Optimisation of a Multi-Functional Piezoelectric Component for a Climbing Robot

Abstract

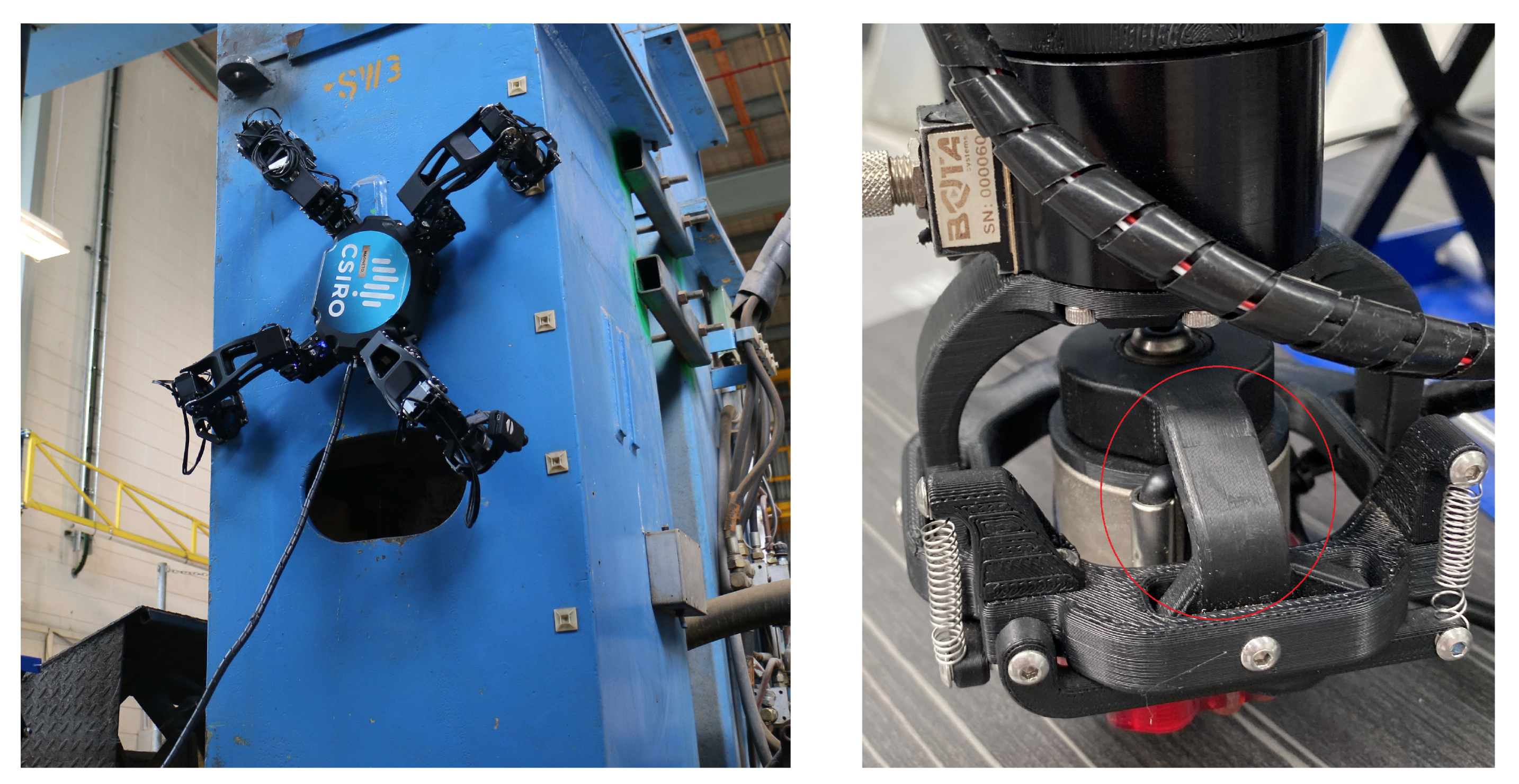

1. Introduction

- Mechanical properties: the component should be lightweight and have low compliance meaning that it will have a small deflection under loading.

- Sensing capability: the component needs sensing capability to replace the off-the-shelf force sensor in each foot. As each force sensor weighs roughly 120 g, this should not only save weight but also provide information regarding the internal stress state of the foot.

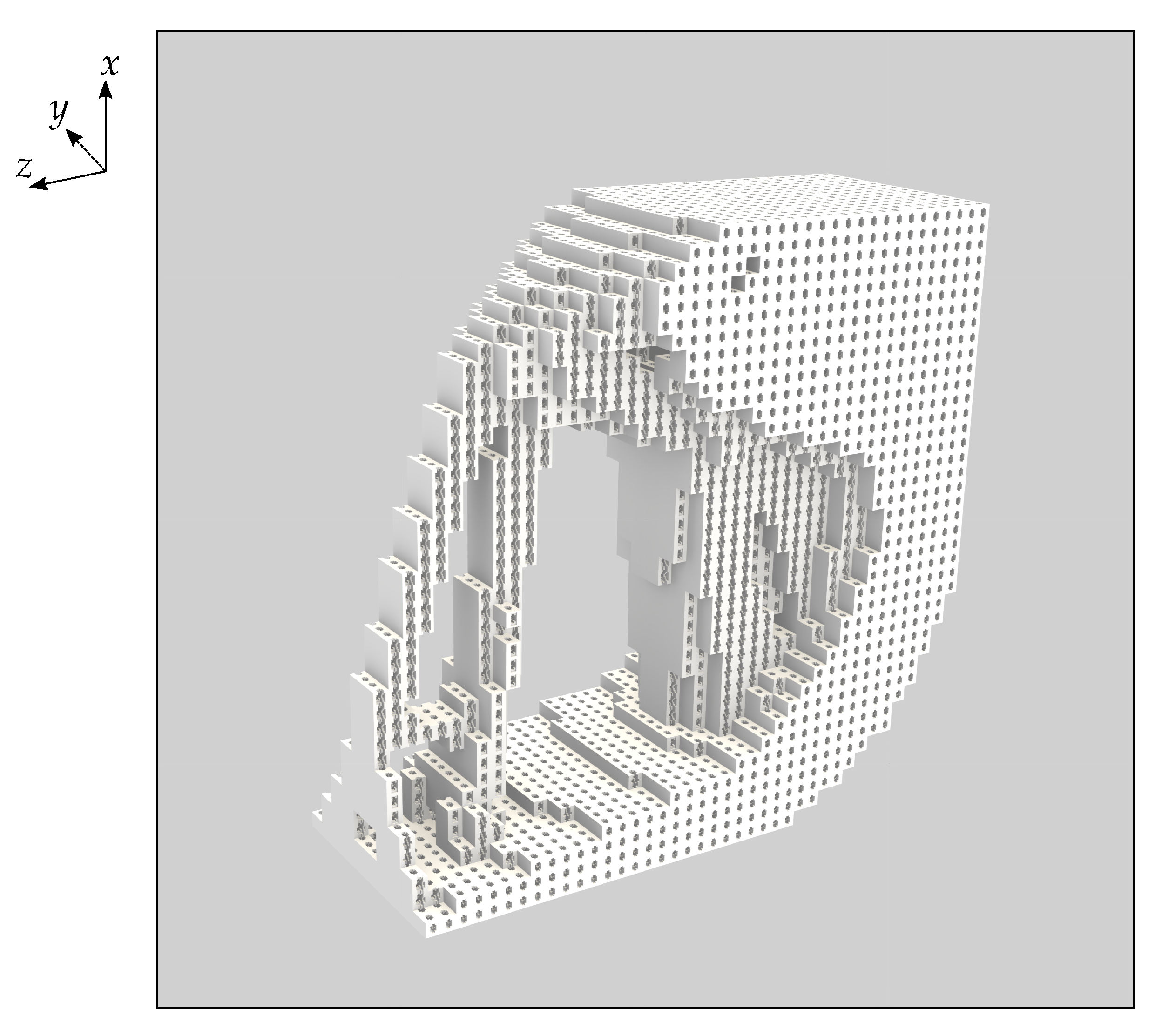

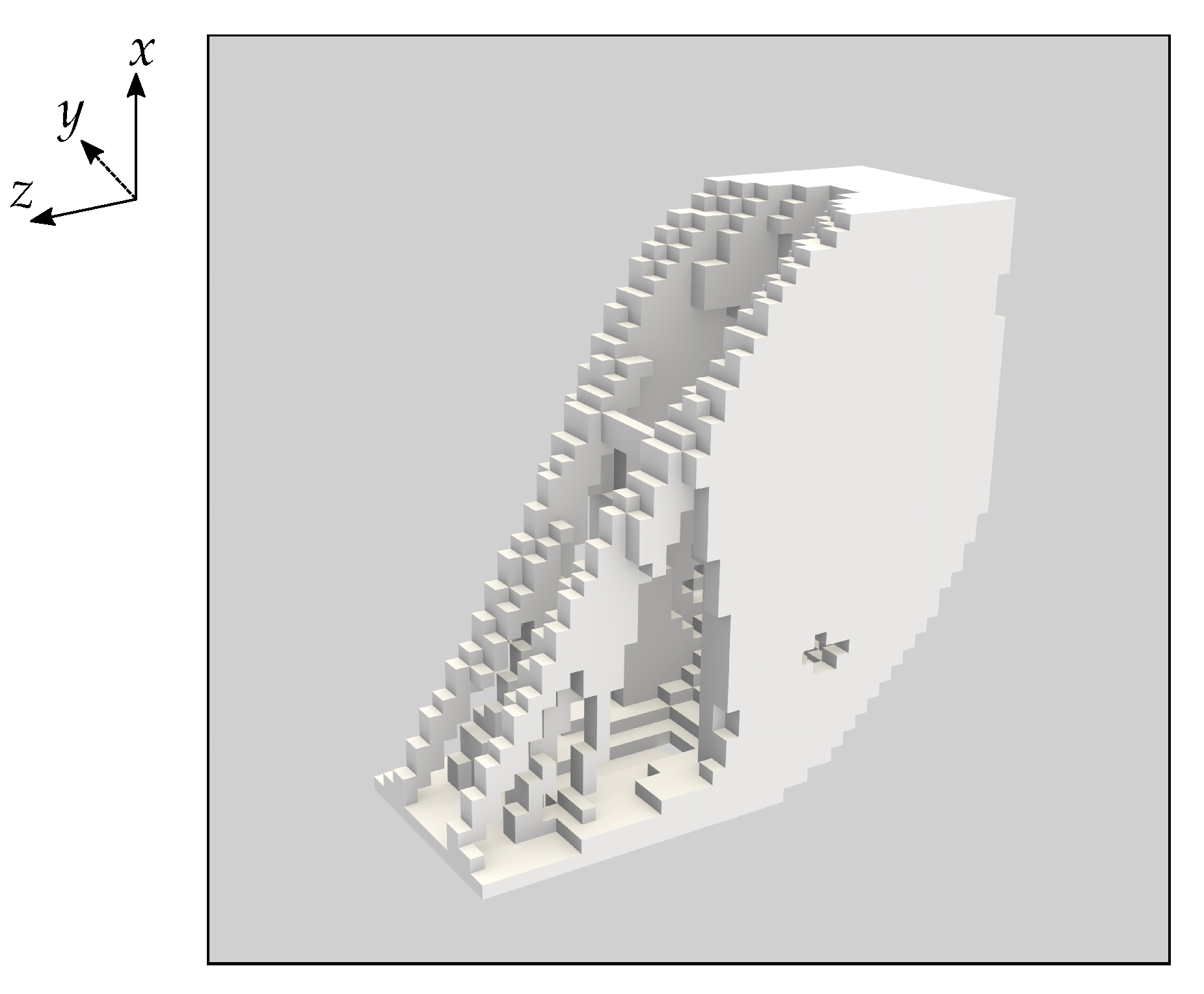

- Robustness to climbing configurations: the component should be functional for at least three actuation cases: horizontal movement, vertical movement, and inverted horizontal movement. These three cases correspond to the base test cases considered in the robot’s engineering design [30].

2. Methods

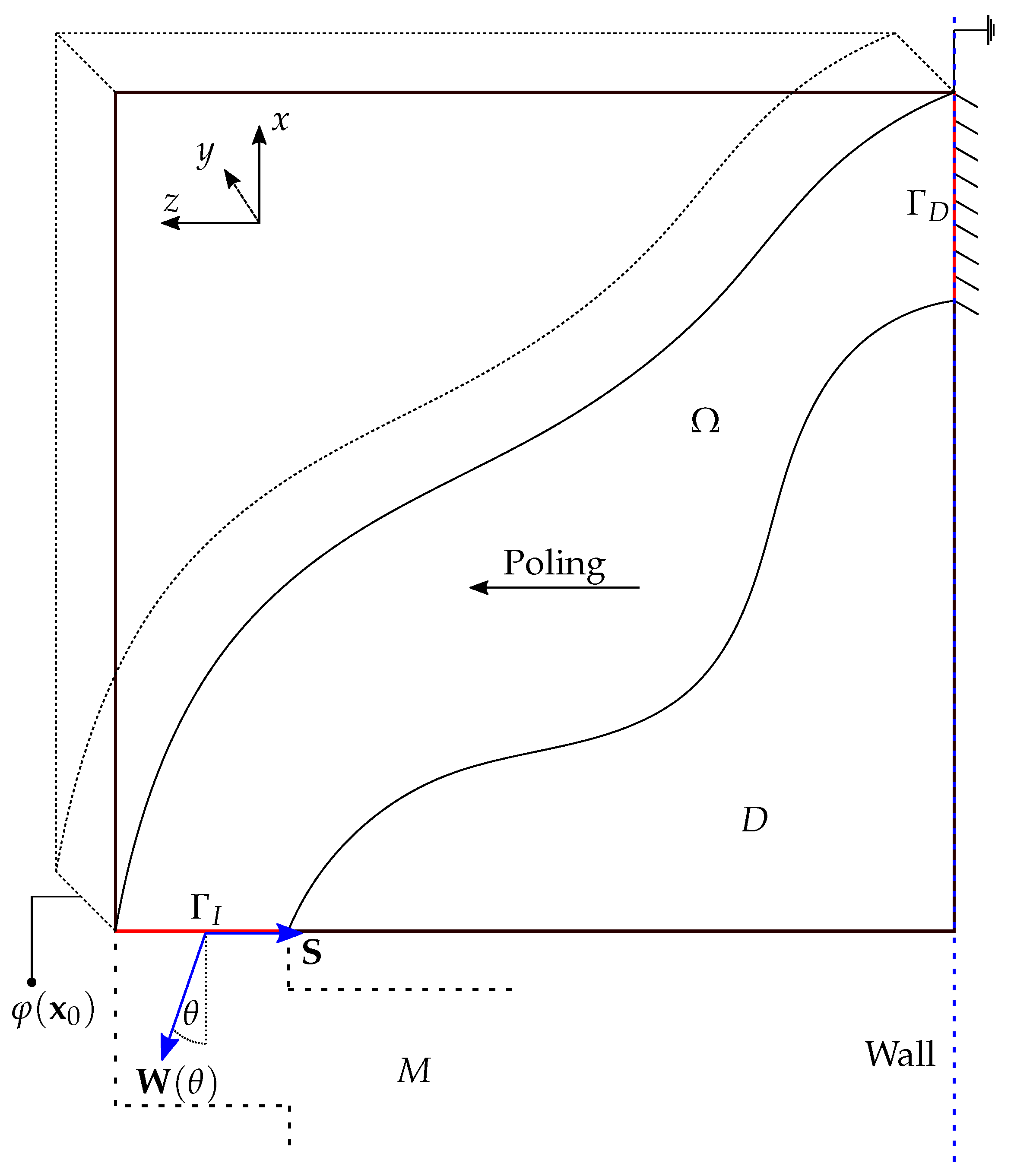

2.1. Design Domain

- : the robot is on a horizontal surface;

- : the robot is on a vertical surface; and

- : the robot is upside down on horizontal surface.

2.2. Optimisation Problem

3. Sensitivity Analysis

3.1. Compliance

3.2. Voltage

4. Numerical Implementation

4.1. Design Parameters

4.2. Base Materials

4.3. Discretisation and Finite Element Method

4.4. Topology Optimisation Algorithm

5. Results

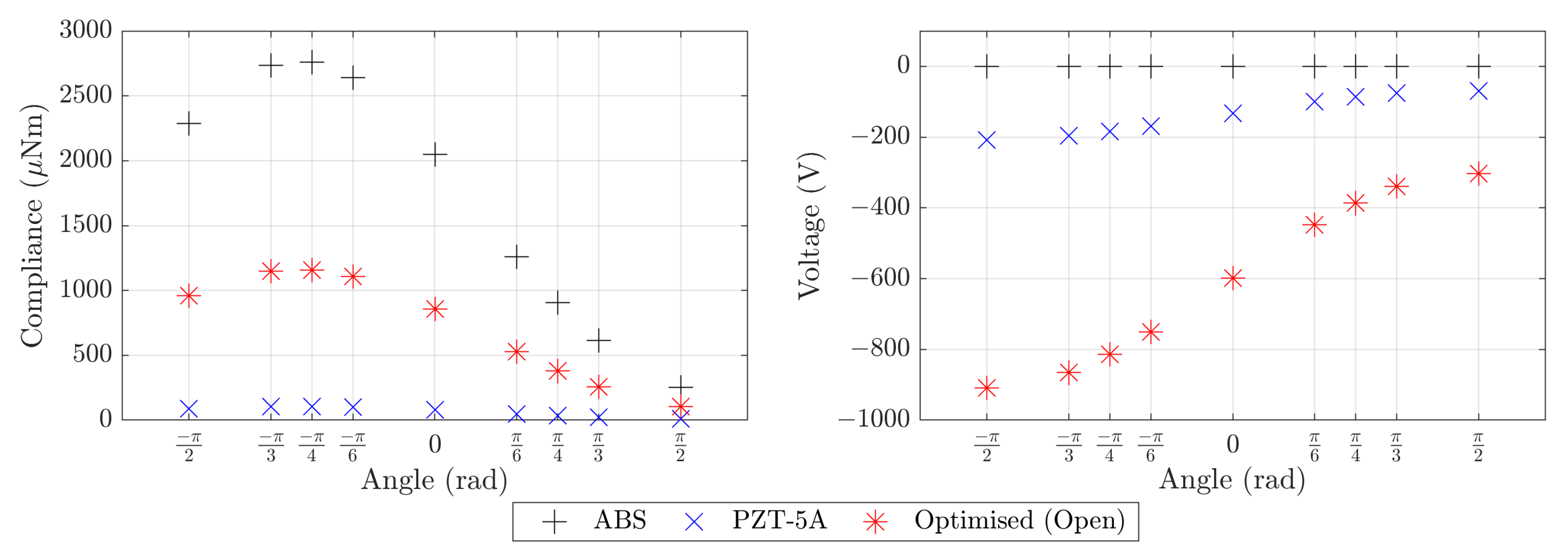

5.1. Reference Component

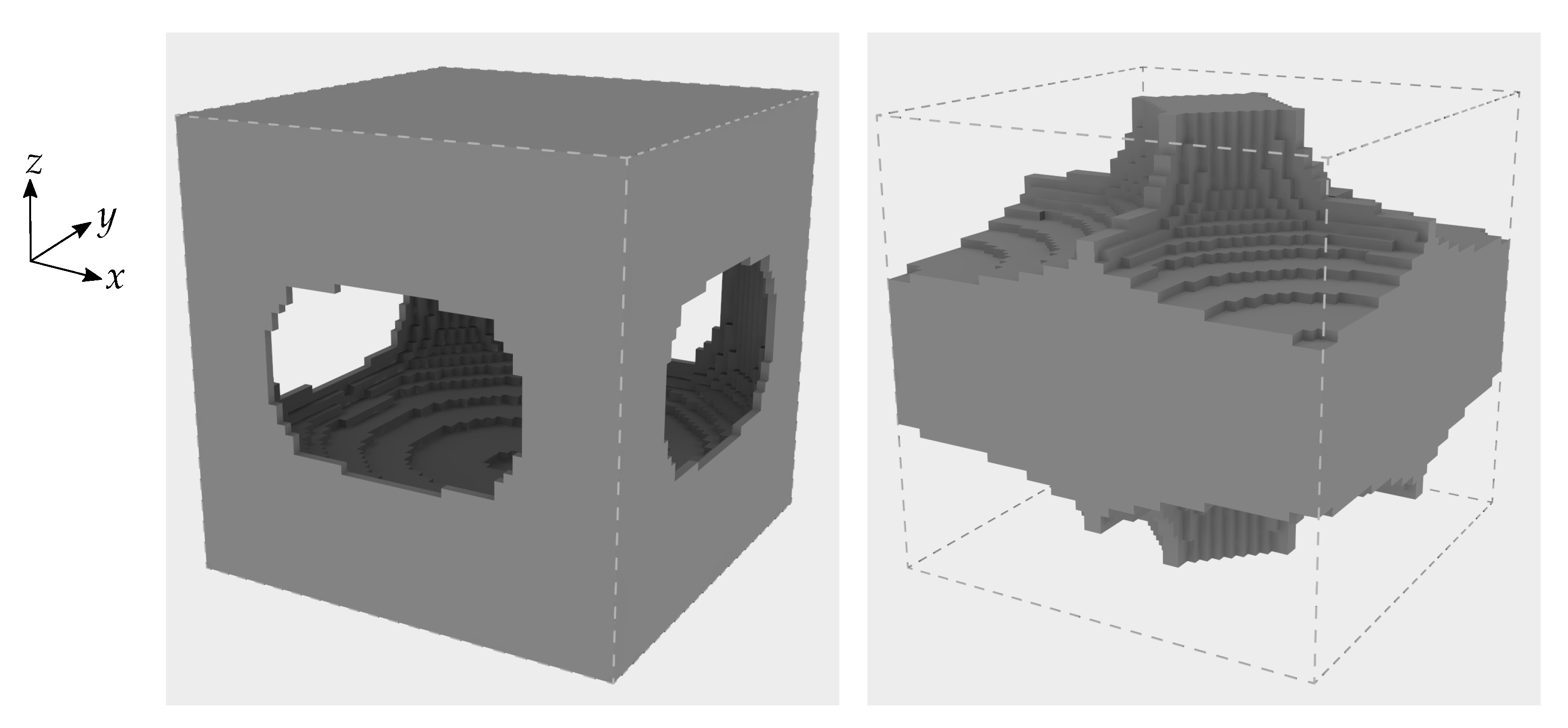

5.2. Optimised Components

5.3. Volume Minimised Component

6. Discussion

- Mechanical properties: lightweight and low compliance.

- Sensing capability: piezoelectric sensing capability.

- Robustness to climbing configurations: functional for inclination angles of , 0, and .

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bendsøe, M.; Sigmund, O. Topology Optimization Theory, Methods, and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Deaton, J.; Grandhi, R. A survey of structural and multidisciplinary continuum topology optimization: Post 2000. Struct. Multidiscip. Optim. 2013, 49, 1–38. [Google Scholar] [CrossRef]

- Wildman, R.; Gaynor, A. 11—Topology optimization for robotics applications. In Robotic Systems and Autonomous Platforms; Walsh, S.M., Strano, M.S., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 251–292. [Google Scholar] [CrossRef]

- Kim, B.J.; Yun, D.K.; Lee, S.H.; Jang, G.W. Topology optimization of industrial robots for system-level stiffness maximization by using part-level metamodels. Struct. Multidiscip. Optim. 2016, 54, 1061–1071. [Google Scholar] [CrossRef]

- Sha, L.; Lin, A.; Zhao, X.; Kuang, S. A topology optimization method of robot lightweight design based on the finite element model of assembly and its applications. Sci. Prog. 2020, 103, 0036850420936482. [Google Scholar] [CrossRef]

- Homayouni-Amlashi, A.; Schlinquer, T.; Mohand-Ousaid, A.; Rakotondrabe, M. 2D topology optimization MATLAB codes for piezoelectric actuators and energy harvesters. Struct. Multidiscip. Optim. 2020, 63, 983–1014. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, X.; Gu, X.D.; Chen, S. Designing Ferromagnetic Soft Robots (FerroSoRo) with Level-Set-Based Multiphysics Topology Optimization. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 10067–10074. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.Y. Topology design of a conforming gripper with distributed compliance via a level set method. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; pp. 2191–2196. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X.; Zhu, B.; Zhang, H.; Chen, B.; Wang, H. Topology optimization of a cable-driven soft robotic gripper. Struct. Multidiscip. Optim. 2020, 62, 2749–2763. [Google Scholar] [CrossRef]

- Wang, Y.R.; Zheng, J.M.; Ren, G.Y.; Zhang, P.H.; Xu, C. A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mater. Struct. 2011, 20, 045009. [Google Scholar] [CrossRef]

- Curry, E.J.; Ke, K.; Chorsi, M.T.; Wrobel, K.S.; Miller, A.N.; Patel, A.; Kim, I.; Feng, J.; Yue, L.; Wu, Q.; et al. Biodegradable Piezoelectric Force Sensor. Proc. Natl. Acad. Sci. USA 2018, 115, 909–914. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Kan, J.W.; Yu, X.C.; Wang, S.Y.; Ma, J.J.; Cao, Z.X. Sensitivity enhancement of piezoelectric force sensors by using multiple piezoelectric effects. AIP Adv. 2016, 6, 075320. [Google Scholar] [CrossRef]

- Chopra, I. Review of State of Art of Smart Structures and Integrated Systems. AIAA J. 2002, 40, 2145–2187. [Google Scholar] [CrossRef]

- Cui, H.; Hensleigh, R.; Yao, D.; Maurya, D.; Kumar, P.; Kang, M.G.; Priya, S.; Zheng, X. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 2019, 18, 234–241. [Google Scholar] [CrossRef]

- Kögl, M.; Silva, E.C.N. Topology optimization of smart structures: Design of piezoelectric plate and shell actuators. Smart Mater. Struct. 2005, 14, 387–399. [Google Scholar] [CrossRef]

- Kang, Z.; Tong, L. Topology optimization-based distribution design of actuation voltage in static shape control of plates. Comput. Struct. 2008, 86, 1885–1893. [Google Scholar] [CrossRef]

- Zheng, B.; Chang, C.J.; Gea, H.C. Topology optimization of energy harvesting devices using piezoelectric materials. Struct. Multidiscip. Optim. 2009, 38, 17–23. [Google Scholar] [CrossRef]

- Kang, Z.; Wang, X. Topology optimization of bending actuators with multilayer piezoelectric material. Smart Mater. Struct. 2010, 19, 075018. [Google Scholar] [CrossRef]

- Gonçalves, J.F.; De Leon, D.M.; Perondi, E.A. Simultaneous optimization of piezoelectric actuator topology and polarization. Struct. Multidiscip. Optim. 2018, 58, 1139–1154. [Google Scholar] [CrossRef]

- Guzmán, D.G.; Silva, E.C.N.; Rubio, W.M. Topology optimization of piezoelectric sensor and actuator layers for active vibration control. Smart Mater. Struct. 2020, 29, 085009. [Google Scholar] [CrossRef]

- He, M.; Zhang, X.; Dos Santos Fernandez, L.; Molter, A.; Xia, L.; Shi, T. Multi-material topology optimization of piezoelectric composite structures for energy harvesting. Compos. Struct. 2021, 265, 113783. [Google Scholar] [CrossRef]

- Moretti, M.; Silva, E.C.N. Topology optimization of piezoelectric bi-material actuators with velocity feedback control. Front. Mech. Eng. 2019, 14, 190–200. [Google Scholar] [CrossRef]

- Nakasone, P.H.; Kiyono, C.Y.; Silva, E.C.N. Design of piezoelectric sensors, actuators, and energy harvesting devices using topology optimization. In Proceedings of the Sensors and Smart Structures Technologies for Civil Mechanical, and Aerospace Systems, San Diego, CA, USA, 9–13 March 2008; Volume 6932, p. 69322W. [Google Scholar] [CrossRef]

- Schlinquer, T.; Homayouni-Amlashi, A.; Rakotondrabe, M.; Mohand-Ousaid, A. Design of Piezoelectric Actuators By Optimizing the Electrodes Topology. IEEE Robot. Autom. Lett. 2021, 6, 72–79. [Google Scholar] [CrossRef]

- Zhang, X.; Takezawa, A.; Kang, Z. Topology optimization of piezoelectric smart structures for minimum energy consumption under active control. Struct. Multidiscip. Optim. 2018, 58, 185–199. [Google Scholar] [CrossRef]

- Homayouni-Amlashi, A.; Mohand-Ousaid, A.; Rakotondrabe, M. Topology optimization of 2DOF piezoelectric plate energy harvester under external in-plane force. J. Micro-Bio Robot. 2020, 16, 65–77. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, Z. Dynamic topology optimization of piezoelectric structures with active control for reducing transient response. Comput. Methods Appl. Mech. Eng. 2014, 281, 200–219. [Google Scholar] [CrossRef]

- Zheng, B.; Lu, C.; Huang, H.Z. Topology Optimization of Piezoelectric Force Sensor. In Proceedings of the 2008 International Conference on Apperceiving Computing and Intelligence Analysis, Chengdu, China, 13–15 December 2008; pp. 132–136. [Google Scholar] [CrossRef]

- Wegert, Z.J.; Roberts, A.P.; Challis, V.J. Multi-objective structural optimisation of piezoelectric materials. Int. J. Solids Struct. 2022, 248, 111666. [Google Scholar] [CrossRef]

- Bandyopadhyay, T.; Steindl, R.; Talbot, F.; Kottege, N.; Dungavell, R.; Wood, B.; Barker, J.; Hoehn, K.; Elfes, A. Magneto: A Versatile Multi-Limbed Inspection Robot. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 2253–2260. [Google Scholar] [CrossRef]

- Wegert, Z.J. Analysis and Optimisation of Periodic Piezoelectric Materials. Master’s Thesis, Queensland University of Technology, Brisbane, Australia, 2022. [Google Scholar]

- Silva, E.C.N.; Fonseca, J.S.O.; De Espinosa, F.M.; Crumm, A.T.; Brady, G.A.; Halloran, J.W.; Kikuchi, N. Design of Piezocomposite Materials and Piezoelectric Transducers Using Topology Optimization—Part I. Arch. Comput. Methods Eng. 1999, 6, 117–182. [Google Scholar] [CrossRef]

- Badia, S.; Verdugo, F. Gridap: An extensible Finite Element toolbox in Julia. J. Open Source Softw. 2020, 5, 2520. [Google Scholar] [CrossRef]

- Svanberg, K. The method of moving asymptotes—A new method for structural optimization. Int. J. Numer. Methods Eng. 1987, 24, 359–373. [Google Scholar] [CrossRef]

- Svanberg, K. MMA and GCMMA—Two Methods for Nonlinear Optimization. 2007. Available online: https://people.kth.se/~krille/mmagcmma.pdf (accessed on 6 July 2023).

- Zou, R.; Xia, Y.; Liu, S.; Hu, P.; Hou, W.; Hu, Q.; Shan, C. Isotropic and anisotropic elasticity and yielding of 3D printed material. Compos. Part B Eng. 2016, 99, 506–513. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, J.; To, A.C. Role of anisotropic properties on topology optimization of additive manufactured load bearing structures. Scr. Mater. 2017, 135, 148–152. [Google Scholar] [CrossRef]

- Stegmann, J.; Lund, E. Discrete material optimization of general composite shell structures. Int. J. Numer. Methods Eng. 2005, 62, 2009–2027. [Google Scholar] [CrossRef]

- Nomura, T.; Dede, E.M.; Lee, J.; Yamasaki, S.; Matsumori, T.; Kawamoto, A.; Kikuchi, N. General topology optimization method with continuous and discrete orientation design using isoparametric projection. Int. J. Numer. Methods Eng. 2015, 101, 571–605. [Google Scholar] [CrossRef]

| Material | Compliance (Nm) | Voltage (V) | |

|---|---|---|---|

| ABS | −/2 | 2287 | 0 |

| 3.218 g | 0 | 2047 | 0 |

| /2 | 254.1 | 0 | |

| Avg: | 1529 | 0 | |

| PZT-5A | −/2 | 87.24 | −208.2 |

| 22.82 g | 0 | 79.25 | −133.4 |

| /2 | 9.694 | −69.41 | |

| Avg: | 58.73 | −137.0 | |

| Optimised (Open) | −/2 | 959.9 | −909.5 |

| 11.41 g | 0 | 856.7 | −597.8 |

| /2 | 106.6 | −303.2 | |

| Avg: | 641.1 | −603.5 |

| Case | Compliance (Nm) | Voltage (V) | |

|---|---|---|---|

| PZT-5A | −/2 | 43.59 | −296.1 |

| 0 | 43.33 | −199.8 | |

| 23.80 g | /2 | 4.844 | −98.71 |

| Avg: | 30.59 | −198.21 | |

| Optimised (Open) | −/2 | 427.1 | −1561 |

| 0 | 414.4 | −1037 | |

| 11.93 g | /2 | 47.45 | −520.4 |

| Avg: | 296.3 | −1039 | |

| PZT-5A | −/2 | 52.59 | −482.8 |

| 0 | 52.79 | −321.2 | |

| 16.84 g | /2 | 5.843 | −160.9 |

| Avg: | 37.07 | −321.7 | |

| Optimised (Open) | −/2 | 510.1 | −2544 |

| 0 | 495.4 | −1675 | |

| 8.372 g | /2 | 56.68 | −848.1 |

| Avg: | 354.0 | −1689 |

| Mass | Compliance (Nm) | Voltage (V) | |

|---|---|---|---|

| 14.38 g | −/2 | 59.83 | −597.0 |

| 0 | 61.40 | −399.7 | |

| /2 | 6.647 | −199.0 | |

| Avg: | 42.62 | −398.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wegert, Z.J.; Roberts, A.P.; Bandyopadhyay, T.; Challis, V.J. Optimisation of a Multi-Functional Piezoelectric Component for a Climbing Robot. Materials 2023, 16, 5076. https://doi.org/10.3390/ma16145076

Wegert ZJ, Roberts AP, Bandyopadhyay T, Challis VJ. Optimisation of a Multi-Functional Piezoelectric Component for a Climbing Robot. Materials. 2023; 16(14):5076. https://doi.org/10.3390/ma16145076

Chicago/Turabian StyleWegert, Zachary J., Anthony P. Roberts, Tirthankar Bandyopadhyay, and Vivien J. Challis. 2023. "Optimisation of a Multi-Functional Piezoelectric Component for a Climbing Robot" Materials 16, no. 14: 5076. https://doi.org/10.3390/ma16145076

APA StyleWegert, Z. J., Roberts, A. P., Bandyopadhyay, T., & Challis, V. J. (2023). Optimisation of a Multi-Functional Piezoelectric Component for a Climbing Robot. Materials, 16(14), 5076. https://doi.org/10.3390/ma16145076