Evaluation of Powder Metallurgy Workpiece Prepared by Equal Channel Angular Rolling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

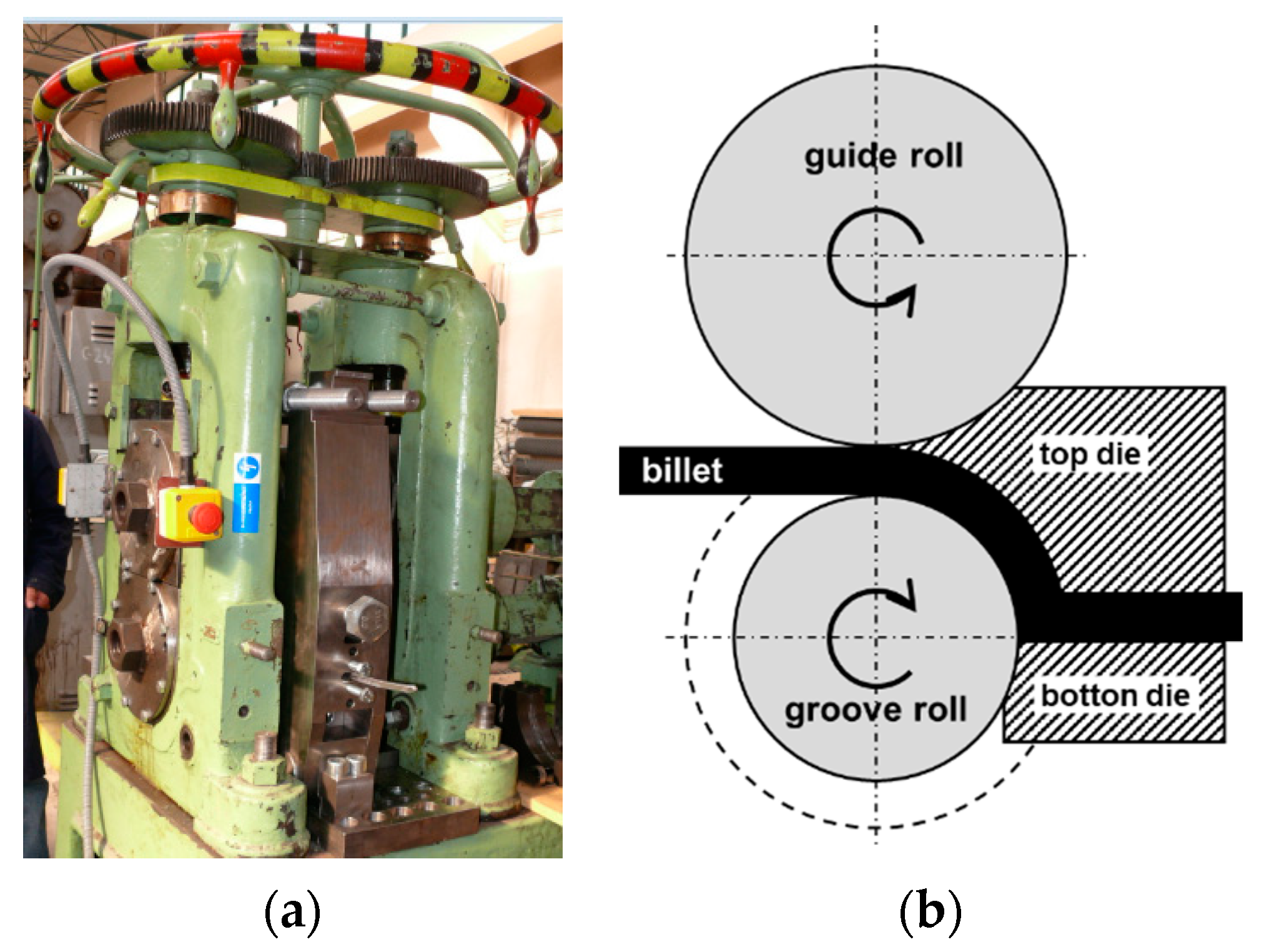

2.2. The ECAR Processing

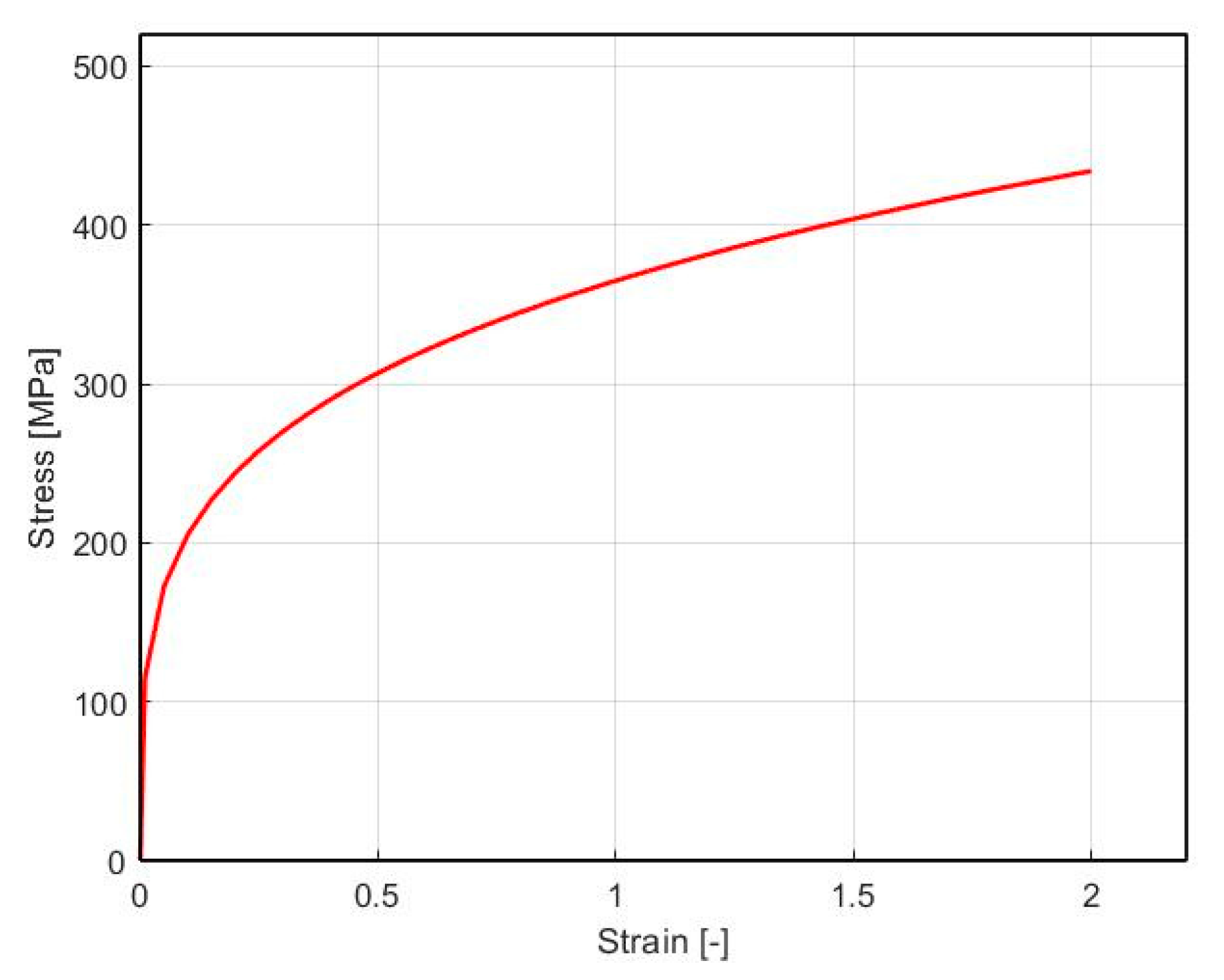

2.3. Formability of Alumix 321

2.4. Initial Conditions for Numerical Simulations of the ECAR Process

3. Results

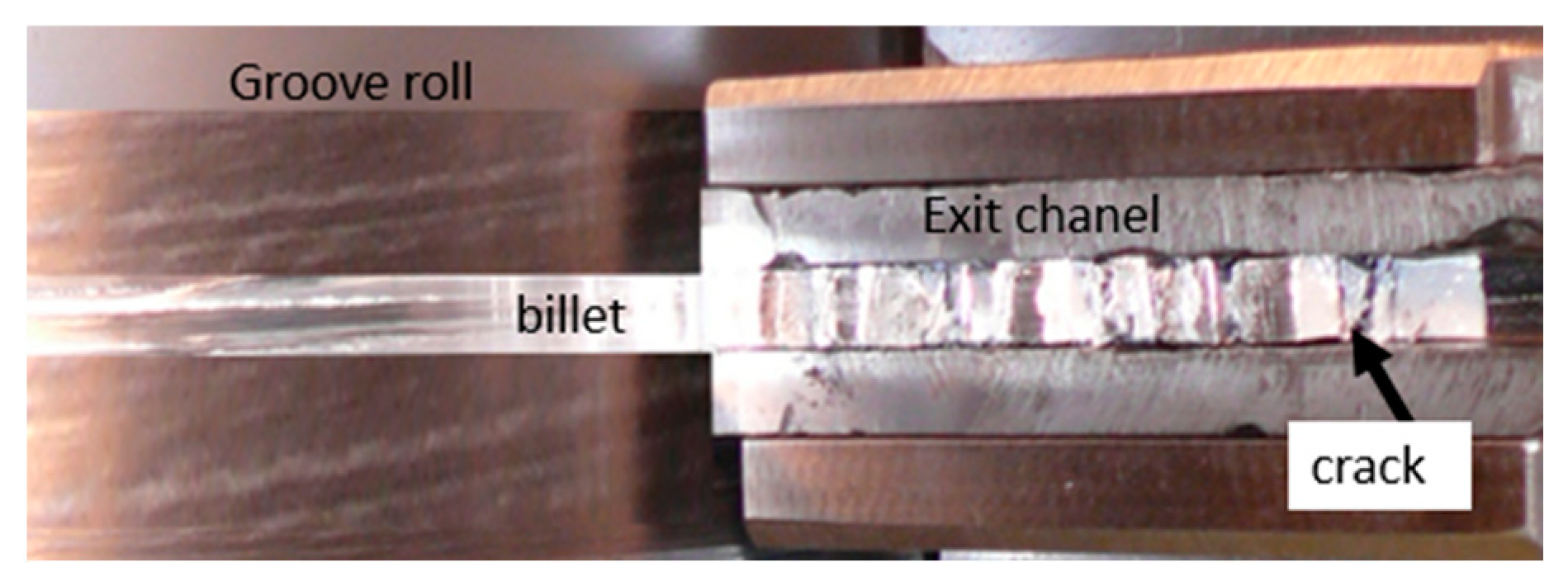

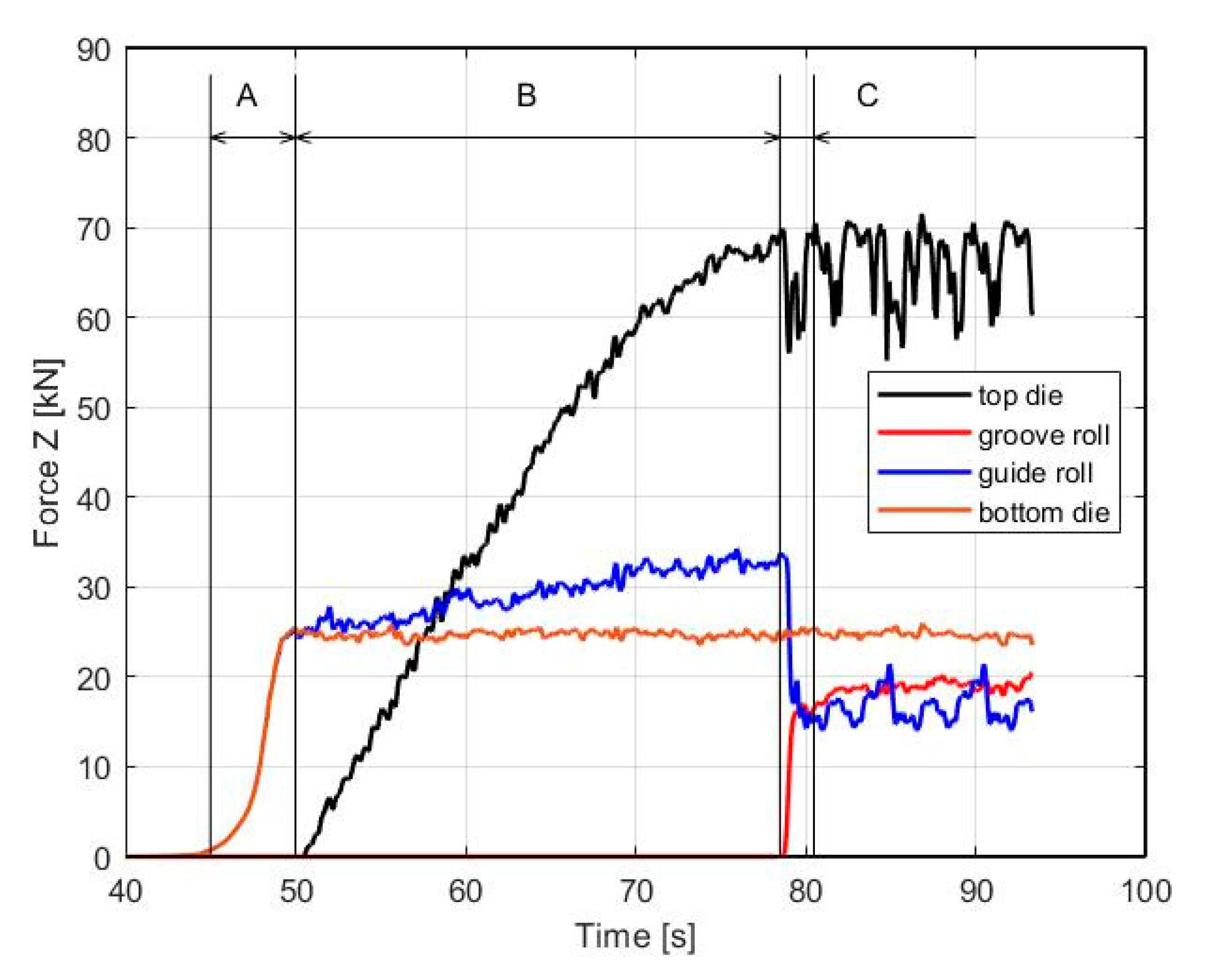

3.1. The ECAR Processing

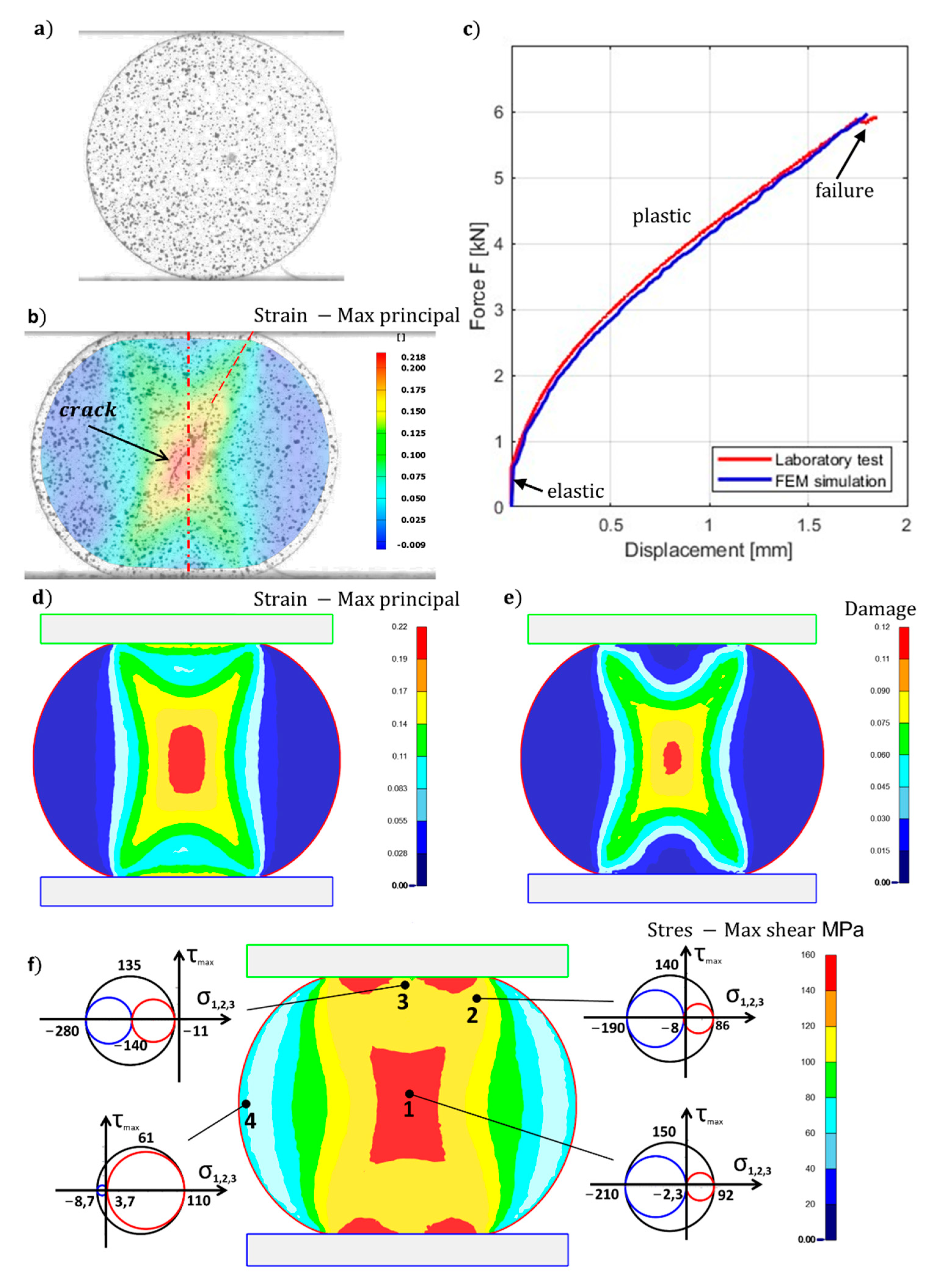

3.2. Formability of Alumix 321

3.3. FEM Simulation of the ECAR Process

4. Discussion

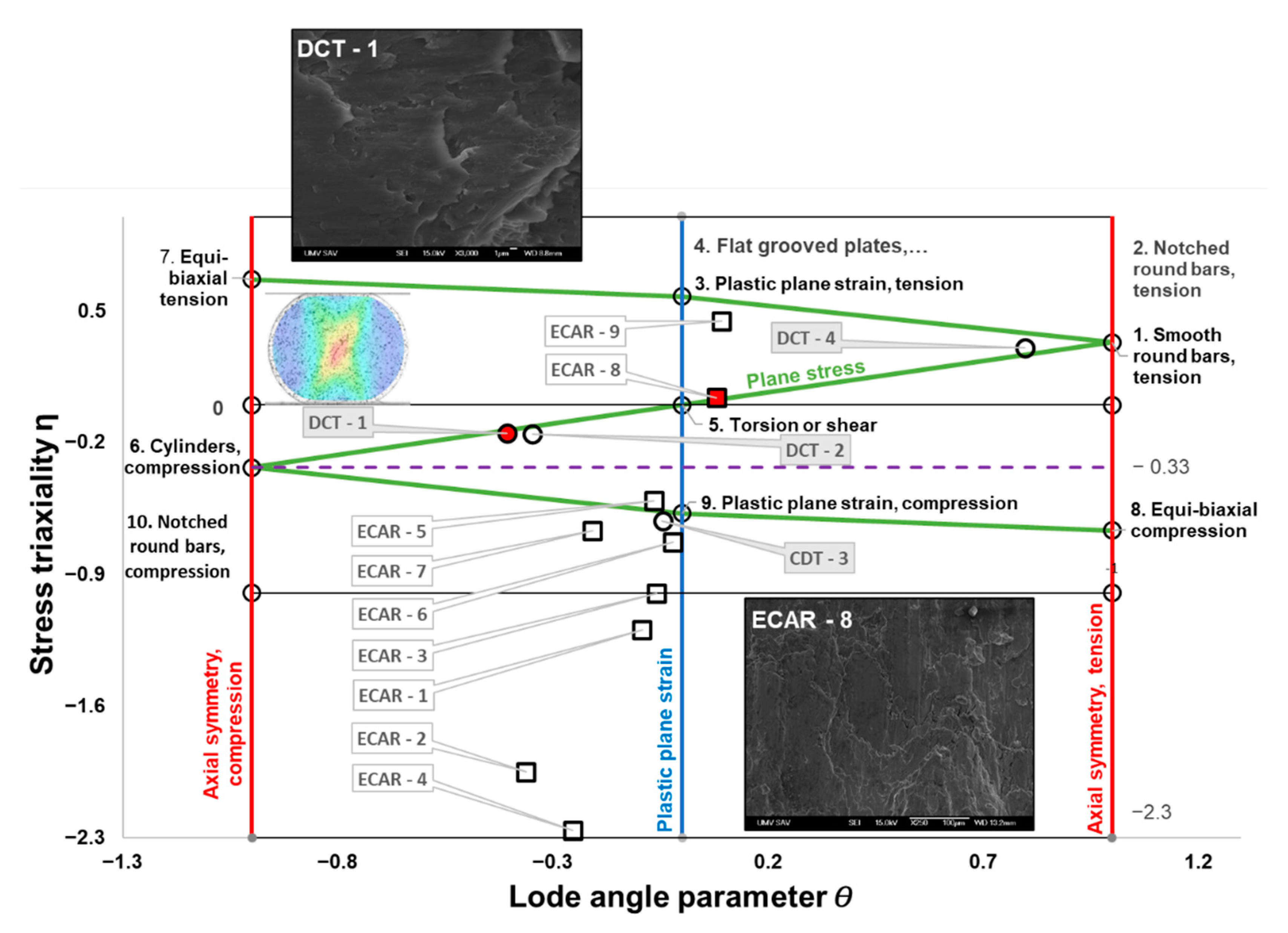

4.1. Distribution and Evolution of Stress Triaxiality

4.2. The Stress Triaxiality of the DC Test

4.3. The Stress Triaxiality of the ECAR Process

5. Conclusions

- -

- the DIC and FEM were used to study the stress state of the ECAR process and the DC test;

- -

- the relationship between the stress state parameters and failure mode was evaluated using the stress triaxiality versus Lode parameter diagram;

- -

- the damage factor was determined from the DC test, which reaches a value of 0.12 in the place of the crack;

- -

- from FEM simulations is possible to divide the deformation process of the ECAR processing into three deformation areas: shape rolling zone, upsetting zones, and SPD zone, which take place under the plane strain conditions;

- -

- due to the high-pressure hydrostatic stresses in the deformation zones, the material was probably compacted close to 100%;

- -

- the damage factor in the output channel of the ECAR process reaches a value of up to 0.5, which is several times higher than the value measured using the DC test;

- -

- materials with reduced formability, such as sintered PM material, cannot be additionally ennobled by plastic deformations in the ECAR process because in the main deformation zone of the process stress conditions for the pure shear are created, which will cause material violations by shearing fracture;

- -

- when evaluating the formability of the PM material by the DC test, it was found that the DC test can be used for the calibration and verification of various fracture criteria for the stress state located between the pure shear and the axial symmetry compression.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Bidulská, J.; Bidulský, R.; Actis Grande, M.; Kvačkaj, T. Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy. Materials 2019, 12, 3724. [Google Scholar] [CrossRef]

- Kvackaj, T.; Bidulska, J. From micro to nano scale structure by plastic deformations. Mater. Sci. Forum. 2014, 783–786, 842–847. [Google Scholar] [CrossRef]

- Vicenzi, B.; Boz, K.; Aboussouan, L. Powder Metallurgy in Aerospace—Fundamentals of PM Processes and Examples of Applications. Acta Metall. Slovaca 2020, 26, 144–160. [Google Scholar] [CrossRef]

- Xia, K.; Wu, X. Back pressure equal channel angular consolidation of pure Al particles. Scr. Mater. 2005, 53, 1225–1229. [Google Scholar] [CrossRef]

- Bidulská, J.; Kvackaj, T.; Kocisko, R.; Bidulský, R.; Actis Grande, M. Influence of ECAP-Back pressure on the porosity distri-bution. Acta Phys. Pol. A 2010, 117, 864–868. [Google Scholar] [CrossRef]

- Druh, J.; Zhilyaev, A.; Zielinska, M.; Nogués, J.; Surinach, S.; Thibault, J.; Baró, M.D. Microstructural Effects and Large Microhardness in Cobalt Processed by High Pressure Torsion Consolidation of Ball Milled Powders. Acta Mater. 2003, 51, 6385–6393. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. Processing nanocrystalline Ti and its nanocomposites from micrometer-sized Ti powder using high pressure torsion. Mater. Sci. Eng. A 2000, 282, 78–85. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Hashemi, R. Experimental evaluation of forming limit diagram and mechanical properties of nano/ultra-fine grained aluminum strips fabricated by accumulative roll bonding. Int. J. Mater. Res. 2017, 108, 1036–1044. [Google Scholar] [CrossRef]

- Lee, J.C.; Seok, H.K.; Han, J.H.; Chung, Y.H. Controlling the Textures of the Metal Strips via the Continuous Con fi ned Strip Shearing (C2S2) Process. Mater. Res. Bull. 2001, 36, 997–1004. [Google Scholar] [CrossRef]

- Lee, J.C.; Seok, H.K.; Suh, J.Y. Microstructural Evolutions of the Al Strip Prepared by Cold Rolling and Continuous Equal Channel Angular Pressing. Acta Mater. 2002, 50, 4005–4019. [Google Scholar] [CrossRef]

- Xu, S.; Zhao, G.; Ren, X.; Guan, Y. Numerical investigation of aluminum deformation behavior in three-dimensional continuous confined strip shearing process. Mater. Sci. Eng. A 2008, 476, 281–289. [Google Scholar] [CrossRef]

- Raab, G.J.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Continuous processing of ultrafine grained Al by ECAP–Conform. Materials Sci. Eng. A 2004, 382, 30–34. [Google Scholar] [CrossRef]

- Xu, C.; Schroeder, S.; Berbon, P.B.; Langdon, T.G. Principles of ECAP–Conform as a continuous process for achieving grain refinement: Application to an aluminum alloy. Acta Mater. 2010, 58, 1379–1386. [Google Scholar] [CrossRef]

- Kvackaj, T.; Kvackaj, M.; Stoyka, V.; Kocisko, R.; Bidulska, J.; Bacso, J. Influence of ECAR processing on OFHC Cu material properties. Mater. Sci. Forum 2011, 667–669, 133–137. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Chen, Z.; Xia, W. Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature. Mater. Charact. 2007, 58, 617–622. [Google Scholar] [CrossRef]

- Kvačkaj, T.; Kováčová, A.; Kvačkaj, M.; Kočiško, R.; Lityńska-Dobrzyńska, L.; Stoyka, V.; Miháliková, M. TEM studies of structure in OFHC copper processed by equal channel angular rolling. Micron 2012, 43, 720–724. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Chen, Z.; Xia, W.; Zhou, T. Effect of channel clearance on crystal orientation development in AZ31 magnesium alloy sheet produced by equal channel angular rolling. J. Mater. Process. Technol. 2007, 184, 97–101. [Google Scholar] [CrossRef]

- Kvackaj, T.; Kočiško, R.; Tiža, J.; Bidulska, J.; Kovacoca, G.; Bidulsky, R.; Bacsó, J.; Vlado, M. Application of workability test to SPD processing. Arch. Metall. Mater. 2013, 58, 407–412. [Google Scholar] [CrossRef]

- Chung, Y.H.; Park, J.W.; Lee, K.H. Controlling the Thickness Uniformity in Equal Channel Angular Rolling (ECAR). Mater. Sci. Forum 2007, 539–543, 2872–2877. [Google Scholar] [CrossRef]

- Gouveia, B.P.P.A.; Rodrigues, J.M.C.; Martins, P.A.F. Ductile fracture in metalworking: Experimental and theoretical research. J. Mater. Process. Technol. 2000, 1–3, 52–63. [Google Scholar] [CrossRef]

- Li, H.; Fu, M.W.; Lu, J.; Yang, H. Ductile fracture: Experiments and computations. Int. J. Plast. 2011, 27, 147–180. [Google Scholar] [CrossRef]

- Appa Rao, J.; Rao, J.B.; Kamaluddin, S.; Sarcar, M.M.M.; Bhargava, N.R.M.R. Studies on cold workability limits of pure copper using machine vision system and its finite element analysis. Mater. Des. 2009, 30, 2143–2151. [Google Scholar] [CrossRef]

- Kováčová, A.; Kvačkaj, T.; Kočiško, R.; Tiža, J. Physical and numerical determination of workability in aluminium alloys. Acta Metall. Slovaca 2014, 20, 279–286. [Google Scholar] [CrossRef]

- Cockcroft, M.G.; Latham, D.J. Ductility and the workability of metals. J. Inst. Met. 1968, 96, 33–39. [Google Scholar]

- Wierzbicki, T.; Bao, Y.; Lee, Y.-W.; Bai, Y. Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Stebunov, S.; Vlasov, A.; Biba, N. Prediction of fracture in cold forging with modified Cockcroft-Latham criterion. Procedia Manuf. 2018, 15, 519–526. [Google Scholar] [CrossRef]

- Selcuk, L.; Asma, D. Experimental investigation of the rock–concrete bi materials influence of inclined interface on strength and failure behavior. Int. J. Rock Mech. Min. Sci. 2019, 123, 104119. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, S.; Kou, P.; Li, S.; Li, P.; Yan, S. Investigation of Damage Evolution in Heterogeneous Rock Based on the Grain-Based Finite-Discrete Element Model. Materials 2021, 14, 3969. [Google Scholar] [CrossRef]

- García-Leiva, M.C.; Ocaña, I.; Martín-Meizoso, A.; Martínez-Esnaola, J.M. Fracture mechanics of sigma sm1140+ fibre. Eng. Fract. Mech. 2002, 69, 1007–1013. [Google Scholar] [CrossRef]

- Furukawaa, R.; Chenb, Y.; Horiguchib, A.; Takagakia, K.; Nishia, J.; Konishia, A.; Shirakawac, Y.; Sugimotoa, M.; Narisawa, S. Numerical evaluation of the capping tendency of microcrystalline cellulose tablets during a diametrical compression test. Int. J. Pharm. 2015, 493, 182–191. [Google Scholar] [CrossRef]

- Jonsén, P.; Haggblad, H.-A. Fracture energy based constitutive models for tensile fracture of metal powder compacts. Int. J. Solids Struct. 2007, 44, 6398–6411. [Google Scholar] [CrossRef]

- Bonollo, F.; Molinas, B.; Tangerini, I.; Zambon, A. Diametral compression testing of metal matrix composites. Mater. Sci. Technol. 1994, 10, 558–564. [Google Scholar] [CrossRef]

- Degnan, C.C.; Kennedy, A.R.; Shipway, P.H. Fracture toughness measurements of powder metallurgical (P/M) green compacts: A novel method of sample preparation. J. Mater. Sci. 2004, 39, 2605–2607. [Google Scholar] [CrossRef]

- Alabi, A.A.; Tahir, S.M.; Zahari, N.I.; Azmah Hanim, M.A.; Anuar, M.S. A modified diametrical compression test technique (MDCTT) for mode II fracture toughness of iron powder compact. Powder Technol. 2017, 319, 356–364. [Google Scholar] [CrossRef]

- ASTM D 3967; ASTM: Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2008.

- Peng, J.; Zhou, P.; Wang, Y.; Dai, Q.; Knowles, D.; Mostafavi, M. Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch. Metals 2021, 11, 1627. [Google Scholar] [CrossRef]

- Lou, Y.; Yoon, J.W.; Huh, H. Modeling of shear ductile fracture considering a changeable cut-off value for stress triaxiality. Int. J. Plast. 2014, 54, 56–80. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Ziółkowski, A.G. Parametrization of Cauchy Stress Tensor Treated as Autonomous Object Using Isotropy Angle and Skewness Angle. Eng. Trans. 2022, 70, 239–286. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Kalinin, Y.; Brykov, M.; Petryshynets, I.; Efremenko, V.; Hesse, O.; Kunert, M.; Andrushchenko, M.; Osipov, M.; Berezhnyy, S.; Bykovskiy, O. Structure of High-Carbon Steel after Welding with Rapid Cooling. Acta Met. Slovaca 2019, 25, 114–122. [Google Scholar] [CrossRef]

- Shen, W.Q.; Cao, Y.J.; Shao, J.F.; Liu, Z.B. Prediction of plastic yield surface for porous materials by a machine learning approach. Mater. Today Commun. 2020, 25, 101477. [Google Scholar] [CrossRef]

- Cheng, L.; de Saxcé, G.; Kondo, D. A stress-based variational model for ductile porous materials. Int. J. Plast. 2013, 55, 133–151. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Q.; Zheng, K.; Jin, C.; Pan, L. Mesoscale Study on Splitting Tensile Damage Characteristics of Concrete Based on X-ray Computed Tomography and Digital Image Correlation Technology. Materials 2022, 15, 4416. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ahmadi, M.; Pahlavani, M.; Hashemi, R. DIC-based experimental study of fracture toughness through R-curve tests in a multi-layered Al-Mg (LZ91) composite fabricated by ARB. J. Alloys Compd. 2021, 883, 160843. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Shahmirzaloo, A.; Hashemi, R.; Farahani, M. Using digital image correlation for characterizing the elastic and plastic parameters of ultrafine-grained Al 1050 strips fabricated via accumulative roll bonding process. Mater. Res. Express 2019, 6, 086542. [Google Scholar] [CrossRef]

- Kvačkaj, T.; Tiža, J.; Kováčová, A.; Kočiško, R.; Bacsó, J. Determination of ductile fracture criteria for bulk and PM materials. Kov. Mater. 2014, 52, 249–259. [Google Scholar] [CrossRef]

- Procopio, A.T.; Zavaliangos, A.; Cunningham, J.C. Analysis of the diametrical compression test and the applicability to plastically deforming materials. J. Mater. Sci. 2003, 38, 3629–3639. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Serati, M.; Masoumi, H.; Rahimi, E. Numerical assessment of rupture mechanisms in Brazilian test of brittle materials. Int. J. Solids Struct. 2019, 180–181, 1–12. [Google Scholar] [CrossRef]

- Li, D.; Li, B.; Han, Z.; Zhu, Q. Evaluation on Rock Tensile Failure of the Brazilian Discs under Different Loading Configurations by Digital Image Correlation. Appl. Sci. 2020, 10, 5513. [Google Scholar] [CrossRef]

- García, V.J.; Márquez, C.O.; Zúñiga-Suárez, A.R.; Zuñiga-Torres, B.C.; Villalta-Granda, L.J. Brazilian Test of Concrete Specimens Subjected to Different Loading. Int. J. Concr. Struct. Mater. 2017, 11, 343–363. [Google Scholar] [CrossRef]

- Kvačkaj, T.; Kočiško, R.; Kováčová, A. Local analysis of plastic deformation in ECAP and ECARprocesses. Chem. Listy 2012, 106, 464–467. [Google Scholar]

- Güley, V.; Güzel, A.; Jäger, A.; Ben Khalifa, N.; Tekkaya, A.E.; Misiolek, W.Z. Effect of die design on the welding quality during solid state recycling of AA6060 chips by hot extrusion. Mater. Sci. Eng. A 2013, 574, 163–175. [Google Scholar] [CrossRef]

- Kočiško, R.; Bidulský, R.; Dragošek, L.; Škrobian, M. Various Possibilities of the Hot Extrusion in Aluminum Chips Processing. Acta Metall. Slovaca 2014, 20, 302–308. [Google Scholar] [CrossRef]

- Kvačkaj, T.; Kovacova, A.; Kocisko, R.; Bidulska, J.; Lityńska–Dobrzyńsk, L.; Jenei, P.; Gubicza, J. Microstructure evolution and mechanical performance of copper processed by equal channel angular rolling. Mater. Charact. 2017, 134, 246–252. [Google Scholar] [CrossRef]

- Wu, P.-Y.; Xie, S.S.; LI, H.; Yan, M.; Huang, G.-J.; Cheng, L. Effect of extrusion wheel angular velocity on continuous extrusion forming process of copper concave bus bar. Trans. Nonferrous Met. Soc. China 2007, 17, 280–286. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On the cut-off value of negative triaxiality for fracture. Eng. Fract. Mech. 2005, 72, 1049–1069. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kočiško, R.; Kvačkaj, T.; Bidulská, J.; Bidulský, R.; Petroušek, P.; Pokorný, I.; Lupták, M.; Actis Grande, M. Evaluation of Powder Metallurgy Workpiece Prepared by Equal Channel Angular Rolling. Materials 2023, 16, 601. https://doi.org/10.3390/ma16020601

Kočiško R, Kvačkaj T, Bidulská J, Bidulský R, Petroušek P, Pokorný I, Lupták M, Actis Grande M. Evaluation of Powder Metallurgy Workpiece Prepared by Equal Channel Angular Rolling. Materials. 2023; 16(2):601. https://doi.org/10.3390/ma16020601

Chicago/Turabian StyleKočiško, Róbert, Tibor Kvačkaj, Jana Bidulská, Róbert Bidulský, Patrik Petroušek, Imrich Pokorný, Miloslav Lupták, and Marco Actis Grande. 2023. "Evaluation of Powder Metallurgy Workpiece Prepared by Equal Channel Angular Rolling" Materials 16, no. 2: 601. https://doi.org/10.3390/ma16020601

APA StyleKočiško, R., Kvačkaj, T., Bidulská, J., Bidulský, R., Petroušek, P., Pokorný, I., Lupták, M., & Actis Grande, M. (2023). Evaluation of Powder Metallurgy Workpiece Prepared by Equal Channel Angular Rolling. Materials, 16(2), 601. https://doi.org/10.3390/ma16020601