A Pulsed Current Application to the Deformation Processing of Materials

Abstract

:1. Introduction

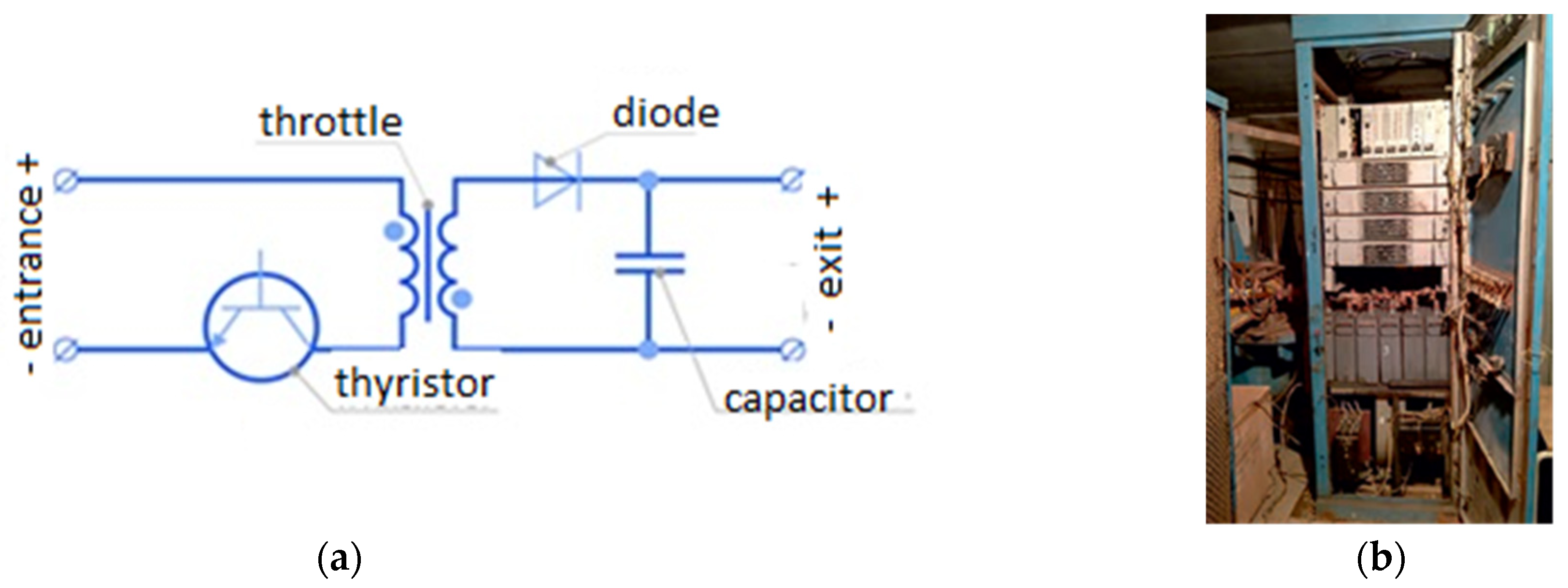

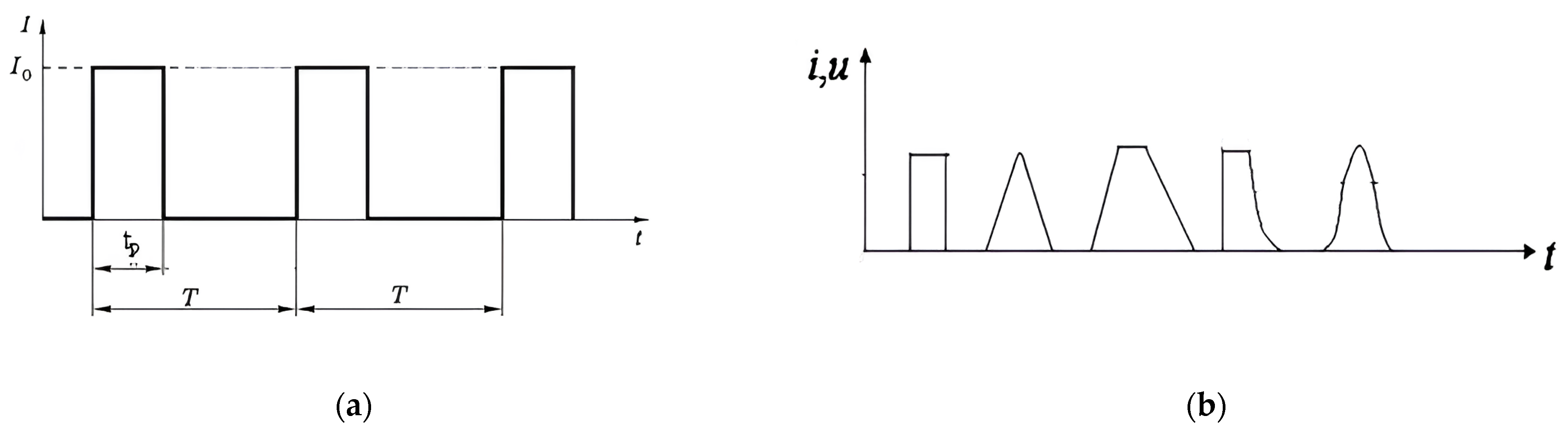

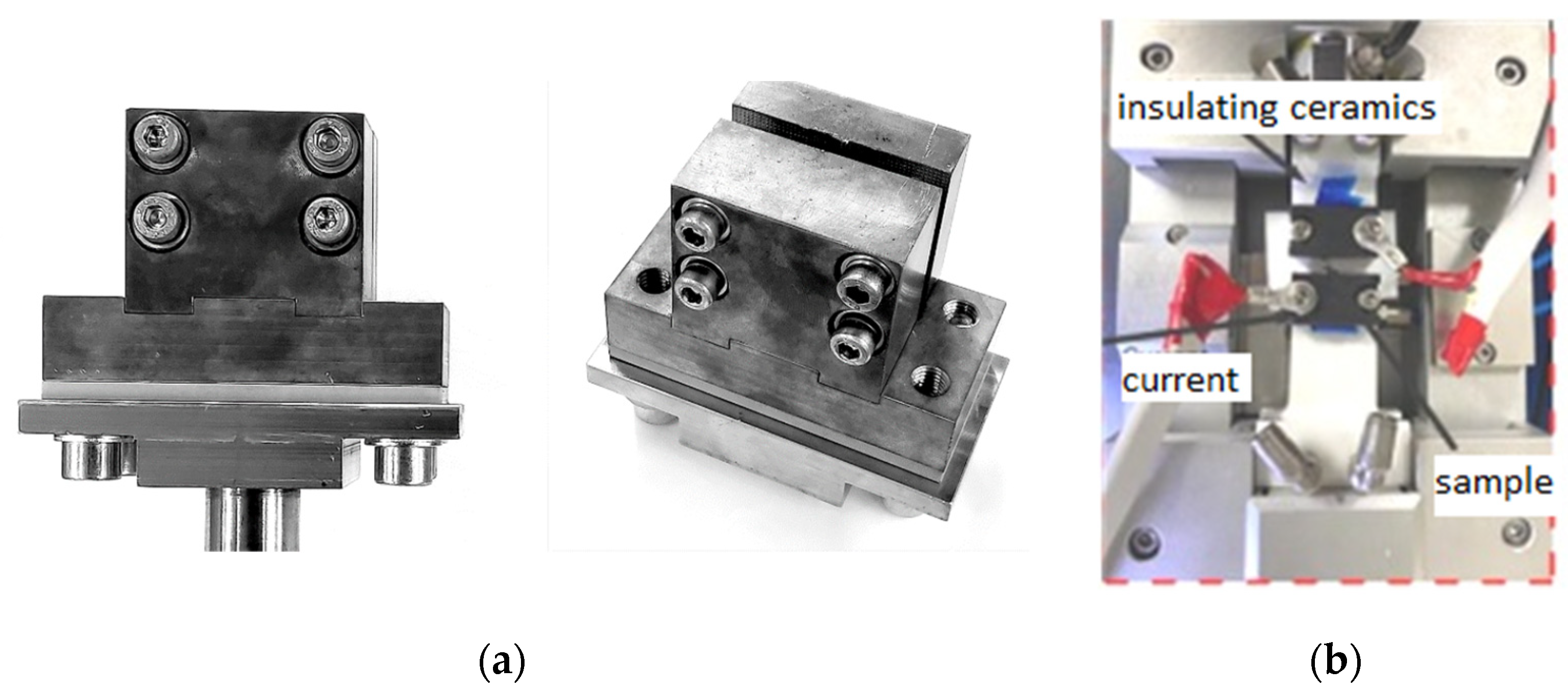

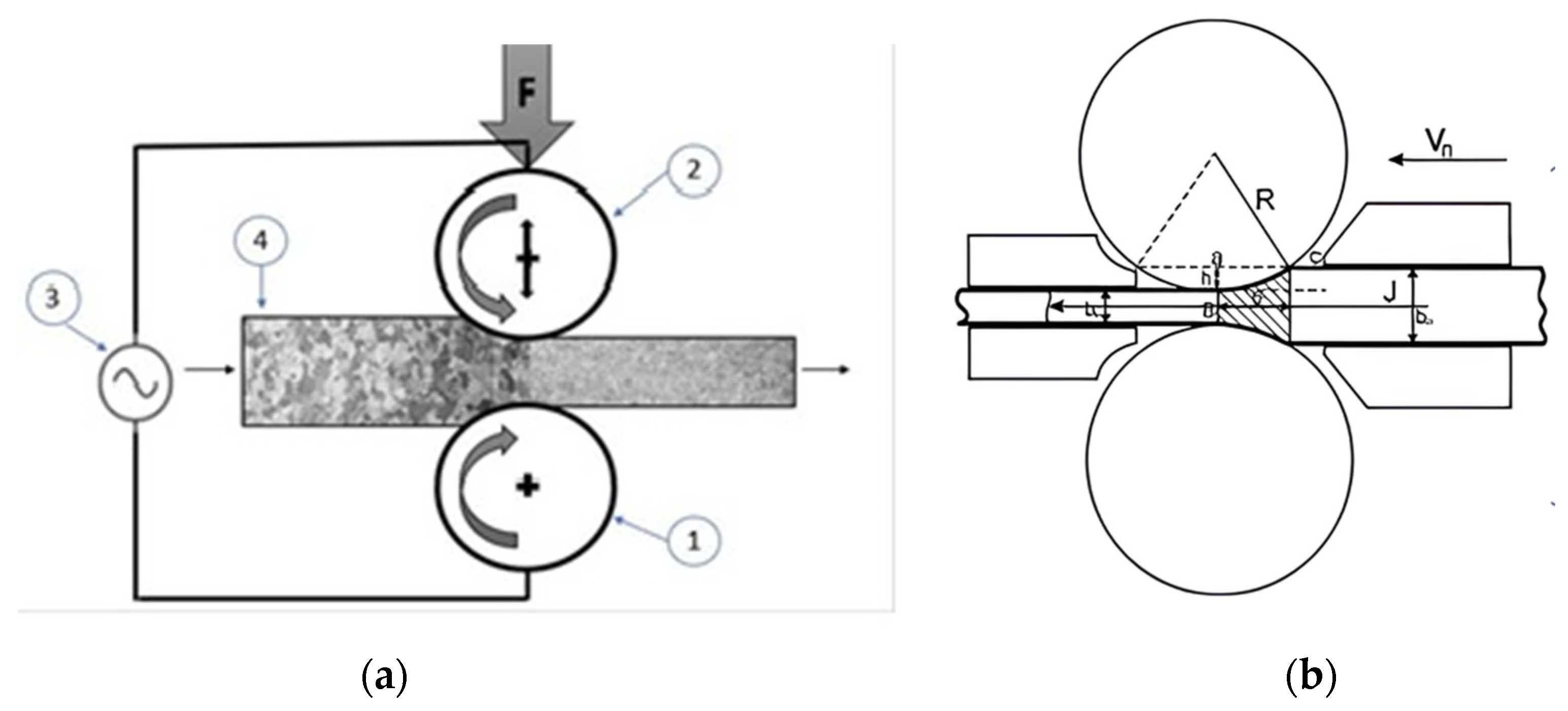

2. Methods of Current Introduction

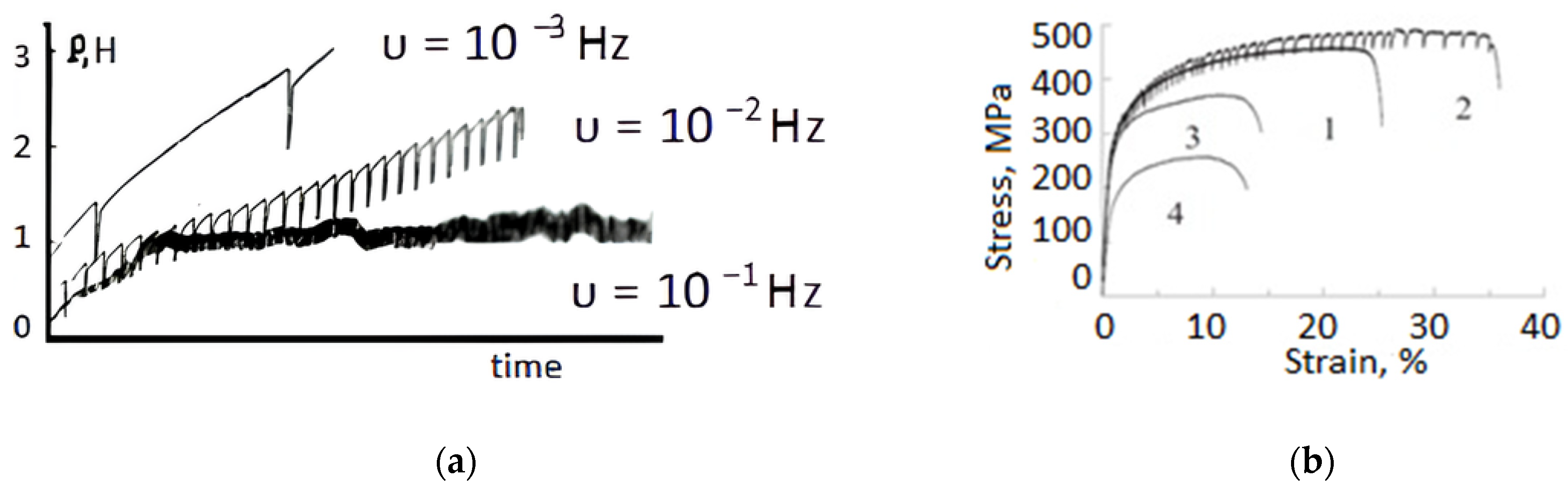

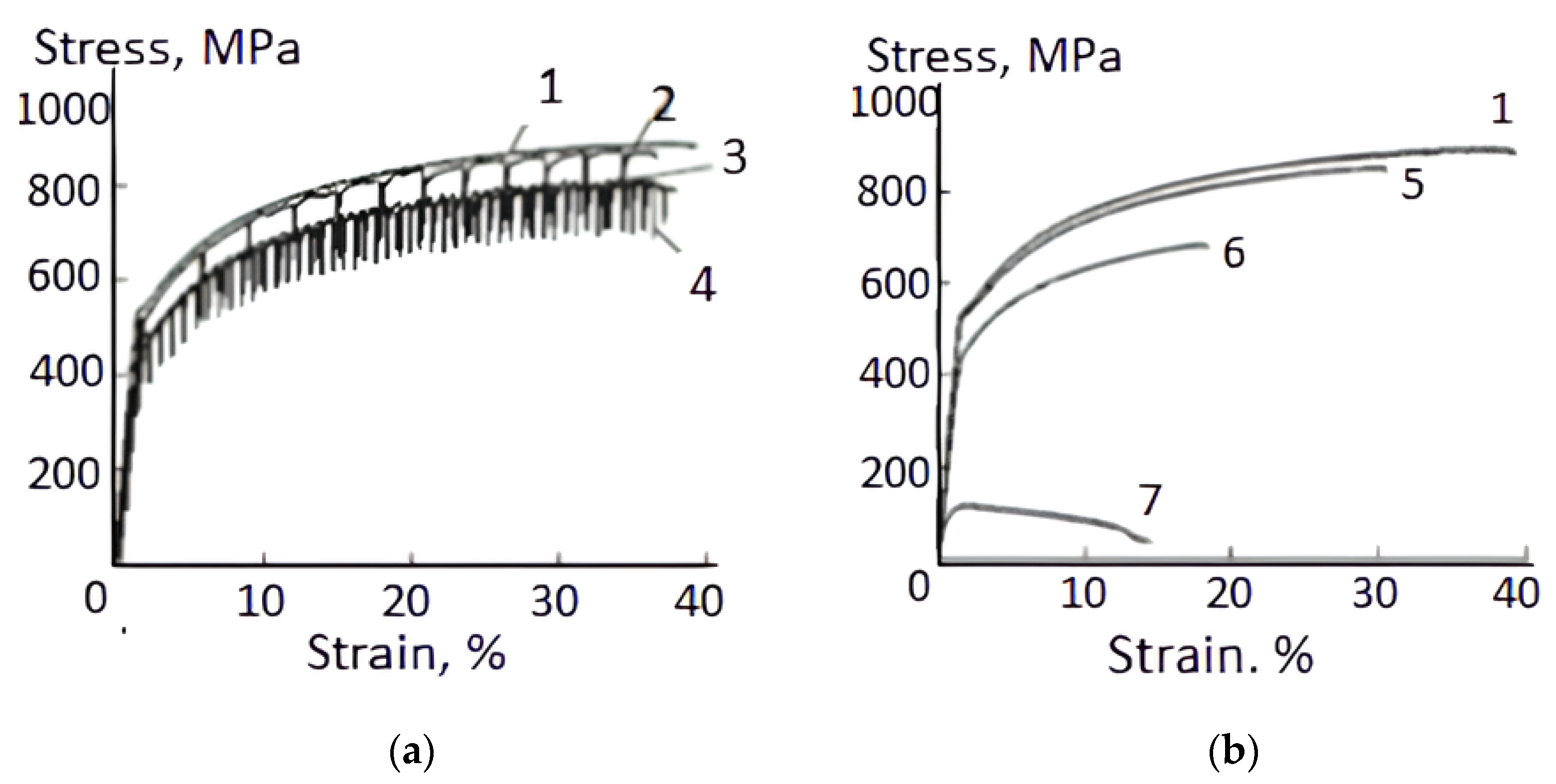

3. Deformation Behavior

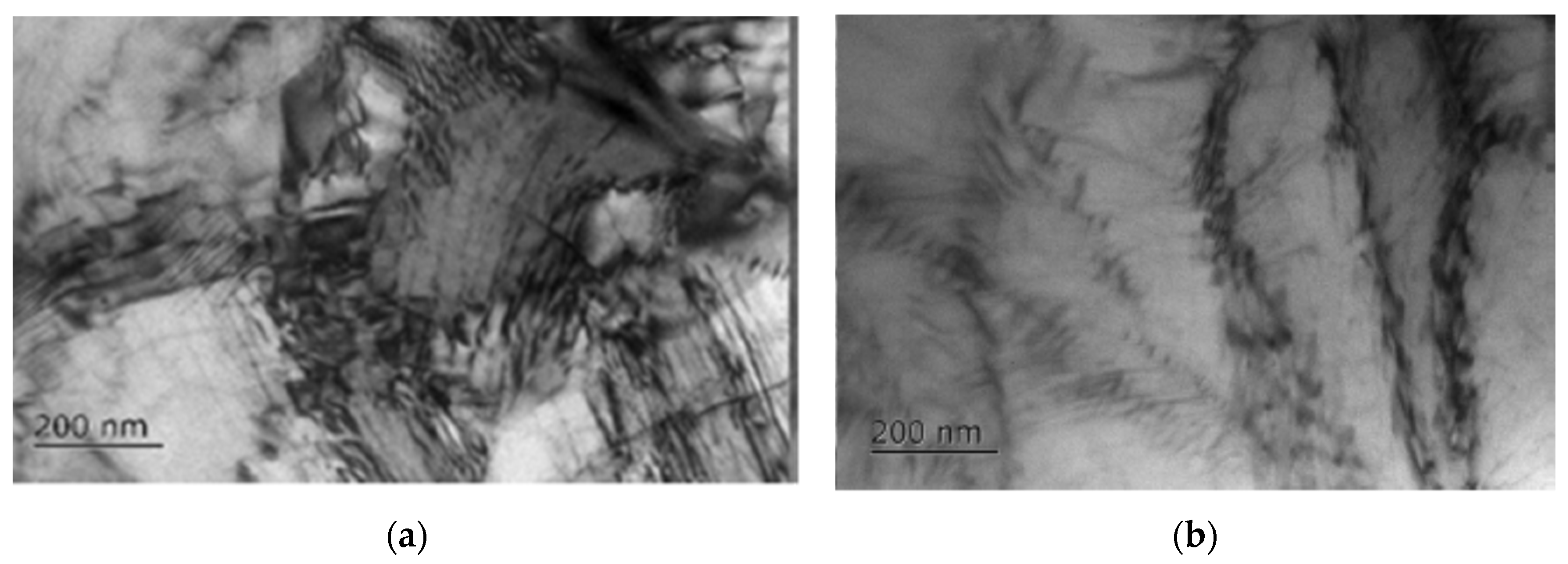

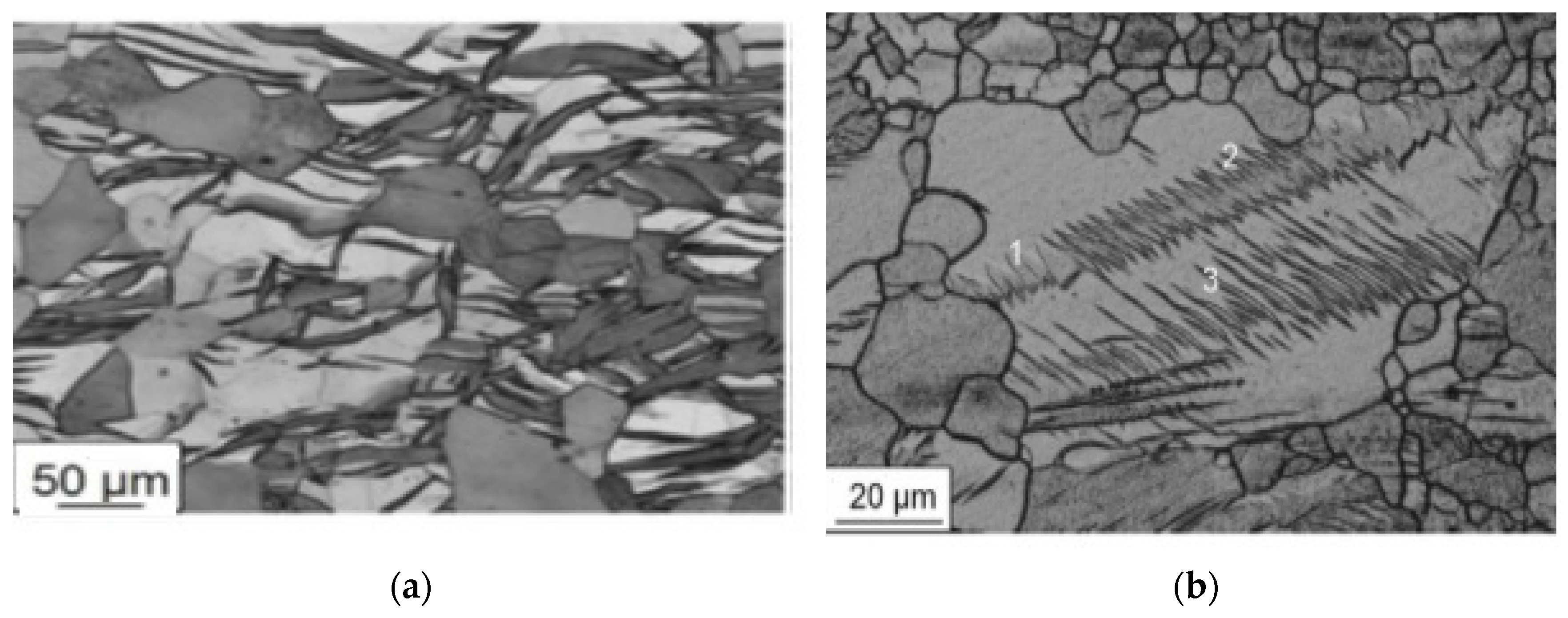

4. Microstructure Features

5. Physical–Mechanical and Technological Properties

6. The Mechanisms and Modeling of EPE

7. Application of EPE

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheng, Y.; Hua, Y.; Wang, X.; Zhao, X.; Chen, L.; Zhou, H.; Wang, J.; Berndt, C.C.; Li, W. Application of high-density electropulsing to improve the performance of metallic materials: Mechanisms, microstructure and properties. Materials 2018, 11, 185. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Choi, S.-W.; Narayana, P.L.; Nguyet Nguyen, T.A.; Hong, S.-T.; Kim, J.H.; Kang, N.; Hong, J.-K. Effect of electric current heat treatment on commercially pure titanium sheets. Metals 2021, 11, 783. [Google Scholar] [CrossRef]

- Pan, D.; Wang, Y.; Guo, Q.; Zhang, D.; Xu, X.; Zhao, Y. Grain refinement of Al–Mg–Si alloy without any mechanical deformation and matrix phase transformation via cyclic electro-pulsing treatment. Mater. Sci. Eng. A 2021, 807, 140916. [Google Scholar] [CrossRef]

- Troitskii, O.A. Electromechanical effect in metals. JETP Lett. 1969; 1, 18–22. [Google Scholar]

- Stolyarov, V.; Calliari, I.; Gennari, C. Features of the interaction of plastic deformation and pulse current in various materials. Mater. Lett. 2021, 299, 130049. [Google Scholar] [CrossRef]

- Minko, D.V. Analysis of the prospects of the application of the electroplastic effect in the processes of processing metals with pressure. Foundry Prod. Metall. 2020, 4, 125–130. (In Russian) [Google Scholar] [CrossRef]

- Qin, R.S. Outstanding issues in electropulsing processing. Mater. Sci. Technol. 2015, 31, 203–206. [Google Scholar] [CrossRef]

- Xiao, S.H.; Guo, J.D.; Wu, S.D.; He, G.H.; Li, S.X. Recrystallization in fatigued copper single crystals under electropulsing. Scr. Mater 2002, 46, 1–6. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, Y.; Liu, B. Experimental and simulated investigation of the deformation behavior and microstructural evolution of Ti6554 titanium alloy during an electropulsing-assisted microtension process. Mater. Sci. Eng. 2022, 838, 142745. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, R.; Chong, Y.; Li, X.; Abu-Odeh, A.; Rothchild, E.; Chrzan, D.C.; Asta, M.; Morris, J.W.; Minor, A.M. Defect reconfiguration in a Ti–Al alloy via electroplasticity. Nat. Mater. 2021, 20, 468–472. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, J.; Peng, L.; Lai, X. In situ observation of deformation behavior of Ti6Al4V subjected to electrically-assisted forming process. Procedia Manuf. 2020, 50, 647–651. [Google Scholar] [CrossRef]

- Jiang, Y.B.; Tang, G.Y.; Shek, C.H.; Zhu, Y.H. Effect of electropulsing treatment on microstructure and tensile fracture behavior of aged Mg–9Al–1Zn alloy strip. Appl. Phys. A 2009, 97, 607. [Google Scholar] [CrossRef]

- Ostapchuk, P.; Dubinko, V.; Karas, V.I.; Klepikov, V.F.; Potapenko, I. Simulation of enhancement of material plasticity under electric current impulses. Probl. At. Sci. Technol. 2009, 94, 158–166. [Google Scholar]

- Hameed, S.; Gonzalez Rojas, H.A.; Egea, A.J.S.; Alberro, A.N. Electroplastic cutting influence on power consumption during drilling process. Int. J. Adv. Manuf. Technol. 2016, 87, 1835–1841. [Google Scholar] [CrossRef]

- Langer, J.; Hoffmann, M.J.; Guillon, O. Direct comparison between hot pressing and electric field-assisted sintering of submicron alumina. Acta Mater. 2009, 57, 5454–5465. [Google Scholar] [CrossRef]

- Li, X.; Wang, F.; Li, X.; Tang, G.; Zhu, J. Improvement of formability of Mg-3Al-1Zn alloy strip by electroplastic-differential speed rolling. Mater. Sci. Eng. A-Str. 2014, 618, 500–504. [Google Scholar] [CrossRef]

- Skvortsov, O.B.; Stashenko, V.I.; Troitskii, O.A. Electroplastic effect and interaction of an electrical impulse with a conductor. Lett. Mater. 2021, 11, 473–478. [Google Scholar] [CrossRef]

- Kuznetsov, V.A.; Polkovnikov, G.D.; Gromov, V.E.; Kuznetsova, V.A.; Peregudov, O.A. High power current pulse generator based on reversible thyristor converter. Steel translations. 2019, 49, 848–853. [Google Scholar] [CrossRef]

- Gennari, C. Enhancement of Alloys Formability by Electroplastic Effect. Ph.D. Thesis, University of Padova, Venezia, Italy, 2020; 284p. [Google Scholar]

- Troitsky, O.A.; Baranov, Y.V.; Avraamov, Y.S.; Shlyapin, A.D. Physical Bases and Technology of Treatment of Modern Materials, V.1; ICS: Moscow, Russia, 2004; 508p, ISBN 5-93972-335-7. Available online: http://ics.org.ru (accessed on 5 June 2004). (In Russian)

- Stolyarov, V. Role of the pulse current duty cycle during titanium tension. J. Mach. Manuf. Reliab. 2023, 52, 313–319. [Google Scholar] [CrossRef]

- Stolyarov, V.; Korolkov, O.; Pesin, A.; Raab, G. Deformation behavior under tension with pulse current of ultrafine-grain and coarse-grain CP titanium. Materials 2023, 16, 191. [Google Scholar] [CrossRef]

- Pakhomov, M.; Korolkov, O.; Pigato, M.; Gennari, C.; Calliari, I.; Stolyarov, V. Electroplastic effect during tension and bending in duplex stainless steel. Materials 2023, 16, 4119. [Google Scholar] [CrossRef]

- Zuev, L.D.; Gromov, V.E.; Gurevich, L.I. The effect of electric current pulses on the dislocation mobility in Zn single crystals. Phys. Status Solidi 1990, 121, 437–443. [Google Scholar] [CrossRef]

- Zuev, L.D.; Gromov, V.E.; Kurilova, I.F. Mobility of dislocations in single crystals of Zn under the action of current pulses. DAS USSR 1978, 239, 84–87. (In Russian) [Google Scholar]

- Conrad, H. Electroplasticity in metals and ceramics. Mater. Sci. Eng. 2000, 287, 276–287. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, X.; Zhang, H.; Cui, Z. Electroplastic effects on the mechanical responses and deformation mechanisms of AZ31 Mg foils. Materials 2022, 15, 1339. [Google Scholar] [CrossRef] [PubMed]

- Khalik, M.A.; Zahiri, S.H.; Masood, S.H.; Palanisamy, S.; Gulizia, S. In-situ electro plastic treatment for thermomechanical processing of CP titanium. Inter. J. Adv. Manuf. Technol. 2021, 115, 2639–2657. [Google Scholar] [CrossRef]

- Barandiarán, J.M.; Fernández Barquín, L.; Gómez Sal, J.C.; Gorría, P.; Hernando, A. Resistivity changes of some amorphous alloys undergoing nanocrystallization. Mater. Today 2020, 21, 100874. [Google Scholar] [CrossRef]

- Yakovlev, A.V.; Fedorov, V.A. Manifestation electroplastic effect in metallic glass. Bull. Tambov State Univ. 2013, 3, 99–102. (In Russian) [Google Scholar]

- Prasad, K.; Krishnaswamy, H.; Jain, J. Leveraging transient mechanical effects during stress relaxation for ductility improvement in aluminium AA 8011 alloy. J. Mater. Process. Technol. 2018, 255, 1–7. [Google Scholar] [CrossRef]

- Stangebye, S.; Zhang, Y.; Gupta, S.; Hosseinian, E.; Yu, F.; Barr, C.; Hattar, K.; Pierron, O.; Zhu, T.; Kacher, J. Grain growth of nanocrystalline aluminum under tensile deformation: A combined in situ TEM and atomistic study. Materialia 2021, 16, 101068. [Google Scholar] [CrossRef]

- Xie, H.; Dong, X.; Peng, F.; Wang, Q.; Liu, K.; Wang, X.; Chen, F. Investigation on the electrically-assisted stress relaxation of AZ31B magnesium alloy sheet. J. Mater. Process. Technol. 2016, 227, 88–95. [Google Scholar] [CrossRef]

- Pakhomov, M.A.; Savenkov, G.G.; Smakovsky, M.S.; Stolyarov, V.V. Influence of the duty cycle of the pulsed current on the deformation behavior of aluminum bronze. Met. Sci. Heat Treat. 2023, 5, 31–35. (In Russian) [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Simonetto, E.; Gennari, C.; Calliari, I.; Bariani, P. Electroplastic effect on AA1050 aluminium alloy formability. CIRP Ann. 2018, 67, 289–292. [Google Scholar] [CrossRef]

- Li, X.; Tang, G.; Kuang, J.; Li, X.; Zhu, J. Effect of current frequency on the mechanical properties, microstructure and texture evolution in AZ31 magnesium alloy strips during electroplastic rolling. Mater. Sci. Eng. A 2014, 612, 404–413. [Google Scholar] [CrossRef]

- Zhan, L.; Li, R.; Wang, J.; Xue, X.; Wang, Y. Thermoelectric coupling deep drawing process of ZK60 magnesium alloys. Int. J. Adv. Manuf. Technol. 2023, 126, 3005–3014. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, J.; Zhang, H.; Jin, W.; Dong, H.; Xu, B. Recrystallization and microstructure evolution of the rolled Mg-3Al-1Zn alloy strips under electropulsing treatment. J. Alloys Compd. 2015, 622, 229–235. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Pan, J. Extraordinary bending formability of Mg–2.5Nd–0.5Zn–0.5Zr alloy sheet through pulsed current. Met. Mater. Int. 2023, 41–49. [Google Scholar] [CrossRef]

- Zhang, R.K.; Li, X.H.; Kuang, J.; Li, X.P.; Tang, G.Y. Texture modification of magnesium alloys during electropulse treatment. Mater. Sci. Technol. 2017, 33, 1421–1427. [Google Scholar] [CrossRef]

- Kuang, J.; Low, T.S.E.; Niezgoda, S.R.; Li, X.; Geng, Y.; Luo, A.A.; Tang, G. Abnormal texture development in magnesium alloy Mg-3Al-1Zn during large strain electroplastic rolling: Effect of pulsed electric current. Int. J. Plast. 2016, 87, 86–99. [Google Scholar] [CrossRef]

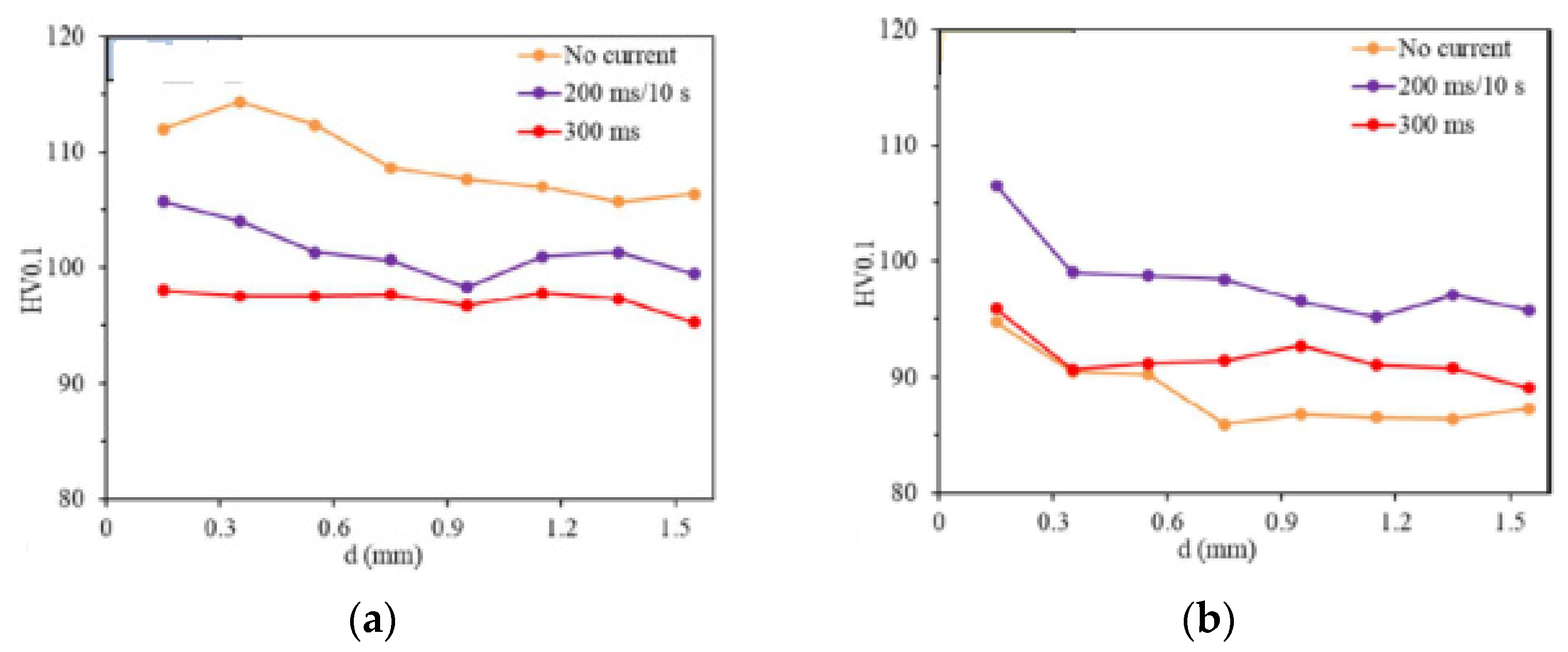

- Dobras, D.; Zimniak, Z.; Zwierzchowski, M. The effect of pulsed electric current on the structural and mechanical behavior of 6016 aluminium alloy in different states of hardening. Archiv. Civ. Mech. Eng. 2023, 23, 166. [Google Scholar] [CrossRef]

- Qi, M.L.; Yao, Y.; Bie, B.X.; Ran, X.X.; Ye, W.; Fan, D.; Li, P. Nucleation and growth of damage in polycrystalline aluminum under dynamic tensile loading. AIP Adv. 2015, 5, 037116. [Google Scholar] [CrossRef]

- Kim, M.-J.; Yoon, S.; Park, S.; Jeong, H.-J.; Park, J.-W.; Kim, K.; Jo, J.; Heo, T.; Hong, S.-T.; Cho, S.-H.; et al. Elucidating the origin of electroplasticity in metallic materials. Appl. Mater. Today 2020, 21, 100874. [Google Scholar] [CrossRef]

- Ao, D.; Chu, X.; Gao, J.; Yang, Y.; Lin, S. Experimental investigation on the deformation behaviors of Ti-6Al-4V sheet in electropulsing-assisted incremental forming. Int. J. Adv. Manuf. Technol. 2019, 104, 4243–4254. [Google Scholar] [CrossRef]

- Reschka, S.; Gerstein, G.; Dalinger, A.; Herbst, S.; Nürnberger, F. Visualization and Observation of Morphological Peculiarities of Twin Formation in Mg-Based Samples After Electrically Assisted Forming. Metallogr. Microstruct. Anal. 2019, 8, 806–814. [Google Scholar] [CrossRef]

- Sánchez Egea, A.; Jorba Peiró, J.; Signorelli, J.; Rojas, H.; Celentano, D. On the microstructure effects when using electropulsing versus furnace treatments while drawing inox 308L. J. Mater. Res. Technol. 2019, 8, 2269–2279. [Google Scholar] [CrossRef]

- Jin, W.; Fan, J.F.; Zhang, H.; Liu, Y.; Dong, H.B.; Xu, B.S. Microstructure, mechanical properties and static recrystallization behavior of the rolled ZK60 magnesium alloy sheets processed by electropulsing treatment. J. Alloys Compd. 2015, 646, 1–9. [Google Scholar] [CrossRef]

- Zhu, R.F.; Jiang, Y.B.; Guan, L.; Li, H.L.; Tang, G.Y. Difference in recrystallization between electropulsing-treated and furnace-treated NiTi alloy. J. Alloys Compd. 2016, 658, 548–554. [Google Scholar] [CrossRef]

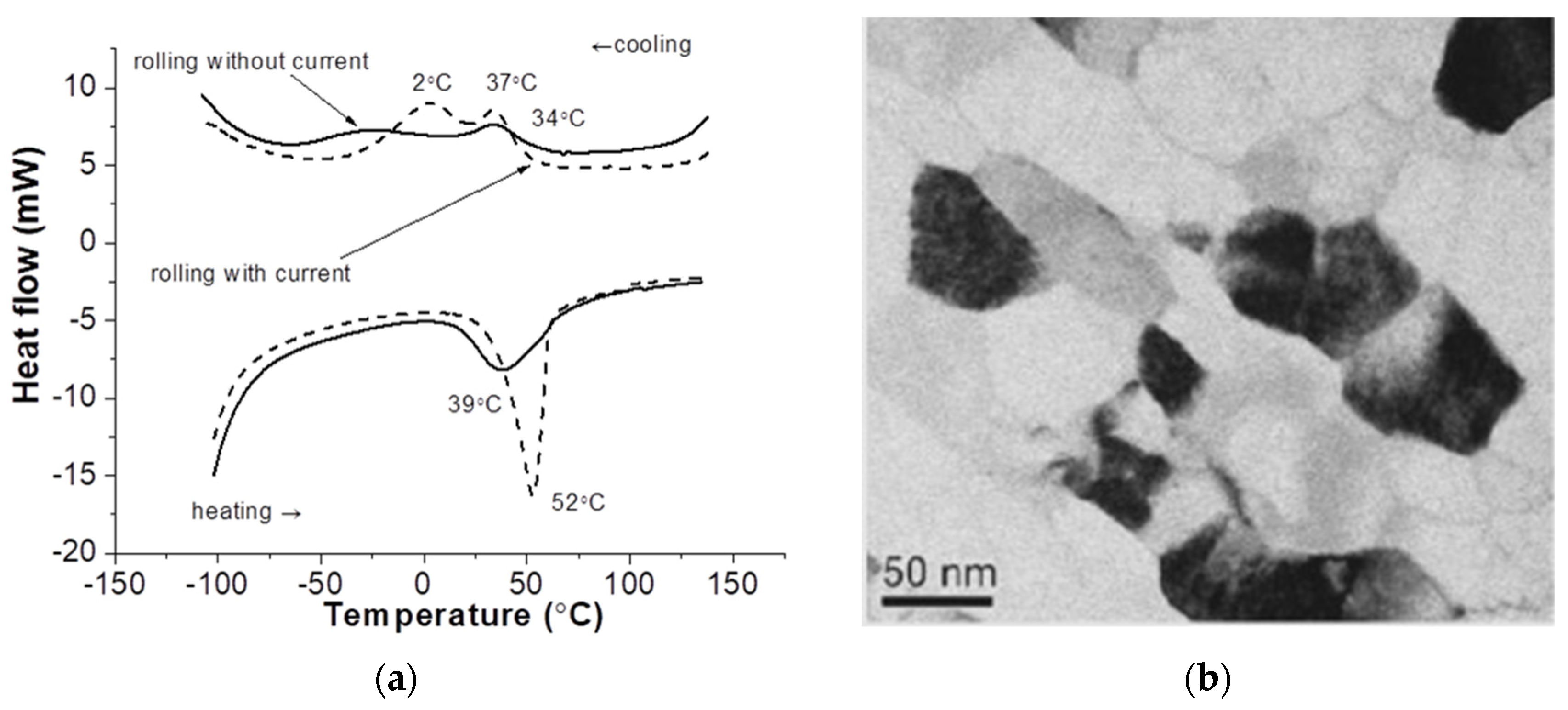

- Potapova, A.A.; Stolyarov, V.V. Structure and martensitic transformations in the Ti50.0Ni50.0 during rolling with current and without current. Mater. Today Proc. 2015, 2, 771–774. [Google Scholar] [CrossRef]

- Potapova, A.A.; Stolyarov, V.V. Relaxation effect of pulse current on Ti50.0Ni50.0 structure during rolling. Mater. Sci. Technol. 2015, 31, 1541–1544. [Google Scholar] [CrossRef]

- Li, M.; Guo, D.; Li, J.; Zhu, S.; Xu, C.; Li, K.; Zhao, Y.; Wei, B.; Zhang, Q.; Zhang, X. Achieving heterogeneous structure in hcp Zr via electroplastic rolling. Mater. Sci. Eng. A 2018, 722, 93–98. [Google Scholar] [CrossRef]

- Konkova, T.; Valeev, I.; Mironov, S.; Korznikov, A.; Korznikova, G.; Myshlyaev, M.M.; Semiatin, S. Microstructure response of cryogenically-rolled Cu-30Zn brass to electric-current pulsing. J. Alloys Compd. 2015, 659, 184–192. [Google Scholar] [CrossRef]

- Lin, S.X.; Chu, X.R.; Bao, W.K.; Gao, J.; Ruan, L.Q. Experimental investigation of pulse current on mechanical behaviour of AZ31 alloy. Mater. Sci. Technol. 2014, 31, 1131–1138. [Google Scholar] [CrossRef]

- Yin, F.; Ma, S.; Hu, S.; Liu, Y.; Hua, L.; Cheng, G.J. Understanding the microstructure evolution and mechanical behavior of titanium alloy during electrically assisted plastic deformation process. Mater. Sci. Eng. A 2023, 869, 144815. [Google Scholar] [CrossRef]

- Hosoi, A.; Yano, T.; Morita, Y.; Ju, Y. Quantitative evaluation of the displacement distribution and stress intensity factor of fatigue cracks healed by a controlled high-density electric current field. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1025–1033. [Google Scholar] [CrossRef]

- Siopis, M.S.; Kinsey, B.L. Experimental investigation of grain and specimen size effects during electrical-assisted forming. ASME J. Manuf. Sci. Eng. 2010, 132, 0210041–0210047. [Google Scholar] [CrossRef]

- Fan, R.; Magargee, J.; Hu, P.; Cao, J. Influence of grain size and grain boundaries on the thermal and mechanical behavior of 70/30 brass under electrically-assisted deformation. Mater. Sci. Eng. A 2013, 574, 218–225. [Google Scholar] [CrossRef]

- Li, X.; Ji, B.; Zhou, Q.; Chen, J.; Gao, P. Influence of grain size on electrically assisted tensile behavior of Ti-6Al-4V alloy. JMEPEG 2016, 25, 4514–4520. [Google Scholar] [CrossRef]

- Korolkov, O.E.; Pakhomov, M.A.; Stolyarov, V.V. Electroplastic effect in titanium alloys during tension. Fact. Laboratory. Diagn. Mater. 2022, 88, 73–82. (In Russian) [Google Scholar] [CrossRef]

- Tskhondiya, G.A.; Beklemishev, N.N. Simulating the effect of a high density electric current pulse on the stress field during plastic deformation. Int. J. Mater. Form. 2012, 5, 157–162. [Google Scholar] [CrossRef]

- Ao, D.-W.; Chu, X.-R.; Lin, S.-X.; Yang, Y.; Gao, J. Hot tensile behaviors and microstructure evolution of Ti-6Al-4V titanium alloy under electropulsing. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 1287–1296. [Google Scholar] [CrossRef]

- Bao, W.K.; Chu, X.R.; Lin, S.X.; Gao, J. Experimental investigation on formability and microstructure of AZ31B alloy in electropulse-assisted incremental forming. Mater. Des. 2015, 87, 632–639. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, S.; Zhang, J.; Liu, C.; Wang, Z.; Zhao, H. Plastic deformation of AZ31B magnesium alloy in the preform and electropulsing treatment process. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 237, 914–924. [Google Scholar] [CrossRef]

- Dinh, K.-A.; Hong, S.-T.; Choi, S.-J.; Kim, M.-J. The effect of pre-strain and subsequent electrically assisted annealing on the mechanical behaviors of two different aluminum alloys. Int. J. Precis. 2020, 21, 2345–2358. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, M.-G.; Hariharan, K.; Hong, S.-T.; Choi, I.-S.; Kim, D.; Oh, K.H.; Han, H.N. Electric current-assisted deformation behavior of Al-Mg-Si alloy under uniaxial tension. Int. J. Plast. 2017, 94, 148–170. [Google Scholar] [CrossRef]

- Potapova, A.A.; Stolyarov, V.V. Deformability and structural features of shape memory TiNi alloys processed by rolling with current. Mater. Sci. Eng. A 2013, 579, 114–117. [Google Scholar] [CrossRef]

- Zhu, R.; Tang, G. The improved plasticity of NiTi alloy via electropulsing in rolling. Mater. Sci. Technol. 2016, 33, 1743–2847. [Google Scholar] [CrossRef]

- Han, C.; Ye, F.; Du, H.; Liu, B.; Liang, Y.; Li, H.; Li, H. Improved ductility of Fe-6.5wt%Si alloy under electropulsing tension. Mater. Sci. Eng. A 2022, 851, 143639. [Google Scholar] [CrossRef]

- Magargee, J.; Morestin, F.; Cao, J. Characterization of flow stress for commercially pure titanium subjected to electrically assisted deformation. J. Eng. Mater.-Technol. ASME 2013, 135, 215. [Google Scholar] [CrossRef]

- Simonetti, E.; Brusch, S.; Ghiotti, A. Electroplastic effect on AA1050 plastic flow behavior in H24 tempered and fully annealed conditions. Procedia Manuf. 2019, 34, 83–89. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Hou, H.; Zhang, Y.; Wang, Y. The effect of pulsed current on the shear deformation behavior of Ti-6Al-4V alloy. Sci. Rep. 2018, 8, 14748. [Google Scholar] [CrossRef]

- Jiang, Y.B.; Guan, L.; Tang, G.Y.; Zhang, Z.H. Improved mechanical properties of Mg-9Al-1Zn alloy by the combination of aging, cold-rolling and electropulsing treatment. J. Alloys Compd. 2015, 626, 297–303. [Google Scholar] [CrossRef]

- Misochenko, A.A.; Stolyarov, V.V.; Chertovskikh, S.V.; Shuster, L.S. Influence of Grain Size and Contact Temperature on the Tribological Behaviour of Shape Memory Ti49.3Ni50.7 Alloy. Tribol. Lett. 2017, 65, 131. [Google Scholar] [CrossRef]

- Lesiuk, G.; Zimniak, Z.; Wisniewski, W.; Correia, J. Fatigue lifetime improvement in AISI 304 stainless steel due to high-density electropulsing. Procedia Struct. Integr. 2017, 5, 928–934. [Google Scholar] [CrossRef]

- Zhu, R.F.; Tang, G.; Shi, S.Q.; Fu, M.W. Effect of electroplastic rolling on the ductility and superelasticity of TiNi shape memory alloy. Mater. Des. 2013, 44, 606–611. [Google Scholar] [CrossRef]

- Potapova, A.A.; Stolyarov, V.V. Deformability and shape memory properties in Ti50,0Ni50,0 rolled with electric current. Mater. Sci. Forum Vols 2013, 738–739, 383–387. [Google Scholar] [CrossRef]

- Potapova, A.A.; Stolyarov, V.V.; Resnina, N.N. Shape memory effects in TiNi-based alloys subjected to electroplastic rolling. J. Mater. Eng. Perform. 2014, 23, 2391–2395. [Google Scholar] [CrossRef]

- Dimitrov, N.K.; Liu, Y.; Horstemeyer, M.F. Electroplasticity: A review of mechanisms in electro-mechanical coupling of ductile metals. Mech. Adv. Mater. Struct. 2020, 29, 705–716. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.-J.; Lee, M.-G.; Song, J.H.; Choi, S.; Han, H.N.; Kim, D. Experimental and numerical study on the deformation mechanism in AZ31B Mg alloy sheets under pulsed electric-assisted tensile and compressive tests. Metall. Mater. Trans. A 2016, 47, 2783–2794. [Google Scholar] [CrossRef]

- Hariharan, K.; Lee, M.-G.; Kim, M.-J.; Han, H.N.; Kim, D.; Choi, S. Decoupling thermal and electrical effect in an electrically assisted uniaxial tensile test using finite element analysis. Metall. Mater. Trans. A 2015, 46, 3043–3051. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Mears, L.; Roth, J.T. Investigation of heterogeneous joule heating as the explanation for the transient electroplastic stress drop in pulsed tension of 7075-T6 Aluminum. J. Manuf. Sci. Eng. 2018, 140, 091014. [Google Scholar] [CrossRef]

- Lahiri, A.; Shanthraj, P.; Roters, F. Understanding the mechanisms of electroplasticity from a crystal plasticity perspective. Model. Simul. Mater. Sci. Eng. 2019, 27, 085006. [Google Scholar] [CrossRef]

- Zheng, Q.; Shimizu, T.; Shiratori, T.; Yang, M. Tensile properties and constitutive model of ultrathin pure titanium foils at elevated temperatures in microforming assisted by resistance heating method. Mater. Des. 2014, 63, 389–397. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Jiang, Z.; Zhu, W.-L.; Shan, D.; Guo, B.; Cao, J. Size effects on flow stress behavior during electrically-assisted micro-tension in a magnesium alloy AZ31. Mater. Sci. Eng. A 2016, 659, 215–224. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Shan, D.; Guo, B.; Cao, J. Effects of specimen and grain size on electrically-induced softening behavior in uniaxial micro-tension of AZ31 magnesium alloy: Experiment and modeling. Mater. Des. 2017, 127, 134–143. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I.; Mears, L.; Roth, J.T. A review of electrically assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Shan, D.; Guo, B.; Cao, J. Modeling of thermal and mechanical behavior of a magnesium alloy AZ31 during electrically-assisted micro-tension. Int. J. Plast. 2016, 85, 230–257. [Google Scholar] [CrossRef]

- Dimitrov, N.; Liu, Y.; Horstemeyer, M. An electroplastic internal state variable (ISV) model for nonferromagnetic ductile metals. Mech. Adv. Mater. Struct. 2020, 29, 761–772. [Google Scholar] [CrossRef]

- Zhao, Y.; Wan, M.; Meng, B.; Xu, J.; Shan, D. Pulsed current assisted forming of ultrathin superalloy sheet: Experimentation and modelling. Mater. Sci. Eng. A 2019, 767, 138412. [Google Scholar] [CrossRef]

- Liu, Y.; Wan, M.; Meng, B. Multiscale modeling of coupling mechanisms in electrically assisted deformation of ultrathin sheets: An example on a nickel-based superalloy. Int. J. Mach. Tools Manuf. 2021, 162, 103689. [Google Scholar] [CrossRef]

- Tiwari, J.; Balaji, V.; Krishnaswamy, H.; Amirthalingam, M. Dislocation density based modelling of electrically assisted deformation process by finite element approach. Int. J. Mech. Sci. 2022, 227, 107433. [Google Scholar] [CrossRef]

- Rudolf, C.; Goswami, R.; Kang, W.; Thomas, J. Effects of electric current on the plastic deformation behavior of pure copper, iron, and titanium. Acta Mater. 2021, 209, 116776. [Google Scholar] [CrossRef]

- Savenko, B.C.; Demidenko, A.P. Modification of aluminum microstructure after electroplastic deformation. Bull. TSU 2010, 15, 1244–1246. (In Russian) [Google Scholar]

- Yuryev, V.A.; Baranov, Y.V.; Stolyarov, V.V.; Shulga, V.A.; Kostina, I.V. Influence of electroplastic treatment on the structure of aluminum-lithium alloy 1463. Izv. RAS. Phys. Ser. 2008, 72, 1317–1319. [Google Scholar] [CrossRef]

- Brodova, I.G.; Shirinkina, I.G.; Astaf’ev, V.V.; Yablonskikh, T.I.; Potapova, A.A.; Stolyarov, V.V. Effect of pulsed current on structure of Al–Mg–Si aluminum based alloy during cold deformation. Phys. Met. Metallogr. 2013, 114, 940–946. [Google Scholar] [CrossRef]

- Xu, Z.; Tang, G.; Tian, S.; Ding, F.; Tian, H. Research of electroplastic rolling of AZ31 Mg alloy strip. J. Mater. Process. Technol. 2007, 182, 128–133. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Andreev, V.A.; Karelin, R.D.; Ugurchiev, U.K.; Cherkasov, V.V.; Komarov, V.S.; Yusupov, V.S. Deformability of TiNiHf shape memory alloy under rolling with pulsed current. Met. Process. 2022, 24, 66–75. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, J.; Yan, Y.; Zhou, H.; Feng, W. The engineering application of the electroplastic effect in the cold-drawing of stainless steel wire. J. Mater. Process. Technol. 2003, 137, 96–99. [Google Scholar] [CrossRef]

- Guan, L.; Tang, G.; Chu, P.K. Recent advances and challenges in electroplastic manufacturing processing of metals. J. Mater. Res. 2010, 25, 1215–1224. [Google Scholar] [CrossRef]

- Savchenko, V.S.; Shavrey, S.D.; Soloviev, M.B.; Markevich, A.L. Electroplastic effect in deformation aluminum. Bull. Mosc. State Pedagog. Univ. Technol. Sci. 2008, 67, 165–168. (In Russian) [Google Scholar]

- Liu, J.; Du, Z.; Jiang, S.; Shen, H.; Li, Z.; Xing, D.; Ma, W.; Sun, J. Tailoring giant magnetoimpedance effect of Co-based microwires for optimum efficiency by self-designed square-wave pulse current annealing. J. Magn. Magn. Mater. 2015, 385, 145–150. [Google Scholar] [CrossRef]

- Phan, M.H.; Peng, H.X. Giant magnetoimpedance materials: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 323–420. [Google Scholar] [CrossRef]

- Jones, J.J.; Mears, L.; Roth, J.T. Electrically-assisted forming of magnesium AZ31: Effect of current magnitude and deformation rate on forge ability. J. Manuf. Sci. Eng. 2012, 134, 034504. [Google Scholar] [CrossRef]

- Guan, H.; Zhong, Y.; Zou, W.; Sun, P.; Zhai, J.; Qu, S. Research on the Electric-Pulse-Assisted Turning Behavior of TC27 Alloy. Metals 2023, 13, 702. [Google Scholar] [CrossRef]

- Salnikov, S.V. Device of electric current intensification of the cutting process. News Tula. Technol. Sci. 2018, 6, 357–362. (In Russian) [Google Scholar]

- Salnikov, V.S.; Shadsky, G.V.; Shadsky, V.G.; Puzanov, A.E.; Segal, Z.M. Method of Metal Processing with Electric Current Supply to the Cutting. Zone. Patent RU 2410206, IPC B23B 1/00, 27 January 2011. [Google Scholar]

- Vovchenko, A.I.; Demidenko, L.Y.; Polovinka, V.D. The influence of current pulse parameters on the development of physical contact during pressure welding of metals. Electron. Process. Mater. 2013, 49, 30–34. (In Russian) [Google Scholar]

- Ivanov, A.M.; Stolyarov, V.V.; Ivanov, V.A.; Ugurchiev, U.H. Device for Equal-Channel Angular Pressing of. Metals. Patent RU 2429926, 27 September 2011. [Google Scholar]

- Dobras, D.; Zimniak, Z.; Zwierzchowski, M. Electrically-assisted deep drawing of 5754 aluminum alloy sheet. Mater. Res. Proc. 2023, 28, 987–1006. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, T.; Huang, J.; Peng, L.; Lai, X.; Fu, M.W. Electroplasticity in electrically-assisted forming: Process phenomena, performances and modelling. Inter. J. Mach. Tools Manuf. 2022, 175, 103871. [Google Scholar] [CrossRef]

- Troitsky, O.A.; Kim, S.K.; Stashenko, V.I. Electroplastic rolling mill for stainless steel strip without intermediate annealing. Bull. Ferr. Metall. 2016, 10, 41–47. (In Russian) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stolyarov, V.; Misochenko, A. A Pulsed Current Application to the Deformation Processing of Materials. Materials 2023, 16, 6270. https://doi.org/10.3390/ma16186270

Stolyarov V, Misochenko A. A Pulsed Current Application to the Deformation Processing of Materials. Materials. 2023; 16(18):6270. https://doi.org/10.3390/ma16186270

Chicago/Turabian StyleStolyarov, Vladimir, and Anna Misochenko. 2023. "A Pulsed Current Application to the Deformation Processing of Materials" Materials 16, no. 18: 6270. https://doi.org/10.3390/ma16186270

APA StyleStolyarov, V., & Misochenko, A. (2023). A Pulsed Current Application to the Deformation Processing of Materials. Materials, 16(18), 6270. https://doi.org/10.3390/ma16186270