Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field

Abstract

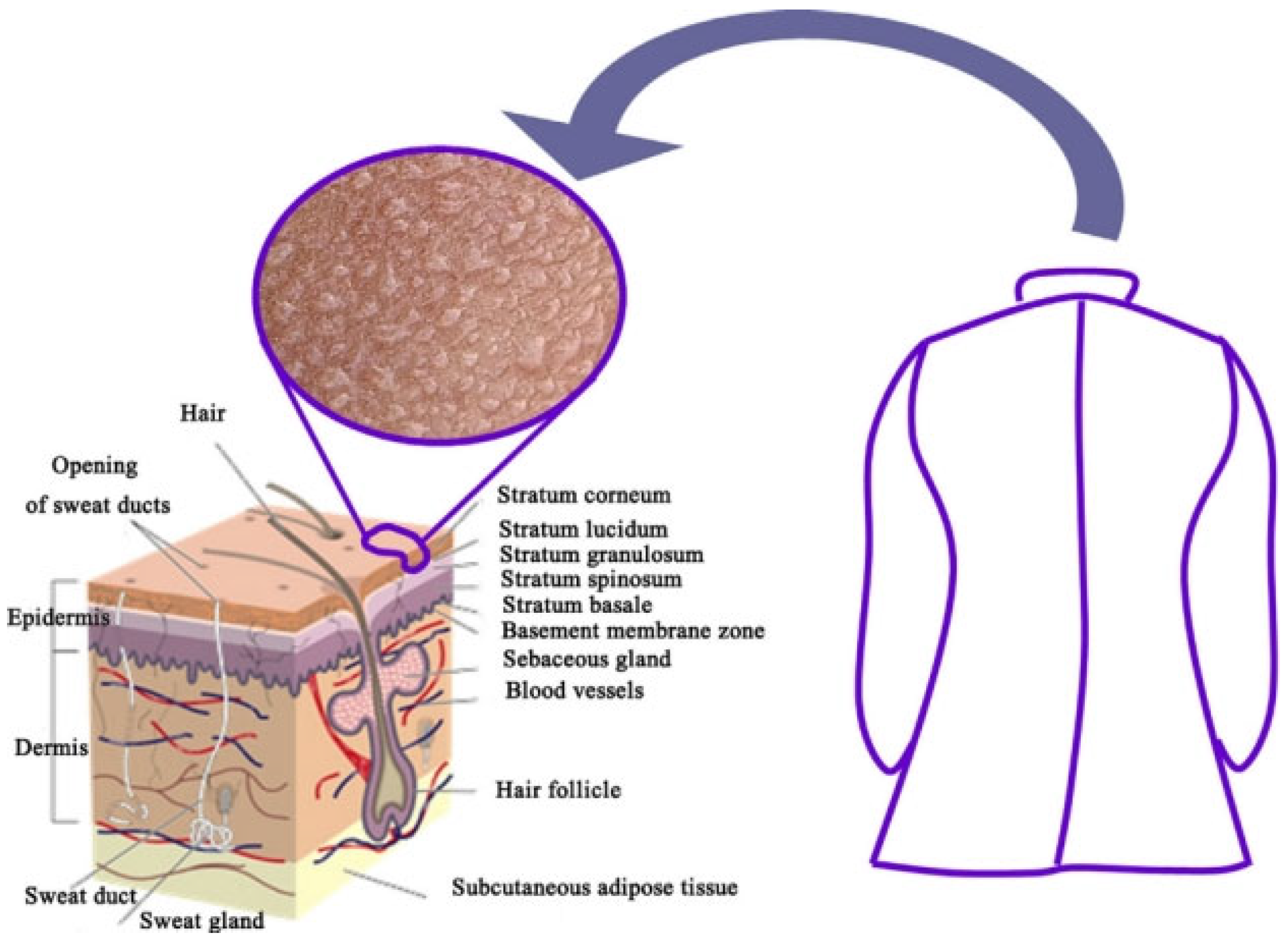

1. Introduction

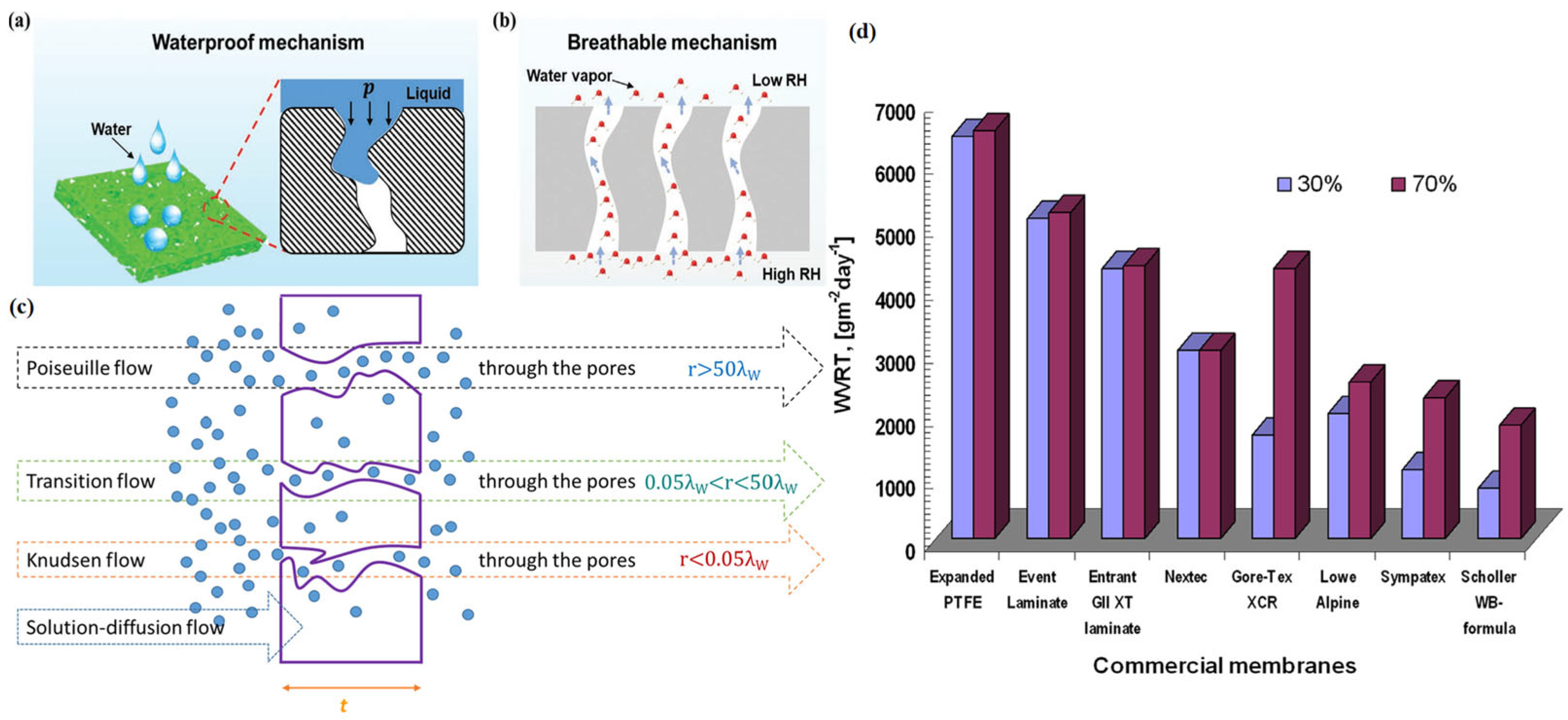

2. Mechanisms of Waterproofness and Breathability

2.1. Hydrophilic Non-Porous Membranes

2.2. Hydrophobic Microporous Membranes

3. Evaluation Criteria for WBMs

3.1. Evaluation Criteria for Water Resistance

3.1.1. Hydrostatic Pressure

3.1.2. Water Contact Angle (WCA)

3.2. Evaluation Criteria for Water Vapor Permeability

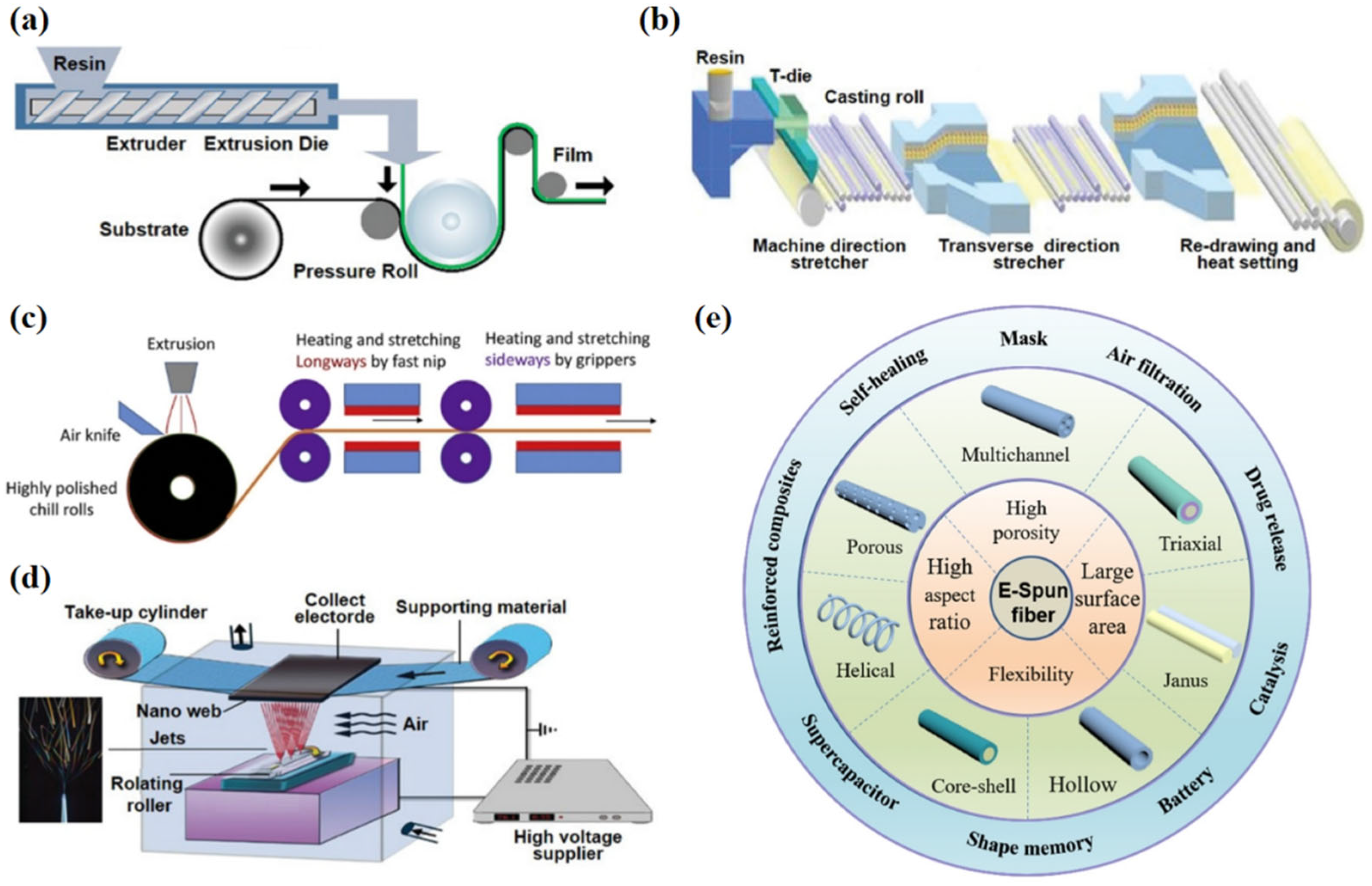

4. Preparation Methods of WBMs

4.1. Melt Extrusion

4.2. Biaxial Stretching

4.3. Electrospinning

5. Treatment for Enhancing Water Resistance and Water Vapor Permeability

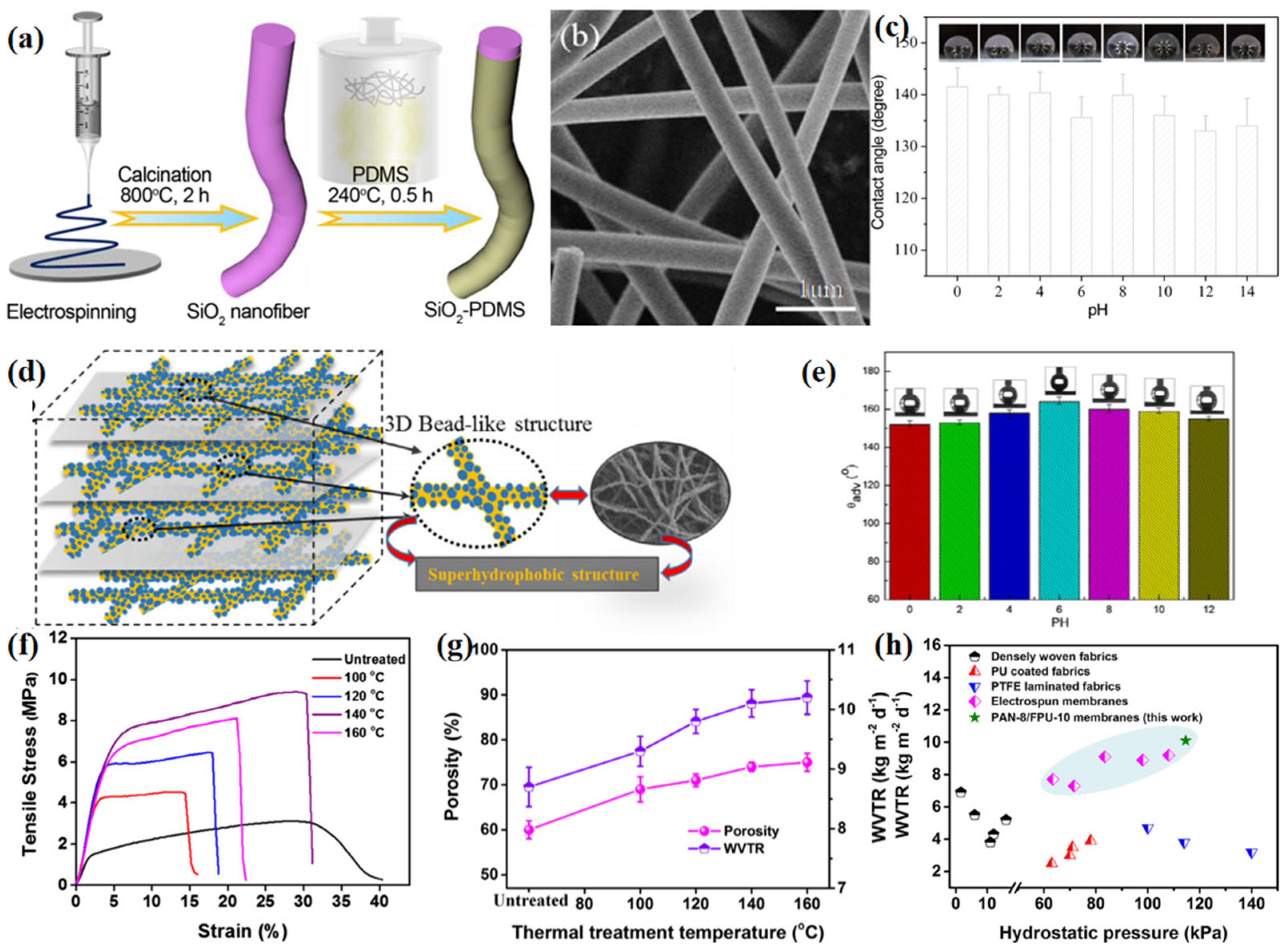

5.1. Doping Modification

5.1.1. Fluorinated Polymers

5.1.2. Hydrophobic Nanoparticles

5.2. Post-Processing

5.2.1. Dip Coating

5.2.2. Vapor Deposition (VD)

5.2.3. Heat Treatment

6. Applications of WBMs in the Textile Field

6.1. Daily Outdoor Sportswear

6.2. Special Protective Clothing

6.3. Wound Dressing

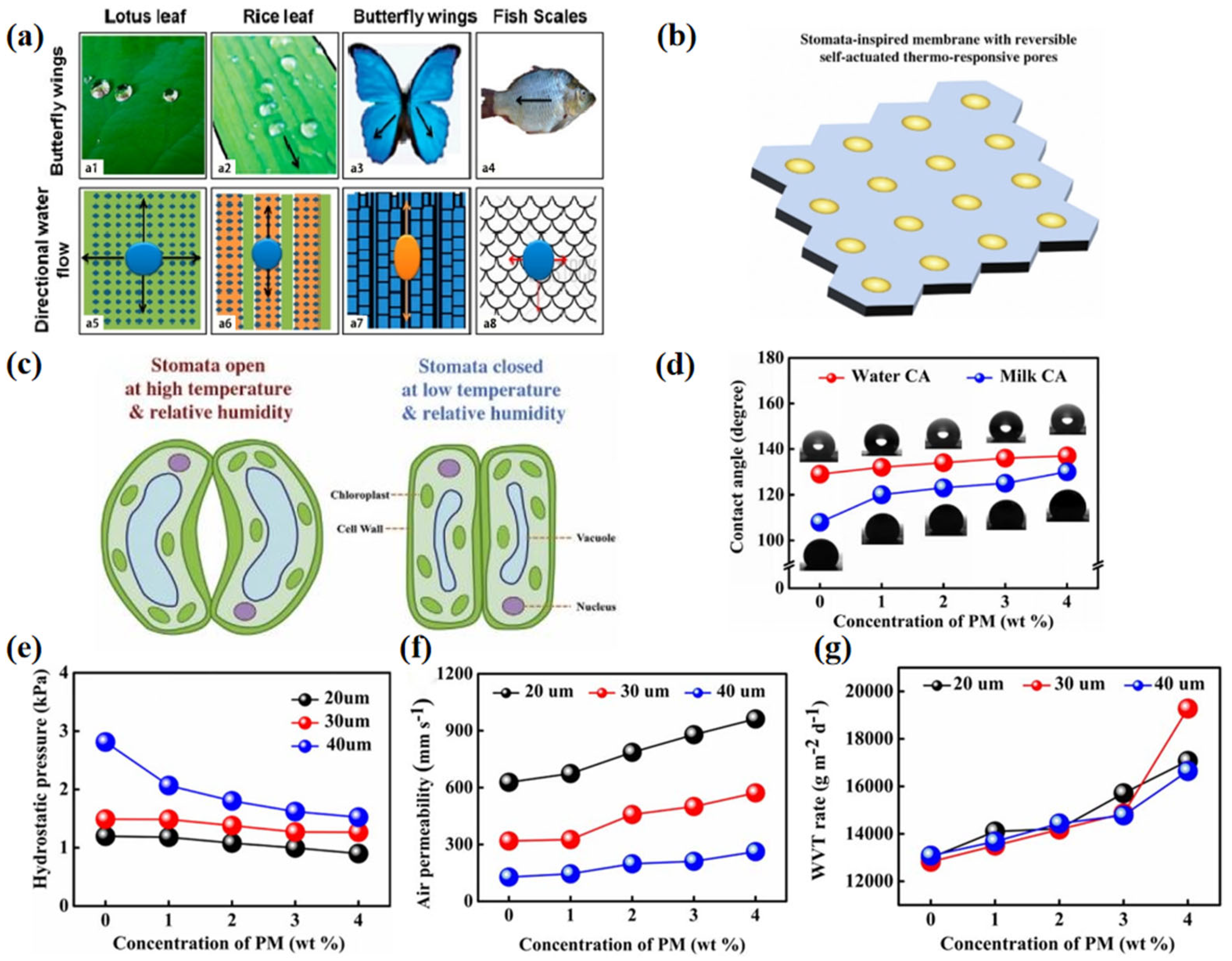

6.4. Bionic Textiles

7. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scott, C.L.; Henri, S.; Guilliams, M. Mononuclear phagocytes of the intestine, the skin, and the lung. Immunol. Rev. 2014, 262, 9–24. [Google Scholar] [CrossRef]

- Zhong, W.; Xing, M.M.Q.; Pan, N.; Maibach, H.I. Textiles and human skin, microclimate, cutaneous reactions: An overview. Cutan. Ocul. Toxicol. 2006, 25, 23–39. [Google Scholar] [CrossRef] [PubMed]

- Gugliuzza, A.; Drioli, E. A review on membrane engineering for innovation in wearable fabrics and protective textiles. J. Membr. Sci. 2013, 446, 350–375. [Google Scholar] [CrossRef]

- Ferreira, A.; Novoa, P.R.O.; Marques, A.T. Multifunctional Material Systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35. [Google Scholar] [CrossRef]

- Ahn, H.W.; Park, C.H.; Chung, S.E. Waterproof and breathable properties of nanoweb applied clothing. Text. Res. J. 2011, 81, 1438–1447. [Google Scholar] [CrossRef]

- Zhang, S.C.; Liu, H.; Yu, J.Y.; Luo, W.J.; Ding, B. Microwave structured polyamide-6 nanofiber/net membrane with embedded poly(m-phenylene isophthalamide) staple fibers for effective ultrafine particle filtration. J. Mater. Chem. A 2016, 4, 6149–6157. [Google Scholar] [CrossRef]

- Gorji, M.; Jeddi, A.A.A.; Gharehaghaji, A.A. Fabrication and characterization of polyurethane electrospun nanofiber membranes for protective clothing applications. J. Appl. Polym. Sci. 2012, 125, 4135–4141. [Google Scholar] [CrossRef]

- Huizing, R.; Mérida, W.; Ko, F. Impregnated electrospun nanofibrous membranes for water vapour transport applications. J. Membr. Sci. 2014, 461, 146–160. [Google Scholar] [CrossRef]

- Fu, Z.; Li, K.; Pu, L.; Ge, B.; Chen, Z. Waterproof Breathable Membrane Used as Gas Diffusion Layer in Activated Carbon Air Cathode Microbial Fuel Cells. Fuel Cells 2016, 16, 839–844. [Google Scholar] [CrossRef]

- Eynolghasi, M.B.; Mohammadi, T.; Tofighy, M.A. Fabrication of polystyrene (PS)/cyclohexanol-based carbon nanotubes (CNTs) mixed matrix membranes for vacuum membrane distillation application. J. Environ. Chem. Eng. 2022, 10, 108175. [Google Scholar] [CrossRef]

- Shi, S.; Si, Y.; Han, Y.; Wu, T.; Iqbal, M.I.; Fei, B.; Li, R.K.Y.; Hu, J.; Qu, J. Recent Progress in Protective Membranes Fabricated via Electrospinning: Advanced Materials, Biomimetic Structures, and Functional Applications. Adv. Mater. 2022, 34, e2107938. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liang, P.; Huang, X.; Ren, Z.J. A novel microbial fuel cell sensor with a gas diffusion biocathode sensing element for water and air quality monitoring. Chemosphere 2018, 203, 21–25. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Xiong, R.; Li, C.; Pecht, M.G. Water-Resistant Smartphone Technologies. IEEE Access 2019, 7, 42757–42773. [Google Scholar] [CrossRef]

- Wang, L.; Cao, T.; Dykstra, J.E.; Porada, S.; Biesheuvel, P.M.; Elimelech, M. Salt and Water Transport in Reverse Osmosis Membranes: Beyond the Solution-Diffusion Model. Environ. Sci. Technol. 2021, 55, 16665–16675. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; He, J.; Heiranian, M.; Fan, H.; Song, L.; Li, Y.; Elimelech, M. Water transport in reverse osmosis membranes is governed by pore flow, not a solution-diffusion mechanism. Sci. Adv. 2023, 9, eadf8488. [Google Scholar] [CrossRef]

- Al-Furaiji, M.; Kadhom, M.; Kalash, K.; Waisi, B.; Albayati, N. Preparation of thin-film composite membranes supported with electrospun nanofibers for desalination by forward osmosis. Drink. Water Eng. Sci. 2020, 13, 51–57. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Xu, M.D.; Cheng, J.X.; Du, X.F.; Guo, Q.; Huang, Y.; Huang, Q.L. Amphiphobic electrospun PTFE nanofibrous membranes for robust membrane distillation process. J. Membr. Sci. 2022, 641, 119876. [Google Scholar] [CrossRef]

- Ye, H.; Wang, J.; Wang, Y.; Chen, X.-P.; Shi, S.-P. Effects of simultaneous chemical cross-linking and physical filling on separation performances of PU membranes. Iran. Polym. J. 2013, 22, 623–633. [Google Scholar] [CrossRef]

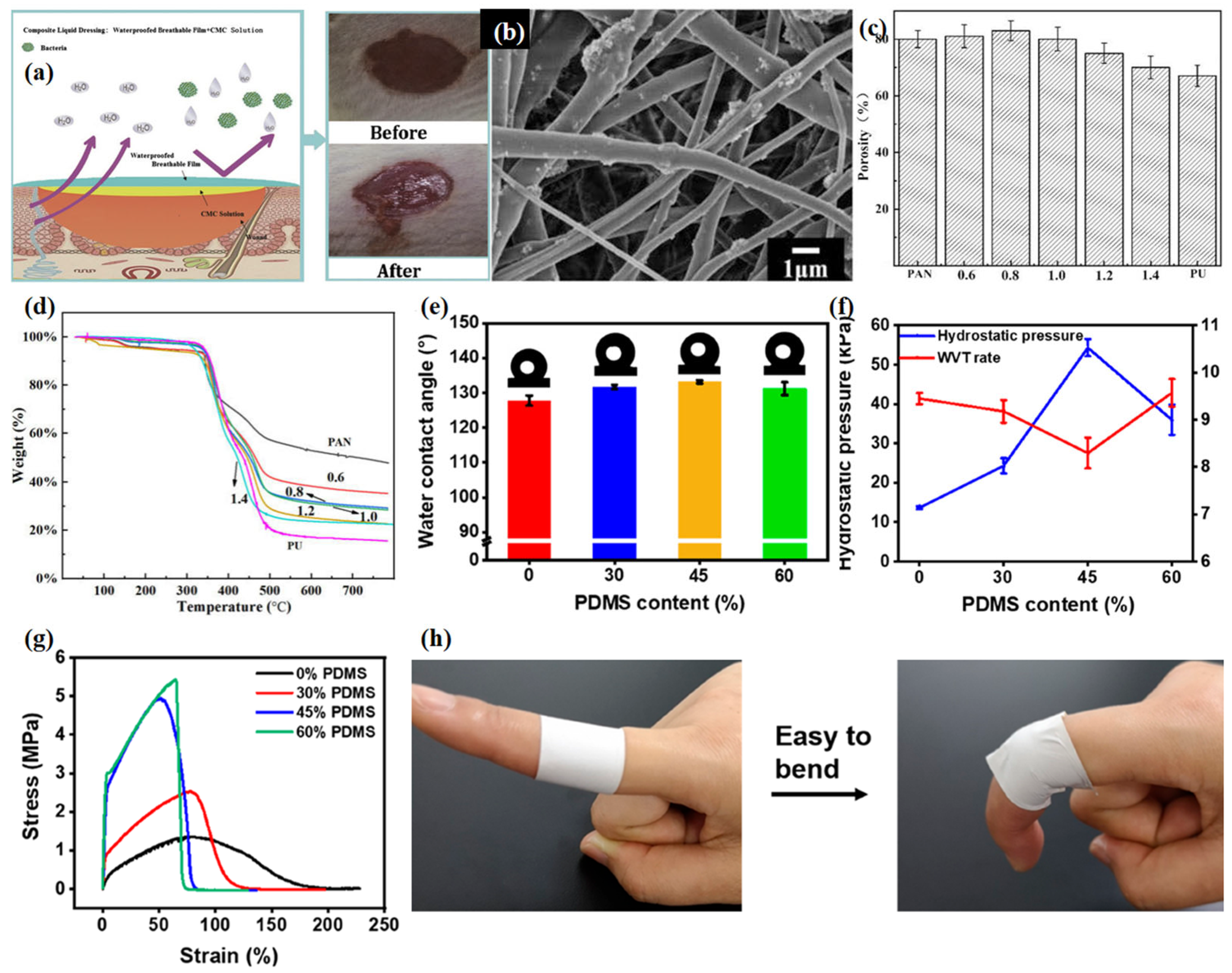

- Sheng, J.; Zhang, M.; Xu, Y.; Yu, J.; Ding, B. Tailoring Water-Resistant and Breathable Performance of Polyacrylonitrile Nanofibrous Membranes Modified by Polydimethylsiloxane. ACS Appl. Mater. Interfaces 2016, 8, 27218–27226. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Latifi, M.; Najar, S.S.; Tehran, M.A.; Gorji, M.; Kong, L. Transport properties of multi-layer fabric based on electrospun nanofiber mats as a breathable barrier textile material. Text. Res. J. 2012, 82, 70–76. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, B.; Zhong, M.; Liu, W.; Yu, D.; Wang, Y.; Tam, K.C.; Zhou, G.; Zhang, Z. Sustainable and Versatile Superhydrophobic Cellulose Nanocrystals. ACS Sustain. Chem. Eng. 2022, 10, 5939–5948. [Google Scholar] [CrossRef]

- Rouhani, S.T.; Fashandi, H. Breathable dual-layer textile composed of cellulose dense membrane and plasma-treated fabric with enhanced comfort. Cellulose 2018, 25, 5427–5442. [Google Scholar] [CrossRef]

- Pang, H.; Tian, K.; Li, Y.; Su, C.; Duan, F.; Xu, Y. Super-hydrophobic PTFE hollow fiber membrane fabricated by electrospinning of Pullulan/PTFE emulsion for membrane deamination. Sep. Purif. Technol. 2021, 274, 118186. [Google Scholar] [CrossRef]

- Wu, J.; Wang, N.; Wang, L.; Dong, H.; Zhao, Y.; Jiang, L. Electrospun Porous Structure Fibrous Film with High Oil Adsorption Capacity. ACS Appl. Mater. Interfaces 2012, 4, 3207–3212. [Google Scholar] [CrossRef]

- Gu, J.; Xu, S.; Lu, X.; Ma, R.; Zhang, S.; Zheng, S.; Wang, H.; Shen, H. Study on the membrane formation mechanism of PVDF/PVDF-CTFE blends. J. Taiwan Inst. Chem. Eng. 2023, 142, 104655. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Popa, A.M.; Stelzig, T.; Sava, I.; Rossi, R.M.; Fortunato, G. Preparation and characterization of thermally stable polyimide membranes by electrospinning for protective clothing applications. Text. Res. J. 2015, 85, 1763–1775. [Google Scholar] [CrossRef]

- Eykens, L.; De Sitter, K.; Dotremont, C.; Pinoy, L.; Van der Bruggen, B. Characterization and performance evaluation of commercially available hydrophobic membranes for direct contact membrane distillation. Desalination 2016, 392, 63–73. [Google Scholar] [CrossRef]

- Manshahia, M.; Das, A. Moisture management of high active sportswear. Fibers Polym. 2014, 15, 1221–1229. [Google Scholar] [CrossRef]

- Akhtar, F.H.; Kumar, M.; Vovusha, H.; Shevate, R.; Villalobos, L.F.; Schwingenschlögl, U.; Peinemann, K.-V. Scalable Synthesis of Amphiphilic Copolymers for CO2- and Water-Selective Membranes: Effect of Copolymer Composition and Chain Length. Macromolecules 2019, 52, 6213–6226. [Google Scholar] [CrossRef]

- Pantelic, J.; Teitelbaum, E.; Bozlar, M.; Kim, S.; Meggers, F. Development of moisture absorber based on hydrophilic nonporous membrane mass exchanger and alkoxylated siloxane liquid desiccant. Energy Build. 2018, 160, 34–43. [Google Scholar] [CrossRef]

- Zhu, F.-L.; Zhou, Y.; He, J.-X. Moisture transport through non-porous hydrophilic membranes used in protective clothing. Therm. Sci. 2013, 17, 1293–1298. [Google Scholar] [CrossRef][Green Version]

- Mukhopadhyay, A.; Midha, V.K. A Review on Designing the Waterproof Breathable Fabrics Part I: Fundamental Principles and Designing Aspects of Breathable Fabrics. J. Ind. Text. 2008, 37, 225–262. [Google Scholar] [CrossRef]

- Yu, Y.G.; Liu, Y.; Zhang, F.L.; Jin, S.X.; Xiao, Y.Q.; Xin, B.J.; Zheng, Y.S. Preparation of Waterproof and Breathable Polyurethane Fiber Membrane Modified by Fluorosilane-modified Silica. Fibers Polym. 2020, 21, 954–964. [Google Scholar] [CrossRef]

- Marathe, R.; Tatiya, P.; Chaudhari, A.; Lee, J.; Mahulikar, P.; Sohn, D.; Gite, V. Neem acetylated polyester polyol—Renewable source based smart PU coatings containing quinoline (corrosion inhibitor) encapsulated polyurea microcapsules for enhance anticorrosive property. Ind. Crop. Prod. 2015, 77, 239–250. [Google Scholar] [CrossRef]

- De Smet, D.; Wéry, M.; Uyttendaele, W.; Vanneste, M. Bio-Based Waterborne PU for Durable Textile Coatings. Polymers 2021, 13, 4229. [Google Scholar] [CrossRef]

- Vincent, O.; Marguet, B.; Stroock, A.D. Imbibition Triggered by Capillary Condensation in Nanopores. Langmuir 2017, 33, 1655–1661. [Google Scholar] [CrossRef]

- Ge, J.; Si, Y.; Fu, F.; Wang, J.; Yang, J.; Cui, L.; Ding, B.; Yu, J.; Sun, G. Amphiphobic fluorinated polyurethane composite microfibrous membranes with robust waterproof and breathable performances. RSC Adv. 2013, 3, 2248–2255. [Google Scholar] [CrossRef]

- Gong, X.; Yin, X.; Wang, F.; Liu, X.; Yu, J.; Zhang, S.; Ding, B. Electrospun Nanofibrous Membranes: A Versatile Medium for Waterproof and Breathable Application. Small 2023, 19, 2205067. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Zhu, L.; Ahmad, Z.; Li, J.; Chang, M. Elastic antibacterial membranes comprising particulate laden fibers for wound healing applications. J. Appl. Polym. Sci. 2019, 136, 47105. [Google Scholar] [CrossRef]

- Su, Y.; Li, R.; Yang, J.; Xiang, C.; Song, G.; Li, J. Influence of Transport Properties of Laminated Membrane-fabric on Thermal Protective Performance Against Steam Hazard. Fibers Polym. 2019, 20, 2433–2442. [Google Scholar] [CrossRef]

- Natarajan, E.; Santhosh, M.S.; Markandan, K.; Sasikumar, R.; Saravanakumar, N.; Dilip, A.A. Mechanical and wear behaviour of PEEK, PTFE and PU: Review and experimental study. J. Polym. Eng. 2022, 42, 407–417. [Google Scholar] [CrossRef]

- Lakshmi, R.; Bharathidasan, T.; Bera, P.; Basu, B.J. Fabrication of superhydrophobic and oleophobic sol–gel nanocomposite coating. Surf. Coat. Technol. 2012, 206, 3888–3894. [Google Scholar] [CrossRef]

- Lü, X.; Wang, X.; Guo, L.; Zhang, Q.; Guo, X.; Li, L. Preparation of PU modified PVDF antifouling membrane and its hydrophilic performance. J. Membr. Sci. 2016, 520, 933–940. [Google Scholar] [CrossRef]

- Tehrani-Bagha, A.R. Waterproof breathable layers—A review. Adv. Colloid Interface Sci. 2019, 268, 114–135. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, Y.; Xie, Y.; Zhou, M.; Gu, Q.; Zhong, Z.; Xing, W. Silicon carbide microfiltration membranes for oil-water separation: Pore structure-dependent wettability matters. Water Res. 2022, 216, 4591–4602. [Google Scholar] [CrossRef]

- Ahmad, I.; Kan, C.-W. A Review on Development and Applications of Bio-Inspired Superhydrophobic Textiles. Materials 2016, 9, 892. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Dimitrakellis, P.; Sarkiris, P.; Gogolides, E. A Review of Fabrication Methods, Properties and Applications of Superhydrophobic Metals. Processes 2021, 9, 666. [Google Scholar] [CrossRef]

- Gao, S.J.; Shi, Z.; Bin Zhang, W.; Zhang, F.; Jin, J. Photoinduced Superwetting Single-Walled Carbon Nanotube/TiO2 Ultrathin Network Films for Ultrafast Separation of Oil-in-Water Emulsions. ACS Nano 2014, 8, 6344–6352. [Google Scholar] [CrossRef]

- Si, Y.; Fu, Q.; Wang, X.; Zhu, J.; Yu, J.; Sun, G.; Ding, B. Superelastic and Superhydrophobic Nanofiber-Assembled Cellular Aerogels for Effective Separation of Oil/Water Emulsions. ACS Nano 2015, 9, 3791–3799. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczynski, K. General model of polymer melting in extrusion process. Polimery 2018, 63, 444–452. [Google Scholar] [CrossRef]

- Repka, A.M.; Shah, S.; Lu, J.; Maddineni, S.; Morott, J.; Patwardhan, K.; Mohammed, N.N. Melt extrusion: Process to product. Expert Opin. Drug Deliv. 2012, 9, 105–125. [Google Scholar] [CrossRef] [PubMed]

- Saerens, L.; Vervaet, C.; Remon, J.P.; De Beer, T. Process monitoring and visualization solutions for hot-melt extrusion: A review. J. Pharm. Pharmacol. 2014, 66, 180–203. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Wu, X.; Si, Y.; Wang, X.; Yu, J.; Ding, B. Waterproof and Breathable Electrospun Nanofibrous Membranes. Macromol. Rapid Commun. 2019, 40, e1800931. [Google Scholar] [CrossRef] [PubMed]

- Gugliuzza, A.; Fabiano, R.; Garavaglia, M.; Spisso, A.; Drioli, E. Study of the surface character as responsible for controlling interfacial forces at membrane–feed interface. J. Colloid Interface Sci. 2006, 303, 388–403. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Wang, J.; Guo, H.; Liu, L.; Xu, W.; Duan, G. Structural design toward functional materials by electrospinning: A review. E-Polymers 2020, 20, 682–712. [Google Scholar] [CrossRef]

- Chen, X.; Xiang, D.; Zhou, Z.; Wu, Y.; Li, H.; Zhao, C.; Li, Y. Biaxial Stretching of Polymer Nanocomposites: A Mini-Review. Front. Mater. 2021, 8, 725422. [Google Scholar] [CrossRef]

- Gontarek-Castro, E.; Castro-Muñoz, R.; Lieder, M. New insights of nanomaterials usage toward superhydrophobic membranes for water desalination via membrane distillation: A review. Crit. Rev. Environ. Sci. Technol. 2022, 52, 2104–2149. [Google Scholar] [CrossRef]

- Ouchiar, S.; Stoclet, G.; Cabaret, C.; Addad, A.; Gloaguen, V. Effect of biaxial stretching on thermomechanical properties of polylactide based nanocomposites. Polymer 2016, 99, 358–367. [Google Scholar] [CrossRef]

- Meng, L.-P.; Lin, Y.-F.; Xu, J.-L.; Chen, X.-W.; Li, X.-Y.; Zhang, Q.-L.; Zhang, R.; Tian, N.; Li, L.-B. A Universal equipment for biaxial stretching of polymer films. Chin. J. Polym. Sci. 2015, 33, 754–762. [Google Scholar] [CrossRef]

- Sas, I.; Gorga, R.E.; Joines, J.A.; Thoney, K.A. Literature review on superhydrophobic self-cleaning surfaces produced by electrospinning. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 824–845. [Google Scholar] [CrossRef]

- Ismail, N.; Maksoud, F.J.; Ghaddar, N.; Ghali, K.; Tehrani-Bagha, A. Simplified modeling of the electrospinning process from the stable jet region to the unstable region for predicting the final nanofiber diameter. J. Appl. Polym. Sci. 2016, 133, 43. [Google Scholar] [CrossRef]

- Maksoud, F.J.; Lameh, M.; Fayyad, S.; Ismail, N.; Tehrani-Bagha, A.R.; Ghaddar, N.; Ghali, K. Electrospun waterproof breathable membrane with a high level of aerosol filtration. J. Appl. Polym. Sci. 2018, 135, 45660. [Google Scholar] [CrossRef]

- Liao, X.; Dulle, M.; Silva, J.M.D.S.E.; Wehrspohn, R.B.; Agarwal, S.; Förster, S.; Hou, H.; Smith, P.; Greiner, A. High strength in combination with high toughness in robust and sustainable polymeric materials. Science 2019, 366, 1376–1379. [Google Scholar] [CrossRef]

- Tebyetekerwa, M.; Xu, Z.; Yang, S.; Ramakrishna, S. Electrospun Nanofibers-Based Face Masks. Adv. Fiber Mater. 2020, 2, 161–166. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Xu, L.; Si, N.; Tang, X.-P. Thermal treatment for nanofibrous membrane. Therm. Sci. 2014, 18, 1685–1687. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Sun, H.; Wang, L.; Zhang, J.; Deng, L.; Ma, T. An Optical Fiber Sensor Coated with Electrospinning Polyvinyl Alcohol/Carbon Nanotubes Composite Film. Sensors 2020, 20, 6996. [Google Scholar] [CrossRef]

- De Bruycker, K.; Delahaye, M.; Cools, P.; Winne, J.; Du Prez, F.E. Covalent Fluorination Strategies for the Surface Modification of Polydienes. Macromol. Rapid Commun. 2017, 38, 1700122. [Google Scholar] [CrossRef]

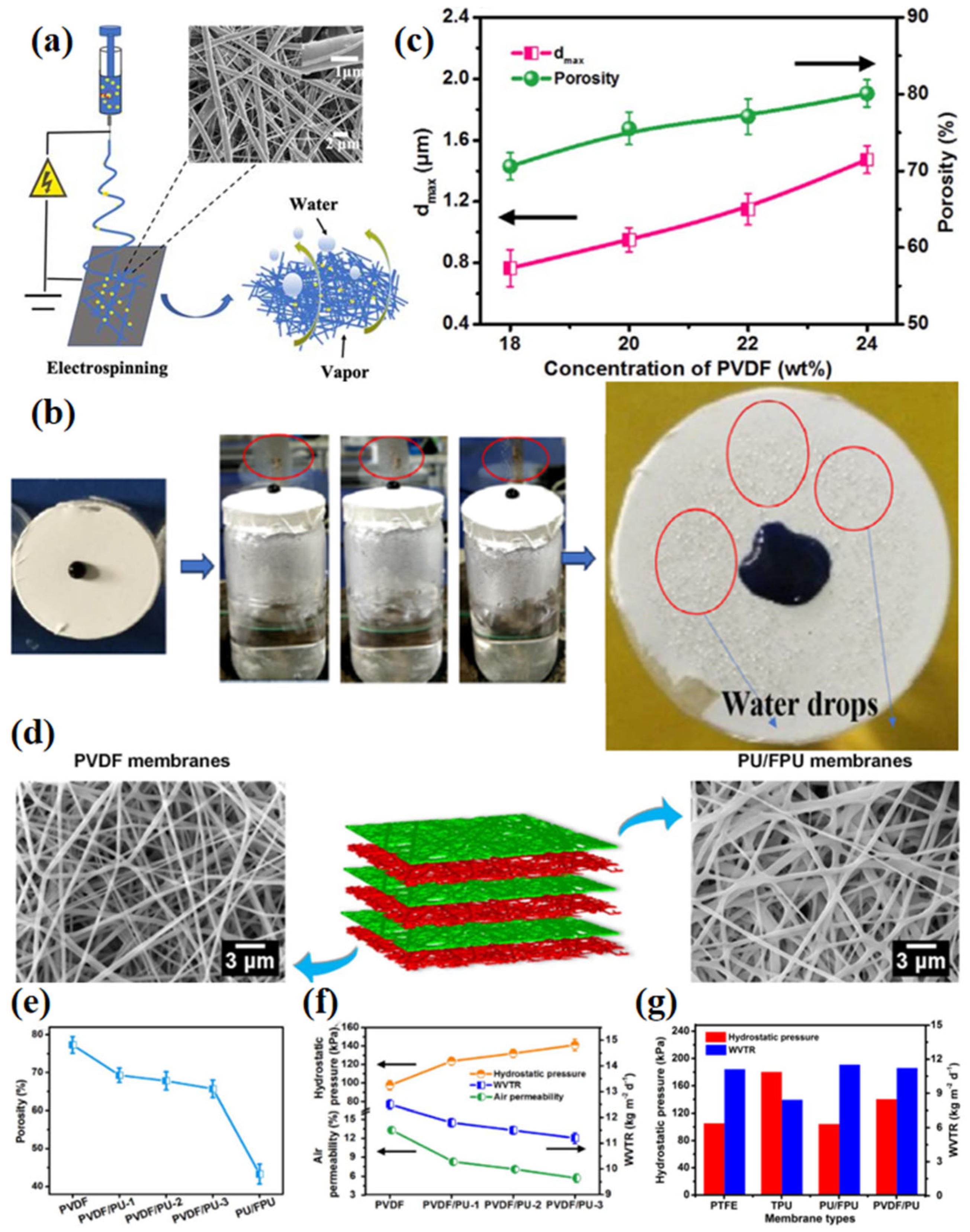

- Cui, H.M.; Li, Y.Y.; Zhao, X.L.; Yin, X.; Yu, J.Y.; Ding, B. Multilevel porous structured polyvinylidene fluoride/polyurethane fibrous membranes for ultrahigh waterproof and breathable application. Compos. Commun. 2017, 6, 63–67. [Google Scholar] [CrossRef]

- Mao, X.; Chen, Y.; Si, Y.; Li, Y.; Wan, H.; Yu, J.; Sun, G.; Ding, B. Novel fluorinated polyurethane decorated electrospun silica nanofibrous membranes exhibiting robust waterproof and breathable performances. RSC Adv. 2013, 3, 7562–7569. [Google Scholar] [CrossRef]

- Peng, C.; Chen, Z.; Tiwari, M.K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance. Nat. Mater. 2018, 17, 355–360. [Google Scholar] [CrossRef] [PubMed]

- Navarrini, W.; Venturini, F.; Tortelli, V.; Basak, S.; Pimparkar, K.P.; Adamo, A.; Jensen, K.F. Direct fluorination of carbon monoxide in microreactors. J. Fluor. Chem. 2012, 142, 19–23. [Google Scholar] [CrossRef]

- Arvaniti, O.S.; Hwang, Y.; Andersen, H.R.; Stasinakis, A.S.; Thomaidis, N.S.; Aloupi, M. Reductive degradation of perfluorinated compounds in water using Mg-aminoclay coated nanoscale zero valent iron. Chem. Eng. J. 2015, 262, 133–139. [Google Scholar] [CrossRef]

- Gao, J.; Huang, X.; Xue, H.; Tang, L.; Li, R.K. Facile preparation of hybrid microspheres for super-hydrophobic coating and oil-water separation. Chem. Eng. J. 2017, 326, 443–453. [Google Scholar] [CrossRef]

- Hammami, M.A.; Croissant, J.G.; Francis, L.; Alsaiari, S.K.; Anjum, D.H.; Ghaffour, N.; Khashab, N.M. Engineering Hydrophobic Organosilica Nanoparticle-Doped Nanofibers for Enhanced and Fouling Resistant Membrane Distillation. ACS Appl. Mater. Interfaces 2017, 9, 1737–1745. [Google Scholar] [CrossRef]

- Jin, S.; Park, Y.; Park, C.H. Preparation of breathable and superhydrophobic polyurethane electrospun webs with silica nanoparticles. Text. Res. J. 2016, 86, 1816–1827. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermoconductive, Moisture-Permeable, and Superhydrophobic Nanofibrous Membranes with Interpenetrated Boron Nitride Network for Personal Cooling Fabrics. ACS Appl. Mater. Interfaces 2020, 12, 32078–32089. [Google Scholar] [CrossRef]

- Jesswein, I.; Hirth, T.; Schiestel, T. Continuous dip coating of PVDF hollow fiber membranes with PVA for humidification. J. Membr. Sci. 2017, 541, 281–290. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, W.; Chen, L.; Hou, C.; Chen, X.; Zhang, X. One-step dip-coating method for preparation of ceramic nanofiber membrane with high permeability and low cost. J. Eur. Ceram. Soc. 2021, 41, 358–368. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Xu, Y.; He, P.; Si, Y.; Liu, L.; Yu, J.; Ding, B. Multifunctional, Waterproof, and Breathable Nanofibrous Textiles Based on Fluorine-Free, All-Water-Based Coatings. ACS Appl. Mater. Interfaces 2020, 12, 15911–15918. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Shen, C.; Liu, C.; Liu, X. Facile Thermally Impacted Water-Induced Phase Separation Approach for the Fabrication of Skin-Free Thermoplastic Polyurethane Foam and Its Recyclable Counterpart for Oil-Water Separation. Macromol. Rapid Commun. 2018, 39, e1800635. [Google Scholar] [CrossRef] [PubMed]

- Dianat, G.; Movsesian, N.; Gupta, M. Vapor Deposition of Functional Porous Polymer Membranes. ACS Appl. Polym. Mater. 2020, 2, 98–104. [Google Scholar] [CrossRef]

- Chang, M.-J.; Chai, X.-J.; Cui, W.-N.; Liu, J. Facile Fabrication of Electrospun Silica Nanofibrous Membrane with Hydrophobic, Oleophilic and Breathable Performances. Fibers Polym. 2018, 19, 760–766. [Google Scholar] [CrossRef]

- Dizge, N.; Shaulsky, E.; Karanikola, V. Electrospun cellulose nanofibers for superhydrophobic and oleophobic membranes. J. Membr. Sci. 2019, 590, 117271. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R. A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 2015, 356, 15–30. [Google Scholar] [CrossRef]

- Liang, Y.; Cheng, S.; Zhao, J.; Zhang, C.; Sun, S.; Zhou, N.; Qiu, Y.; Zhang, X. Heat treatment of electrospun Polyvinylidene fluoride fibrous membrane separators for rechargeable lithium-ion batteries. J. Power Sources 2013, 240, 204–211. [Google Scholar] [CrossRef]

- Liang, Y.; Ju, J.; Deng, N.; Zhou, X.; Yan, J.; Kang, W.; Cheng, B. Super-hydrophobic self-cleaning bead-like SiO2@PTFE nanofiber membranes for waterproof-breathable applications. Appl. Surf. Sci. 2018, 442, 54–64. [Google Scholar] [CrossRef]

- Sheng, J.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermal inter-fiber adhesion of the polyacrylonitrile/fluorinated polyurethane nanofibrous membranes with enhanced waterproof-breathable performance. Sep. Purif. Technol. 2016, 158, 53–61. [Google Scholar] [CrossRef]

- Lalia, B.S.; Kochkodan, V.; Hashaikeh, R.; Hilal, N. A review on membrane fabrication: Structure, properties and performance relationship. Desalination 2013, 326, 77–95. [Google Scholar] [CrossRef]

- Ghezal, I.; Moussa, A.; Ben Marzoug, I.; El-Achari, A.; Campagne, C.; Sakli, F. Development and Surface State Characterization of a Spacer Waterproof Breathable Fabric. Fibers Polym. 2020, 21, 910–920. [Google Scholar] [CrossRef]

- Maity, S.; Chauhan, V.; Pandit, P. 12-Waterproof breathable fabrics and suits. In Protective Textiles from Natural Resources; Mondal, M.I.H., Ed.; Woodhead Publishing: Sawston, CA, USA, 2022; pp. 347–375. [Google Scholar]

- Kim, H.-A. Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing. Coatings 2021, 12, 12. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Wang, D.; Li, H.; Li, L.; Zhang, S.; Zhou, C.; Zheng, X.; Men, Q.; Zhong, J.; et al. Preparation and Chemical Protective Clothing Application of PVDF Based Sodium Sulfonate Membrane. Membranes 2020, 10, 190. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, W.; Wang, L.; Dong, Y.; Yu, J.; Li, X.; Ding, B. Stretchable PDMS Embedded Fibrous Membranes Based on an Ethanol Solvent System for Waterproof and Breathable Applications. ACS Appl. Bio Mater. 2019, 2, 5949–5956. [Google Scholar] [CrossRef]

- Sun, G.F.; Wang, P.; Jiang, Y.X.; Sun, H.C.; Liu, T.; Li, G.X.; Yu, W.; Meng, C.Z.; Guo, S.J. Bioinspired flexible, breathable, waterproof and self-cleaning iontronic tactile sensors for special underwater sensing applications. Nano Energy 2023, 110, 108367. [Google Scholar] [CrossRef]

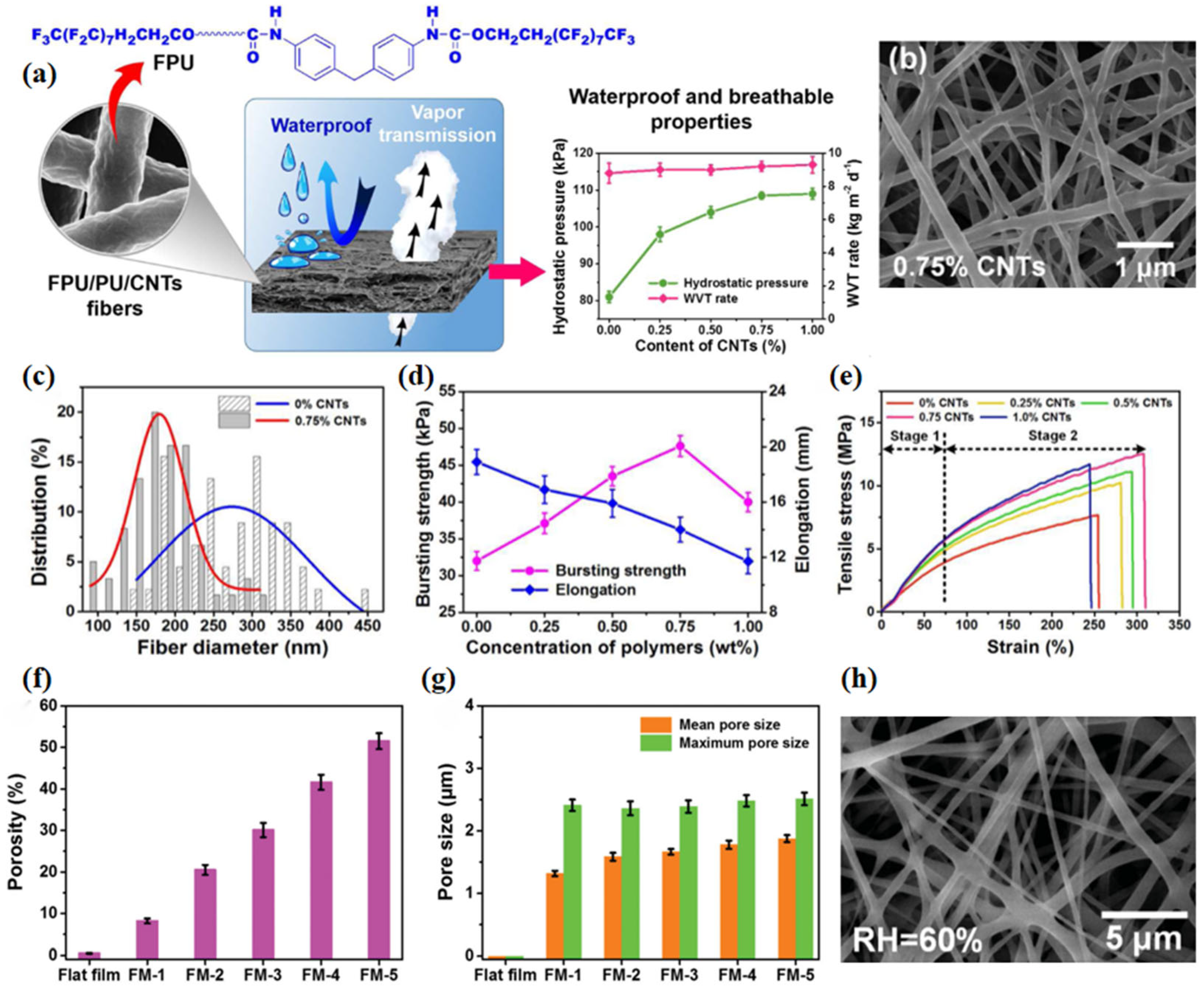

- Li, Y.; Zhu, Z.; Yu, J.; Ding, B. Carbon Nanotubes Enhanced Fluorinated Polyurethane Macroporous Membranes for Waterproof and Breathable Application. ACS Appl. Mater. Interfaces 2015, 7, 13538–13546. [Google Scholar] [CrossRef]

- Zhou, W.; Gong, X.; Li, Y.; Si, Y.; Zhang, S.; Yu, J.; Ding, B. Waterborne electrospinning of fluorine-free stretchable nanofiber membranes with waterproof and breathable capabilities for protective textiles. J. Colloid Interface Sci. 2021, 602, 105–114. [Google Scholar] [CrossRef]

- Li, Y.; Yang, F.; Yu, J.; Ding, B. Hydrophobic Fibrous Membranes with Tunable Porous Structure for Equilibrium of Breathable and Waterproof Performance. Adv. Mater. Interfaces 2016, 3, 1600516. [Google Scholar] [CrossRef]

- Xue, C.-H.; Chen, J.; Yin, W.; Jia, S.-T.; Ma, J.-Z. Superhydrophobic conductive textiles with antibacterial property by coating fibers with silver nanoparticles. Appl. Surf. Sci. 2012, 258, 2468–2472. [Google Scholar] [CrossRef]

- Wei, Y.H.; Zhang, H.Y.; Su, Z.W.; Tao, S.Q.; Cao, X.J.; Wan, Z.H.; Pan, W. Develop an optimal daily washing care for technical jacket by balancing washing efficiency and functional degradation. J. Eng. Fibers Fabr. 2023, 18. [Google Scholar] [CrossRef]

- Elise, H.; Kevin, K.; Kristen, M.; Jennifer, J. Dragonfly Jacket Waterproof Jacket and Climbing Pant for Female Rock Climbers. Int. Text. Appar. Assoc. Annu. Conf. Proc. 2022, 79. [Google Scholar] [CrossRef]

- Sadighzadeh, A.; Valinejad, M.; Gazmeh, A.; Rezaiefard, B. Synthesis of polymeric electrospun nanofibers for application in waterproof-breathable fabrics. Polym. Eng. Sci. 2016, 56, 143–149. [Google Scholar] [CrossRef]

- Manning, K.C.; Kotagama, P.; Burgin, T.P.; Rykaczewski, K. Breathable, Stimuli-Responsive, and Self-Sealing Chemical Barrier Material Based on Selectively Superabsorbing Polymer. Ind. Eng. Chem. Res. 2020, 59, 12282–12286. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, J.; Zhang, J.; Hong, Y.; Wan, Y.; Wang, Q.; Gong, M.; Wu, Z.; Guo, C.F. Thermal, Waterproof, Breathable, and Antibacterial Cloth with a Nanoporous Structure. ACS Appl. Mater. Interfaces 2018, 10, 2026–2032. [Google Scholar] [CrossRef] [PubMed]

- Baji, A.; Agarwal, K.; Oopath, S.V. Emerging Developments in the Use of Electrospun Fibers and Membranes for Protective Clothing Applications. Polymers 2020, 12, 492. [Google Scholar] [CrossRef] [PubMed]

- Knížek, R.; Karhánková, D.; Bajzík, V.; Jirsák, O. Lamination of Nanofibre Layers for Clothing Applications. Fibres Text. East. Eur. 2019, 27, 16–22. [Google Scholar] [CrossRef]

- Cai, L.; Xu, L.; Si, Y.; Yu, J.; Ding, B. Autoclavable, Breathable, and Waterproof Membranes Tailored by Ternary Nanofibers for Reusable Medical Protective Applications. ACS Appl. Polym. Mater. 2022, 4, 556–564. [Google Scholar] [CrossRef]

- Xia, D.-L.M.; Chen, Y.-P.M.; Wang, Y.-F.M.; Li, X.-D.B.; Bao, N.; He, H.M.; Gu, H.-Y. Fabrication of Waterproof, Breathable Composite Liquid Dressing and Its Application in Diabetic Skin Ulcer Repair. Adv. Ski. Wound Care 2016, 29, 499–508. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Liu, Y.; Zheng, Y.; Xin, B.; Jiang, Z.; Peng, X.; Jin, S. Waterproof and breathable polyacrylonitrile/(polyurethane/fluorinated-silica) composite nanofiber membrane via side-by-side electrospinning. J. Mater. Res. 2020, 35, 1173–1181. [Google Scholar] [CrossRef]

- Shi, S.; Zhu, K.; Chen, X.; Hu, J.; Zhang, L. Cross-Linked Cellulose Membranes with Robust Mechanical Property, Self-Adaptive Breathability, and Excellent Biocompatibility. ACS Sustain. Chem. Eng. 2019, 7, 19799–19806. [Google Scholar] [CrossRef]

- Wang, S.; Liu, K.; Yao, X.; Jiang, L. Bioinspired Surfaces with Superwettability: New Insight on Theory, Design, and Applications. Chem. Rev. 2015, 115, 8230–8293. [Google Scholar] [CrossRef]

- Mayser, M.J.; Bohn, H.F.; Reker, M.; Barthlott, W. Measuring air layer volumes retained by submerged floating-ferns Salvinia and biomimetic superhydrophobic surfaces. Beilstein J. Nanotechnol. 2014, 5, 812–821. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Gutierrez, M.P.; Lee, L.P. Reversible Self-Actuated Thermo-Responsive Pore Membrane. Sci. Rep. 2016, 6, 39402. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, S.G.; Parsimehr, H.; Ehsani, A. Multifunctional superhydrophobic surfaces. Adv. Colloid Interface Sci. 2021, 290, 102397. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.-N.; Yan, X.; You, M.-H.; Fu, J.; Nie, G.-D.; Yu, M.; Ning, X.; Wan, Y.; Long, Y.-Z. Reversible photochromic nanofibrous membranes with excellent water/windproof and breathable performance. J. Appl. Polym. Sci. 2018, 135, 46342. [Google Scholar] [CrossRef]

| Materials | WCA (°) | Hydrostatic Pressure (kPa) | WVRT (kg m−2 d−1) | Refs. |

|---|---|---|---|---|

| F-SiO2/PU | 135 | 50 | 10.4 | [34] |

| PVDF/PU | / | 140 | 11.3 | [68] |

| PVDF | 148 | 109 | 12.3 | [68] |

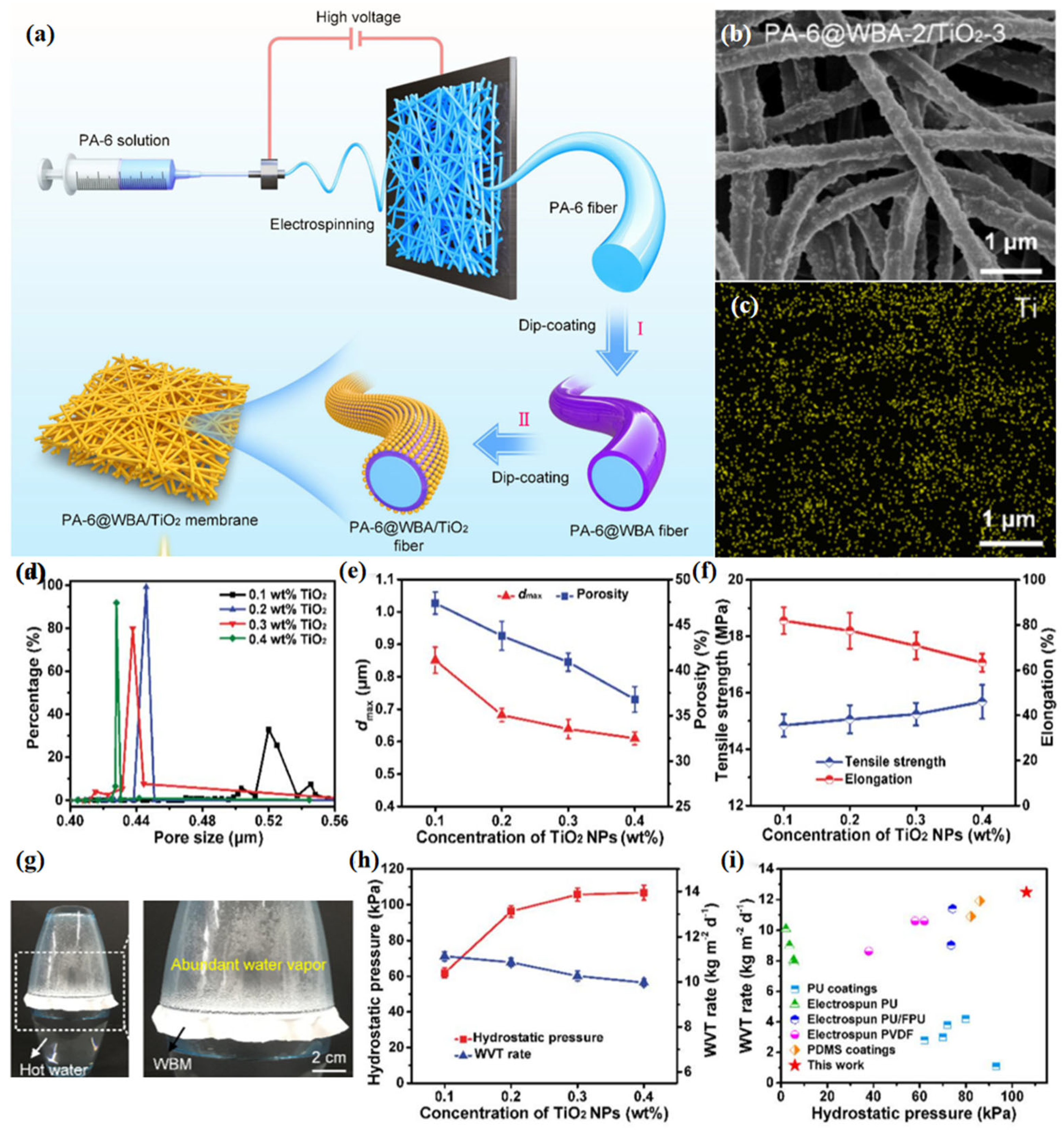

| PA-6@WBA/TiO2 | 129.8 | 106.2 | 10.3 | [79] |

| SiO2@PTFE | 155 | / | 9.7 | [86] |

| PAN/FPU | 151 | 114.6 | 10.1 | [87] |

| FPU/PU/CNTs | / | 108 | 9.2 | [93] |

| PU/FPU | 117 | 86 | 11.9 | [96] |

| (PU/F–SiO2)/PAN | 137.2 | / | 10.3 | [97] |

| PVB/PDMS | 133.16 | 54.32 | 8.98 | [98] |

| TPU/PM | 137 | 2.81 | 19.3 | [99] |

| PU/SSNPs/TEOS | 138 | 23.5 | 5.91 | [89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.; Liu, F. Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field. Materials 2023, 16, 5339. https://doi.org/10.3390/ma16155339

Chang Y, Liu F. Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field. Materials. 2023; 16(15):5339. https://doi.org/10.3390/ma16155339

Chicago/Turabian StyleChang, Yawen, and Fujuan Liu. 2023. "Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field" Materials 16, no. 15: 5339. https://doi.org/10.3390/ma16155339

APA StyleChang, Y., & Liu, F. (2023). Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field. Materials, 16(15), 5339. https://doi.org/10.3390/ma16155339