Strong and Flexible Braiding Pattern of Carbon Nanotubes for Composites: Stiff and Robust Structure Active in Composite Materials

Abstract

1. Introduction

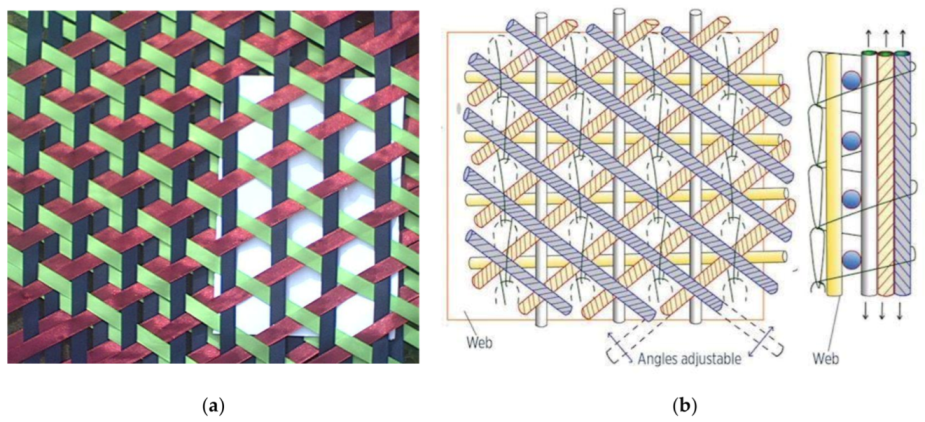

2. Development of Braiding Patterns

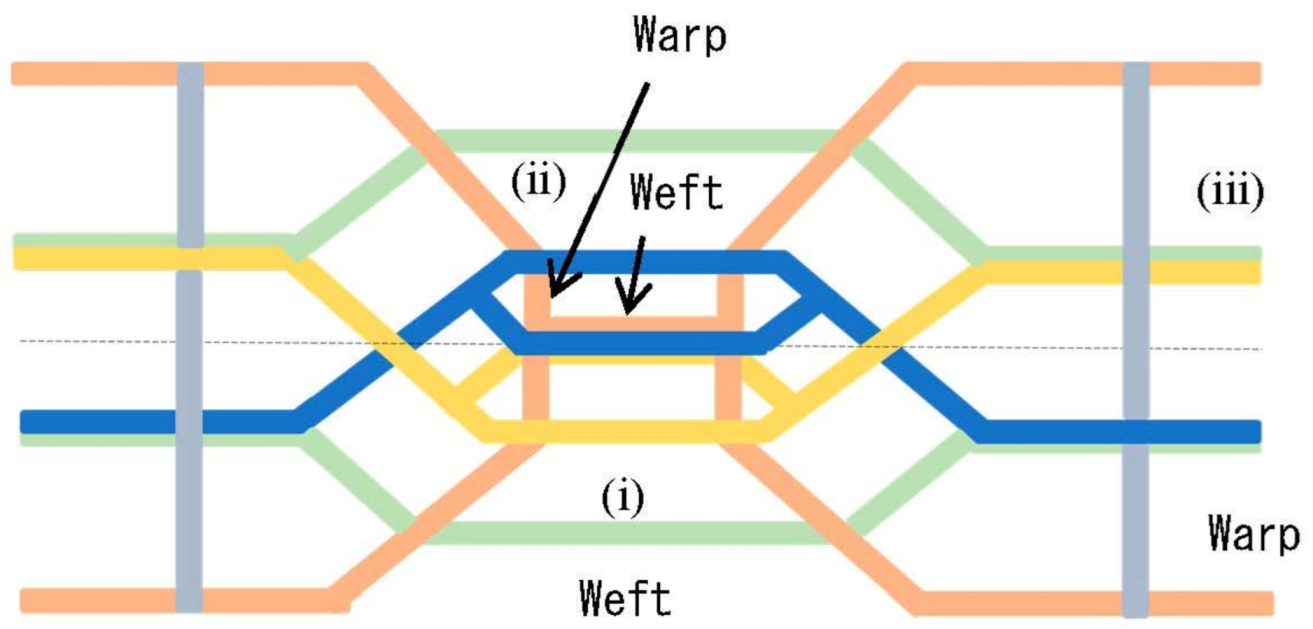

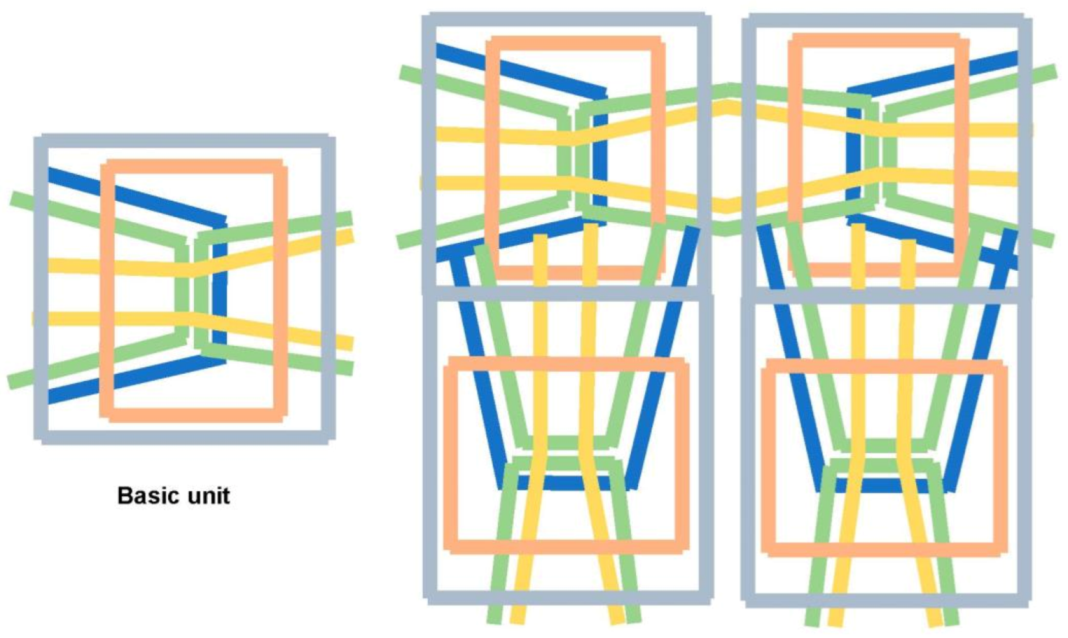

2.1. Braided Spider Net

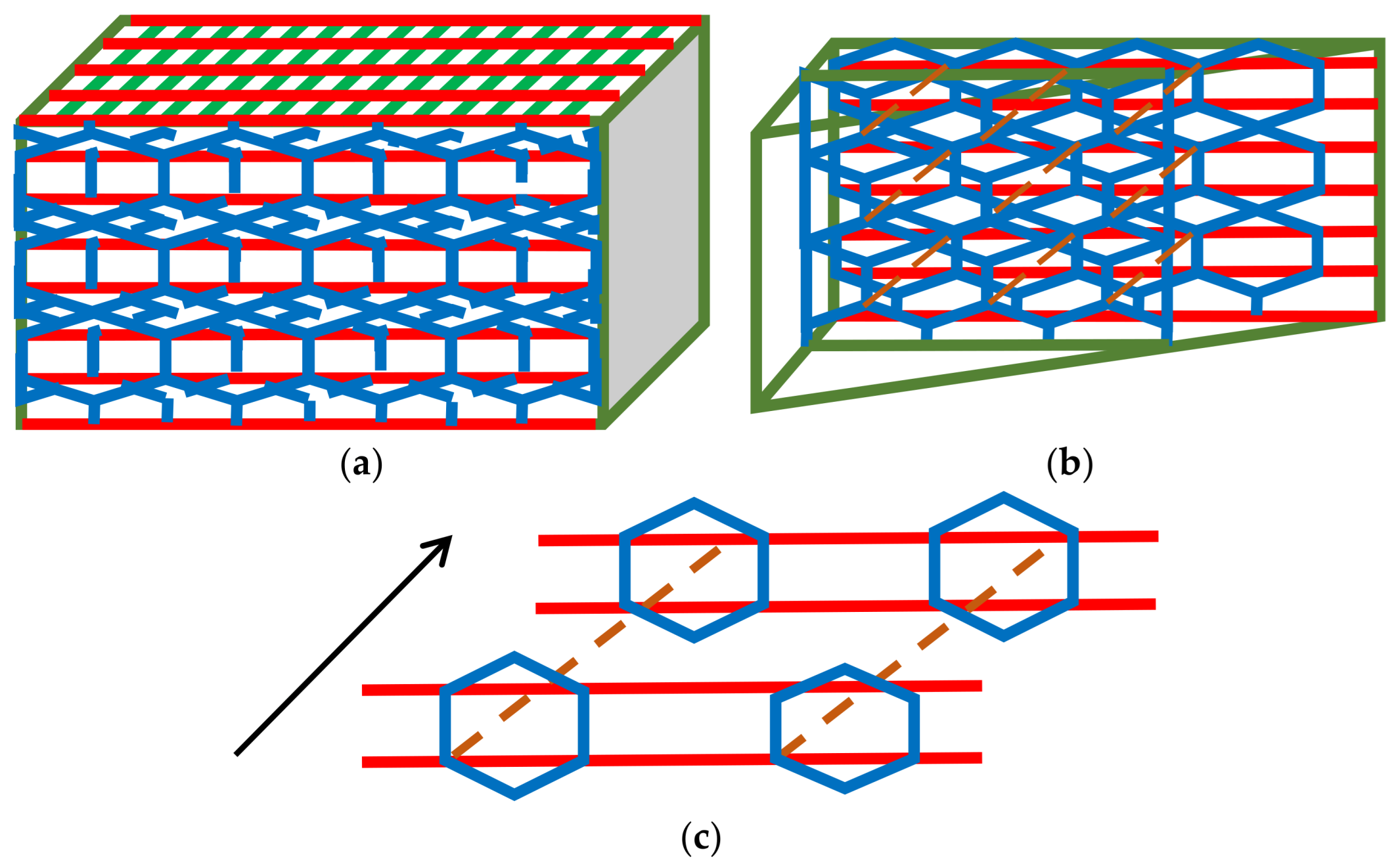

2.2. Braided Pattern Based on Honeycomb

3. Basic Calculation of Mechanical Properties

4. Consideration: Braided Patterns Revisited and Proposal of Mechanisms to Maintain Overall Stability

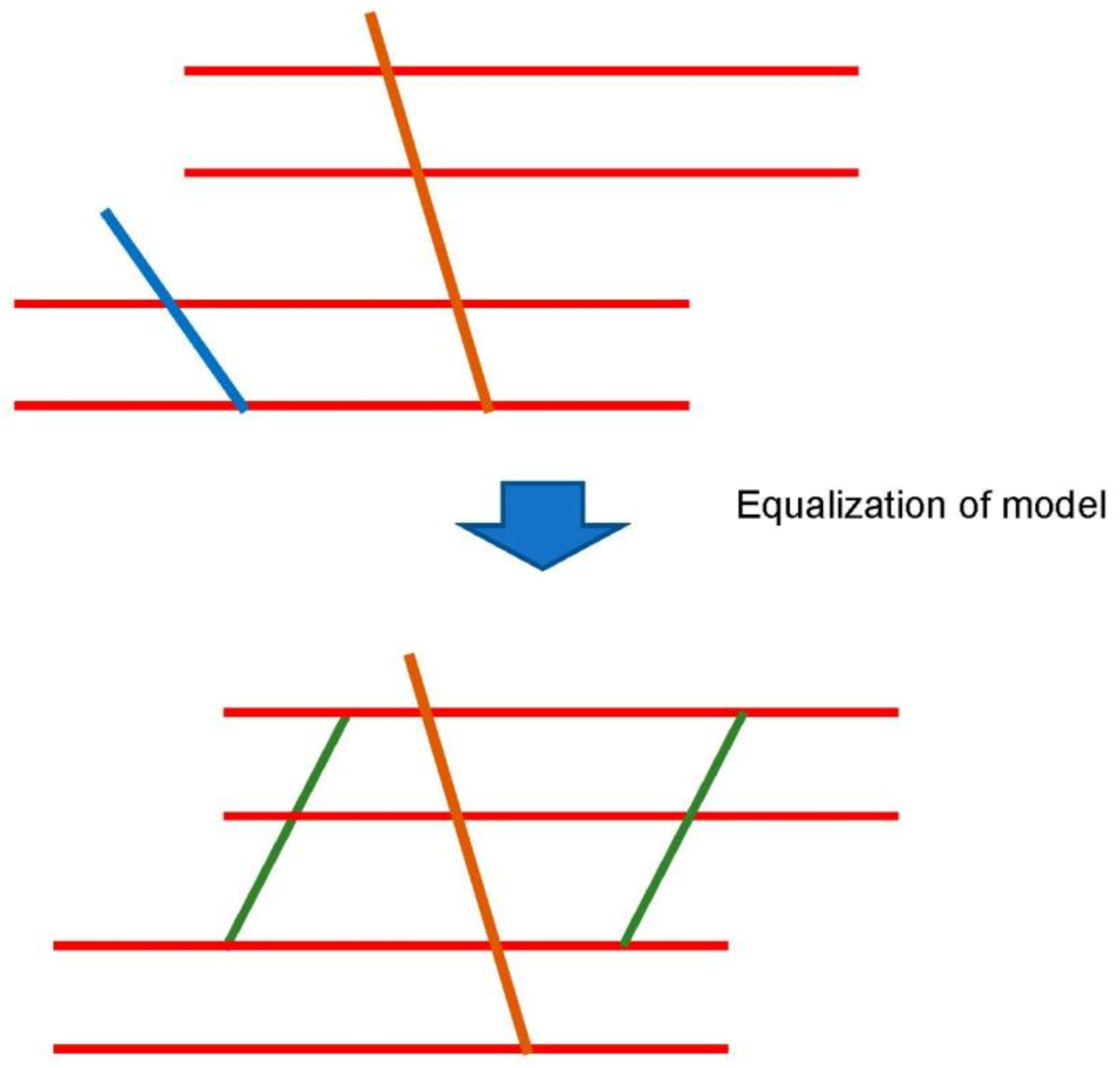

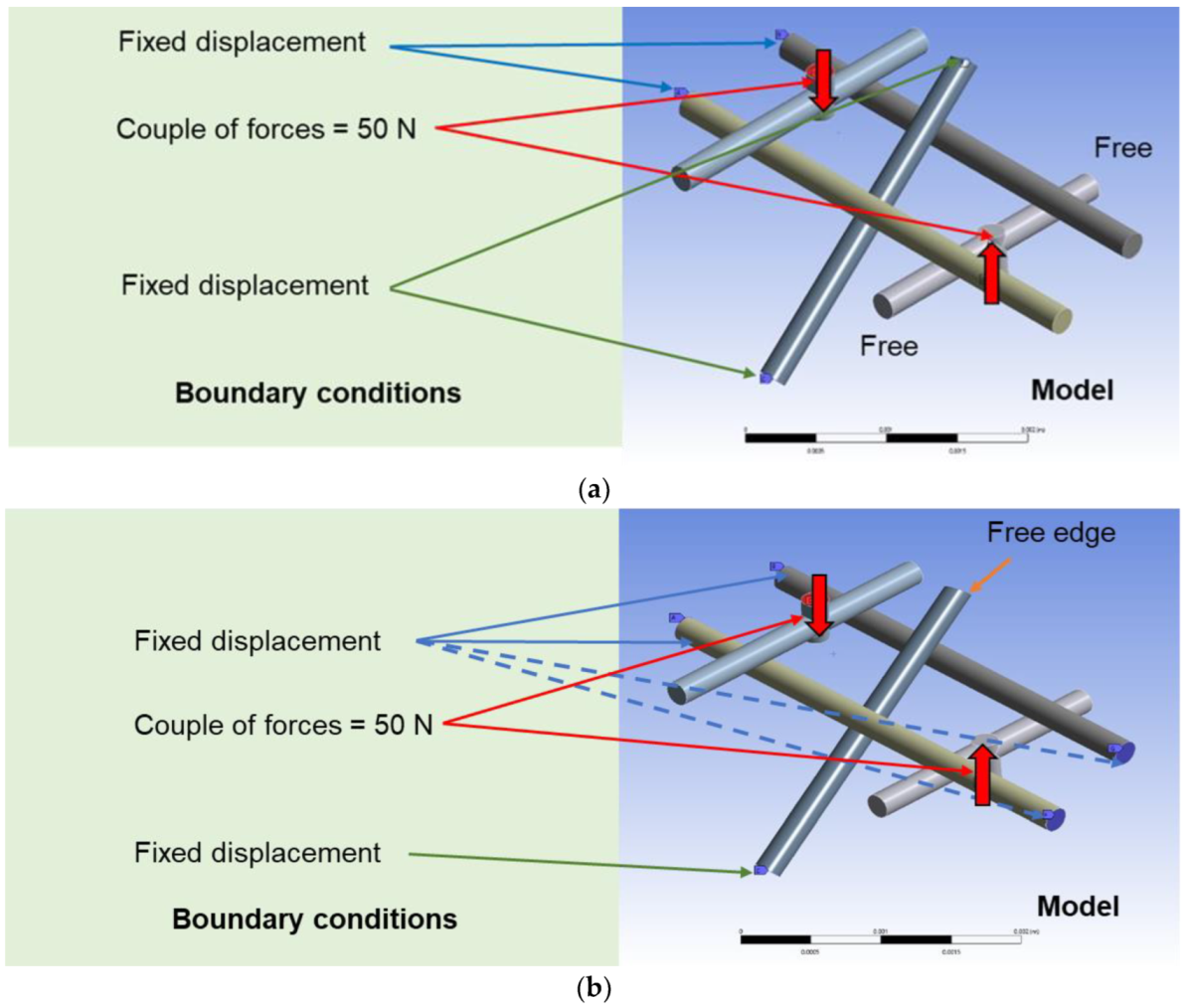

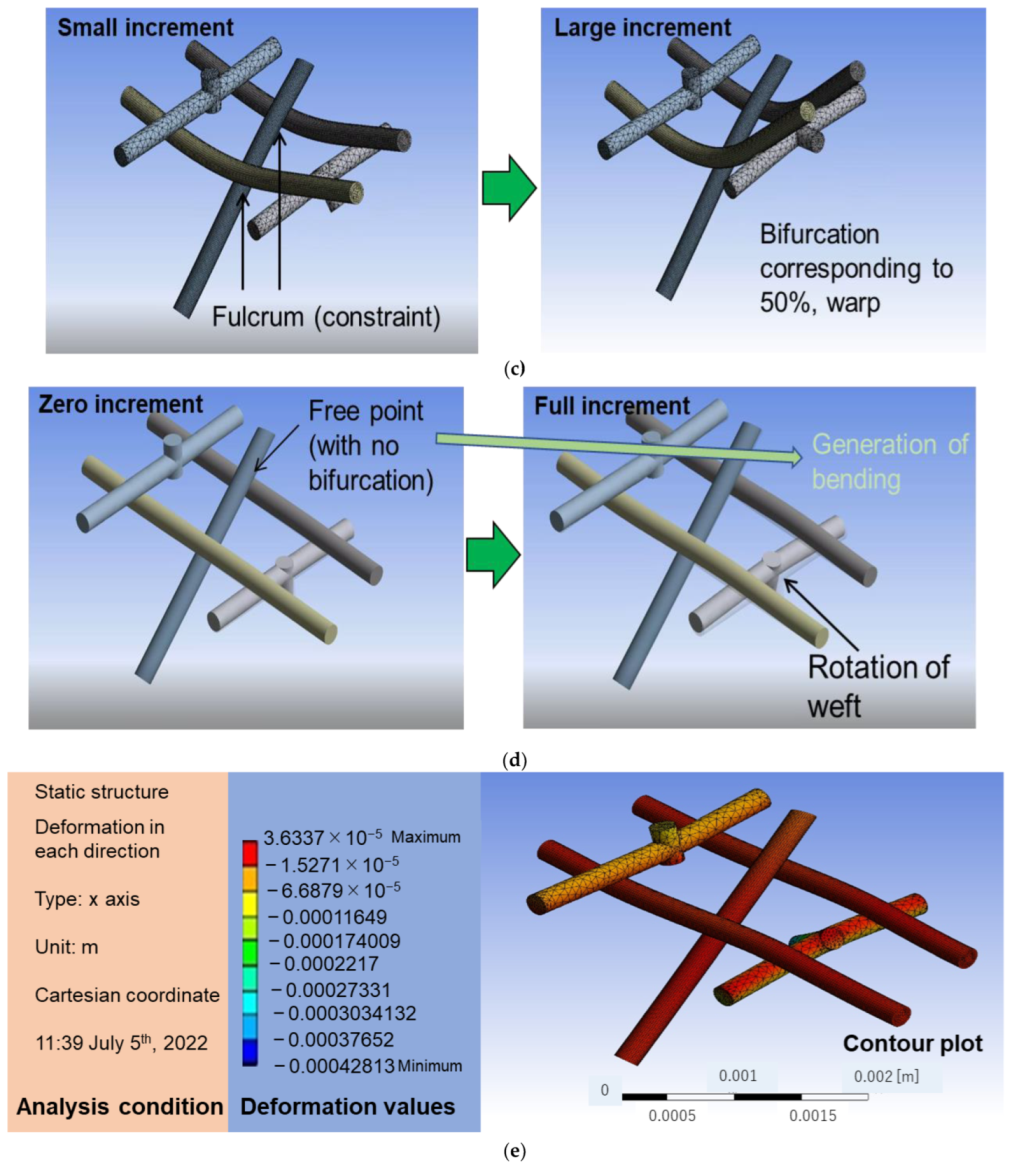

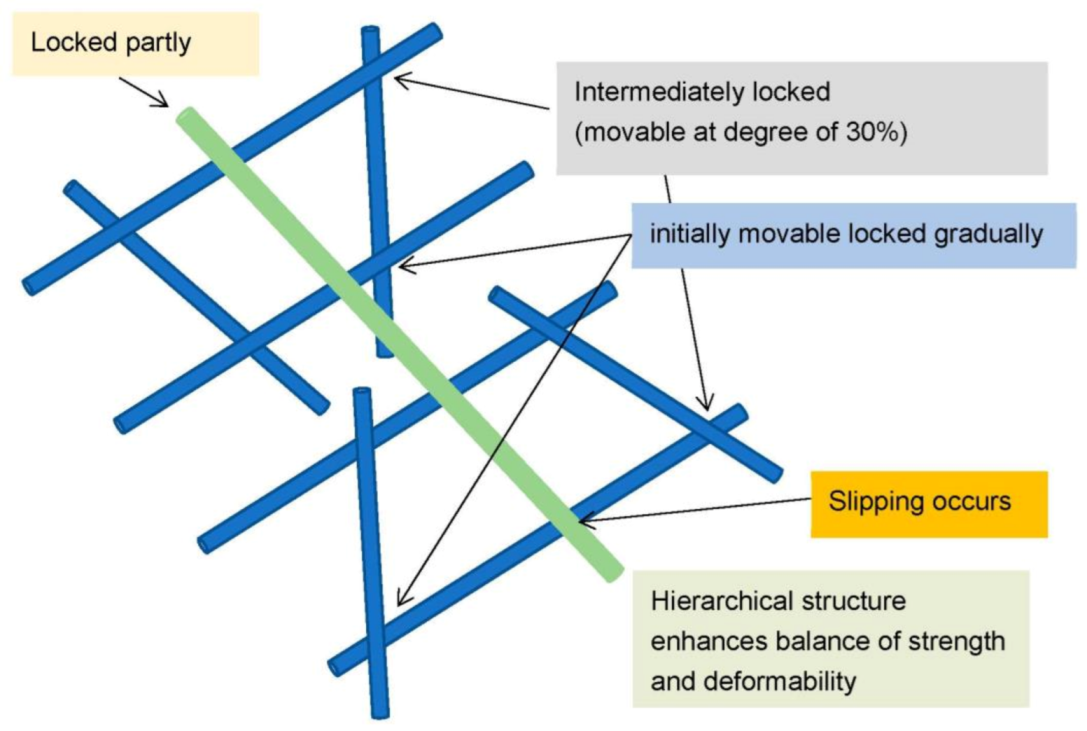

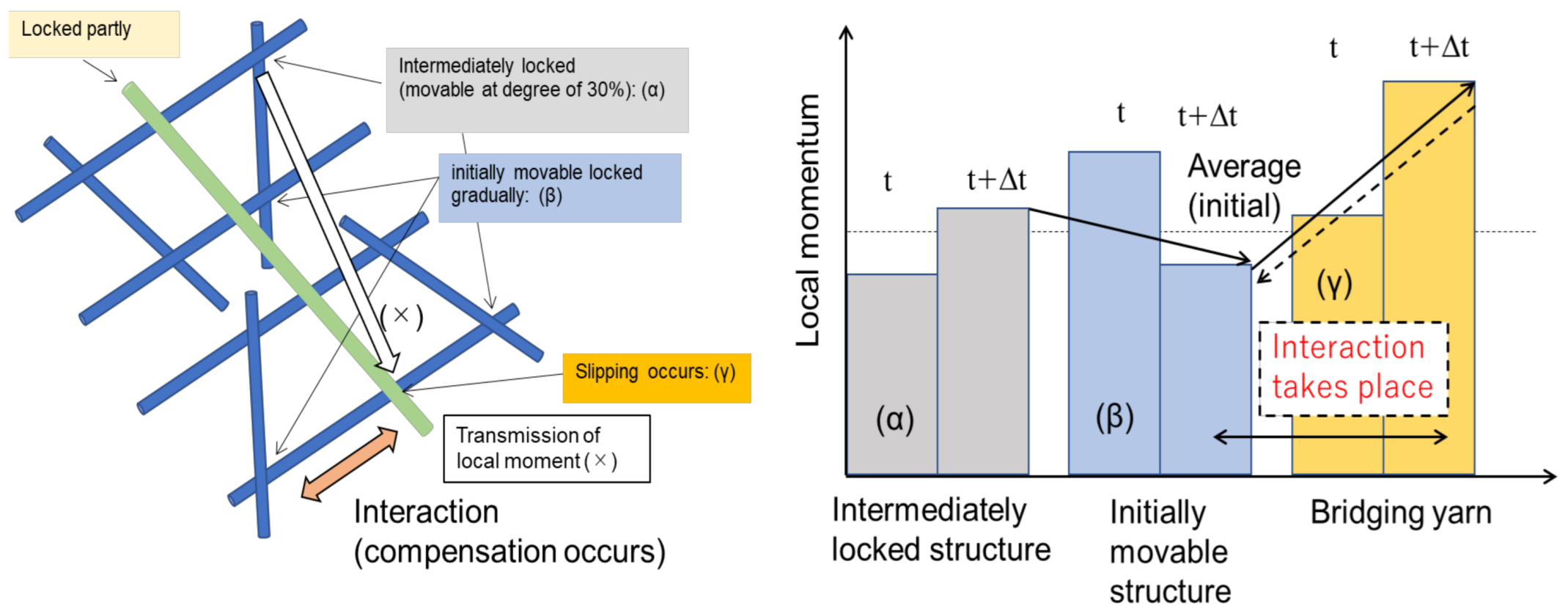

4.1. Braiding Patterns with Inclined Reinforcement Bar Assisted by Diagonal Bridges

- Construction of a stiff framework to improve strength.

- The sliding at the contact point of webs is beneficial to reduce the stresses; however, this is the degree problem.

- A hierarchical structure is essential to avoid unfavorable overload and enhance flexibility.

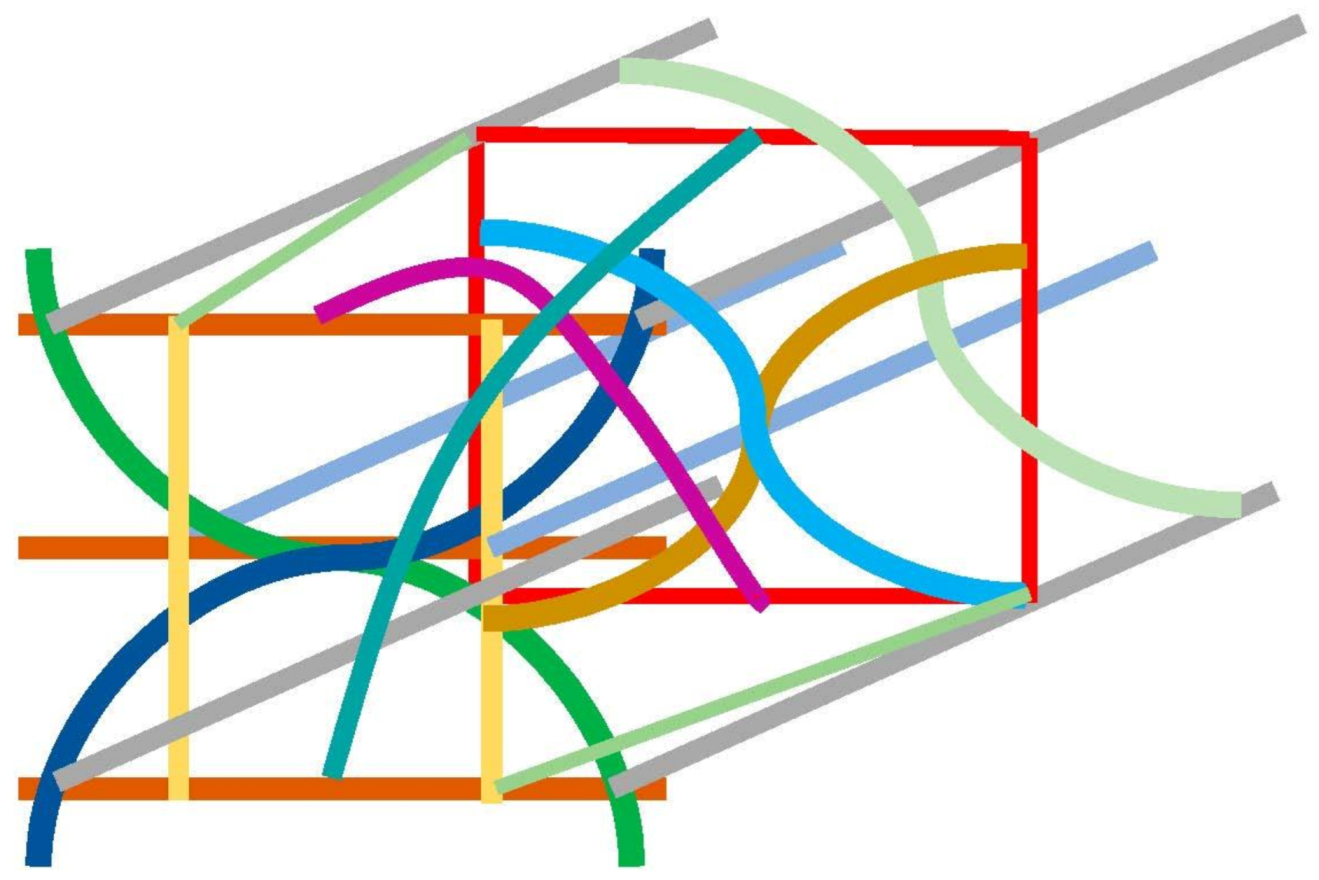

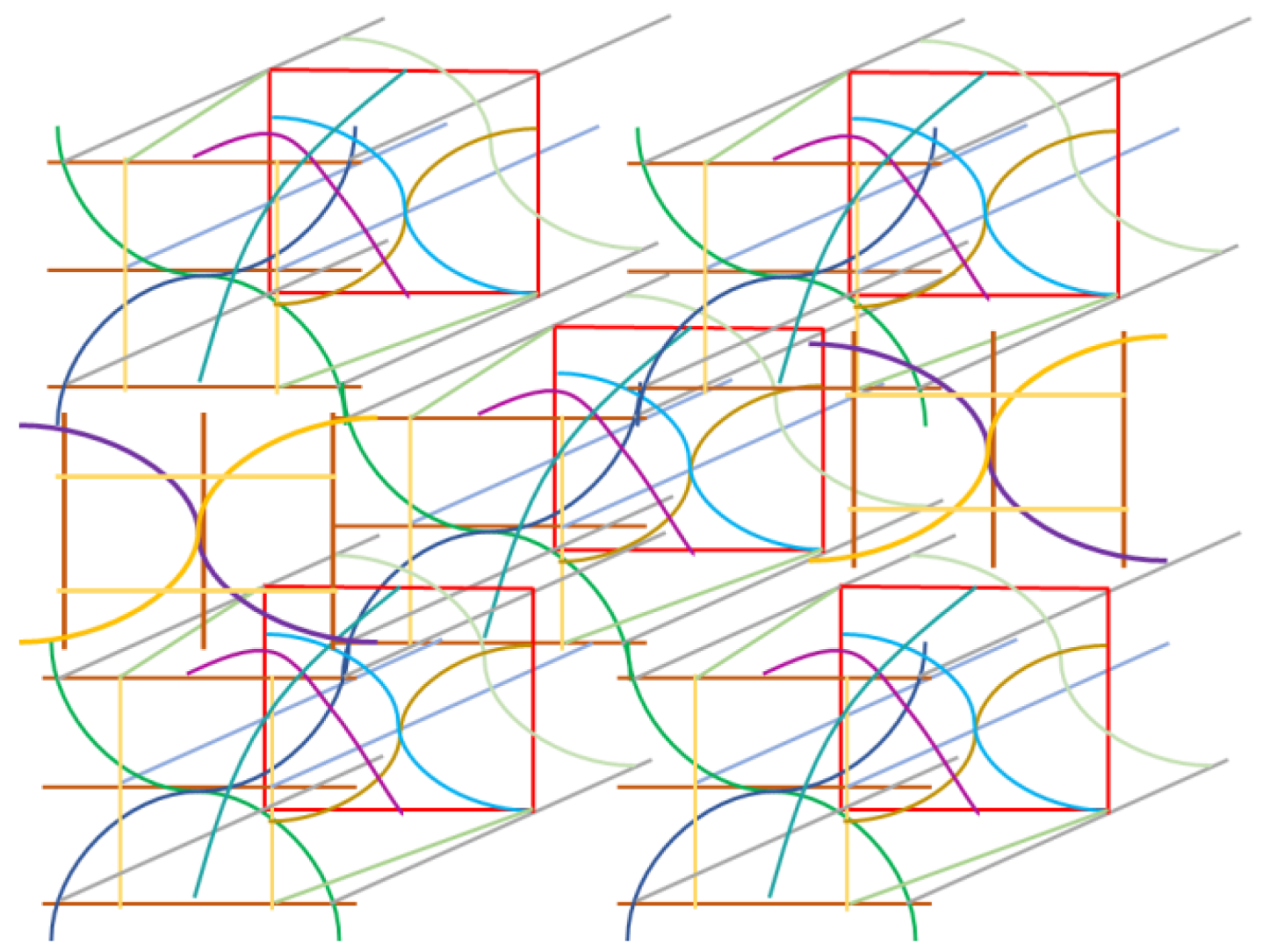

4.2. Ultimate System Comprising CNTs Available in Composites and Engineering Belts

5. Conclusions

- This study proposed three types of braiding patterns based on spider net and honeycomb. The first pattern combines sliding and tight-yet-flexible sewing between the wefts and warps to provide both strength and flexibility. The second pattern combines the wefts and warps into boxes to balance strength and flexibility by utilizing the continuity and discontinuity. The final pattern was generated through the combination of rectangular wefts and hexagonal webs. The wefts were surrounded by hierarchical hexagonal webs, with variations in their positions in the depth direction. This results in the stress distribution and resilience to fracture at low strains.

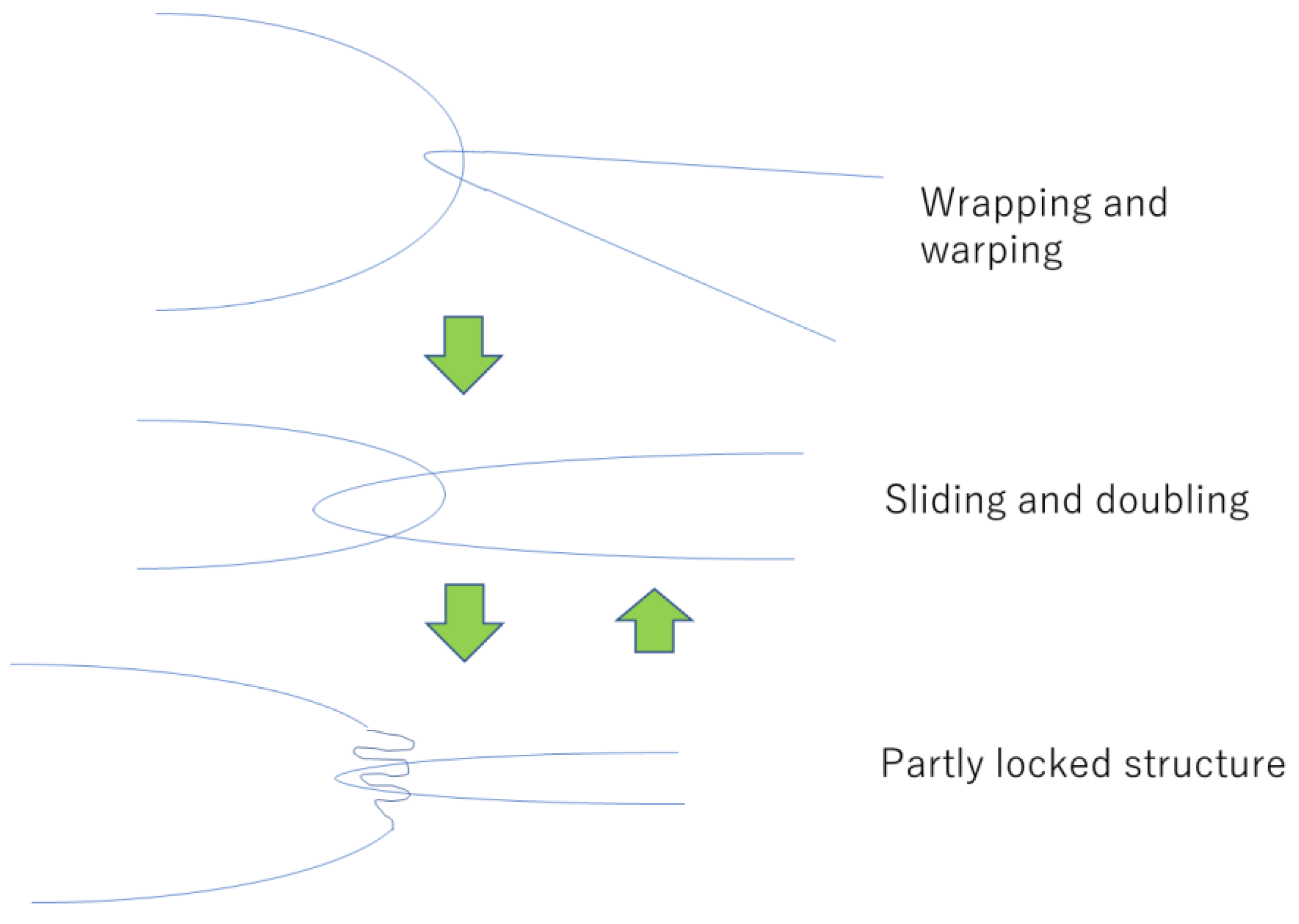

- The basic FEA analysis was performed for the honeycomb pattern, which elucidated that the load borne by the webs and the partly generated slippage contributed to the reduction in overall stresses. The constraint between the webs does not necessarily increase the stress in CNT webs and utilizing their interaction can effectively yield both strength and fracture resilience with the generation of flexibility. Thus, wrapping and warping, sliding and doubling, and partly locked structures have been proposed as a mechanism for generation of strength and flexibility. The recovery of structures from the interaction to the independent state is vital to generate fracture resistance with low strains.

- We propose the finalized structure specialized for CNTs. The combination of curled CNTs and straight CNTs can transfer the load associated with tension and sagging. The hierarchical pattern in which the braiding density is spatially altered is unique and can generate strong and resilient structural components. Compared with conventional braiding patterns, a balance of strength and flexibility can be expected in our proposed braiding pattern. Furthermore, we discussed its similarities and dissimilarities with high-stiffness structural board materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mouritz, A.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Michel, J.; Moulinec, H.; Suquet, P. Effective properties of composite materials with periodic microstructure: A computational approach. Comput. Methods Appl. Mech. Eng. 1999, 172, 109–143. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Naik, N.; Sekher, Y.C.; Meduri, S. Damage in woven-fabric composites subjected to low-velocity impact. Compos. Sci. Technol. 2000, 60, 731–744. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Satish, S.B.; Sultan, M.T.H.; Kini, C.R.; Shenoy, K.R.; Samant, R.; Sarvade, P.P.; Basri, A.A.; Mustapha, F. Influence of fabric orientation and compression factor on the mechanical properties of 3D E-glass reinforced epoxy composites. J. Mater. Res. Technol. 2020, 9, 8517–8527. [Google Scholar] [CrossRef]

- Tang, Z.; Postle, R. Mechanics of three-dimensional braided structures for composite materials—Part I: Fabric structure and fibre volume fraction. Compos. Struct. 2000, 49, 451–459. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, L.; Fu, Y.; Yao, X.; Yang, H. Prediction of mechanical properties on 3D braided composites with void defects. Compos. Part B Eng. 2020, 197, 108164. [Google Scholar] [CrossRef]

- Daniel, I.M.; Luo, J.-J.; Schubel, P.M. Three-dimensional characterization of textile composites. Compos. Part B Eng. 2008, 39, 13–19. [Google Scholar] [CrossRef]

- Bilisik, K. Three-dimensional braiding for composites: A review. Text. Res. J. 2013, 83, 1414–1436. [Google Scholar] [CrossRef]

- Bilisik, K. Multiaxis three-dimensional weaving for composites: A review. Text. Res. J. 2012, 82, 725–743. [Google Scholar] [CrossRef]

- Wang, X.; Chen, L.; Wang, J.; Li, X.; Zhang, Z. A novel multiaxial three-dimensional woven preform: Process and structure. J. Reinf. Plast. Compos. 2018, 37, 247–266. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, Y.; Li, D.; Sun, X.; Li, M.; Chen, L. Experimental characterization of the compressive properties and failure mechanism of novel multiaxial 3D woven composites. Compos. Commun. 2021, 28, 100905. [Google Scholar] [CrossRef]

- Labanieh, A.R.; Liu, Y.; Vasiukov, D.; Soulat, D.; Panier, S. Influence of off-axis in-plane yarns on the mechanical properties of 3D composites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 45–57. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, Y.; Li, D.; Guo, R.; Ma, M.; Chen, L. Effect of bias yarn on tensile fracture mechanism of multiaxial 3D angle-interlock woven composites. Thin Walled Struct. 2021, 159, 107269. [Google Scholar] [CrossRef]

- Saleh, M.N.; Soutis, C. Recent advancements in mechanical characterisation of 3D woven composites. Mech. Adv. Mater. Mod. Process. 2017, 3, 2. [Google Scholar] [CrossRef]

- Umer, R.; Alhussein, H.; Zhou, J.; Cantwell, W. The mechanical properties of 3D woven composites. J. Compos. Mater. 2017, 51, 1703–1716. [Google Scholar] [CrossRef]

- Behera, B.K.; Dash, B.P. Mechanical behavior of 3D woven composites. Mater. Des. 2015, 67, 261–271. [Google Scholar] [CrossRef]

- Cranford, S.W.; Tarakanova, A.; Pugno, N.M.; Buehler, M.J. Nonlinear material behaviour of spider silk yields robust webs. Nature 2012, 482, 72–76. [Google Scholar] [CrossRef]

- Wray, G.R. The Application of Mechanism Theory to a Textile Machinery Innovation. Proc. Inst. Mech. Eng. 1976, 190, 367–378. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. Part B Eng. 2022, 232, 109605. [Google Scholar] [CrossRef]

- Narumi, T.; Uemichi, K.; Honda, H.; Osaki, K. Self-organization at the first stage of honeycomb construction: Analysis of an attachment-excavation model. PLoS ONE 2018, 13, e0205353. [Google Scholar] [CrossRef]

- Yi, T. Mechanical properties of a hierarchical honeycomb with sandwich walls. J. Mech. Eng. Sci. 2016, 230, 2765–2775. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Bayraktar, G.B.; Kianoosh, A.; Bilen, D. Fabrication of woven honeycomb structures for advanced composites. Text. Leather Rev. 2018, 1, 114–119. [Google Scholar] [CrossRef]

- Kamble, Z.; Behera, B.K. Investigation of role of cell geometry on compression behavior of 3-D woven hemp honeycomb composites. J. Text. Apparel Technol. Manag. (JTATM) 2022, 12, 1–13. [Google Scholar]

- Duan, Y.; Keefe, M.; Bogetti, T.; Powers, B. Finite element modeling of transverse impact on a ballistic fabric. Int. J. Mech. Sci. 2006, 48, 33–43. [Google Scholar] [CrossRef]

- Meyer, C.S.; O’Brien, D.J.; Haque, B.Z.G.; Gillespie, J.W., Jr. Mesoscale modeling of ballistic impact experiments on a single layer of plain weave composite. Compos. Part B Eng. 2022, 235, 109753. [Google Scholar] [CrossRef]

- Chocron, S.; Anderson, C.E., Jr.; Samant, K.R.; Figueroa, E.; Nicholls, A.E.; Walker, J.D. Measurement of strain in fabrics under ballistic impact using embedded nichrome wires, part II: Results and analysis. Int. J. Impact Eng. 2010, 37, 69–81. [Google Scholar] [CrossRef]

- Mamivand, M.; Liaghat, G. A model for ballistic impact on multi-layer fabric targets. Int. J. Impact Eng. 2010, 37, 806–812. [Google Scholar] [CrossRef]

- Frontczak-Wasiak, I.; Snycerski, M.; Ciesielska-Wrobel, I. Textile structures modeled on a spider’s net. Fibres Text. East. Eur. 2008, 16, 54–58. [Google Scholar]

- Das, S.; Shanmugam, N.; Kumar, A.; Jose, S. Review: Potential of biomimicry in the field of textile technology. Bioinspired Biomim. Nanobiomaterials 2017, 6, 224–235. [Google Scholar] [CrossRef]

- Guan, X.; Gong, J.; Xu, B. Three-Dimensional Conformal Porous Microstructural Engineering of Textile Substrates with Customized Functions of Brick Materials and Inherent Advantages of Textiles. ACS Appl. Mater. Interfaces 2020, 12, 17967–17978. [Google Scholar] [CrossRef]

- Huang, J.; Boisse, P.; Hamila, N.; Gnaba, I.; Soulat, D.; Wang, P. Experimental and numerical analysis of textile composite draping on a square box. Influence of the weave pattern. Compos. Struct. 2021, 267, 113844. [Google Scholar] [CrossRef]

| Parameters | Value | Mesh Type | Analysis Method |

|---|---|---|---|

| Young’s modulus | 200 GPa (Assuming multiply twisted yarns) | Adaptive mesh (P-method) Approximately 70,000 elements | Contact (Severe constraint) Large deformation (Compensate) |

| Poisson’s ratio | 0.3 |

| Model | Maximum Stress (GPa) | Minimum Stress (Pa) | Average Stress (MPa) |

|---|---|---|---|

| (A) | 392 | 39.7 | 2402 |

| (B) | 255 | 3012 | 1044 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogawa, F.; Liu, F.; Hashida, T. Strong and Flexible Braiding Pattern of Carbon Nanotubes for Composites: Stiff and Robust Structure Active in Composite Materials. Materials 2023, 16, 1725. https://doi.org/10.3390/ma16041725

Ogawa F, Liu F, Hashida T. Strong and Flexible Braiding Pattern of Carbon Nanotubes for Composites: Stiff and Robust Structure Active in Composite Materials. Materials. 2023; 16(4):1725. https://doi.org/10.3390/ma16041725

Chicago/Turabian StyleOgawa, Fumio, Fan Liu, and Toshiyuki Hashida. 2023. "Strong and Flexible Braiding Pattern of Carbon Nanotubes for Composites: Stiff and Robust Structure Active in Composite Materials" Materials 16, no. 4: 1725. https://doi.org/10.3390/ma16041725

APA StyleOgawa, F., Liu, F., & Hashida, T. (2023). Strong and Flexible Braiding Pattern of Carbon Nanotubes for Composites: Stiff and Robust Structure Active in Composite Materials. Materials, 16(4), 1725. https://doi.org/10.3390/ma16041725