Effect of Thermal Aging on the Interfacial Reaction Behavior and Failure Mechanism of Ni-xCu/Sn Soldering Joints under Shear Loading

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

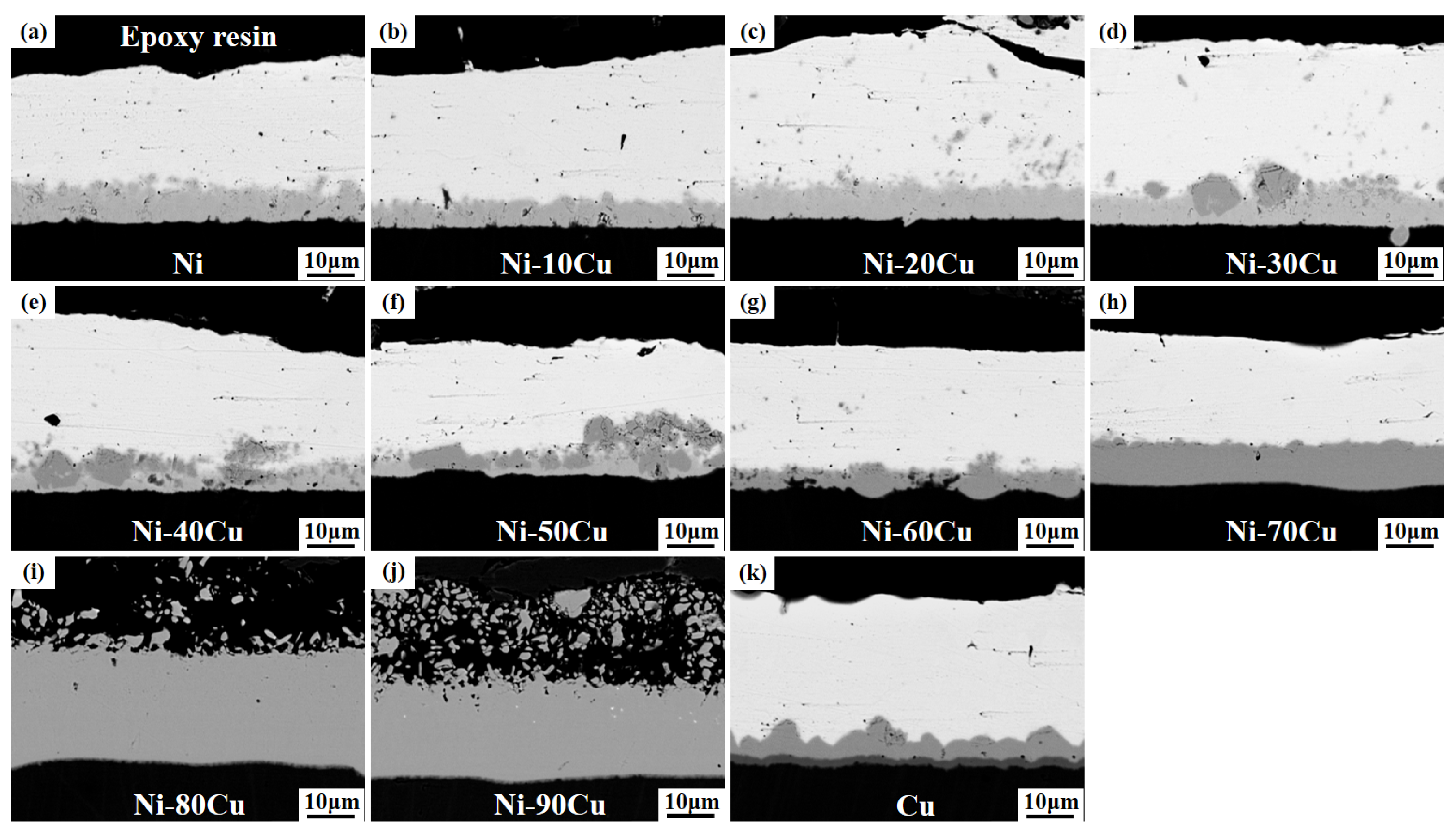

3.1. Microstructure and Phase Components

3.2. Mechanical Properties and Failure Mechanism of the Joints

4. Conclusions

- The phase composition of IMCs exhibited a Cu content-dependent transformation from the (Ni,Cu)3Sn4 phase to the (Cu,Ni)6Sn5 phase at the Ni-xCu/Sn interface, and a Cu3Sn layer was observed exclusively at the Cu/Sn interface;

- The morphology of the IMC layer underwent a transition from a continuous layer to a layer with particles above it, and finally to a continuous layer again. The IMC layer thickness at the Ni-xCu/Sn interface remains relatively consistent, except for cases where a full-IMC layer was formed at Cu contents of 80 and 90 wt.%;

- The shear strength of the Ni-xCu/Sn/Ni-xCu soldering joints after aging exhibited an initial decrease followed by an increase, except for a significant enhancement at a Cu content of 60 wt.%. The decline in mechanical properties of the aging joints could be attributed to solder brittleness, the growth of (Cu,Ni)6Sn5 particles, and the presence of shrinkage cavities in the center of full-IMC welds. Notably, at a Cu content of 60 wt.%, the (Cu,Ni)6Sn5 phase exhibited a slow growth rate with refined grains at the interface, resulting in improved mechanical properties of the joint.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Luo, Y.; Xiao, F.; Liu, B. Failure mechanism of die-attach solder joints in IGBT modules under pulse high-current power cycling. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 7, 99–107. [Google Scholar] [CrossRef]

- Zhang, P.; Xue, S.; Wang, J. New challenges of miniaturization of electronic devices: Electromigration and thermomigration in lead-free solder joints. Mater. Design 2020, 192, 108726. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, Y.; Guo, F.; Ma, L.; Han, J. The Evolution of IMCs in Single Crystal Sn3.0Ag0.5Cu and Sn3.0Ag3.0Bi3.0In BGA Solder Joints with Au/Ni/Cu Pads Under Current Stressing. J. Electron. Mater. 2019, 48, 2770–2779. [Google Scholar] [CrossRef]

- Kannojia, H.K.; Dixit, P. A review of intermetallic compound growth and void formation in electrodeposited Cu–Sn Layers for microsystems packaging. J. Mater. Sci. Mater. Electron. 2021, 32, 6742–6777. [Google Scholar] [CrossRef]

- Lv, Y.; Chen, M.; Cai, M.; Liu, S. A reliable Cu–Sn stack bonding technology for 3D-TSV packaging. Semicond. Sci. Tech. 2014, 29, 025003. [Google Scholar] [CrossRef]

- Shang, M.; Dong, C.; Yao, J.; Wang, C.; Ma, H.; Ma, H.; Wang, Y. Competitive growth of Cu3Sn and Cu6Sn5 at Sn/Cu interface during various multi-reflow processes. J. Mater. Sci. Mater. Electron. 2021, 32, 22771–22779. [Google Scholar] [CrossRef]

- Lin, K.; Ling, H.; Hu, A.; Wu, Y.; Gao, L.; Hang, T.; Li, M. Growth behavior and formation mechanism of porous Cu3Sn in Cu/Sn solder system. Mater. Charact. 2021, 178, 111271. [Google Scholar] [CrossRef]

- Wang, Y.W. Effects of surface diffusion and solder volume on porous-type Cu3Sn in Cu/Sn/Cu microjoints. Mater. Chem. Phys. 2022, 275, 125307. [Google Scholar] [CrossRef]

- Yang, G.; Li, X.; Ren, E.; Li, S. Morphology evolution and grain orientations of intermetallic compounds during the formation of full Cu3Sn joint. Intermetallics 2022, 145, 107555. [Google Scholar] [CrossRef]

- Yao, P.; Li, X.; Liang, X.; Yu, B. Investigation of soldering process and interfacial microstructure evolution for the formation of full Cu3Sn joints in electronic packaging. Mater. Sci. Semicon. Proc. 2017, 58, 39–50. [Google Scholar] [CrossRef]

- Lai, Y.; Hu, X.; Li, Y.; Jiang, X. Interfacial microstructure evolution and shear strength of Sn0.7Cu–xNi/Cu solder joints. J. Mater. Sci. Mater. Electron. 2018, 29, 11314–11324. [Google Scholar] [CrossRef]

- Mehreen, S.U.; Nogita, K.; McDonald, S.D.; Yasuda, H.; StJohn, D.H. Effect of Ni, Zn, Au, Sb and In on the Suppression of the Cu3Sn Phase in Sn-10 wt.%Cu Alloys. J. Electron. Mater. 2021, 50, 881–892. [Google Scholar] [CrossRef]

- Guo, X.J.; Li, Z.L.; Song, X.G.; Tian, H.; Dong, H.J.; Zhao, H.Y. Influence of Ni particle addition on grain refinement of Cu-Sn intermetallic compound joints bonded at various temperatures. J. Alloys Compd. 2019, 774, 721–726. [Google Scholar] [CrossRef]

- Liu, S.; Yang, C.; Ling, H.; Hu, A.; Hang, T.; Gao, L.; Li, M. Inhibiting effects of the Ni barrier layer on the growth of porous Cu3Sn in 10-μm microbumps. J. Mater. Sci. Mater. Electron. 2021, 32, 17655–17661. [Google Scholar] [CrossRef]

- Ren, S.; Sun, M.; Jin, Z.; Guo, Y.; Ling, H.; Hu, A.-m.; Li, M. Formation Mechanism of Novel Sidewall Intermetallic Compounds in Micron Level Sn/Ni/Cu Bumps. Electron. Mater. Lett. 2019, 15, 562–571. [Google Scholar] [CrossRef]

- Lee, B.-S.; Jung, S.-B.; Yoon, J.-W. Enhancement of Cu pillar bumps by electroless Ni plating. Microelectron. Eng. 2017, 180, 52–55. [Google Scholar] [CrossRef]

- Yang, C.; Ren, S.; Zhang, X.; Hu, A.; Li, M.; Gao, L.; Ling, H.; Hang, T. Effect of Sn surface diffusion on growth behaviors of intermetallic compounds in Cu/Ni/SnAg microbumps. Mater. Charact. 2020, 159, 110030. [Google Scholar] [CrossRef]

- Baheti, V.A.; Kashyap, S.; Kumar, P.; Chattopadhyay, K.; Paul, A. Effect of Ni on growth kinetics, microstructural evolution and crystal structure in the Cu (Ni)–Sn system. Philos. Mag. 2017, 97, 1782–1802. [Google Scholar] [CrossRef]

- Tan, X.F.; Gu, Q.; Bermingham, M.; McDonald, S.D.; Nogita, K. Systematic investigation of the effect of Ni concentration in Cu-xNi/Sn couples for high temperature soldering. Acta Mater. 2022, 226, 117661. [Google Scholar] [CrossRef]

- Vuorinen, V.; Yu, H.; Laurila, T.; Kivilahti, J.K. Formation of Intermetallic Compounds Between Liquid Sn and Various CuNixMetallizations. J. Electron. Mater. 2008, 37, 792–805. [Google Scholar] [CrossRef]

- Kodentsov, A.; Wojewoda-Budka, J.; Litynska-Dobrzynska, L.; Zieba, P.; Wierzbicka-Miernik, A. Formation of intermetallic compounds in reaction between Cu–Ni alloys and solid Sn—A new look at the prominent effect of Ni. J. Alloys Compd. 2021, 858, 157677. [Google Scholar] [CrossRef]

- Kajihara, M.; Minho, O.; Nakane, A.; Suzuki, T. Observation on Isothermal Reactive Diffusion between Solid Ni and Liquid Sn. Mater. Trans. 2016, 57, 838–845. [Google Scholar] [CrossRef]

- He, H.; Huang, S.; Xiao, Y.; Goodall, R. Diffusion reaction-induced microstructure and strength evolution of Cu joints bonded with Sn-based solder containing Ni-foam. Mater. Lett. 2020, 281, 128642. [Google Scholar] [CrossRef]

- He, H.; Huang, S.; Ye, Y.; Xiao, Y.; Zhang, Z.; Li, M.; Goodall, R. Microstructure and mechanical properties of Cu joints soldered with a Sn-based composite solder, reinforced by metal foam. J. Alloys Compd. 2020, 845, 156240. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Li, X.; Li, C.; Sun, F.; Liu, M.; Zhu, L.; Li, M. The effects of solder joint height on the solid–liquid interface diffusion in micro solder joints. Mater. Lett. 2022, 316, 131969. [Google Scholar] [CrossRef]

- Sohn, Y.-C.; Yu, J. Correlation between chemical reaction and brittle fracture found in electroless Ni (P)/immersion gold–solder interconnection. J. Mater. Res. 2005, 20, 1931–1934. [Google Scholar] [CrossRef]

| Specimens | Positions | Element Component (at.%) | Phase | ||

|---|---|---|---|---|---|

| Sn | Ni | Cu | |||

| Ni/Sn | 1 | 57.40 | 42.60 | / | Ni3Sn4 |

| Ni-10Cu/Sn | 2 | 58.23 | 38.10 | 3.67 | (Ni,Cu)3Sn4 |

| Ni-20Cu/Sn | 3 | 57.15 | 35.02 | 7.83 | (Ni,Cu)3Sn4 |

| Ni-30Cu/Sn | 4 | 57.38 | 36.05 | 6.56 | (Ni,Cu)3Sn4 |

| 5 | 46.45 | 21.44 | 32.11 | (Cu,Ni)6Sn5 | |

| Ni-40Cu/Sn | 6 | 57.23 | 34.56 | 8.21 | (Ni,Cu)3Sn4 |

| 7 | 45.65 | 23.28 | 31.07 | (Cu,Ni)6Sn5 | |

| Ni-50Cu/Sn | 8 | 57.57 | 33.65 | 8.79 | (Ni,Cu)3Sn4 |

| 9 | 46.56 | 20.42 | 33.02 | (Cu,Ni)6Sn5 | |

| Ni-60Cu/Sn | 10 | 46.39 | 16.67 | 36.94 | (Cu,Ni)6Sn5 |

| 11 | 45.97 | 18.68 | 35.35 | (Cu,Ni)6Sn5 | |

| Ni-70Cu/Sn | 12 | 46.47 | 15.18 | 38.35 | (Cu,Ni)6Sn5 |

| Ni-80Cu/Sn | 13 | 45.84 | 8.18 | 45.99 | (Cu,Ni)6Sn5 |

| Ni-90Cu/Sn | 14 | 46.92 | 6.67 | 46.41 | (Cu,Ni)6Sn5 |

| Cu/Sn | 15 | 46.48 | / | 53.52 | Cu6Sn5 |

| 16 | 73.71 | / | 26.29 | Cu3Sn | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Cheng, K.; Liu, J.; He, Y.; Xiao, Y. Effect of Thermal Aging on the Interfacial Reaction Behavior and Failure Mechanism of Ni-xCu/Sn Soldering Joints under Shear Loading. Materials 2023, 16, 5253. https://doi.org/10.3390/ma16155253

Li Z, Cheng K, Liu J, He Y, Xiao Y. Effect of Thermal Aging on the Interfacial Reaction Behavior and Failure Mechanism of Ni-xCu/Sn Soldering Joints under Shear Loading. Materials. 2023; 16(15):5253. https://doi.org/10.3390/ma16155253

Chicago/Turabian StyleLi, Zhigang, Kai Cheng, Jiajun Liu, Yigang He, and Yong Xiao. 2023. "Effect of Thermal Aging on the Interfacial Reaction Behavior and Failure Mechanism of Ni-xCu/Sn Soldering Joints under Shear Loading" Materials 16, no. 15: 5253. https://doi.org/10.3390/ma16155253

APA StyleLi, Z., Cheng, K., Liu, J., He, Y., & Xiao, Y. (2023). Effect of Thermal Aging on the Interfacial Reaction Behavior and Failure Mechanism of Ni-xCu/Sn Soldering Joints under Shear Loading. Materials, 16(15), 5253. https://doi.org/10.3390/ma16155253