Morphology and Phase Compositions of FePt and CoPt Nanoparticles Enriched with Noble Metal

Abstract

:1. Introduction

2. Materials and Methods

2.1. FePt and CoPt Nanoparticles Fabrication

2.2. Specimen Characterization

2.3. Theoretical Modeling

3. Results

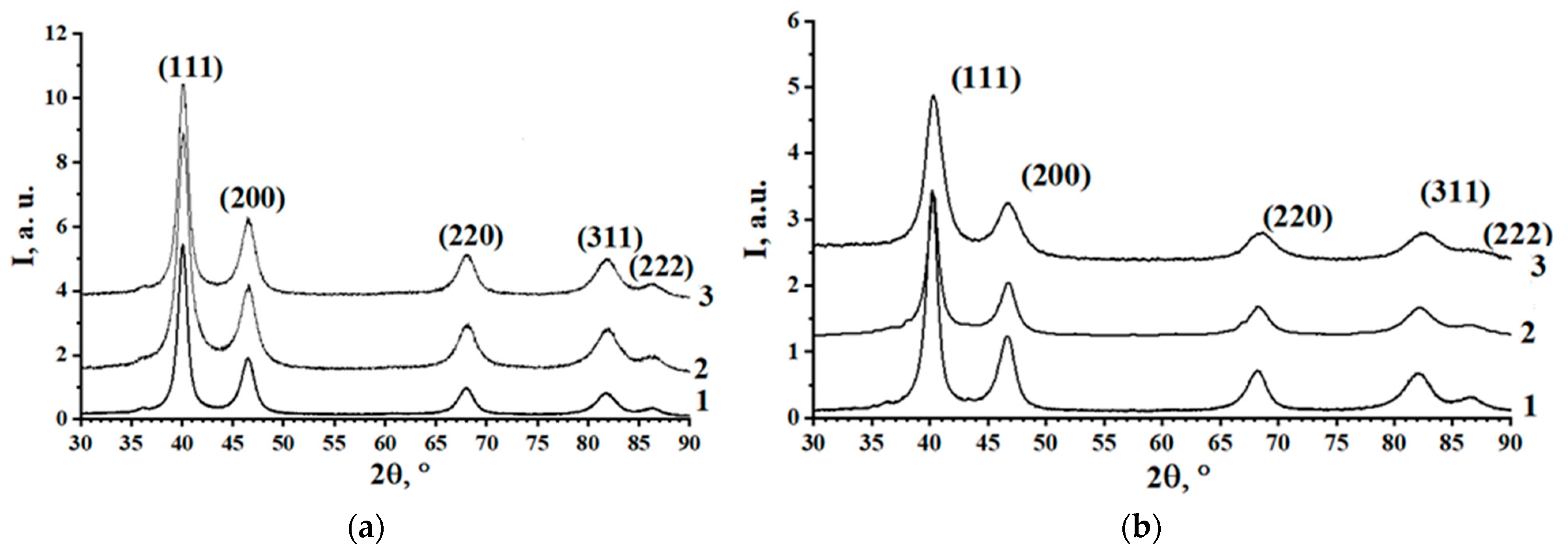

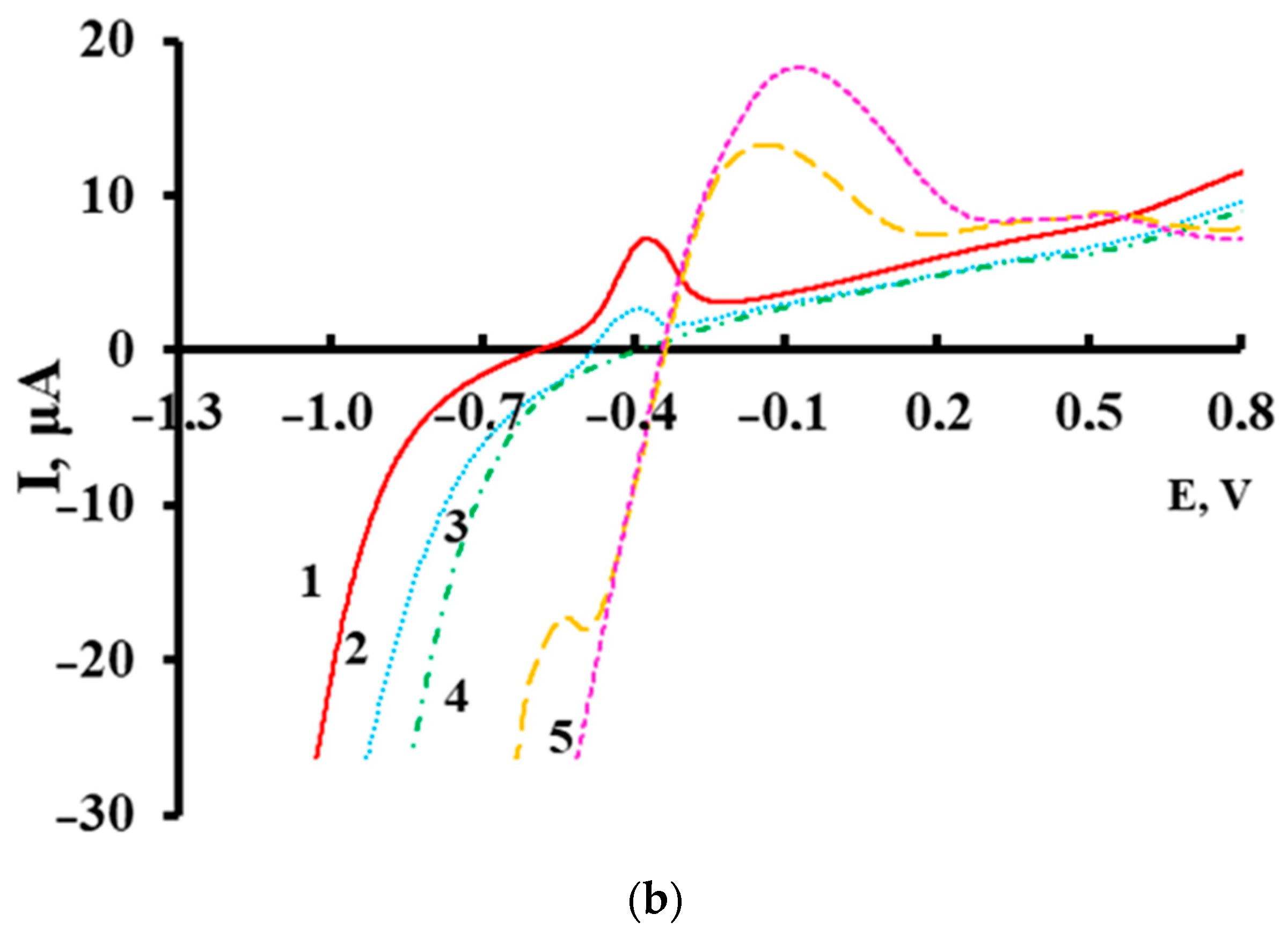

3.1. X-ray Detectable Phase—FCC (A1-Type Phase) Solid Solution, XRDPh

- -

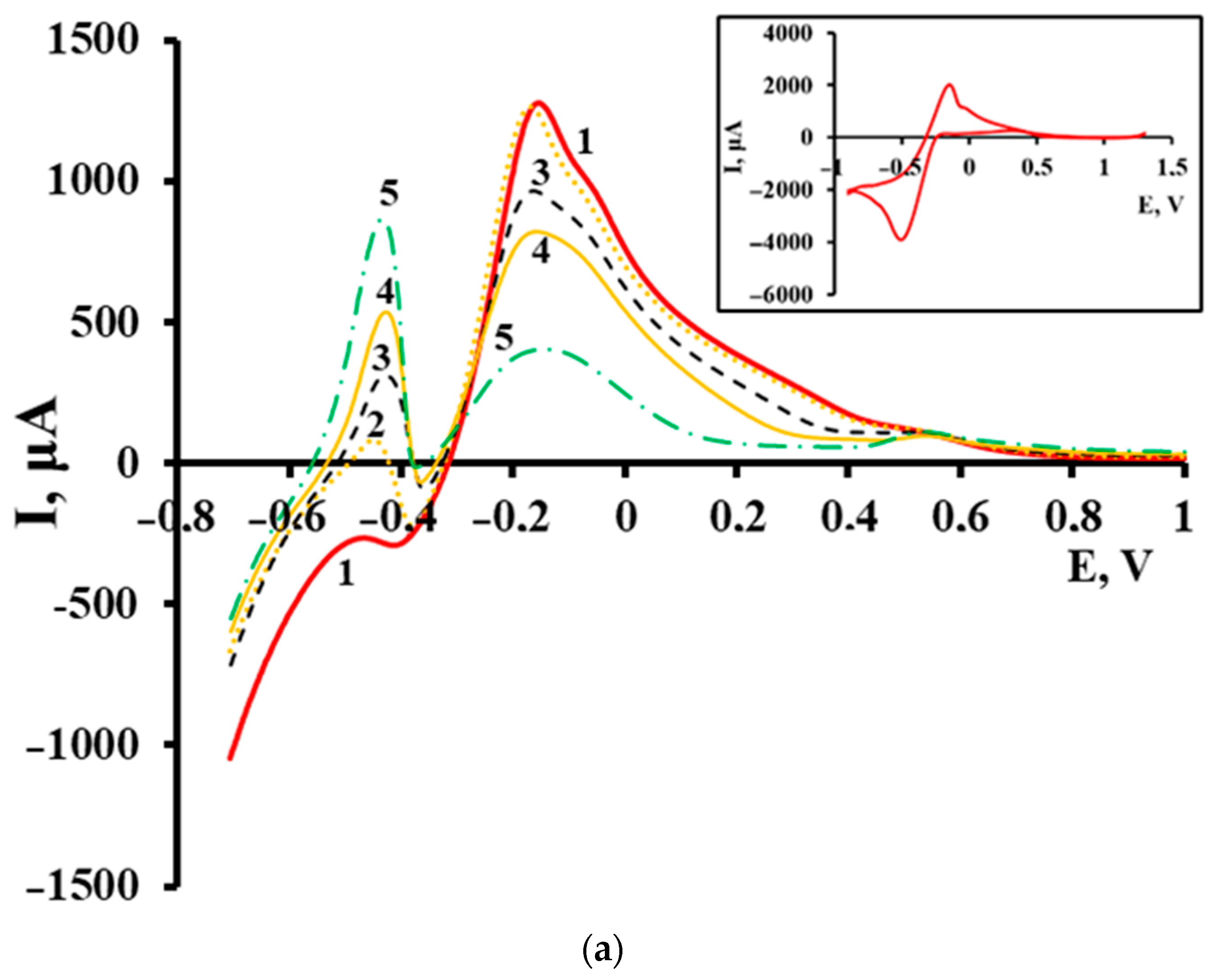

- there was practical independence between the component ratio and the position and intensity of the peak in the +0.55 V region, which was in agreement with a small solubility limit of Fe in Pt (Figure 2) and with an insignificant variation of the amount of solid solution (intensity of diffraction peaks) when changing the component ratio;

- -

- II.

- Intermediate reactions were probable to proceed as:

- III.

- The adsorption of [PtCl4]2− and Fe2+ ions on the surface of Pt clusters and their sequential reduction to form a Pt-rich solid solution was as follows:

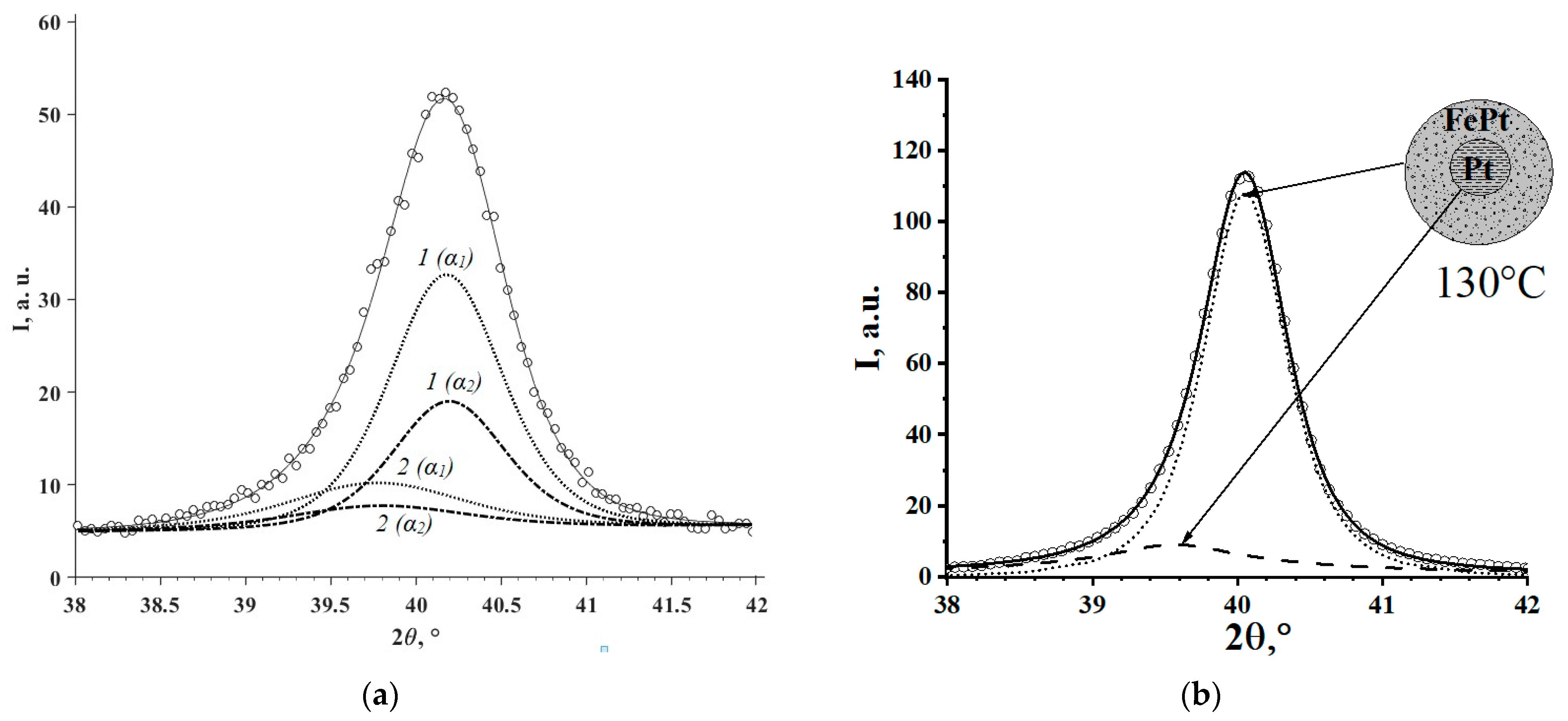

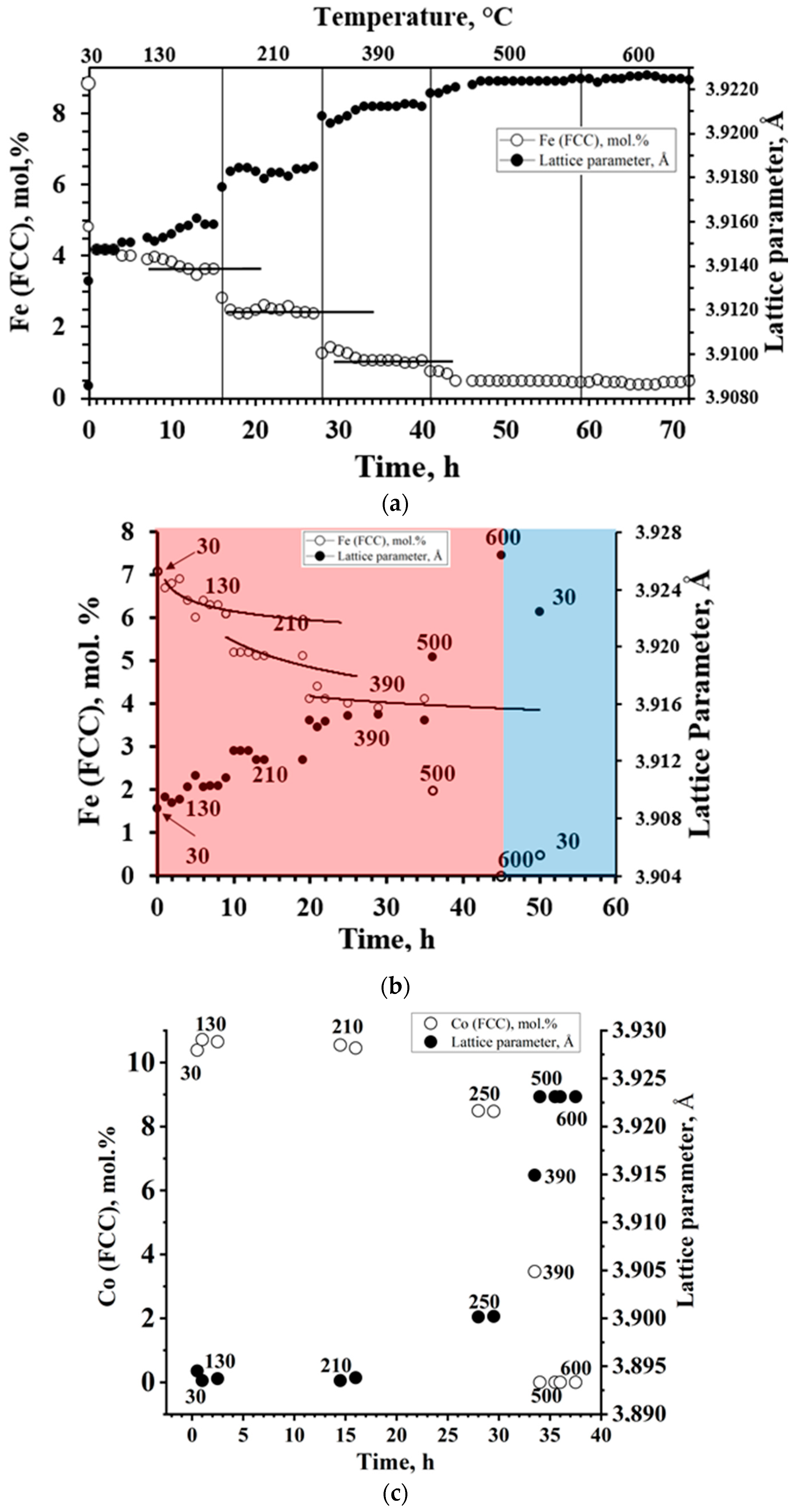

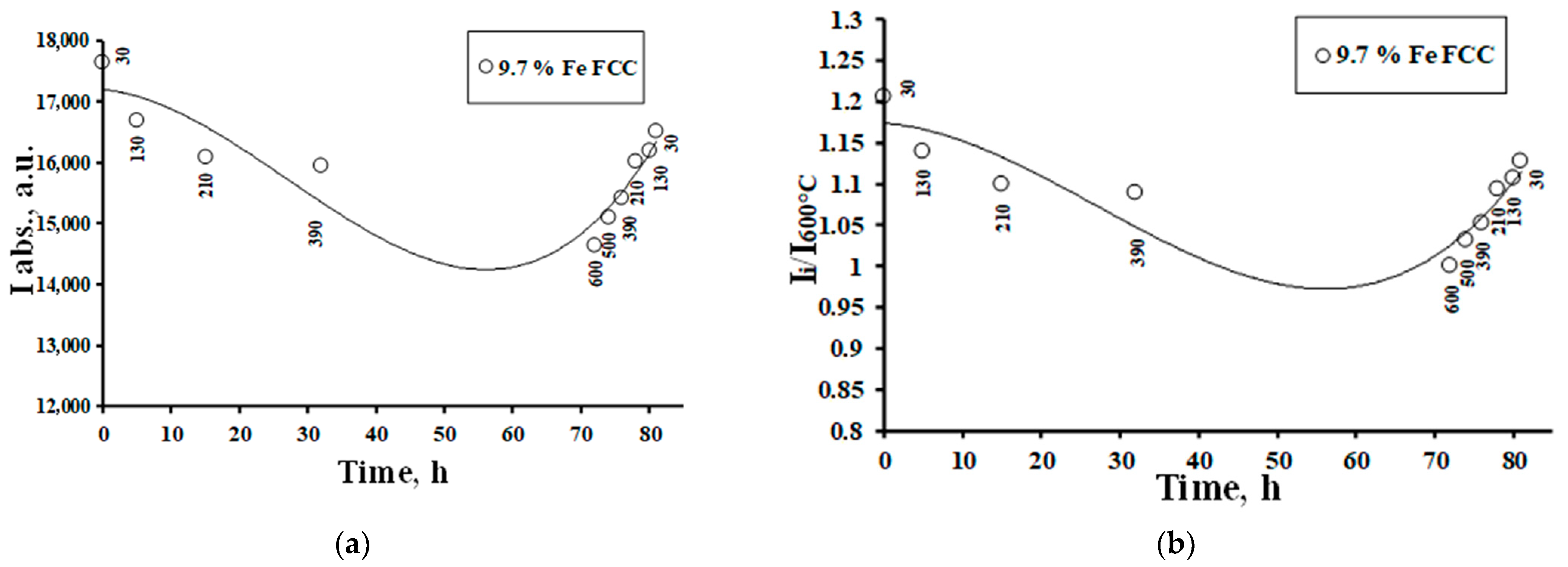

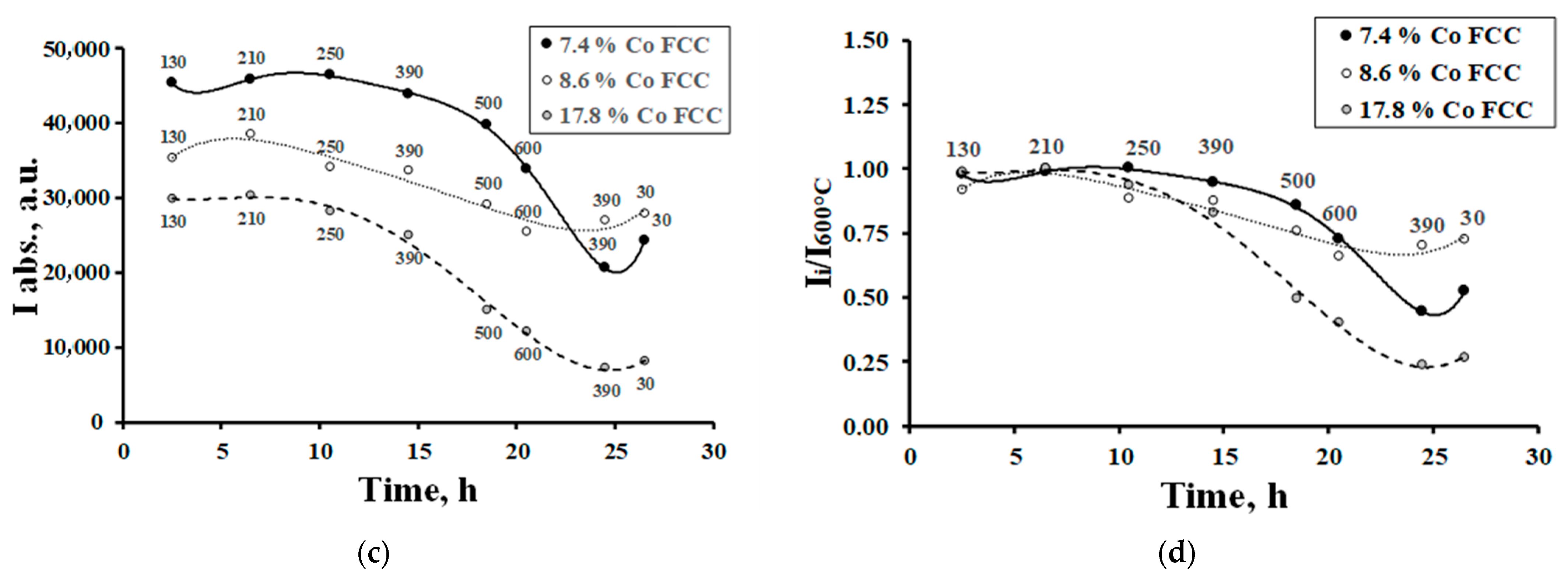

3.2. Phase Transformations When NP Specimens Heated

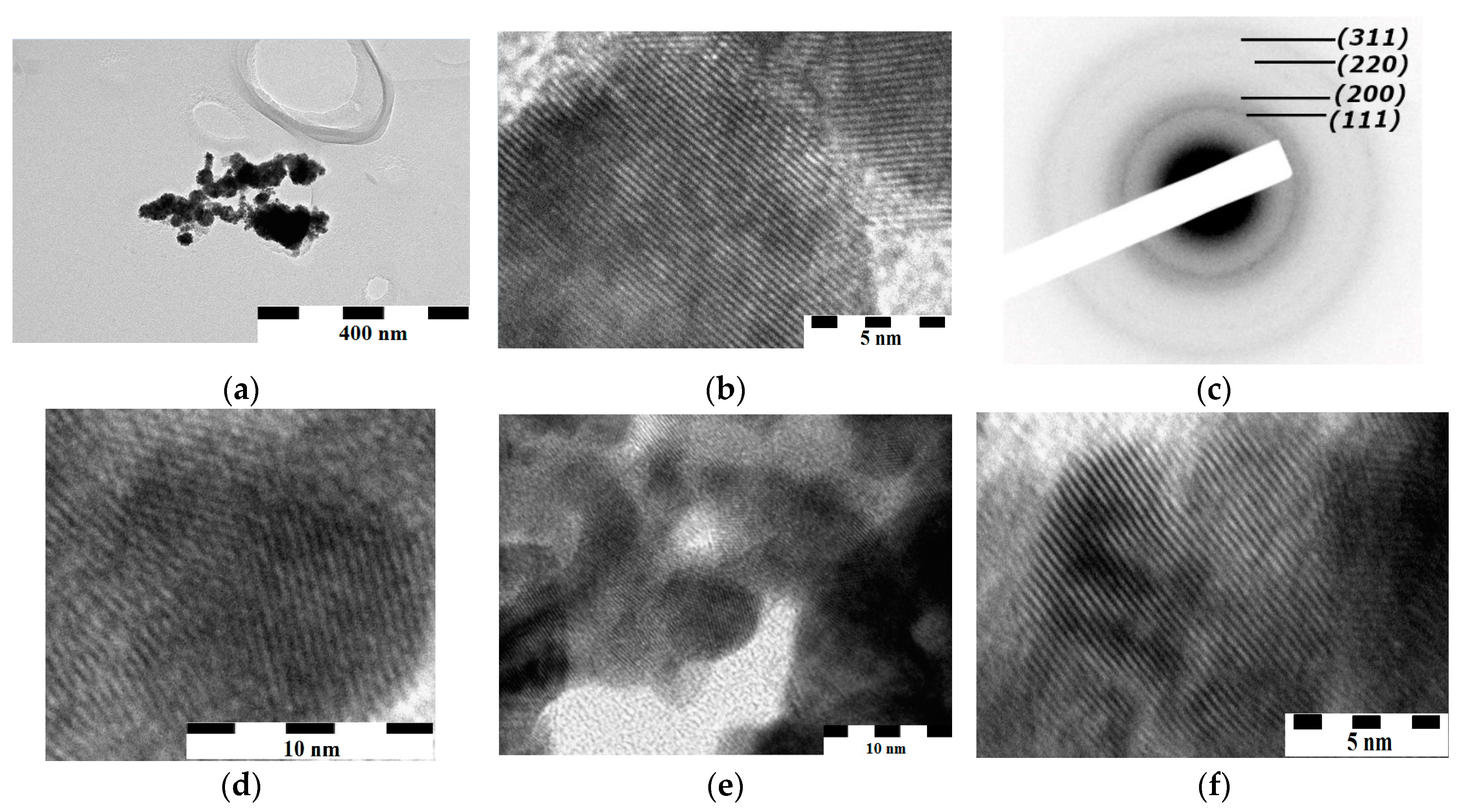

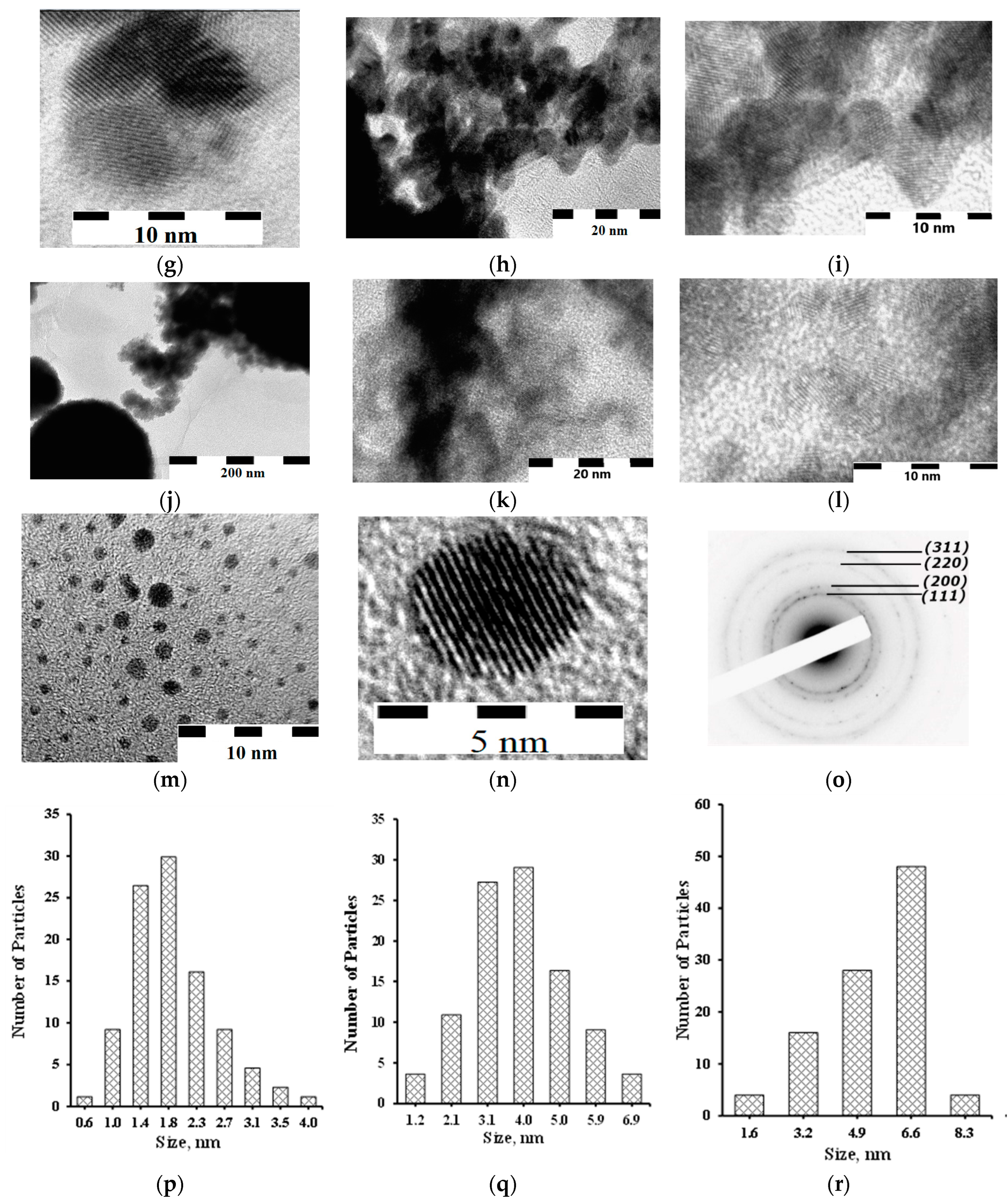

3.3. X-ray Non-Detectable Phases—XRNDPh-1 and XRNDPh-2

- -

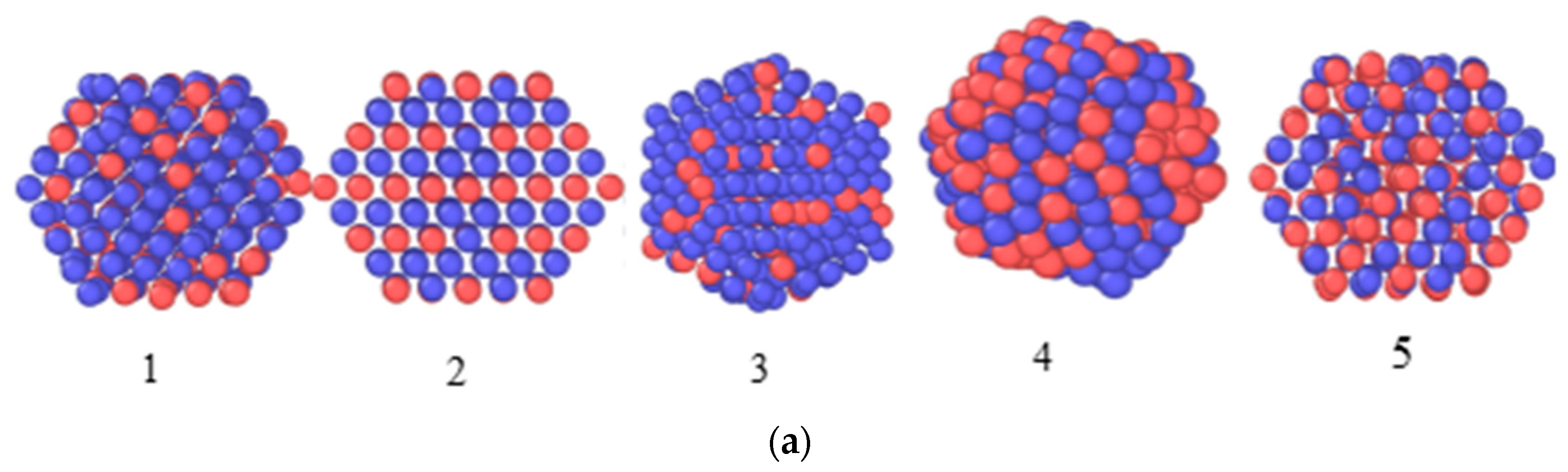

- A1 phase clusters (FCC SS) were the most stable, with no strong effect of the habitus on the stability;

- -

- For the FePt3 composition, (ordered L12) cubic shape was more stable.

4. Conclusions

- -

- There is only an FCC-A1-type disordered platinum-rich solid solution (XRDPhs), according to the XRD method. The solubility limits of Fe and Co were determined (11.4 ± 0.7% and 17.5 ± 0.6%, respectively). The structural blockiness of the main fraction of crystals (4–10 nm) and the established distributions of their sizes were found. The presence of especially fine-dispersed particles of 1–4 nm was revealed, from which, probably, the main fractions were composed; Heterogeneity in the composition of crystals of the main fraction was found, i.e., there were inner (deep) regions enriched with platinum. Based on above results, the paper proposes a model of solid-solution formation during the reduction of components with significantly different redox potentials (Eh);

- -

- There was formation along with the diffraction-registered phase and the X-ray non-detectable phase (XRNDPh-1) when the Fe and Co contents in the nanosystems were above the solubility limits, the presence of which were confirmed by the HRTEM and SAXS methods and which were composed, probably, of the crystallites (1–3 nm) and amorphous arrays;

- -

- Heating of solid solutions with compositions C(Fe,Co) < LS above the threshold temperatures led to phase transformations, with the formation of Pt-rich XRDPh and XRNDPh-2 with high contents of Fe(Co). A model of phase transformation was proposed.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zakharov, N.S.; Tikchonova, I.N.; Zakharov, Y.A.; Popova, A.N.; Pugachev, V.M.; Russakov, D.M. Study of the Pt-rich nanostructured FePt and CoPt alloys: Oddities of phase composition. Lett. Mater. 2022, 12, 480–485. [Google Scholar] [CrossRef]

- Zakharov, N.S.; Pugachev, V.M.; Popova, A.N. Platinum-rich solid solution in nanostructured FePt system. Chem. Sustain. Dev. 2021, 29, 536–542. [Google Scholar] [CrossRef]

- Pugachev, V.M.; Zakharov, Y.A.; Popova, A.N.; Russakov, D.M.; Zakharov, N.S. Phase transformations of the nanostructured iron-platinum system upon heating. J. Phys. Conf. Ser. 2021, 1749, 012036. [Google Scholar] [CrossRef]

- Pei, W.; Zhao, D.; Wu, C.; Sun, Z.; Liu, C.; Wang, X.; Zheng, J.; Yan, M.; Wang, J.; Wang, Q. Direct Synthesis of L 10-FePt Nanoparticles with High Coercivity via Pb Addition for Applications in Permanent Magnets and Catalysts. ACS Appl. Nano Mater. 2020, 3, 1098–1103. [Google Scholar] [CrossRef]

- Poudyal, N.; Chaubey, G.S.; Rong, C.B.; Liu, J.P. Shape control of FePt nanocrystals. J. Appl. Phys. 2009, 105, 07A749–07A751. [Google Scholar] [CrossRef]

- Wittig, J.E.; Bentley, J.; Allard, L.F. In situ investigation of ordering phase transformations in FePt magnetic nanoparticles. Ultramicroscopy 2017, 176, 218–232. [Google Scholar] [CrossRef] [PubMed]

- Massalski, T.B. Binary Alloys Phase Diagram; ASM International: Materials Park, OH, USA, 1992. [Google Scholar]

- Okamoto, H. Phase Diagrams of Binary Iron Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Schneider, S.; Pohl, D.; Löffler, S.; Rusz, J.; Kasinathan, D.; Schattschneider, P.; Schultz, L.; Rellinghaus, B. Magnetic properties of single nanomagnets: Electron energy-loss magnetic chiral dichroism on FePt nanoparticles. Ultramicroscopy 2016, 171, 186–194. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Schulthess, T.C.; Mryasov, O.N. Magnetic anisotropy of FePt nanoparticles: Temperature-dependent free energy barrier for switching. IEEE Trans. Magn. 2007, 43, 2950–2952. [Google Scholar] [CrossRef]

- Lyberatos, A.; Weller, D.; Parker, G.J.; Stipe, B.C. Size dependence of the Curie temperature of L10-FePt nanoparticles. J. Appl. Phys. 2012, 112, 113915. [Google Scholar] [CrossRef]

- Luo, H.B.; Xia, W.X.; Ruban, A.V.; Du, J.; Zhang, J.; Liu, J.P.; Yan, A. Effect of stoichiometry on the magnetocrystalline anisotropy of Fe–Pt and Co–Pt from first-principles calculation. J. Condens. Matter Phys. 2014, 26, 386002. [Google Scholar] [CrossRef] [PubMed]

- Natekar, N.A.; Hsu, W.H.; Victora, R.H. Calculated dependence of FePt damping on external field magnitude and direction. AIP Adv. 2017, 7, 056004. [Google Scholar] [CrossRef]

- Chen, S.; Andre, P. Colloidal syntheses of FePt nanoparticles. Int. J. Nanotechnol. 2012, 9, 39–68. [Google Scholar] [CrossRef]

- Li, J.; Sun, S. Intermetallic nanoparticles: Synthetic control and their enhanced electrocatalysis. Acc. Chem. Res. 2019, 52, 2015–2025. [Google Scholar] [CrossRef] [PubMed]

- Chrobak, A. High and ultra-high coercive materials in spring-exchange systems—Review, simulations and perspective. Materials 2022, 15, 6506. [Google Scholar] [CrossRef] [PubMed]

- Dalavi, S.B.; Panda, R.N. Observation of high coercive fields in chemically synthesized coated Fe-Pt nanostructures. J. Magn. Magn. Mater. 2017, 428, 306–312. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Lyubina, J.; Müller, K.H.; Schultz, L. FePt hard magnets. Adv. Eng. Mater. 2005, 7, 208–212. [Google Scholar] [CrossRef]

- Rellinghaus, B.; Stappert, S.; Acet, M.; Wassermann, E.F. Magnetic properties of FePt nanoparticles. J. Magn. Magn. Mater. 2003, 266, 142–154. [Google Scholar] [CrossRef]

- Chou, S.W.; Zhu, C.L.; Neeleshwar, S.; Chen, C.L.; Chen, Y.Y.; Chen, C.C. Controlled growth and magnetic property of FePt nanostructure: Cuboctahedron, octapod, truncated cube, and cube. Chem. Mater. 2009, 21, 4955–4961. [Google Scholar] [CrossRef]

- Komorida, Y.; Mito, M.; Deguchi, H.; Takagi, S.; Iwamoto, T.; Kitamoto, Y. Pressure-induced enhancement of the blocking temperature in FePt nanoparticles. J. Phys. Conf. Ser. 2010, 200, 072054. [Google Scholar] [CrossRef]

- Liang, J.; Ma, F.; Hwang, S.; Wang, X.; Sokolowski, J.; Li, Q.; Wu, G.; Su, D. Atomic Arrangement Engineering of Metallic Nanocrystals for Energy-Conversion Electrocatalysis. Joule 2019, 3, 956–991. [Google Scholar] [CrossRef]

- Li, Q.; Wu, L.; Wu, G.; Su, D.; Lv, H.; Zhang, S.; Zhu, W.; Casimir, A.; Zhu, H.; Mendoza-Garcia, A.; et al. New Approach to Fully Ordered fct-FePt Nanoparticles for Much Enhanced Electrocatalysis in Acid. Nano Lett. 2015, 15, 2468–2473. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Y.; Wang, C.; Jiang, M.; Li, H.; Ren, Y.; Qin, G. Redetermination of the Fe–Pt phase diagram by using diffusion couple technique combined with key alloys. Int. J. Mater. Res. 2022, 113, 428–439. [Google Scholar] [CrossRef]

- Yang, B.; Asta, M.; Mryasov, O.N.; Klemmer, T.J.; Chantrell, R.W. Equilibrium Monte Carlo simulations of A1–L10 ordering in FePt nanoparticles. Scr. Mater. 2005, 53, 417–422. [Google Scholar] [CrossRef]

- Zakharov, N.S.; Popova, A.N.; Zakharov, Y.A.; Pugachev, V.M.; Russakov, D.M. Transmission Electron Microscopy: Study of the Bimetallic Nanoparticle Features. Russ. J. Phys. Chem. 2022, 16, 780–786. [Google Scholar] [CrossRef]

- Yakubik, D.G.; Sadykova, L.R.; Zakharov, Y.A.; Zakharov, N.S.; Popova, A.N.; Pugachev, V.M. Stability of FePt, FePt3 Nanoclusters of Different Habits. Eurasian Chem.-Technol. J. 2022, 24, 215–220. [Google Scholar] [CrossRef]

- Zakharov, Y.A.; Pugachev, V.M.; Korchuganova, K.A.; Ponomarchuk, Y.V.; Larichev, T.A. Analysis of phase composition and CSR sizes in non-equilibrium nanostructured systems Fe-Co and Ni-Cu using diffraction maxima simulations in a doublet radiation. J. Struc. Chem. 2020, 61, 994–1000. [Google Scholar] [CrossRef]

- Whyte, T.E., Jr.; Kirklin, P.W.; Gould, R.W.; Heinemann, H. Small angle X-ray scattering investigation of platinum metal dispersions on alumina catalysts. J. Catal. 1972, 25, 407–415. [Google Scholar] [CrossRef]

- White, H.W. Particle size distribution that cannot be distinguished by their integral moments. J. Colloid Interface Sci. 1990, 135, 297–299. [Google Scholar] [CrossRef]

- Li, T.; Senesi, A.J.; Lee, B. Small Angle X-ray Scattering for Nanoparticle Research. Chem. Rev. 2016, 116, 11128–11180. [Google Scholar] [CrossRef]

- Dodonov, V.G.; Zakharov, Y.A.; Pugachev, V.M.; Vasiljeva, O.V. Determination of the surface structure peculiarities of nanoscale metal particles via small-angle X-ray scattering. Inorg. Mater. Appl. Res. 2016, 7, 804–814. [Google Scholar] [CrossRef]

- Ivanova, N.; Lobanov, A.; Andyyakova, A.; Zakharov, Y.; Popova, A.; Kolmykov, R. The electrochemical synthesis and investigation of nanostructured Fe-Pt and Co-Pt systems. IOP Conf. Ser. Mater. Sci. Eng. 2020, 848, 012028. [Google Scholar] [CrossRef]

- LAMMPS. Available online: www.lammps.org (accessed on 21 July 2023).

- Lee, B.; Baskes, M.I.; Kim, H.; Cho, Y.K. Second nearest-neighbor modified embedded atom method potentials for bcc transition metals. Phys. Rev. B 2001, 64, 184102. [Google Scholar] [CrossRef]

- Interatomic Potentials Repository. Available online: https://www.ctcms.nist.gov/potentials/ (accessed on 21 July 2023).

- Liu, X.; Wang, H.; Zuo, S.; Zhang, T.; Dong, Y.; Li, D.; Jiang, C. Dispersible and manipulable magnetic L10-FePt nanoparticles. Nanoscale 2020, 12, 7843–7848. [Google Scholar] [CrossRef]

- Dmitrieva, O.; Rellinghaus, B.; Kästner, J.; Dumpich, G. Quantitative structure analysis of L10-ordered FePt nanoparticles by HRTEM. J. Cryst. Growth 2007, 303, 645–650. [Google Scholar] [CrossRef]

- Dai, Z.R.; Sun, S.; Wang, Z.L. Phase transformation, coalescence, and twinning of monodisperse FePt nanocrystals. Nano Lett. 2001, 1, 443–447. [Google Scholar] [CrossRef]

- Bard, A.J.; Parsons, R.; Jordan, J. Standard Potentials in Aqueous Solutions; Routledge: New York, NY, USA, 1985. [Google Scholar]

- Sahyun, M.R.V. Towards a quantum chemical model of the photographic process. Photogr. Sci. Engng. 1978, 22, 317–321. [Google Scholar]

- Belous, V.M. Review of luminescence studies on latent image formation in silver halide emulsions. J. Imaging Sci. Technol. 1997, 41, 85–98. [Google Scholar] [CrossRef]

- Hamilton, J.F. The silver halide photographic process. Adv. Phys. 1988, 37, 359–441. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, W.; Cheng, C.H.; Lee, J.Y.; Liu, Z. Pt-decorated PdFe nanoparticles as methanol-tolerant oxygen reduction electrocatalyst. ACS Appl. Mater. Interfaces 2010, 2, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Cotton, S. Chemistry of Precious Metals; Springer Science & Business Media: London, UK, 1997. [Google Scholar]

- IUPAC-NIST Solubility Database (Version 1.1), NIST Standard Reference Database 106. 2012. Office of Data and Informatics of the National Institute of Standards and Technology (NIST), USA. Available online: https://srdata.nist.gov/solubility (accessed on 20 September 2023). [CrossRef]

- Koch, E. International Tables for Crystallography; Springer: London, UK, 2006; Volume C. [Google Scholar]

- Chen, X.; Zhang, S.; Li, C.; Liu, Z.; Sun, X.; Cheng, S.; Zakharov, D.N.; Hwang, S.; Zhu, Y.; Fang, J.; et al. Composition-dependent ordering transformations in Pt–Fe nanoalloys. Proc. Natl. Acad. Sci. USA 2022, 119, e2117899119. [Google Scholar] [CrossRef] [PubMed]

| System | FePt | |||||

| CFe 1 as synthesized, mol.% | 5 | 7 | 13 | 15 | 22 | 28 |

| CLP, Å | 3.907 ± 0.001 | 3.907 ± 0.001 | 3.9089 ± 0.0001 | 3.9032 ± 0.0004 | 3.897 ± 0.001 | 3.8985 ± 0.0004 |

| CCo 2 in FCC, mol. % | 8.0 | 8.0 | 7.1 | 9.8 | 12.6 | 11.9 |

| System | CoPt | |||||

| CCo 1 as synthesized, mol.% | 6 | 11 | 14 | 20 | 26 | 31 |

| CLP, Å | 3.902 ± 0.002 | 3.898 ± 0.001 | 3.898 ± 0.001 | 3.895 ± 0.001 | 3.876 ± 0.001 | 3.870 ± 0.002 |

| CCo 2 in FCC, mol. % | 7.3 | 8.6 | 8.9 | 10.2 | 15.9 | 17.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakharov, Y.A.; Popova, A.N.; Pugachev, V.M.; Zakharov, N.S.; Tikhonova, I.N.; Russakov, D.M.; Dodonov, V.G.; Yakubik, D.G.; Ivanova, N.V.; Sadykova, L.R. Morphology and Phase Compositions of FePt and CoPt Nanoparticles Enriched with Noble Metal. Materials 2023, 16, 7312. https://doi.org/10.3390/ma16237312

Zakharov YA, Popova AN, Pugachev VM, Zakharov NS, Tikhonova IN, Russakov DM, Dodonov VG, Yakubik DG, Ivanova NV, Sadykova LR. Morphology and Phase Compositions of FePt and CoPt Nanoparticles Enriched with Noble Metal. Materials. 2023; 16(23):7312. https://doi.org/10.3390/ma16237312

Chicago/Turabian StyleZakharov, Yuri A., Anna N. Popova, Valery M. Pugachev, Nikita S. Zakharov, Irina N. Tikhonova, Dmitry M. Russakov, Vadim G. Dodonov, Denis G. Yakubik, Natalia V. Ivanova, and Lilia R. Sadykova. 2023. "Morphology and Phase Compositions of FePt and CoPt Nanoparticles Enriched with Noble Metal" Materials 16, no. 23: 7312. https://doi.org/10.3390/ma16237312

APA StyleZakharov, Y. A., Popova, A. N., Pugachev, V. M., Zakharov, N. S., Tikhonova, I. N., Russakov, D. M., Dodonov, V. G., Yakubik, D. G., Ivanova, N. V., & Sadykova, L. R. (2023). Morphology and Phase Compositions of FePt and CoPt Nanoparticles Enriched with Noble Metal. Materials, 16(23), 7312. https://doi.org/10.3390/ma16237312