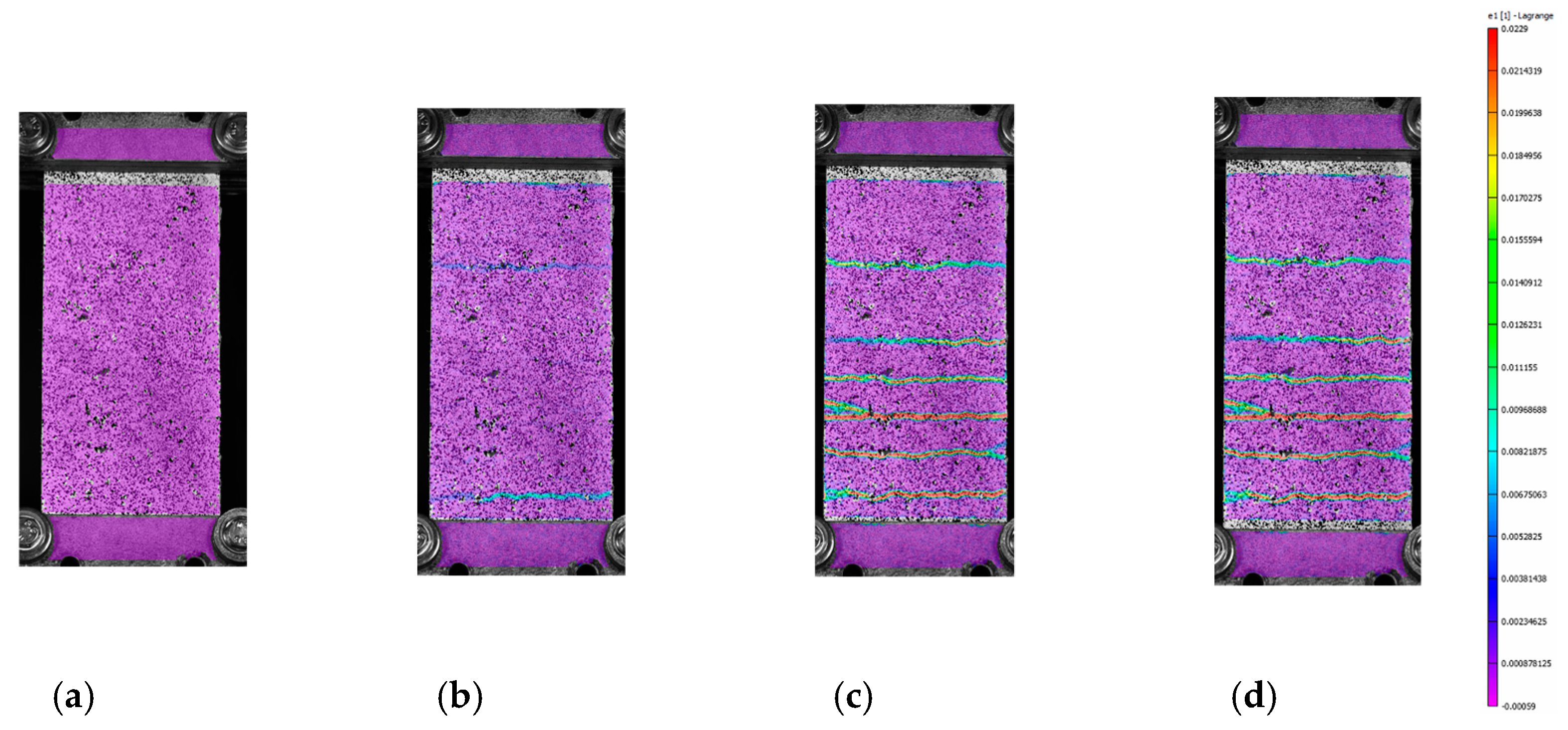

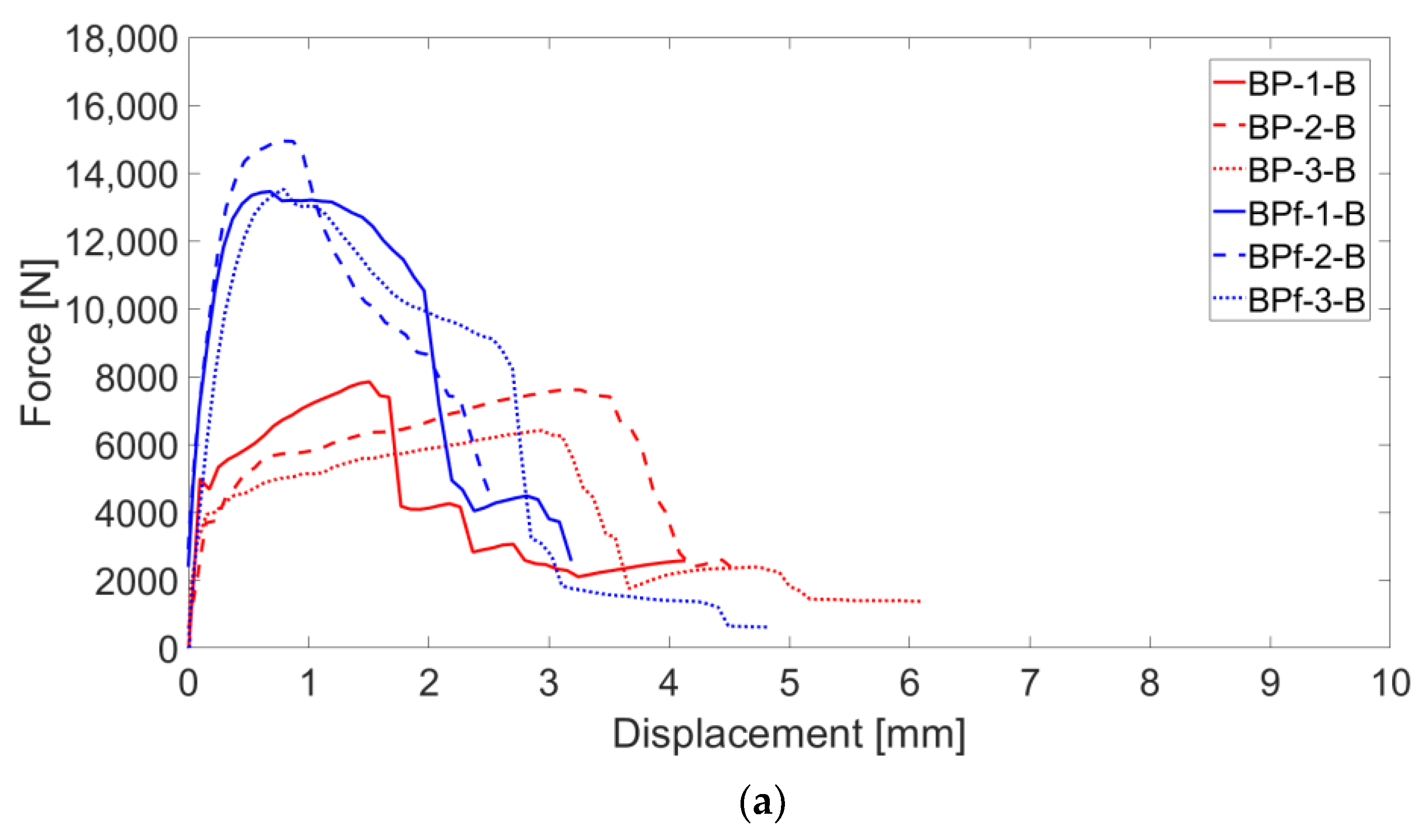

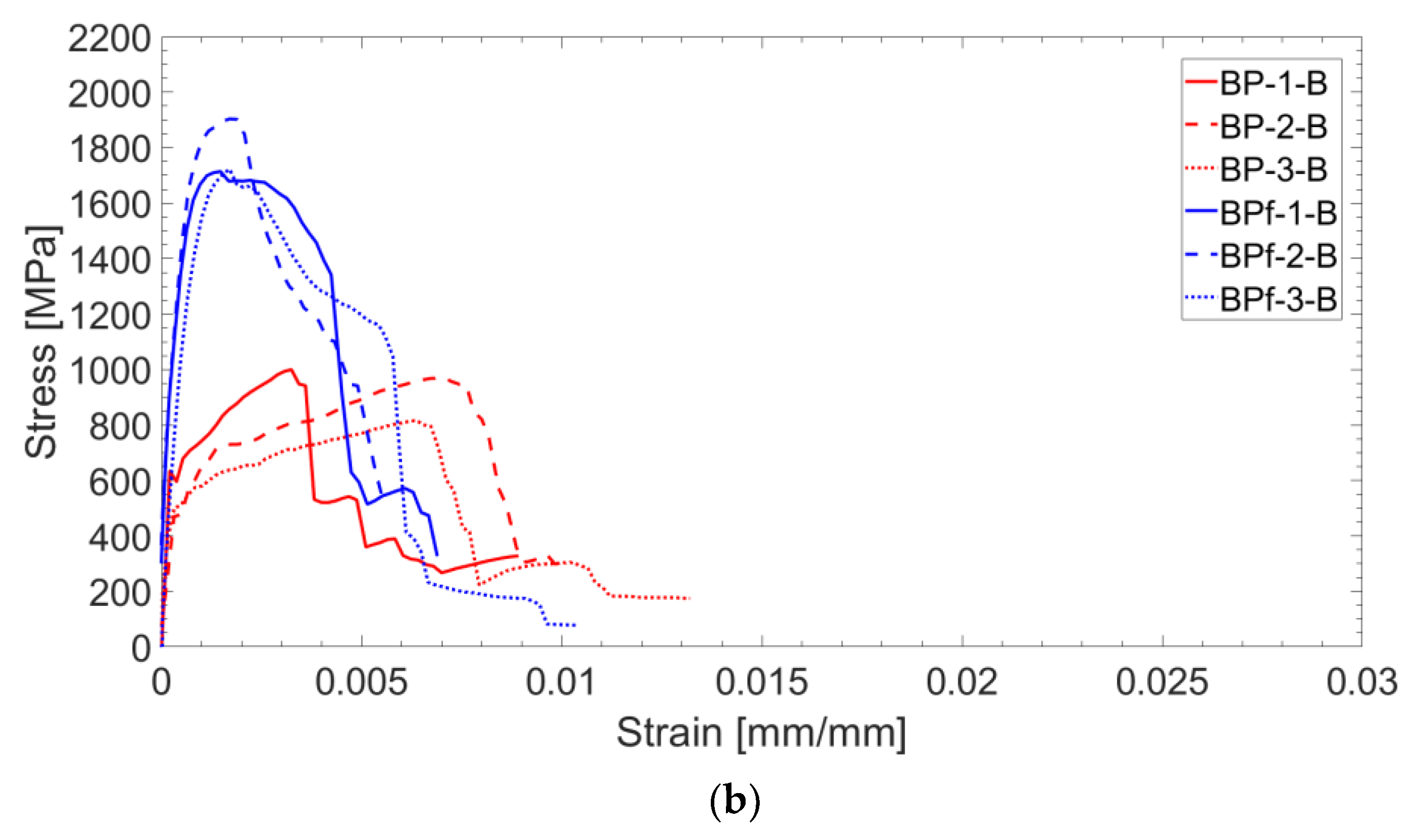

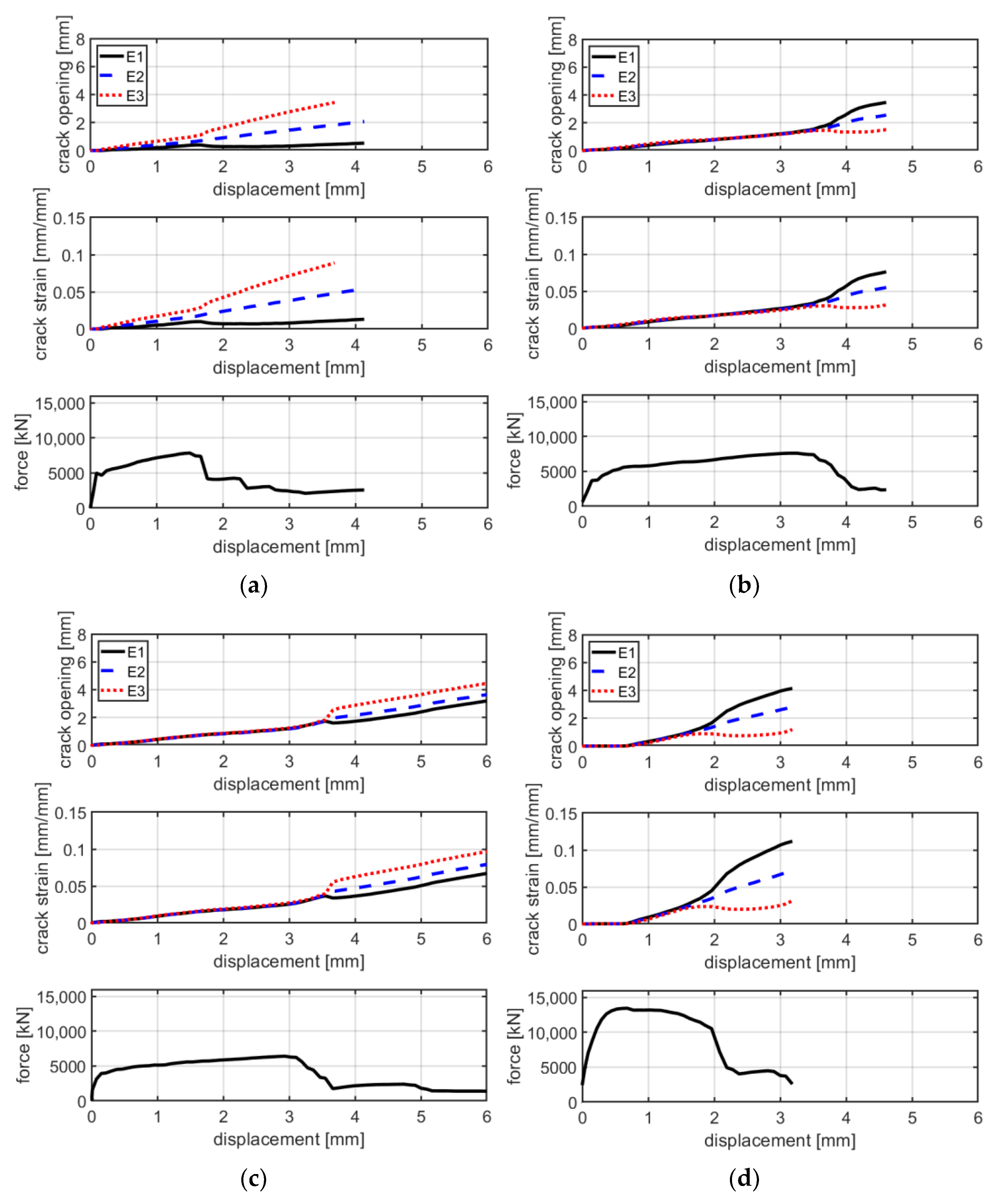

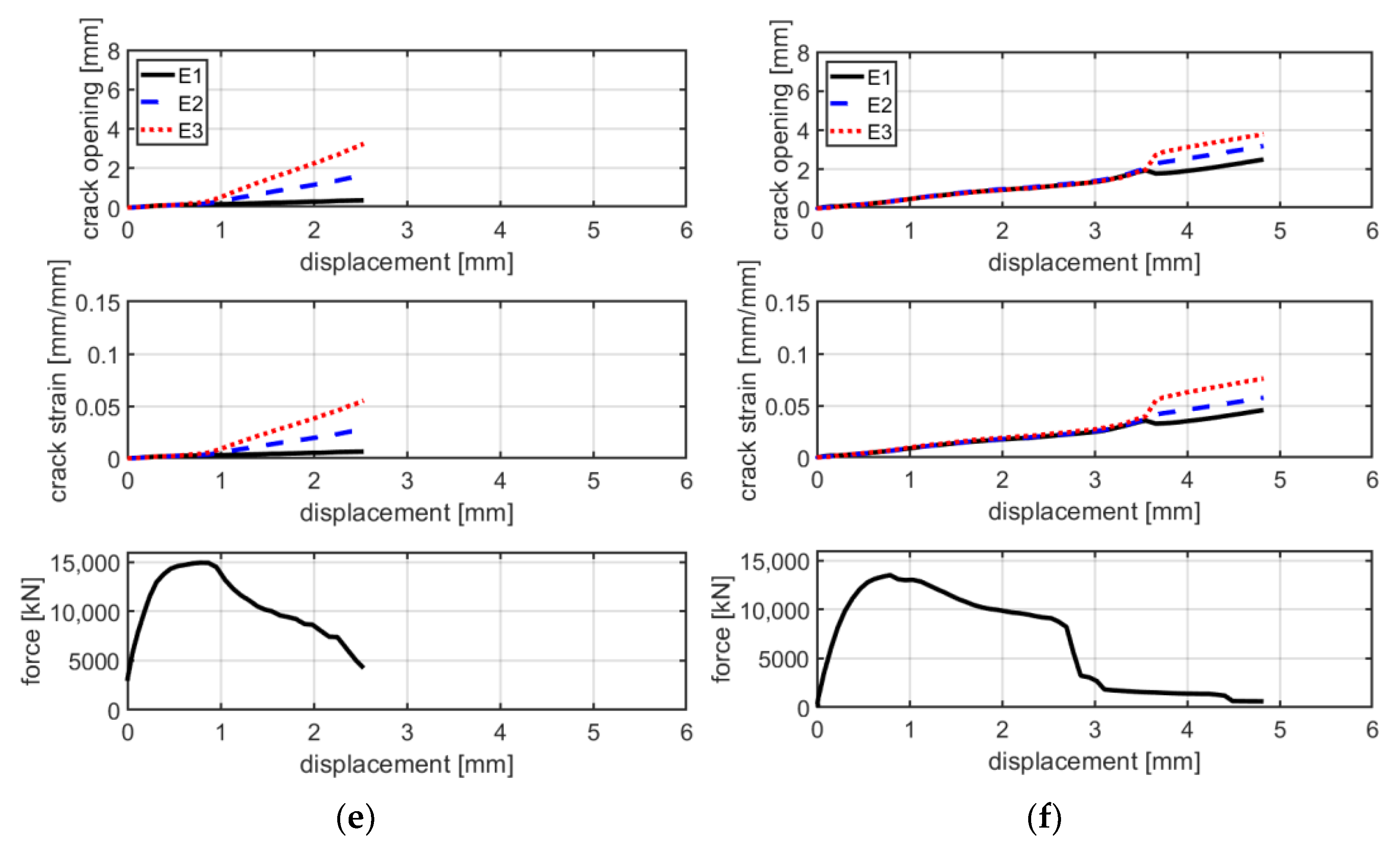

4.2.1. B-TRC vs. B-F/TRC

4.2.2. C-TRC vs. C-F/TRC

5. Discussion

5.1. B-TRC vs. B-F/TRC Series A

5.2. C-TRC vs. C-F/TRC Series A

5.3. B-TRC vs. B-F/TRC Series B

5.4. C-TRC vs. C-F/TRC Series B

6. Conclusions

- Carbon-retrofitted specimens perform better, in terms of maximum tensile load, compared with those retrofitted with basalt textile fabric. In this experimental test campaign, the average maximum loads are 66.7% and 22.2% higher for TRC specimens and 7.5% and 11.9% higher for F/TRC specimens of series A and B, respectively.

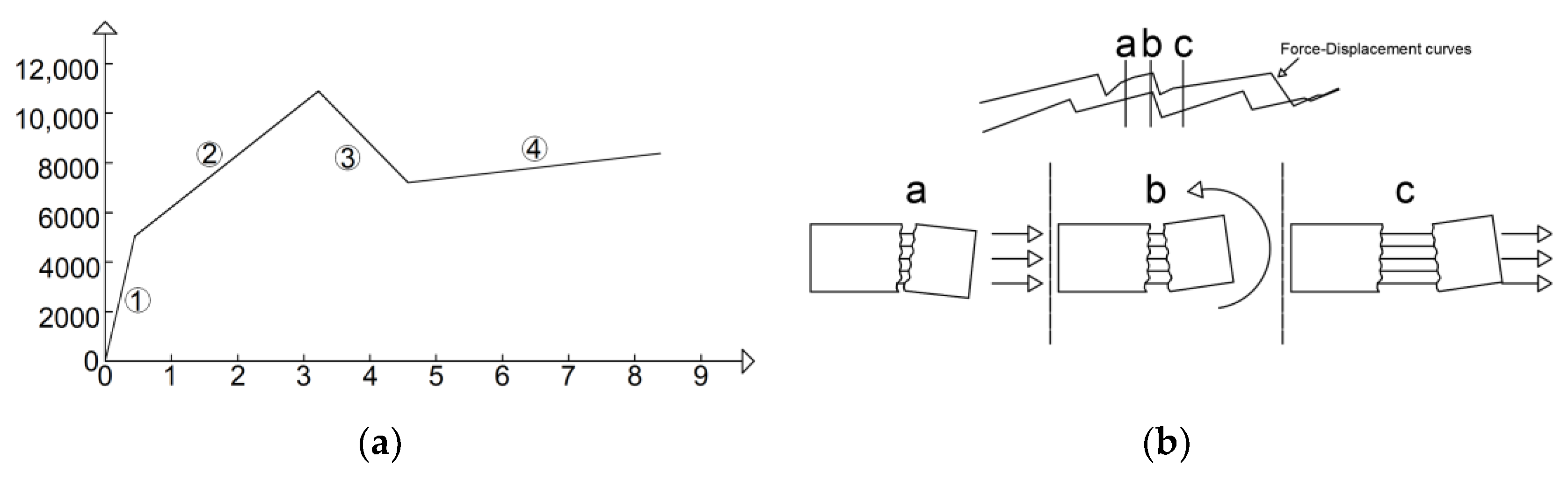

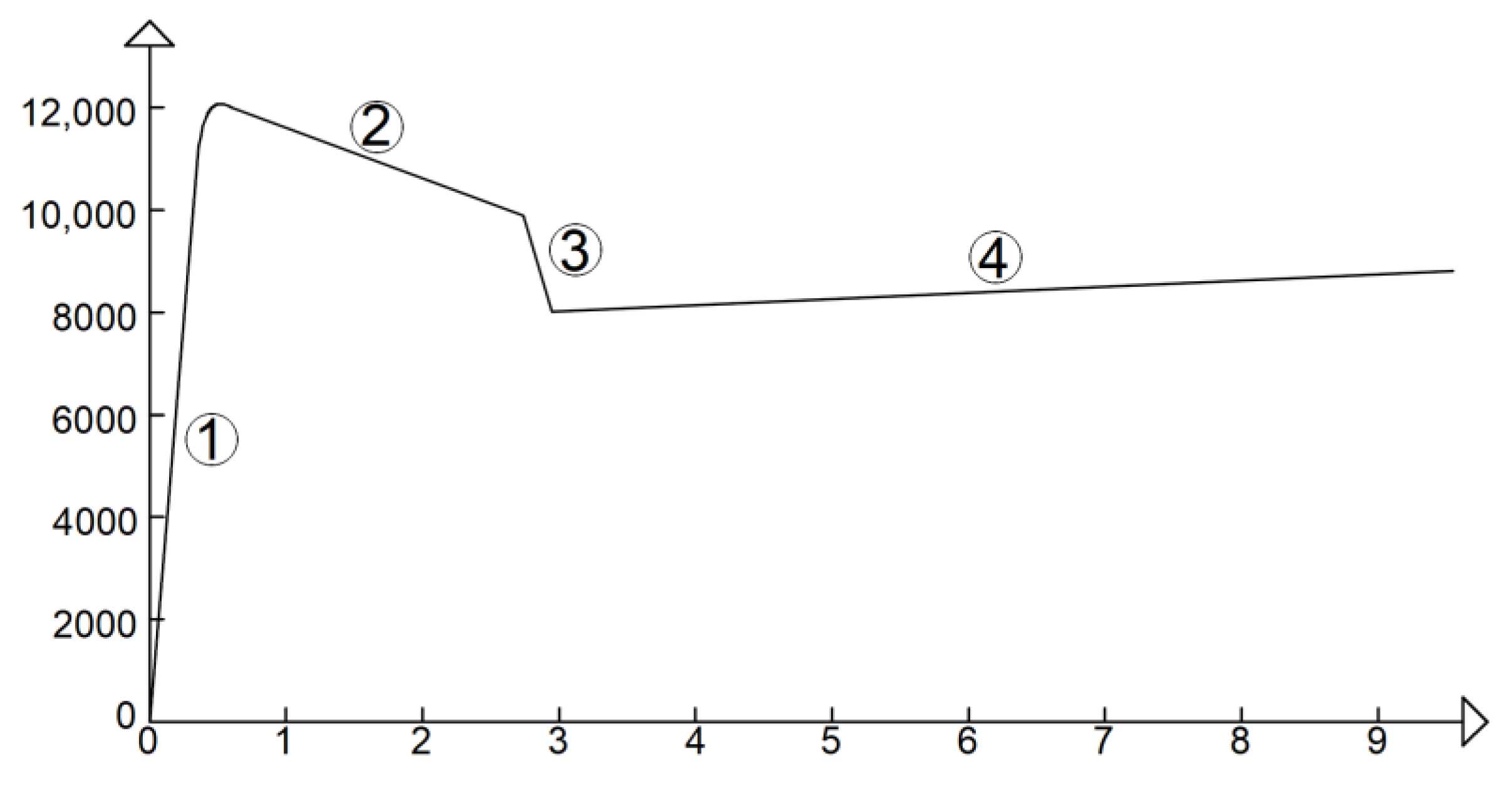

- Short steel fibers improve the performance of both basalt- and carbon-retrofitted specimens. The propagation of transversal cracks, which causes the reduction in stiffness of the first branch of the force–displacement curve, occurs at higher levels of load. The range of loads in which the stiffness of the force displacement curves decreases due to the propagation of transversal cracks increases from approximately 3000–4000 N to 9000–10,000 N in series A and from approximately 4000 N to 12,000–13,000 N in series B.

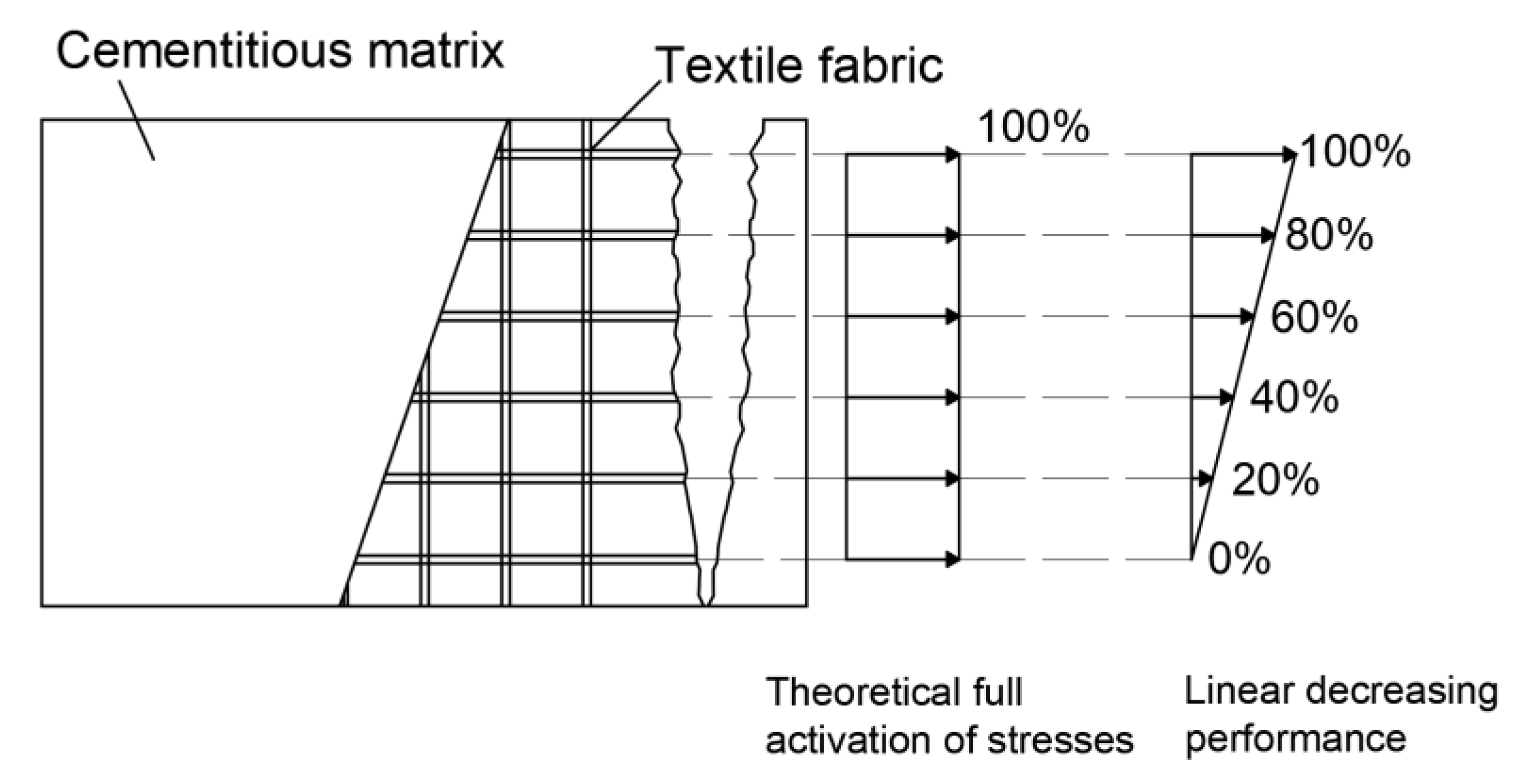

- Ductile failure characterizes carbon-retrofitted specimens. In this experimental test campaign, C-TRC and C-F/TRC specimens fail due to the pull-out of the textile fabric from the cementitious matrix. During the pull-out of C-TRC specimens, the average load is 85% and 84% of the average maximum load for series A and B, respectively. For C-F/TRC specimens, the average load during the pull-out of the textile fabric is approximately 72% and 60% of the average maximum load of series A and B, respectively.

- The assumed overlap length is long enough to avoid premature failures during the tests. The mode of failure of specimens with overlap of the textile fabric is similar to that of specimens without overlap of the textile fabric.

- A simple method to estimate the load capacity of basalt composites is proposed. The difference between the theoretical and experimental results is lower than 5.6% and 21% for series A and B, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Consiglio Nazionale Delle Ricerche (CNR). Istruzioni per la Progettazione, l’Esecuzione ed il Controllo di Interventi di Consolidamento Statico mediante l’utilizzo di Compositi Fibrorinforzati a Matrice Inorganica. 2020. Available online: https://www.cnr.it/it/node/9347 (accessed on 19 April 2022).

- Mechtcherine, V.; Schneider, K.; Brameshuber, W. 2-Mineral-based matrices for textile-reinforced. In Textile Fibre Composites in Civil Engineering; Triantafillou, T., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 25–43. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.; Zissimopoulos, P.; Laourdekis, T. Concrete Confinement with Textile-Reinforced Mortar Jackets. ACI Struct. J. 2006, 103, 28–37. [Google Scholar] [CrossRef]

- Bournas, D.A.; Triantafillou, T.; Papanicolaou, C.G. Retrofit of Seismically Deficient RC Columns with Textile- Reinforced Mortar (TRM) Jackets. In Proceedings of the 4th Colloquium on Textile Reinforced Structures (CTRS4), Dresden, Germany, 3–5 June 2009; pp. 471–490. [Google Scholar]

- Bournas, D.A.; Lontou, P.; Papanicolaou, C.; Triantafillou, T.C. Textile-Reinforced Mortar versus Fiber-Reinforced Polymer Confinement in Reinforced Concrete Columns. ACI Struct. J. 2007, 104, 740–748. [Google Scholar] [CrossRef]

- De Domenico, D.; Maugeri, N.; Longo, P.; Ricciardi, G.; Gullì, G.; Calabrese, L. Clevis-Grip Tensile Tests on Basalt, Carbon and Steel FRCM Systems Realized with Customized Cement-Based Matrices. J. Compos. Sci. 2022, 6, 275. [Google Scholar] [CrossRef]

- Rossi, E.; Randl, N.; Harsányi, P.; Mészöly, T. Experimental study of fibre-reinforced TRC shear strengthening applications on non-stirrup reinforced concrete T-beams. Eng. Struct. 2020, 256, 113923. [Google Scholar] [CrossRef]

- Rossi, E.; Randl, N.; Mészöly, T.; Harsányi, P. Effect of TRC and F/TRC Strengthening on the Cracking Behaviour of RC Beams in Bending. Materials 2021, 14, 4863. [Google Scholar] [CrossRef]

- Rossi, E.; Randl, N.; Harsányi, P.; Mészöly, T. Overlapped joints in Textile Reinforced Concrete with UHPC matrix: An experimental investigation. Mater. Struct. 2021, 54, 1–15. [Google Scholar] [CrossRef]

- Mészöly, T.; Ofner, S.; Randl, N. Effect of Combining Fiber and Textile Reinforcement on the Flexural Behavior of UHPC Plates. Adv. Mater. Sci. Eng. 2020, 2020, 1–8. [Google Scholar] [CrossRef]

- Rossi, E.; Randl, N.; Mészöly, T.; Harsányi, P. Flexural Strengthening with Fiber-/Textile-Reinforced Concrete. ACI Struct. J. 2021, 118, 4. [Google Scholar] [CrossRef]

- Deng, M.; Dong, Z.; Zhang, C. Experimental investigation on tensile behavior of carbon textile reinforced mortar (TRM) added with short polyvinyl alcohol (PVA) fibers. Constr. Build. Mater. 2020, 235, 117801. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Effect of short, dispersed glass and carbon fibres on the behaviour of textile-reinforced concrete under tensile loading. Eng. Fract. Mech. 2012, 92, 56–71. [Google Scholar] [CrossRef]

- Rampini, M.C.; Zani, G.; Colombo, M.; di Prisco, M. Mechanical Behaviour of TRC Composites: Experimental and Analytical Approaches. Appl. Sci. 2019, 9, 1492. [Google Scholar] [CrossRef]

- Ortlepp, R.; Ortlepp, S. Textile reinforced concrete for strengthening of RC columns: A contribution to resource conservation through the preservation of structures. Constr. Build. Mater. 2017, 132, 150–160. [Google Scholar] [CrossRef]

- Wang, J.; Wan, C.; Zeng, Q.; Shen, L.; Malik, M.; Yan, D. Effect of eccentricity on retrofitting efficiency of basalt textile reinforced concrete on partially damaged masonry columns. Compos. Struct. 2020, 232, 111585. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.; Hofer, L.; Toska, K.; De Domenico, D.; Pellegrino, C. Confinement of reinforced concrete columns with glass fiber reinforced cementitious matrix jackets. Eng. Struct. 2020, 218, 110847. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.; Hofer, L.; Pellegrino, C. Experimental behavior of reinforced concrete columns confined with carbon-FRCM composites. Constr. Build. Mater. 2020, 243, 118296. [Google Scholar] [CrossRef]

- Peled, A.; Bentur, A.; Mobasher, B. Textiles. In Textile Reinforced Concrete, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–473. [Google Scholar]

- De Fazio, P. Basalt fiber: From earth an ancient material for innovative and modern application. Energ. Ambient. Innov. 2011, 3, 89–96. [Google Scholar]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Di Ruocco, G. Basalt fibers: The green material of the XXI-century, for a sustainable restoration of historical buildings. Vitr. Int. J. Archit. Technol. Sustain. 2016, 1, 25–39. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Y.; Randl, N. Investigation on the alkali resistance of basalt fiber and its textile in different alkaline environments. Constr. Build. Mater. 2021, 272, 121670. [Google Scholar] [CrossRef]

- RILEM Technical Committee 232-TDT (W. Brameshuber). Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete. Uniaxial tensile test: Test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- Hartig, J.; Jesse, F.; Schicktanz, K.; Häußler-Combe, U. Influence of experimental setups on the apparent uniaxial tensile load-bearing capacity of Textile Reinforced Concrete specimens. Mater. Struct. 2012, 45, 433–446. [Google Scholar] [CrossRef]

- Hegger, J.; Will, N.; Bruckermann, O.; Voss, S. Load–bearing behaviour and simulation of textile reinforced concrete. Mater. Struct. 2006, 39, 765–776. [Google Scholar] [CrossRef]

- Hojdys, Ł.; Krajewski, P. Tensile Behaviour of FRCM Composites for Strengthening of Masonry Structures—An Experimental Investigation. Materials 2021, 14, 3626. [Google Scholar] [CrossRef] [PubMed]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- de Felice, G.; Garmendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenço, P.; Oliveira, D.; Paolacci, F.; Papanicolaou, C.G. Mortar-based systems for externally bonded strengthening of masonry. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef]

- Caggegi, G.P.L.C.; Ceroni, F.; De Santis, S.; Krajewski, P.; Lourenço, P.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Pronta, A.; Zuccarino, L. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; San-José, J.; Garmendia, L. Non-linear analytical model of composites based on basalt textile reinforced mortar under uniaxial tension. Compos. Part B Eng. 2013, 55, 518–527. [Google Scholar] [CrossRef]

- Beßling, M.; Groh, M.; Koch, V.; Auras, M.; Orlowsky, J.; Middendorf, B. Repair and Protection of Existing Steel-Reinforced Concrete Structures with High-Strength, Textile-Reinforced Mortars. Buildings 2022, 12, 1615. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, H.; Du, Y.; Liu, L.; Zhu, D.; Pan, W. Uniaxial Tensile Behavior of Carbon Textile Reinforced Mortar. Materials 2019, 12, 374. [Google Scholar] [CrossRef]

- Mattarollo, G.; Randl, N.; Pauletta, M.; Rossi, E. Experimental investigation on confinement of columns with TRC: A comparison between basalt and carbon textile fabrics. In Proceedings of the 14th fib International PhD Symposium in Civil Engineering, Rome, Italy, 5–7 September 2022; pp. 517–524. [Google Scholar]

- Mattarollo, G.; Randl, N.; Pauletta, M.; Rossi, E. Confinement of Columns with Textile Reinforced Concrete: An Experimental Comparison between Basalt and Carbon Textile Reinforced Concrete. In Proceedings of the 6th fib International Congress, Oslo, Norway, 12–16 June 2022; Novus Press: Oslo, Norway, 2022; pp. 2286–2295. [Google Scholar]

- Deutsches Institut fur Bautechnik, “Verfahren zur Verstarkung von Stahlbeton mit TUDALIT (Textilbewehrter Beton)”. 2016. Available online: https://www.dibt.de/de/service/zulassungsdownload/detail/z-3110-182 (accessed on 31 January 2022).

- HITEXBAU, Albani Group. Art.279136 HTC 21/21-40 Technical Data Sheet. Available online: https://www.hitexbau.com/menu/products/ (accessed on 27 July 2021).

- Kimia, S.P.A. Certificato di Valutazione Tecnica. 2022. Available online: https://www.kimia.it/sites/default/files/doc/CVT/cvt-kimia-compositi-frcm-n-207 (accessed on 13 October 2022).

- Kimia, S.P.A. Kimitech BS ST 400 ST2-0319 Tessuti di Armatura in Fibra di Basalto per Rinforzi FRCM Techncal Data Sheet. Available online: https://www.kimia.it/it/prodotti/kimitech-bs-st-400 (accessed on 31 August 2020).

- Park, R. Evaluation of ductility of structures and structural assemblages from laboratory testing. Bull. N. Z. Soc. Earthq. Eng. 1989, 22, 155–166. [Google Scholar] [CrossRef]

- Ortlepp, R.; Lorenz, E. Bond Behavior of Textile Reinforcements—Development of a Pull-Out Test and Modeling of the Respective Bond versus Slip Relation. In High Performance Fiber Reinforced Cement Composites 6; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2012; pp. 1–8. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G. Tensile behaviour of mortar-based composites for externally bonded reinforcement systems. Compos. Part B Eng. 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B Eng. 2017, 128, 100–119. [Google Scholar] [CrossRef]

- Leone, M.; Aiello, M.; Balsamo, A.; Carozzi, F.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B Eng. 2017, 127, 196–214. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Morganti, M.; Santandrea, M.; Valluzzi, M.; Viskovic, A. Round Robin Test on tensile and bond behaviour of Steel Reinforced Grout systems. Compos. Part B Eng. 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Caggegi, C.; Carozzi, F.; De Santis, S.; Fabbrocino, F.; Focacci, F.; Hojdys, Ł.; Lanoye, E.; Zuccarino, L. Experimental analysis on tensile and bond properties of PBO and aramid fabric reinforced cementitious matrix for strengthening masonry structures. Compos. Part B Eng. 2017, 127, 175–195. [Google Scholar] [CrossRef]

| Authors | Type of Inorganic Matrix | fc | Short Fibers | Textile Fabric |

|---|---|---|---|---|

| De Domenico et al. [6] | Cementitious matrix | 22.03 29.30 19.87 | Polymer | Basalt Carbon Steel |

| D’Antino and Papanicolaou [28] | Tixotropic fiber-reinforced cement-based matrix Lime-based mortar with silica sand Lime-based mortar with pozzolanic binders, synthetic fibers and graded sand | 16.40 12.10 10.30 | Carbon Basalt Glass Steel | |

| De Felice et al. [29] | Pozzolanic-cement mortar Pozzolan lime-based mortar Cementitious mortar | 37.0 13.0 22.6 | Steel Carbon Basalt | |

| Lignola et al. [30] | Cement based Lime based | 25 12 15 15 | Basalt | |

| Larrinaga et al. [31] | Cement-based mortar | 19.8 | Basalt | |

| Hojdys and Krajewski [27] | Cement based one-component mortar Cement-free NHL-based one-component mortar Natural hydraulic lime-based mortar Cement-based mortar | 15.4 14.9 9.8 44.3 | Synthetic fibers Fiber-reinforced | Carbon Glass PBO |

| Beßling et al. [32] | UHPC HPC | 83 ± 7 60 ± 5 | Carbon Basalt | |

| Zhou et al. [33] | HPC | 76.7 | Steel | Carbon |

| fc (MPa) | ft (MPa) | |

|---|---|---|

| Cement matrix with short steel fibers | 105.2 | 10.9 |

| Cement matrix without short steel fibers | 93.6 | 3.6 |

| g (mm) | A (mm2/m) | σt,tex Lengthways (MPa) | σt,tex Crossways (MPa) | εu Lengthways | εu Crossways | E (GPa) | |

|---|---|---|---|---|---|---|---|

| Carbon textile fabric | 22 | 71 | 2531 | 2841 | 1.71% | 1.47% | |

| Basalt textile fabric | 20 | 65 | 1495 | 1495 | 1.61% | 1.61% | 92.7 |

| Specimen ID | Maximum Load (N) | Average Maximum Load (N) (Stress (MPa)) | CV Max Load | δy (mm) | δu (mm) | μ | μ Average | CV μ |

|---|---|---|---|---|---|---|---|---|

| BP-1-A | 6364.5 | 6178.3 (792.1) | 0.04 | 0.029 | 2.8 | 96.6 | 71.0 | 0.45 |

| BP-2-A | 6253.4 | 0.047 | 3.8 | 80.9 | ||||

| BP-3-A | 5916.9 | 0.090 | 3.2 | 35.6 | ||||

| BPf-1-A | 11,231 | 11,308 (1449.7) | 0.01 | 0.65 | 2.2 | 3.38 | 4.4 | 0.21 |

| BPf-2-A | 11,386 | 0.45 | 2.2 | 4.9 | ||||

| BPf-3-A | 11,306 | 0.38 | 1.9 | 5 | ||||

| CP-1-A | 11,107 | 10,296.7 (1311.7) | 0.07 | 0.06 | 3.76 | 62.7 | 71.5 | 0.40 |

| CP-2-A | 10,135 | 0.04 | 4.14 | 103.5 | ||||

| CP-3-A | 9648 | 0.07 | 3.38 | 48.3 | ||||

| CPf-1-A | 12,365 | 12,159 (1548.9) | 0.03 | 0.57 | 4.43 | 7.77 | 5.65 | 0.38 |

| CPf-2-A | 12,315 | 0.49 | 2.78 | 5.67 | ||||

| CPf-3-A | 11,797 | 0.46 | 1.61 | 3.5 | ||||

| BP-1-B | 7848 | 7289.7 (934.6) | 0.11 | 0.077 | 1.77 | 22.96 | 41.23 | 0.39 |

| BP-2-B | 7610 | 0.07 | 3.77 | 53.85 | ||||

| BP-3-B | 6411 | 0.07 | 3.28 | 46.89 | ||||

| BPf-1-B | 13,455 | 13,973.7 (1791.5) | 0.06 | 0.78 | 1.96 | 2.51 | 8.46 | 1.28 |

| BPf-2-B | 14,944 | 0.63 | 1.22 | 1.94 | ||||

| BPf-3-B | 13,522 | 0.077 | 1.61 | 20.93 | ||||

| CP-1-B | 8708.9 | 8905.1 (1134.4) | 0.12 | 0.18 | 6.37 | 35.39 | 18.18 | 0.84 |

| CP-2-B | 10,066 | 0.82 | 5.37 | 6.55 | ||||

| CP-3-B | 7940.6 | 0.17 | 2.14 | 12.59 | ||||

| CPf-1-B | 15,382 | 15,638.7 (1992.2) | 0.02 | 0.88 | 1.54 | 1.75 | 3.2 | 0.47 |

| CPf-2-B | 15,482 | 0.69 | 2.14 | 3.11 | ||||

| CPf-3-B | 16,052 | 0.52 | 2.47 | 4.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mattarollo, G.; Randl, N.; Pauletta, M. Investigation of the Failure Modes of Textile-Reinforced Concrete and Fiber/Textile-Reinforced Concrete under Uniaxial Tensile Tests. Materials 2023, 16, 1999. https://doi.org/10.3390/ma16051999

Mattarollo G, Randl N, Pauletta M. Investigation of the Failure Modes of Textile-Reinforced Concrete and Fiber/Textile-Reinforced Concrete under Uniaxial Tensile Tests. Materials. 2023; 16(5):1999. https://doi.org/10.3390/ma16051999

Chicago/Turabian StyleMattarollo, Giorgio, Norbert Randl, and Margherita Pauletta. 2023. "Investigation of the Failure Modes of Textile-Reinforced Concrete and Fiber/Textile-Reinforced Concrete under Uniaxial Tensile Tests" Materials 16, no. 5: 1999. https://doi.org/10.3390/ma16051999

APA StyleMattarollo, G., Randl, N., & Pauletta, M. (2023). Investigation of the Failure Modes of Textile-Reinforced Concrete and Fiber/Textile-Reinforced Concrete under Uniaxial Tensile Tests. Materials, 16(5), 1999. https://doi.org/10.3390/ma16051999