Hard Wear-Resistant Ti-Si-C Coatings for Cu-Cr Electrical Contacts

Abstract

1. Introduction

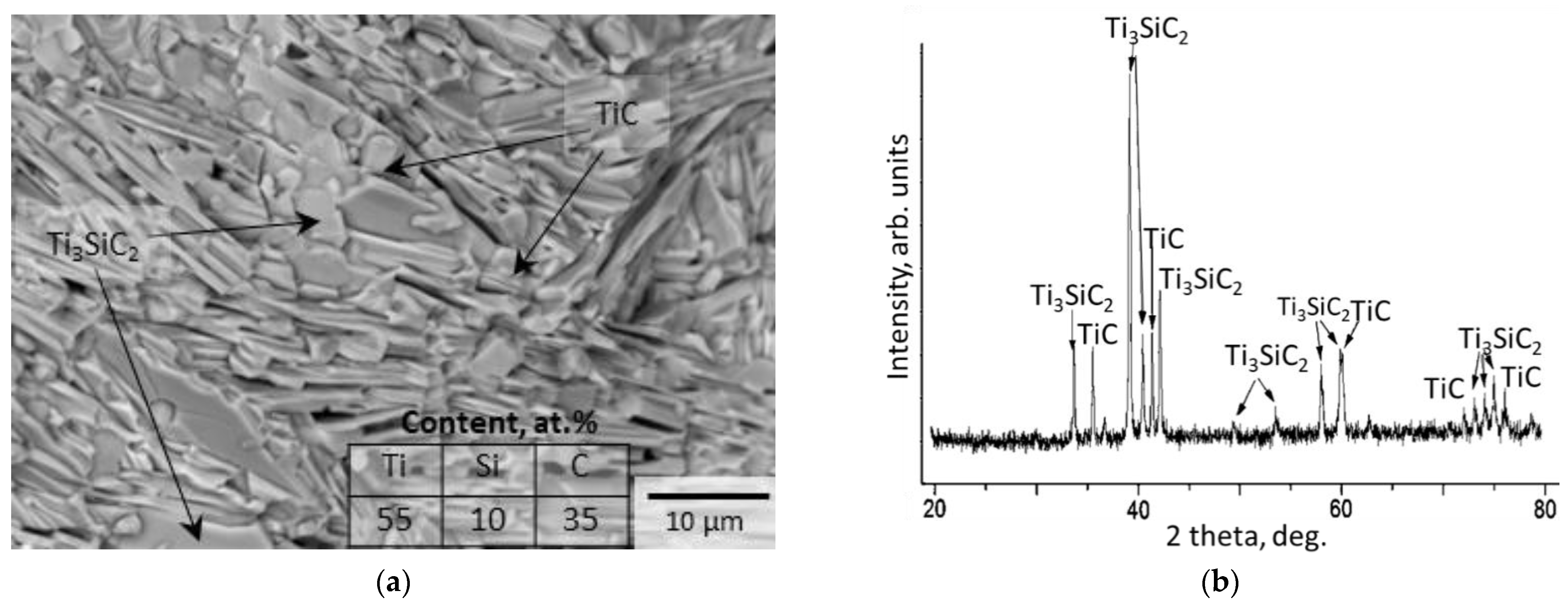

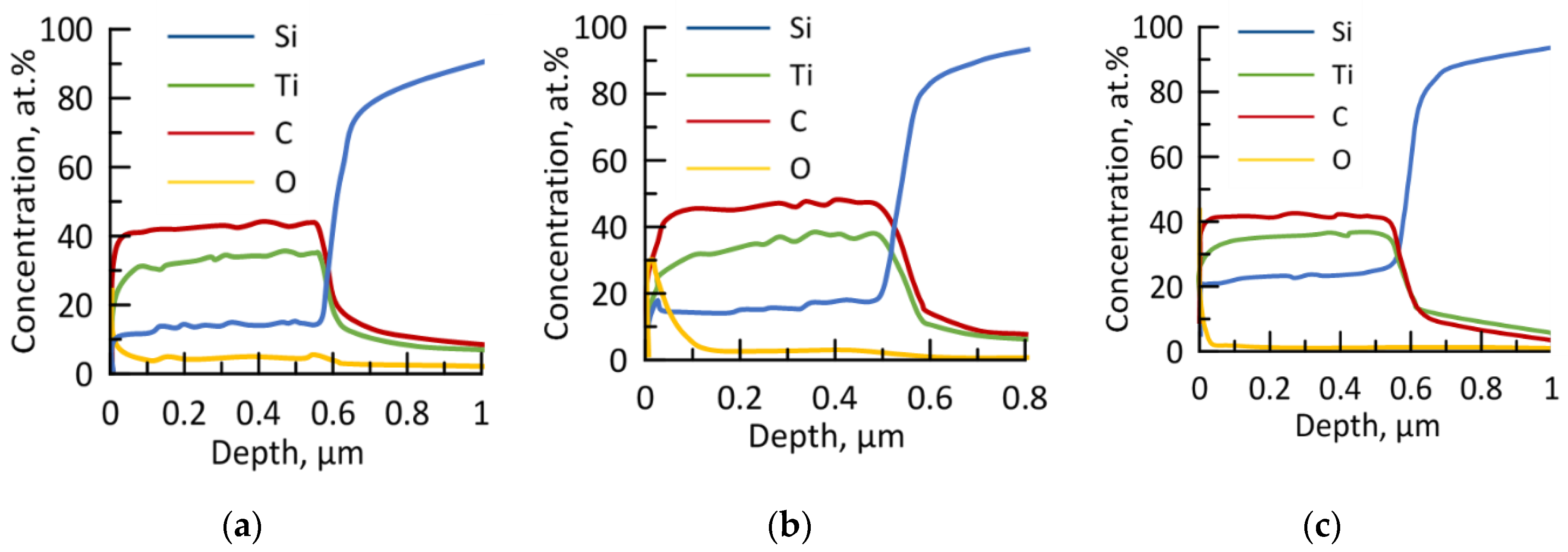

2. Materials and Methods

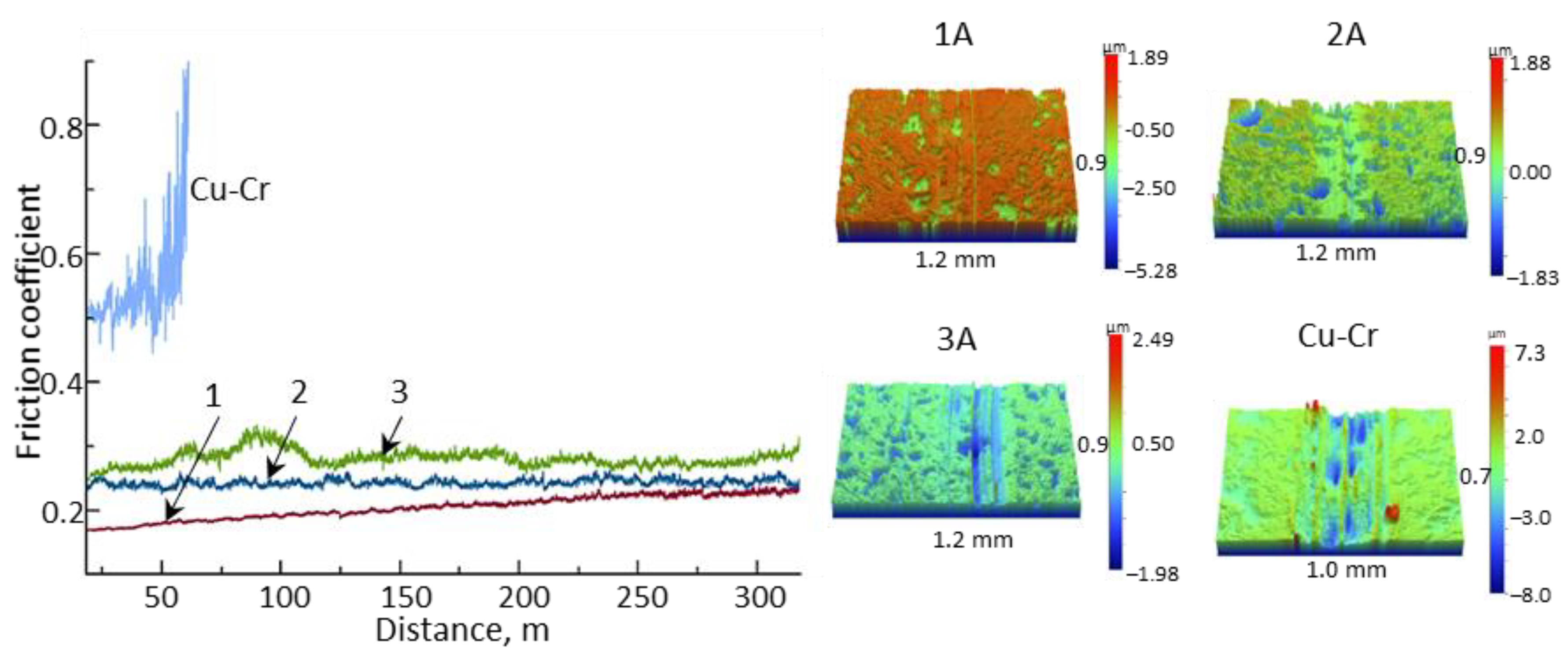

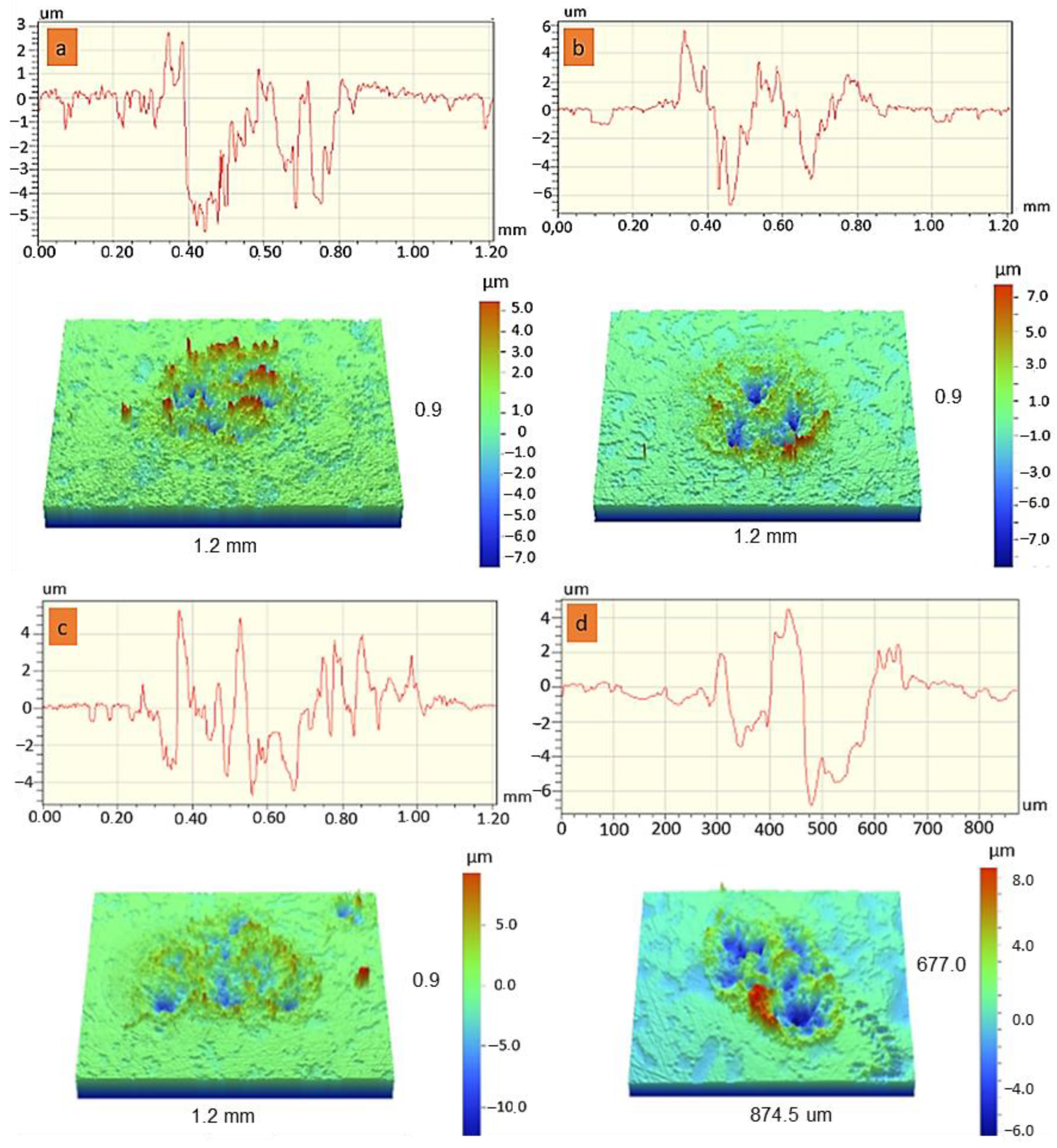

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.; Yang, X.; Kang, Y.; Li, Z.; Li, H. Progress on Current-Carry Friction and Wear: An Overview from Measurements to Mechanism. Coatings 2022, 12, 1345. [Google Scholar] [CrossRef]

- Wang, D.W.; Li, F.Q.; Chen, X.; Xiang, Z.Y.; Zhao, F. Probing the Effect of the Electric Current on the Tribological Performances of the Electrical Contact Surfaces with Graphene Coating. Tribol. Int. 2023, 178, 108121. [Google Scholar] [CrossRef]

- Raman, K.H.T.; Kiran, M.S.R.N.; Ramamurty, U.; Rao, G.M. Structure and Mechanical Properties of TiC Films Deposited Using Combination of Pulsed DC and Normal DC Magnetron Co-Sputtering. Appl. Surf. Sci. 2012, 258, 8629–8635. [Google Scholar] [CrossRef]

- Fogarassy, Z.; Oláh, N.; Cora, I.; Horváth, Z.E.; Csanádi, T.; Sulyok, A.; Balázsi, K. The Structural and Mechanical Characterization of TiC and TiC/Ti Thin Films Grown by DC Magnetron Sputtering. J. Eur. Ceram Soc. 2018, 38, 2886–2892. [Google Scholar] [CrossRef]

- Pei, Y.T.; Galvan, D.; de Hosson, J.T.M. TiC/a-C Nanocomposite Coatings for Low Friction and Wear Resistance. Mater. Sci. Forum 2005, 475–479, 3655–3660. [Google Scholar] [CrossRef]

- Stüber, M.; Leiste, H.; Ulrich, S.; Holleck, H.; Schild, D. Microstructure and Properties of Low Friction TiC-C Nanocomposite Coatings Deposited by Magnetron Sputtering. Surf. Coat. Technol. 2002, 150, 218–226. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Mishra, B.; Pinkas, M.; Sproul, W.D. Syntheses and Characterization of TiC/a:C Composite Coatings Using Pulsed Closed Field Unbalanced Magnetron Sputtering (P-CFUBMS). Thin. Solid. Film. 2008, 517, 1131–1135. [Google Scholar] [CrossRef]

- Alawajji, R.A.; Kannarpady, G.K.; Nima, Z.A.; Kelly, N.; Watanabe, F.; Biris, A.S. Electrical Properties of Multilayer (DLC-TiC) Films Produced by Pulsed Laser Deposition. Appl. Surf. Sci. 2018, 437, 429–440. [Google Scholar] [CrossRef]

- André, B.; Lewin, E.; Jansson, U.; Wiklund, U. Friction and Contact Resistance of Nanocomposite Ti–Ni–C Coatings. Wear 2011, 270, 555–566. [Google Scholar] [CrossRef]

- Grandin, M.; Nedfors, N.; Sundberg, J.; Jansson, U.; Wiklund, U. Ti–Ni–C Nanocomposite Coatings Evaluated in a Sliding Electrical Contact Application. Surf. Coat. Technol. 2015, 276, 210–218. [Google Scholar] [CrossRef]

- Lindquist, M.; Wilhelmsson, O.; Jansson, U.; Wiklund, U. Tribofilm Formation from TiC and Nanocomposite TiAlC Coatings, Studied with Focused Ion Beam and Transmission Electron Microscopy. Wear 2009, 266, 988–994. [Google Scholar] [CrossRef]

- Råsander, M.; Lewin, E.; Wilhelmsson, O.; Sanyal, B.; Klintenberg, M.; Eriksson, O.; Jansson, U. Carbon Release by Selective Alloying of Transition Metal Carbides. J. Phys. Condens. Matter 2011, 23, 355401. [Google Scholar] [CrossRef] [PubMed]

- Wilhelmsson, O.; Råsander, M.; Carlsson, M.; Lewin, E.; Sanyal, B.; Wiklund, U.; Eriksson, O.; Jansson, U. Design of Nanocomposite Low-Friction Coatings. Adv. Funct. Mater. 2007, 17, 1611–1616. [Google Scholar] [CrossRef]

- Lauridsen, J.; Eklund, P.; Joelsson, T.; Ljungcrantz, H.; Öberg, Å.; Lewin, E.; Jansson, U.; Beckers, M.; Högberg, H.; Hultman, L. High-Rate Deposition of Amorphous and Nanocomposite Ti–Si–C Multifunctional Coatings. Surf. Coat. Technol. 2010, 205, 299–305. [Google Scholar] [CrossRef]

- Eklund, P.; Emmerlich, J.; Högberg, H.; Wilhelmsson, O.; Isberg, P.; Birch, J.; Persson, P.O.A.; Jansson, U.; Hultman, L. Structural, Electrical, and Mechanical Properties of Nc-TiC∕a-SiC Nanocomposite Thin Films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2005, 23, 2486. [Google Scholar] [CrossRef]

- GULBISKI, W. Ti-Si-C Sputter Deposited Thin Film Coatings. Surf. Coat. Technol. 2004, 180–181, 341–346. [Google Scholar] [CrossRef]

- Krzanowski, J.E.; Koutzaki, S.H. Mechanical Properties of Sputter-Deposited Titanium-Silicon-Carbon Films. J. Am. Ceram. Soc. 2001, 84, 672–674. [Google Scholar] [CrossRef]

- Bai, P.; Wang, S.; Zhao, B.; Wang, X.; Ma, J.; Zhou, Y. Electrically Conductive and Corrosion Resistant MAX Phases with Superior Electromagnetic Wave Shielding Performance. J. Eur. Ceram Soc. 2022, 42, 7414–7420. [Google Scholar] [CrossRef]

- Sauvage, X.; Jessner, P.; Vurpillot, F.; Pippan, R. Nanostructure and Properties of a Cu–Cr Composite Processed by Severe Plastic Deformation. Scr. Mater. 2008, 58, 1125–1128. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Z.; Wang, Y.; Ding, B.; Guo, Y. Preparation of CuCr25 Contact Materials by Vacuum Induction Melting. J. Mater Process. Technol. 2006, 178, 283–286. [Google Scholar] [CrossRef]

- Kojima, H.; Hayakawa, N.; Nishimura, R.; Okubo, H.; Sato, H.; Saito, H.; Noda, Y. Conditioning Mechanism of Cu-Cr Electrode Based on Electrode Surface State under Impulse Voltage Application in Vacuum. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 2108–2114. [Google Scholar] [CrossRef]

- Shkodich, N.F.; Rogachev, A.S.; Vadchenko, S.G.; Moskovskikh, D.O.; Sachkova, N.V.; Rouvimov, S.; Mukasyan, A.S. Bulk Cu–Cr Nanocomposites by High-Energy Ball Milling and Spark Plasma Sintering. J. Alloys Compd. 2014, 617, 39–46. [Google Scholar] [CrossRef]

- Rogachev, A.S.; Kuskov, K.V.; Shkodich, N.F.; Moskovskikh, D.O.; Orlov, A.O.; Usenko, A.A.; Karpov, A.V.; Kovalev, I.D.; Mukasyan, A.S. Influence of High-Energy Ball Milling on Electrical Resistance of Cu and Cu/Cr Nanocomposite Materials Produced by Spark Plasma Sintering. J. Alloys Compd. 2016, 688, 468–474. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chen, S.-H.; Huang, K.-T.; Liang, C. Improvement in Sintering Characteristics and Electrical Properties of Cr60Cu40 Alloy Targets by Hot Isostatic Pressing Treatment. Powder Metall. 2013, 56, 77–82. [Google Scholar] [CrossRef]

- Abedi, M.; Sovizi, S.; Azarniya, A.; Giuntini, D.; Seraji, M.E.; Hosseini, H.R.M.; Amutha, C.; Ramakrishna, S.; Mukasyan, A. An Analytical Review on Spark Plasma Sintering of Metals and Alloys: From Processing Window, Phase Transformation, and Property Perspective. Crit. Rev. Solid State Mater. Sci. 2022, 1–46. [Google Scholar] [CrossRef]

- Abedi, M.; Asadi, A.; Vorotilo, S.; Mukasyan, A.S. A Critical Review on Spark Plasma Sintering of Copper and Its Alloys. J. Mater. Sci. 2021, 56, 19739–19766. [Google Scholar] [CrossRef]

- Kuskov, K.V.; Abedi, M.; Moskovskikh, D.O.; Serhiienko, I.; Mukasyan, A.S. Comparison of Conventional and Flash Spark Plasma Sintering of Cu–Cr Pseudo-Alloys: Kinetics, Structure, Properties. Metals 2021, 11, 141. [Google Scholar] [CrossRef]

- Kuskov, K.V.; Sedegov, A.S.; Novitskii, A.P.; Nepapushev, A.A.; Moskovskikh, D.O.; Shkodich, N.F.; Rogachev, A.S.; Mukasyan, A.S. Influence of Chromium in Nanocrystalline Copper–Chromium Pseudoalloy on Its Structure and Properties. Nanotechnol. Russ. 2017, 12, 40–48. [Google Scholar] [CrossRef]

- Mukasyan, A.S.; Shuck, C.E.; Pauls, J.M.; Manukyan, K.V.; Moskovskikh, D.O.; Rogachev, A.S. The Solid Flame Phenomenon: A Novel Perspective. Adv. Eng. Mater. 2018, 20, 1701065. [Google Scholar] [CrossRef]

- Mukasyan, A.S.; Moskovskikh, D.O.; Nepapushev, A.A.; Pauls, J.M.; Roslyakov, S.I. Ceramics from Self-Sustained Reactions: Recent Advances. J. Eur. Ceram. Soc. 2019, 40, 2512–2526. [Google Scholar] [CrossRef]

- Moskovskikh, D.O.; Mukasyan, A.S.; Rogachev, A.S. Self-Propagating High-Temperature Synthesis of Silicon Carbide Nanopowders. Dokl. Phys. Chem. 2013, 449, 41–43. [Google Scholar] [CrossRef]

- Vidyuk, T.M.; Korchagin, M.A.; Dudina, D.V.; Bokhonov, B.B. Synthesis of Ceramic and Composite Materials Using a Combination of Self-Propagating High-Temperature Synthesis and Spark Plasma Sintering (Review). Combust Explos Shock. Waves 2021, 57, 385–397. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Sviridova, T.A.; Sidorenko, D.A.; Andreev, N.V.; Klechkovskaya, V.V.; Polčak, J.; Levashov, E.A. Effects of Doping with Zr and Hf on the Structure and Properties of Mo-Si-B Coatings Obtained by Magnetron Sputtering of Composite Targets. Surf. Coat. Technol. 2022, 442, 128141. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, F.V. Possibilities of Glow Discharge Optical Emission Spectroscopy in the Investigation of Coatings. Russ. J. Non-Ferr. Met. 2014, 55, 494–504. [Google Scholar] [CrossRef]

- Yeh, C.L.; Shen, Y.G. Effects of TiC Addition on Formation of Ti3SiC2 by Self-Propagating High-Temperature Synthesis. J. Alloys Compd. 2008, 458, 286–291. [Google Scholar] [CrossRef]

- Yeh, C.L.; Shen, Y.G. Effects of SiC Addition on Formation of Ti3SiC2 by Self-Propagating High-Temperature Synthesis. J. Alloys Compd. 2008, 461, 654–660. [Google Scholar] [CrossRef]

- Mareš, P.; Dubau, M.; Polášek, J.; Mates, T.; Kozák, T.; Vyskočil, J. High Deposition Rate Films Prepared by Reactive HiPIMS. Vacuum 2021, 191, 110329. [Google Scholar] [CrossRef]

- Naveed, M.; Obrosov, A.; Zak, A.; Dudzinski, W.; Volinsky, A.A.; Weiß, S. Sputtering Power Effects on Growth and Mechanical Properties of Cr2AlC MAX Phase Coatings. Metals 2016, 6, 265. [Google Scholar] [CrossRef]

- Musil, J.; Baroch, P.; Vlček, J.; Nam, K.H.; Han, J.G. Reactive Magnetron Sputtering of Thin Films: Present Status and Trends. Thin Solid Film. 2005, 475, 208–218. [Google Scholar] [CrossRef]

- Martynenko, Y.V.; Rogov, A.V.; Shul’ga, V.I. Angular Distribution of Atoms during the Magnetron Sputtering of Polycrystalline Targets. Tech. Phys. 2012, 57, 439–444. [Google Scholar] [CrossRef]

- Saldaña-Ramírez, A.; Cruz, M.R.A.; Juárez-Ramírez, I.; Torres-Martínez, L.M. Influence of the Power Density and Working Pressure in the Magnetron Co-Sputtering Deposition of ZnO–SnO2 Thin Films and Their Effect in Photocatalytic Hydrogen Production. Opt. Mater. 2020, 110, 110501. [Google Scholar] [CrossRef]

- Meng, X.; Du, Y.; Gao, X. Face–Centered Cubic p–Type NiO Films Room–Temperature Prepared via Direct-Current Reactive Magnetron Sputtering–Influence of Sputtering Power on Microstructure, Optical and Electrical Behaviors. Phys. B Condens. Matter 2020, 579, 411987. [Google Scholar] [CrossRef]

- Pansila, P.; Witit-Anun, N.; Chaiyakun, S. Influence of Sputtering Power on Structure and Photocatalyst Properties of DC Magnetron Sputtered TiO2 Thin Film. Procedia Eng. 2012, 32, 862–867. [Google Scholar] [CrossRef]

- Arun Kumar Thilipan, G.; Rao, A. Influence of Power on the Physical and Electrical Properties of Magnetron Sputtered Gadolinium Oxide Thin Films for MOS Capacitors. Mater. Sci. Semicond Process. 2021, 121, 105408. [Google Scholar] [CrossRef]

- Srinivas, K.; Manivel Raja, M.; Sridhara Rao, D.V.; Kamat, S.V. Effect of Sputtering Pressure and Power on Composition, Surface Roughness, Microstructure and Magnetic Properties of as-Deposited Co2FeSi Thin Films. Thin Solid Film. 2014, 558, 349–355. [Google Scholar] [CrossRef]

- Singh, A.; Bakshi, S.R.; Virzi, D.A.; Keshri, A.K.; Agarwal, A.; Harimkar, S.P. In-Situ Synthesis of TiC/SiC/Ti3SiC2 Composite Coatings by Spark Plasma Sintering. Surf. Coat. Technol. 2011, 205, 3840–3846. [Google Scholar] [CrossRef]

- Lopes, C.; Parreira, N.M.G.; Carvalho, S.; Cavaleiro, A.; Rivière, J.P.; le Bourhis, E.; Vaz, F. Magnetron Sputtered Ti–Si–C Thin Films Prepared at Low Temperatures. Surf. Coat. Technol. 2007, 201, 7180–7186. [Google Scholar] [CrossRef]

- Chen, Z.S.; Li, H.J.; Fu, Q.G.; Yang, D.; Shen, Q.L. Annealing Effect on Microstructure and Mechanical Properties of Magnetron Sputtering Ti–Si–C Thin Film. Mater. Sci. Technol. 2013, 29, 975–979. [Google Scholar] [CrossRef]

- Lofaj, F.; Németh, D. The Effects of Tip Sharpness and Coating Thickness on Nanoindentation Measurements in Hard Coatings on Softer Substrates by FEM. Thin Solid Film. 2017, 644, 173–181. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Michailidis, N.; Skordaris, G. Hardness Determination by Means of a FEM-Supported Simulation of Nanoindentation and Applications in Thin Hard Coatings. Surf. Coat. Technol. 2005, 200, 867–871. [Google Scholar] [CrossRef]

- Eriksson, A.O.; Zhu, J.Q.; Ghafoor, N.; Johansson, M.P.; Sjölen, J.; Jensen, J.; Odén, M.; Hultman, L.; Rosén, J. Layer Formation by Resputtering in Ti–Si–C Hard Coatings during Large Scale Cathodic Arc Deposition. Surf. Coat. Technol. 2011, 205, 3923–3930. [Google Scholar] [CrossRef]

- Öberg, Å.; Kassman, Å.; André, B.; Wiklund, U.; Lindquist, M.; Lewin, E.; Jansson, U.; Högberg, H.; Joelsson, T.; Ljungcrantz, H. Conductive Nanocomposite Ceramics as Tribological and Electrical Contact Materials. Eur. Phys. J. Appl. Phys. 2010, 49, 22902. [Google Scholar] [CrossRef]

- Eklund, P.; Joelsson, T.; Ljungcrantz, H.; Wilhelmsson, O.; Czigány, Z.; Högberg, H.; Hultman, L. Microstructure and Electrical Properties of Ti–Si–C–Ag Nanocomposite Thin Films. Surf. Coat. Technol. 2007, 201, 6465–6469. [Google Scholar] [CrossRef]

- Lewin, E.; André, B.; Urbonaite, S.; Wiklund, U.; Jansson, U. Synthesis, Structure and Properties of Ni-Alloyed TiCx-Based Thin Films. J. Mater. Chem. 2010, 20, 5950. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhu, Y.; Dong, M.; Xu, L.; Cui, T.; Wang, C.; Guo, W.; Li, J.; Zhu, L. Effect of Target Power on Microstructure, Tribological Properties of the Graphite-like Carbon Based Nanocomposite Coating. Diam. Relat. Mater 2021, 117, 108489. [Google Scholar] [CrossRef]

- Gulbiński, W.; Suszko, T.; Gilewicz, A.; Warcholiński, B.; Kukliński, Z. Structure and High-Temperature Tribological Behavior of Ti–Si–C Nanocomposite Thin Films. Surf. Coat. Technol. 2006, 200, 4179–4184. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Kuptsov, K.A.; Kiryukhantsev-Korneev, P.V.; Sheveiko, A.N.; Fernandez, A.; Petrzhik, M.I. Comparative Investigation of Al- and Cr-Doped TiSiCN Coatings. Surf. Coat. Technol. 2011, 205, 4640–4648. [Google Scholar] [CrossRef]

- Jiao, Q.; Guo, F.; Li, C.; Zheng, G.; He, J.; Zhao, H.; Qin, Y.; Yin, F. Effects of Mo Addition on Tribological Performance of Plasma-Sprayed Ti–Si–C Coatings. Ceram Int. 2020, 46, 12948–12954. [Google Scholar] [CrossRef]

| № | Current, A | Power, W | Duration, min | Chemical Composition (GDOES), at.% | Ra, nm | H, GPa | E, GPa | Ω, µOhm·cm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Si | C | O | ||||||||

| 1 | 1 | 450 | 30 | 35.2 | 16.5 | 43.4 | 4.9 | 304 | 23 ± 2 | 245 ± 27 | 302 |

| 2 | 2 | 800 | 20 | 35.8 | 16.3 | 45.2 | 2.7 | 355 | 25 ± 4 | 268 ± 21 | 297 |

| 3 | 3 | 1230 | 10 | 37.1 | 20.6 | 41.5 | 0.8 | 360 | 25 ± 2 | 247 ± 14 | 291 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiryukhantsev-Korneev, P.; Sytchenko, A.; Moskovskikh, D.; Kuskov, K.; Volkova, L.; Poliakov, M.; Pogozhev, Y.; Yudin, S.; Yakushko, E.; Nepapushev, A. Hard Wear-Resistant Ti-Si-C Coatings for Cu-Cr Electrical Contacts. Materials 2023, 16, 936. https://doi.org/10.3390/ma16030936

Kiryukhantsev-Korneev P, Sytchenko A, Moskovskikh D, Kuskov K, Volkova L, Poliakov M, Pogozhev Y, Yudin S, Yakushko E, Nepapushev A. Hard Wear-Resistant Ti-Si-C Coatings for Cu-Cr Electrical Contacts. Materials. 2023; 16(3):936. https://doi.org/10.3390/ma16030936

Chicago/Turabian StyleKiryukhantsev-Korneev, Ph., A. Sytchenko, D. Moskovskikh, K. Kuskov, L. Volkova, M. Poliakov, Y. Pogozhev, S. Yudin, E. Yakushko, and A. Nepapushev. 2023. "Hard Wear-Resistant Ti-Si-C Coatings for Cu-Cr Electrical Contacts" Materials 16, no. 3: 936. https://doi.org/10.3390/ma16030936

APA StyleKiryukhantsev-Korneev, P., Sytchenko, A., Moskovskikh, D., Kuskov, K., Volkova, L., Poliakov, M., Pogozhev, Y., Yudin, S., Yakushko, E., & Nepapushev, A. (2023). Hard Wear-Resistant Ti-Si-C Coatings for Cu-Cr Electrical Contacts. Materials, 16(3), 936. https://doi.org/10.3390/ma16030936