Design of Functional Polymer Systems to Optimize the Filler Retention in Obtaining Cellulosic Substrates with Improved Properties

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

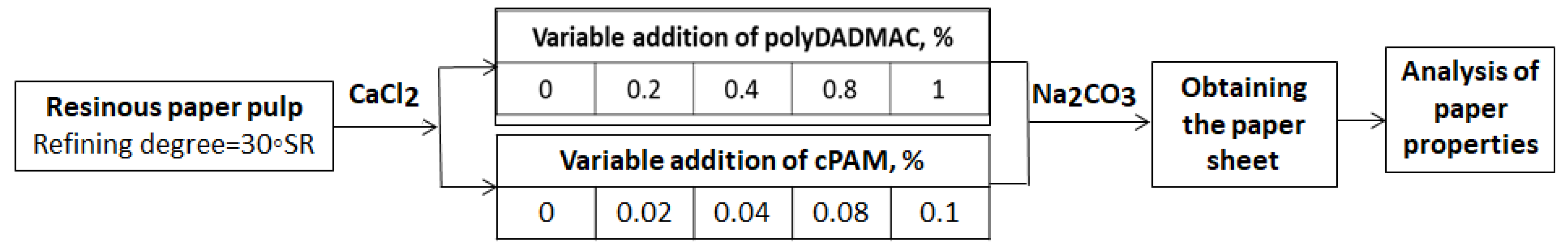

2.3. Experimental Procedure

- pulp fibers/35% PCC

- pulp fibers/35% PCC/polyDADMAC (0%, 0.2%, 0.4%, 0.8% and 1%)

- pulp fibers/35% PCC/cPAM (0%, 0.02%, 0.04%, 0.08% and 0.1%).

3. Results and Discussion

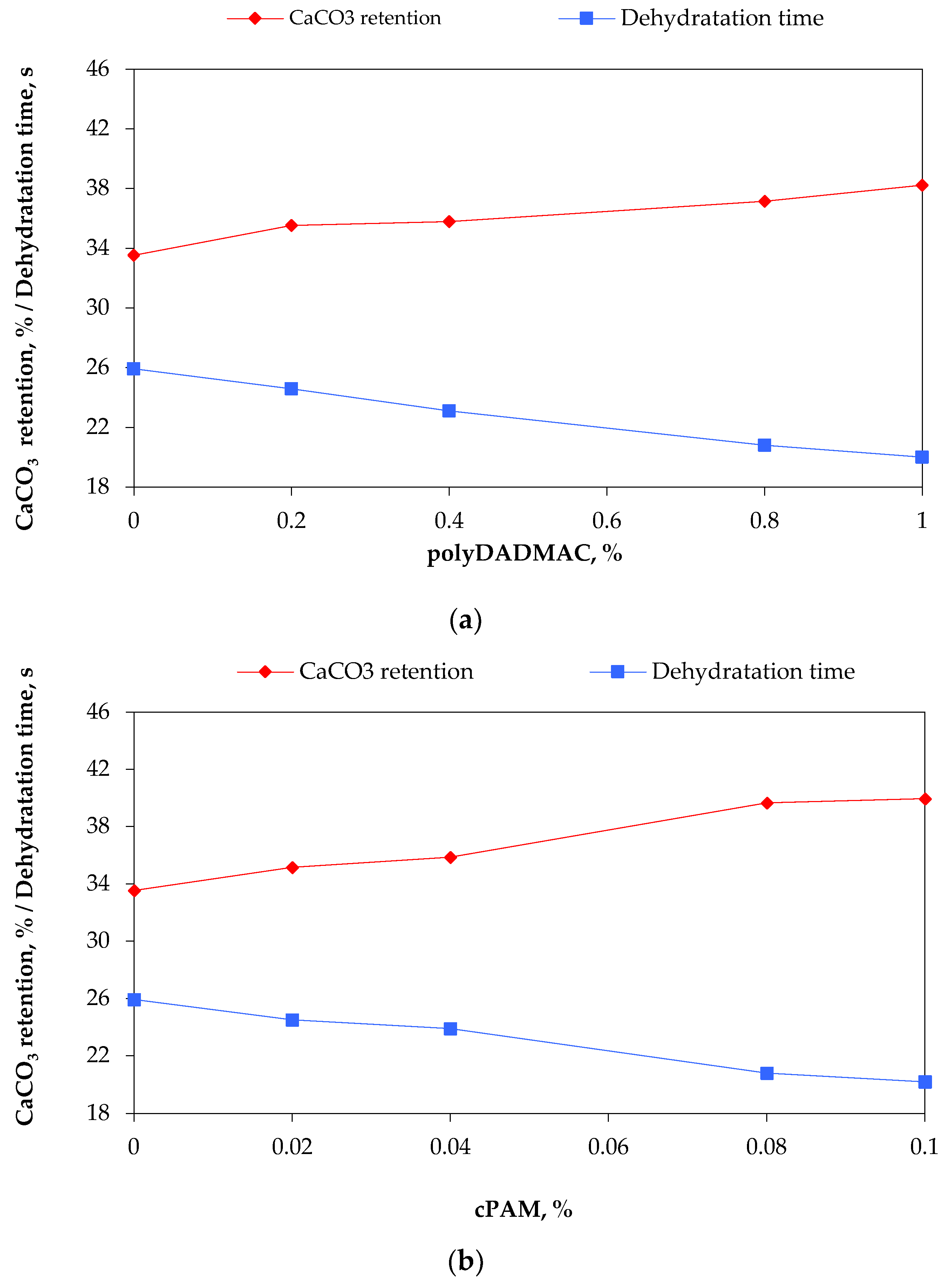

3.1. Effects of Polymers on Paper Stock Properties

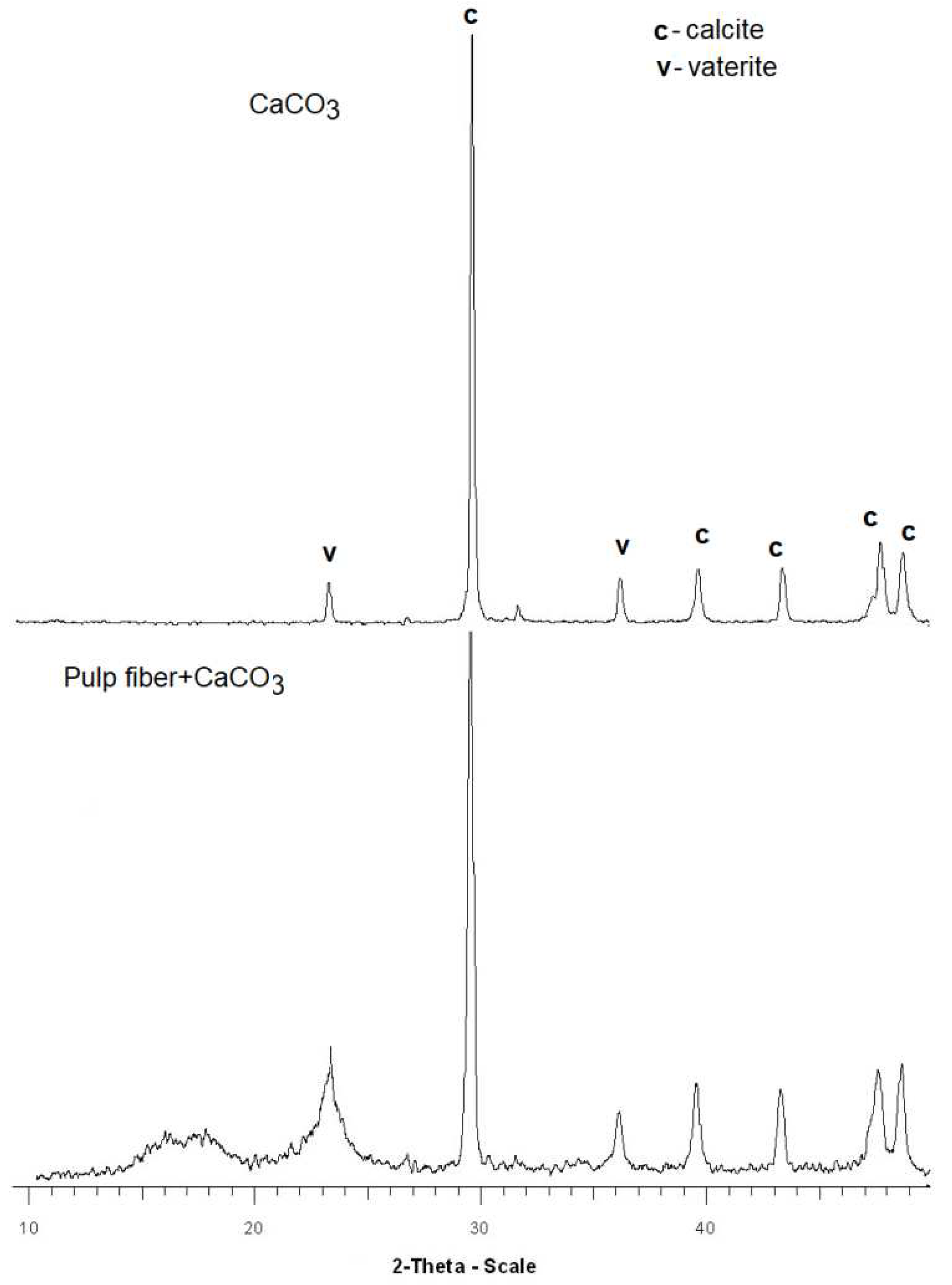

3.2. X-Ray Diffraction

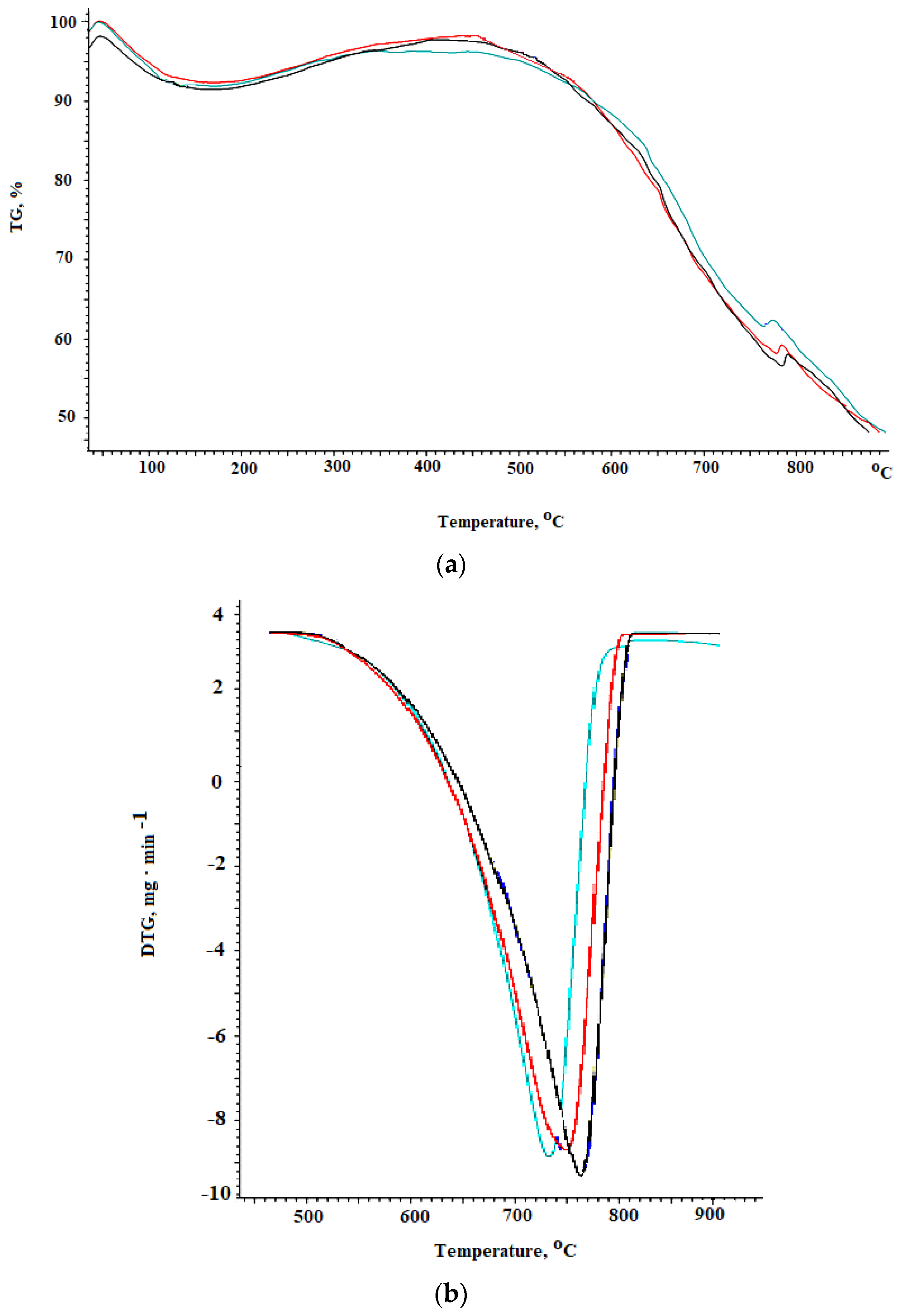

3.3. Thermogravimetric Analysis

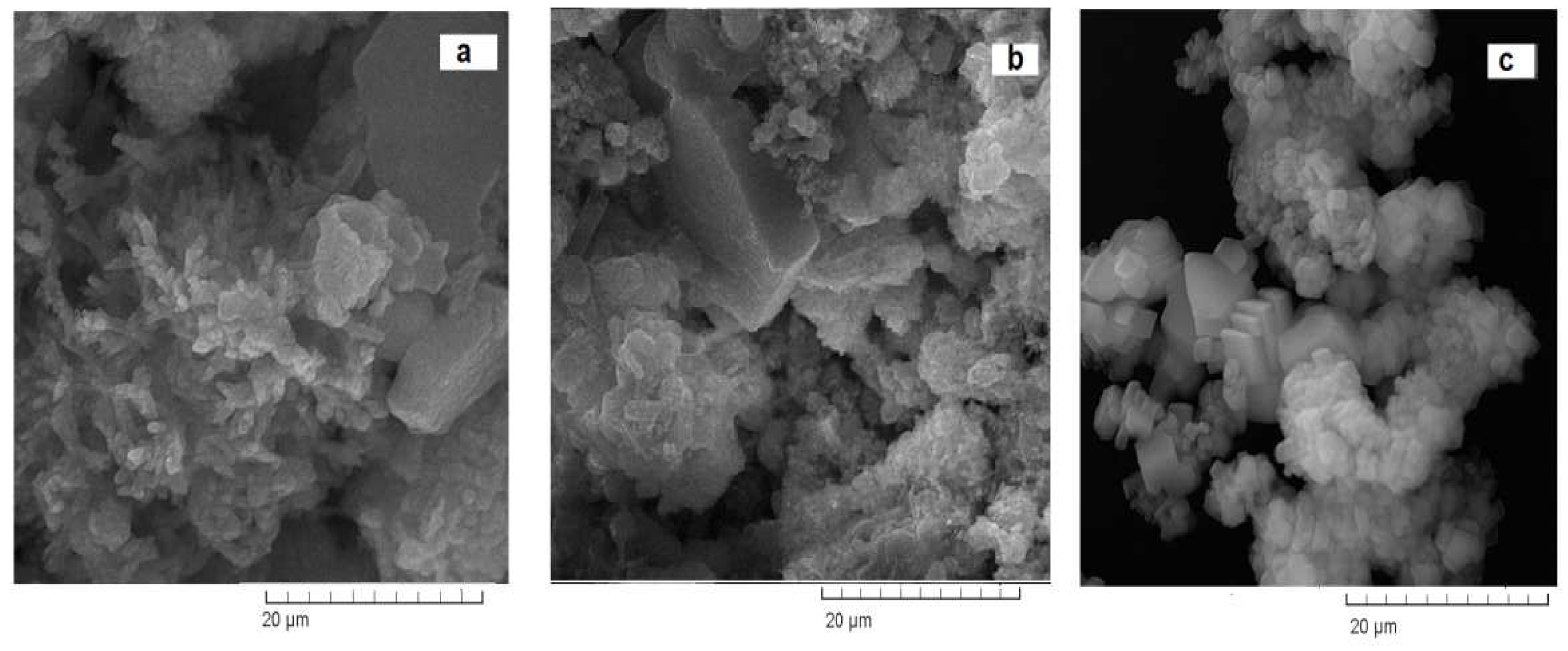

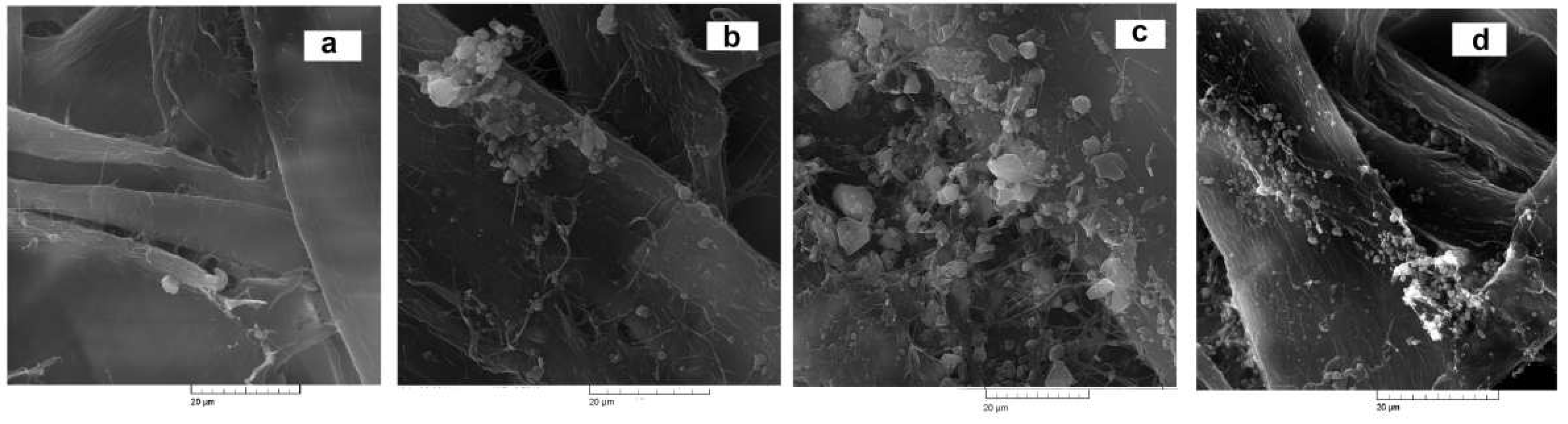

3.4. Scanning Electron Microscopic Images (SEM)

3.5. Optical Properties

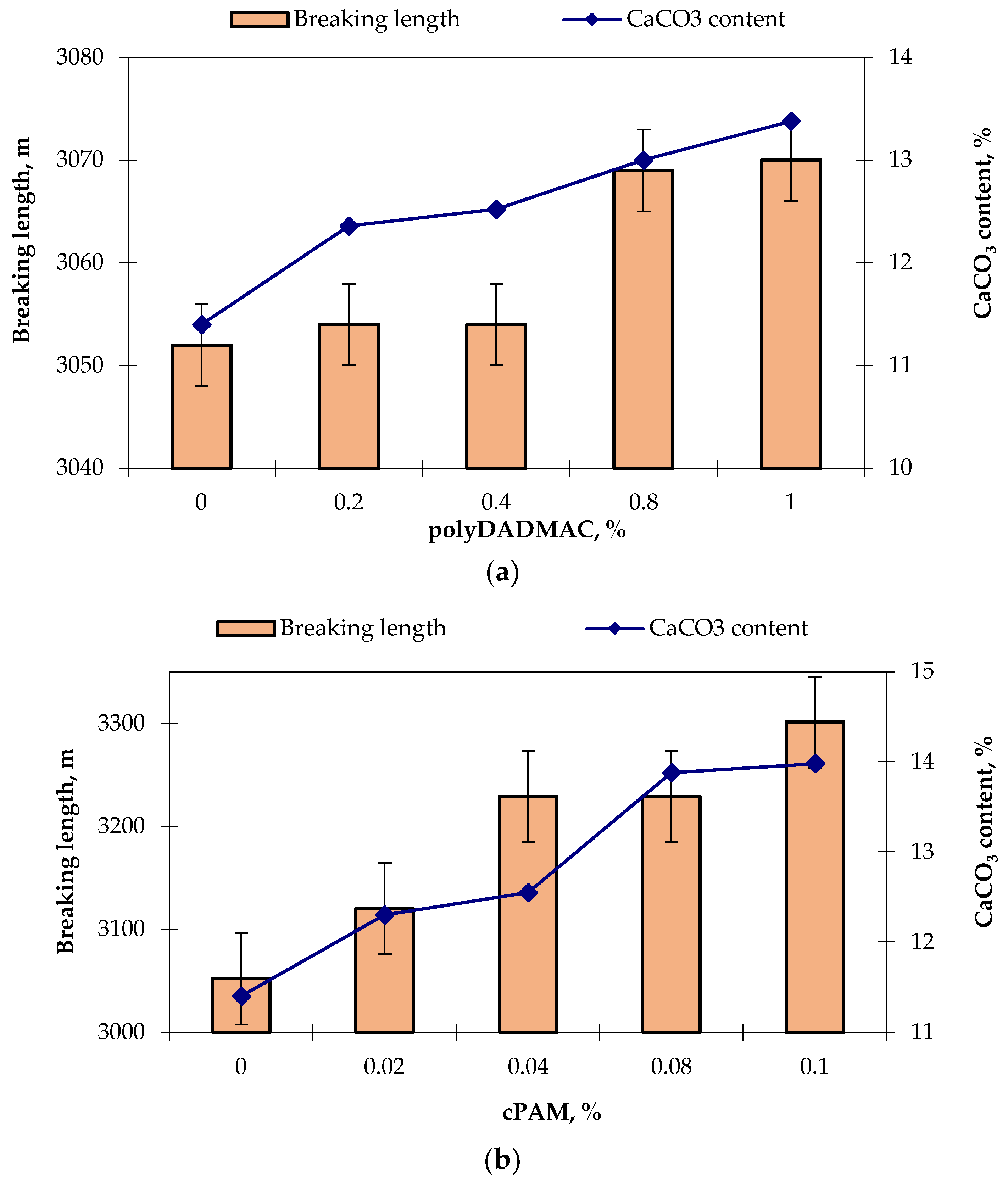

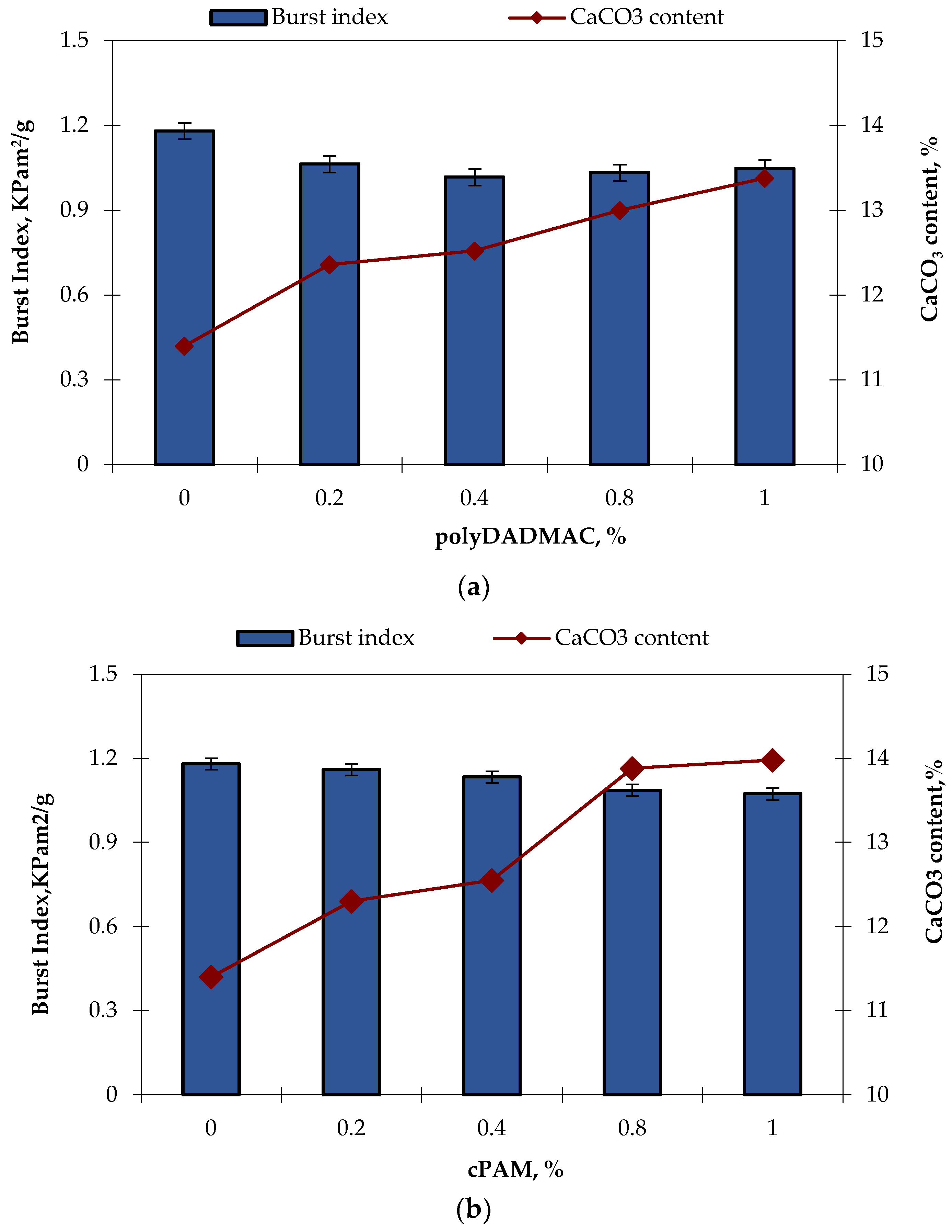

3.6. Physical-Mechanical Properties of Paper Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hubbe, M.A.; Gill, R.A. Fillers of papermaking: A review of their properties, usage practices, and their mechanistic role. BioResources 2016, 11, 2886–2963. [Google Scholar] [CrossRef]

- Fortună, M.E. Fibrous Pigments of Nanocomposite Type; Pim: Iasi, Romania, 2022; pp. 21–119. ISBN 978-606-13-6707-8. [Google Scholar]

- Chauhan, S.V.; Singh, P.S.; Pramod, K.B. Fiber loading of hardwood pulp by in-situ precipitation of aluminosilicate. BioResources 2007, 2, 560–571. [Google Scholar]

- Fortună, M.E.; Ungureanu, E.; Jităreanu, C.D. Calcium Carbonate–Carboxymethyl Chitosan Hybrid Materials. Materials 2022, 14, 3336. [Google Scholar] [CrossRef] [PubMed]

- Othman, R.; Zakaria, S.; Chia, C.H.; Zuriyati, A.; Isa, N. Mechanical and optical properties of CaCO3 lumen-loaded paper: Effect of polyethylenimine and plum. Sains Malays. 2010, 39, 435–439. [Google Scholar]

- Miroslav, A.; Volf, P.; Pointe-Claire, P.; Pointe-Claire, L.; Baie D’Urfe, S.; Beaconsfield, M. Papermaking Additive Cross-Reference to Related Applications. U.S. Patent 7,875,150 B2, 25 January 2011. [Google Scholar]

- Fortuna, M.E.; Harja, M.; Bucur, D.; Cimpeanu, S.M. Obtaining and Utilizing Cellulose Fibers with in-Situ Loading as an Additive for Printing Paper. Materials 2013, 6, 4532–4544. [Google Scholar] [CrossRef]

- Fortună, M.E.; Ignat, M.; Asandulesa, M.; Rotaru, R.; Pricop, L.; Harabagiu, V. Improved physico-chemical properties of mesoporous carbon by functionalization with aminopropyl-polydimethylsiloxane (AP-PDMS). J. Inorg. Organomet. Polym. Mater. 2018, 28, 2275–2287. [Google Scholar] [CrossRef]

- Jimoh, O.A.; Ariffin, K.S.; Hussin, H.B.; Temitope, A.E. Synthesis of precipitated calcium carbonate: A review. Carbonates Evaporites 2018, 33, 331–346. [Google Scholar] [CrossRef]

- Saghavaz, K.M.; Resalati, H.; Ghasemian, A. Cellulose-precipitated calcium carbonate composites and their effect on paper properties. Chem. Pap. 2014, 68, 774–781. [Google Scholar]

- Selin, J.; Hangaslammi, A. Method of Adding Pigment to Paper. Patent WO0214603, 21 February 2002. [Google Scholar]

- Klungness, J.H.; Sykes, M.S.; Tan, F.; Abubakr, S.; Eisenwasser, J.D. Effect of fiber loading on paper properties. Tappi J. 1996, 79, 297–301. [Google Scholar]

- Fortună, M.E.; Lobiuc, A.; Cosovanu, L.M.; Harja, M. Effects of in-situ filler loading vs. conventional filler and the use of retention-related additives on properties of paper. Materials 2020, 13, 5066. [Google Scholar] [CrossRef]

- Lin, L.; Yin, X.; Retulainen, E.; Nazhad, M.M. Effect of chemical pulp fines on filler retention and paper properties. Appita J. 2007, 60, 469–473. [Google Scholar]

- Silenius, P. Preparation of Filler Containing Papermaking Materials by Precipitating Calcium Carbonate In-Situ in the Presence of Cellulosic Materials. Master’s Thesis, Department of Chemical Technology, Lappeenranta University of Technology, Lappeenranta, Finland, 1996. [Google Scholar]

- Li, L.; Collis, A.; Pelton, R. A new analysis of filler effects on paper strength. J. Pulp Pap. Sci. 2002, 28, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu, E.; Căpraru, A.M.; Ungureanu, O.; Jităreanu, C.D.; Iacob, V.; Ulea, E.; Popa, V.I. Ecologycal biocide systems based on unmodified and epoxydation lignins, furan resin and copper. Cell. Chem. Technol. 2012, 46, 599–603. [Google Scholar]

- Ungureanu, E.; Trofin, A.; Trincă, L.C.; Ariton, A.M.; Ungureanu, O.C.; Fortună, M.E.; Jităreanu, C.D.; Popa, V.I. Studies on kinetics and adsorption equilibrium of lead and zinc ions from aqueous solutions on Sarkanda Grass lignin. Cell. Chem. Technol. 2021, 55, 939–948. [Google Scholar] [CrossRef]

- Ungureanu, E.; Jităreanu, C.D.; Trofin, A.; Fortună, M.E.; Ungureanu, O.C.; Ariton, A.M.; Trincă, L.C.; Brezuleanu, S.; Popa, V.I. Use Of Sarkanda Grass Lignin as a possible adsorbent for As (III) from aqueous solutions—Kinetic and equilibrium studies. Cell. Chem. Technol. 2022, 56, 681–689. [Google Scholar] [CrossRef]

- Middleton, S.R.; Desmeules, J.; Scallan, A.M. Lumen loading with calcium carbonate fillers. J. Pulp Pap. Sci. 2003, 29, 241–246. [Google Scholar]

- Hubbe, M.A.; Nanko, H.; McNeal, M.R. Retention aid polymer interactions with cellulosic surfaces and suspensions: A review. BioResources 2009, 4, 850–906. [Google Scholar] [CrossRef]

- Ungureanu, E. Aspects of Composites Biodegradation Based on Lignocelluloses Materials. Ph.D. Thesis, “Gh. Asachi” Polytechnic University of Iasi, Iasi, Romania, 2008; pp. 34–62. [Google Scholar]

- Nicke, R.; Pensold, S.; Tappe, M.; Hartmann, H.J. Poly-diallyldimethylammonium Chloride as a Flocculating Agent. Wochenbl. Papierfabr. 1992, 14, 559–564. [Google Scholar]

- Swerin, A.; nWågberg, L. Size-Exclusion Chromatography for Characterizationof Cationic Polyelectrolytes Used in Papermaking. Nordic Pulp Paper Res. J. 1994, 9, 18–25. [Google Scholar] [CrossRef]

- Ungureanu, E. Lignin, Aromatic Natural Polymer with High Potential for Recovery; Pim: Iasi, Romania, 2011; pp. 103–194. ISBN 978-606-13-0384-7. [Google Scholar]

- Bown, R. Physical and chemical aspects of the use of fillers in paper. In Paper Chemistry; Roberts, J.C., Ed.; Backie Academic & Professional: Hong Kong, China, 1996; Chapter 11; pp. 202–229. [Google Scholar]

- Anerek, A.V. Filler Retention in Papermaking by Polymeric and Microparticulate Retention Aid Systems; Department of Chemistry McGill University Montréal: Montreal, QC, Canada, 2004; pp. 2–245. [Google Scholar]

- Siven, S.K.; Manner, H.J. Fibre loading using an aluminum compound. Appita J. 2003, 56, 438–441. [Google Scholar]

- Laukala, T.; Lyytikäinen, J.; Mielonen, K.; Backfolk, K. Effect of PCC crystallization and morphology on flocculation with microfibrillated cellulose, on sheet densification and liquid absorption behavior. Cellulose 2020, 27, 10151. [Google Scholar] [CrossRef]

| Properties | % polyDADMAC | ||||

|---|---|---|---|---|---|

| 0 | 0.2 | 0.4 | 0.8 | 1 | |

| Ionic charge, meq/g | −14.28 | 8.49 | 10.46 | 11.49 | 16.16 |

| CaCO3 content, % | 11.4 | 12.36 | 12.52 | 13.00 | 13.38 |

| Air permeability, μm/kPa·s | 190 | 191 | 193 | 195 | 195 |

| Properties | % cPAM | ||||

| 0.02 | 0.04 | 0.08 | 0.1 | ||

| CaCO3 content, % | 12.30 | 12.55 | 13.88 | 13.98 | |

| Ionic charge, meq/g | −27.5 | −25.77 | −24.96 | −23.26 | |

| Air permeability, μm/kPa·s | 196 | 198.5 | 202 | 204.5 | |

| Samples | Stages | Tonset | Tpeak | Tendset | PPC% | Residuum |

|---|---|---|---|---|---|---|

| PCC | I | 676 | 764 | 778 | 44.12 | 55.28 |

| PCC/cPAM | I | 657 | 768 | 780 | 44.18 | 55.82 |

| PCC/polyDADMAC | I | 662 | 757 | 774 | 44.08 | 55.92 |

| Optical Properties | % p-DADMAC | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 0.2 | 0.4 | 0.8 | 1 | ||||

| Brightness, % | 86 | 86.4 | 86.9 | 87.3 | 87.7 | |||

| Opacity, % | 87.3 | 87.7 | 87.4 | 87.9 | 88 | |||

| Optical Properties | % cPAM | |||||||

| 0.02 | 0.04 | 0.08 | 0.1 | |||||

| Brightness, % | 86.2 | 87.1 | 87.9 | 88.1 | ||||

| Opacity, % | 87.56 | 87.93 | 88 | 88.1 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ungureanu, E.; Fortună, M.E.; Țopa, D.C.; Lobiuc, A.; Ungureanu, O.C.; Jităreanu, D.C. Design of Functional Polymer Systems to Optimize the Filler Retention in Obtaining Cellulosic Substrates with Improved Properties. Materials 2023, 16, 1904. https://doi.org/10.3390/ma16051904

Ungureanu E, Fortună ME, Țopa DC, Lobiuc A, Ungureanu OC, Jităreanu DC. Design of Functional Polymer Systems to Optimize the Filler Retention in Obtaining Cellulosic Substrates with Improved Properties. Materials. 2023; 16(5):1904. https://doi.org/10.3390/ma16051904

Chicago/Turabian StyleUngureanu, Elena, Maria E. Fortună, Denis C. Țopa, Andrei Lobiuc, Ovidiu C. Ungureanu, and Doina C. Jităreanu. 2023. "Design of Functional Polymer Systems to Optimize the Filler Retention in Obtaining Cellulosic Substrates with Improved Properties" Materials 16, no. 5: 1904. https://doi.org/10.3390/ma16051904

APA StyleUngureanu, E., Fortună, M. E., Țopa, D. C., Lobiuc, A., Ungureanu, O. C., & Jităreanu, D. C. (2023). Design of Functional Polymer Systems to Optimize the Filler Retention in Obtaining Cellulosic Substrates with Improved Properties. Materials, 16(5), 1904. https://doi.org/10.3390/ma16051904