Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

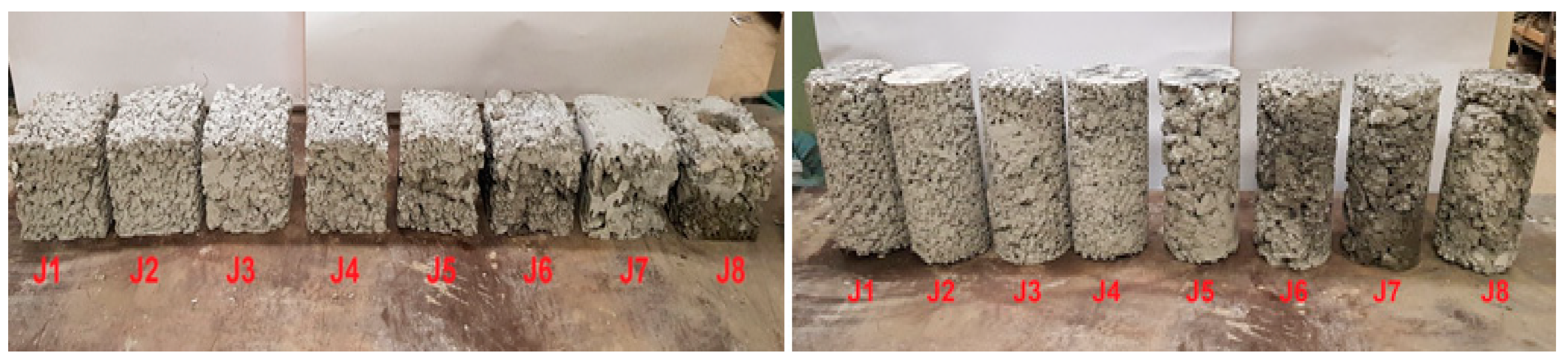

2.2. Preparation of Test Specimens

2.3. Test Methods and Data Analysis

3. Results and Discussion

4. Conclusions

5. Further Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EPA 832-F-99-023Storm Water Technology Fact Sheet Porous Pavement; United States. Environmental Protection Agency. Office of Water. Available online: http://www.epa.gov/npdes/pubs/porouspa.pdf (accessed on 3 September 1999).

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.; Yahia, A. Pervious Concrete: Mix Design, Properties and Applications. RILEM Tech. Lett. 2016, 1, 109–115. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, T.; Wang, C.; Yang, Y.; Bogush, A.; Khayrulina, E.; Huang, Z.; Wei, J.; Yu, Q. Mixture Proportion Design of Pervious Concrete Based on the Relationships between Fundamental Properties and Skeleton Structures. Cem. Concr. Compos. 2020, 113, 103693. [Google Scholar] [CrossRef]

- Tang, C.W.; Cheng, C.K.; Tsai, C.Y. Mix Design and Mechanical Properties of High-Performance Pervious Concrete. Materials 2019, 12, 2577. [Google Scholar] [CrossRef]

- Sičáková, A.; Kováč, M. Relationships between Functional Properties of Pervious Concrete. Sustainability 2020, 12, 6318. [Google Scholar] [CrossRef]

- Alex, A.G.; Jose, P.A.; Saberian, M.; Li, J. Green Pervious Concrete Containing Diatomaceous Earth as Supplementary Cementitous Materials for Pavement Applications. Materials 2022, 16, 48. [Google Scholar] [CrossRef]

- Silva, F.A.N.; Delgado, J.M.P.Q.; Azevedo, A.C.; Lima, A.G.B.; Vieira, C.S. Preliminary Analysis of the Use of Construction Waste to Replace Conventional Aggregates in Concrete. Buildings 2021, 11, 81. [Google Scholar] [CrossRef]

- Paula Junior, A.; Jacinto, C.; Oliveira, T.; Polisseni, A.; Brum, F.; Teixeira, E.; Mateus, R. Characterisation and Life Cycle Assessment of Pervious Concrete with Recycled Concrete Aggregates. Crystals 2021, 11, 209. [Google Scholar] [CrossRef]

- Hua, M.; Chen, B.; Liu, Y.; Liu, H.; Zhu, P.; Chen, C.; Wang, X. Durability and Abrasion Resistance of Innovative Recycled Pervious Concrete with Recycled Coarse Aggregate of Different Quality under Sulfate Attack. Appl. Sci. 2021, 11, 9647. [Google Scholar] [CrossRef]

- Anwar, F.H.; El-Hassan, H.; Hamouda, M.; Hinge, G.; Mo, K.H. Meta-Analysis of the Performance of Pervious Concrete with Cement and Aggregate Replacements. Buildings 2022, 12, 461. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Kareem, Q.; İpek, S. Effect of Different Substitution of Natural Aggregate by Recycled Aggregate on Performance Characteristics of Pervious Concrete. Mater. Struct. 2016, 49, 521–536. [Google Scholar] [CrossRef]

- Deb, P.; Debnath, B.; Hasan, M.; Alqarni, A.S.; Alaskar, A.; Alsabhan, A.H.; Khan, M.A.; Alam, S.; Hashim, K.S. Development of Eco-Friendly Concrete Mix Using Recycled Aggregates: Structural Performance and Pore Feature Study Using Image Analysis. Materials 2022, 15, 2953. [Google Scholar] [CrossRef]

- Aamer Rafique Bhutta, M.; Hasanah, N.; Farhayu, N.; Hussin, M.W.; Tahir, M.b.M.; Mirza, J. Properties of Porous Concrete from Waste Crushed Concrete (Recycled Aggregate). Constr. Build. Mater. 2013, 47, 1243–1248. [Google Scholar] [CrossRef]

- Kevern, J.T.; Schaefer, V.R.; Wang, K. Evaluation of Pervious Concrete Workability Using Gyratory Compaction. J. Mater. Civ. Eng. 2009, 21, 764–770. [Google Scholar] [CrossRef]

- Bonicelli, A.; Fuentes, L.G.; Dawd Bermejo, I.K. Laboratory Investigation on the Effects of Natural Fine Aggregates and Recycled Waste Tire Rubber in Pervious Concrete to Develop More Sustainable Pavement Materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032081. [Google Scholar] [CrossRef]

- Dodoo Arhin, D.; Mensah, S.; Yaya, A.; Agyei-Tuffour, B. Application of Discarded Rubber Car Tyres as Synthetic Coarse Aggregates in Light Weight Pavement Concretes. Am. J. Mater. Sci. 2015, 2015, 75–83. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and Freezing–Thawing Resistance of Pervious Concretes Containing Waste Rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Kevern, J.T. Advancements in Pervious Concrete Technology. Retrospective Theses and Dissertations. Iowa State University, Ames, IA, USA, 2008. Available online: https://lib.dr.iastate.edu/rtd/93 (accessed on 1 January 2008).

- Kurpińska, M.; Pawelska-Mazur, M.; Gu, Y.; Kurpiński, F. The Impact of Natural Fibers’ Characteristics on Mechanical Properties of the Cement Composites. Sci. Rep. 2022, 12, 20565. [Google Scholar] [CrossRef]

- Mussato, J.; Toralles, B.; Sandoval, G. Performance of pervious concrete reinforced with polypropylene fibers. MIX Sustentável 2017, 3, 195–197. [Google Scholar] [CrossRef]

- Kevern, J.T.; Biddle, D.; Cao, Q. Effects of Macrosynthetic Fibers on Pervious Concrete Properties. J. Mater. Civ. Eng. 2015, 27, 06014031. [Google Scholar] [CrossRef]

- Chavan, P.; Patare, D.; Wagh, M. Enhancement of Pervious Concrete Properties by Using Polypropylene Fiber. Int. J. Eng. Res. Gen. Sci. 2019, 7, 17–25. [Google Scholar]

- Wu, J.; Pang, Q.; Lv, Y.; Zhang, J.; Gao, S. Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete. Materials 2022, 15, 6527. [Google Scholar] [CrossRef]

- Schaefer, V.; Wang, K.; Suleiman, M.; Kevern, J. Mix Design Development for Pervious Concrete in Cold Weather Climates; Center for Transportation Research and Education, Lowa State University: Ames, IA, USA, 2006; pp. 8–72. [Google Scholar]

- Wang, K.; Schaefer, V.R.; Kevern, J.T. Development of Mix Proportion for Functional and Durable Pervious Concrete. In Proceedings of the 2006 NRMCA Concrete Technology Forum—Focus on Pervious Concrete, Nashville, TN, USA, 24–25 May 2006; pp. 1–12. [Google Scholar]

- ACI Committee 522; Report on Pervious Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2010; ISBN 9780870313646.

- Yang, J.; Jiang, G. Experimental Study on Properties of Pervious Concrete Pavement Materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Liew, M.S.; Alaloul, W.S.; Khed, V.C.; Hoong, C.Y.; Adamu, M. Properties of Nano-Silica Modified Pervious Concrete. Case Stud. Constr. Mater. 2018, 8, 409–422. [Google Scholar] [CrossRef]

- Banevičienė, V.; Malaiškienė, J.; Boris, R.; Zach, J. The Effect of Active Additives and Coarse Aggregate Granulometric Composition on the Properties and Durability of Pervious Concrete. Materials 2022, 15, 1035. [Google Scholar] [CrossRef]

- Liu, R.; Liu, H.; Sha, F.; Yang, H.; Zhang, Q.; Shi, S.; Zheng, Z. Investigation of the Porosity Distribution, Permeability, and Mechanical Performance of Pervious Concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of Fly Ash and Metakaolin on Pervious Concrete Properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Yasin, A.A. Investigation of Mechanical and Physical Properties of No-Fines Concrete. Int. J. Eng. Innov. Res. 2015, 4, 799–802. [Google Scholar]

- Kováč, M.; Sičáková, A. Pervious Concrete as an Environmental Solution for Pavements: Focus on Key Properties. Environments 2018, 5, 11. [Google Scholar] [CrossRef]

- Huang, B.; Cao, J.; Chen, X.; Shu, X. Laboratory and Analytical Study of Permeability and Strength Properties of Pervious Concrete; National Ready Mixed Concrete Association: Alexandria, VA, USA, 2006. [Google Scholar]

- Mahalingam, R.; Mahalingam, S.V. Analysis of Pervious Concrete Properties. Gradjevinar 2016, 68, 493–501. [Google Scholar] [CrossRef]

- Zhao, C.; Li, H.; Peng, Y.; Jia, X.; Rahman, A. Toughness Behavior of Sbr Acrylate Copolymer-Modified Pervious Concrete with Single-Sized Aggregates. Materials 2021, 14, 89. [Google Scholar] [CrossRef]

- Chandrashekar, V. Effect on the Engineering Properties of Pervious Concrete by Partial Replacement of Cement with GGBS. GRD J. Glob. Res. Dev. J. Eng. 2018, 3, 1–7. [Google Scholar]

- Aoki, Y. Development of Pervious Concrete Certificate of Authorship. Master’s Thesis, Sydney Faculty of Engineering and Information Technology, University of Technology, Sydney, NSW, Australia, 2009. Available online: https://opus.lib.uts.edu.au/bitstream/2100/1203/2/02Whole.pdf (accessed on 1 June 2009).

- Kim, H.H.; Kim, C.S.; Jeon, J.H.; Park, C.G. Effects on the Physical and Mechanical Properties of Porous Concrete for Plant Growth of Blast Furnace Slag, Natural Jute Fiber, and Styrene Butadiene Latex Using a Dry Mixing Manufacturing Process. Materials 2016, 9, 84. [Google Scholar] [CrossRef]

- Ramkrishnan, R.; Abilash, B.; Trivedi, M.; Varsha, P.; Varun, P.; Vishanth, S. Effect of Mineral Admixtures on Pervious Concrete. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; Volume 5, pp. 24014–24023. [Google Scholar]

- Dean, S.W.; Kevern, J.T.; Schaefer, V.R.; Wang, K.; Suleiman, M.T. Pervious Concrete Mixture Proportions for Improved Freeze-Thaw Durability. J. ASTM Int. 2008, 5, 101320. [Google Scholar] [CrossRef]

- Sharif, A.A.M.; Shahidan, S.; Koh, H.B.; Kandash, A.; Mohd Zuki, S.S. Strength Development of Pervious Concrete Containing Engineered Biomass Aggregate. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012002. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Investigating Properties of Pervious Concretes Containing Waste Tire Rubbers. Constr. Build. Mater. 2014, 63, 206–213. [Google Scholar] [CrossRef]

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-6; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 12390-5; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-13; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. European Committee for Standardization: Brussels, Belgium, 2021.

- Rahal, K. Mechanical Properties of Concrete with Recycled Coarse Aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of Recycled Aggregates on Mechanical Properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of Rice Husk Ash and Fiber on Mechanical Properties of Pervious Concrete Pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar] [CrossRef]

- R, M.; Chakrawarthi, V.; Nagaraju, T.V.; Avudaiappan, S.; Awolusi, T.F.; Roco-Videla, Á.; Azab, M.; Kozlov, P. Performance of Recycled Bakelite Plastic Waste as Eco-Friendly Aggregate in the Concrete Beams. Case Stud. Constr. Mater. 2023, 18, e02200. [Google Scholar] [CrossRef]

| Void Ratio [%] | Unit Weight [kg/m3] | Permeability [cm/s] | 28-Day Compressive Strength [Mpa] | Flexural Strength [Mpa] | Tensile Strength [Mpa] | w/b | a/b | Aggregates (Size) | Additive (% by Binder Weight) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 16.4–20.7 | - | 0.21–0.26 | - | - | - | 0.40 | 4.0–12.0 | Coarse | - | [34] |

| 23.0–26.0 | 1890–1930 | 0.86–1.02 | 14.5–17.5 | - | 1.6–2.0 | 0.25–0.35 | - | Coarse (<8 mm) | - | [35] |

| 26.5–35.1 | - | 1.5–1.7 | - | - | - | 0.35 | 4.5 | Gravel (4.75–12.5 mm) | - | [36] |

| 21.0–28.0 | - | 0.86–2.00 | 5.1–15.9 | 1.9–3.2 | 1.15–1.70 | 0.35 | 3.0–7.0 | Coarse (4.75–12.5 mm) | - | [37] |

| - | - | - | 13.5 | 2.8 | - | 0.41 | 3.33 | Limestone (4.75–12.5 mm) | - | [38] |

| 19.9 | 4.4 | - | SBR | |||||||

| 11.5–22.6 | 4.6–5.8 | - | SBR + AP | |||||||

| - | - | 0.35–0.85 | 18.5–21.5 | 2.5–3.5 | - | 0.25–0.35 | - | Recycled concrete (5–10 mm) | PPTF 55 mm (0.6–1.5) | [2] |

| 0.55–0.60 | 0.30 | CCF 12 mm (1.0–1.9) | ||||||||

| 0.45–0.60 | 0.30 | PPF 12 mm (0.1–0.3) | ||||||||

| 31.0–34.2 | 1921–1950 | 0.18–0.29 | 9.1–21.5 | 3.1–4.0 | 0.54–1.56 | 0.31 | 4.8 | Coarse | GGBS (0–80) | [39] |

| - | 1800–2500 | 0.9–1.4 | 10.0–5.7 | - | - | 0.35 | 4.0 | Crushed gravel (10 mm) | Fly ash (0–50) | [40] |

| 22.0–28.0 | - | - | 11.9–15.5 | - | - | 0.66 | 10.88 | Coarse/Slag (<25 mm) | SBR latex (0.94) | [41] |

| 26.0–28.5 | 10.0–8.0 | NJF (12.5) | ||||||||

| - | 2090 | 0.81 | 15.1 | - | - | 0.30 | 4.4 | Coarse | MK (10) | [42] |

| 2030 | 1.77 | 12.2 | Fly ash (10) | |||||||

| 1930 | 1.05 | 16.6 | UFGGBS (10) | |||||||

| 12.9 | 2165 | - | - | - | - | 0.22–0.27 | 4.1–4.7 | River gravel (4.75–9.5 mm) | SBR (10) | [26] |

| 33.0 | 1790 | Silica fume (5) | ||||||||

| - | 1769–1929 | 0.27–1.18 | 21.4 | - | 2.40–2.45 | 0.27 | 4.7 | River gravel (4.75–9.5 mm) | FM300 12.7/19.1 mm (0.10–0.26) | [43] |

| 1759–1916 | 0.02–1.03 | 17.8 | 1.30–2.05 | FC500 50 mm (0.10–0.26) | ||||||

| - | 1778–1985 | 1.0–1.2 | 2.6–8.1 | - | - | 0.30 | - | Crushed granite (<20 mm) | EBA (5–25) | [44] |

| - | 1829–1841 | 0.6–3.0 | - | - | 0.64–0.69 | 0.30–0.35 | 5.0 | Coarse | CR 0.6/2.5 mm (5–10) | [17] |

| 1915–1926 | 0.34–0.60 | FCR 0.08–1 mm (5–10) | ||||||||

| - | 1900–2030 | 0.20–0.33 | 9.1–14.5 | 1.14–1.60 | - | 0.27 | 2.9–3.3 | River coarse (>10 mm) | CTC (10–20) | [45] |

| 2030–2130 | 0.15–0.26 | 13.1–19.0 | 1.11–1.57 | CR 4 mm (10–20) | ||||||

| 2180–2240 | 0.26–0.27 | 14.4–21.6 | 1.49–1.56 | FCR 1 mm (10–20) |

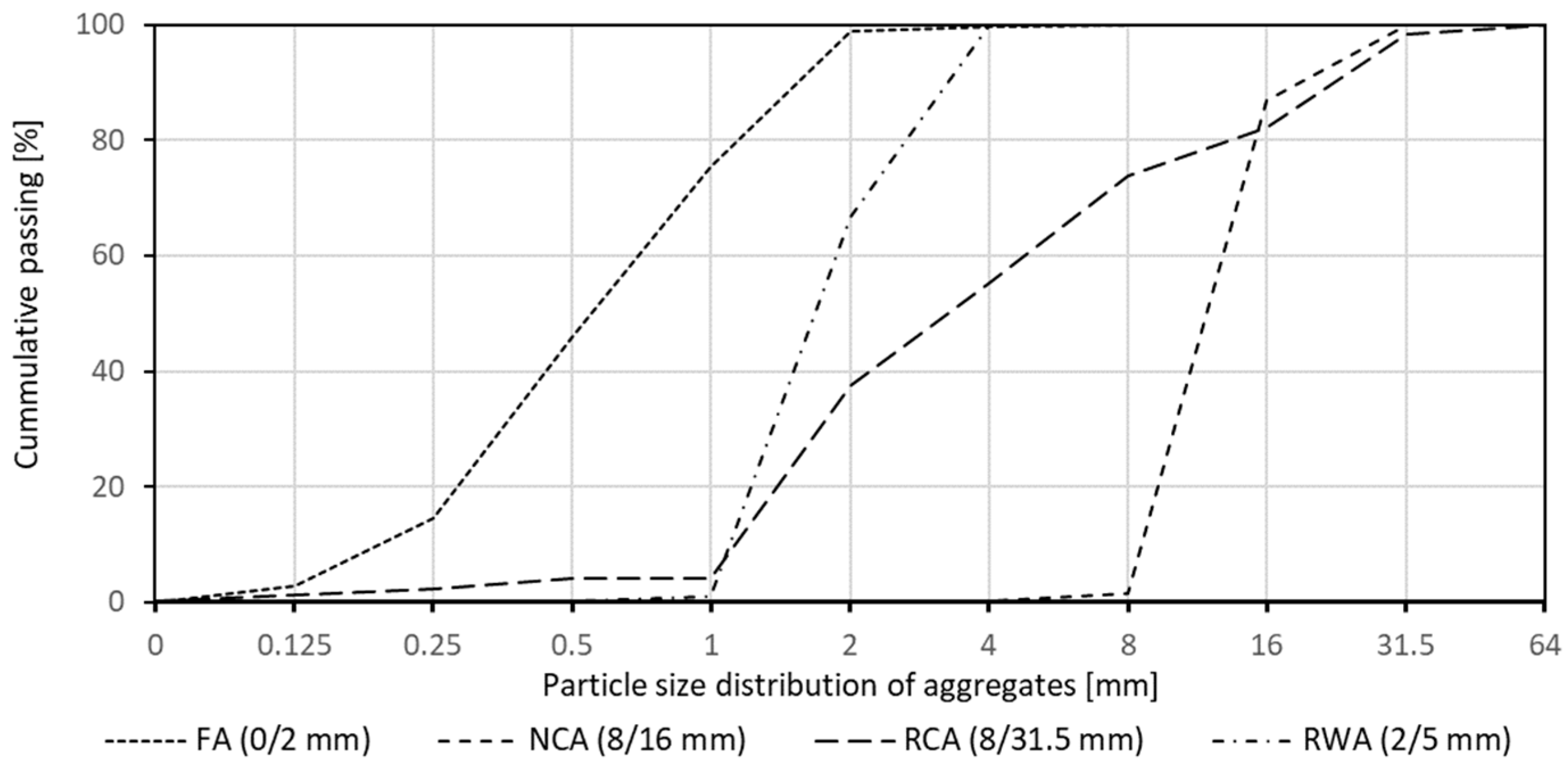

| Type | Sieve Size, % Passing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.125 | 0.25 | 0.5 | 1 | 2 | 4 | 8 | 16 | 31.5 | 64 | |

| FA (0/2 mm) | 0.0 | 2.9 | 14.6 | 45.8 | 75.5 | 99.0 | 99.8 | 100 | 100 | 100 | 100 |

| NCA (8/16 mm) | 0.0 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 1.6 | 86.8 | 100 | 100 |

| RCA (8/31.5 mm) | 0.3 | 1.1 | 2.3 | 4.1 | 5.2 | 37.5 | 55.2 | 73.8 | 82.3 | 98.3 | 100 |

| RWA (2/5 mm) | 0 | 0.1 | 0.1 | 0.1 | 0.9 | 66.9 | 100 | 100 | 100 | 100 | 100 |

| Initial Setting Time [min] | Final Setting Time [min] | Compressive Strength [MPa] | Blaine Fineness [cm2/g] | Loss on Ignition [%] | Water Demand [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 Days | 28 Days | ||||||||||||||

| 155 | 195 | 30.2 | 57.3 | 3504 | 3.4 | 27.5 | |||||||||

| Chemical composition [%] | |||||||||||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | TiO2 | Cl | ||||||

| 21.7 | 6.2 | 3.1 | 63.4 | 1.0 | 3.9 | 0.16 | 0.64 | 0.25 | 0.06 | ||||||

| Mineral composition [%] | |||||||||||||||

| Na2Oeq | C3S | C2S | C3A | C4AF | |||||||||||

| 0.7 | 63.1 | 7.6 | 6.1 | 8.9 | |||||||||||

| Natural Aggregate | Recycled Aggregate | |||||||

|---|---|---|---|---|---|---|---|---|

| Mix ID | J1 | J2 | J3 | J4 | J5 | J6 | J7 | J8 |

| Binder (cement) | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Water | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| w/b | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 |

| a/b | 4.3 | 4.3 | 4.3 | 4.3 | 3.9 | 3.9 | 3.9 | 3.9 |

| FA (0/2 mm) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| NCA (2/8 mm) | - | - | - | - | - | - | - | - |

| NCA (8/16 mm) | 1520 | 1520 | 760 | 760 | 1370 | 1370 | 610 | 610 |

| RCA (8/31.5 mm) | - | - | 760 | 760 | - | - | 760 | 760 |

| RWA (2/5 mm) | - | - | - | - | 50 | 50 | 50 | 50 |

| PF (54 mm) | - | 2 | - | 2 | - | 2 | - | 2 |

| Superplasticizer | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

| Sample Type | Quantity | Test |

|---|---|---|

| Cube (150 × 150 × 150 mm) | 9 | Compressive strength Tensile splitting strength |

| Cylinder (ø150 mm, h = 300 mm) | 6 | Tensile splitting strength Modulus of elasticity |

| Beam (700 × 150 × 150 mm) | 3 | Flexural strength |

| Natural Aggregate | Recycled Aggregate | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mix ID | J1 | J2 | J3 | J4 | J5 | J6 | J7 | J8 | |

|

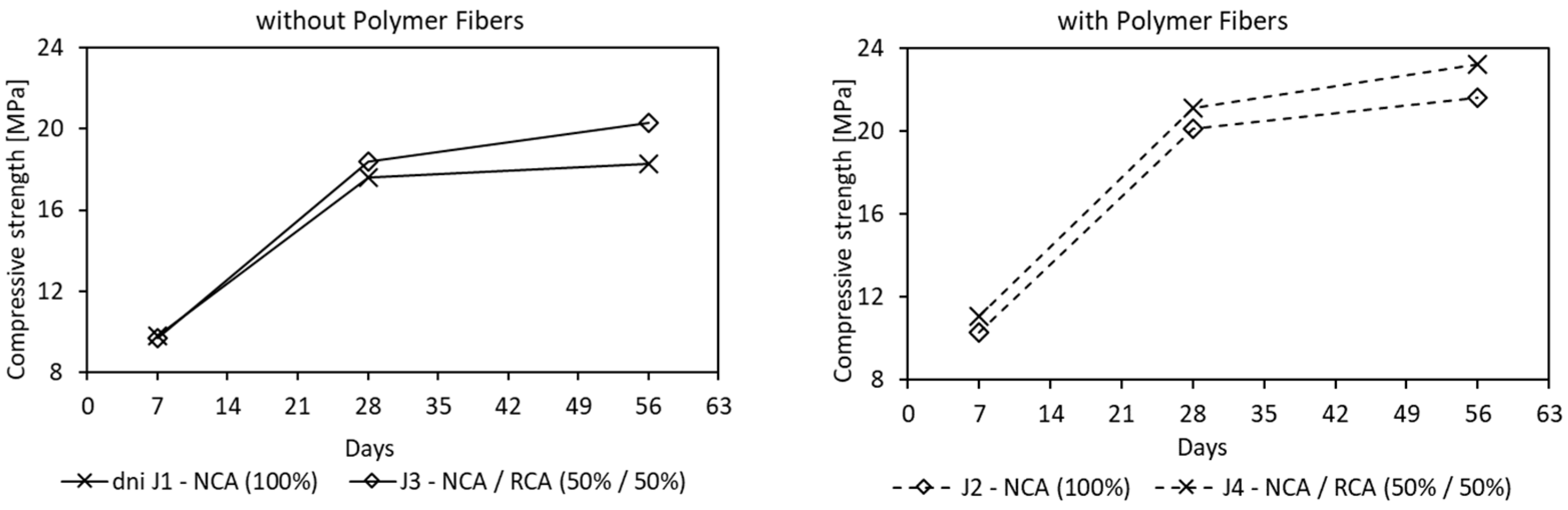

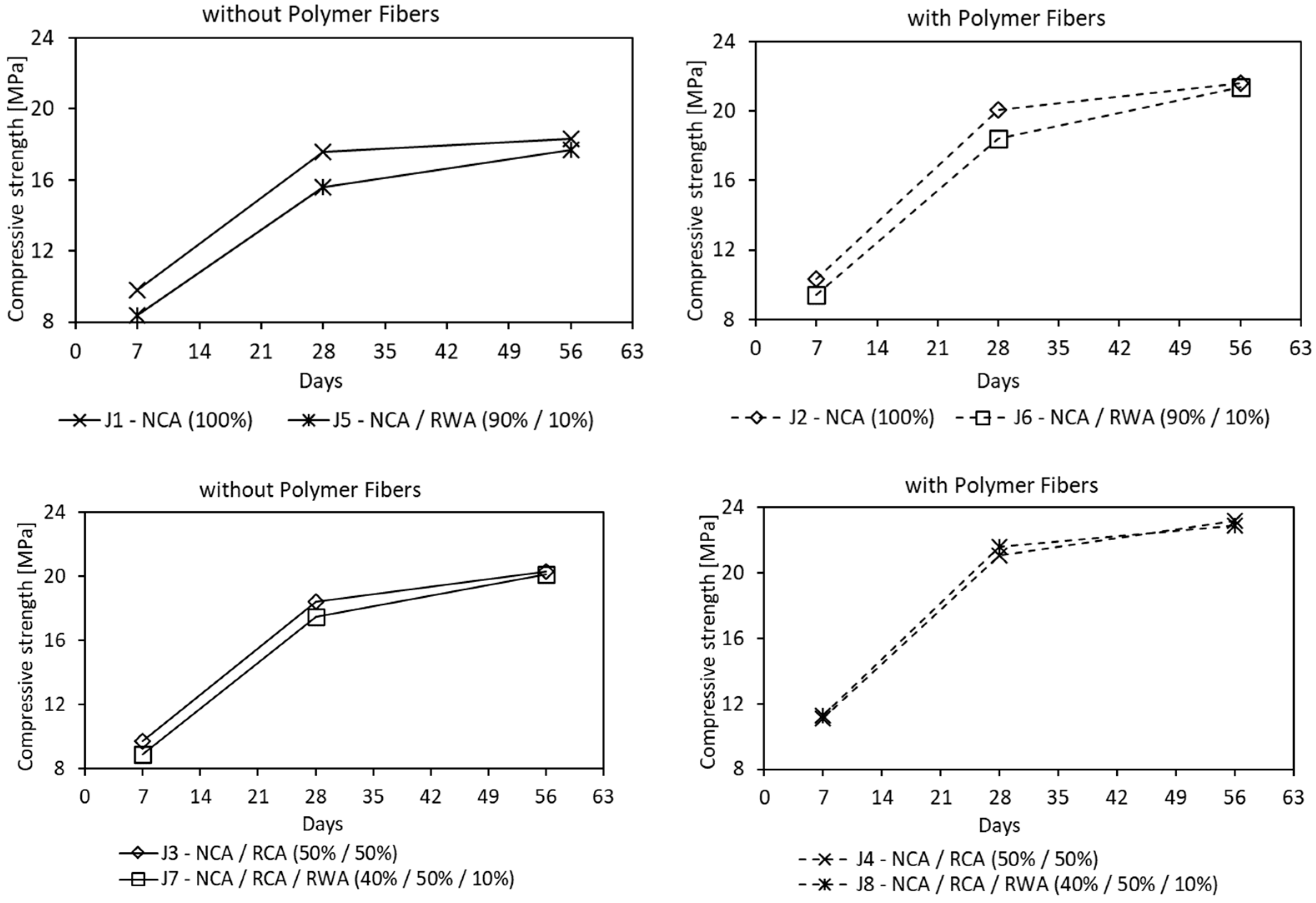

Compressive strength fcm [MPa] | 7 days | 9.8 | 10.3 | 9.7 | 11.1 | 8.4 | 9.4 | 8.9 | 11.3 |

| 28 days | 17.6 | 20.1 | 18.4 | 21.1 | 15.6 | 18.4 | 17.5 | 21.6 | |

| 56 days | 18.3 | 21.6 | 20.3 | 23.2 | 17.7 | 21.4 | 20.1 | 22.9 | |

| Tensile strength [MPa] | cubic | 2.9 | 3.4 | 3.0 | 3.5 | 2.8 | 3.5 | 3.4 | 3.7 |

| cylindrical | 3.2 | 3.7 | 3.5 | 3.9 | 3.3 | 3.9 | 3.6 | 4.1 | |

| Flexural strength [MPa] | 3.5 | 4.1 | 2.4 | 2.8 | 2.5 | 2.9 | 4.0 | 4.9 | |

| Unit weight [kg/m3] | 2034 | 2063 | 2024 | 1970 | 1779 | 1769 | 1975 | 1822 | |

| Modulus of elasticity Ecm [GPa] | 10.6 | 12.7 | 10.9 | 12.4 | 11.2 | 12.2 | 8.6 | 11.0 | |

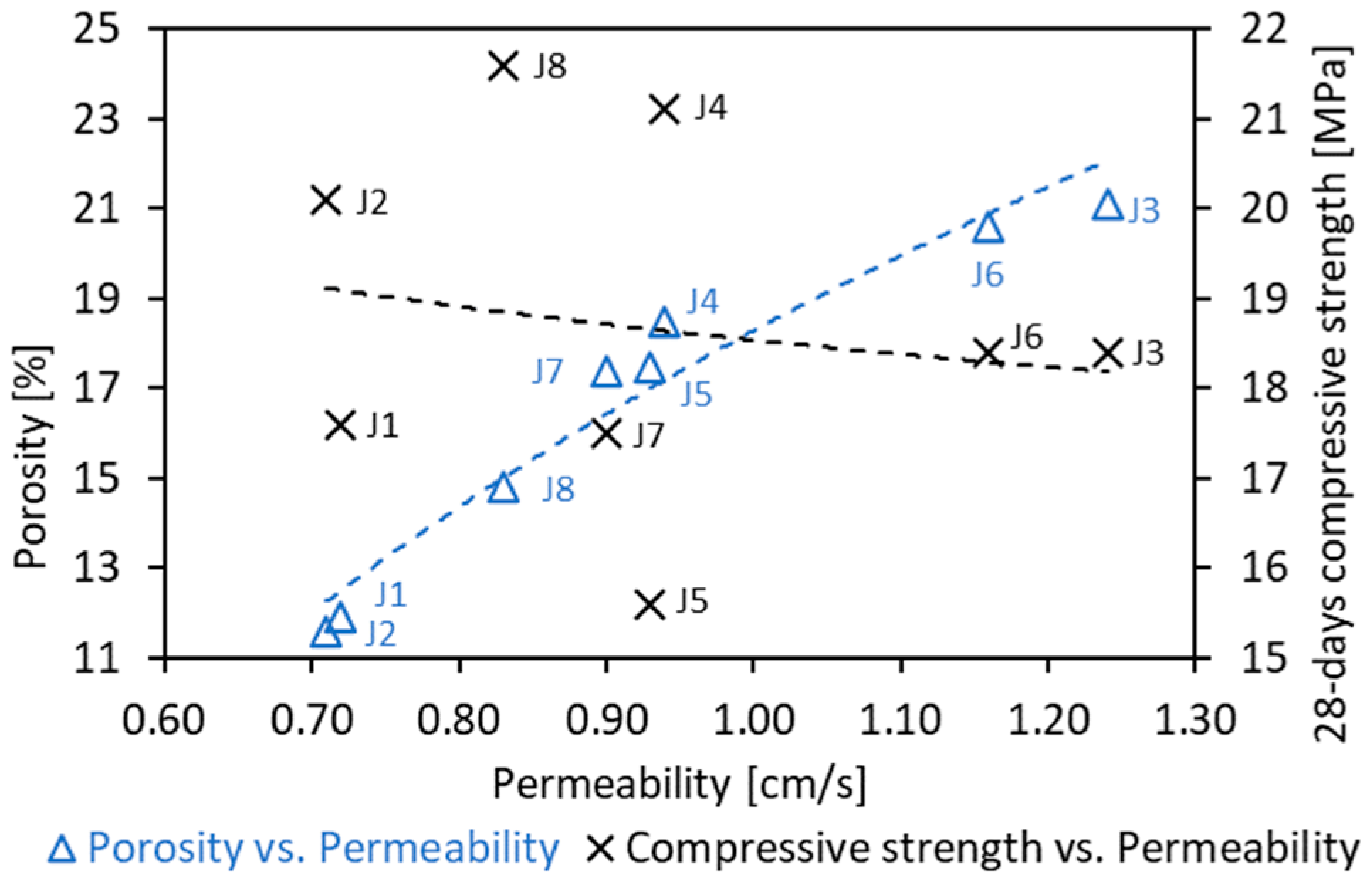

| Void ratio (porosity) [%] | 11.9 | 11.6 | 21.1 | 18.5 | 17.5 | 20.6 | 17.4 | 14.8 | |

| Permeability, k [cm/s] | 0.72 | 0.71 | 1.24 | 0.94 | 0.93 | 1.16 | 0.90 | 0.83 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitrosz, O.; Kurpińska, M.; Miśkiewicz, M.; Brzozowski, T.; Abdelgader, H.S. Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete. Materials 2023, 16, 5222. https://doi.org/10.3390/ma16155222

Mitrosz O, Kurpińska M, Miśkiewicz M, Brzozowski T, Abdelgader HS. Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete. Materials. 2023; 16(15):5222. https://doi.org/10.3390/ma16155222

Chicago/Turabian StyleMitrosz, Oskar, Marzena Kurpińska, Mikołaj Miśkiewicz, Tadeusz Brzozowski, and Hakim Salem Abdelgader. 2023. "Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete" Materials 16, no. 15: 5222. https://doi.org/10.3390/ma16155222

APA StyleMitrosz, O., Kurpińska, M., Miśkiewicz, M., Brzozowski, T., & Abdelgader, H. S. (2023). Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete. Materials, 16(15), 5222. https://doi.org/10.3390/ma16155222