A Novel Equivalent Method for Computing Mechanical Properties of Random and Ordered Hyperelastic Cellular Materials

Abstract

:1. Introduction

- (1)

- Equivalent constitutive model [9,10,11]. The unit cells of cellular materials can exhibit random or ordered arrangements. A brief simulation method was established according to the constitutive model for the continuous materials. When the macroscopic scale of cellular materials is much larger than the microscopic scale of their unit cells, they can be treated as continuous solid materials. Based on the experimental results, an equivalent constitutive model is developed to describe the macroscopic equivalent stress-strain curves. However, this method neglects the micro-architecture properties.

- (2)

- Modeling based on representative volume element (RVE) [12,13,14,15,16,17,18,19,20]. Cellular materials include materials with either uniform or non-uniform unit cells. In the case of non-uniform cellular material, an RVE is constituted by enough characteristic unit cells or mesoscopic models [12,13,14]. Then, the simplified RVE, such as the primitive cubic model, Kelvin model, Voronoi model, and so on, is established. In the case of uniform cellular material [16,17], such as periodic lattices and triply periodic minimal surfaces, the RVE consists of specific unit cells. This method effectively describes the deformation behavior of cellular materials and reflects their basic structure characteristics (the micro-architecture shape), while also demonstrating computational efficiency. However, this method overlooks the influence of the micro-architecture parameters (size, wall thickness, distribution, and material properties) on the mechanical properties, thus emphasizing that selecting an appropriate RVE is crucial for accurately determining the overall mechanical properties.

- (3)

- Modeling based on reconstructed microstructure [21,22,23,24,25]. With the development of computational ability and micro-computerized tomography, reconstructed microstructures can be used to simulate the deformation behavior of actual materials. The discrepancies arising from design and manufacturing contribute to the unstable mechanical responses observed in cellular materials through foaming or 3D printing [22,23,24]. By employing reconstruction technology, the actual micro-structural models are constructed for finite element simulation, enabling a comprehensive understanding of complex cellular materials and an accurate prediction of their deformation behaviors. However, this direct modeling method requires significant computational resources due to the incorporation of complex micro-architectures with large finite element meshes into finite element software, thereby limiting its practical applicability in engineering contexts.

2. Generic Strategy for Equivalent Calculation Method

3. Simulated Procedure

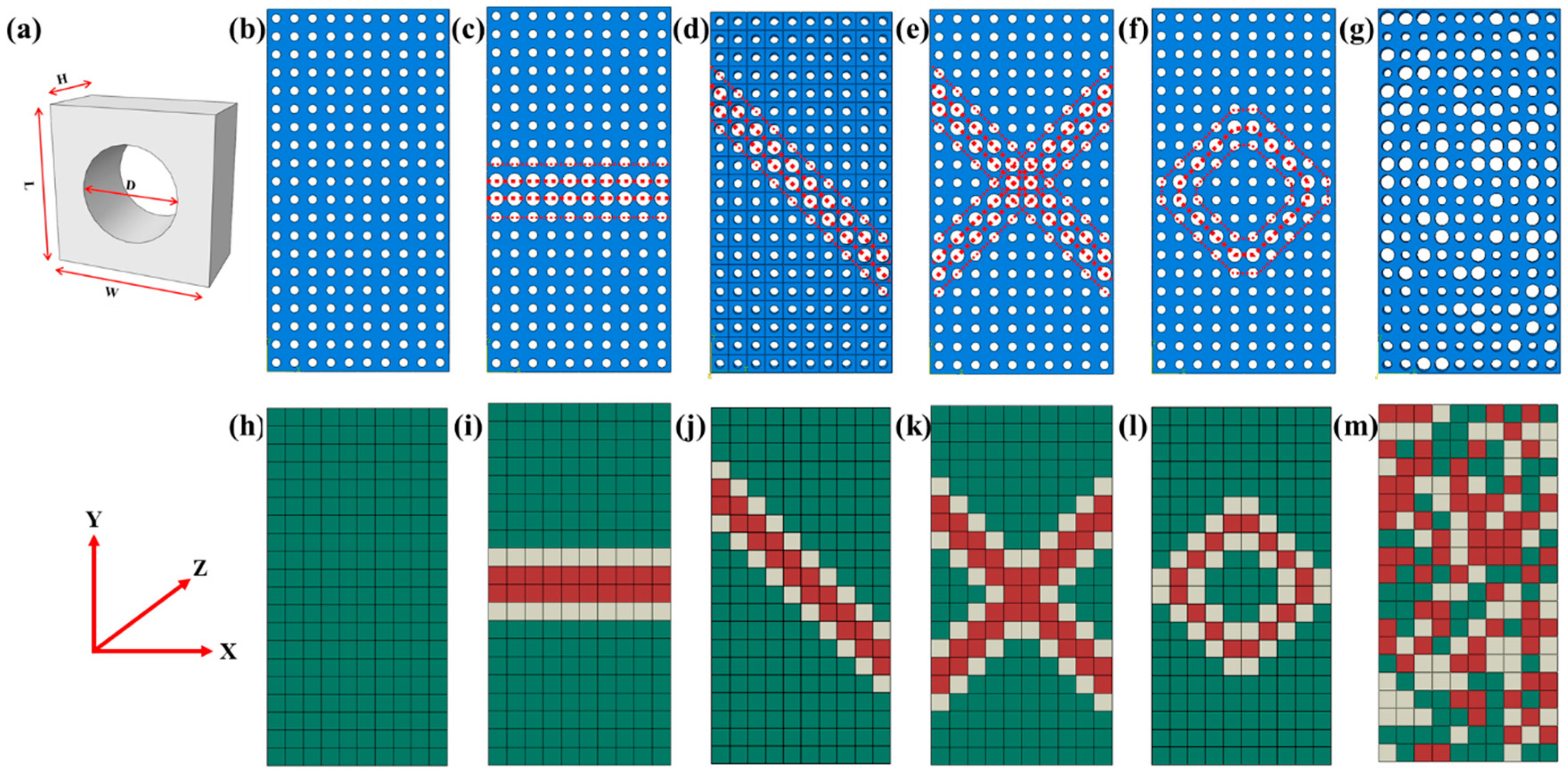

3.1. Simulated Model Generation

3.2. Finite Element Modeling, Boundary Conditions, and Mesh

3.3. The Constitutive Models and Their Material Parameters for the Cellular Materials and Their Equivalent Materials

3.3.1. The Constitutive Model and the Material Parameters for the Cellular Material

3.3.2. The Constitutive Model and the Material Parameters for the Equivalent Material

4. Results and Discussions

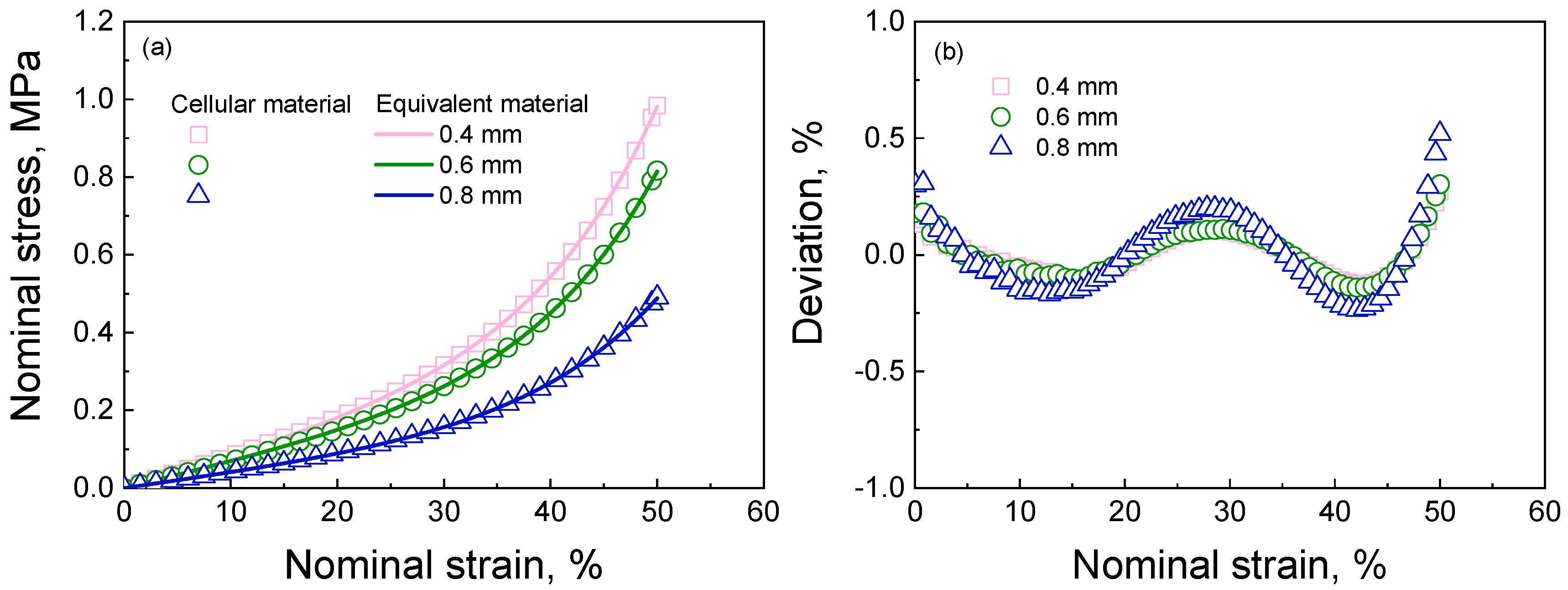

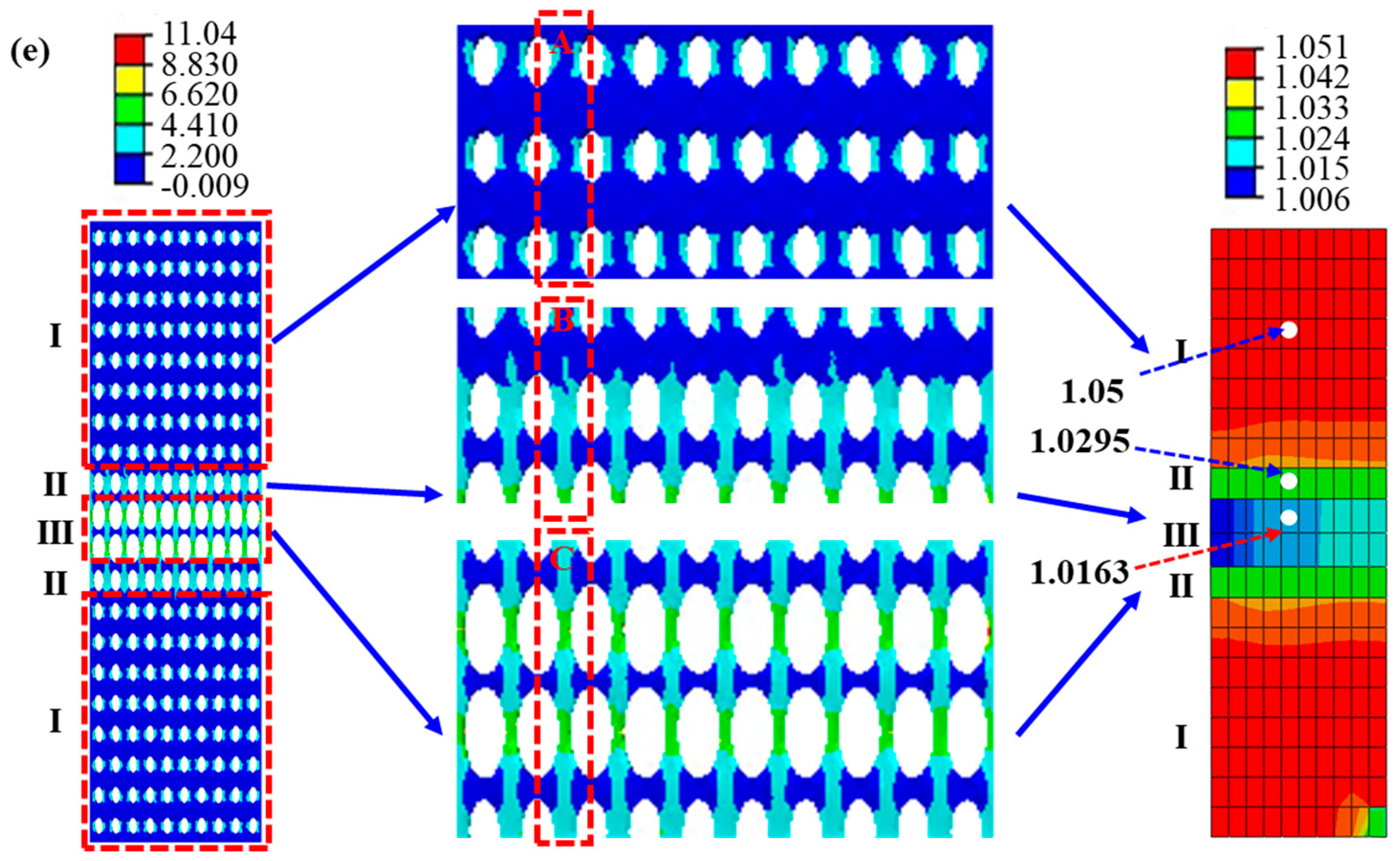

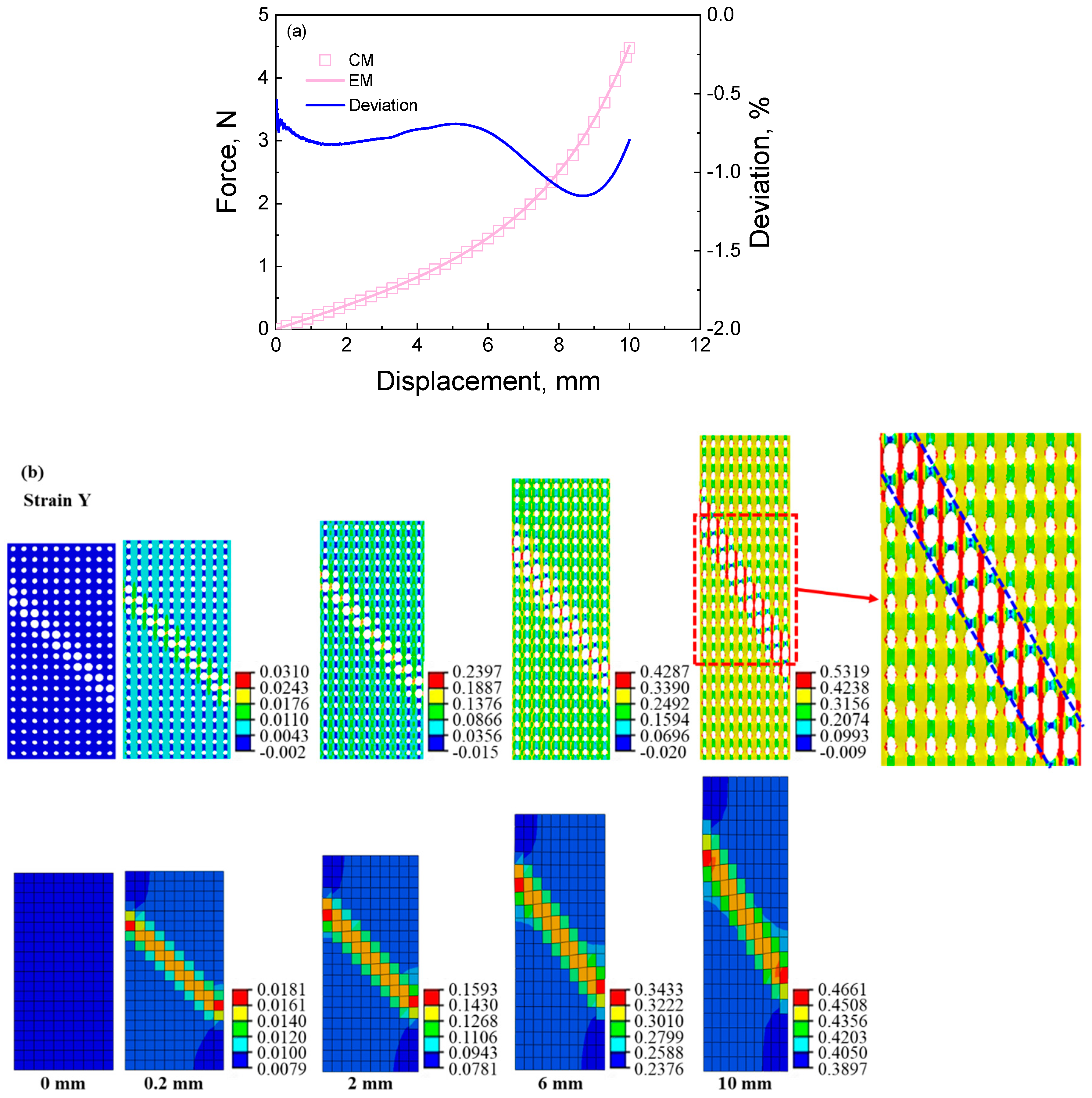

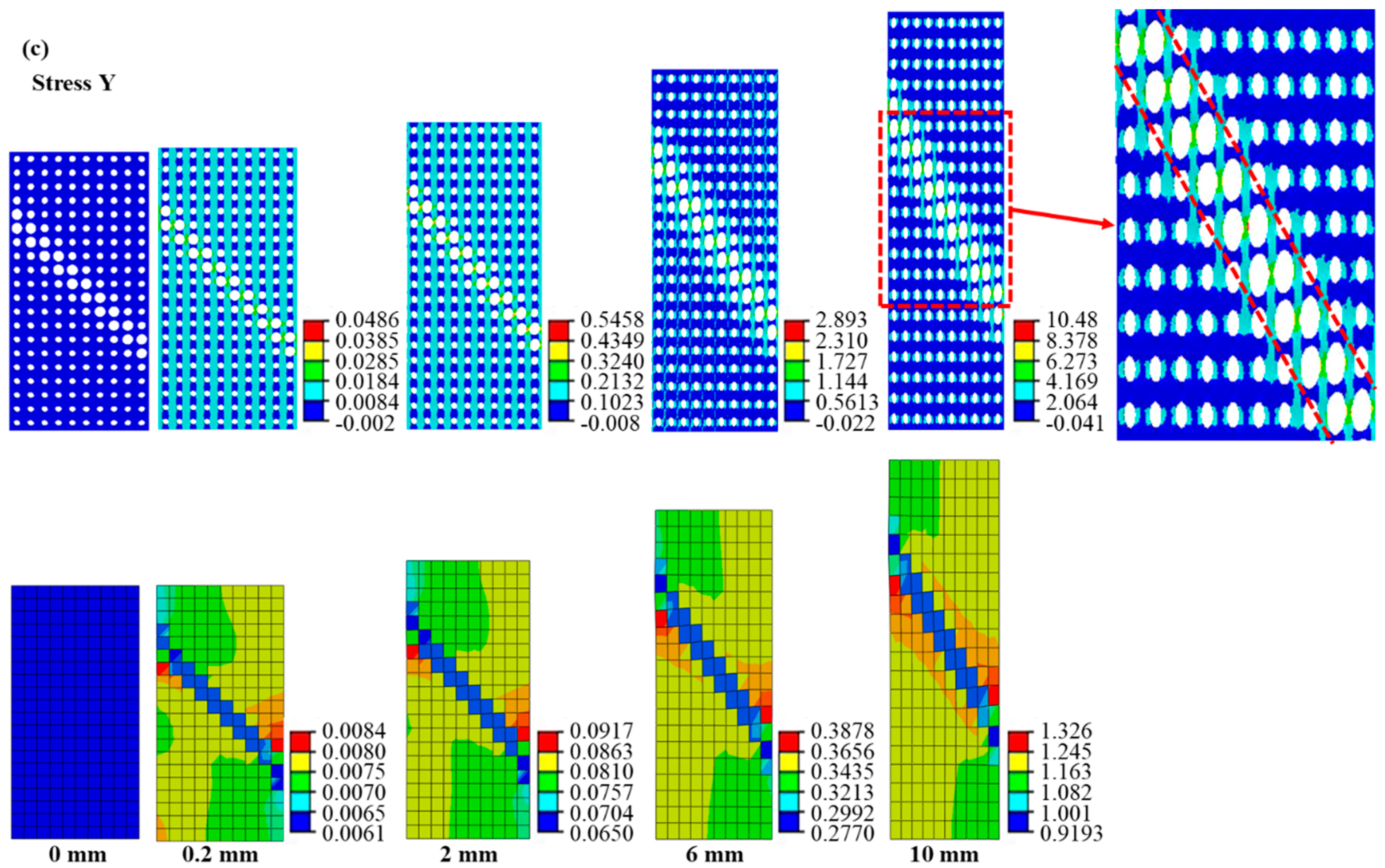

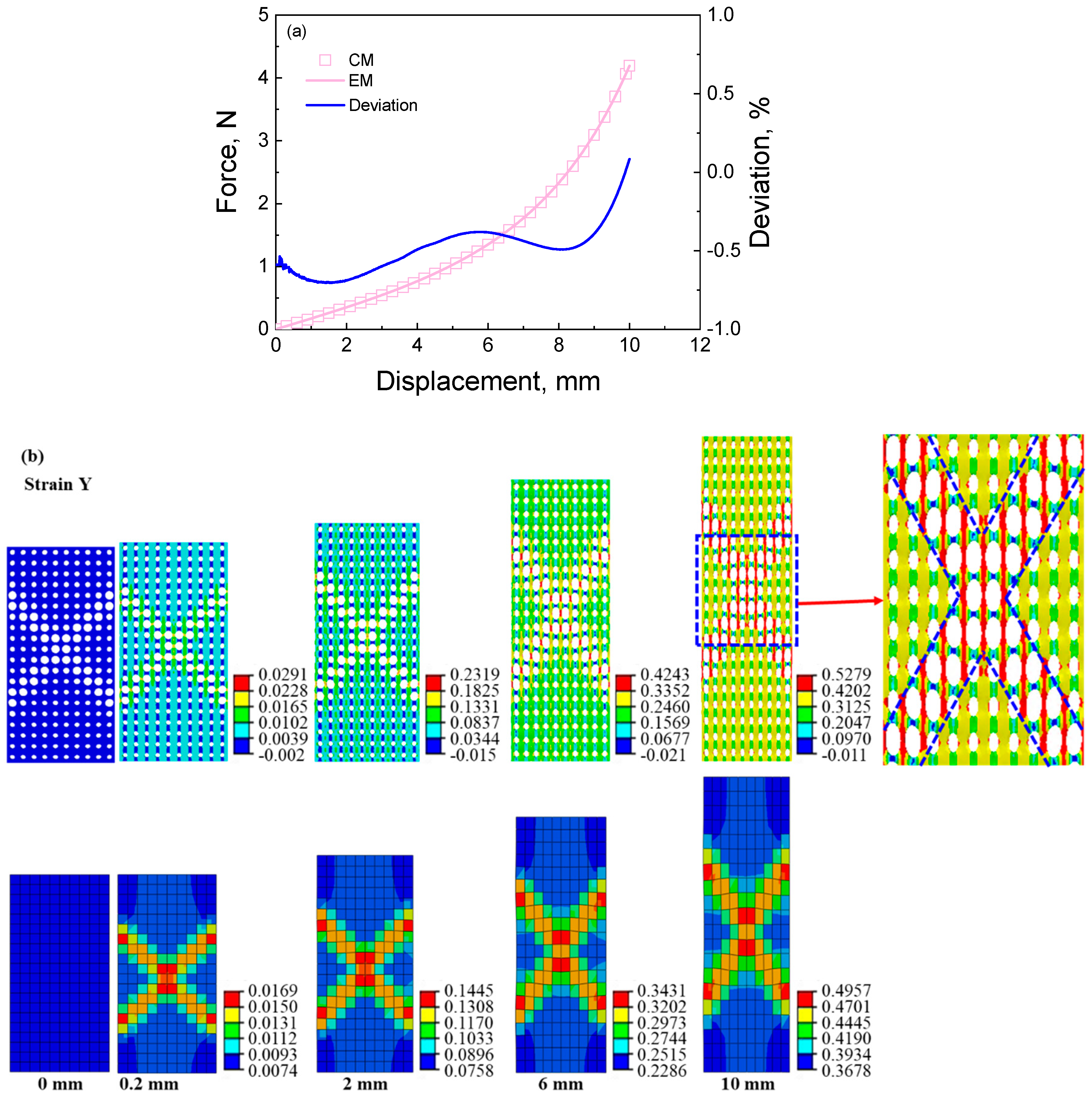

4.1. The Equivalent Computation Results for the Ordered and Random Cellular Materials

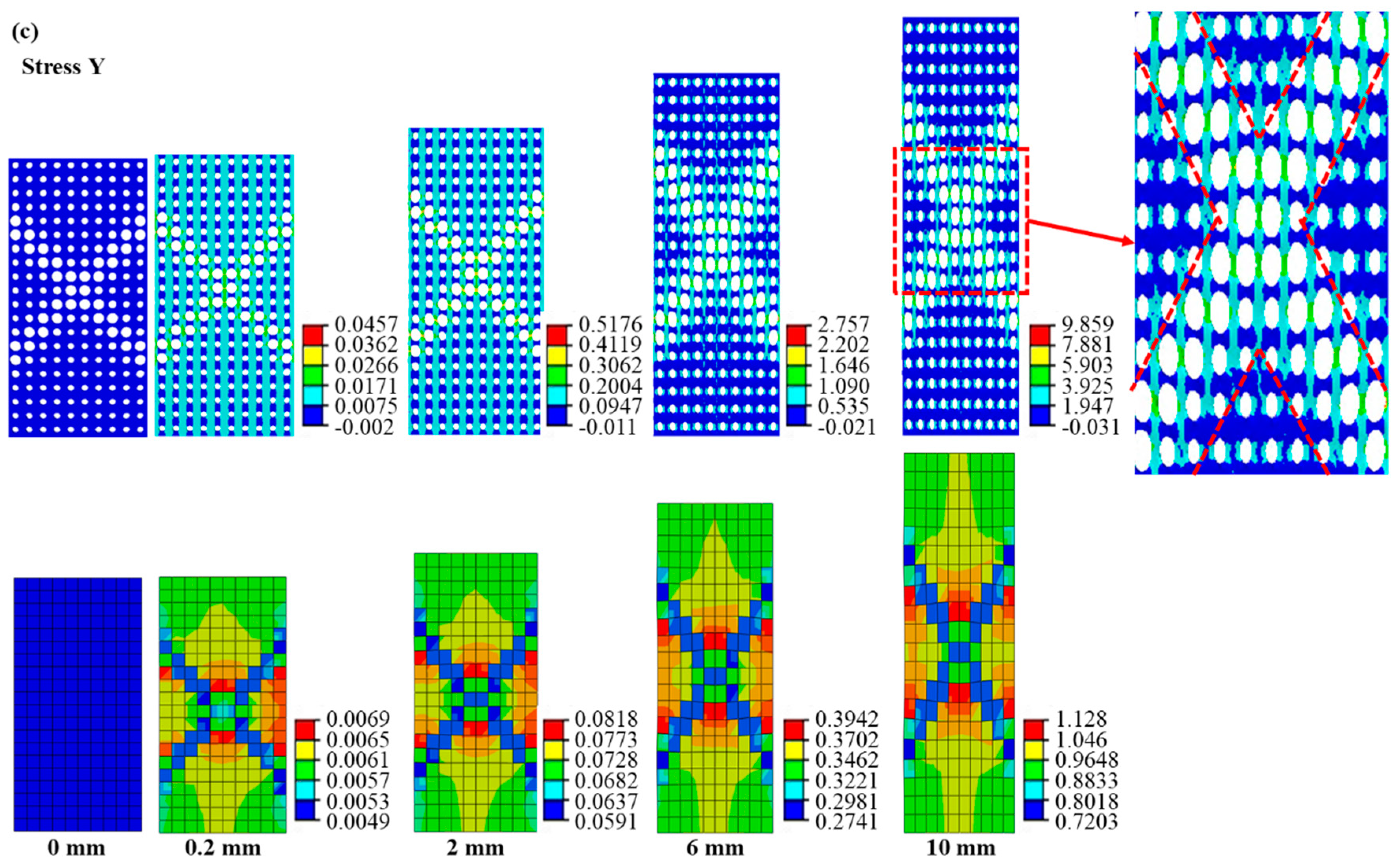

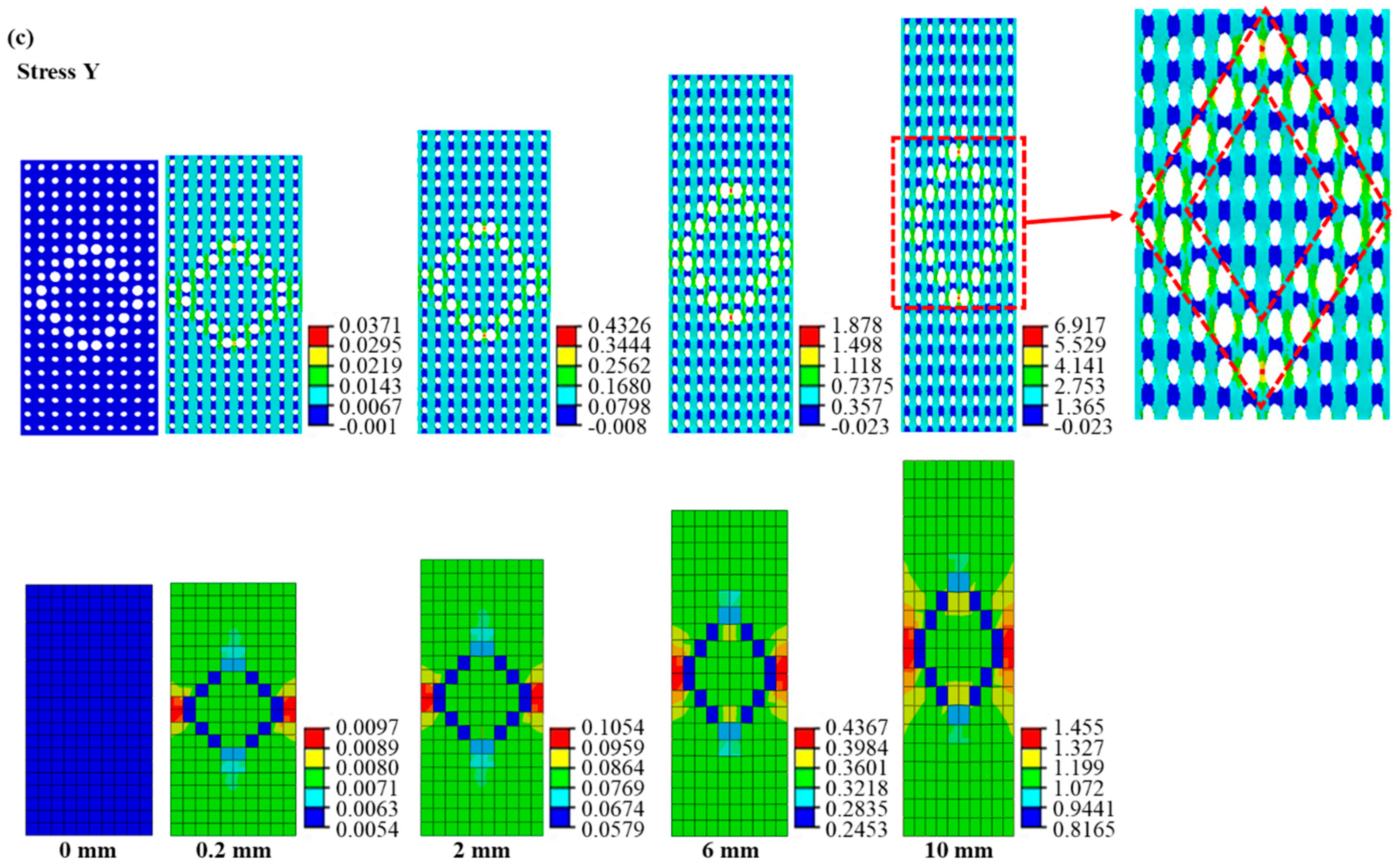

4.1.1. The Deformation Response of the Cellular and Equivalent Materials with Different Deformation Features under Axial Tension

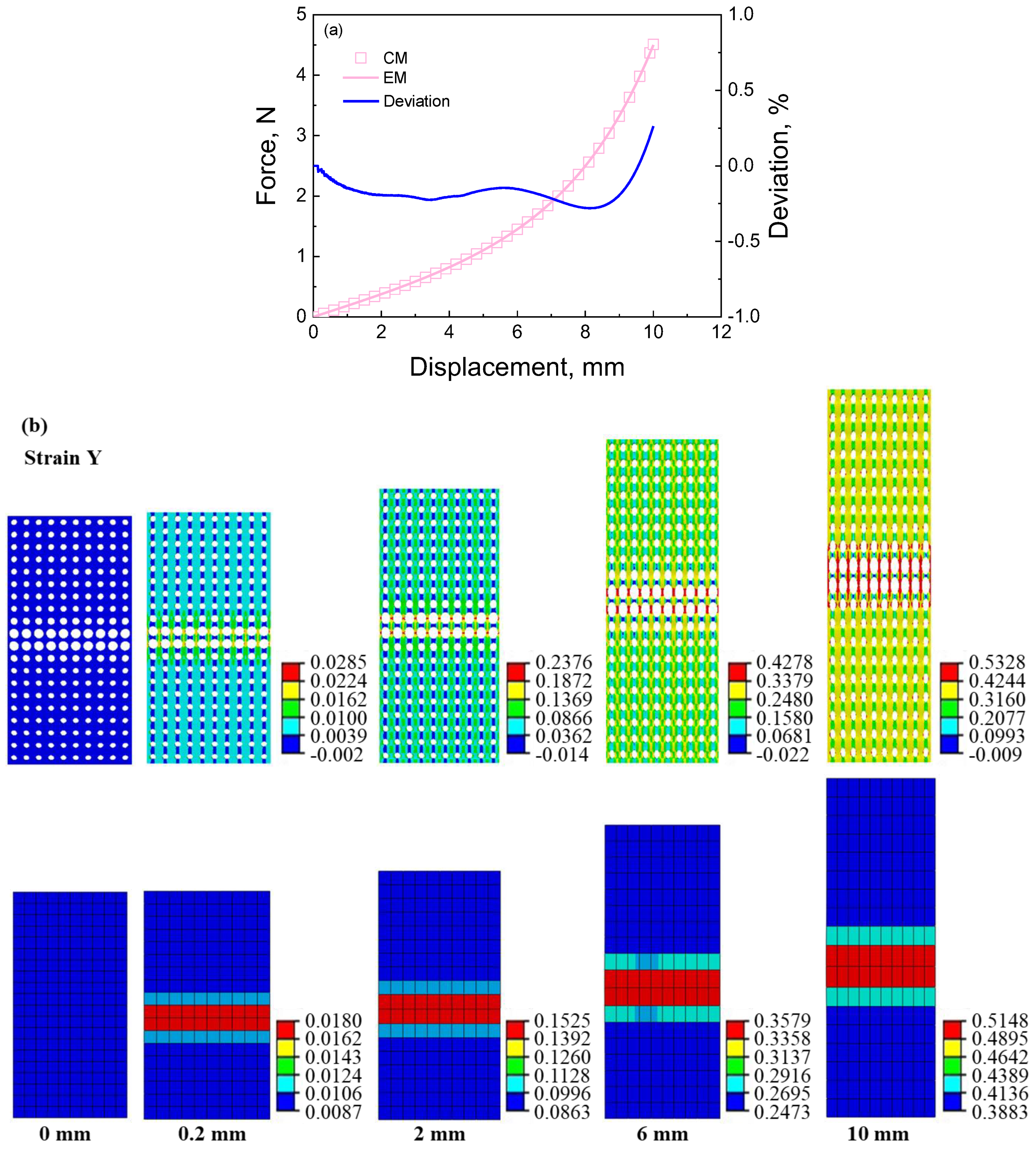

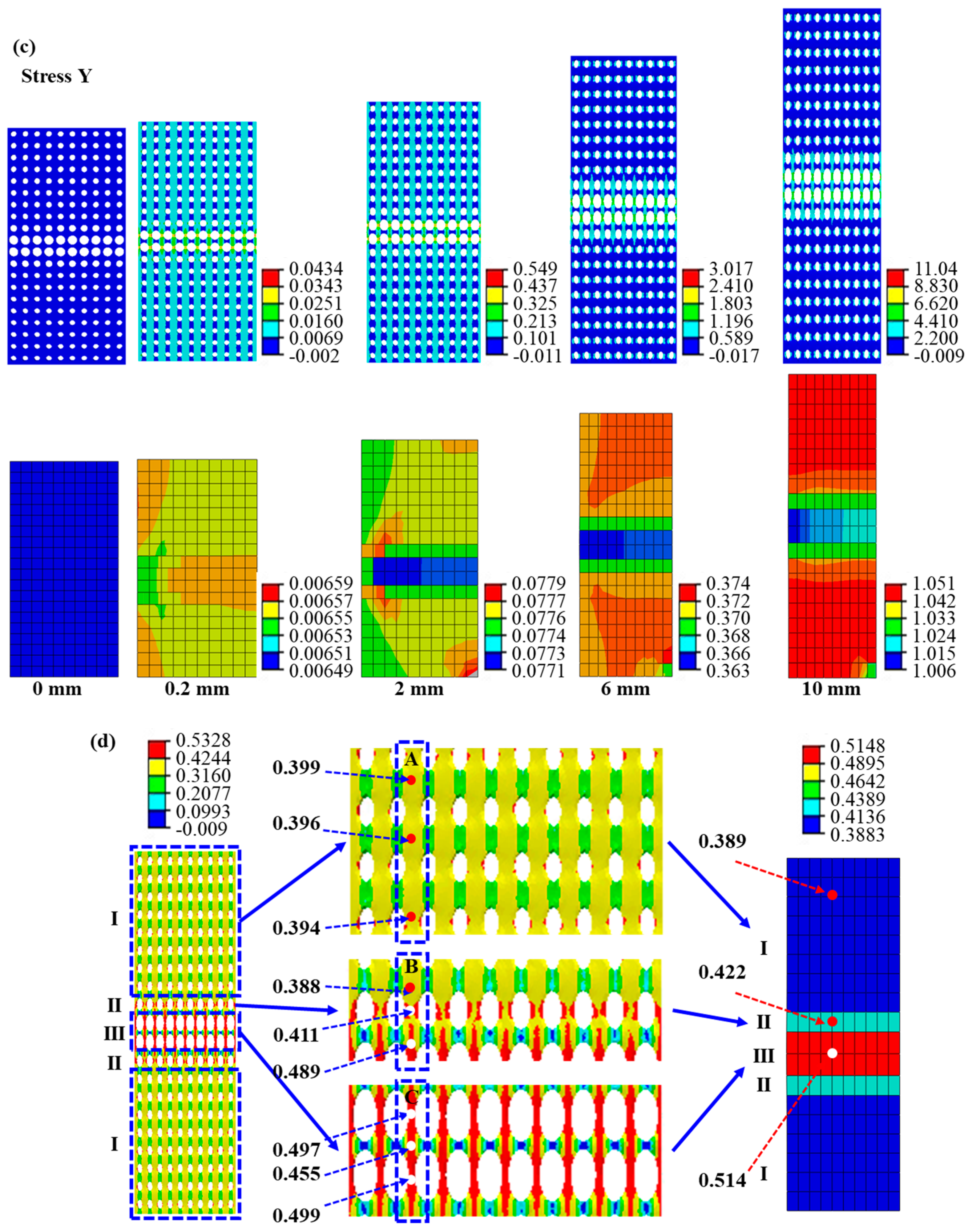

4.1.2. The Deformation Response of the Cellular and Equivalent Materials under Shearing Loading

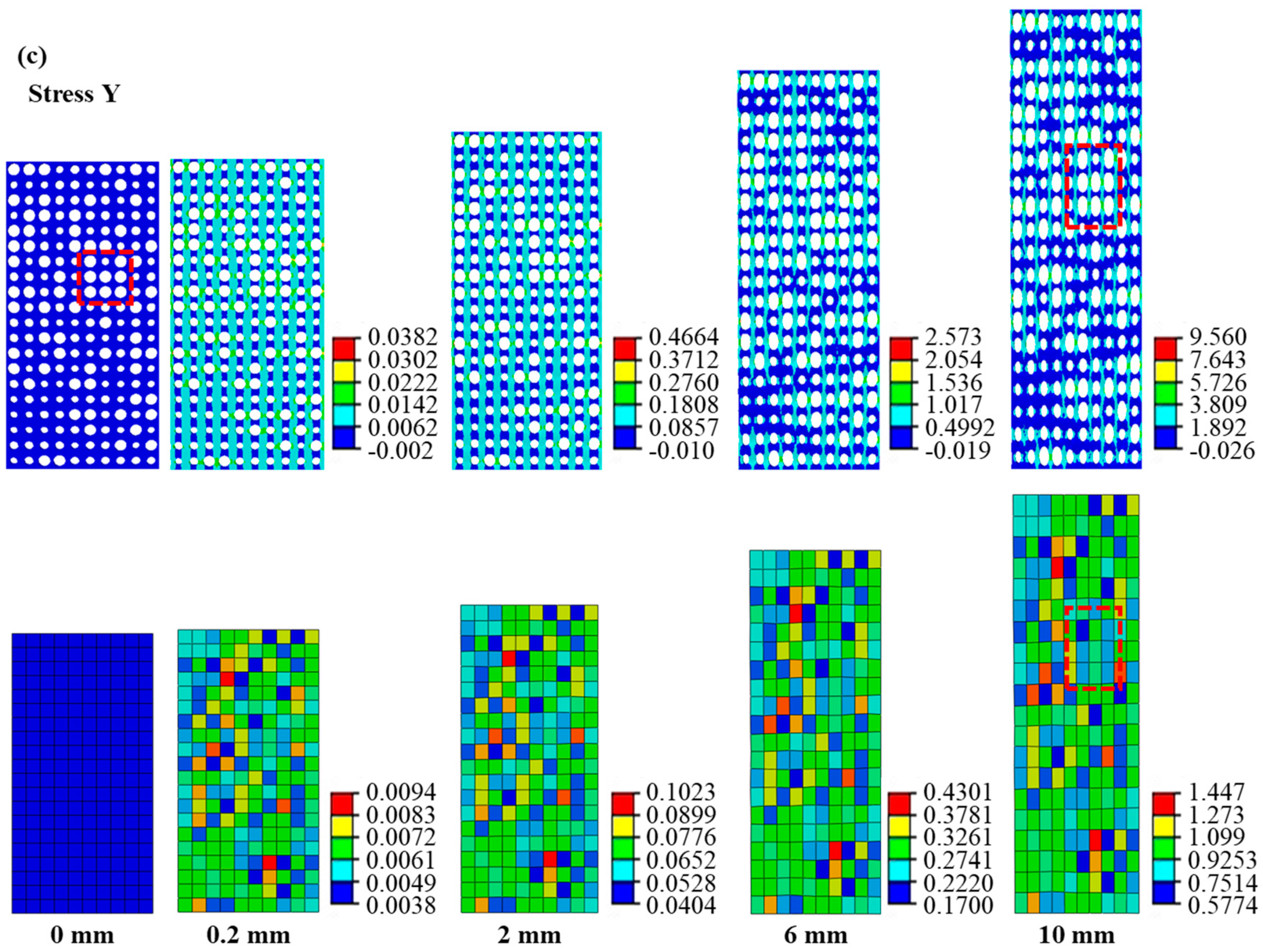

4.1.3. The Prediction for the Deformation Response of the Random Cellular Material under Axial Tension

4.1.4. The Effect of the Randomness on the Deformation Response of the Random Cellular Material under Axial Tension

4.2. The Computational Efficiency between the Cellular and Their Equivalent Materials

5. Conclusions

- (1)

- The equivalent calculation method can reasonably compute the macroscopic force-displacement curves of the random and ordered cellular materials with different deformation features. The average deviation is 1.67% when contrasting the results of the cellular materials and equivalent materials. The deviation is more pronounced in random cellular materials than ordered cellular materials due to intricate deformations arising from neighboring pores. Shearing loading produces a more noticeable deviation than tensile loading owing to the complex shearing deformation endured by pore walls.

- (2)

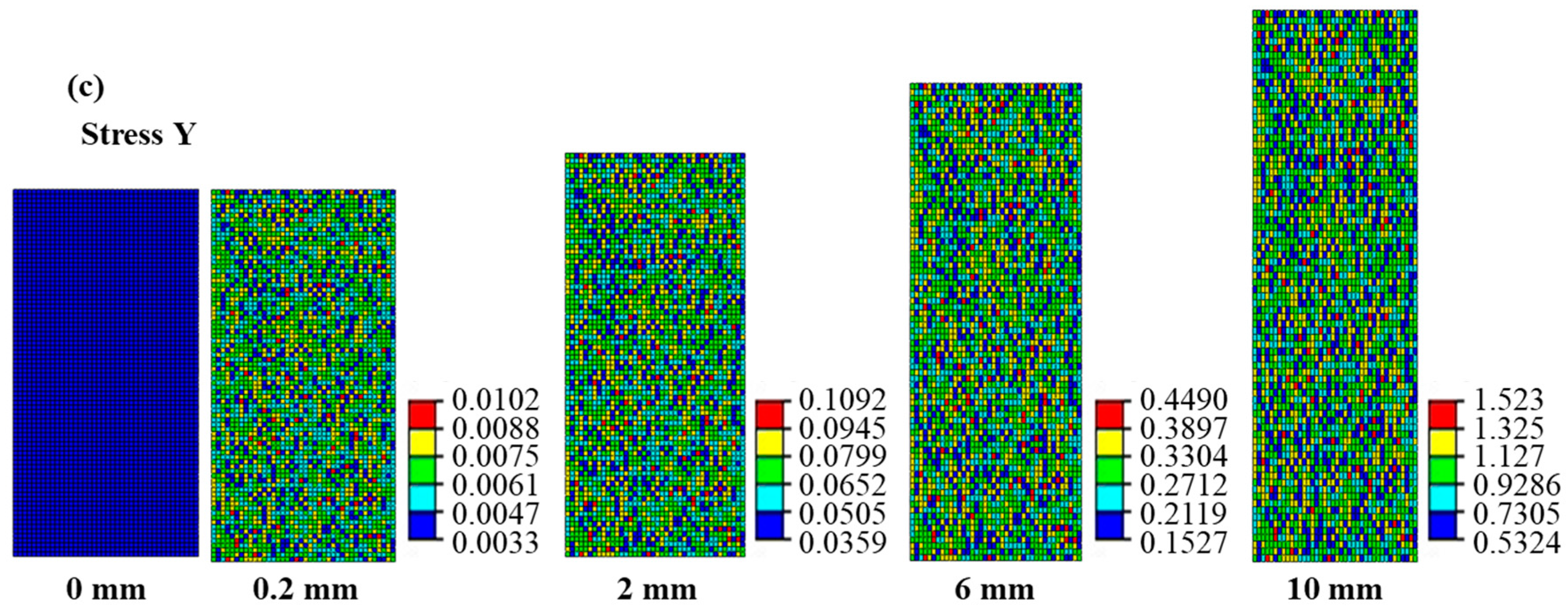

- The equivalent calculation method can reasonably describe the stress and strain distributions. Equivalent materials exhibit localized strains in regions with distinctive deformation features, with cellular material strains closely approximating their equivalent counterparts. Moreover, the equivalent material model can predict the cellular material’s stress distribution in reverse. Notably, the region of maximum stress distribution in cellular material corresponds to the minimum stress distribution in the equivalent material, a result of the smaller equivalent modulus within the deformation feature zone. Discrepancies between cellular and equivalent material contours stem from surrounding structural influences.

- (3)

- The equivalent calculation method saves huge computational burdens. Compared with the results of the cellular materials, equivalent materials showcase a substantial reduction, presenting 99.78% in element count, 99.62% in result size, and 99.78% in computation time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

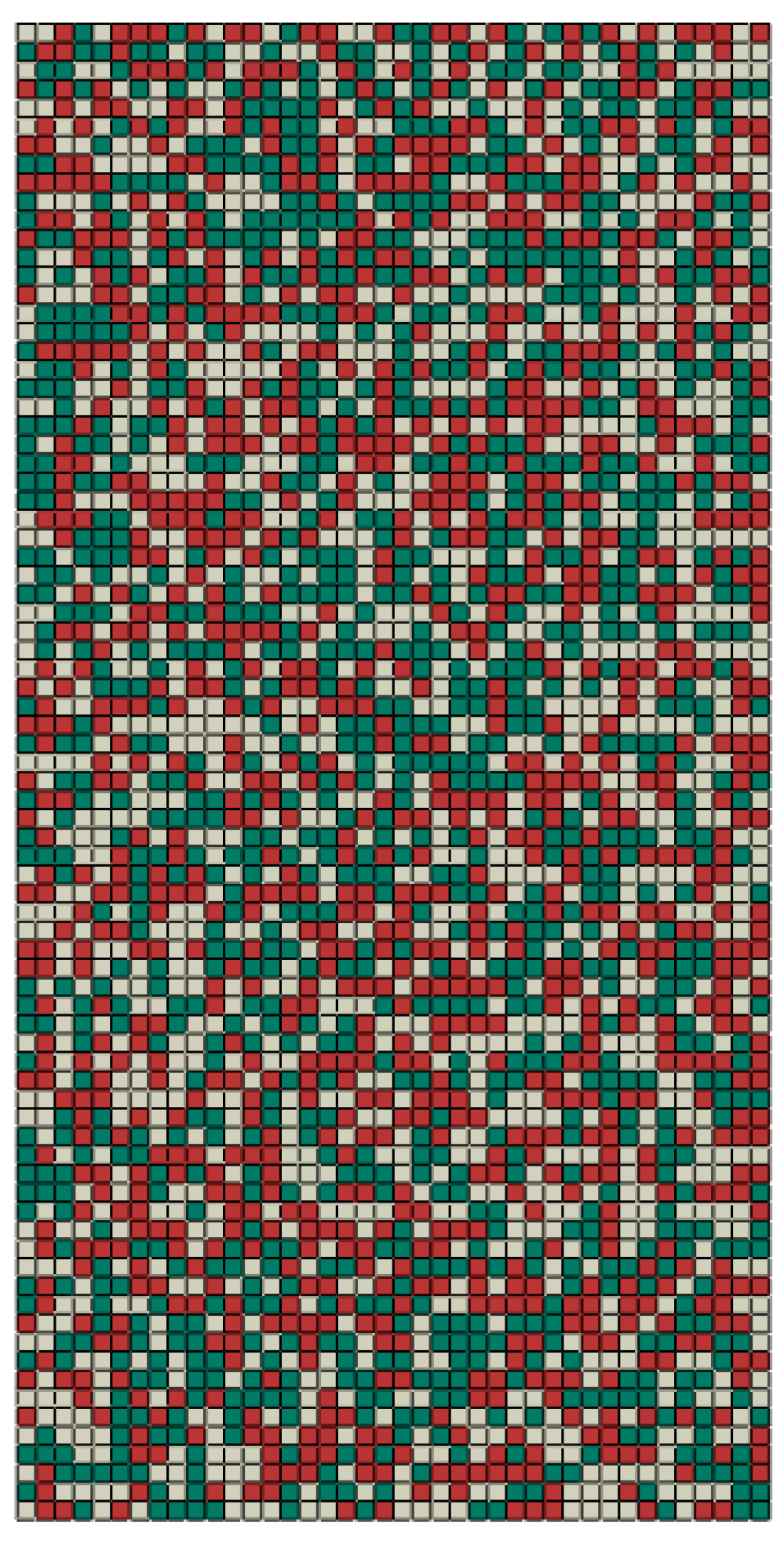

Appendix A. Python Script for Establishing the Random Equivalent Material

from abaqus import *

from abaqus Constants import *

import random

myModel = mdb.models[“Model-random”]

myPart = myModel.parts[‘Part-1’]

myElement = myPart.elements

for iter in range(len(myElement)):

randNum = random.randint(1, 3)

setName = ‘Set-{0}’.format(iter)

myPart.Set(elements=myElement[iter:iter+1], name=setName)

myPart.SectionAssignment(region=myPart.sets[setName],

sectionName=‘Section-{0}’.format(randNum), offset=0.0,

offsetType=MIDDLE_SURFACE, offsetField=”,

thicknessAssignment=FROM_SECTION)

Appendix B. The Hyperelastic Ogden Model

Appendix C. Experimental Method and Results

Appendix D. The Hyper-Foam Model

References

- Benedetti, M.; Du Plessis, A.; Ritchie, R.O.; Dallago, M.; Razavi, S.M.J.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R Rep. 2021, 144, 100606. [Google Scholar] [CrossRef]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar]

- Cai, Y.; Cui, J.; Chen, M.; Zhang, M.; Han, Y.; Qian, F.; Zhao, H.; Yang, S.; Yang, Z.; Bian, H.; et al. Multifunctional enhancement for highly stable and efficient perovskite solar cells. Adv. Funct. Mater. 2021, 31, 2005776. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Wu, L.; Mustafa, M.; Segurado, J.; Noels, L. Second-order computational homogenisation enhanced with non-uniform body forces for non-linear cellular materials and metamaterials. Comput. Methods Appl. Mech. Eng. 2023, 407, 115931. [Google Scholar] [CrossRef]

- Al-Ketan, O. Programmed plastic deformation in mathematically-designed architected cellular materials. Metals 2021, 11, 1622. [Google Scholar] [CrossRef]

- Shaker, A.; Salem, M.S.; Jayan, K.D. Analysis and design of pn homojunction Sb2Se3 solar cells by numerical simulation. Sol. Energy 2022, 242, 276–286. [Google Scholar] [CrossRef]

- Jemiolo, S.; Turteltaub, S. A parametric model for a class of foam-like isotropic hyperelastic materials. J. Appl. Mech. 2000, 67, 248–254. [Google Scholar] [CrossRef]

- Liu, Q.; Subhash, G. A phenomenological constitutive model for foams under large deformations. Polym. Eng. Sci. 2004, 44, 463–473. [Google Scholar] [CrossRef]

- Li, P.; Guo, Y.; Shim, V. A rate-sensitive constitutive model for anisotropic cellular materials—Application to a transversely isotropic polyurethane foam. Int. J. Solids Struct. 2020, 206, 43–58. [Google Scholar] [CrossRef]

- Vesenjak, M.; Fiedler, T.; Ren, Z.; Öchsner, A. Behaviour of syntactic and partial hollow sphere structures under dynamic loading. Adv. Eng. Mater. 2008, 10, 185–191. [Google Scholar] [CrossRef]

- Yang, C.; An, Y.; Tort, M.; Hodgson, P.D. Fabrication, modelling and evaluation of microstructured materials in a digital framework. Comput. Mater. Sci. 2014, 81, 89–97. [Google Scholar] [CrossRef]

- Daxner, T. Finite element modeling of cellular materials. Cell. Porous Mater. Struct. Process. 2010, 521, 47–106. [Google Scholar]

- Somnic, J.; Jo, B.W. Homogenization Methods of Lattice Materials. Encyclopedia 2022, 2, 1091–1102. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Abu Al-Rub, R.K. Multifunctional mechanical metamaterials based on triply periodic minimal surface lattices. Adv. Eng. Mater. 2019, 21, 1900524. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Effective Mechanical Properties of Additive Manufactured Strut-Lattice Structures: Experimental and Finite Element Study. Adv. Eng. Mater. 2022, 24, 2100879. [Google Scholar] [CrossRef]

- Ashok, D.; Bahubalendruni, M.V.A.R.; Mhaskar, A.; Choudhary, V.; Balamurali, G.; Turaka, S. Experimental and numerical investigation on 2.5-dimensional nature-inspired infill structures under out-plane quasi-static loading. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 09544089231197853. [Google Scholar] [CrossRef]

- Ashok, D.; Bahubalendruni, M.V.A.R. Design and Characterization of 2.5 D Nature-Inspired Infill Structures under Out-Plane Quasi-Static Loading Condition. Adv. Mater. Sci. Eng. 2023, 2023, 8918937. [Google Scholar] [CrossRef]

- Dara, A.; Bahubalendruni, M.A.; Mertens, A.J.; Balamurali, G. Numerical and experimental investigations of novel nature inspired open lattice cellular structures for enhanced stiffness and specific energy absorption. Mater. Today Commun. 2022, 31, 103286. [Google Scholar] [CrossRef]

- Huang, M.; Li, Y. X-ray tomography image-based reconstruction of microstructural finite element mesh models for heterogeneous materials. Comput. Mater. Sci. 2013, 67, 63–72. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by Selective Laser Melting. J. Mech. Phys. Solids. 2017, 107, 160–184. [Google Scholar] [CrossRef]

- Lei, H.; Li, C.; Meng, J.; Zhou, H.; Liu, Y.; Zhang, X.; Wang, P.; Fang, D. Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater. Des. 2019, 169, 107685. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Li, C.; Qi, J.; Wang, P.; Lei, H.; Fang, D. Deep learning-based X-ray computed tomography image reconstruction and prediction of compression behavior of 3D printed lattice structures. Addit. Manuf. 2022, 54, 102774. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties in metal additive manufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Abaqus Analysis User’s Guide: Theory Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2010.

- Jigh, B.H.G.; Toudeshky, H.H.; Farsi, M.A. Experimental and multi-scale analyses of open-celled aluminum foam with hole under compressive quasi-static loading. J. Alloys Compd. 2017, 695, 133–141. [Google Scholar] [CrossRef]

| Sample | Number of Elements | The Size of Computational Results (Mega Byte) | Computing Time (s) | Average Deviation | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CM | EM | ICE (%) | CM | EM | ICE (%) | CM | EM | ICE (%) | ||

| Uniform deforming feature with a diameter of 0.4 mm | 103,010 | 200 | 99.81 | 6492.16 | 22 | 99.66 | 8718 | 17.5 | 99.80 | 0.0035% |

| Uniform deforming feature with a diameter of 0.6 mm | 97,845 | 200 | 99.80 | 6215.68 | 22 | 99.65 | 8274.7 | 17.6 | 99.79 | 0.0024% |

| Uniform deforming feature with a diameter of 0.8 mm | 64,465 | 200 | 99.69 | 4229.12 | 22 | 99.48 | 4735.3 | 17.4 | 99.63 | 0.00015% |

| Stretching feature | 99,630 | 200 | 99.80 | 6266.88 | 22 | 99.65 | 8534 | 17.2 | 99.80 | 0.170% |

| Shearing feature | 93,105 | 200 | 99.76 | 5898.24 | 22 | 99.63 | 8076 | 16.9 | 99.79 | 0.851% |

| Double shearing feature | 94,740 | 200 | 99.79 | 6010.88 | 22 | 99.63 | 8153 | 16.9 | 99.79 | 0.489% |

| Circular deforming feature | 98,725 | 200 | 99.80 | 6236.16 | 22 | 99.65 | 8423 | 17.7 | 99.79 | 0.458% |

| Double shearing feature under shearing loading | 94,740 | 200 | 99.79 | 6010.88 | 22.1 | 99.63 | 10,902 | 17.2 | 99.84 | 8.316% |

| Random deforming feature | 88,540 | 200 | 99.77 | 5601.28 | 22 | 99.61 | 10,166 | 17.3 | 99.83 | 4.74% |

| μ1/MPa | μ2/MPa | μ3/MPa | a1 | a2 | a3 | K/MPa |

|---|---|---|---|---|---|---|

| 0.43 | 0.011 | −0.015 | 4.55 | 16.54 | −7.22 | 332.72 |

| μ1/MPa | μ2/MPa | μ3/MPa | a1 | a2 | a3 | β1/MPa | |

|---|---|---|---|---|---|---|---|

| ① | −1.244 | 1.249 | 0.130 | 14.448 | 14.454 | 4.866 | −980.116 |

| ② | −2.148 | 1.945 | 0431 | 10.762 | 10.994 | 6.914 | −110.087 |

| ③ | −2.577 | 2.334 | 0.519 | 10.772 | 11.004 | 6.923 | −57.183 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhao, J.; Kan, Q.; Tian, Y.; Yu, L.; Peng, Y.; Huang, X. A Novel Equivalent Method for Computing Mechanical Properties of Random and Ordered Hyperelastic Cellular Materials. Materials 2023, 16, 6990. https://doi.org/10.3390/ma16216990

Li J, Zhao J, Kan Q, Tian Y, Yu L, Peng Y, Huang X. A Novel Equivalent Method for Computing Mechanical Properties of Random and Ordered Hyperelastic Cellular Materials. Materials. 2023; 16(21):6990. https://doi.org/10.3390/ma16216990

Chicago/Turabian StyleLi, Jian, Jianfeng Zhao, Qianhua Kan, Yuyu Tian, Li Yu, Yunqiang Peng, and Xicheng Huang. 2023. "A Novel Equivalent Method for Computing Mechanical Properties of Random and Ordered Hyperelastic Cellular Materials" Materials 16, no. 21: 6990. https://doi.org/10.3390/ma16216990

APA StyleLi, J., Zhao, J., Kan, Q., Tian, Y., Yu, L., Peng, Y., & Huang, X. (2023). A Novel Equivalent Method for Computing Mechanical Properties of Random and Ordered Hyperelastic Cellular Materials. Materials, 16(21), 6990. https://doi.org/10.3390/ma16216990