Possibilities of Rock Processing with a High-Pressure Abrasive Waterjet with an Aspect Terms to Minimizing Energy Consumption

Abstract

1. Introduction

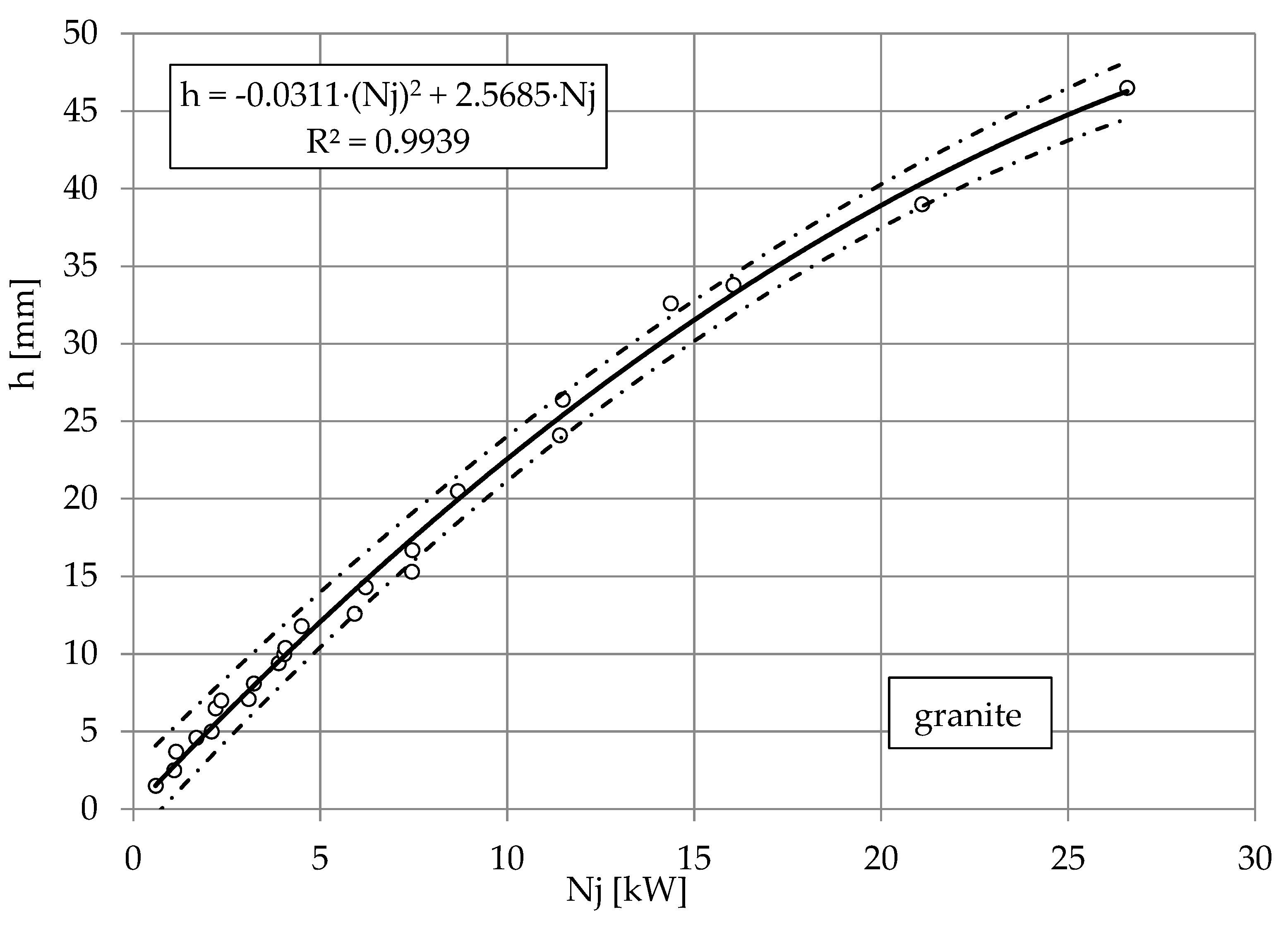

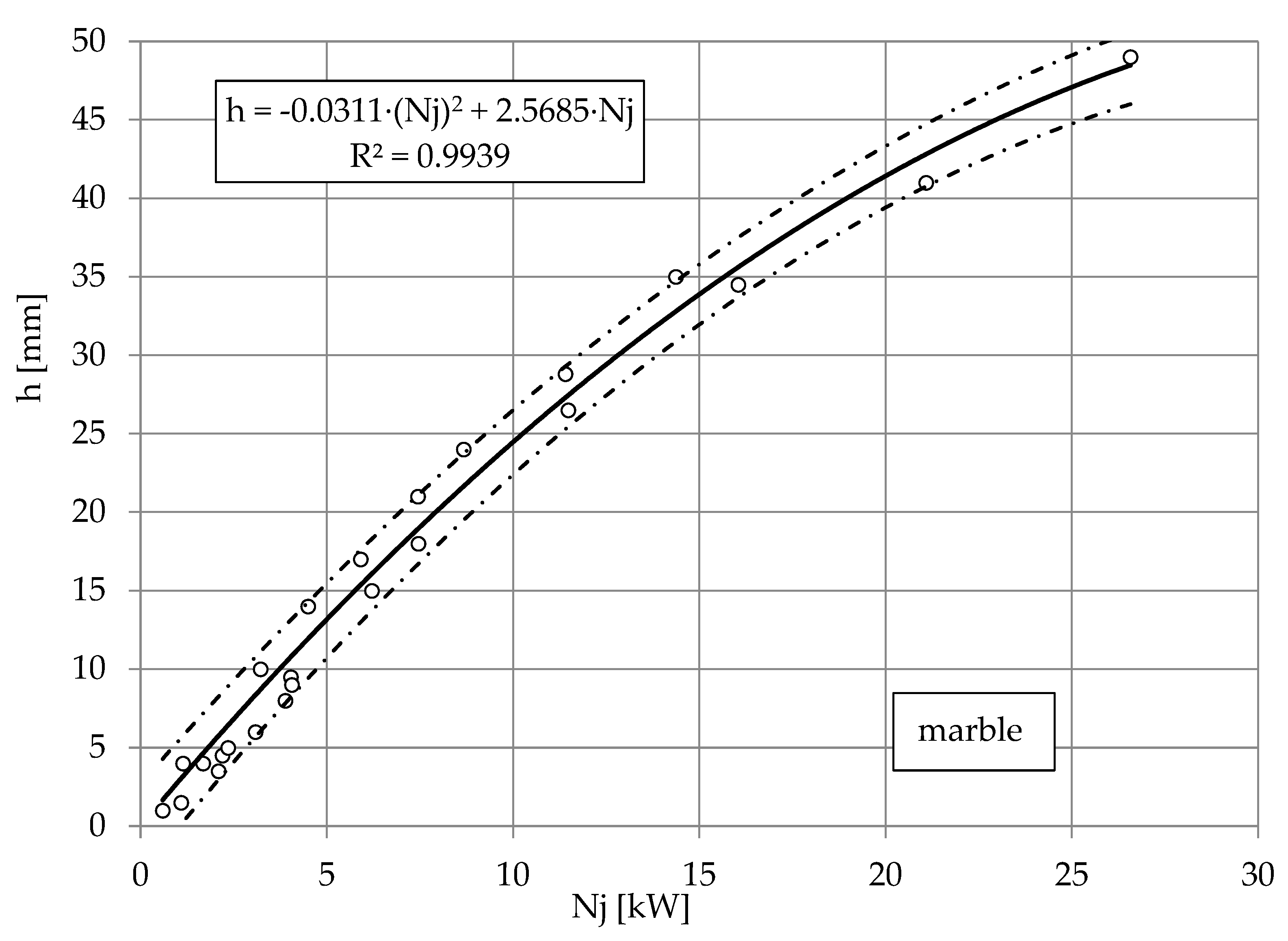

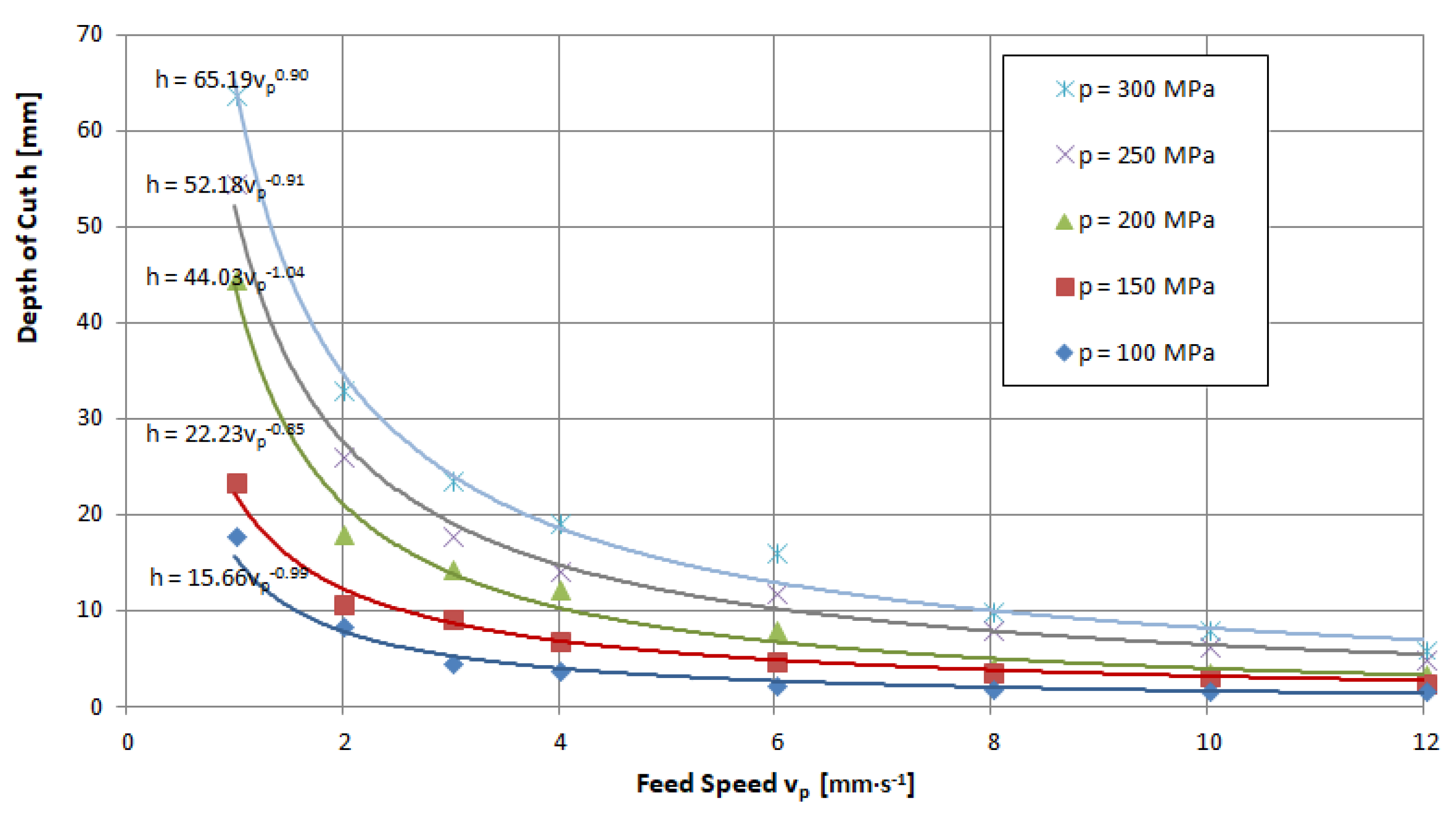

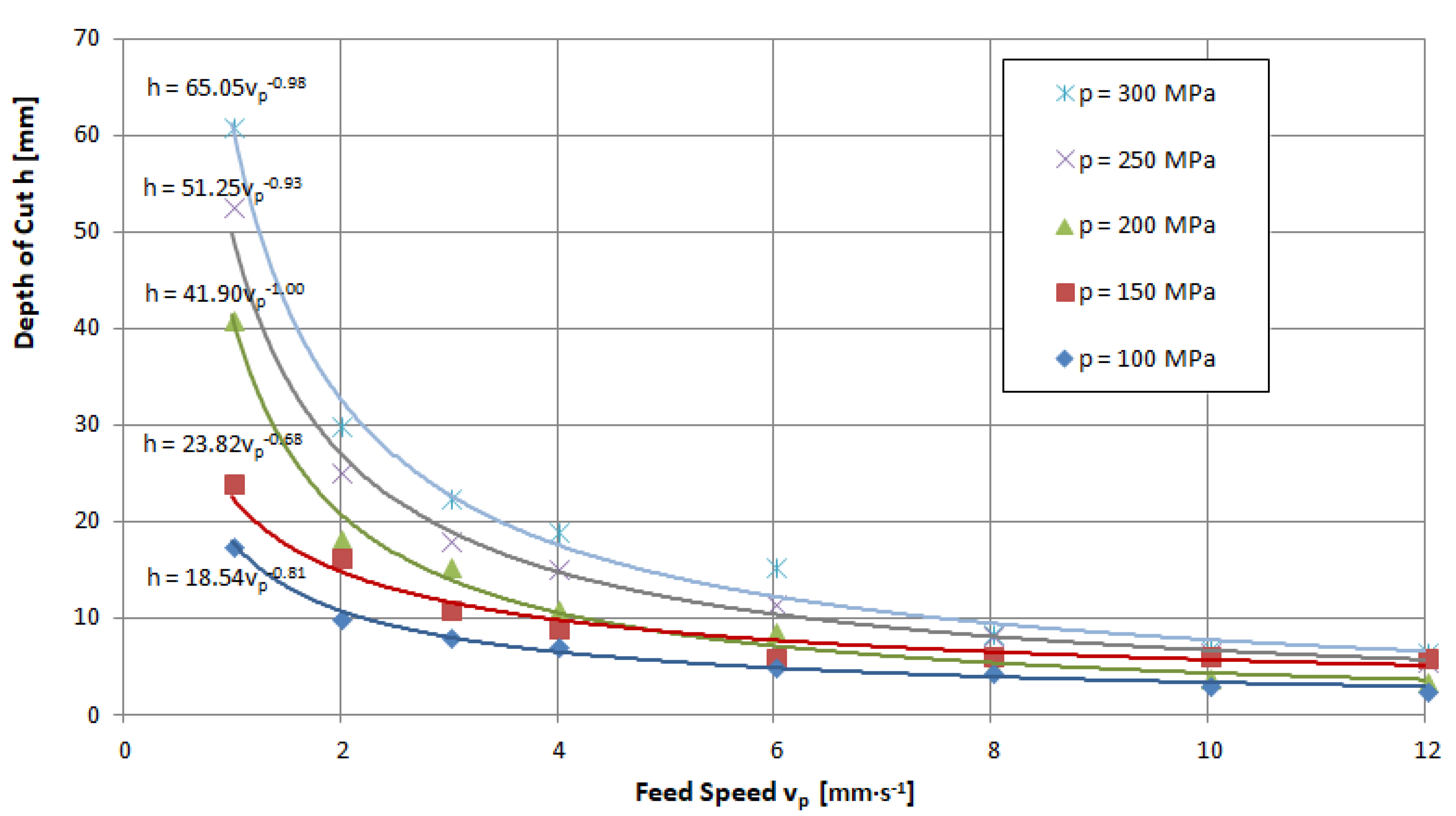

2. Materials and Methods

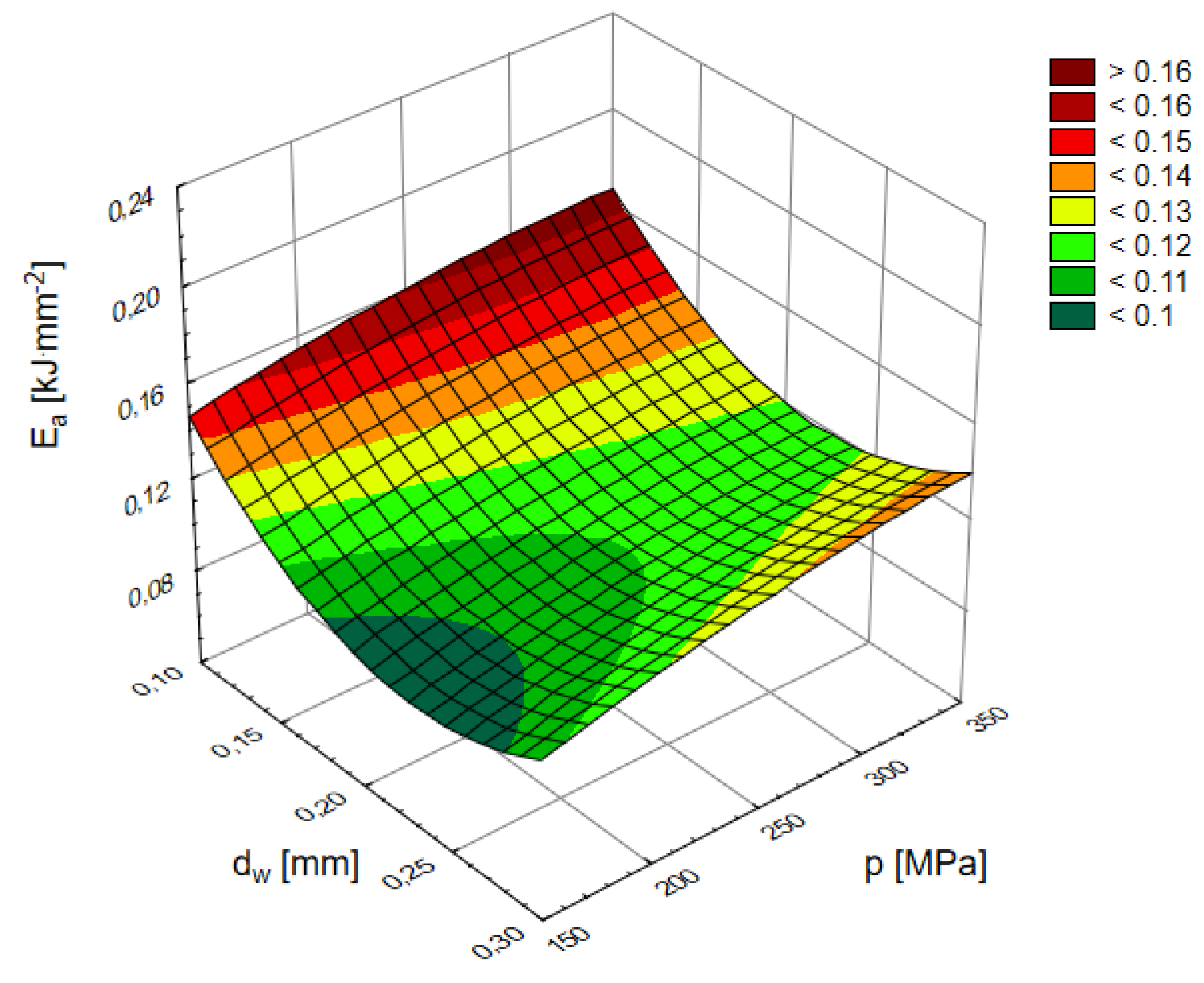

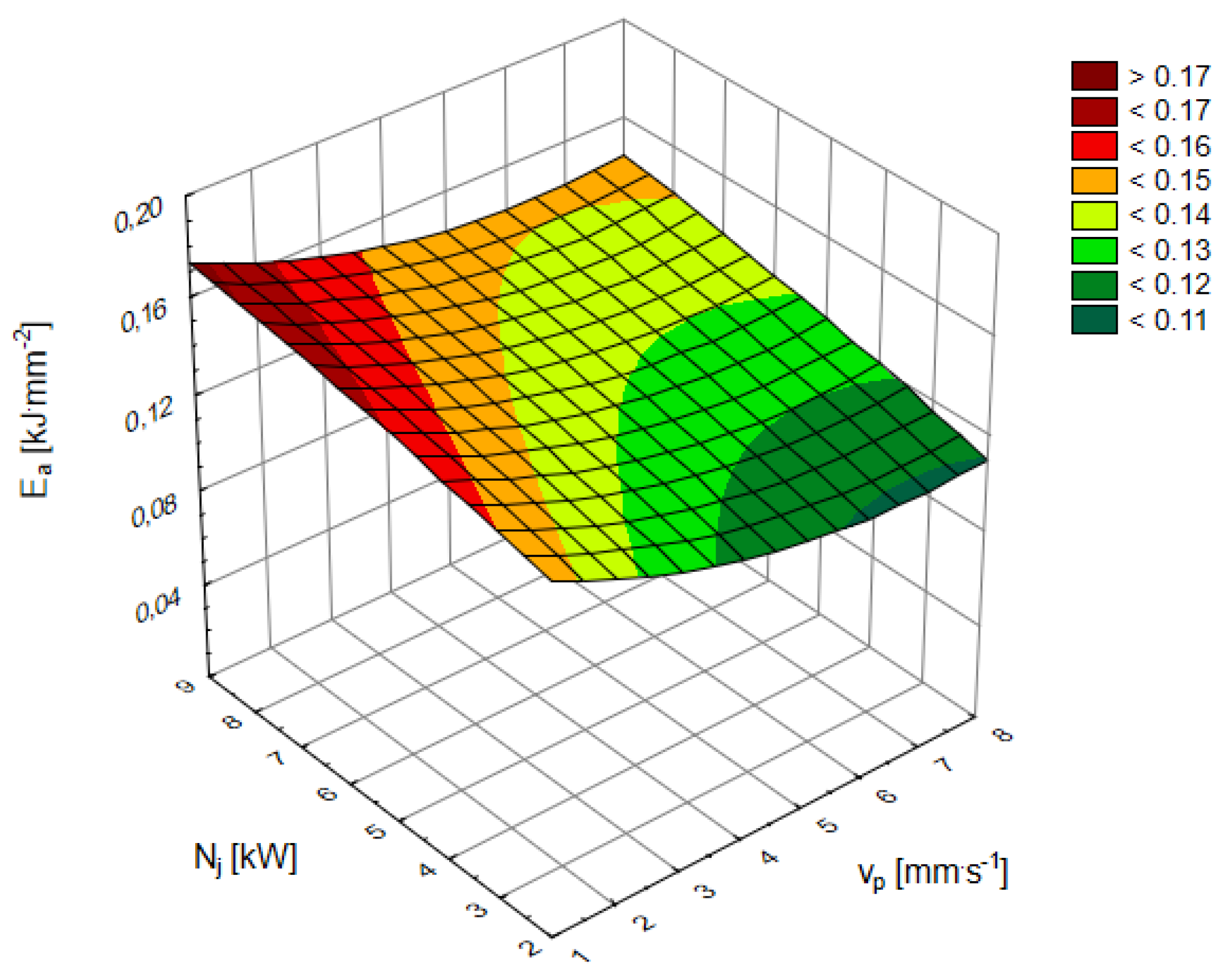

2.1. Cutting Efficiency

- –

- specific energy (Ev, kJ·mm−3) is dependent on the volume of the groove, which, with the decreasing depth of the cut, increases with multiple cuts or a large distance of the nozzle from the workpiece,

- –

- machining efficiency index does not take into account the temporal parameters of the process by which its comparison requires results obtained at a constant feed speed,

- –

- the specific energy of cutting Er, kJ·mm−1 may vary depending on the length of cuts or their duration,

- –

- the specific energy of intersection Ea, kJ·mm−2 by capturing energy as a relationship between the power of the jet and the feed speed, eliminates the above disadvantages and fully captures the time-energy aspects of machining.

2.2. Materials

- –

- specific density -ϱ = 2.65 Mg·m−3,

- –

- compressive strength -Rc =160–170 MPa,

- –

- abrasiveness in Deval’s drum -MDE = 1.7–5.5%

- –

- Mohs hardness -MH = 6–7.

- –

- specific density -ϱ = 2.75 Mg·m−3,

- –

- compressive strength -Rc =92–125 MPa,

- –

- abrasiveness in Deval’s drum -MDE = 4.3–23.5%

- –

- Mohs hardness -MH = max. 3.

- –

- specific density -ϱ = approx. 2.72 Mg·m−3,

- –

- compressive strength -Rc =52–58 MPa,

- –

- abrasiveness in Deval’s drum -MDE = 2.7–7.5%

- –

- Mohs hardness -MH = 3.

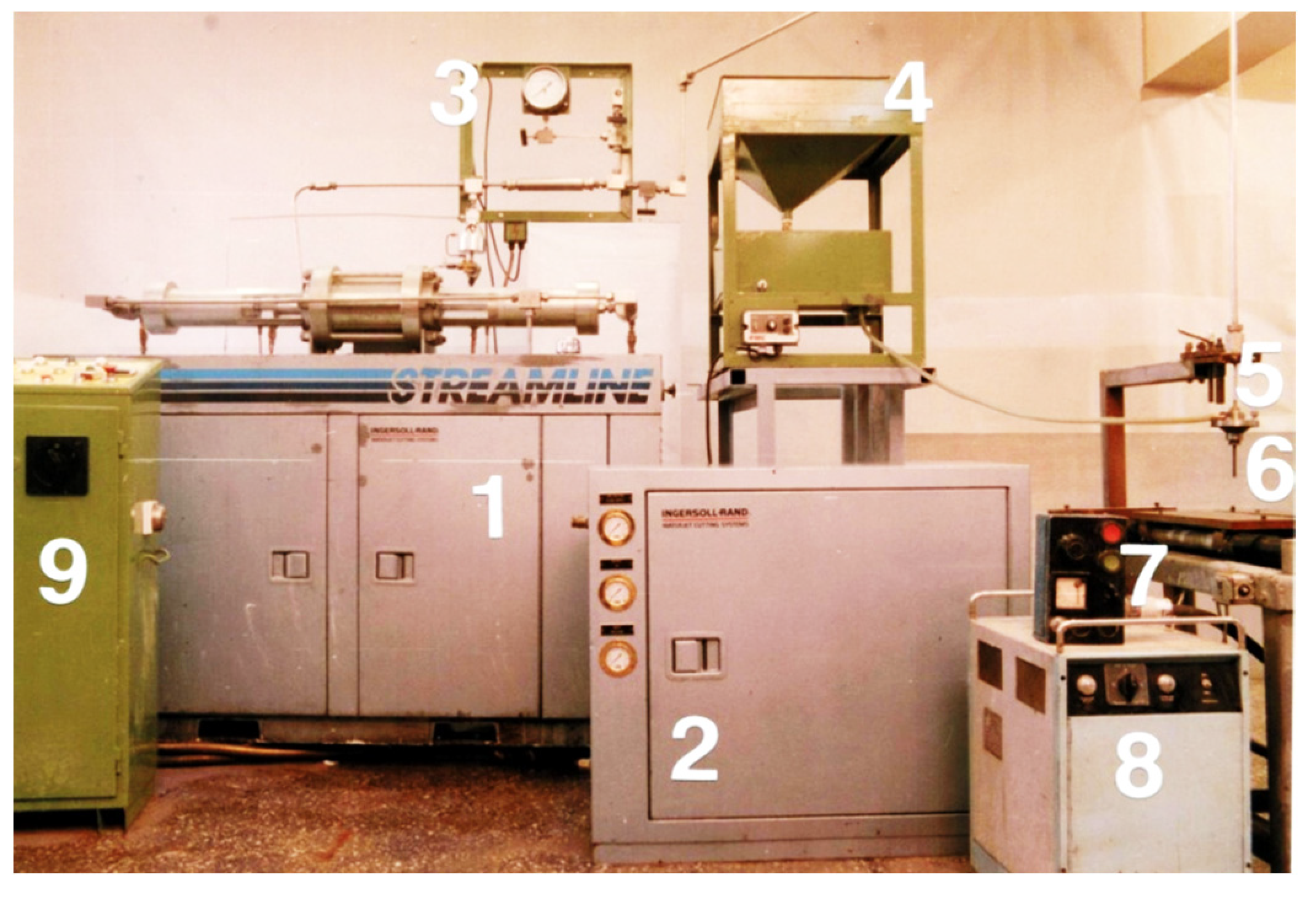

2.3. Methods and Test Rig

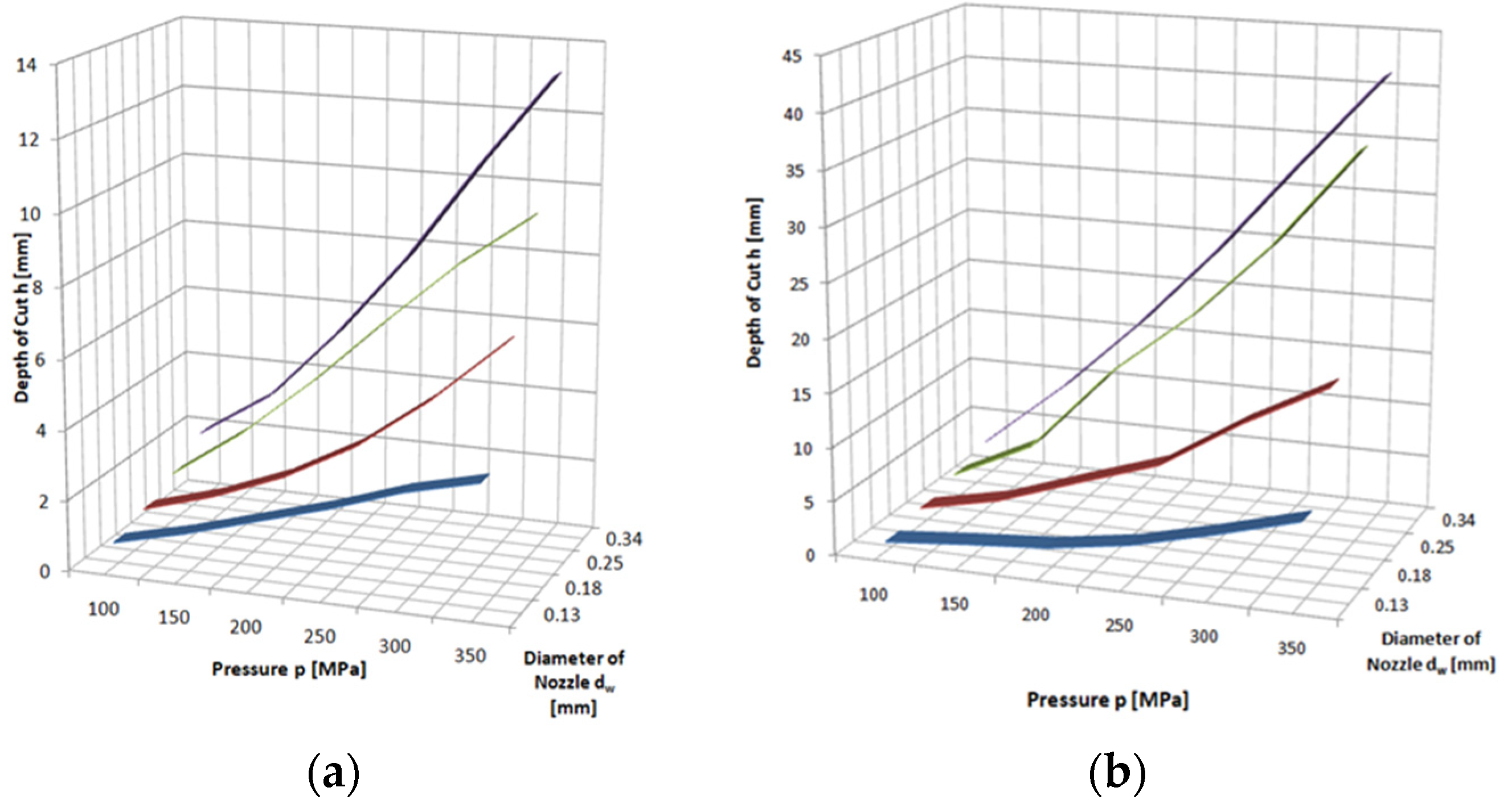

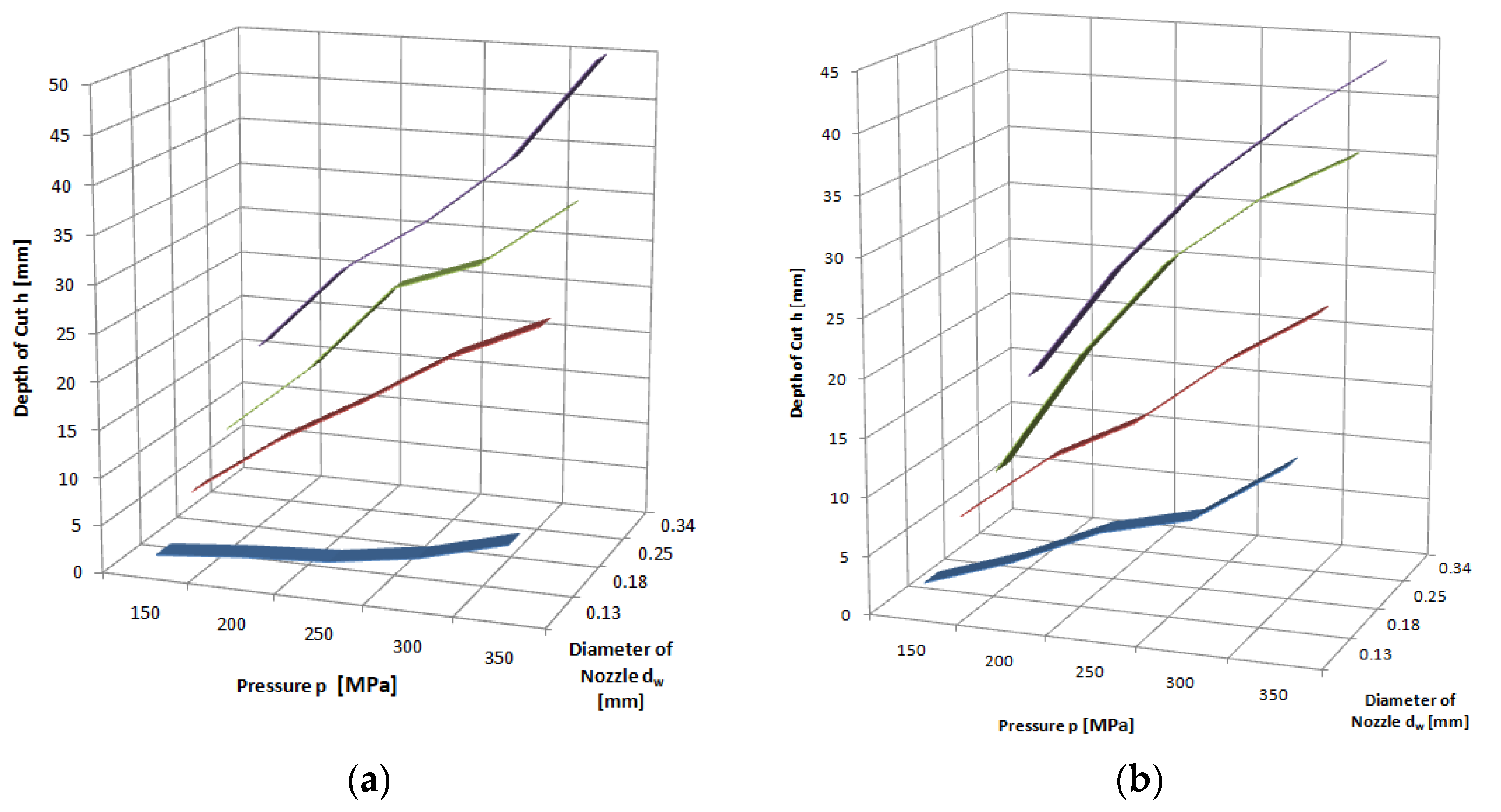

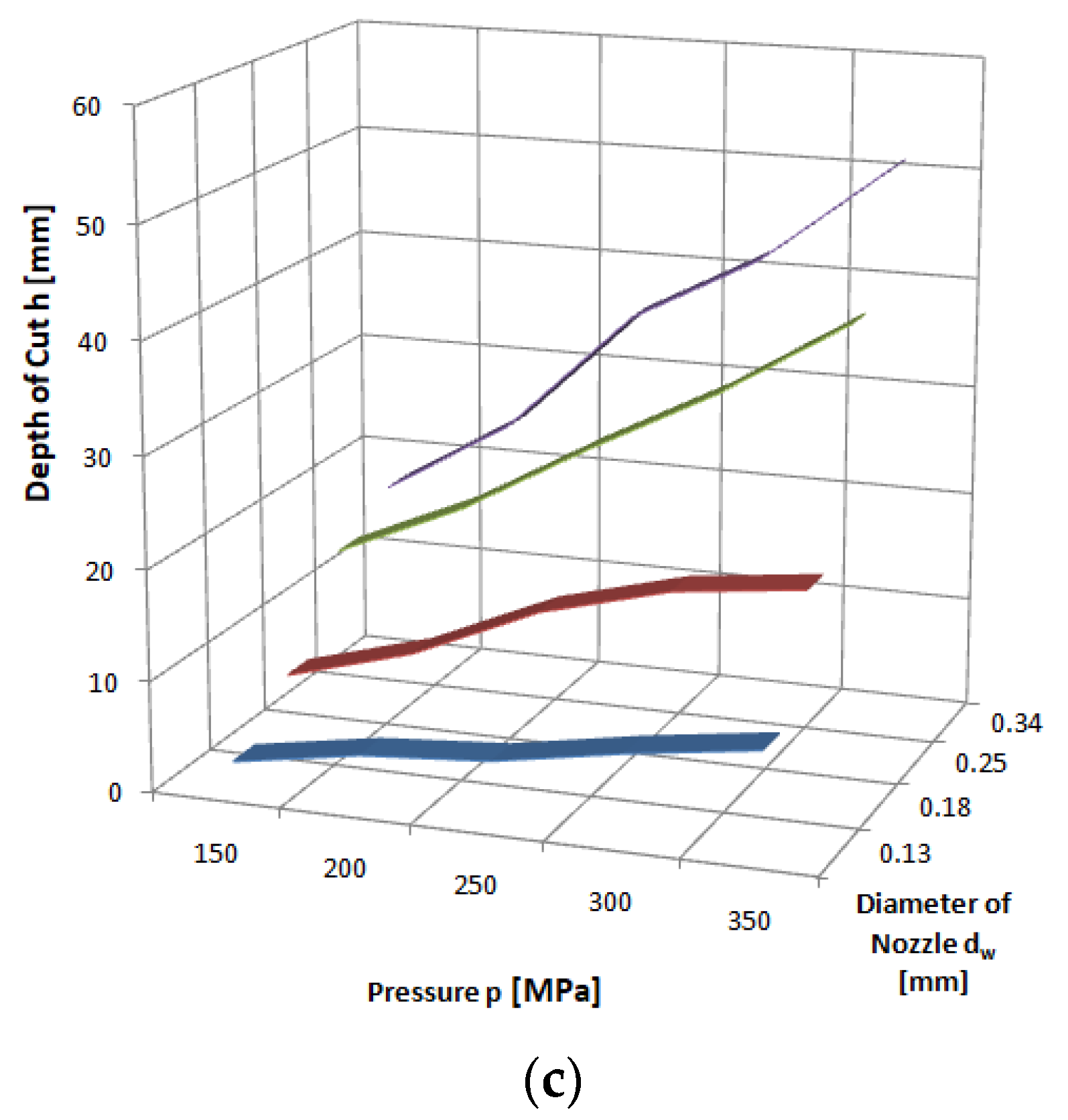

3. Results and Discussion

- Determination of variability range of the studied parameters.

- Choice of the class of the mathematical model.

- Coding the analyzed parameters.

- Gathering the experiment results.

- Elimination of results with gross mistakes.

- Calculating the inter-row variance and standard deviation.

- Checking the homogeneity of variance.

- Calculating the coefficients of regression function.

- Statistical analysis of the regression function.

- Examination of the significance level of the correlation coefficient.

- Checking the adequacy of the mathematical model.

- Decoding the regression function.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oertel, J.; Gaab, M.R.; Warzok, R.; Piek, J. Waterjet dissection in the brain: Review of the experimental and clinical data with special reference to meningioma surgery. Neurosurg. Rev. 2003, 26, 168–174. [Google Scholar] [CrossRef] [PubMed]

- Hreha, P.; Hloch, S.; Magurova, D.; Valicek, J.; Kozak, D.; Harnicarova, M.; Rakin, M. Water jet technology used in medicine. Tehnicki Vjesnik. 2010, 17, 237–240. [Google Scholar]

- Alitavoli, M.; McGeough, J.A. An expert process planning system for meat cutting by high pressure water-jet. J. Mater. Process. Technol. 1998, 84, 130–135. [Google Scholar] [CrossRef]

- Sitek, L.; Bodnárová, L.; Válek, J.; Zeleňák, M.; Klich, J.; Foldyna, J.; Novotný, M. Effects of Water Jet on Heat-Affected Concretes. Procedia Eng. 2013, 57, 1036–1044. [Google Scholar] [CrossRef]

- Kasperowicz, M.; Chomka, G.; Chudy, J. Determining the supply pressure depending on the feed speed and the diameter of the nozzle. Carpathian J. Food Sci. Technol. 2018, 10, 17–23. [Google Scholar]

- Kasperowicz, M.; Chomka, G.; Bil, T. Determination of supply pressure during cutting fish using high-pressure water stream taking into account the place and diameter of the water nozzle. DEGRUYTER Cutting. Int. J. Food Eng. 2019, 16. [Google Scholar] [CrossRef]

- McGeough, J.A. Cutting of food products by iceparticles in a water-jet. Procedia CIRP 2016, 42, 863–865. [Google Scholar] [CrossRef]

- Deo, A.; Bagal, D.K.; Pattanaik, A.K.; Panda, S.N.; Barua, A.; Barkey, R.K.; Jeet, S. Recent advancements in ice jet machining process as an alternative of AWJM. Mater. Today Proc. 2022, 50, 981–985. [Google Scholar] [CrossRef]

- Gupta, K.; Avvari, M.; Mashamba, A.; Mallaiah, M. Ice Jet Machining: A Sustainable Variant of Abrasive Water Jet Machining. In Sustainable Machining; Springer: Cham, Switzerland, 2017; pp. 67–78. [Google Scholar]

- Huang, F.; Mi, J.; Li, D.; Wang, R.; Zhao, Z. Comparative investigation of the damage of coal subjected to pure water jets, ice abrasive water jets and conventional abrasive water jets. Powder Technol. 2021, 394, 909–925. [Google Scholar] [CrossRef]

- Spur, G.; Uhlmann, E.; Elbing, F. Dry-ice blasting for cleaning: Process, optimization and application. Wear 1999, 233–235, 402–411. [Google Scholar] [CrossRef]

- Chomka, G.; Chudy, J. Analysis and interpretation of measurements of surface machining effectiveness in the process of varnish removal by a water-ice jet. Teh. Tech. Gaz. 2013, 20, 847–852. [Google Scholar]

- Valíček, J.; Harničárová, M.; Hlavatý, I.; Grznárik, R.; Kušnerová, M.; Hutyrová, Z.; Panda, A. A new approach for the determination of technological parameters for hydroabrasive cutting of materials. Mater. Werkst. 2016, 47, 462–471. [Google Scholar] [CrossRef]

- Nag, A.; Ščučka, J.; Hlaváček, P.; Klichová, D.; Srivastava, A.K.; Hloch, S.; Dixit, A.R.; Foldyna, J.; Zelenak, M. Hybrid aluminium matrix composite AWJ turning using olivine and Barton garnet. Int. J. Adv. Manuf. Technol. 2017, 94, 2293–2300. [Google Scholar] [CrossRef]

- Martín, C.G.; Lauand, C.; Hennies, W.; Ciccu, R. Abrasives in Water Jet Cutting Systems; Informa UK Limited: London, UK, 2018; pp. 641–645. [Google Scholar]

- Perec, A.; Pude, F.; Grigoryev, A.; Kaufeld, M.; Wegener, K. A study of wear on focusing tubes exposed to corundum-based abrasives in the waterjet cutting process. Int. J. Adv. Manuf. Technol. 2019, 104, 2415–2427. [Google Scholar] [CrossRef]

- Chomka, G.; Chodór, J.; Kukiełka, L.; Kasperowicz, M. The Use of a High-Pressure Water-Ice Jet for Removing Worn Paint Coating in Renovation Process. Materials 2022, 15, 1168. [Google Scholar] [CrossRef]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Boud, F.; Carpenter, C.; Folkes, J.; Shipway, P.H. Abrasive waterjet cutting of a titanium alloy: The influence of abrasive morphology and mechanical properties on workpiece grit embedment and cut quality. J. Mater. Process. Technol. 2010, 210, 2197–2205. [Google Scholar] [CrossRef]

- Kong, M.C.; Axinte, D. Response of titanium aluminide alloy to abrasive waterjet cutting: Geometrical accuracy and surface integrity issues versus process parameters. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 19–42. [Google Scholar] [CrossRef]

- Patel, D.; Tandon, P. Experimental investigations of thermally enhanced abrasive water jet machining of hard-to-machine metals. CIRP J. Manuf. Sci. Technol. 2015, 10, 92–101. [Google Scholar] [CrossRef]

- Meshcheryakov, A.V.; Shulepov, A.P. Productivity of abrasive water-jet machining. Russ. Engin. Res. 2017, 37, 747–750. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Kawecka, E. Efficiency of Tool Steel Cutting by Water Jet with Recycled Abrasive Materials. Materials 2022, 15, 3978. [Google Scholar] [CrossRef] [PubMed]

- Supriya, S.B.; Srinivas, S. Machinability Studies on Stainless steel by abrasive water jet -Review. Mater. Today Proc. 2018, 5, 2871–2876. [Google Scholar] [CrossRef]

- Löschner, P.; Jarosz, K.; Niesłony, P. Investigation of the effect of cutting speed on surface quality in abrasive water jet cutting of 316L stainless steel. Procedia Eng. 2016, 149, 276–282. [Google Scholar] [CrossRef]

- Akkurt, A.; Kulekci, M.K.; Seker, U.; Ercan, F. Effect of feed rate on surface roughness in abrasive waterjet cutting applications. J. Mater. Process. Technol. 2004, 147, 389–396. [Google Scholar] [CrossRef]

- Kmec, J.; Gombár, M.; Harničárová, M.; Valíček, J.; Kušnerová, M.; Kříž, J.; Kadnár, M.; Karková, M.; Vagaská, A. The Predictive Model of Surface Texture Generated by Abrasive Water Jet for Austenitic Steels. Appl. Sci. 2020, 10, 3159. [Google Scholar] [CrossRef]

- Llanto, J.M.; Tolouei-Rad, M.; Vafadar, A.; Aamir, M. Impacts of Traverse Speed and Material Thickness on Abrasive Waterjet Contour Cutting of Austenitic Stainless Steel AISI 304L. Appl. Sci. 2021, 11, 4925. [Google Scholar] [CrossRef]

- Ahmed, T.M.; Mesalamy, A.S.E.; Youssef, A.; Midany, T.T. El, Improving surface roughness of abrasive waterjet cutting process by using statistical modeling. CIRP J. Manuf. Sci. Technol. 2018, 22, 30–36. [Google Scholar] [CrossRef]

- Jegaraj, J.J.R.; Babu, N.R. A soft computing approach for controlling the quality of cut with abrasive waterjet cutting system experiencing orifice and focusing tube wear. J. Mater. Process. Technol. 2007, 185, 217–227. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Kumar, M.P. Cutting of aluminium alloy with abrasive water jet and cryogenic assisted abrasive water jet: A comparative study of the surface integrity approach. Wear 2016, 362, 18–32. [Google Scholar] [CrossRef]

- Wang, S.; Hu, D.; Yang, F.; Lin, P. Research on Kerf error of aluminum alloy 6061-T6 cut by abrasive water jet. Int. J. Adv. Manuf. Technol. 2022, 118, 2513–2521. [Google Scholar] [CrossRef]

- Wang, S.; Hu, D.; Yang, F.; Lin, P. Investigation on kerf taper in abrasive waterjet machining of aluminium alloy 6061-T6. J. Mater. Res. Technol. 2021, 15, 427–433. [Google Scholar] [CrossRef]

- Hlaváček, P.; Valíček, J.; Hloch, S.; Greger, M.; Foldyna, J.; Ivandić, Ž.; Zeleńák, M. Measurement of fine grain copper surface texture created by abrasive water jet cutting. Stroj. Časopis Za Teor. I Praksu U Stroj. 2009, 51, 273–279. [Google Scholar]

- Spadło, S.; Krajcarz, D. Study of the geometrical structure of copper surface after abrasive waterjet cutting. IOP Conf. Series Mater. Sci. Eng. 2018, 461, 012045. [Google Scholar] [CrossRef]

- Wang, J.; Guo, D.M. A predictive depth of penetration model for abrasive waterjet cutting of polymer matrix composites. J. Mater. Process. Technol. 2002, 121, 390–394. [Google Scholar] [CrossRef]

- Ramulu, M.; Arola, D. The influence of abrasive waterjet cutting conditions on the surface quality of graphite/epoxy laminates. Int. J. Mach. Tools Manuf. 1994, 34, 295–313. [Google Scholar] [CrossRef]

- Hashish, M. Machining of Advanced Composites with Abrasive-Waterjets. In Proceedings of the ASME Winter Annual Meeting, Chicago, IL, USA, 16 December 1998. [Google Scholar]

- Bañon, F.; Sambruno, A.; Batista, M.; Bartolome, S.; Jorge, S. Study of the surface quality of carbon fiber–reinforced thermoplastic matrix composite (CFRTP) machined by abrasive water jet (AWJM). Int. J. Adv. Manuf. Technol. 2020, 107, 3299–3313. [Google Scholar] [CrossRef]

- Sutowska, M.; Łukianowicz, C.; Szada-Borzyszkowska, M. Sequential Smoothing Treatment of Glass Workpieces Cut by Abrasive Water Jet. Materials 2022, 15, 6894. [Google Scholar] [CrossRef]

- Sutowska, M.; Kapłonek, W.; Pimenov, D.Y.; Gupta, M.K.; Mia, M.; Sharma, S. Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials 2020, 13, 4277. [Google Scholar] [CrossRef]

- Hashish, M.; Whalen, J. Precision Drilling of Ceramic-Coated Components With Abrasive-Waterjets. ASME. J. Eng. Gas Turbines Power 1993, 115, 148–154. [Google Scholar] [CrossRef]

- Aydin, G.; Kaya, S.; Karakurt, I. Utilization of solid-cutting waste of granite as an alternative abrasive in abrasive waterjet cutting of marble. J. Clean. Prod. 2017, 159, 241–247. [Google Scholar] [CrossRef]

- Karakurt, I.; Aydin, G.; Aydiner, K. An experimental study on the depth of cut of granite in abrasive waterjet cutting. Mater. Manuf. Process. 2012, 27, 538–544. [Google Scholar] [CrossRef]

- Barabas, S.; Florescu, A. Reduction of Cracks in Marble Appeared at Hydro-Abrasive Jet Cutting Using Taguchi Method. Materials 2022, 15, 486. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.Z.; Hou, R.G.; Wang, J.; Feng, Y.X. The effect of high pressure abrasive water jet cutting parameters on cutting performance of granite. In Key Engineering Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2006; Volume 304, pp. 560–564. [Google Scholar]

- Aydin, G. Recycling of abrasives in abrasive water jet cutting with different types of granite. Arab. J. Geosci. 2014, 7, 4425–4435. [Google Scholar] [CrossRef]

- Perec, A. Research into the disintegration of abrasive materials in the abrasive water jet machining process. Materials 2021, 14, 3940. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A. Experimental Research into Marble Cutting by Abrasive Water Jet. Facta Univ. Series: Mech. Eng. 2022, 20, 145–156. [Google Scholar] [CrossRef]

- Perec, A. Investigation of Limestone Cutting Efficiency by the Abrasive Water Suspension Jet. In Advances in Manufacturing Engineering and Materials; Hloch, S., Klichová, D., Krolczyk, G.M., Chattopadhyaya, S., Ruppenthalová, L., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 124–134. ISBN 978-3-319-99352-2. [Google Scholar]

- Radomska-Zalas, A.; Perec, A.; Fajdek-Bieda, A. IT Support for Optimisation of Abrasive Water Cutting Process Using the TOPSIS Method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 710, 012008. [Google Scholar] [CrossRef]

- Perec, A. Multiple Response Optimization of Abrasive Water Jet Cutting Process Using Response Surface Methodology (RSM). Procedia Comput. Sci. 2021, 192, 931–940. [Google Scholar] [CrossRef]

- Hashish, M. On the modeling of abrasive—Waterjet cutting. In Proceedings of the 7th International Symposium on Jet Cutting Technology, Ottawa, ON, Canada, 26–28 June 1984; pp. 249–265. [Google Scholar]

- Iioshi, S.; Nakao, K.; Torii, K.; Ishii, T. Preliminary Study on Abrasive Water Jet Assist Roadheader. In Proceedings of the 8th International Symposium on Jet Cutting Technology, Durham, UK, 9–11 September 1986; pp. 71–77. [Google Scholar]

- Rehbinder, G. A theory about cutting rock with a water jet. Rock Mech. 1980, 12, 247–257. [Google Scholar] [CrossRef]

- Galecki, G.; Summers, D.A.; Sprung, J.; Yount, J. Development of a Waste Excavation End Effector. In Proceedings of the 12th International Conference on Jet Cutting Technology, Rouen, France, 25–27 October 1994; pp. 637–647. [Google Scholar]

- Xu, J.; Summers, D.A. Experimental Evaluation of the Performance of Fan Jet Systems. In Proceedings of the 12th International Symposium of Jet Cutting Technology, Rouen, France, 25–27 October 1994; pp. 37–43. [Google Scholar]

- Racinkowski, R. Collective Work: Engineering Geology with Elements of Petrography and Hydrology; Wydawnictwa Uczelniane Politechniki Szczecińskiej: Szczecin, Poland, 1987. [Google Scholar]

- Vijay, M.M.; Wenzhuo, Y. Water jet cutting techniques for processing of hard rock material. Int. J. Surf. Min. Reclam. Environ. 1989, 3, 59–69. [Google Scholar] [CrossRef]

- Kukiełka, L. Fundamentals of Engineering Studies; PWN: Warsaw, Poland, 2022. (In Polish) [Google Scholar]

| Group | Magmatic | Sedimentary | Ethamorphic | |||

|---|---|---|---|---|---|---|

| Type | Deep Rocks | Efflorescent | Clastic Sediments | Organic Sediments | Chemical Sediments | (transformed) |

| Kind of Rock | granite syenite diorite peridotite | porphyry andesite basalt tuff | breccia sandstone clay slate | limestone dolomite chalk marl | travertine gypsum anhydrite alabaster bauxite | gneiss serpentinite quartzite marble |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chomka, G.; Kasperowicz, M.; Chodór, J.; Chudy, J.; Kukiełka, L. Possibilities of Rock Processing with a High-Pressure Abrasive Waterjet with an Aspect Terms to Minimizing Energy Consumption. Materials 2023, 16, 647. https://doi.org/10.3390/ma16020647

Chomka G, Kasperowicz M, Chodór J, Chudy J, Kukiełka L. Possibilities of Rock Processing with a High-Pressure Abrasive Waterjet with an Aspect Terms to Minimizing Energy Consumption. Materials. 2023; 16(2):647. https://doi.org/10.3390/ma16020647

Chicago/Turabian StyleChomka, Grzegorz, Maciej Kasperowicz, Jarosław Chodór, Jerzy Chudy, and Leon Kukiełka. 2023. "Possibilities of Rock Processing with a High-Pressure Abrasive Waterjet with an Aspect Terms to Minimizing Energy Consumption" Materials 16, no. 2: 647. https://doi.org/10.3390/ma16020647

APA StyleChomka, G., Kasperowicz, M., Chodór, J., Chudy, J., & Kukiełka, L. (2023). Possibilities of Rock Processing with a High-Pressure Abrasive Waterjet with an Aspect Terms to Minimizing Energy Consumption. Materials, 16(2), 647. https://doi.org/10.3390/ma16020647