Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions

Abstract

1. Introduction

2. Material and Methods

3. Results and Discussion

4. Summary

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Sun, F.; Duan, Y.; Yin, Z.; Luo, W.; Huang, Y.; Chen, J.J. Highly sensitive, temperature-dependent gas sensor based on hierarchical ZnO nanorod arrays. Mater. Chem. C 2015, 3, 11397. [Google Scholar] [CrossRef]

- Richards, B. Luminescent layers for enhanced silicon solar cell performance: Down-conversion. Sol. Energy Mat. Sol. Cells 2006, 90, 1189. [Google Scholar] [CrossRef]

- Socol, M.; Preda, N.; Breazu, C.; Florica, C.; Costas, A.; Istrate, C.; Stanculescu, A.; Girtan, M.; Gherendi, F. Organic heterostructures obtained on ZnO/Ag/ZnO electrode. Vacuum 2018, 154, 366. [Google Scholar] [CrossRef]

- Jagadish, C.; Pearton, S.J. Thin Films and Nanostructures; Elsevier: Amsterdam, The Netherlands, 2006; ISBN 978-0-08-044722-3. [Google Scholar]

- Thomas, D.G. The Exciton Spectrum of Zinc Oxide. J. Phys. Chem. Solids 1960, 15, 86. [Google Scholar] [CrossRef]

- Özgür, Y.; Alivov, C.; Liu, A.; Teke, M.; Reshchikov, S.; Dogan, V.; Avrutin, S.-J.; Cho, H.; Morkoc, J. A comprehensive review of ZnO materials and devices. J. Appl. Phys. 2005, 98, 041301. [Google Scholar] [CrossRef]

- Mishra, Y.; Adelung, R. ZnO tetrapod materials for functional applications. Mater. Today 2018, 21, 631–651. [Google Scholar] [CrossRef]

- Rasmidi, R.; Duinong, M.; Chee, F.P. Radiation damage effects on zinc oxide (ZnO) based semiconductor devices—A review. Radiat. Phys. Chem. 2021, 184, 109455. [Google Scholar] [CrossRef]

- Wendler, E.; Wesch, W.; Azarov, A.Y.; Catarino, N.; Redondo-Cubero, A.; Alves, E.; Lorenz, K. Comparison of low- and room-temperature damage formation in Ar ion implanted GaN and ZnO. Nucl. Instr. Meth. Phys. Res. B 2013, 307, 394. [Google Scholar] [CrossRef]

- Kenyon, A.J. Recent developments in rare-earth doped materials for optoelectronics. Prog. Quantum El. 2002, 26, 225. [Google Scholar] [CrossRef]

- Favennec, P.N.; L’Haridon, H.; Salvi, M.; Moutonnet, D.; Le Guillou, Y. Luminescence of erbium implanted in various semiconductors: IV, III-V and II-VI materials. Electron. Lett. 1989, 25, 718–719. [Google Scholar] [CrossRef]

- Jadwisienczak, W.; Lozykowski, H.; Xu, A.; Patel, B.J. Visible emission from ZnO doped with rare-earth ions. Electron. Mater. 2002, 31, 776. [Google Scholar] [CrossRef]

- Vařák, P.; Mrázek, J.; Jasim, A.; Bysakh, S.; Dhar, A.; Kamrádek, M.; Podrazký, O.; Kašík, I.; Bartoň, I.; Nekvindová, P. Thermal stability and photoluminescence properties of RE-doped (RE = Ho, Er, Tm) alumina nanoparticles in bulk and fiber-optic silica glass. Opt. Mater. 2021, 118, 111239. [Google Scholar] [CrossRef]

- Singh, A.; Arya, P.; Choudhary, D.; Kumar, S.; Srivastava, A.; Singh, I.B. Cost-effective ZnO–Eu3+ films with efficient energy transfer between host and dopant. SN Appl. Sci. 2020, 2, 870. [Google Scholar] [CrossRef]

- Kumar, R.; Mishra, S. Enhancement in the luminescence of green-emission from emissive surface defects of Dy3+doped ZnO nanoluminophores: A simple, mass-scale productive approach for optoelectronic devices. Appl. Surf. Sci. Adv. 2022, 9, 100256. [Google Scholar] [CrossRef]

- Poate, J.; Williams, S. Ion Implantation and Beam Processing; Williams, J.S., Poate, J.M., Eds.; Academic Press: Sydney, Astralia, 1984; p. 13. ISBN 0127569804. [Google Scholar]

- Ratajczak, R.; Guziewicz, E.; Prucnal, S.; Łuka, G.; Böttger, R.; Heller, R.; Mieszczynski, C.; Wozniak, W.; Turos, A. Luminescence in the Visible Region from Annealed Thin ALD-ZnO Films Implanted with Different Rare Earth Ions. Phys. Status Solidi A 2018, 215, 1700889. [Google Scholar] [CrossRef]

- Zhou, X.; Ning, L.; Qiao, J.; Zhao, Y.; Xiong, P.; Xia, Z. Interplay of defect levels and rare earth emission centers in multimode luminescent phosphors. Nat. Commun. 2022, 13, 7589. [Google Scholar] [CrossRef]

- Masai, H.; Okada, G.; Kawaguchi, N.; Yanagida, T. Relationship between defect formation by X-ray irradiation and thermally stimulated luminescence of binary zinc phosphate glasses. Opt. Mater. Express 2019, 9, 2037–2045. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Williams, J.S.; Jagadish, C.; Zou, J.; Evans, C.; Nelson, A.J.; Hamza, A.V. Ion-beam-produced structural defects in ZnO. Phys. Rev. B 2003, 67, 094115. [Google Scholar] [CrossRef]

- Wendler, E.; Bilani, O.; Gaertner, K.; Wesch, W.; Hayes, M.; Auret, F.D.; Lorenz, K.; Alves, E. Radiation damage in ZnO ion implanted at 15 K. Nucl. Instrum. Methods B 2009, 267, 2708. [Google Scholar] [CrossRef]

- Azarov, A.Y.; Titov, A.I.; Karaseov, P.A.; Kucheyev, S.O.; Hallen, A.; Kuznetsov, A.Y.; Svenson, B.G.; Pathak, A.P. Structural damage in ZnO bombarded by heavy ions. Vacuum 2010, 84, 1058. [Google Scholar] [CrossRef]

- Azarov, A.Y.; Kucheyev, S.; Titov, A.; Karaseov, P.J. Effect of the density of collision cascades on ion implantation damage in ZnO. Appl. Phys. 2007, 102, 083547. [Google Scholar] [CrossRef]

- Azarov, A.; Wendler, E.; Kuznetsov, A.Y.; Svenson, B. Crucial role of implanted atoms on dynamic defect annealing in ZnO. Appl. Phys. Lett. 2014, 104, 052101. [Google Scholar] [CrossRef]

- Jagerová, A.; Malinsky, P.; Miksova, R.; Nekvindova, P.; Cajzl, J.; Akhmadaliev, S.; Holy, V.; Mackova, A. Distinct defect appearance in Gd implanted polar and nonpolar ZnO surfaces in connection to ion channeling effect. J. Vac. Sci. Technol. A 2019, 37, 061406. [Google Scholar] [CrossRef]

- Nekvindová, P.; Cajzl, J.; Macková, A.; Malinský, P.; Oswald, J.; Böttger, R.; Yatskiv, R. Er implantation into various cuts of ZnO – experimental study and DFT modelling. J. Alloys Compd. 2020, 816, 152455. [Google Scholar] [CrossRef]

- Turos, A.; Jóźwik, P.; Wójcik, M.; Gaca, J.; Ratajczak, R.; Stonert, A. Mechanism of damage buildup in ion bombarded ZnO. Acta Mater. 2017, 134, 249. [Google Scholar] [CrossRef]

- Jozwik, P.; Magalhães, S.; Ratajczak, R.; Mieszczynski, C.; Sequeira, M.; Turos, A.; Böttger, R.; Heller, R.; Lorenz, K.; Alves, E. RBS/C, XRR, and XRD Studies of Damage Buildup in Er-Implanted ZnO. Phys. Status Solidi B 2019, 256, 1800364. [Google Scholar] [CrossRef]

- Ratajczak, R.; Mieszczynski, C.; Prucnal, S.; Krajewski, T.A.; Guziewicz, E.; Wozniak, W.; Kopalko, K.; Heller, R.; Akhmadaliev, S. Correlations between the structural transformations and concentration quenching effect for RE-implanted ZnO systems. Appl. Surf. Sci. 2020, 521, 146421. [Google Scholar] [CrossRef]

- Demchenko, I.N.; Melikhov, Y.; Konstantynov, P.; Ratajczak, R.; Turos, A.; Guziewicz, E. Resonant Photoemission Spectroscopy Study on the Contribution of the Yb 4f States to the Electronic Structure of ZnO. Acta Phys. Pol. A 2018, 133, 907. [Google Scholar] [CrossRef]

- Anjana, R.; Jayaraj, M.K.; Yadav, A.K.; Jha, S.N.; Bhattacharyya, D.J. Investigating the evolution of local structure around Er and Yb in ZnO:Er and ZnO:Er, Yb on annealing using X-ray absorption spectroscopy. App. Phys. 2018, 123, 153102. [Google Scholar] [CrossRef]

- Myers, M.; Charnvanichborikarn, S.; Shao, L.; Kucheyev, S. Effect of the surface on ion-beam damage build-up in ZnO. Scr. Mater. 2012, 67, 65. [Google Scholar] [CrossRef]

- Myers, M.T.; Charnvanichborikarn, S.; Wei, C.C.; Luo, Z.P.; Aitkaliyeva, A.; Shao, L.; Kucheyev, S.O. Defect microstructure in heavy-ion-bombarded (0 0 0 1) ZnO. Acta Mater. 2012, 60, 6086. [Google Scholar] [CrossRef]

- Chu, W.; Mayer, J.; Nicolet, M. Backscattering Spectrometry; Academic Press: Orlando, FL, USA, 1978; ISBN 1-12-173850-7. [Google Scholar]

- Feldman, L.; Mayer, J.; Picraux, S. Materials Analysis by Ion Channeling; Academic Press: New York, NY, USA, 1982; ISBN 9780323139816. [Google Scholar]

- Azarov, A.; Galeckas, A.; Hallen, A.; Kuznetsov, A.; Monakhov, E.; Svensson, B.G. Optical activity and defect/dopant evolution in ZnO implanted with Er. J. Appl. Phys. 2015, 118, 125703. [Google Scholar] [CrossRef]

- Azarov, A.; Titov, A.I.; Kucheyev, S.O. Effect of pre-existing disorder on surface amorphization in GaN. Appl. Phys. 2010, 108, 033505. [Google Scholar] [CrossRef]

- Ratajczak, R.; Mieszczynski, C.; Prucnal, S.; Guziewicz, E.; Stachowicz, M.; Snigurenko, D.; Gaca, J.; Böttger, R.; Wojcik, M.; Heller, R.; et al. Structural and optical studies of Pr implanted ZnO films subjected to a long-time or ultra-fast thermal annealing. Thin Solid Film. 2017, 643, 24. [Google Scholar] [CrossRef]

- Ratajczak, R.; Prucnal, S.; Guziewicz, E.; Mieszczynski, C.; Snigurenko, D.; Stachowicz, M.; Skorupa, W.; Turos, A.J. The photoluminescence response to structural changes of Yb implanted ZnO crystals subjected to non-equilibrium processing. App. Phys. 2017, 121, 075101. [Google Scholar] [CrossRef]

- Miranda, S.; Peres, M.; Monteiro, T.; Alves, E.; Sun, H.; Geruschke, T.; Vianden, R.; Lorenz, K. Rapid thermal annealing of rare earth implanted ZnO epitaxial layers. Opt. Mater. 2011, 33, 1139. [Google Scholar] [CrossRef]

- Alves, E.; Rita, E.; Wahl, U.; Correia, J.; Monteiro, T.; Soares, J.; Boemare, C. Lattice site location and optical activity of Er implanted ZnO. Nucl. Instr. Meth. Phys. Res. B 2003, 206, 1047. [Google Scholar] [CrossRef]

- Murmu, P.; Kennedy, J.; Ruck, B.J.; Williams, G.V.M.; Markowitz, A.; Rubanov, S.; Suvorov, A.A. Correlation between microstructural and magnetic properties of Tb implanted ZnO. AIP Conf. Proc. 2013, 1525, 300. [Google Scholar] [CrossRef]

- Rita, E.; Alves, E.; Wahl, U.; Correia, J.G.; Neves, A.J.; Soares, M.J.; Monteiro, T. Optical doping of ZnO with Tm by ion implantation. Physica B 2003, 340, 235. [Google Scholar] [CrossRef]

- Azarov, A.; Hallén, A.; Du, X.; Liu, Z.; Svensson, B.; Kuznetsov, A. Thermally induced surface instability in ion-implanted MgxZn1-xO films. Phys. Rev. B. 2011, 84, 014114. [Google Scholar] [CrossRef]

- Dolabella, S.; Borzì, A.; Dommann, A.; Neels, A. Lattice Strain and Defects Analysis in Nanostructured Semiconductor Materials and Devices by High-Resolution X-Ray Diffraction: Theoretical and Practical Aspects. Small Methods 2022, 6, 2100932. [Google Scholar] [CrossRef]

- Knutsen, K.; Galeckas, A.; Zubiaga, A.; Tuomisto, F.; Farlow, G.; Svensson, B.; Kuznetsov, A.Y. Zinc vacancy and oxygen interstitial in ZnO revealed by sequential annealing and electron irradiation. Phys. Rev. B 2012, 86, 121203. [Google Scholar] [CrossRef]

- Meng, Z.; Mo, X.; Cheng, X.; Zhou, Y.; Tao, X.; Ouyang, Y. Interactions between Er dopant and intrinsic point defects of ZnO: A first-principles study. Mater. Res. Express 2017, 4, 035903. [Google Scholar] [CrossRef]

- Krajewski, T.; Ratajczak, R.; Kobyakov, S.; Wozniak, W.; Kopalko, K.; Guziewicz, E. Electrical properties of ZnO films implanted with rare earth and their relationship with structural and optical parameters. Mater. Sci. Eng. B 2022, 275, 115526. [Google Scholar] [CrossRef]

- Gehring, P.; Weng, Y.; Wu, Z.; Strunk, H.J. Photoluminescence from Alx In1−xN layers doped with Tb3+ ions. Phys. Conf. Ser. 2011, 281, 012014. [Google Scholar] [CrossRef]

- Ajimsha, R.; Das, A.; Singh, B.; Misra, P.; Kukreja, L.M. Structural, electrical and optical properties of Dy doped ZnO thin films grown by buffer assisted pulsed laser deposition. Phys. E 2010, 42, 1838. [Google Scholar] [CrossRef]

- Benz, F.; Guerra, J.; Weng, Y.; Zanatta, A.; Weingärtner, R.; Strunk, H.J. Concentration quenching of the green photoluminescence from terbium ions embedded in AlN and SiC matrices. J. Lumin 2013, 137, 73. [Google Scholar] [CrossRef]

- Benz, F.; Gonser, A.; Völker, R.; Walther, T.; Mosebach, J.-T.; Schwanda, B.; Mayer, N.; Richter, G.; Strunk, H.J. Concentration quenching of the luminescence from trivalent thulium, terbium, and erbium ions embedded in an AlN matrix. J. Lumin 2014, 145, 855. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, C.; Liu, Y.; Shao, C.; Li, X. A new approach to white light emitting diodes of p-GaN/i-ZnO/n-ZnO heterojunctions. Appl. Phys. B 2008, 92, 185–188. [Google Scholar] [CrossRef]

- Ayoub, I.; Kumar, V.; Abolhassani, R.; Sehgal, R.; Sharma, V.; Sehgal, R.; Swart, H.; Mishra, Y. Advances in ZnO: Manipulation of defects for enhancing their technological potentials. Nanotechnol. Rev. 2022, 11, 575. [Google Scholar] [CrossRef]

- Hansen, D.M.; Zhang, R.; Perkins, N.R.; Safvi, S.; Zhang, L.; Bray, K.L.; Kuech, T.F. Photoluminescence of erbium-implanted GaN and in situ-doped GaN:Er. Appl. Phys. Lett. 1998, 72, 1244. [Google Scholar] [CrossRef]

- Guziewicz, E.; Ratajczak, R.; Stachowicz, M.; Snigurenko, D.; Krajewski, T.; Mieszczynski, C.; Mazur, K.; Witkowski, B.; Dluzewski, P.; Morawiec, K. Atomic layer deposited ZnO films implanted with Yb: The influence of Yb location on optical and electrical properties. Thin Solid Film. 2017, 643, 7–15. [Google Scholar] [CrossRef]

- Sarwar, M.; Ratajczak, R.; Ivanov, V.; Mishra, S.; Turek, M.; Wierzbicka, A.; Woźniak, W.; Guziewicz, E. Crystal Lattice Damage and Recovery of Rare-Earth implanted Wide Bandgap Oxides. Adv. Sci. Technol. Res. J. 2022, 16, 147–154. [Google Scholar] [CrossRef]

- Lchi-Ghazaani, M.; Parvin, P. Fiber Laser; Mukul Chandra Paul: London, UK, 2016. [Google Scholar] [CrossRef]

- Jozwik, P.; Nowicki, L.; Ratajczak, R.; Stonert, A.; Mieszczynski, C.; Turos, A.; Morawiec, K.; Lorenz, K.; Alves, E. Monte Carlo simulations of ion channeling in crystals containing dislocations and randomly displaced atoms. J. Appl. Phys. 2019, 126, 195107. [Google Scholar] [CrossRef]

- Jozwik, P.; Nowicki, L.; Ratajczak, R.; Mieszczynski, C.; Stonert, A.; Turos, A.; Lorenz, K.; Alves, E. Advanced Monte Carlo Simulations for Ion-Channeling Studies of Complex Defects in Crystals. In Theory, and Simulation in Physics for Materials Applications; Levchenko, E.V., Dappe, Y.J., Ori, G., Eds.; Springer: Cham, Switzerland, 2020; pp. 133–160. [Google Scholar]

- Mursal; Irhamni; Bukhari; Jalil, Z.J. Structural and Optical Properties of Zinc Oxide (ZnO) based Thin Films Deposited by Sol-Gel Spin Coating Method. Phys. Conf. Ser. 2018, 1116, 032020. [Google Scholar] [CrossRef]

- Lindberg, P.; Bregolin, F.L.; Wiesenhütter, K.; Wiesenhütter, U.; Riise, H.; Vines, L.; Prucnal, S.; Skorupa, W.; Svensson, B.G.; Monakhov, E.J. The effect of millisecond flash lamp annealing on electrical and structural properties of ZnO:Al/Si structures. Appl. Phys. 2016, 119, 185305. [Google Scholar] [CrossRef]

- Rebohle, L.; Prucnal, S.; Reichel, D. Flash Lamp Annealing—from Basics to Application; Springer Series in Materials Science (SSMATERIALS): New York, NY, USA, 2019; Volume 288, ISBN 978-3-030-23298-6. [Google Scholar]

- Naliwajko, P.; Peppel, T.; Strunk, J. Thermal and light induced infrared blackening of ZnO revisited: Rediscovery of fundamental scientific knowledge. React. Kinet. Mech. Catal. 2022, 135, 2291–2305. [Google Scholar] [CrossRef]

| RBS | PL | |||

|---|---|---|---|---|

| χmin (%) | fs (%) | The Backscattering Yield of Yb Ions on the Surface (Counts) | Intensity (a.u.) | |

| virgin | 3.2 | - | - | - |

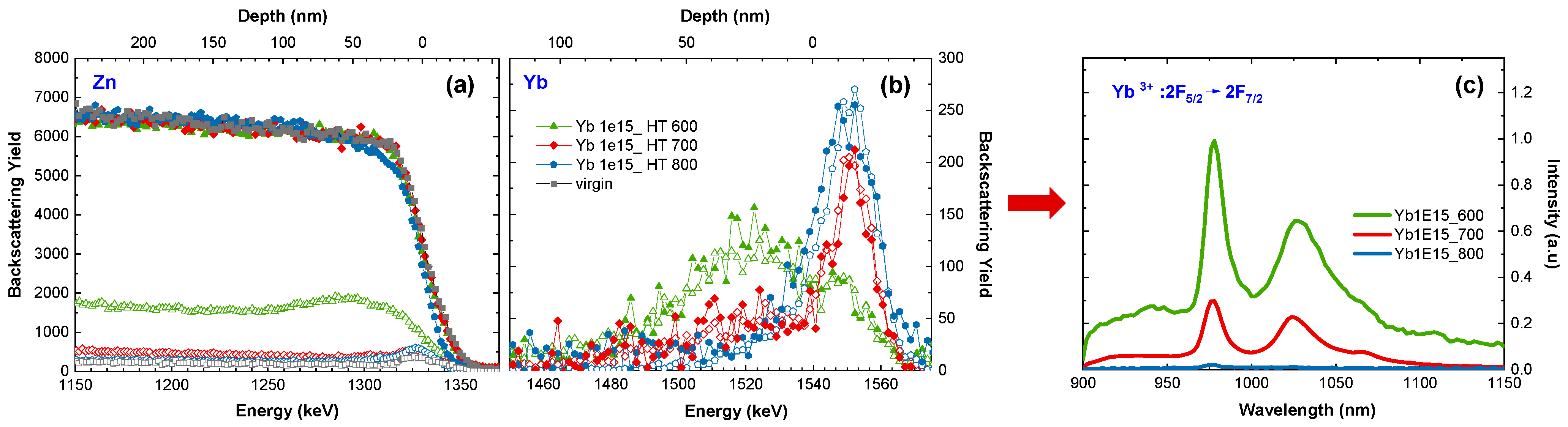

| HT-impl 600 | 27.0 | 20.6 | 88 | 1.00 |

| HT-impl 700 | 6.6 | 5.6 | 205 | 0.30 |

| HT-impl 800 | 4.2 | 3.5 | 248 | 0.03 |

| RBS | PL | |||

|---|---|---|---|---|

| χmin (%) | fs (%) | The Backscattering Yield of Yb Ions on the Surface (Counts) | Intensity (a.u.) | |

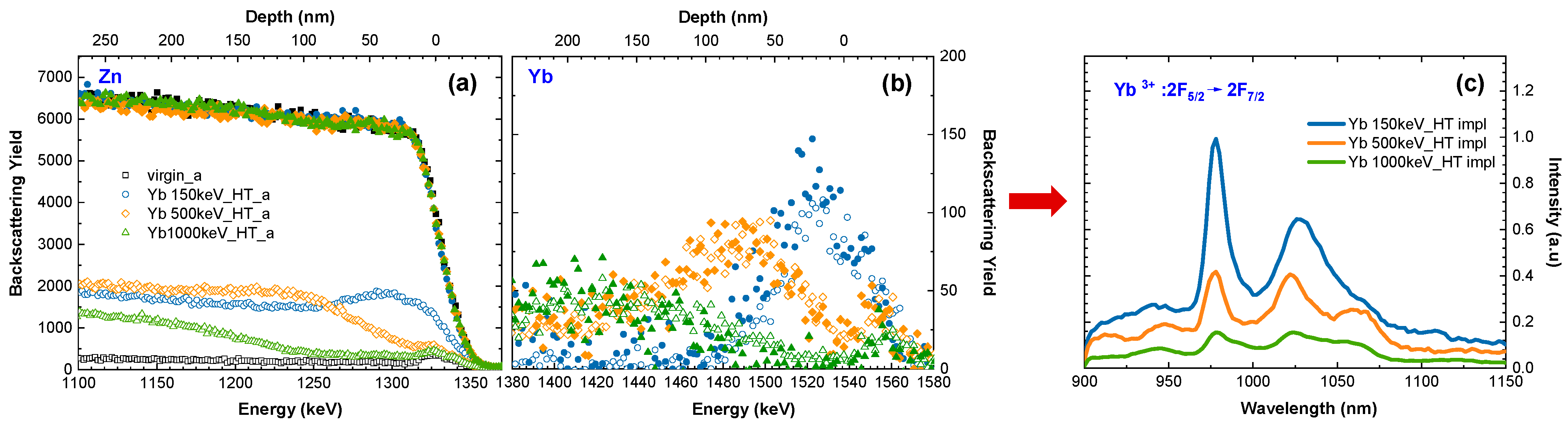

| Virgin | 2.9 | - | - | - |

| RT-impl | 20.4 | 64.9 | 7 | 0.02 |

| RT-impl+RTA O2 | 6.2 | 40.1 | 20 | 1.00 |

| RT-impl+RTA N2 | 5.6 | 55.9 | 16 | 0.56 |

| RT-impl+RTA Ar | 12.0 | 16.5 | 20 | 0.16 |

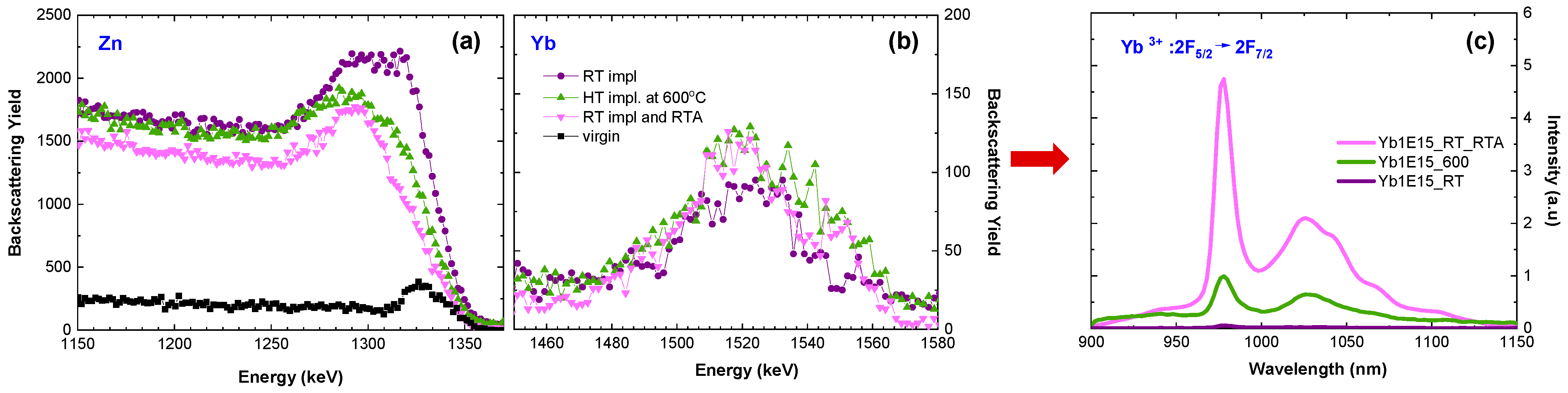

| RBS | PL | |||

|---|---|---|---|---|

| χmin (%) | fs (%) | The Backscattering Yield of Yb Ions on the Surface (Counts) | χmin (%) | |

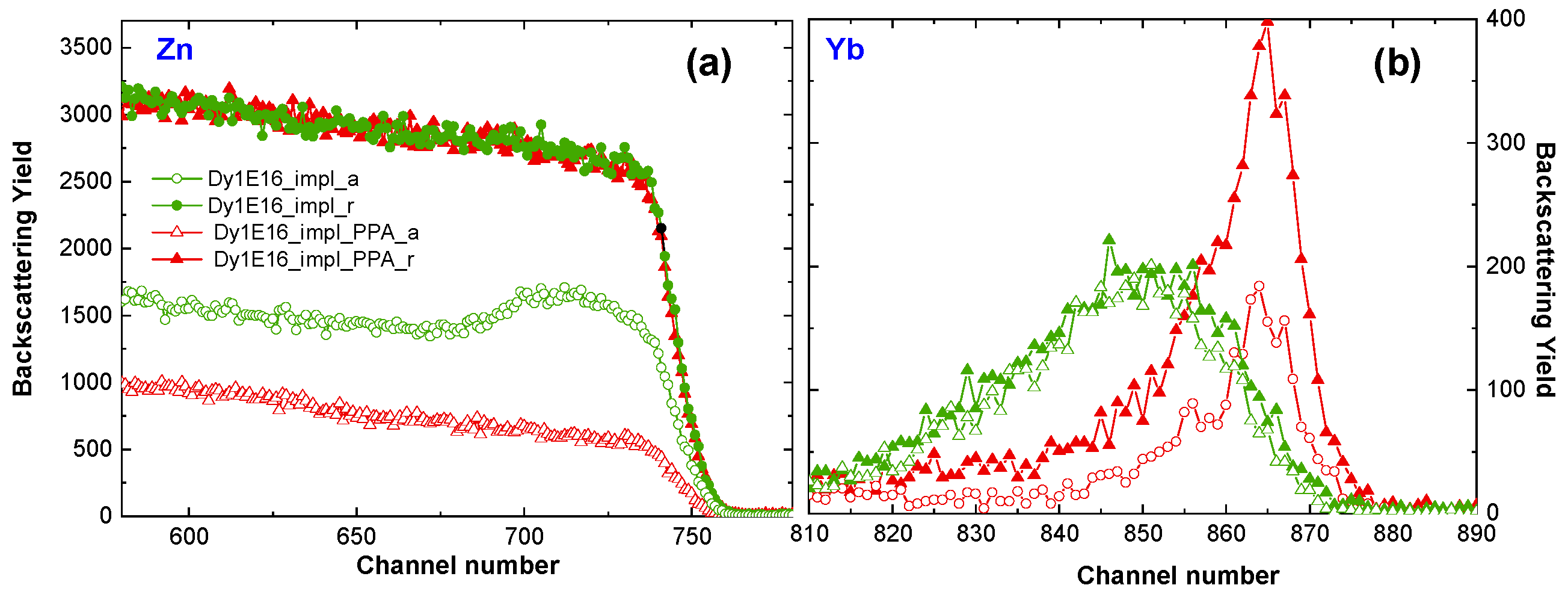

| virgin | 3.2 | - | - | - |

| HT 600 | 27.0 | 20.6 | 88 | 1.00 |

| RT | 28.6 | 49.1 | 25 | 0.04 |

| RT+RTA | 23.7 | 26.5 | 64 | 4.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ratajczak, R.; Guziewicz, E.; Prucnal, S.; Mieszczynski, C.; Jozwik, P.; Barlak, M.; Romaniuk, S.; Gieraltowska, S.; Wozniak, W.; Heller, R.; et al. Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions. Materials 2023, 16, 1756. https://doi.org/10.3390/ma16051756

Ratajczak R, Guziewicz E, Prucnal S, Mieszczynski C, Jozwik P, Barlak M, Romaniuk S, Gieraltowska S, Wozniak W, Heller R, et al. Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions. Materials. 2023; 16(5):1756. https://doi.org/10.3390/ma16051756

Chicago/Turabian StyleRatajczak, Renata, Elzbieta Guziewicz, Slawomir Prucnal, Cyprian Mieszczynski, Przemysław Jozwik, Marek Barlak, Svitlana Romaniuk, Sylwia Gieraltowska, Wojciech Wozniak, René Heller, and et al. 2023. "Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions" Materials 16, no. 5: 1756. https://doi.org/10.3390/ma16051756

APA StyleRatajczak, R., Guziewicz, E., Prucnal, S., Mieszczynski, C., Jozwik, P., Barlak, M., Romaniuk, S., Gieraltowska, S., Wozniak, W., Heller, R., Kentsch, U., & Facsko, S. (2023). Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions. Materials, 16(5), 1756. https://doi.org/10.3390/ma16051756