Preliminary Studies into Cutting of a Novel Two Component 3D-Printed Stainless Steel–Polymer Composite Material by Abrasive Water Jet

Abstract

:1. Introduction

2. Materials and Methods

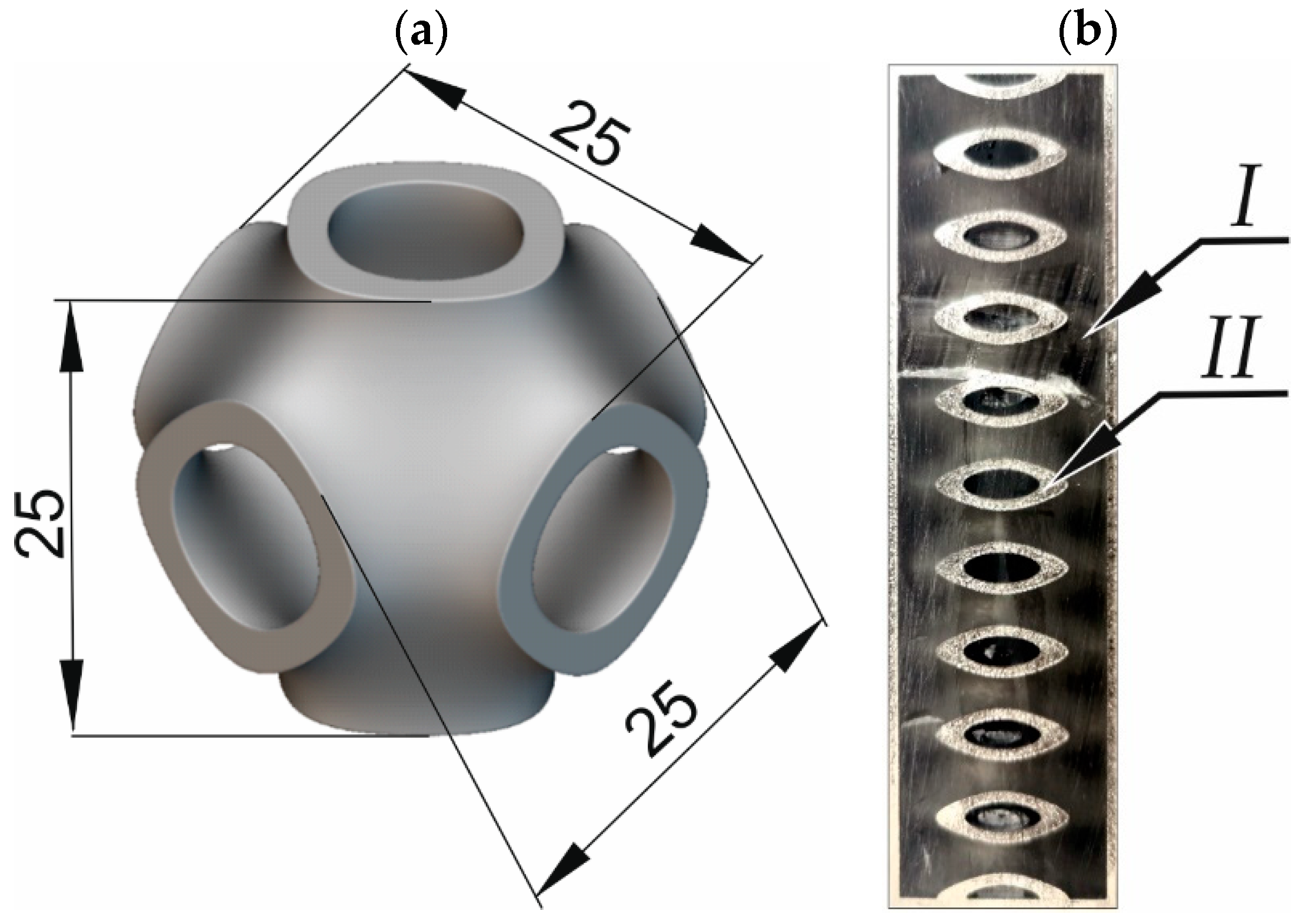

2.1. Cut Material

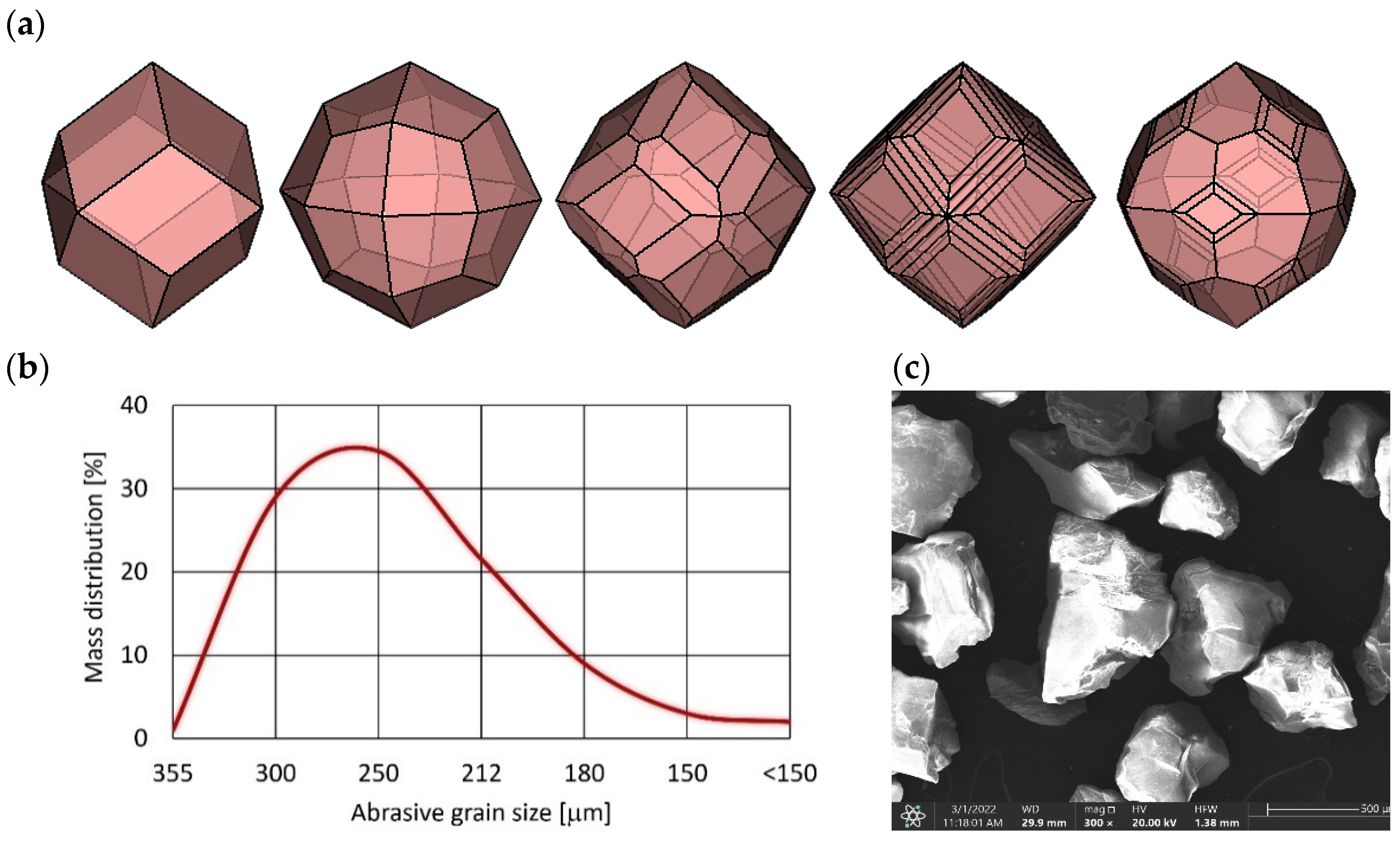

2.2. Abrasive Material

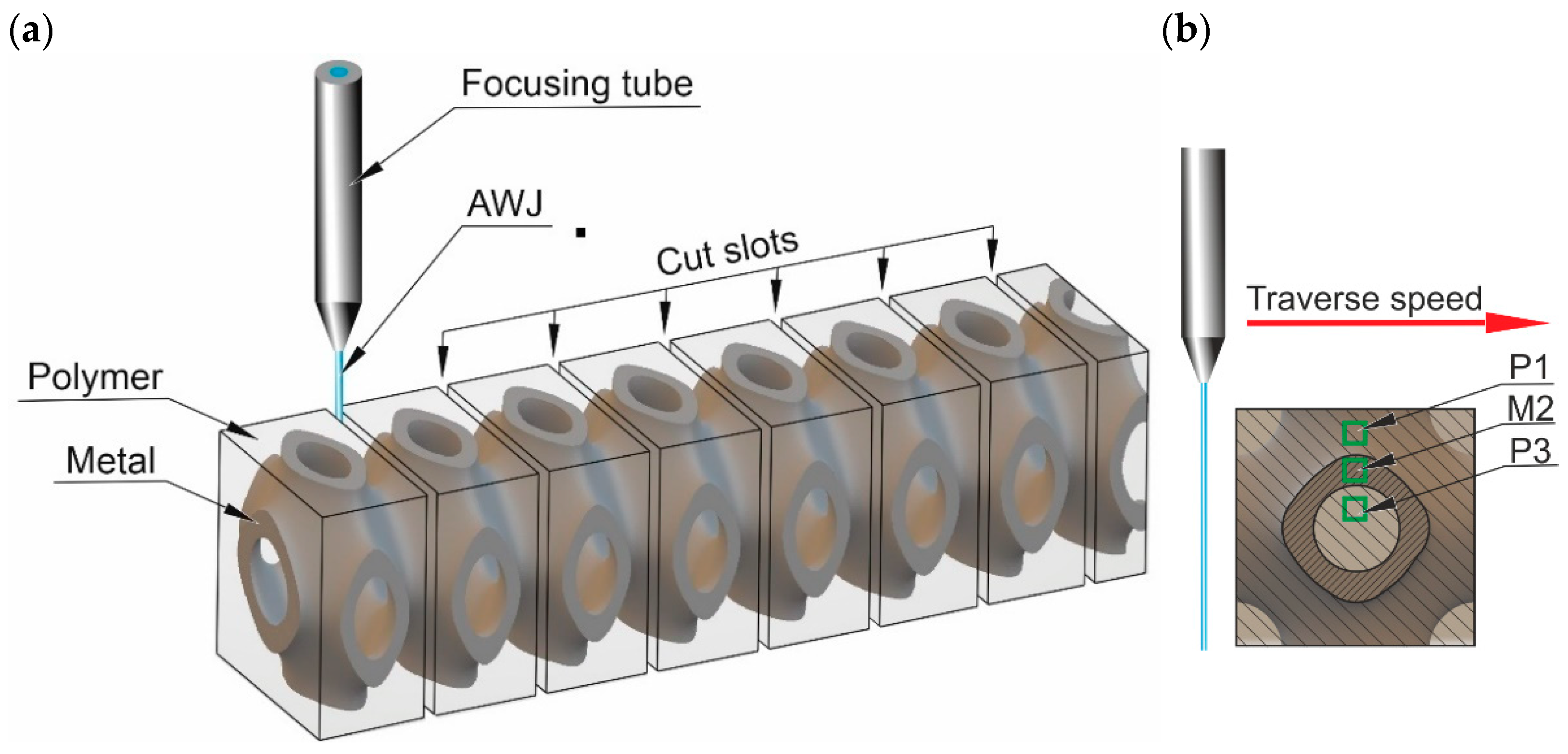

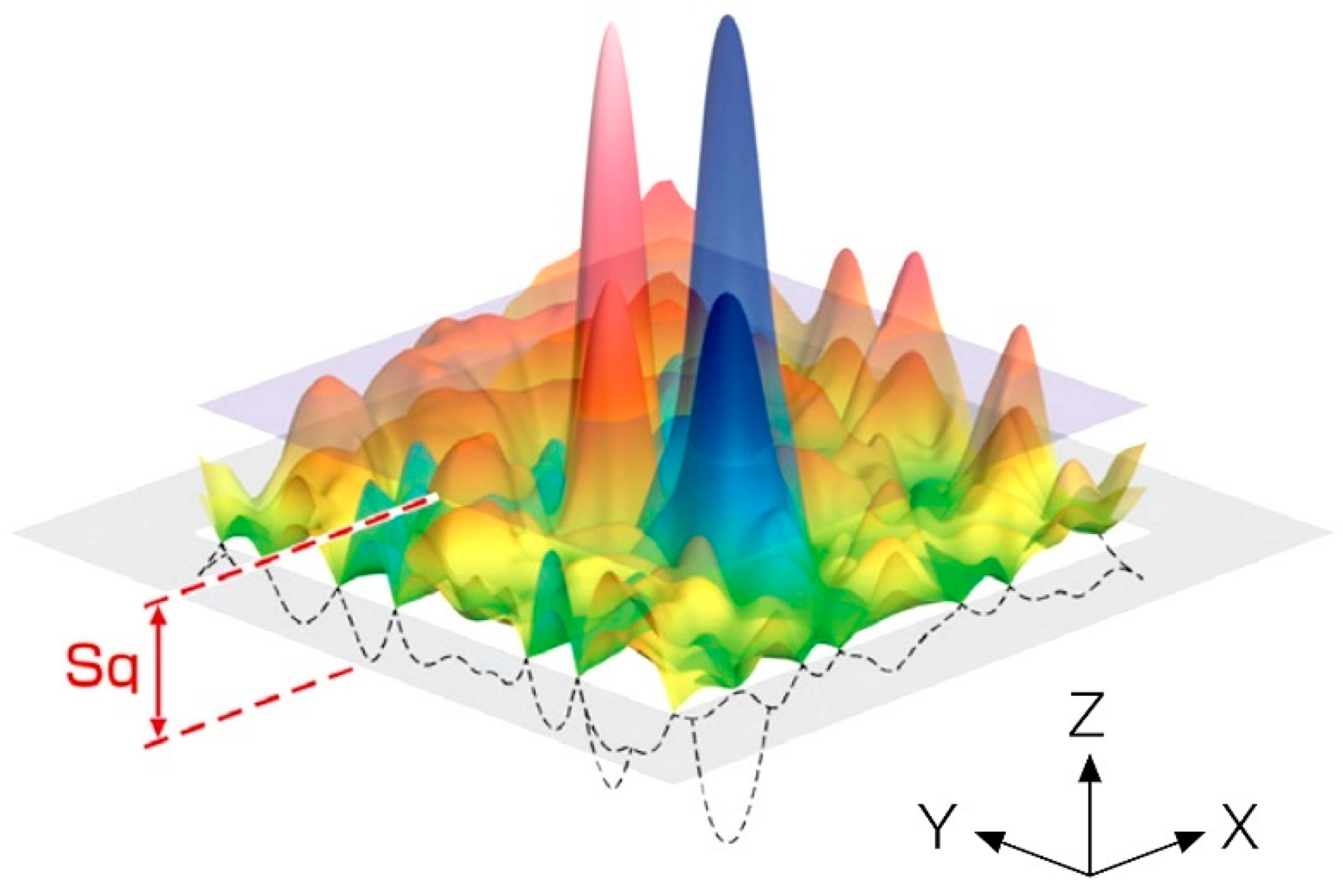

2.3. Research Method

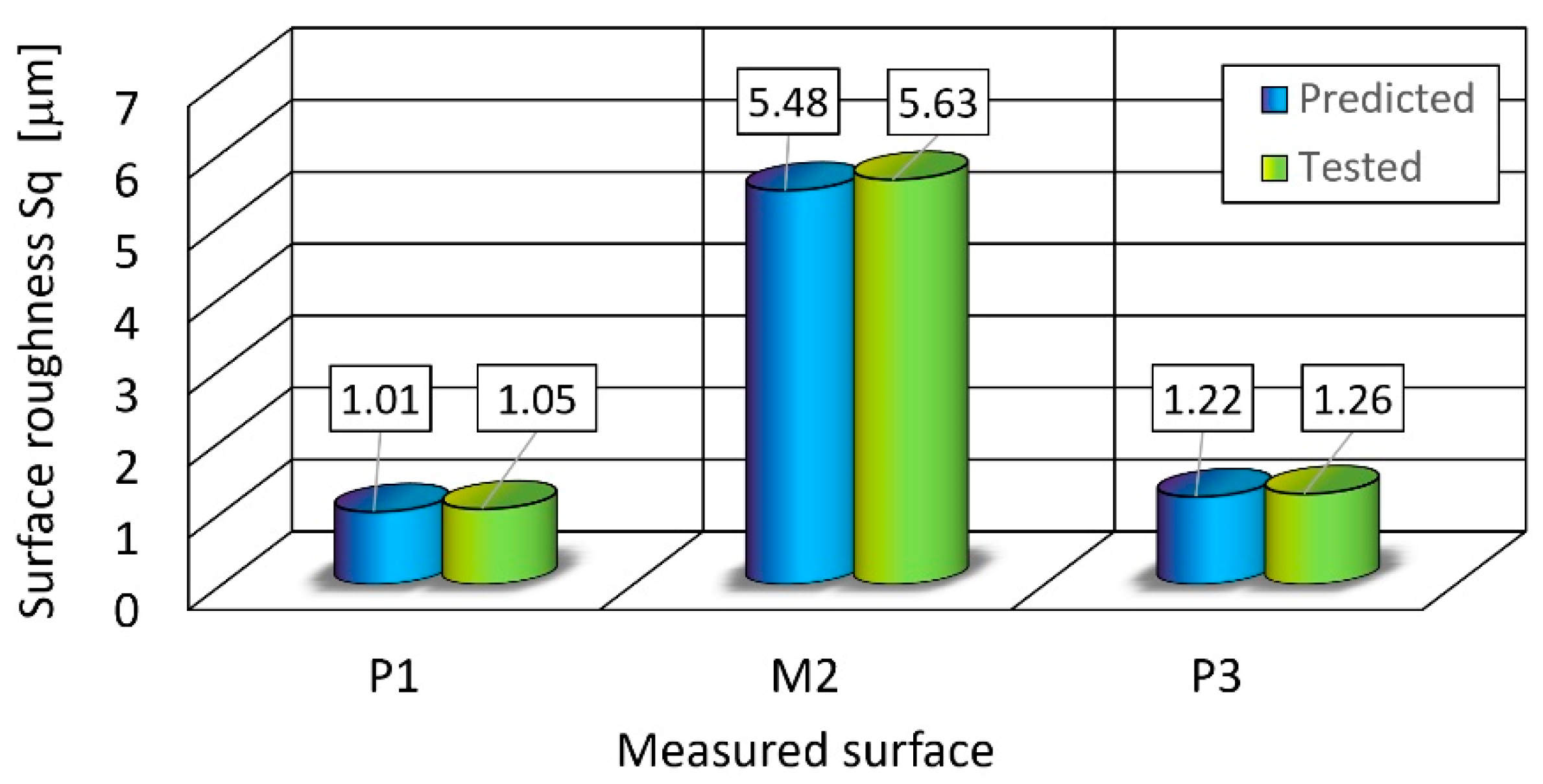

- P1—the polymer area located in the middle of the distance from the top sample surface to the metal part,

- M2—the area in the center of the cut metal part,

- P3—the polymer area located in the middle of the sample.

- Traverse speed: 100–300 mm/min,

- The abrasive expenditure: 250–450 g/min,

- Pressure: 360–400 MPa.

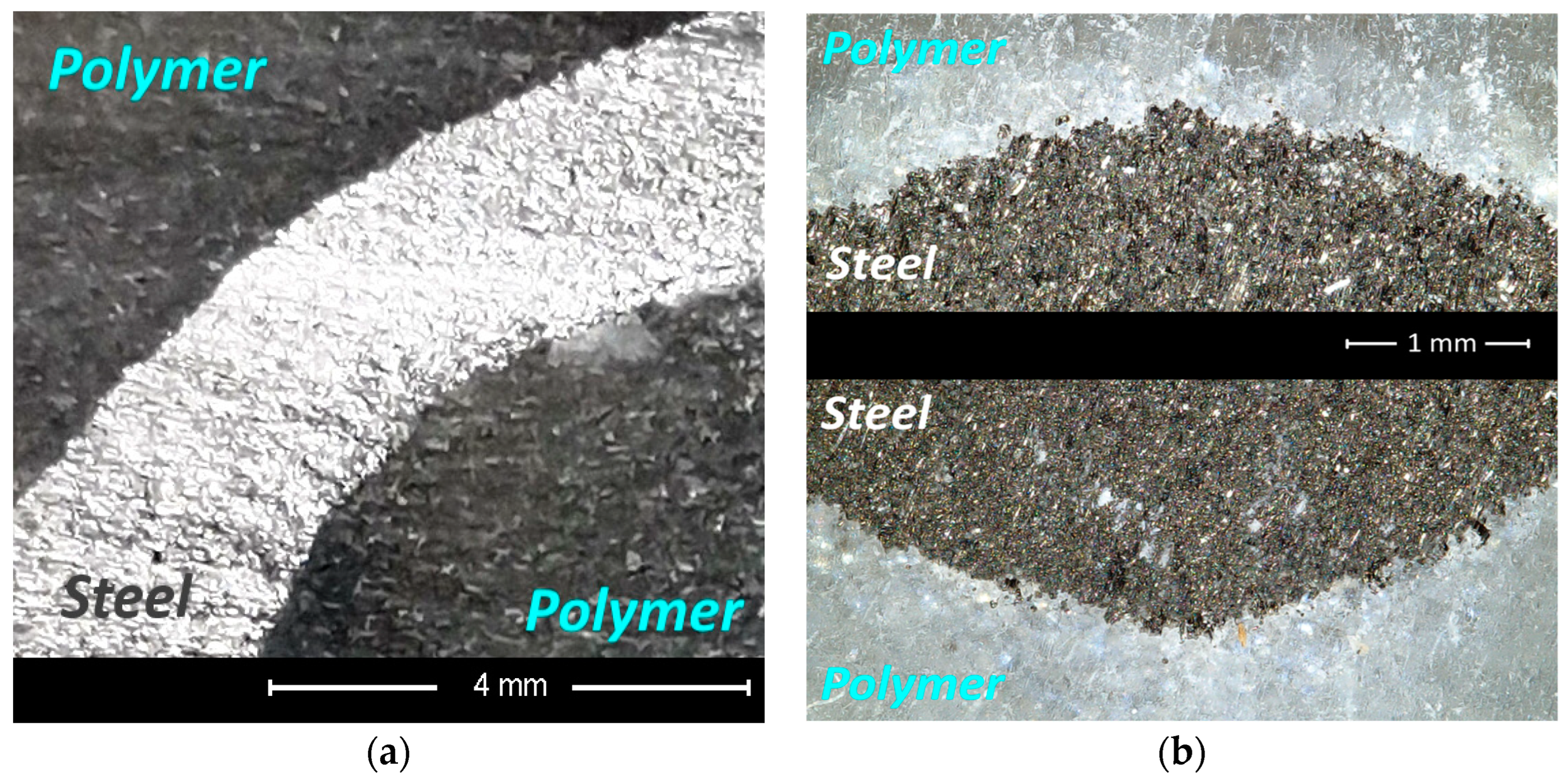

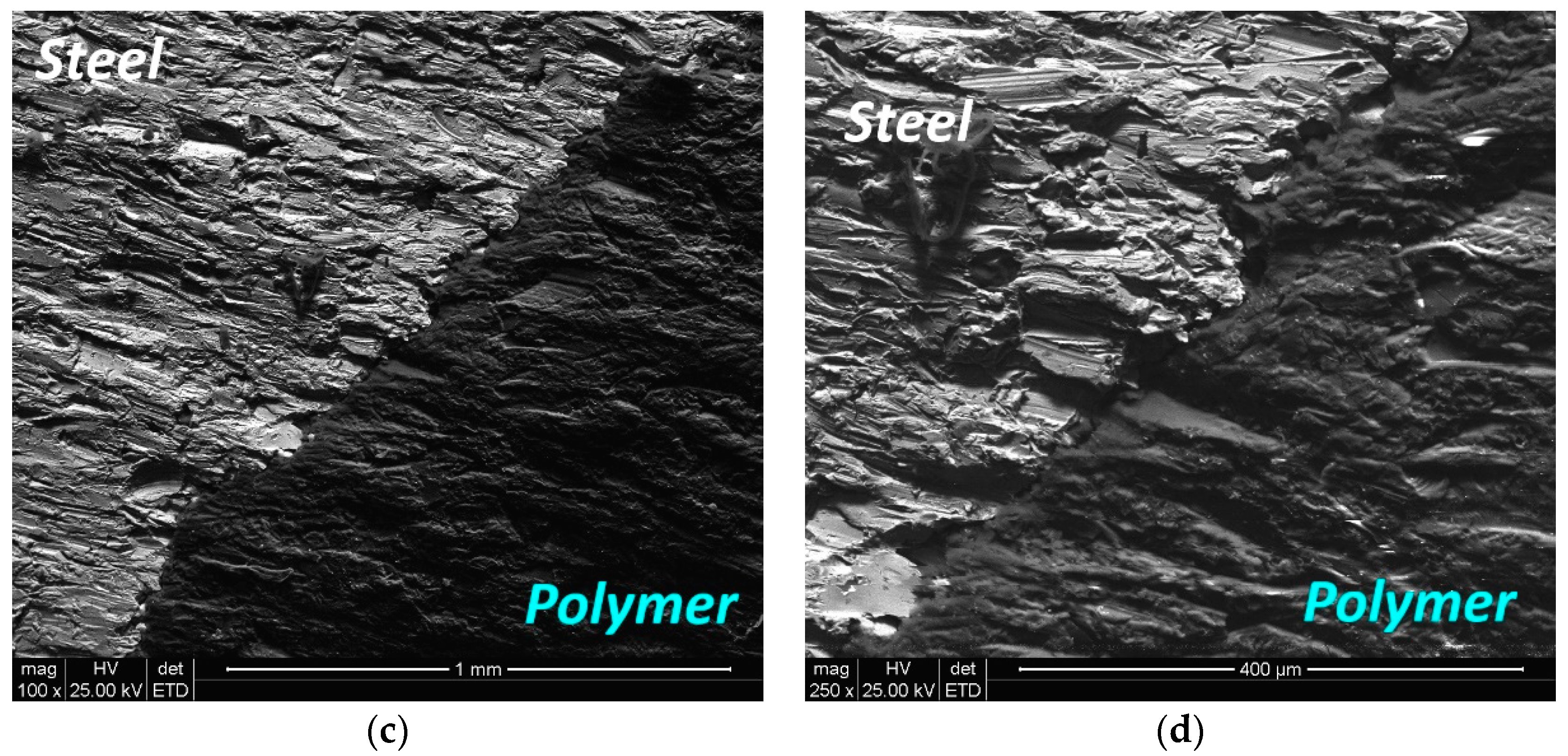

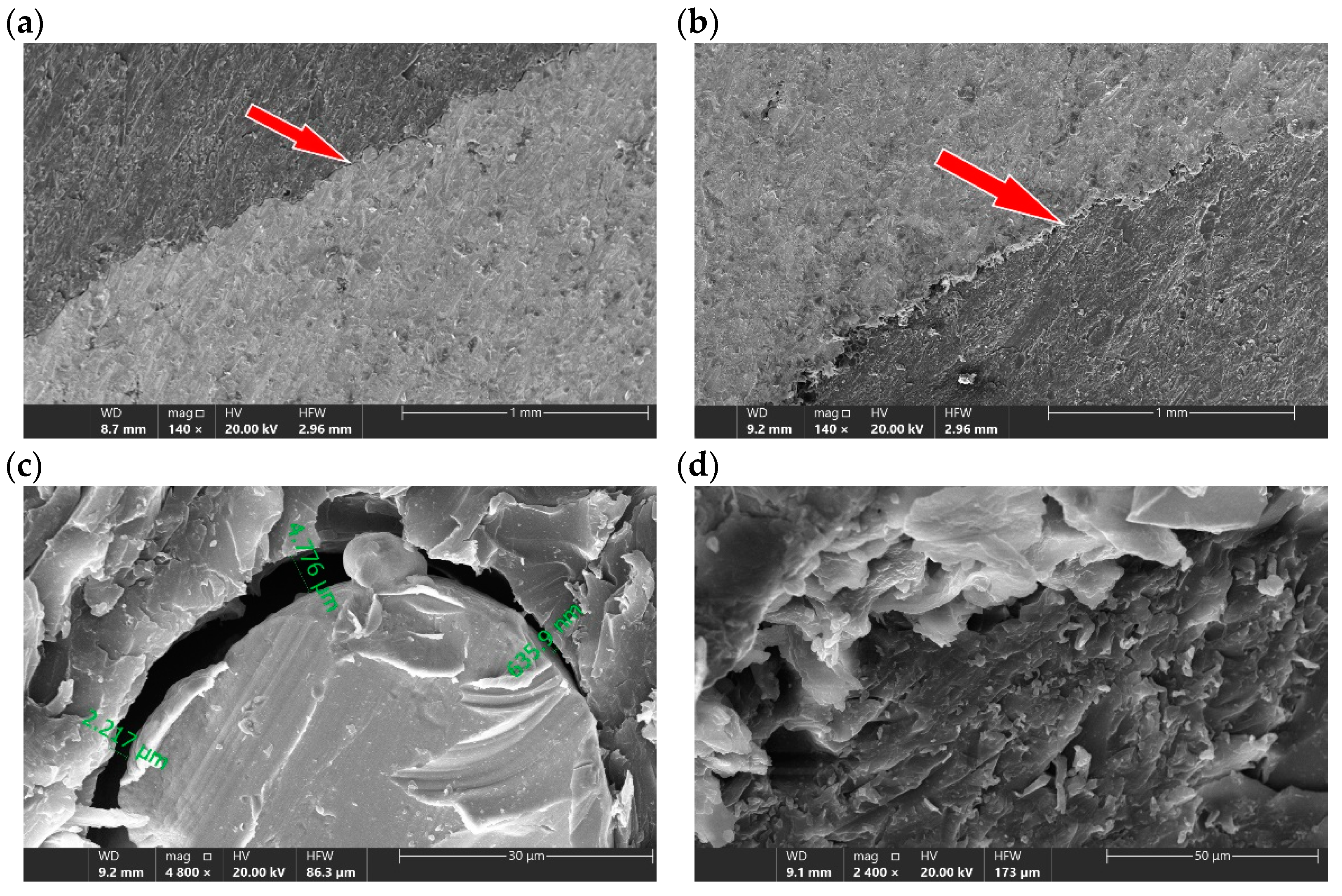

3. Results and Discussion

- Pressure: 380 MPa,

- abrasive output: 350 g/min,

- traverse speed: 100 mm/min.

4. Conclusions

- pressure: 380 MPa,

- abrasive output: 350 g/min,

- traverse speed: 100 mm/min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Michalska-Pozoga, I.; Rydzkowski, T. The Effect of Extrusion Conditions for a Screw-Disk Plasticizing System on the Mechanical Properties of Wood-Polymer Composites (WPC). Polimery 2016, 61, 202–210. [Google Scholar] [CrossRef]

- Perec, A.; Trieb, F.; Pude, F. Some Investigations into 1000 MPa Pure Waterjet Cutting. In Advances in Water Jetting; Klichová, D., Sitek, L., Hloch, S., Valentinčič, J., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 155–163. ISBN 978-3-030-53490-5. [Google Scholar]

- Carach, J.; Lehocka, D.; Legutko, S.; Hloch, S.; Chattopadhyaya, S.; Dixit, A.R. Surface Roughness of Graphite and Aluminium Alloy After Hydro-Abrasive Machining. In Advances in Manufacturing (Manufacturing 2017); Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 805–813. ISBN 978-3-319-68619-6. [Google Scholar]

- Perec, A. Investigation of Limestone Cutting Efficiency by the Abrasive Water Suspension Jet. In Advances in Manufacturing Engineering and Materials; Hloch, S., Klichová, D., Krolczyk, G.M., Chattopadhyaya, S., Ruppenthalová, L., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 124–134. ISBN 978-3-319-99352-2. [Google Scholar]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A. Modeling of High Pressure Abrasive Water Jet Cutting of Marble. Facta Univ. Ser. Mech. Eng. 2022, 20, 145–156. [Google Scholar] [CrossRef]

- Barabas, B.; Deaconescu, T.; Barabas, S. Reduction of Dimensional Variability of Pieces, Resulted in AWJ Process, Using Robust Design Method. In Proceedings of the 8th International Conference on Manufacturing Science and Education (MSE 2017)—Trends in New Industrial Revolution 2017, Sibiu, Romania, 7–9 June 2017; p. 121. [Google Scholar]

- Lehocka, D.; Klich, J.; Botko, F.; Simkulet, V.; Foldyna, J.; Krejci, L.; Storkan, Z.; Kepic, J.; Hatala, M. Comparison of Ultrasonically Enhanced Pulsating Water Jet Erosion Efficiency on Mechanical Surface Treatment on the Surface of Aluminum Alloy and Stainless Steel. Int. J. Adv. Manuf. Technol. 2019, 103, 1647–1656. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Kawecka, E. Efficiency of Tool Steel Cutting by Water Jet with Recycled Abrasive Materials. Materials 2022, 15, 3978. [Google Scholar] [CrossRef] [PubMed]

- Perec, A.; Pude, F.; Grigoryev, A.; Kaufeld, M.; Wegener, K. A Study of Wear on Focusing Tubes Exposed to Corundum-Based Abrasives in the Waterjet Cutting Process. Int. J. Adv. Manuf. Technol. 2019, 104, 2415–2427. [Google Scholar] [CrossRef]

- Hlavacova, I.M.; Geryk, V. Abrasives for Water-Jet Cutting of High-Strength and Thick Hard Materials. Int. J. Adv. Manuf. Technol. 2017, 90, 1217–1224. [Google Scholar] [CrossRef]

- Bohdal, Ł.; Kukielka, L.; Kukielka, K.; Kułakowska, A.; Malag, L.; Patyk, R. Three Dimensional Finite Element Simulation of Sheet Metal Blanking Process. Appl. Mech. Mater. 2014, 474, 430–435. [Google Scholar] [CrossRef]

- Kaldunski, P.; Kukielka, L. Numerical Analysis and Simulation of Drawpiece Forming Process by Finite Element Method. In Novel Trends in Production Devices and Systems; Velisek, K., Kostal, P., Nad, M., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 474, pp. 153–158. ISBN 978-3-03785-944-5. [Google Scholar]

- Perec, A. Environmental Aspects of Abrasive Water Jet Cutting. Rocz. Ochr. Srodowiska Annu. Set Environ. Prot. 2018, 20, 258–274. [Google Scholar]

- Perec, A.; Radomska-Zalas, A. WASPAS Optimization in Advanced Manufacturing. Procedia Comput. Sci. 2022, 207, 1193–1200. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, T.; Kovacevic, R. Erosion and Corrosion Resistance of Laser Cladded AISI 420 Stainless Steel Reinforced with VC. Appl. Surf. Sci. 2017, 410, 225–240. [Google Scholar] [CrossRef]

- Zhang, Z.; Kovacevic, R. Laser Cladding of Iron-Based Erosion Resistant Metal Matrix Composites. J. Manuf. Process. 2019, 38, 63–75. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmed, N.; Rehman, A.U.; Hussain, A.; Umer, U.; Al-Zabidi, A. Minimizing the Micro-Edge Damage at Each Constituent Layer of the Clad Composite during AWJM. Materials 2020, 13, 2685. [Google Scholar] [CrossRef]

- Mohankumar, V.; Kanthababu, M. Semi-Empirical Model for Depth of Cut in Abrasive Waterjet Machining of Metal Matrix Composites. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 507. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Dwivedi, S.P.; Maurya, N.K.; Sahu, R. Surface Roughness Report and 3D Surface Analysis of Hybrid Metal Matrix Composites (MMC) During Abrasive Water Jet (AWJ) Cutting. Rev. Des Compos. Et Des Mater. Av. J. Compos. Adv. Mater. 2020, 30, 169–174. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M.; Hashish, M. Abrasive Water Jet Machining (AWJ) of Hybrid Titanium/Graphite Composite Laminate: Preliminary Results. In Proceedings of the BHR Group—22nd International Conference on Water Jetting 2014, Haarlem, The Netherlands, 3–5 September 2014; pp. 83–95. [Google Scholar]

- Pahuja, R.; Ramulu, M. Abrasive Water Jet Machining of Titanium (Ti6Al4V)–CFRP Stacks—A Semi-Analytical Modeling Approach in the Prediction of Kerf Geometry. J. Manuf. Process. 2019, 39, 327–337. [Google Scholar] [CrossRef]

- Naveen Reddy, V.; Venkatesh, B. Optimization of Parameters in Abrasive Water Jet Machining of Glass Laminate Aluminium Reinforced Epoxy (GLARE). Mater. Today Proc. 2019, 19, 890–894. [Google Scholar] [CrossRef]

- Gnanavelbabu, A.; Rajkumar, K.; Saravanan, P. Investigation on the Cutting Quality Characteristics of Abrasive Water Jet Machining of AA6061-B4C-HBN Hybrid Metal Matrix Composites. Mater. Manuf. Process. 2018, 33, 1313–1323. [Google Scholar] [CrossRef]

- Putz, M.; Rennau, A.; Dix, M. High Precision Machining of Hybrid Layer Composites by Abrasive Waterjet Cutting. In 15th Global Conference on Sustainable Manufacturing; Seliger, G., Wertheim, R., Kohl, H., Shpitalni, M., Fischer, A., Eds.; Procedia Manufacturing; Elsevier Science BV: Amsterdam, The Netherlands, 2018; Volume 21, pp. 583–590. [Google Scholar]

- Singh, N.P.; Srinivasu, D.S.; Ramesh Babu, N. A Study on the Interaction of Jet with Constituent Layers of Multilayered Structure in through Kerfing with Abrasive Waterjets. J. Manuf. Process. 2020, 60, 117–133. [Google Scholar] [CrossRef]

- Vedernikov, A.; Gemi, L.; Madenci, E.; Özkılıç, Y.O.; Yazman, Ş.; Gusev, S.; Sulimov, A.; Bondareva, J.; Evlashin, S.; Konev, S.; et al. Effects of High Pulling Speeds on Mechanical Properties and Morphology of Pultruded GFRP Composite Flat Laminates. Compos. Struct. 2022, 301, 116216. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Kuzminova, Y.; Gusev, S.; Sulimov, A.; Gulyaev, A.; Kreslavskaya, A.; Prosyanoy, I.; Xian, G.; Akhatov, I.; et al. Effects of the Quality of Pre-Consolidated Materials on the Mechanical Properties and Morphology of Thermoplastic Pultruded Flat Laminates. Compos. Commun. 2022, 35, 101281. [Google Scholar] [CrossRef]

- Katzer, J.; Szatkiewicz, T. Effect of 3D Printed Spatial Reinforcement on Flexural Characteristics of Conventional Mortar. Materials 2020, 13, 3133. [Google Scholar] [CrossRef] [PubMed]

- Katzer, J.; Szatkiewicz, T. Properties of Concrete Elements with 3-D Printed Formworks Which Substitute Steel Reinforcement. Constr. Build. Mater. 2019, 210, 157–161. [Google Scholar] [CrossRef]

- Skoratko, A.; Szatkiewicz, T.; Katzer, J.; Jagoda, M. Mechanical Properties of Mortar Beams Reinforced by Gyroid 3D Printed Plastic Spatial Elements. Cem. Concr. Compos. 2022, 134, 104809. [Google Scholar] [CrossRef]

- Katzer, J.; Skoratko, A. Using 3D Printed Formworks for the Creation of Steel Fibre Reinforced Concrete-Plastic Columns. Constr. Build. Mater. 2022, 337, 127586. [Google Scholar] [CrossRef]

- Blanquer, S.B.G.; Grijpma, D.W. Triply Periodic Minimal Surfaces (TPMS) for the Generation of Porous Architectures Using Stereolithography. In Computer-Aided Tissue Engineering; Rainer, A., Moroni, L., Eds.; Methods in Molecular Biology; Springer: New York, NY, USA, 2021; Volume 2147, pp. 19–30. ISBN 978-1-07-160610-0. [Google Scholar]

- NTopology. Engineering, Design & Simulation Software. Available online: https://ntopology.com/ntopology-software/ (accessed on 19 December 2022).

- Szatkiewicz, T.; Laskowska, D.; Bałasz, B.; Mitura, K. The Influence of the Structure Parameters on the Mechanical Properties of Cylindrically Mapped Gyroid TPMS Fabricated by Selective Laser Melting with 316L Stainless Steel Powder. Materials 2022, 15, 4352. [Google Scholar] [CrossRef]

- Hershel Friedman and Minerals. Almandine Garnet: The Mineral Almandine Information and Pictures. Available online: https://www.minerals.net/mineral/almandine.aspx (accessed on 26 November 2022).

- Lianyungang Jinhong Mining Co., Ltd. 80 Mesh Waterjet Abrasive Garnet. Available online: http://www.lygjhky.com/Hva_En/Catalog.pdf (accessed on 23 January 2023).

- Krolczyk, G.; Kacalak, W.; Wieczorowski, M. 3D Parametric and Nonparametric Description of Surface Topography in Manufacturing Processes. Materials 2021, 14, 1987. [Google Scholar] [CrossRef]

- Kacalak, W.; Lipiński, D.; Różański, R.; Królczyk, G.M. Assessment of the Classification Ability of Parameters Characterizing Surface Topography Formed in Manufacturing and Operation Processes. Measurement 2021, 170, 108715. [Google Scholar] [CrossRef]

- Olympus. Surface Roughness Measurement—Parameter. Available online: https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/#!cms[focus]=023 (accessed on 13 December 2022).

- Perec, A.; Musial, W.; Prazmo, J.; Sobczak, R.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Nagnajewicz, S.; Pude, F. Multi-Criteria Optimization of the Abrasive Waterjet Cutting Process for the High-Strength and Wear-Resistant Steel Hardox®500. In Advances in Water Jetting; Klichová, D., Sitek, L., Hloch, S., Valentinčič, J., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 145–154. ISBN 978-3-030-53490-5. [Google Scholar]

- Perec, A.; Musial, W. Multiple Criteria Optimization of Abrasive Water Jet Cutting Using Entropy-VIKOR Approach. In Advances in Manufacturing Engineering and Materials II; Hloch, S., Klichová, D., Pude, F., Krolczyk, G.M., Chattopadhyaya, S., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 50–62. ISBN 978-3-030-71955-5. [Google Scholar]

- Hocheng, H.; Hsu, M.Y. Erosion Wear of Stainless Steel by Abrasives Entrained in a Water Jet. Arab. J. Sci. Eng. 2000, 25, 187–202. [Google Scholar]

- Hlavac, L.; Krajcarz, D.; Spadlo, S.; Hlavacova, I. Influence Traverse Speed on Surface Quality after Water-Jet Cutting for Hardox Steel. In Proceedings of the 24th International Conference on Metallurgy and Materials METAL 2015, Brno, Czech Republic, 3–5 June 2015; pp. 723–728, ISBN 978-80-87294-62-8. [Google Scholar]

- Bańkowski, D.; Spadło, S. The Use of Abrasive Waterjet Cutting to Remove Flash from Castings. Arch. Foundry Eng. 2019, 19, 94–98. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Pude, F. Process Optimization by Applying the Response Surface Methodology (RSM) to the Abrasive Suspension Water Jet Cutting of Phenolic Composites. Facta Univ. Ser. Mech. Eng. 2022, 1–16. Available online: http://casopisi.junis.ni.ac.rs/index.php/FUMechEng/article/view/10193 (accessed on 1 January 2023). [CrossRef]

| Mineral Composition [%] | ||||||

|---|---|---|---|---|---|---|

| Amandine | Ilmenite | Omphacite | Rutile | Quartz | Hornblende | Free Silica |

| 90–96 | 1.0 | 1.5 | 0.6 | <0.1 | <0.5 | <0.5% |

| Chemical Composition [%] | ||||||

| Fe2O3 | SiO2 | TiO2 | Al2O3 | FeO | CaO | MgO |

| 17 | 39 | 0.05 | 21 | 8 | 9.5 | 5 |

| Physical Characteristics | ||||||

| Density [kg/dm3] | Bulk Gravity [kg/dm3] | Mohs Hardness | Color | Grain shape | Conductivity | Acid solubility (HCL) |

| 3.8–4.1 | 2.3–2.4 | 7.5–8.0 | Dark red | Sub angular | <25 S/m | <1.0% |

| No | Pressure [MPa] | AFR [g/min] | Traverse Speed [mm/min] | Sq P1 [μm] | Sq M2 [μm] | Sq P3 [μm] |

|---|---|---|---|---|---|---|

| 1 | 360 | 250 | 100 | 1.18 | 6.88 | 1.31 |

| 2 | 360 | 350 | 200 | 1.21 | 7.32 | 1.44 |

| 3 | 360 | 450 | 300 | 1.28 | 8.94 | 1.81 |

| 4 | 380 | 250 | 200 | 1.14 | 6.63 | 1.39 |

| 5 | 380 | 350 | 300 | 1.18 | 7.16 | 1.61 |

| 6 | 380 | 450 | 100 | 1.09 | 6.29 | 1.29 |

| 7 | 400 | 250 | 300 | 1.49 | 9.29 | 1.88 |

| 8 | 400 | 350 | 100 | 1.13 | 7.12 | 1.39 |

| 9 | 400 | 450 | 200 | 1.25 | 8.64 | 1.48 |

| P1 | M2 | P3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Level | Pressure | AFR | Traverse Speed | Pressure | AFR | Traverse Speed | Pressure | AFR | Traverse Speed |

| 1 | −1.746 | −2.013 | −1.083 | −17.69 | −17.51 | −16.59 | 1.520 | 1.527 | 1.330 |

| 2 | −1.108 | −1.385 | −1.577 | −16.50 | −17.15 | −17.48 | 1.430 | 1.480 | 1.437 |

| 3 | −2.154 | −1.610 | −2.349 | −18.38 | −17.91 | −18.50 | 1.583 | 1.527 | 1.767 |

| Delta | 1.046 | 0.628 | 1.266 | 1.88 | 0.76 | 1.90 | 0.153 | 0.047 | 0.437 |

| Rank | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 |

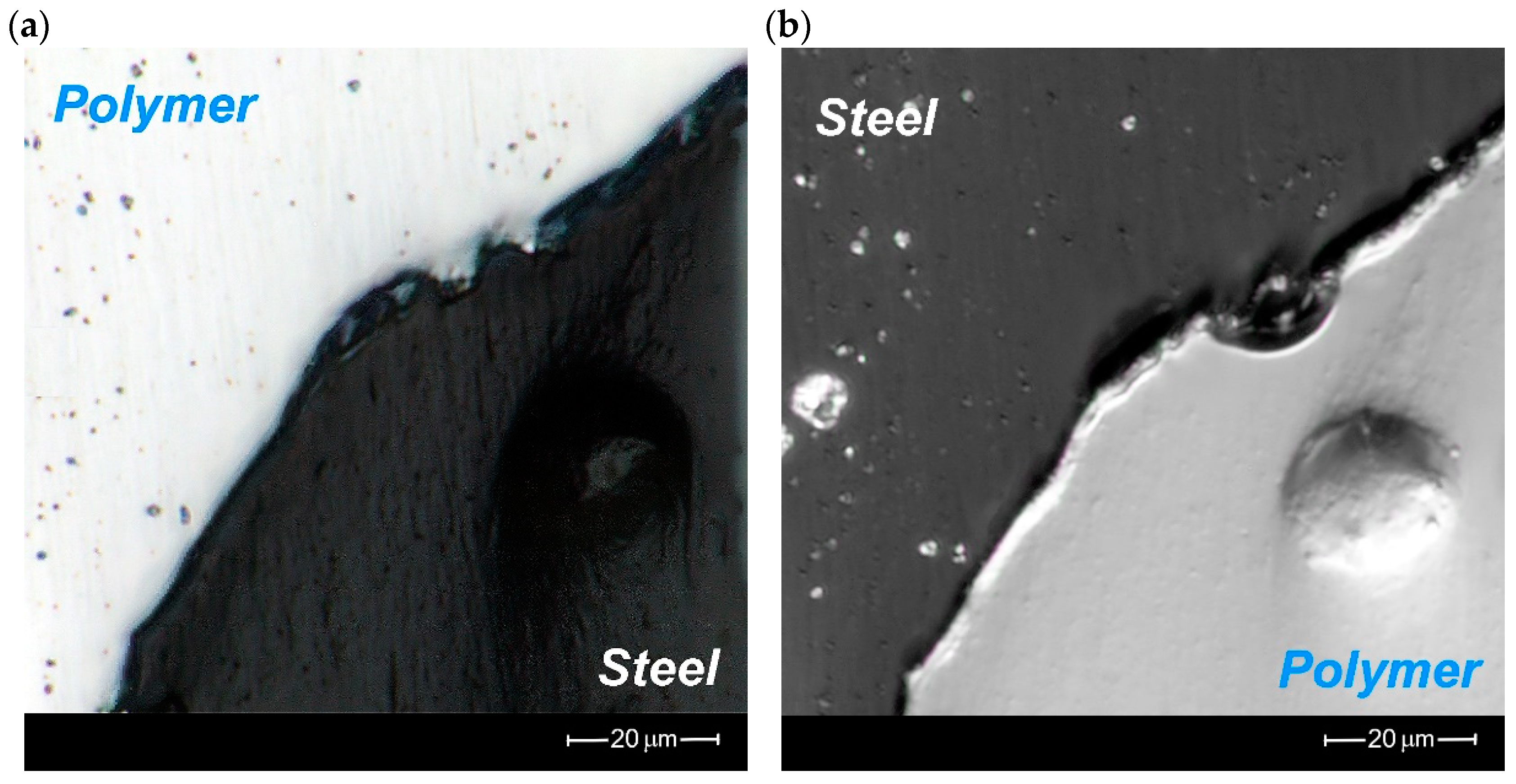

| Test | Unit | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Ave. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polymer/Steel | [μm] | 2.31 | 3.56 | 2.09 | 1.60 | 1.68 | 1.91 | 2.52 | 2.94 | 2.46 | 1.75 | 2.35 |

| Steel/Polymer | [μm] | 0.55 | 0.61 | 0.79 | 0.97 | 0.84 | 0.58 | 0.56 | 0.7 | 0.82 | 0.64 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szatkiewicz, T.; Perec, A.; Radomska-Zalas, A.; Banaszek, K.; Balasz, B. Preliminary Studies into Cutting of a Novel Two Component 3D-Printed Stainless Steel–Polymer Composite Material by Abrasive Water Jet. Materials 2023, 16, 1170. https://doi.org/10.3390/ma16031170

Szatkiewicz T, Perec A, Radomska-Zalas A, Banaszek K, Balasz B. Preliminary Studies into Cutting of a Novel Two Component 3D-Printed Stainless Steel–Polymer Composite Material by Abrasive Water Jet. Materials. 2023; 16(3):1170. https://doi.org/10.3390/ma16031170

Chicago/Turabian StyleSzatkiewicz, Tomasz, Andrzej Perec, Aleksandra Radomska-Zalas, Kamil Banaszek, and Blazej Balasz. 2023. "Preliminary Studies into Cutting of a Novel Two Component 3D-Printed Stainless Steel–Polymer Composite Material by Abrasive Water Jet" Materials 16, no. 3: 1170. https://doi.org/10.3390/ma16031170

APA StyleSzatkiewicz, T., Perec, A., Radomska-Zalas, A., Banaszek, K., & Balasz, B. (2023). Preliminary Studies into Cutting of a Novel Two Component 3D-Printed Stainless Steel–Polymer Composite Material by Abrasive Water Jet. Materials, 16(3), 1170. https://doi.org/10.3390/ma16031170