Fracture Behavior of AA7075-AA6061 and AA7075-Cu Friction-Stir Welded Joints Containing Blunt V-Notches under Opening-Mode Loading

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Program

2.2. Theoretical Models

3. Results and Discussion

4. Conclusions

- ▪

- The fracture of specimens made of the AA7075-AA6061 and AA7075-Cu FSW materials containing V-shaped notches and subjected to pure opening-mode loading was investigated.

- ▪

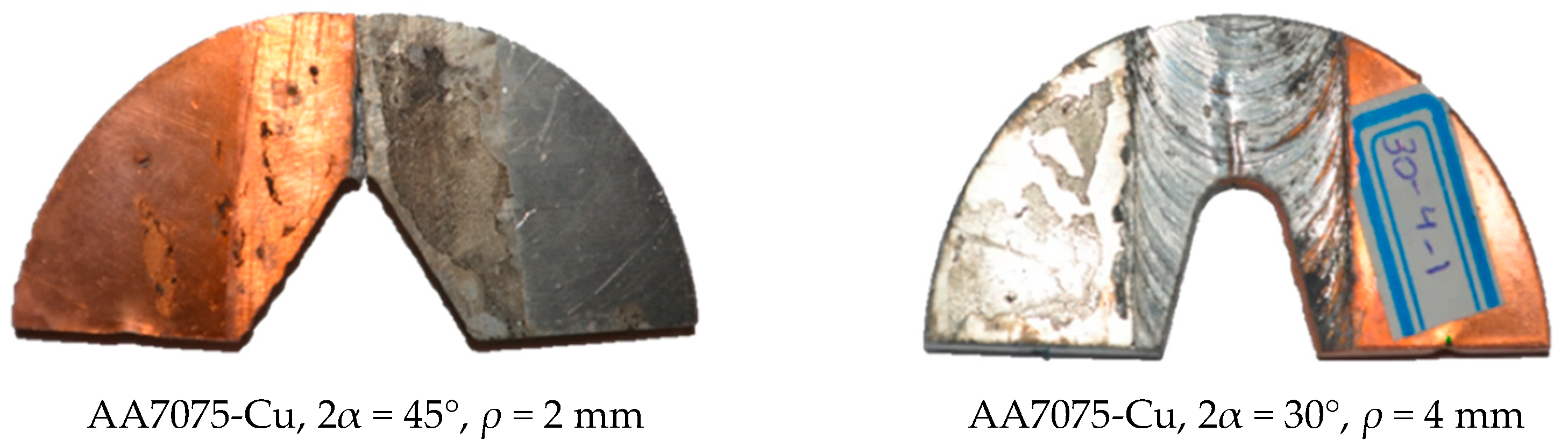

- It was observed that for the specimens made of AA7075-AA6061 weld material, the elastoplastic fracture regime was small scale yielding (SSY), whereas for those made of AA7075-Cu, the fracture regime was moderate scale yielding (MSY).

- ▪

- In order to utilize brittle fracture criteria for estimating the notch fracture toughness (NFT) values of the tested V-notched specimens, the EMC was employed.

- ▪

- It was observed that the combination of EMC with the two brittle fracture criteria (maximum tangential stress—MTS criterion and mean stress-MS criterion) can result in successful predictions of the experimental results of the notched FSWed AA7075-AA6061 and AA7075-Cu materials subjected to mode I loading.

- ▪

- Based on the results obtained, both the EMC-MTS and EMC-MS criteria provide acceptable predictions, but due to its simplicity, the EMC-MTS criterion is preferred here.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AA | Aluminum alloy |

| a | Crack length |

| dc | Critical distance of the mean stress criterion measured from the notch tip |

| dc* | Critical distance of the mean stress criterion |

| E | Elastic modulus |

| EMC | Equivalent material concept |

| FSW | Friction-stir welding |

| LBC | Load bearing capacity |

| LSY | Large scale yielding |

| k | Strain-hardening coefficient |

| KI | Mode I notch stress intensity factor (NSIF) |

| Kc | Fracture toughness |

| KIc | Plane-strain fracture toughness |

| MS | Mean stress |

| MSY | Moderate scale yielding |

| MTS | Maximum tangential stress |

| n | Strain-hardening exponent |

| NFT | Notch fracture toughness |

| NZ | Nugget zone |

| PS | Point stress |

| rc | Critical distance of the MTS criterion measured from the notch tip |

| r0 | Distance between the coordinate origin and the notch tip |

| SED | Strain energy density |

| SCB | Semi-circular bend specimen |

| SSY | Small scale yielding |

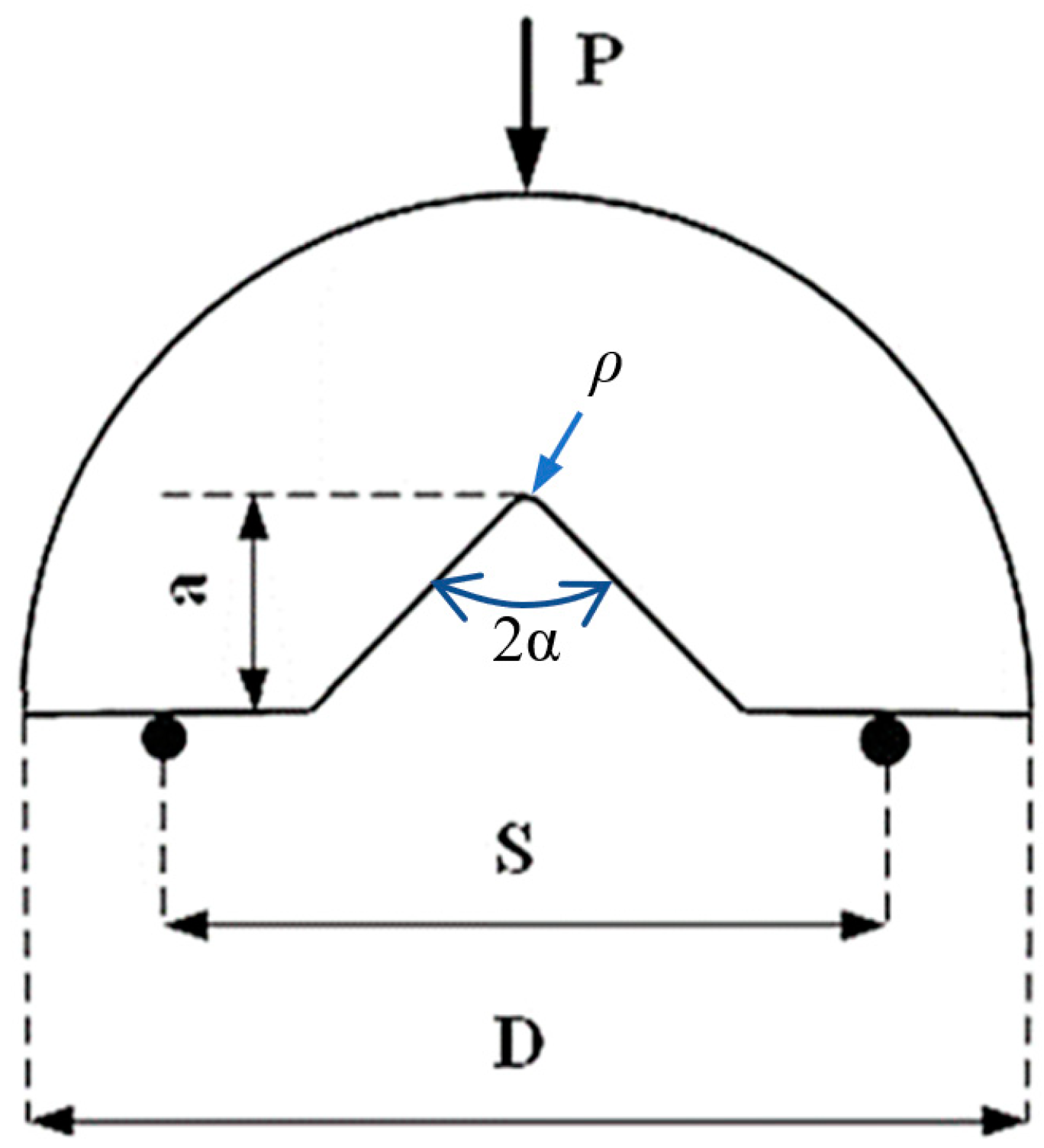

| 2α | Notch rotation angle |

| εu,true | True plastic strain at maximum load |

| ρ | Notch radius |

| σ | True stress |

| σc | Critical stress |

| σf* | Tensile strength of the equivalent material |

| σθθ | Tangential stress |

| σθθc | Material critical stress |

| σu | Ultimate tensile strength |

| σY | Yield strength |

References

- Sutton, M.A.; Reynolds, A.P.; Yang, B.; Taylor, R. Mixed mode I/II fracture of 2024-T3 friction stir welds. Eng. Fract. Mech. 2003, 70, 2215–2234. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Santos, T.; Tavares, S.M.O.; Richter-Trummer, V.; Vilaça, P.; de Castro, P.M.S.T. Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Sinke, J.; Benedictus, R. Global and local mechanical properties and microstructure of friction stir welds with dissimilar materials and/or thicknesses. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 3365–3378. [Google Scholar] [CrossRef]

- Reynolds, A.P. R-curve behaviour of friction stir welds in aluminium-lithium alloy 2195. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 283–290. [Google Scholar]

- Mokhtar, S.N.F.; Wahab, A.A.; Karuppanan, S. Fracture toughness and fatigue crack growth study of friction stir welded plates. J. Appl. Sci. 2012, 12, 2469–2473. [Google Scholar] [CrossRef]

- Sutton, M.A.; Reynolds, A.P.; Yang, B.; Taylor, R. Mode I fracture and microstructure for 2024-T3 friction stir welds. Mater. Sci. Eng. A 2003, 354, 6–16. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Fotouhi, Y.; Berto, F. Experimental notched fracture resistance study for the interface of Al–Cu bimetal joints welded by friction stir welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2192–2200. [Google Scholar] [CrossRef]

- Yan, J.; Sutton, M.A.; Reynolds, A.P. Notch tensile response of mini-regions in AA2024 and AA2524 friction stir welds. Mater. Sci. Eng. A 2006, 427, 289–300. [Google Scholar] [CrossRef]

- Syafiq, W.M.; Rojan, M.A.; Abdul Majid, M.S.; Jaafar, N.A. Fracture toughness of friction stir welded aluminium alloy. ARPN J. Eng. Appl. Sci. 2016, 11, 3102–3108. [Google Scholar]

- Fratini, L.; Pasta, S.; Reynolds, A.P. Fatigue crack growth in 2024-T351 friction stir welded joints: Longitudinal residual stress and microstructural effects. Int. J. Fatigue 2009, 31, 495–500. [Google Scholar] [CrossRef]

- Pouget, G.; Reynolds, A.P. Residual stress and microstructure effects on fatigue crack growth in AA2050 friction stir welds. Int. J. Fatigue 2008, 30, 463–472. [Google Scholar] [CrossRef]

- Bahemmat, P.; Besharati, M.K.; Haghpanahi, M.; Rahbari, A.; Salekrostam, R. Mechanical, micro-, and macrostructural analysis of AA7075–T6 fabricated by friction stir butt welding with different rotational speeds and tool pin profiles. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 419–433. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Shahheidari, M.; Bisadi, M.; Akbari, M.; Hossain, S. Mechanical and metallurgical properties of dissimilar AA6061-T6 and AA7277-T6 joint made by FSW technique. Int. J. Adv. Manuf. Technol. 2016, 86, 2551–2565. [Google Scholar] [CrossRef]

- Hatamleh, O.; Forth, S.; Reynolds, A.P. Fatigue Crack Growth of Peened Friction Stir-Welded 7075 Aluminum Alloy under Different Load Ratios. J. Mater. Eng. Perform. 2009, 19, 99–106. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; de Jesus, A.M.P.; Ribeiro, A.S.; de Castro, P.M.S.T. Fatigue crack growth in friction stir welds of 6082-T6 and 6061-T6 aluminium alloys: A comparison. Theor. Appl. Fract. Mech. 2008, 50, 81–91. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Tang, W.; Khandkar, Z.; Khan, J.A.; Lindner, K. Relationships between weld parameters, hardness distribution and temperature history in alloy 7050 friction stir welds. Sci. Technol. Weld. Join. 2005, 10, 190–199. [Google Scholar] [CrossRef]

- Alavi Nia, A.; Shirazi, A. An investigation into the effect of welding parameters on fatigue crack growth rate and fracture toughness in friction stir welded copper sheets. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 232, 191–203. [Google Scholar] [CrossRef]

- Moghadam, D.; Farhangdoost, K. Influence of welding parameters on fracture toughness and fatigue crack growth rate in friction stir welded nugget of 2024-T351 aluminum alloy joints. Trans. Nonferr. Met. Soc. China 2016, 26, 2567–2585. [Google Scholar] [CrossRef]

- Huang, J.; Meng, Q.; Zhan, Z.; Hu, W.; Shen, F. Damage mechanics-based approach to studying effects of overload on fatigue life of notched specimens. Int. J. Damage Mech. 2019, 28, 538–565. [Google Scholar] [CrossRef]

- Zhan, Z.; Ao, N.; Hu, Y.; Liu, C. Defect-induced fatigue scattering and assessment of additively manufactured 300M-AerMet100 steel: An investigation based on experiments and machine learning. Eng. Frac. Mech. 2022, 264, 108352. [Google Scholar] [CrossRef]

- Torabi, A.R. On the use of the equivalent material concept to predict tensile load-bearing capacity of ductile steel bolts containing V-shaped threads. Eng. Fract. Mech. 2013, 97, 136–147. [Google Scholar] [CrossRef]

- Torabi, A.R.; Habibi, R.; Mohammad Hosseini, B. On the ability of the equivalent material concept in predicting ductile failure of u-notches under moderate- and large-scale yielding conditions. Phys. Mesomech. 2015, 18, 337–347. [Google Scholar] [CrossRef]

- Sutton, M.A.; Reynolds, A.P.; Yan, J.; Yang, B.; Yuan, N. Microstructure and mixed mode I/II fracture of AA2524-T351 base material and friction stir welds. Eng. Fract. Mech. 2006, 73, 391–407. [Google Scholar] [CrossRef]

- Torabi, A.R.; Kalantari, M.H.; Aliha, M.R.M. Fracture analysis of dissimilar Al-Al friction stir welded joints under tensile/shear loading. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2040–2053. [Google Scholar] [CrossRef]

- Torabi, A.R.; Mirzavand, M.; Saboori, B. Investigation of notch effects on load-bearing capacity of AA7075-AA7075 friction-stir welded joints under mixed mode I/II loading. Theor. Appl. Fract. Mech. 2022, 118, 103252. [Google Scholar] [CrossRef]

- Torabi, A.R.; Saboori, B.; Mirzavand, M. Elastoplastic fracture analysis of thin notched AA7075-AA2024 dissimilar friction-stir-welded plates under mixed mode I/II loading. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1557–1570. [Google Scholar] [CrossRef]

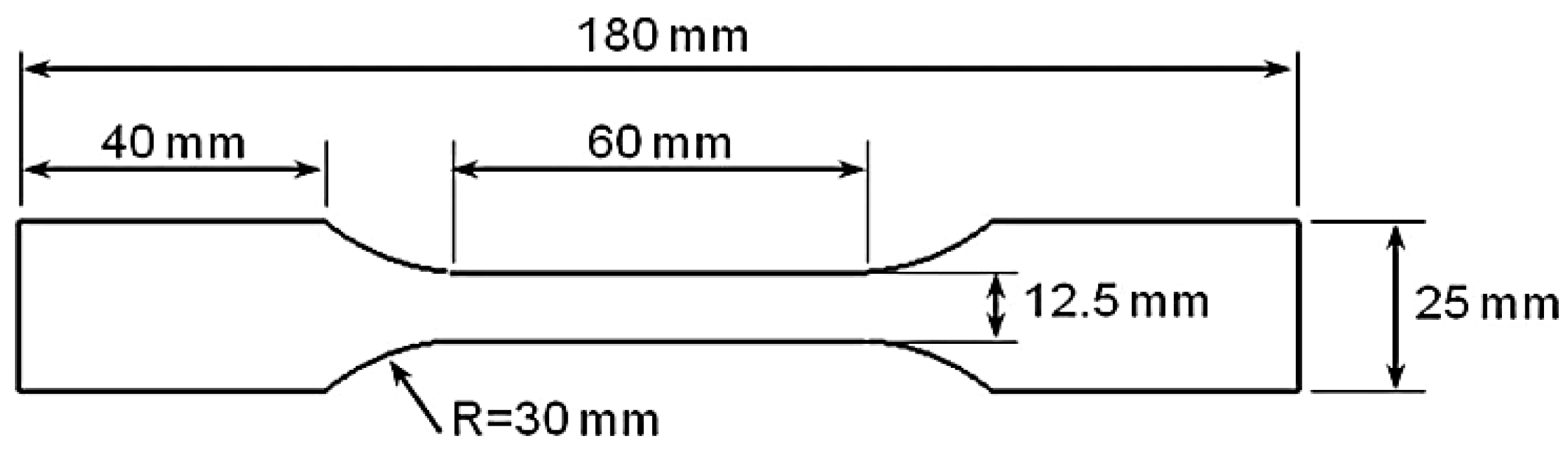

- ASTM E8/E8M-21; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Lazzarin, P.; Filippi, S. A generalized stress intensity factor to be applied to rounded V-shaped notches. Int. J. Solids Struct. 2006, 43, 2461–2478. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Torabi, A.R. Brittle fracture in rounded-tip V-shaped notches. Mater. Des. 2010, 31, 60–67. [Google Scholar] [CrossRef]

- Torabi, A.R. Estimation of tensile load-bearing capacity of ductile metallic materials weakened by a V-notch: The equivalent material concept. Mater. Sci. Eng. A 2012, 536, 249–255. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Kalantari, M.H.; Ghoreishi, S.M.N.; Torabi, A.R.; Etesam, S. Mixed mode I/II crack growth investigation for bi-metal FSW aluminum alloy AA7075-T6/pure copper joints. Theor. Appl. Fract. Mech. 2019, 103, 102243. [Google Scholar] [CrossRef]

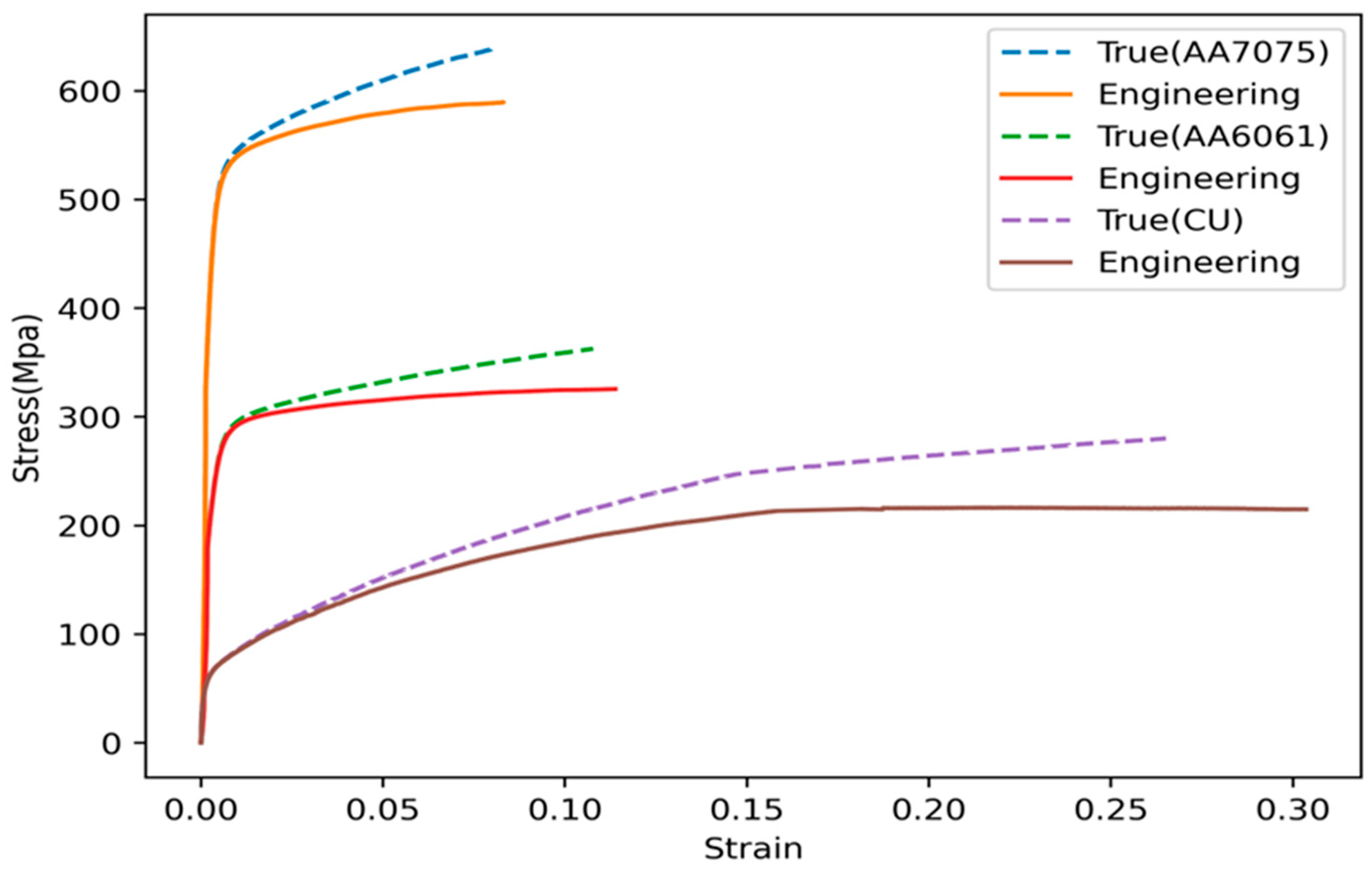

| Material | σY (MPa) | σu (MPa) | Strain at Failure (%) |

|---|---|---|---|

| AA7075 | 521 | 583 | 8 |

| AA6061 | 276 | 292 | 11 |

| Cu | 58 | 230 | 27 |

| AA7075- AA6061 | 215 | 220 | 7.8 |

| AA7075-Cu | 92 | 108 | 12 |

| Specimen | Test 1 (N) | Test 2 (N) | Test 3 (N) | Average (N) ± Avg. Deviation |

|---|---|---|---|---|

| V0-1 | 8845 | 6593 | 6972 | 7470 ± 917 |

| V0-2 | 8195 | 9016 | 8321 | 8510 ± 337 |

| V0-4 | 10,499 | 9400 | 10,001 | 9965 ± 378 |

| V45-1 | 5839 | 6376 | 4601 | 5605 ± 670 |

| V45-2 | 7077 | 6884 | 6795 | 6918 ± 106 |

| V45-4 | 9067 | 9127 | 8817 | 9003 ± 124 |

| Specimen | Test 1 (N) | Test 2 (N) | Test 3 (N) | Average (N) ± Avg. Deviation |

|---|---|---|---|---|

| V30-1 | 3841 | 4130 | 4707 | 4226 ± 321 |

| V30-2 | 5518 | 6070 | 5302 | 5630 ± 293 |

| V30-4 | 7599 | 6639 | 6762 | 7000 ± 399 |

| V60-1 | 3857 | 4589 | 4514 | 4320 ± 309 |

| V60-2 | 6447 | 5607 | 5616 | 5890 ± 371 |

| V60-4 | 7388 | 6335 | 7307 | 7010 ± 450 |

| Test case | (Exp.) | (EMC-MS) | (EMC-MTS) | Discrepancy (%) (EMC-MS) | Discrepancy (%) (EMC-MTS) |

|---|---|---|---|---|---|

| AA7075-AA6061 — | 52.7 | 58.1 | 50.9 | 10.2 | −3.4 |

| AA7075-AA6061 — | 64.1 | 70.8 | 64.8 | 10.4 | 1.1 |

| AA7075-AA6061 — | 82.5 | 91.2 | 86.5 | 10.5 | 4.8 |

| AA7075-AA6061 — | 100.5 | 109.7 | 106 | 9.1 | 5.5 |

| AA 7075-AA6061 — | 133 | 149.4 | 146.7 | 12.3 | 10.3 |

| AA7075-AA6061 — | 186 | 206.7 | 204.7 | 11.1 | 10.1 |

| AA7075-Cu — | 81.2 | 92.2 | 89.6 | 13.5 | 10.3 |

| AA7075-Cu — | 114.3 | 126.6 | 124.7 | 10.8 | 9.1 |

| AA7075-Cu — | 156.2 | 176.1 | 174.8 | 12.7 | 11.9 |

| AA7075-Cu — | 71.9 | 81.8 | 78.8 | 13.8 | 9.6 |

| AA7075-Cu — | 103.5 | 110.5 | 108.3 | 6.8 | 4.6 |

| AA7075-Cu — | 134.3 | 151.9 | 150.4 | 13.1 | 11.9 |

| Mean discrepancy (%) | 11.1 | 7.7 |

| Case | ELS (mm) | PZS (mm) | (PZS/ELS) × 100 (%) | Failure Regime |

|---|---|---|---|---|

| AA7075-AA6061 , ρ = 1 mm | 15 | 0.7 | 4.6 | SSY |

| AA7075-AA6061 , ρ = 2 mm | 15 | 0.5 | 3.3 | SSY |

| AA7075-Cu , ρ = 2 mm | 15 | 3.0 | 20 | MSY |

| AA7075-Cu , ρ = 4 mm | 15 | 2.8 | 18 | MSY |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torabi, A.R.; Mirzavand, M.; Saboori, B.; Cicero, S. Fracture Behavior of AA7075-AA6061 and AA7075-Cu Friction-Stir Welded Joints Containing Blunt V-Notches under Opening-Mode Loading. Materials 2023, 16, 1757. https://doi.org/10.3390/ma16051757

Torabi AR, Mirzavand M, Saboori B, Cicero S. Fracture Behavior of AA7075-AA6061 and AA7075-Cu Friction-Stir Welded Joints Containing Blunt V-Notches under Opening-Mode Loading. Materials. 2023; 16(5):1757. https://doi.org/10.3390/ma16051757

Chicago/Turabian StyleTorabi, Ali Reza, Moslem Mirzavand, Behnam Saboori, and Sergio Cicero. 2023. "Fracture Behavior of AA7075-AA6061 and AA7075-Cu Friction-Stir Welded Joints Containing Blunt V-Notches under Opening-Mode Loading" Materials 16, no. 5: 1757. https://doi.org/10.3390/ma16051757

APA StyleTorabi, A. R., Mirzavand, M., Saboori, B., & Cicero, S. (2023). Fracture Behavior of AA7075-AA6061 and AA7075-Cu Friction-Stir Welded Joints Containing Blunt V-Notches under Opening-Mode Loading. Materials, 16(5), 1757. https://doi.org/10.3390/ma16051757