Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures

Abstract

:1. Introduction

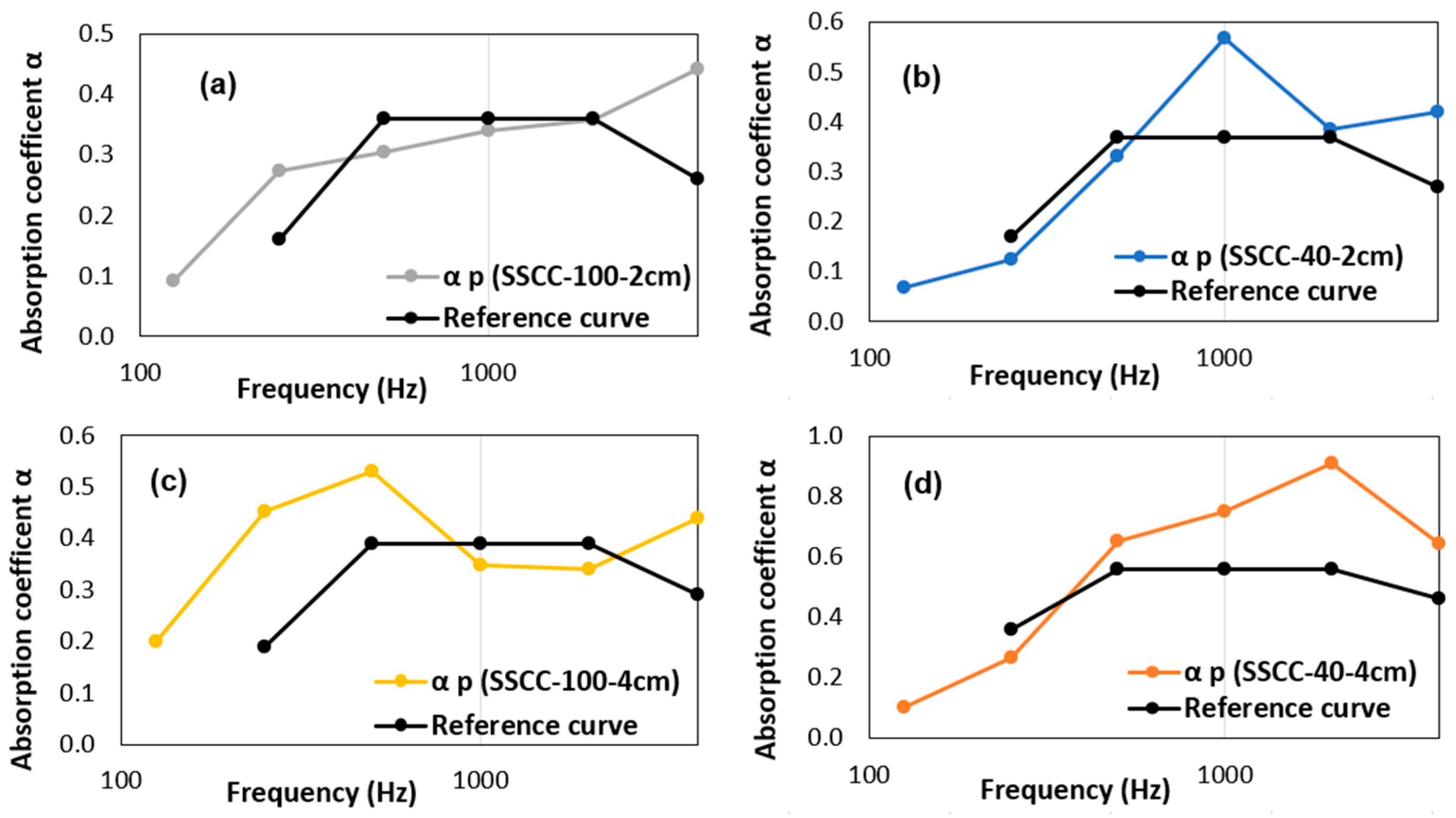

2. Materials and Methods

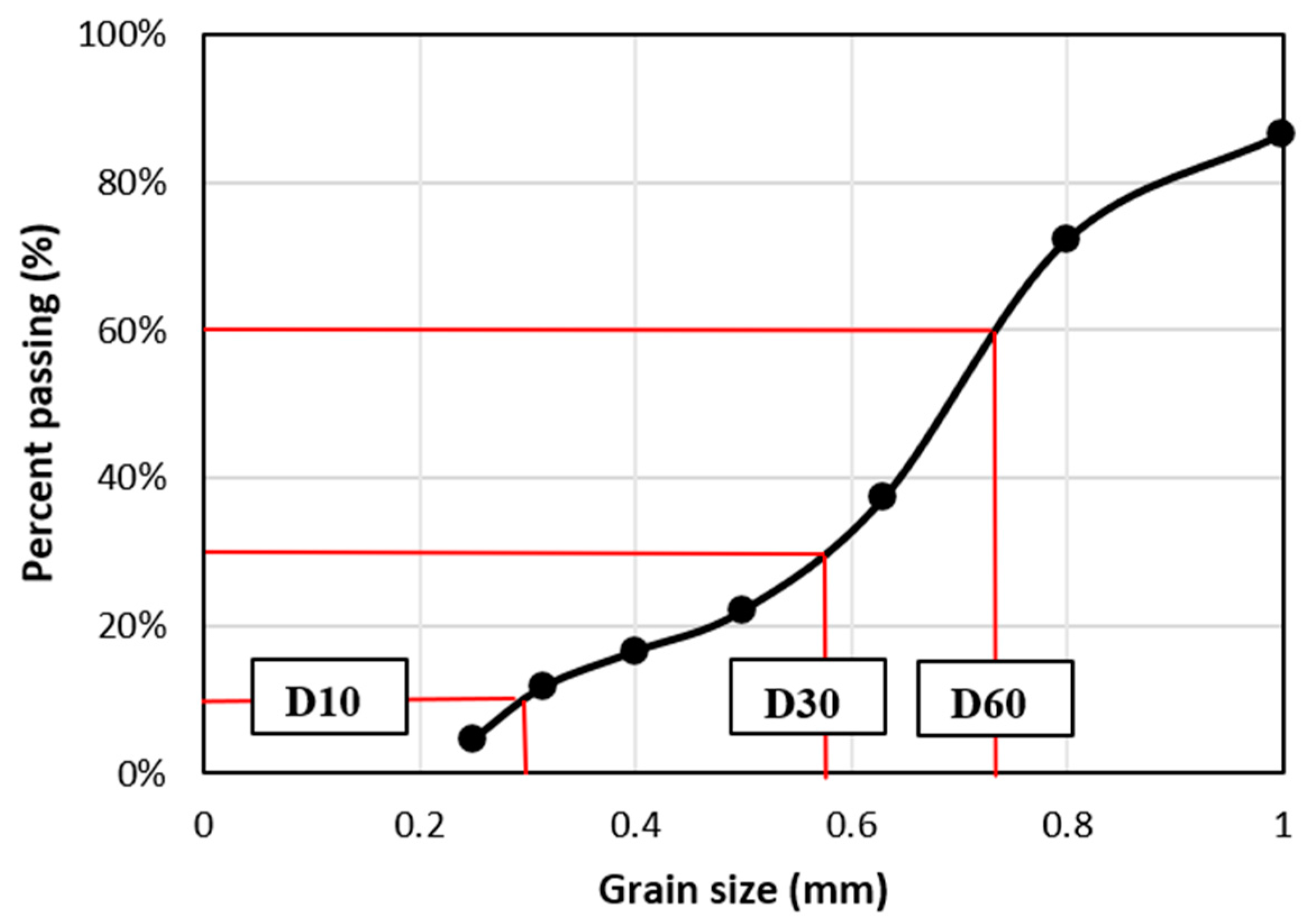

2.1. Granulometry of Spent Coffee Grounds

2.2. SSCC Preparation

2.3. Density and Porosity

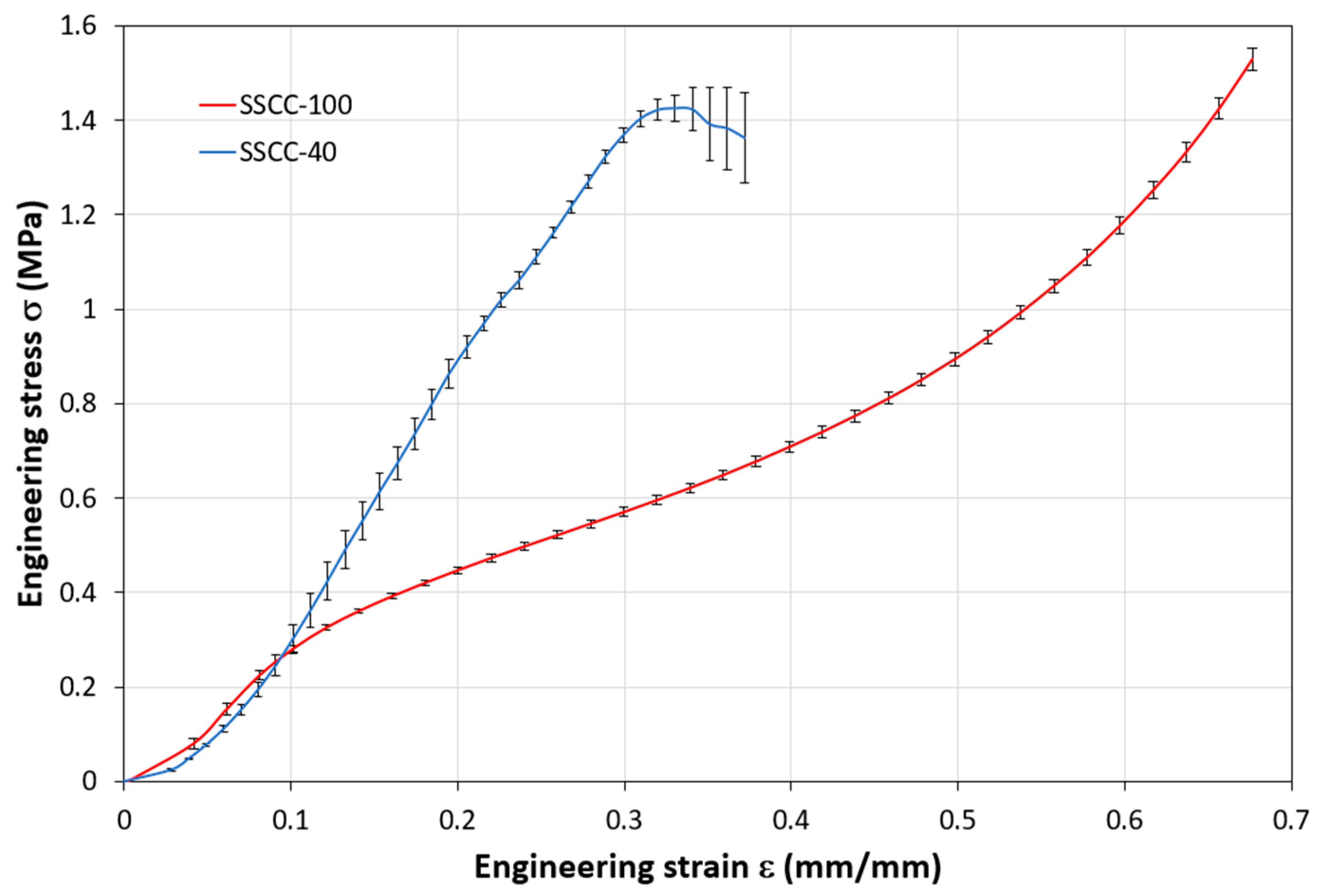

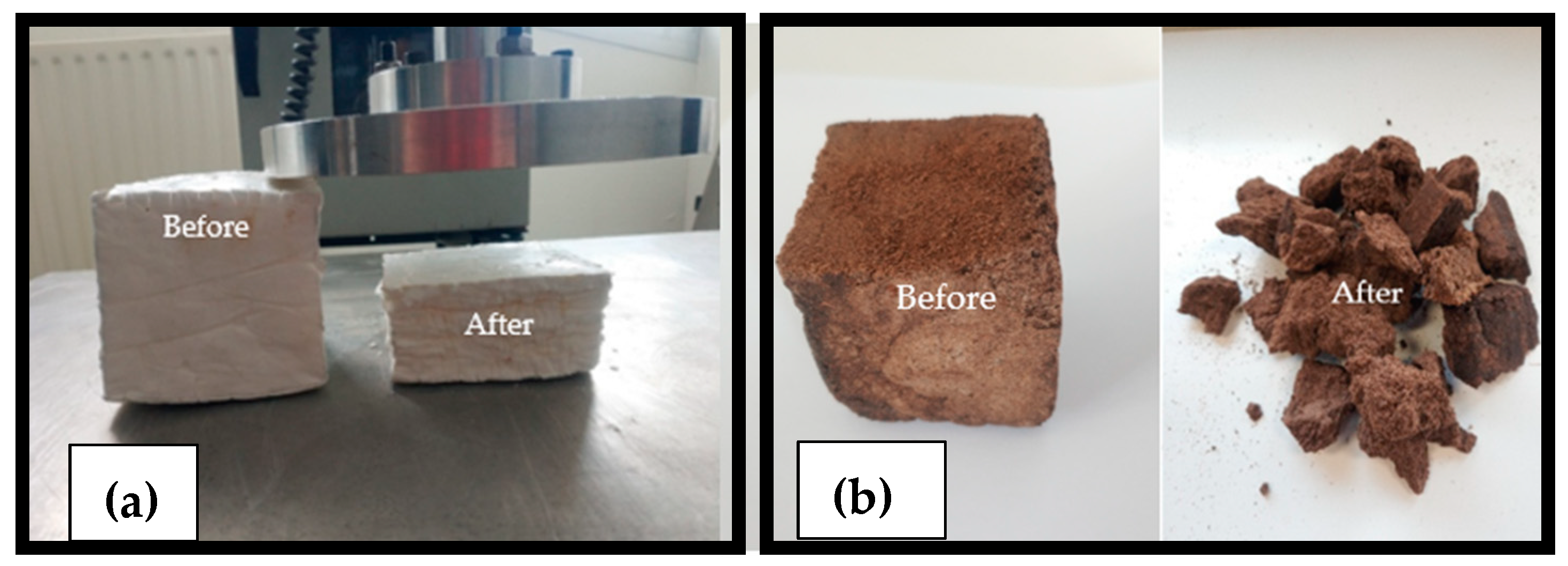

2.4. Mechanical Testing

2.5. Thermal Conductivity

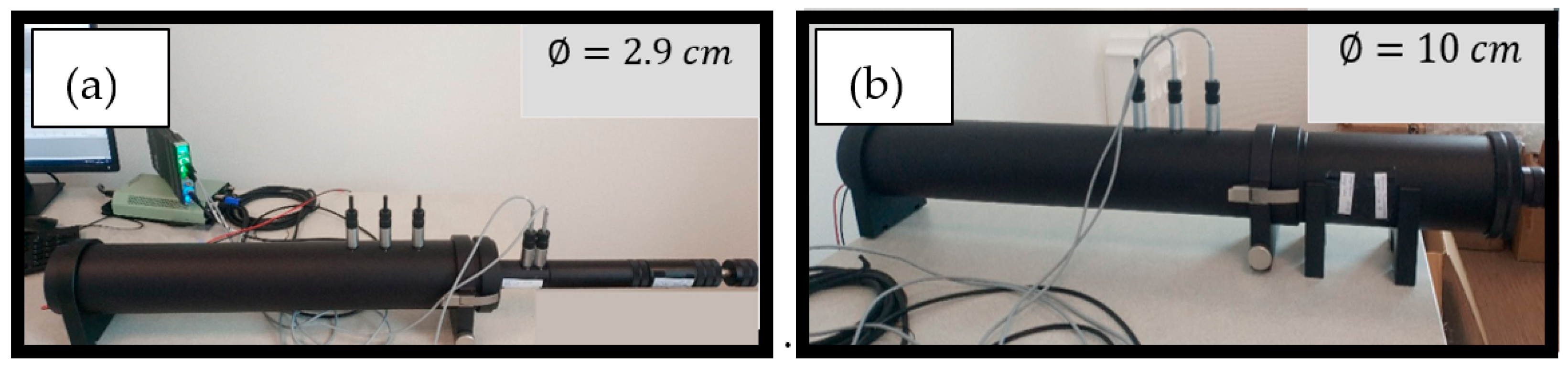

2.6. Acoustic Absorption Coefficient

2.7. Sorption Isotherm

3. Results and Discussions

3.1. Mechanical Properties

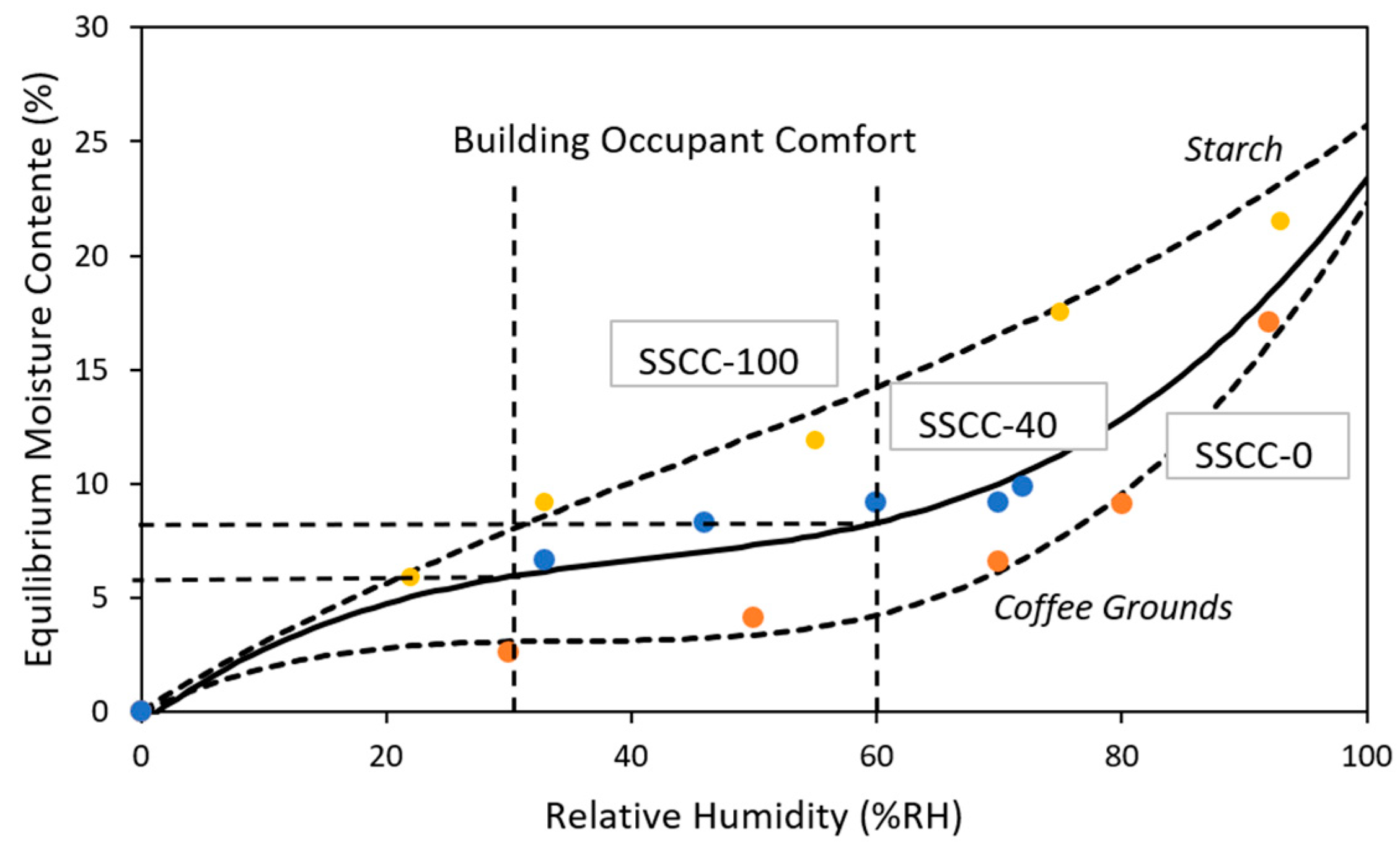

3.2. Thermal Conductivity

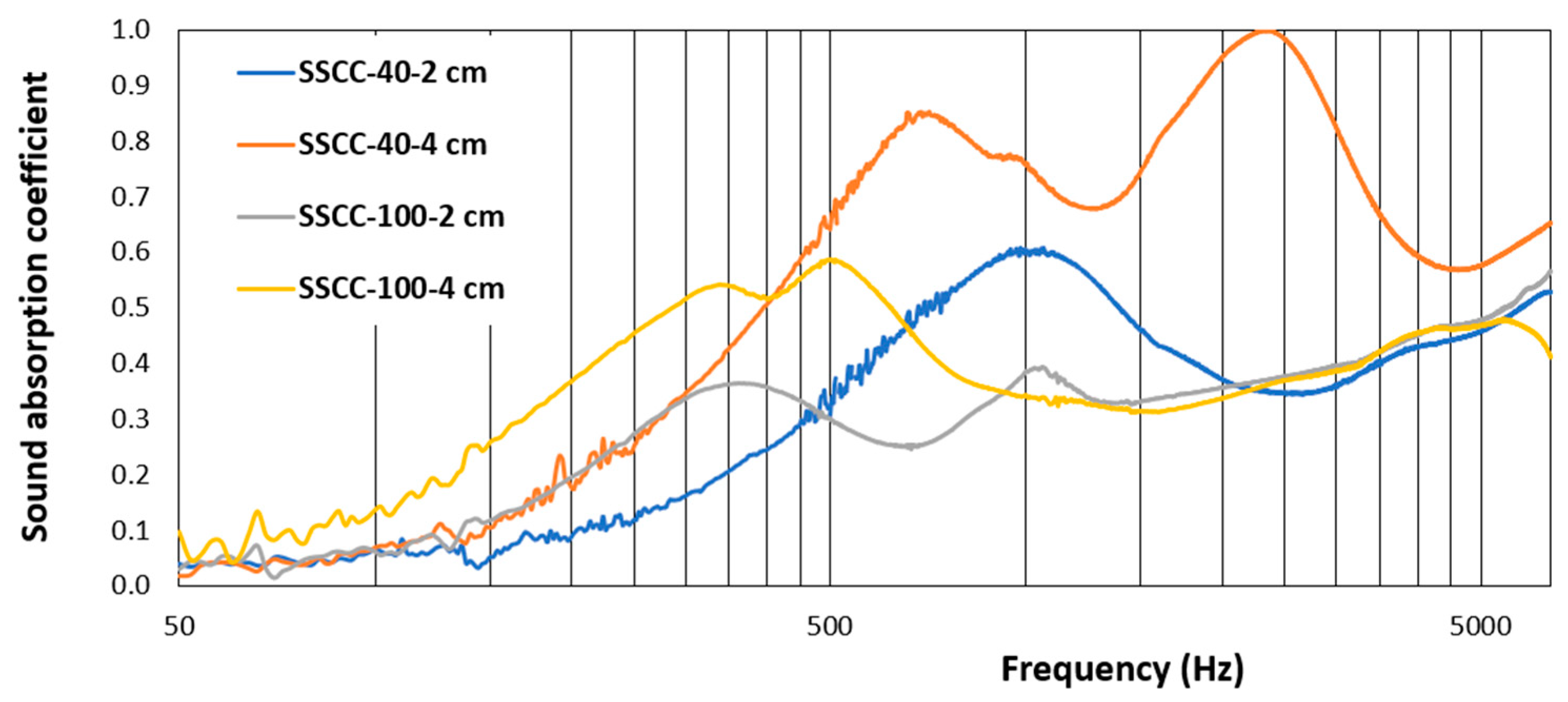

3.3. Acoustic Absorption Coefficient

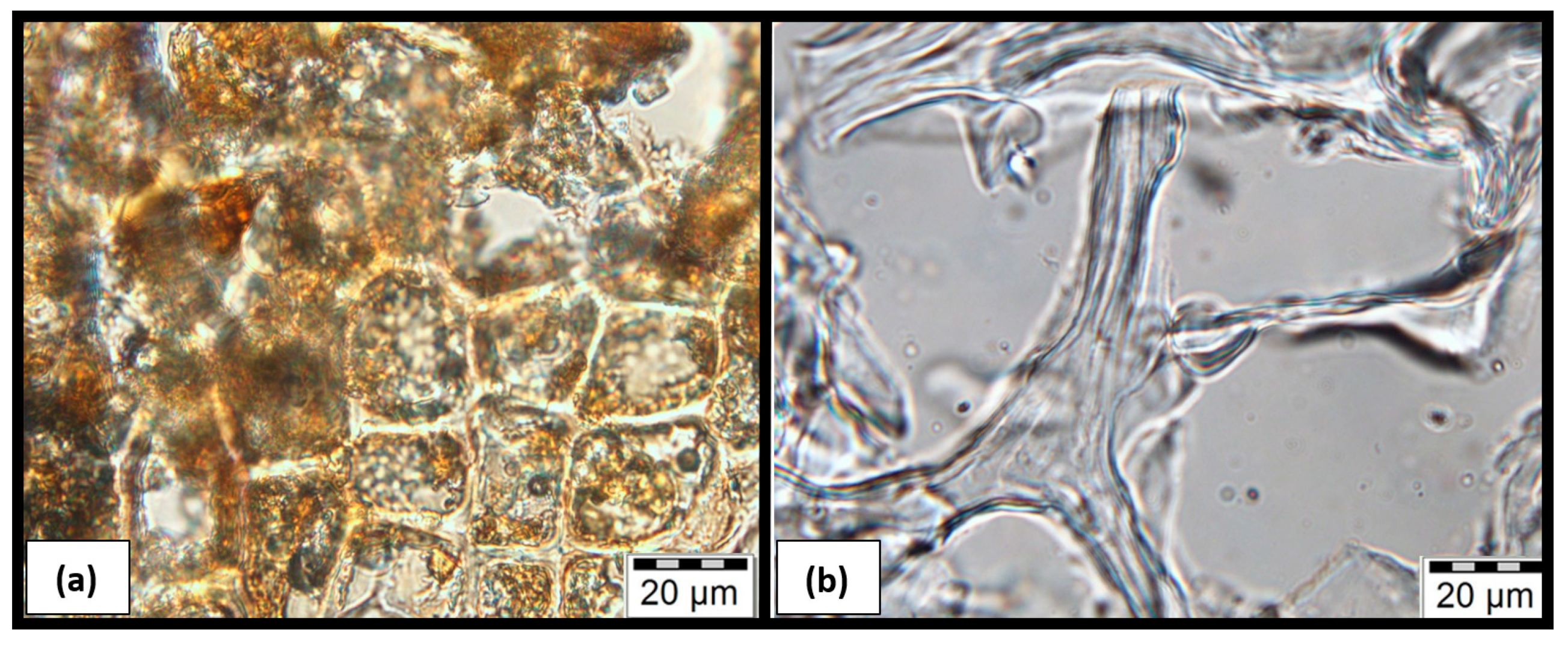

3.4. Sorption Isotherm at T = 23 °C

4. Reflection Tracks and Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Energy & CO2 Status Report 2019—Analysis—IEA. 2019. Available online: https://www.iea.org/reports/global-energy-co2-status-report-2019 (accessed on 10 January 2022).

- International Energy Agency. Global Energy Review 2020. Available online: www.iea.org/corrigenda (accessed on 16 June 2021).

- Collet, F.; Chamoin, J.; Pretot, S.; Lanos, C. Comparison of the hygric behaviour of three hemp concretes. Energy Build. 2013, 62, 294–303. [Google Scholar] [CrossRef]

- Maalouf, C.; Moussa, T.; Umurigirwa, B.S.; Mai, T.H. Hygrothermal behavior of a hemp-starch composite for roof applications. In Proceedings of the BS2015: 14th Conference of International Building Performance Simulation Association, Hyderabad, India, 7–9 December 2015; pp. 618–625. [Google Scholar]

- Niang, I.; Maalouf, C.; Moussa, T.; Bliard, C.; Samin, E.; Thomachot-Schneider, C.; Lachi, M.; Pron, H.; Mai, T.H.; Gaye, S. Hygrothermal performance of various Typha–clay composite. J. Build. Phys. 2018, 42, 316–335. [Google Scholar] [CrossRef]

- Boussetoua, H.; Maalouf, C.; Lachi, M.; Belhamri, A.; Moussa, T. Mechanical and hygrothermal characterisation of cork concrete composite: Experimental and modelling study. Eur. J. Environ. Civ. Eng. 2020, 24, 456–471. [Google Scholar] [CrossRef]

- Moussa, T.; Maalouf, C.; Lachi, M.; Umurigirwa, S.; Mai, T.H.; Henry, J.-F. Development and performance evaluation of a hemp–starch composite. J. Build. Phys. 2016, 40, 278–295. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vázquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of a hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Karaky, H.; Maalouf, C.; Bliard, C.; Moussa, T.; El Wakil, N.; Lachi, M.; Polidori, G. Hygrothermal and Acoustical Performance of Starch-Beet Pulp Composites for Building Thermal Insulation. Materials 2018, 11, 1622. [Google Scholar] [CrossRef] [Green Version]

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501. [Google Scholar] [CrossRef]

- Ingrao, C.; Giudice, A.L.; Tricase, C.; Rana, R.; Mbohwa, C.; Siracusa, V. Recycled-PET fibre based panels for building thermal insulation: Environmental impact and improvement potential assessment for a greener production. Sci. Total Environ. 2014, 493, 914–929. [Google Scholar] [CrossRef]

- Ijaz, N.; Dai, F.; Rehman, Z.U. Paper and wood industry waste as a sustainable solution for environmental vulnerabilities of expansive soil: A novel approach. J. Environ. Manag. 2020, 262, 110285. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Arrêté du 4 août 2021 Relatif aux Exigences de Performance Énergétique et Environnementale des Constructions de Bâtiments en France Métropolitaine et Portant Approbation de la Méthode de Calcul Prévue à L’Article R. 172-6 du Code de la Construction et de L’habitation—Légifrance. Available online: https://www.legifrance.gouv.fr/jorf/id/JORFTEXT000043936431 (accessed on 5 January 2022).

- Exploitation du Café—La Fabrique du Café. Available online: https://www.lafabriqueducafe.fr/culture-cafe/lexique/exploitation/ (accessed on 16 June 2021).

- International Coffee Organization. What’s New. Available online: http://www.ico.org/ (accessed on 18 March 2021).

- Salazar-López, N.J.; López-Rodríguez, C.V.; Hernández-Montoya, D.A.; Campos-Vega, R. Health Benefits of Spent Coffee Grounds. In Food Wastes and By-Products; Wiley: Hoboken, NJ, USA, 2020; pp. 327–351. [Google Scholar]

- Karmee, S.K. A spent coffee grounds based biorefinery for the production of biofuels, biopolymers, antioxidants and biocomposites. Waste Manag. 2018, 72, 240–254. [Google Scholar] [CrossRef] [PubMed]

- Saberian, M.; Li, J.; Donnoli, A.; Bonderenko, E.; Oliva, P.; Gill, B.; Lockrey, S.; Siddique, R. Recycling of spent coffee grounds in construction materials: A review. J. Clean. Prod. 2021, 289, 125837. [Google Scholar] [CrossRef]

- Arulrajah, A.; Maghoolpilehrood, F.; Disfani, M.M.; Horpibulsuk, S. Spent coffee grounds as a non-structural embankment fill material: Engineering and environmental considerations. J. Clean. Prod. 2014, 72, 181–186. [Google Scholar] [CrossRef]

- Da Fonseca, B.S.; Vilão, A.; Galhano, C.; Simão, J.A.R. Reusing coffee waste in manufacture of ceramics for construction. Adv. Appl. Ceram. 2013, 113, 159–166. [Google Scholar] [CrossRef]

- Velasco, P.M.; Mendívil, M.A.; Morales, M.P.; Muñoz, L.; Velasco, L.M. Eco-fired clay bricks made by adding spent coffee grounds: A sustainable way to improve buildings insulation. Mater. Struct. 2015, 49, 641–650. [Google Scholar] [CrossRef]

- Lachheb, A.; Allouhi, A.; El Marhoune, M.; Saadani, R.; Kousksou, T.; Jamil, A.; Rahmoune, M.; Oussouaddi, O. Thermal insulation improvement in construction materials by adding spent coffee grounds: An experimental and simulation study. J. Clean. Prod. 2019, 209, 1411–1419. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Martínez-García, C.; Martínez-Cartas, M.L.M.; Cotes-Palomino, M.T.C.; Pérez-Villarejo, L.; Cruz-Pérez, N.; Corpas-Iglesias, F.A. The use of different forms of waste in the manufacture of ceramic bricks. Appl. Clay Sci. 2011, 52, 270–276. [Google Scholar] [CrossRef]

- Yun, B.Y.; Cho, H.M.; Kim, Y.U.; Lee, S.C.; Berardi, U.; Kim, S. Circular reutilization of coffee waste for sound absorbing panels: A perspective on material recycling. Environ. Res. 2020, 184, 109281. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Li, G.; Yin, Z.-Y.; Dano, C.; Hicher, P.-Y.; Xia, X.-H.; Wang, J.-H. Influence of grading on the undrained behavior of granular materials. C. R. Méc. 2014, 342, 85–95. [Google Scholar] [CrossRef] [Green Version]

- Yoo, J.; Chang, S.J.; Wi, S.; Kim, S. Spent coffee grounds as supporting materials to produce bio-composite PCM with natural waxes. Chemosphere 2019, 235, 626–635. [Google Scholar] [CrossRef] [PubMed]

- Follain, N.; Joly, C.; Dole, P.; Bliard, C. Mechanical properties of starch-based materials. I. Short review and complementary experimental analysis. J. Appl. Polym. Sci. 2005, 97, 1783–1794. [Google Scholar] [CrossRef]

- ASTM D1621—16 Standard Test Method for Compressive Properties of Rigid Cellular Plastics. Available online: https://www.astm.org/Standards/D1621 (accessed on 18 October 2021).

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Shivhare, U.; Arora, S.; Ahmed, J.; Raghavan, G. Moisture adsorption isotherms for mushroom. LWT 2003, 37, 133–137. [Google Scholar] [CrossRef]

- AFNOR NF EN ISO 12572, Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties. 2001. Available online: https://www.iso.org/standard/34000.html (accessed on 16 June 2021).

- AFNOR NF EN ISO 12571, Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties. 2000. Available online: https://www.iso.org/standard/34000.html (accessed on 16 June 2021).

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure & Properties; Cambridge University Press: Oxford, UK, 1988. [Google Scholar] [CrossRef]

- Karaky, H.; Maalouf, C.; Bliard, C.; Gacoin, A.; Lachi, M.; El Wakil, N.; Polidori, G. Characterization of beet-pulp fiber reinforced potato starch biopolymer composites for building applications. Constr. Build. Mater. 2019, 203, 711–721. [Google Scholar] [CrossRef]

- Badouard, C.; Bogard, F.; Bliard, C.; Lachi, M.; Abbes, B.; Polidori, G. Development and characterization of viticulture by-products for building applications. Constr. Build. Mater. 2021, 302, 124142. [Google Scholar] [CrossRef]

- Costantine, G.; Harb, E.; Bliard, C.; Maalouf, C.; Kinab, E.; Abbès, B.; Beaumont, F.; Polidori, G. Experimental characterization of starch/beet-pulp bricks for building applications: Drying kinetics and mechanical behavior. Constr. Build. Mater. 2020, 264, 120270. [Google Scholar] [CrossRef]

- Zhang, X.; Zillig, W.; Künzel, H.M.; Mitterer, C.; Zhang, X. Combined effects of sorption hysteresis and its temperature dependency on wood materials and building enclosures-part II: Hygrothermal modeling. Build. Environ. 2016, 106, 181–195. [Google Scholar] [CrossRef]

- Gourlay, E.; Glé, P.; Marceau, S.; Foy, C.; Moscardelli, S. Effect of water content on the acoustical and thermal properties of hemp concretes. Constr. Build. Mater. 2017, 139, 513–523. [Google Scholar] [CrossRef]

- Glé, P.; Gourdon, E.; Arnaud, L. Acoustical properties of materials made of vegetable particles with several scales of porosity. Appl. Acoust. 2011, 72, 249–259. [Google Scholar] [CrossRef]

- Isover Products Documentation on Their Acoustic. 2021. Available online: https://www.isover.fr/sites/isover.fr/files/assets/documents/catalogue_solutions_78_82_absorption_acoustique.pdfn (accessed on 16 June 2021).

- Rockfon Website, Product Description. 2021. Available online: https://www.rockfon.fr/produits/rockfon-blanka-bas/?SelectedCat= fiches techniques plafonds et panneaux muraux#Performances (accessed on 16 June 2021).

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Wolkoff, P.; Kjærgaard, S.K. The dichotomy of relative humidity on indoor air quality. Environ. Int. 2007, 33, 850–857. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, N.; Redaelli, V.; Rosina, E.; Augelli, F. Moisture detection in wood and plaster by IR thermography. Infrared Phys. Technol. 2004, 46, 161–166. [Google Scholar] [CrossRef]

| Samples/Composition | Bulk Density ρ (kg/m3) | Young’s Modulus E (MPa) | Conductivity λ (W/(m·K)) | Diffusivity a (m2/s−1) |

|---|---|---|---|---|

| SSCC-100 | 161 ± 23 | 3.38 ± 0.50 | 0.066 ± 0.004 | 0.379 ± 0.097 × 10−6 |

| SSCC-40 | 588 ± 12 | 6.10 ± 0.49 | 0.093 ± 0.006 | 0.438 ± 0.054 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moussa, T.; Maalouf, C.; Bliard, C.; Abbes, B.; Badouard, C.; Lachi, M.; do Socorro Veloso Sodré, S.; Bufalino, L.; Bogard, F.; Beaumont, F.; et al. Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials 2022, 15, 1689. https://doi.org/10.3390/ma15051689

Moussa T, Maalouf C, Bliard C, Abbes B, Badouard C, Lachi M, do Socorro Veloso Sodré S, Bufalino L, Bogard F, Beaumont F, et al. Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials. 2022; 15(5):1689. https://doi.org/10.3390/ma15051689

Chicago/Turabian StyleMoussa, Tala, Chadi Maalouf, Christophe Bliard, Boussad Abbes, Céline Badouard, Mohammed Lachi, Silvana do Socorro Veloso Sodré, Lina Bufalino, Fabien Bogard, Fabien Beaumont, and et al. 2022. "Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures" Materials 15, no. 5: 1689. https://doi.org/10.3390/ma15051689

APA StyleMoussa, T., Maalouf, C., Bliard, C., Abbes, B., Badouard, C., Lachi, M., do Socorro Veloso Sodré, S., Bufalino, L., Bogard, F., Beaumont, F., & Polidori, G. (2022). Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials, 15(5), 1689. https://doi.org/10.3390/ma15051689