Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India and Rome

Abstract

1. Introduction

2. Types and Characteristics of Ancient Cements

2.1. The Wisdom of Ancient Rome

2.2. The Wisdom of Ancient China

2.3. The Wisdom of Ancient India

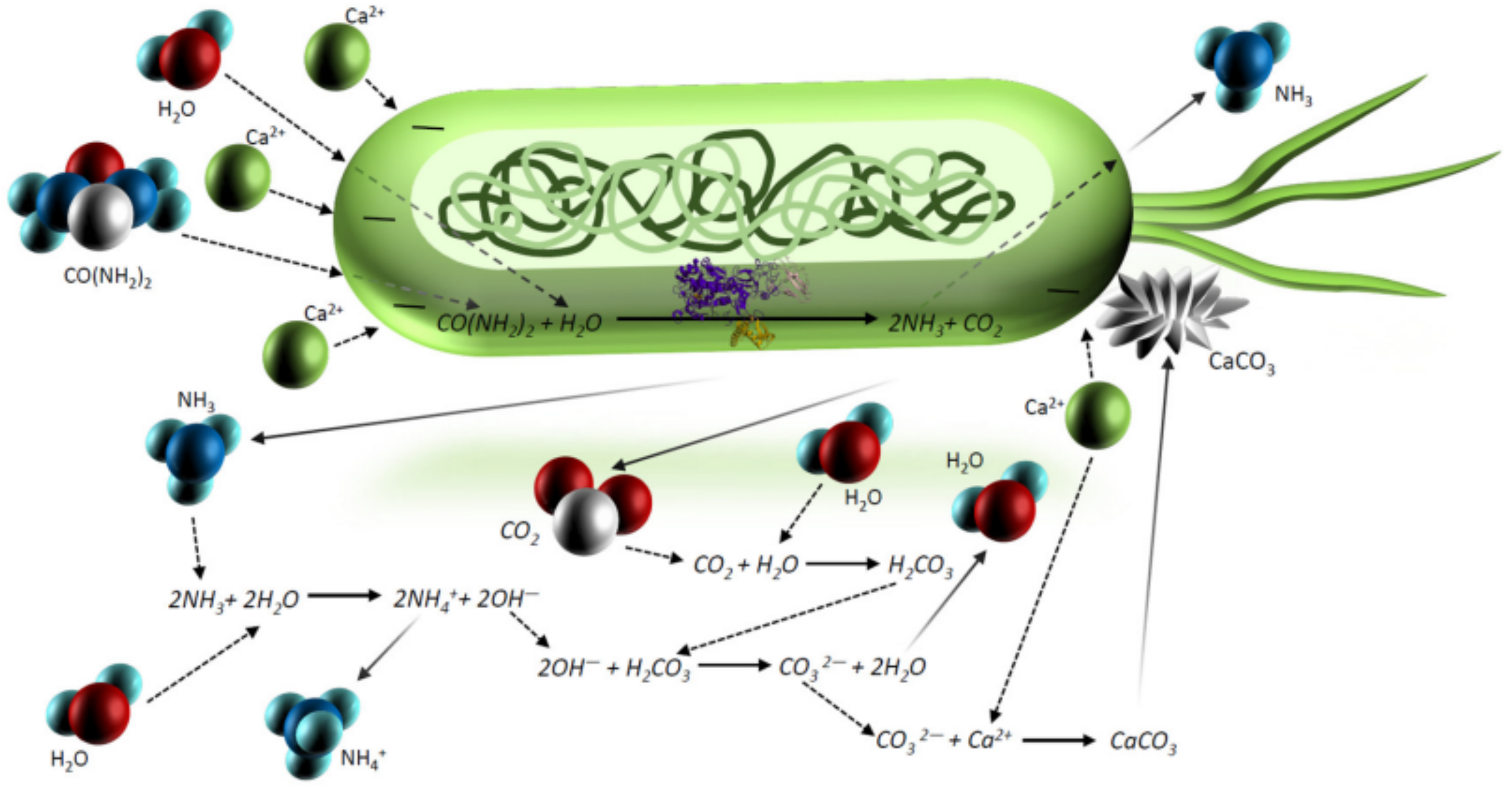

3. Future Prospects for New Ground Consolidation Technologies Learned from Ancient Cements

| Biopolymers | Composition | Cost [$/kg] | Source | Reference |

|---|---|---|---|---|

| Starch | C27H48O20 | 1–5 | Seeds, grains and roots of plants | [84,86,87,88,89,90] |

| Xanthan Gum | C35H49O29 | 2–5 | Xanthomonas campestris | [23,91,92,93,94,95,96] |

| Guar Gum | C10H14N5Na2O12P3 | 1–30 | Cyamopsis tetragonoloba | [18,92,93,97,98,99,100,101,102] |

| Casein | C81H125 N22O39P | 5–50 | Milk | [103,104] |

| Dextran | C18H32O16 | 15–60 | Lactic acid bacteria | [105,106,107,108,109,110,111,112,113,114,115,116,117] |

| Chitosan | C18H35N3O13 | 10–100 | Insects, squid bones, and crustacean shells | [15,39,42,118,119,120,121] |

| Agar Gum | C14H24O9 | 10–100 | Rhodophyta | [22,106,122,123,124,125] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, J.; Varaksin, S.; Klotz, U.; Mengé, P. Construction processes: State-of-the-art report. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 3006–3135. [Google Scholar]

- Kim, A.-R.; Chang, I.; Cho, G.-C.; Shim, S.-H. Strength and Dynamic Properties of Cement-Mixed Korean Marine Clays. KSCE J. Civ. Eng. 2017, 22, 1150–1161. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; Loos, M.C.H.; Meyer, L. Carbon Dioxide Capture and Storage; Intergovernmental Panel on Climate Change: New York, NY, USA, 2005.

- Oss, H.G.V. Cement Statistics and Information; US Geological Survey: Reston, VA, USA, 2014.

- U.S. Geological Survey. Mineral Commodity Summaries 2022: U.S. Geological Survey; U.S. Geological Survey: Reston, VA, USA, 2022; pp. 44–45.

- Song, M.; Ju, T.; Meng, Y.; Han, S.; Lin, L.; Jiang, J. A review on the applications of microbially induced calcium carbonate precipitation in solid waste treatment and soil remediation. Chemosphere 2022, 290, 133229. [Google Scholar] [CrossRef]

- Chen, C.; Xu, R.; Tong, D.; Qin, X.; Cheng, J.; Liu, J.; Zheng, B.; Yan, L.; Zhang, Q. A striking growth of CO2 emissions from the global cement industry driven by new facilities in emerging countries. Environ. Res. Lett. 2022, 17, 044007. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Mishra, U.C.; Sarsaiya, S.; Gupta, A. A systematic review on the impact of cement industries on the natural environment. Environ. Sci. Pollut. Res. 2022, 29, 18440–18451. [Google Scholar] [CrossRef] [PubMed]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancientstructures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Pintea, A.O. New types of mortars obtained by aditiving traditional mortars with natural polymers to increase physico-mechanical performances. Procedia Manuf. 2019, 32, 201–207. [Google Scholar] [CrossRef]

- Lentz, R.D. Polyacrylamide and biopolymer effects on flocculation, aggregate stability, and water seepage in a silt loam. Geoderma 2015, 241–242, 289–294. [Google Scholar] [CrossRef]

- Gupta, B.S.; Ako, J.E. Application of guar gum as a flocculant aid in food processing and potable water treatment. Eur. Food Res. Technol. 2005, 221, 746–751. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.M. Biopolymer additives to reduce erosion-induced soil losses during irrigation. Ind. Crop. Prod. 2000, 11, 19–29. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Awraheem, M.H.; Khalaf, M.M. Geotechnical Properties of a Low-Plasticity Clay with Biopolymer. J. Mater. Civ. Eng. 2018, 30, 04018170. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Guar gum: Processing, properties and food applications—A review. J. Food Sci. Technol. 2014, 51, 409–418. [Google Scholar] [CrossRef]

- Osmałek, T.; Froelich, A.; Tasarek, S. Application of gellan gum in pharmacy and medicine. Int. J. Pharm. 2014, 466, 328–340. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Shear strength behavior and parameters of microbial gellan gum-treated soils: From sand to clay. Acta Geotech. 2018, 14, 361–375. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Majid, M.Z.A.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with bi-opolymer-An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.-C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr Build Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Canakci, H. Direct shear tests on sand treated with xanthan gum. Proc. Instit. Civ. Eng. Ground Improv. 2011, 164, 57–64. [Google Scholar] [CrossRef]

- Khachatoorian, R.; Petrisor, I.G.; Kwan, C.-C.; Yen, T.F. Biopolymer plugging effect: Laboratory-pressurized pumping flow studies. J. Pet. Sci. Eng. 2003, 38, 13–21. [Google Scholar] [CrossRef]

- Zemmouri, H.; Drouiche, M.; Sayeh, A.; Lounici, H.; Mameri, N. Chitosan Application for Treatment of Beni-Amrane’s Water Dam. Energy Procedia 2013, 36, 558–564. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Geotechnical engineering behaviors of gellan gum biopolymer treated sand. Can. Geotech. J. 2016, 53, 1658–1670. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Ham, S.-M.; Kwon, T.-H.; Cho, G.-C.; Chang, I. Surface-erosion behaviour of biopolymer-treated soils assessed by EFA. Géotech. Lett. 2020, 10, 106–112. [Google Scholar] [CrossRef]

- Ham, S.-M.; Chang, I.; Noh, D.-H.; Kwon, T.-H.; Muhunthan, B. Improvement of Surface Erosion Resistance of Sand by Microbial Biopolymer Formation. J. Geotech. Geoenviron. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.-D.; Cho, G.-C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2016, 253–254, 39–47. [Google Scholar] [CrossRef]

- Larson, S.; Newman, J.K.; O’Connor, G.; Griggs, C.; Martin, A.; Nijak, G.; Lord, E.; Duggar, R.; Leeson, A. Biopolymer as an Alternative to Petroleum-Based Polymers to Control Soil Erosion; Environmental Security Technology Certification Program; Iowa Army Ammunition Plant: Alexandria, VA, USA, 2013. [Google Scholar]

- Nugent, R.A.; Zhang, G.; Gambrell, R.P. The Effects of Exopolymers on the Erosional Resistance of Cohesive Sediments. In Proceedings of the International Conference on Scour and Erosion, San Francisco, CA, USA, 7–10 November 2010. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.M.; Gross, R.A. Biopolymer Additives for the Reduction of Soil Erosion Losses during Irrigation. In Biopolymers from Polysaccharides and Agroproteins; American Chemical Society: Washington, DC, USA, 2001; pp. 102–116. [Google Scholar] [CrossRef]

- Miękoś, E.; Zieliński, M.; Kołodziejczyk, K.; Jaksender, M. Application of industrial and biopolymers waste to stabilise the subsoil of road surfaces. Road Mater. Pavement Des. 2017, 20, 440–453. [Google Scholar] [CrossRef]

- Chen, R.; Lee, I.; Zhang, L. Biopolymer Stabilization of Mine Tailings for Dust Control. J. Geotech. Geoenviron. Eng. 2015, 141, 04014100. [Google Scholar] [CrossRef]

- Maghchiche, A.; Haouam, A.; Immirzi, B. Use of polymers and biopolymers for water retaining and soil stabilization in arid and semiarid regions. J. Taibah Univ. Sci. 2010, 4, 9–16. [Google Scholar] [CrossRef]

- Kavazanjian, E.; Iglesias, E.; Karatas, I. Biopolymer soil stabilization for wind erosion control. In Proceedings of the 17th International Con-Ference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 881–884. [Google Scholar]

- Renault, F.; Sancey, B.; Badot, P.-M.; Crini, G. Chitosan for coagulation/flocculation processes–An eco-friendly approach. Eur. Polym. J. 2009, 45, 1337–1348. [Google Scholar] [CrossRef]

- Ruhsing, P.J.; Huang, C.; Chen, S.; Chung, Y.-C. Evaluation of a modified chitosan biopolymer for coagulation of colloidal particles. Colloids Surf. A 1999, 147, 359–364. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Im, J.; Chang, I.; Cho, G.-C. ε-polylysine biopolymer for coagulation of clay suspensions. Géoméch. Eng. 2017, 12, 753–770. [Google Scholar] [CrossRef]

- Aguilar, R.; Nakamatsu, J.; Ramírez, E.; Elgegren, M.; Ayarza, J.; Kim, S.; Pando, M.A.; Ortega-San-Martin, L. The potential use of chitosan as a biopolymer additive for enhanced mechanical properties and water resistance of earthen construction. Constr. Build. Mater. 2016, 114, 625–637. [Google Scholar] [CrossRef]

- Chiet, K.T.P.; Kassim, K.A.; Chen, K.B.; Martula, U.; Yah, C.S.; Arefnia, A. Effect of reagents concentration on bioce-mentation of tropical residual soil. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012030. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Oliveira, P.J.V.; Freitas, L.D.; Carmona, J.P.S.F. Effect of soil type on the enzymatic calcium carbonate precipitation process used for soil improvement. J. Mater. Civ. Eng. 2016, 29, 04016263. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying bio-mediated ground improvement by ureolysis: Large-scale biogrout experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Ivanov, V.; Stabnikov, V.; Stabnikova, O.; Kawasaki, S. Environmental safety and biosafety in construction biotechnology. World J. Microbiol. Biotechnol. 2019, 35, 26. [Google Scholar] [CrossRef]

- Avramenko, M.; Nakashima, K.; Kawasaki, S. State-of-the-Art Review on Engineering Uses of Calcium Phosphate Compounds: An Eco-Friendly Approach for Soil Improvement. Materials 2022, 15, 6878. [Google Scholar] [CrossRef]

- Bao, R.; Li, J.; Li, L.; Cutright, T.J.; Chen, L. Effect of microbialinduced calcite precipitation on surface erosion and scour of granular soils proof of concept. J. Transp. Res. Board 2017, 2657, 10–18. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Zhong, M.; Jing, C.; Guo, B. Research status and development of microbial induced calcium carbonate min-eralization technology. PLoS ONE 2022, 17, e0271761. [Google Scholar]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, WA, Australia, 2004. [Google Scholar]

- Blackman, D.J. Ancient harbours in the Mediterranean. Int. J. Naut. Archaeol. 1982, 11, 79–104. [Google Scholar] [CrossRef]

- Gazda, E.K. Cosa’s Contribution to the Study of Roman Hydraulic Concrete: An Historiographic Commentary. In Classical Studies in Honor of Cleo Rickman Fitch; N. W. Goldman: New York, NY, USA, 2001; pp. 145–177. [Google Scholar]

- Delatte, N.J. Lessons from Roman Cement and Concrete. J. Prof. Issues Eng. Educ. Pr. 2001, 127, 109–115. [Google Scholar] [CrossRef]

- Huang, H.; An, M.; Wang, Y.; Yu, Z.; Ji, W. Effect of environmental thermal fatigue on concrete perfor-mance based on mesostructural and microstructural analyses. Constr. Build. Mater. 2019, 207, 450–462. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ojovan, M.I. 7-Behavior of cementitious SSC’s in mitigating accidents. In Woodhead Publishing Series in Energy, Sustainability of Life Cycle Management for Nuclear Cementation-Based Technologies; Rahman, R.O.A., Ojovan, M.I., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 233–267. [Google Scholar]

- Jackson, M.D.; Vola, G.; Všianský, D.; Oleson, J.P.; Scheetz, B.E.; Brandon, C.; Hohlfelder, R.L. Cement microstructures and durability in ancient Roman seawater concretes. In Historic Mortars, Characterisation, Assessment and Repair; Válek, J., Groot, C., Hughes, J., Eds.; Springer: Berlin, Germany, 2012; pp. 49–76. [Google Scholar]

- University of Utah. How Seawater Strengthens Ancient Roman Concrete. 2017. Available online: https://unews.utah.edu/roman-concrete/ (accessed on 11 December 2017).

- Jackson, M.D. Seawater concretes and their material characteristics. In Building for Eternity: The History and Technology of Roman Concrete Engineering in the Sea; Oleson, J.P., Ed.; Oxbow Books: Oxford, UK, 2014; pp. 141–187. [Google Scholar]

- Dean, A.M. Rock Solid History of Concrete–How Limestone, Rocks, and Volcanic Ash Built the Modern World. 2017. Available online: https://www.concretepavements.org/2017/10/18/rock-solid-history-of-concrete-how-limestone-rocks-and-volcanic-ash-built-the-modern-world/ (accessed on 11 December 2017).

- Massazza, F. Concrete resistance to seawater and marine environment. Il Cemento 1985, 82, 26–85. [Google Scholar]

- Brune, P.; Perucchio, R.; Ingraffea, A.R.; Jackson, M.D. The toughness of imperial roman concrete. In Proceedings of FraMCoS-7; Korea Concrete Institute: Seoul, Republic of Korea, 2010; ISBN 978-89-5708-180-8. [Google Scholar]

- Jackson, M.D.; Logan, J.M.; Scheetz, B.E.; Deocampo, D.M.; Cawood, C.G.; Marra, F.; Vitti, M.; Ungaro, L. Assessment of material characteristics of ancient concretes, Grande Aula, Markets of Trajan, Rome. J. Archaeol. Sci. 2009, 36, 2481–2492. [Google Scholar] [CrossRef]

- Thomas, M. Optimizing the Use of Fly Ash in Concrete; Portland Cement Association: Skokie, IL, USA, 2007. [Google Scholar]

- Yao, Y. The History of Xi’an in Han Dynasty (Science and Technology); Shanxi People’s Publishing House: Xi’an, China, 1993; pp. 477–478. (In Chinese) [Google Scholar]

- Archeology Crew of Henan Province. A Stick Tomb with Colorized Portrait in Deng Country, Henan Provice; Cultural Relic Press: Beijing, China, 1958. (In Chinese) [Google Scholar]

- Zhang, K.; Sui, Y.; Wang, L.; Tie, F.; Yang, F.; Liu, Y.; Zhang, Y. Effects of sticky rice addition on the properties of lime-tile dust mortars. Herit. Sci. 2021, 9, 1–15. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, B.; Ma, Q. Study of Sticky Rice−Lime Mortar Technology for the Restoration of Historical Masonry Construction. Acc. Chem. Res. 2010, 43, 936–944. [Google Scholar] [CrossRef]

- Yuyao, Z.; Zhang, B.; Xiaolin, L. Study on characteristics and consolidation mechanism of historical mortar materials. Sci. Conserv. Archaeol. 2008, 2, 1–7. (In Chinese) [Google Scholar]

- Zeng, Y.; Zhang, B.; Liang, X. A case study and mechanism investigation of typical mortars used on ancient architecture in China. Thermochim. Acta 2008, 473, 1–6. [Google Scholar] [CrossRef]

- Li, H. Studies on Properties and Formula of Traditional Lime Mortar; National Cheng Kung University: Tainan City, Taiwan, 2005. [Google Scholar]

- Zhang, Q.; Li, B.; Zeng, Q.; Deng, J.; Wang, J.; Yan, D. Erosion of aerial lime and sticky rice mortars by cyclic wetting–drying and dilute sulfate acid actions. Adv. Cem. Res. 2020, 32, 343–357. [Google Scholar] [CrossRef]

- Ma, T.; Bai, C.B.; Qi, Y. Studies on the traditional techniques and the conservation method of polychrome paintings on wooden structures of Chinese traditional buildings. Wen Bo 2009, 6, 412. [Google Scholar]

- Zuo, Q.M. (Spring and Autumn Period) Zuo Zhuan; Yuelu Press: Changsha, China, 2001; p. 289. (In Chinese) [Google Scholar]

- Song, Y.X. T’ien-kung K’ai-wu; Shanghai Rarebooks Publishing House: Shanghai, China, 2008; p. 251. (In Chinese) [Google Scholar]

- Fang, S.Q.; Zhang, H.; Zhang, B.J.; Li, G.Q. A study of tung-oil-lime putty–A traditional lime based binder. Int. J. Adhes Adhes 2014, 48, 224–230. [Google Scholar] [CrossRef]

- Thirumalini, P.; Ravi, R.; Sekar, S.; Nambirajan, M. Study on the performance enhancement of lime mortar used in ancient temples and monuments in India. Ind. J. Sci. Technol. 2011, 4, 1484–1487. [Google Scholar] [CrossRef]

- Santhanam, K.; Shanmugavel, D.; Ramadoss, R.; Arakatavemula, V. Characterisation on ancient mortar of Chettinadu house at Kanadukathan, Karaikudi, Tamil Nadu, India. Mater. Today Proc. 2021, 43, 1147–1153. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Rahhal, V.; Irassar, E. Influence of initial curing on the properties of concrete containing limestone blended cement. Cem. Concr. Res. 2000, 30, 703–708. [Google Scholar] [CrossRef]

- Thirumalini, S.; Ravi, R.; Rajesh, M. Experimental investigation on physical and mechanical properties of lime mortar: Effect of organic addition. J. Cult. Herit. 2018, 31, 97–104. [Google Scholar] [CrossRef]

- Sekar, S.K.; Thirumalini, S. Review on Herbs used as Admixture in Lime Mortar used in Ancient Structures. Int. J. Appl. Eng. Res. 2013, 3, 295–298. [Google Scholar]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Smidsrød, O.; Moe, S.T. Biopolymer Chemistry; Tapir Academic Press: Trondheim, Norway, 2008. [Google Scholar]

- Rodrigues, A.; Emeje, M. Recent applications of starch derivatives in nanodrug delivery. Carbohydr. Polym. 2012, 87, 987–994. [Google Scholar] [CrossRef]

- Eliasson, A.-C. Starch in Food: Structure, Function and Applications; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Nachtergaele, W. The Benefits of Cationic Starches for the Paper Industry. Starch 1989, 41, 27–31. [Google Scholar] [CrossRef]

- Vishnuvarthanan, M.; Rajeswari, N. Additives for enhancing the drying properties of adhesives for corrugated boards. Alex. Eng. J. 2013, 52, 137–140. [Google Scholar] [CrossRef]

- Caenn, R.; Chillingar, G.V. Drilling fluids: State of the art. J. Pet. Sci. Eng. 1996, 14, 221–230. [Google Scholar] [CrossRef]

- Baba Hamed, S.; Belhadri, M. Rheological properties of biopolymers drilling fluids. J. Pet. Sci. Eng. 2009, 67, 84–90. [Google Scholar] [CrossRef]

- Milas, M.; Rinaudo, M. Conformational investigation on the bacterial polysaccharide xanthan. Carbohydr. Res. 1979, 76, 189–196. [Google Scholar] [CrossRef]

- García-Ochoa, F.; Santos, V.E.; Casas, J.A.; Gómez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef]

- Becker, A.; Katzen, F.; Pühler, A.; Ielpi, L. Xanthan gum biosynthesis and application: A biochemical/genetic perspective. Appl. Microbiol. Biotechnol. 1998, 50, 145–152. [Google Scholar] [CrossRef]

- Qureshi, M.U.; Chang, I.; Al-Sadarani, K. Strength and durability characteristics of biopolymer-treated desert sand. Géoméch. Eng. 2017, 12, 785–801. [Google Scholar] [CrossRef]

- Cabalar, A.; Wiszniewski, M.; Skutnik, Z. Effects of Xanthan Gum Biopolymer on the Permeability, Odometer, Unconfined Compressive and Triaxial Shear Behavior of a Sand. Soil Mech. Found. Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Lee, S.; Chang, I.; Chung, M.-K.; Kim, Y.; Kee, J. Geotechnical shear behavior of Xanthan Gum biopolymer treated sand from direct shear testing. Géoméch. Eng. 2017, 12, 831–847. [Google Scholar] [CrossRef]

- Risica, D.; Dentini, M.; Crescenzi, V. Guar gum methyl ethers. Part I. Synthesis and macromolecular characterization. Polymer 2005, 46, 12247–12255. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, L.; Budhu, M. Biopolymer Stabilization of Mine Tailings. J. Geotech. Geoenvironmental Eng. 2013, 139, 130128212232006. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of Guar Gum Biopolymer Treatment toward Mitigation of Desiccation Cracking on Slopes Built with Expansive Soils. Transp. Res. Rec. J. Transp. Res. Board 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- Puppala, A.J.; Pedarla, A. Innovative ground improvement techniques for expansive soils. Innov. Infrastruct. Solut. 2017, 2, 24. [Google Scholar] [CrossRef]

- Velimirovic, M.; Tosco, T.; Uyttebroek, M.; Luna, M.; Gastone, F.; De Boer, C.; Klaas, N.; Sapion, H.; Eisenmann, H.; Larsson, P.-O.; et al. Field assessment of guar gum stabilized microscale zerovalent iron particles for in-situ remediation of 1,1,1-trichloroethane. J. Contam. Hydrol. 2014, 164, 88–99. [Google Scholar] [CrossRef]

- Day, S.R.; O’Hannesin, S.F.; Marsden, L. Geotechnical techniques for the construction of reactive barriers. J. Hazard Mater. 1999, 67, 285–297. [Google Scholar] [CrossRef]

- Semenova, M.G.; Dickinson, E.; Burlakova, E.B.; Zaikov, G.E. Biopolymers in Food Col Loids: Thermodynamics and Molecular Interactions; Brill: Boston, MA, USA, 2010. [Google Scholar]

- Rose, R. Effects of an anticariogenic casein phosphopeptide on calcium diffusion in streptococcal model dental plaques. Arch. Oral Biol. 2000, 45, 569–575. [Google Scholar] [CrossRef]

- Ioan, C.E.; Aberle, T.; Burchard, W. Structure Properties of Dextran. 2. Dilute Solution. Macromolecules 2000, 33, 5730–5739. [Google Scholar] [CrossRef]

- Tanford, C.; Huggins, M.L. Physical Chemistry of Macromolecules; Wiley: New York, NY, USA, 1961. [Google Scholar] [CrossRef]

- Kaplan, D.L. Biopolymers from Renewable Resources; Springer: Berlin/Heidelberg, Germany, 2013; p. 420. [Google Scholar]

- Bouhadir, K.H.; Lee, K.Y.; Alsberg, E.; Damm, K.L.; Anderson, K.W.; Mooney, D.J. Degradation of Partially Oxidized Alginate and Its Potential Application for Tissue Engineering. Biotechnol. Prog. 2001, 17, 945–950. [Google Scholar] [CrossRef] [PubMed]

- Lévesque, S.G.; Lim, R.M.; Shoichet, M.S. Macroporous interconnected dextran scaffolds of controlled porosity for tis-sue-engineering applications. Biomaterials 2005, 26, 7436–7446. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Tester, R.F.; Corbett, A.; Karkalas, J. Dextran and 5-aminosalicylic acid (5- ASA) conjugates: Synthesis, characterisation and enzymic hydrolysis. Carbohydr. Res. 2006, 341, 2694–2701. [Google Scholar] [CrossRef] [PubMed]

- Jeans, E.R.A.; Marshall, P.J.; Lowe, C.R. Plasma protein fractionation. Trends Biotechnol. 1985, 3, 267–271. [Google Scholar] [CrossRef]

- Eliasson, A.-C. Carbohydrates in Food, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Blanshard, J.M.V.; Mitchell, J.R. Polysaccharides in Food; Butterworth Heinemann: Oxford, UK, 1979. [Google Scholar]

- Fechner, A.; Knoth, A.; Scherze, I.; Muschiolik, G. Stability and release properties of double-emulsions stabilised by caseinate–dextran conjugates. Food Hydrocoll. 2007, 21, 943–952. [Google Scholar] [CrossRef]

- Bryant, R.S.; Burchfield, T.E. Review of Microbial Technology for Improving Oil Recovery. SPE Reservior Eng. 1989, 4, 151–154. [Google Scholar] [CrossRef]

- Bao, M.; Kong, X.; Jiang, G.; Wang, X.; Li, X. Laboratory study on activating indigenous microorganisms to enhance oil recovery in Shengli Oilfield. J. Pet. Sci. Eng. 2009, 66, 42–46. [Google Scholar] [CrossRef]

- Pini, R.; Canarutto, S.; Guidi, G.V. Soil microaggregation as influenced by uncharged organic conditioners. Commun. Soil Sci. Plant Anal. 1994, 25, 2215–2229. [Google Scholar] [CrossRef]

- Darder, M.; Colilla, M.; Ruiz-Hitzky, E. Chitosan–clay nanocomposites: Application as electrochemical sensors. Appl. Clay Sci. 2005, 28, 199–208. [Google Scholar] [CrossRef]

- Wang, S.F.; Shen, L.; Tong, Y.J.; Chen, L.; Phang, I.Y.; Lim, P.Q.; Liu, T.X. Biopolymer chitosan/montmorillonite nanocomposites: Prepa-ration and characterization. Polym. Degrad. Stab. 2005, 90, 123–131. [Google Scholar] [CrossRef]

- Chang, I. Biopolymer Treated Korean Residual Soil: Geotechnical Behavior and Applications. Ph.D. Thesis, Department of Civil and Environmental Engineering, Korea Advanced Institute of Science and Technology, Seoul, Republic of Korea, 2010. [Google Scholar]

- Wang, C.-C.; Juang, L.-C.; Lee, C.-K.; Hsu, T.-C.; Lee, J.-F.; Chao, H.-P. Effects of exchanged surfactant cations on the pore structure and adsorption characteristics of montmorillonite. J. Colloid Interface Sci. 2004, 280, 27–35. [Google Scholar] [CrossRef]

- Laurienzo, P. Marine Polysaccharides in Pharmaceutical Applications: An Overview. Mar. Drugs 2010, 8, 2435–2465. [Google Scholar] [CrossRef]

- Nakano, M.; Nakamura, Y.; Takikawa, K.; Kouketsu, M.; Arita, T. Sustained release of sulphamethizole from agar beads. J. Pharm. Pharmacol. 1979, 31, 869–872. [Google Scholar] [CrossRef]

- Dumitriu, S. Polymeric Biomaterials, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2002. [Google Scholar]

- Adachi, M.; Watanabe, S. Evaluation of combined deactivators-supplemented agar medium (CDSAM) for recovery of derma-tophytes from patients with tinea pedis. Med. Mycol. 2007, 45, 347–349. [Google Scholar] [CrossRef]

- Almajed, A.; Lateef, M.A.; Moghal, A.A.B.; Lemboye, K. State-of-the-art review of the applicability and challenges of micro-bialinduced calcite precipitation (MICP) and enzyme-induced calcite precipitation (EICP) techniques for geotechnical and geoenvironmental applications. Crystals 2021, 11, 370. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Li, X. Geotechnical Engineering Properties of Soils Solidified by Microbially Induced CaCO3 Precipitation (MICP). Adv. Civ. Eng. 2021, 2021, 6683930. [Google Scholar] [CrossRef]

- Pham, V.; Paassen Lv Nakano, A.; Kanayama, M.; Heimovaara, T. Microbially Induced Carbonate Precipitation (Micp) By Denitrification as Ground Improvement Method-Process Control in Sand Column Experiments; EGU General Assembly: Vienna, Austria, 2013; p. 15. [Google Scholar]

- Sujiritha, P.B.; Vikash, V.L.; Antony, G.S.; Ponesakki, G.; Ayyadurai, N.; Nakashima, K.; Kamini, N.R. Valorization of tannery solid wastes for sustainable enzyme induced carbonate precipitation process. Chemosphere 2022, 308, 136533. [Google Scholar] [CrossRef]

- Gowthaman, S.; Mitsuyama, S.; Nakashima, K.; Komatsu, M.; Kawasaki, S. Biogeotechnical approach for slope soil stabilization using locally isolated bacteria and inexpensive low-grade chemicals: A feasibility study on Hokkaido expressway soil, Japan. Soils Found. 2019, 59, 484–499. [Google Scholar] [CrossRef]

- Imran, A.; Gowthaman, S.; Nakashima, K.; Kawasaki, S. The Influence of the Addition of Plant-Based Natural Fibers (Jute) on Biocemented Sand Using MICP Method. Materials 2020, 13, 4198. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Z.; Yan, Z.; Nakashima, K.; Takano, C.; Kawasaki, S. Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India and Rome. Materials 2023, 16, 603. https://doi.org/10.3390/ma16020603

Su Z, Yan Z, Nakashima K, Takano C, Kawasaki S. Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India and Rome. Materials. 2023; 16(2):603. https://doi.org/10.3390/ma16020603

Chicago/Turabian StyleSu, Zhan, Zhen Yan, Kazunori Nakashima, Chikara Takano, and Satoru Kawasaki. 2023. "Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India and Rome" Materials 16, no. 2: 603. https://doi.org/10.3390/ma16020603

APA StyleSu, Z., Yan, Z., Nakashima, K., Takano, C., & Kawasaki, S. (2023). Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India and Rome. Materials, 16(2), 603. https://doi.org/10.3390/ma16020603