The Strength and Fracture Characteristics of One-Part Strain-Hardening Green Alkali-Activated Engineered Composites

Abstract

1. Introduction

2. Experimental Program, Materials, and Methods

2.1. Materials and Mix Proportions

2.2. Mixing, Casting, and Curing of Specimens

2.3. Test Methods

3. Results and Discussions

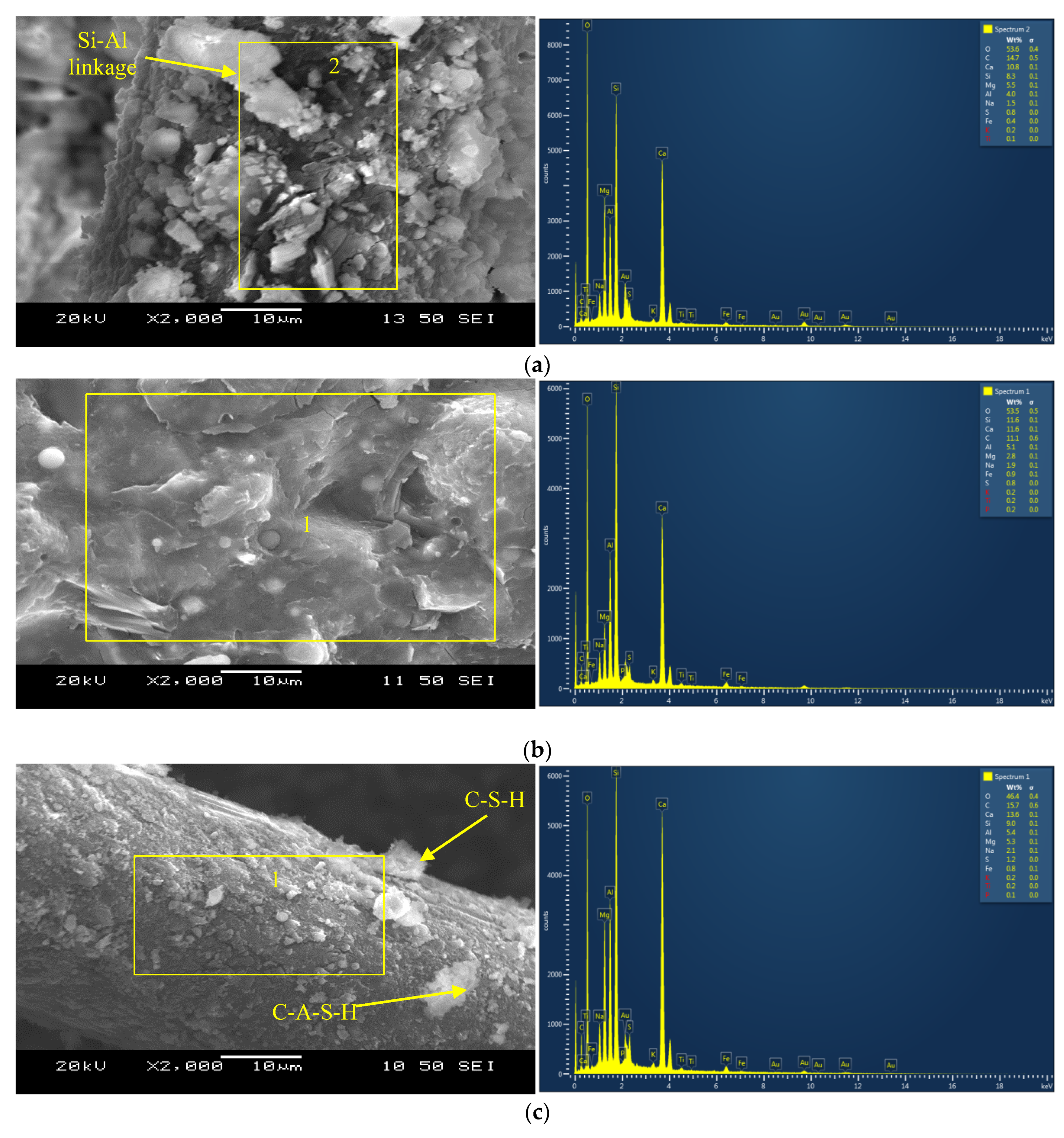

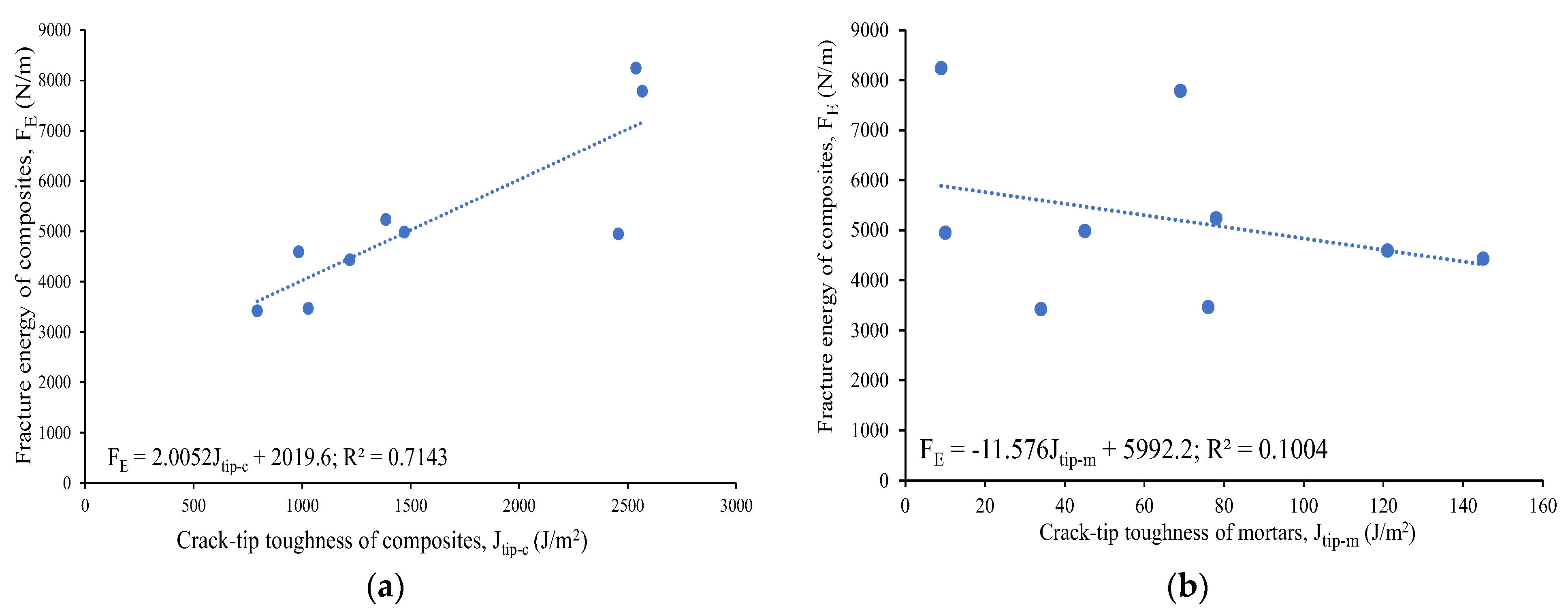

3.1. Microstructural Analyses

3.2. Mechanical Characteristics of Alkali-Activated Engineered Composites

3.2.1. Dry Density, Compressive Strength and UPV

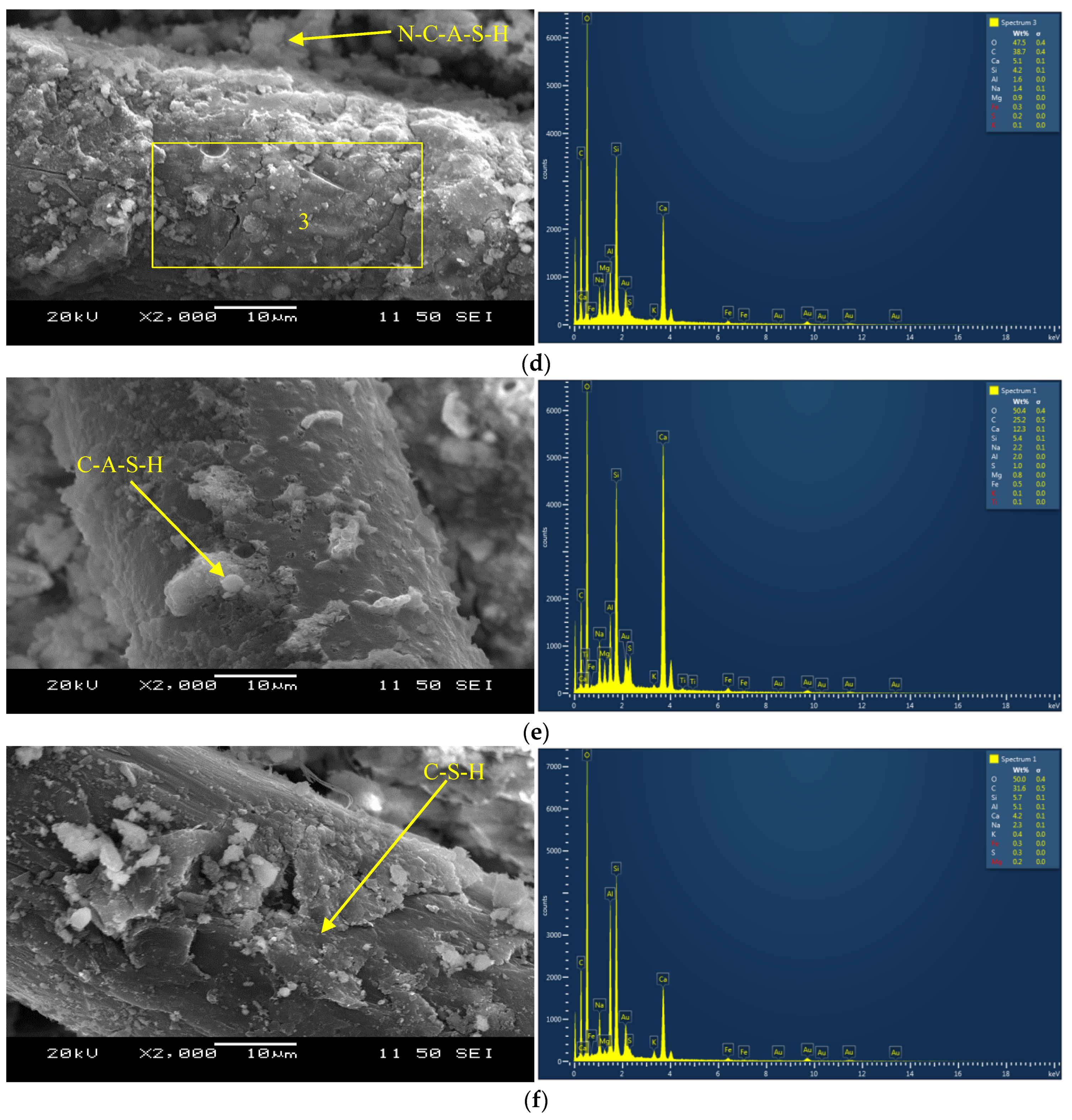

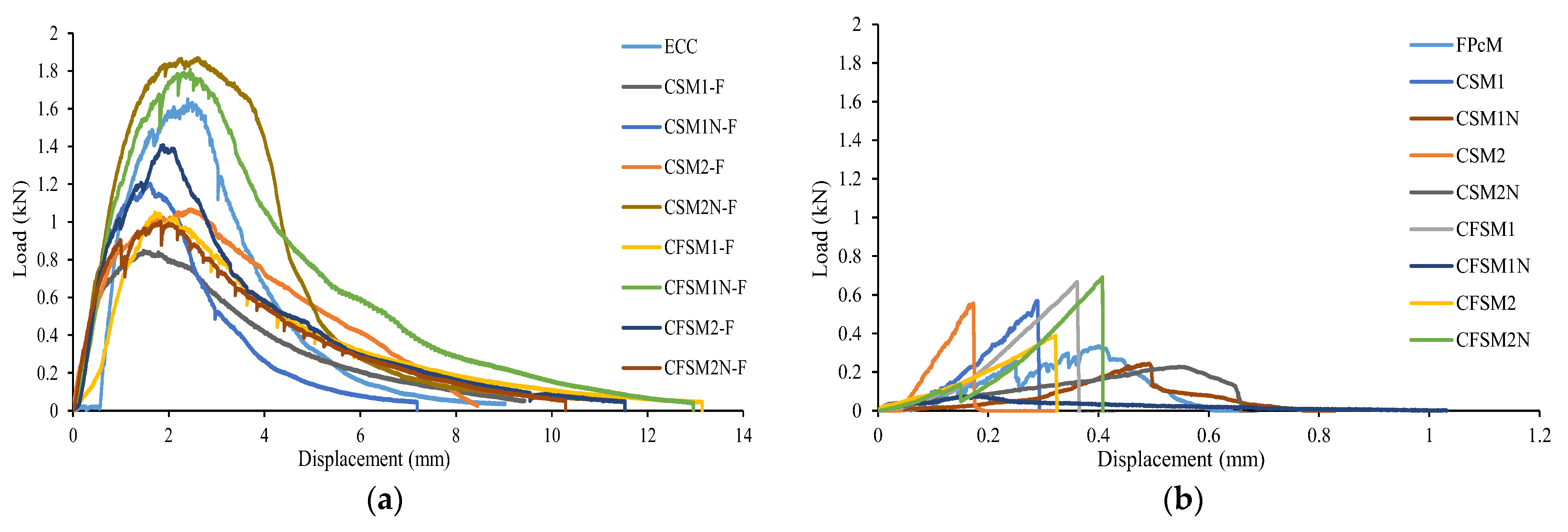

3.2.2. Fracture Characteristics of Mortars and Composites

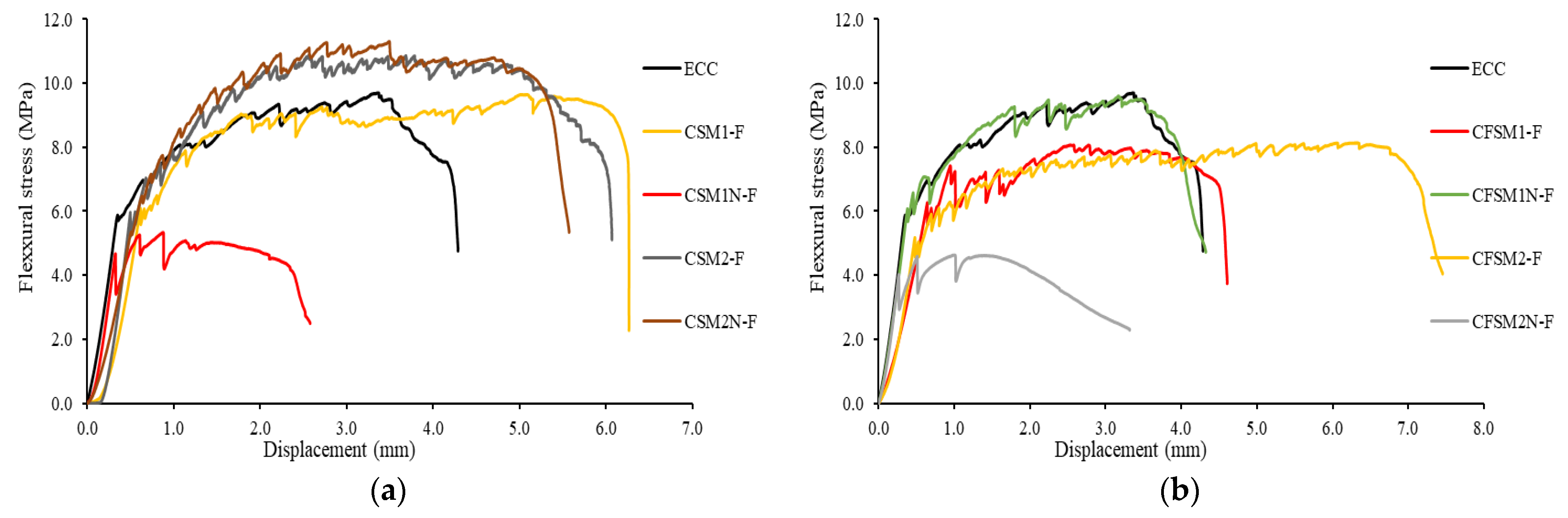

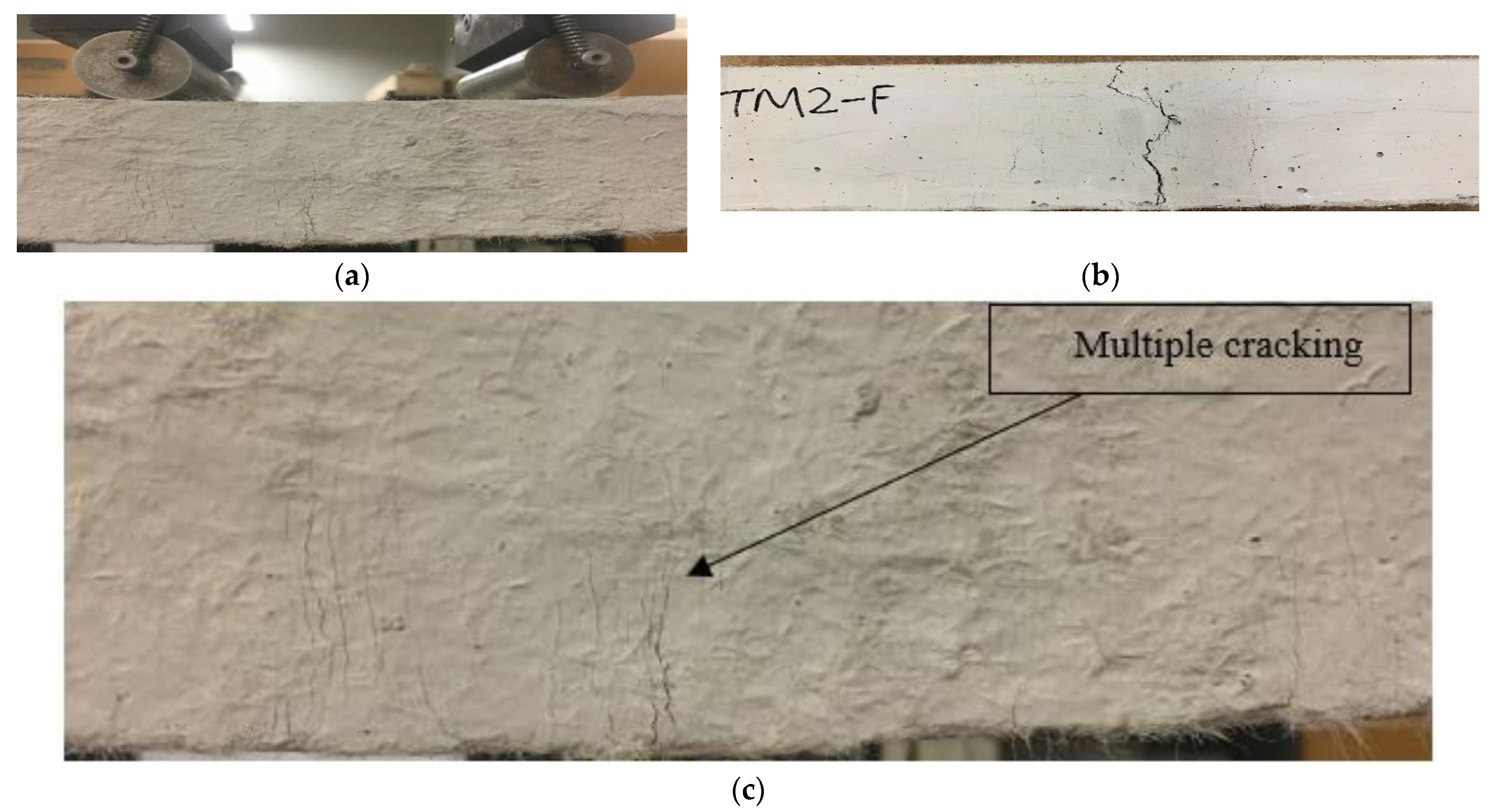

3.2.3. Flexural Strength of Composites

3.2.4. Uniaxial Tension Properties at 28 and 365 Days

4. Conclusions

- (1)

- The binary AAECs obtained higher compressive strengths (ranging from 48 MPa to 52 MPa) than their ternary counterparts (ranging from 39 MPa to 46 MPa) and were comparable to the ECC (50 MPa) at 56 days due to the dominant formation of cementitious reaction products (C-A-S-H/C-S-H) in the binary composites, compared to the notable development of amorphous products (N-C-A-S-H/N-A-S-H) in the ternary composites.

- (2)

- The ternary AAECs exhibited a higher fracture energy than their binary counterparts. In addition, the composites incorporating reagent 2 obtained a higher fracture energy than their counterparts with reagent 1.

- (3)

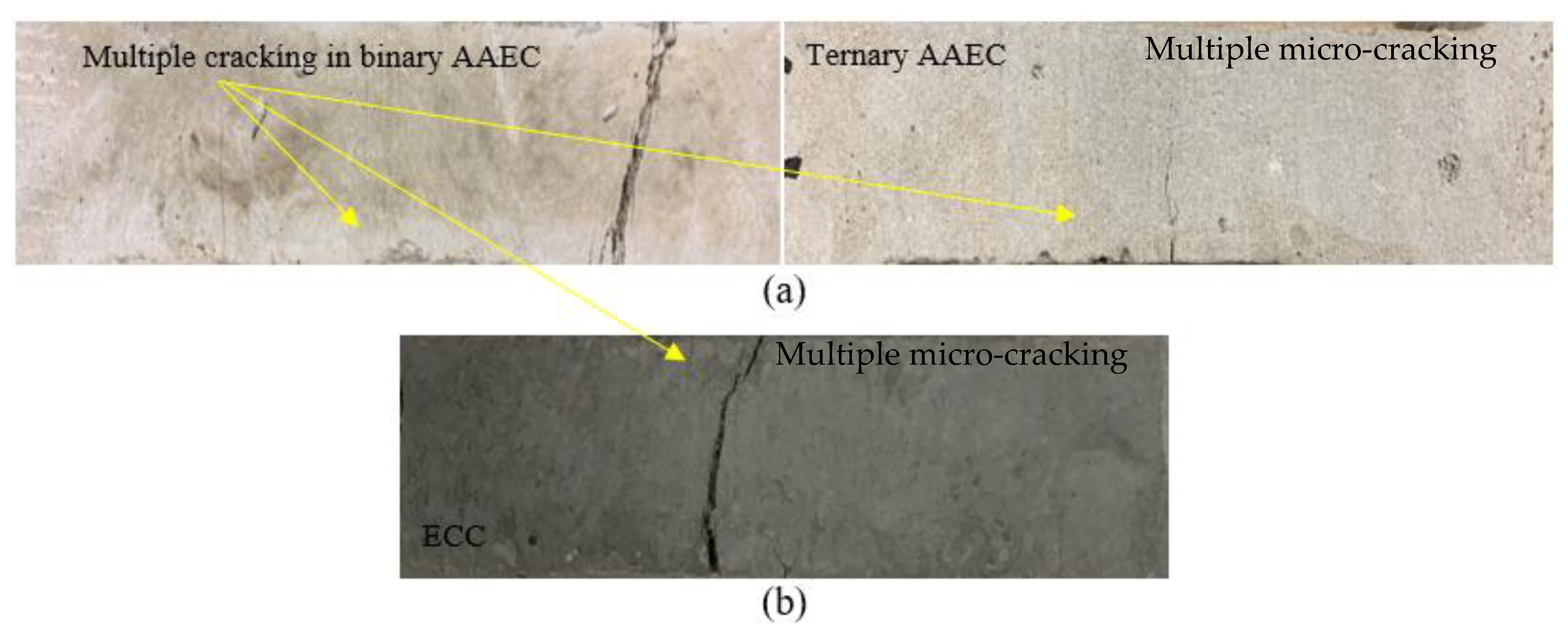

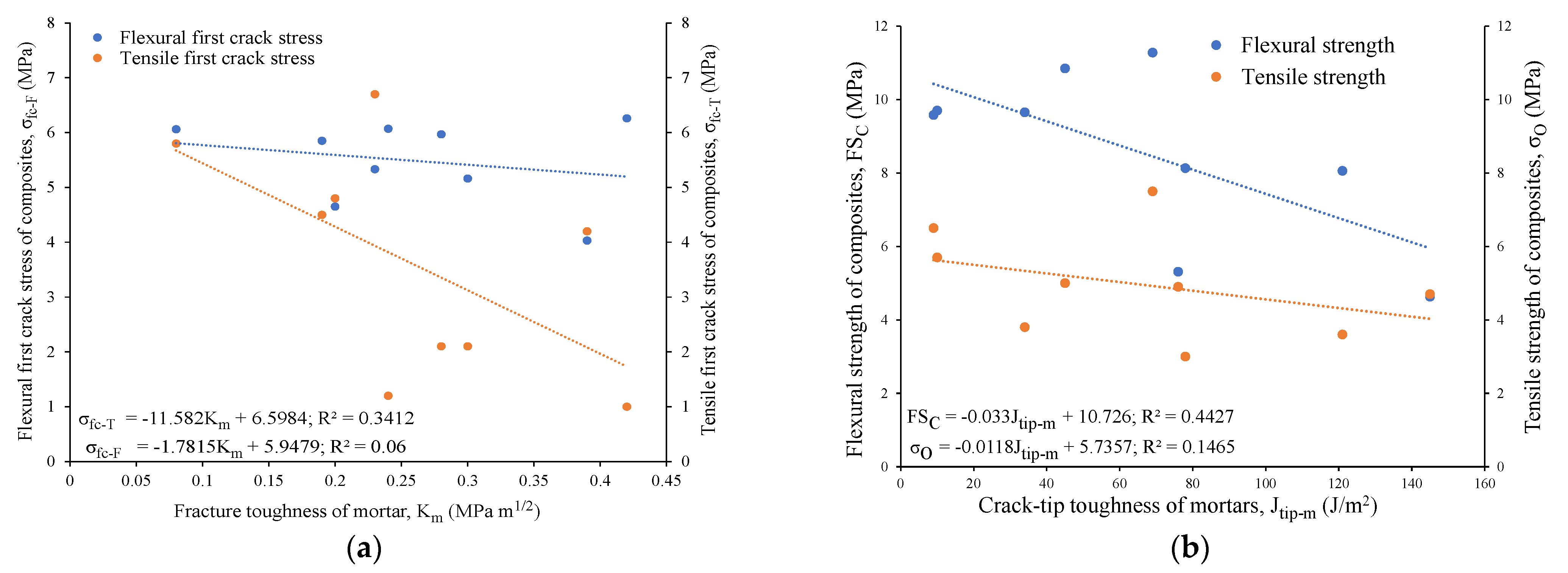

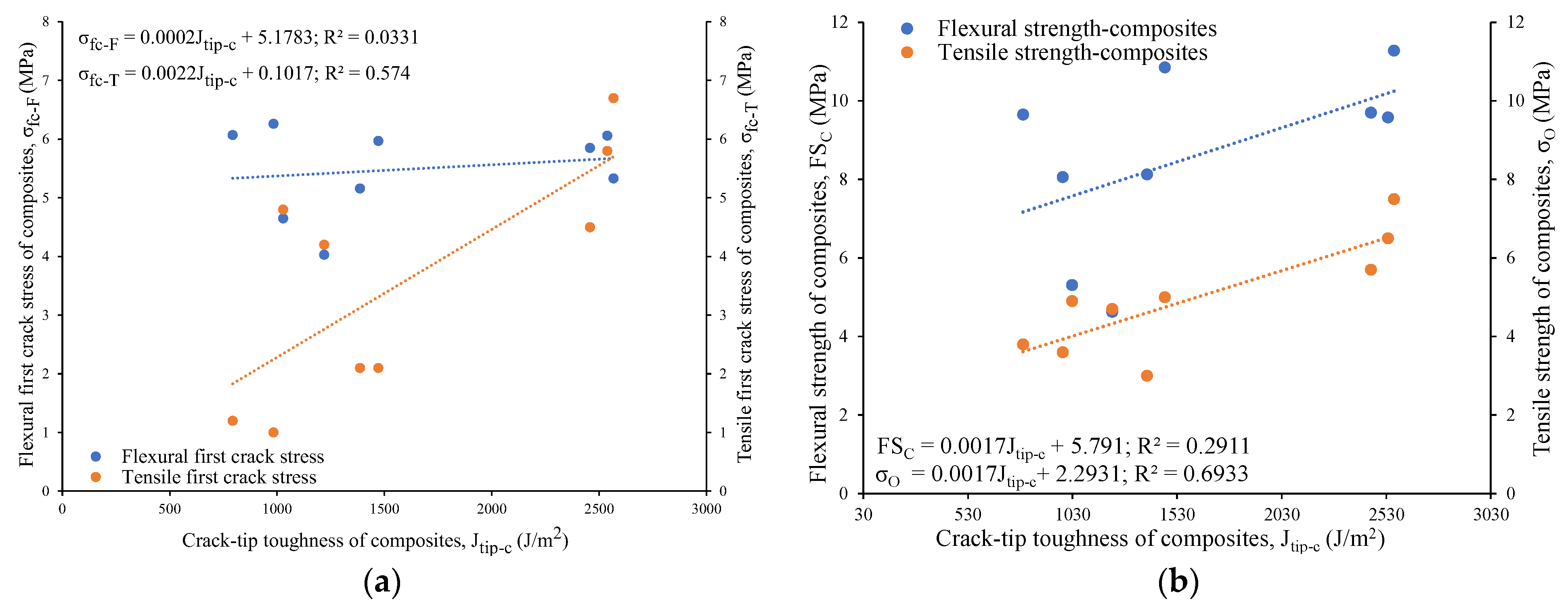

- The lower fracture and crack-tip toughness of the binary AAMs compared to their ternary counterparts facilitated the development of an enhanced flexural strength and energy ductility characteristics of the binary AAECs. The high energy indices because of the low crack-tip toughness values ensured constant crack widths and multiple-cracking/strain-hardening behavior of the AAECs, comparable with the control ECC.

- (4)

- The tensile stress relaxation process was relatively gradual in the binary AAECs compared to their ternary counterparts. A significant improvement of 28% to 100% was observed in the maximum bridging stresses at 365 days for the AAECs incorporating 40% to 45% of GGBFS compared to their counterparts with equal fly ash and GGBFS contents.

- (5)

- In general, the AAECs with 40% to 45% GGBFS content had a superior performance based on their 28-day compressive strength, fracture, and strain-hardening characteristics, in terms of their flexural/tensile ductility indices and stress and energy indices, compared to their counterparts with equal fly ash and GGBFS contents, which was mainly attributed to the lower crack-tip toughness of their mortar matrix. All the AAECs exhibited enhanced or equivalent strain/deflection-hardening characteristics in their tension and flexure, obtaining a comparable tensile/flexural ductility and stress/energy indices with the control ECC.

- (6)

- The mechanical properties of the developed AAECs, such as their fracture energy, flexural/tensile strength, and flexural/tensile ductility indices, increased with a reduction in the fracture and crack-tip toughness of their AAM counterparts, supporting the strain-hardening behavior of the AAECs. Furthermore, these AAEC properties increased with increases in their fracture and crack-tip toughness due to fiber–matrix bonding and the fiber-bridging effect.

- (7)

- No fiber pulling out or rupture in the fracture, flexural, and uniaxial tension tests indicated efficient bonding between the fibers and the reaction products, as evident from the SEM micrographs. The fiber-bridging action and fiber–matrix bonding during loading facilitated the ductile response and strain/deflection-hardening behavior of the AAECs.

- (8)

- Environmentally and user-friendly green AAECs, developed under ambient curing conditions using powder-form reagents and industrial wastes, will support engineers in meeting the sustainability standards in construction by reducing the carbon emissions associated with cement production.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FA-C | fly ash class C |

| FA-F | fly ash class F |

| GGBFS | ground-granulated blast furnace slag |

| AAEC | alkali-activated engineered composite |

| ECC | engineered cementitious composite |

| AAM | alkali-activated mortar |

| PVA | Polyvinyl alcohol |

| HRWRA | high-range water reducer admixture |

| elastic modulus | |

| fracture toughness of mortar | |

| Gf | fracture energy |

| Cracktip toughness | |

| complimentary energy | |

| bridging stress | |

| first cracking stress | |

| strain at first crack | |

| steady-state crack stress | |

| SI | stress index |

| DIC | ductility index of composite |

| TDI | tensile ductility index |

| tensile elasticity | |

| SEM | scanning electron microscope |

| EDS | energy dispersive spectroscopy |

| XRD | x-ray powder diffraction |

| XRF | x-ray fluorescence |

| C-A-S-H | calcium-alumino-silicate-hydrate |

| N-A-S-H | sodium-alumino-silicate-hydrate |

| N-C-A-S-H | calcium-rich sodium-alumino-silicate-hydrate |

| C-S-H | calcium-silicate-hydrate |

References

- Duxson, P.; Fernandez-Jime, A.A.; Provis, A.J.L.; Lukey, G.C.; Palomo, A.A.; Van Deventer, A.J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2006, 42, 2917–2933. [Google Scholar] [CrossRef]

- Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250. [Google Scholar] [CrossRef] [PubMed]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Properties of volcanic pumice based cement and lightweight concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Hassan, A.A.; Lachemi, M.; Hossain, K.M.A. Effect of metakaolin and silica fume on the durability of self-consolidating concrete. Cem. Concr. Res. 2012, 34, 801–807. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Uddin, F.; Shaikh, A. Tensile Strain Hardening Behavior of PVA Fiber-Reinforced Engineered Geopolymer Composite. J. Mater. Civ. Eng. 2015, 27, 1–12. [Google Scholar] [CrossRef]

- Shaikh, F. Deflection hardening behaviour of short fibre reinforced fly ash based geopolymer composites. Mater. Des. 2013, 50, 674–682. [Google Scholar] [CrossRef]

- Rashedi, A.; Marzouki, R.; Raza, A.; Rawi, N.F.M.; Naveen, J. Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O. Polymers 2021, 13, 3852. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, H.C. Tensile strain-hardening behaviour of Polyvinyl Alcohol Engineered Cementitious Composites (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Sherir, M.A.; Hossain, K.M.; Lachemi, M. Structural Performance of Polymer Fiber Reinforced Engineered Cementitious Composites Subjected to Static and Fatigue Flexural Loading. Polymers 2015, 7, 1299–1330. [Google Scholar] [CrossRef]

- Adesina, A.; Das, S. Mechanical performance of engineered cementitious composites incorporating recycled glass powder. Can. J. Civ. Eng. 2020, 47, 1311–1319. [Google Scholar] [CrossRef]

- Lam, C.C.; Gu, J.; Wang, X.; Cai, J. Tensile Behaviors of Textile Grid–Reinforced Engineered Geopolymer Composites. J. Mater. Civ. Eng. 2023, 35, 04023227. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Samal, S.; Blanco, I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers 2021, 9, 23. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Constr. Build. Mater. 2014, 57, 163–168. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Carolina, A.; Trindade, C.; Curosu, I.; Liebscher, M.; Mechtcherine, V.; De Andrade, F. On the mechanical performance of K- and Na-based strain-hardening geopolymer composites (SHGC) reinforced with PVA fibers. Constr. Build. Mater. 2020, 248, 118558. [Google Scholar]

- Zhang, S.; Li, V.C.; Ye, G. Micromechanics-guided development of a slag/fly ash-based strain-hardening geopolymer composite. Cem. Concr. Compos. 2020, 109, 103510. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Li, W.; Shi, G.; Lu, P. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Compos. Part B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Choi, J.I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.B. Tensile properties of a novel fibre reinforced geopolymer composite with enhanced strain hardening characteristics. Compos. Struct. 2017, 168, 402–427. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Sood, D.; Hossain, K.M.A. Fresh State, Rheological and Microstructural Characteristics of Alkali-Activated Mortars Developed Using Novel Dry Mixing Technique under Ambient Conditions. Appl. Sci. 2021, 11, 8920. [Google Scholar] [CrossRef]

- Sood, D.; Hossain, K.M.A. Strength, Fracture and Durability Characteristics of Ambient Cured Alkali—Activated Mortars Incorporating High Calcium. Crystals 2021, 11, 1167. [Google Scholar] [CrossRef]

- ASTM C109/C109 M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C597; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- Karihaloo, B.L.; Nallathambi, P. Effective Crack Model for The Determination of Fracture Toughness (KfJ of Concrete. Eng. Fract. Mech. 1990, 35, 631–645. [Google Scholar]

- Ding, Y.; Shi, C.-J.; Li, N. Fracture properties of slag/fly ash-based geopolymer concrete cured in ambient temperature. Constr. Build. Mater. 2018, 190, 787–795. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- ASTM C78/C78M; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–5.

- ASTM C1609/C1609M; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2012; pp. 1–9.

- Ahmed, S.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments. Sustainability 2020, 12, 3561. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.; Dai, J.; Xu, Q. Effect of superplasticizers on properties of one-part Ca(OH)2/Na2SO4 activated geopolymer pastes. Constr. Build. Mater. 2020, 241, 117990. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete and Commentary, ACI 318-19; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Matrix design of strain hardening fiber reinforced engineered geopolymer composite. Compos. Part B Eng. 2016, 89, 253–265. [Google Scholar] [CrossRef]

- Li, V.C.; Mishra, D.K.; Wu, H.-C. Matrix design for pseudo-strain-hardening fibre reinforced cementitious composites. Mater. Struct. 1995, 28, 586–595. [Google Scholar] [CrossRef]

- Farooq, M.; Bhutta, A.; Banthia, N. Tensile performance of eco-friendly ductile geopolymer composites (EDGC) incorporating different micro-fibers. Cem. Concr. Compos. 2019, 103, 183–192. [Google Scholar] [CrossRef]

| (a) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mix ID (Mortars/ Composites) | Total SCMs (Binder *) | Cement (Pc) | FA-C | FA-F | GGBFS | Reagent Type | Reagent/ Binder Ratio | Silica Sand | Water to Binder Ratio | HR-WRA ** |

| AAM and AAEC (with end letter F in mix ID) mixes; CS: Binary and CFS: Ternary mixes | ||||||||||

| CSM1/ CSM1-F | 1 | 0 | 0.55 | 0 | 0.45 | 1 | 0.09 | 0.3 | 0.35 | 0.02 |

| CSM1N/ CSM1N-F | 1 | 0 | 0.50 | 0 | 0.50 | 1 | 0.09 | 0.3 | 0.35 | 0.02 |

| CFSM1/ CFSM1-F | 1 | 0 | 0.25 | 0.35 | 0.40 | 1 | 0.09 | 0.3 | 0.35 | 0.02 |

| CFSM1N/ CFSM1N-F | 1 | 0 | 0.25 | 0.25 | 0.50 | 1 | 0.09 | 0.3 | 0.35 | 0.02 |

| CSM2/ CSM2-F | 1 | 0 | 0.55 | 0 | 0.45 | 2 | 0.12 | 0.3 | 0.375 | 0.02 |

| CSM2N/ CSM2N-F | 1 | 0 | 0.50 | 0 | 0.50 | 2 | 0.12 | 0.3 | 0.375 | 0.02 |

| CFSM2/ CFSM2-F | 1 | 0 | 0.25 | 0.35 | 0.40 | 2 | 0.12 | 0.3 | 0.375 | 0.02 |

| CFSM2N/ CFSM2N-F | 1 | 0 | 0.25 | 0.25 | 0.50 | 2 | 0.12 | 0.3 | 0.375 | 0.02 |

| Control mortar and engineered cementitious composite (ECC) mixes | ||||||||||

| FPCM/ECC | 1 | 0.45 | 0 | 0.55 | 0 | - | - | 0.36 | 0.27 | 0.006 |

| (b) | ||||||||||

| Chemical Composition (%) | FA-C | FA-F | GGBFS | Cement | ||||||

| SiO2 | 36.53 | 55.66 | 35.97 | 19.35 | ||||||

| Al2O3 | 18.26 | 22.09 | 9.18 | 5.31 | ||||||

| Fe2O3 | 5.66 | 4.26 | 0.50 | 3.10 | ||||||

| CaO | 20.97 | 7.97 | 38.61 | 62 | ||||||

| MgO | 5.08 | 1.16 | 10.99 | 3 | ||||||

| K2O | 0.68 | 1.49 | 0.36 | - | ||||||

| Na2O | 4.04 | 4.10 | 0.28 | 0.23 | ||||||

| MnO | 0.03 | 0.03 | 0.25 | - | ||||||

| TiO2 | 1.26 | 0.61 | 0.39 | - | ||||||

| P2O5 | 0.96 | 0.43 | 0.01 | - | ||||||

| LOI. | 2.18 | 1.05 | 0.74 | 2.40 | ||||||

| Physical properties | FA-C | FA-F | GGBFS | Cement | ||||||

| Density (g/cm3) | 2.61 | 2.02 | 2.87 | 3.15 | ||||||

| Retained on 45 µ (%) | <5 | <10 | <5 | <10 | ||||||

| Blaine fineness (m2/kg) | 315 | 306 | 489.30 | 410 | ||||||

| Mix ID (Mortars/Composites) | Reagent Type | Reagent Component Ratio | Chemical Ratios (SCMs + Reagents) | |||

|---|---|---|---|---|---|---|

| SiO2/Al2O3 | Na2O/SiO2 | CaO/SiO2 | Na2O/Al2O3 | |||

| CSM1/CSM1-F | 1 | 1:2.5 | 2.62 | 0.09 | 0.84 | 0.23 |

| CSM1N/CSM1N-F | 1 | 1:2.5 | 2.71 | 0.08 | 0.87 | 0.23 |

| CFSM1/CFSM1-F | 1 | 1:2.5 | 2.75 | 0.08 | 0.59 | 0.22 |

| CFSM1N/CFSM1N-F | 1 | 1:2.5 | 2.86 | 0.07 | 0.69 | 0.21 |

| CSM2/CSM2-F | 2 | 2.5:1 | 2.56 | 0.14 | 1.02 | 0.35 |

| CSM2N/CSM2N-F | 2 | 2.5:1 | 2.64 | 0.13 | 1.02 | 0.35 |

| CFSM2/CFSM2-F | 2 | 2.5:1 | 2.69 | 0.12 | 0.73 | 0.32 |

| CFSM2N/CFSM2N-F | 2 | 2.5:1 | 2.80 | 0.12 | 0.84 | 0.33 |

| FPCM/ECC | - | - | 2.70 | 0.06 | 0.82 | 0.16 |

| Mix ID (Mortars/Composites) (AAMs/AAECs) | Density * (kg/m3) | Compressive Strength (MPa) * | Ultrasonic Pulse Velocity (UPV) * (m/s) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mortar/ Composites | Mortar | Composites | Mortar/ Composites | ||||||

| 28 Day | 28 Day | 56 Day | 28 Day | 56 Day | % Increase (28 Day to 56 Day) | 365 Day | % Increase (56 Day) w.r.t Mortar | 28 Day | |

| CSM1/ CSM1-F | 2088/2128 | 42.6 | 49.0 | 46.5 | 52.0 | 11.8 | 49.8 | 6.1 | 3240/3358 |

| CSM1N/ CSM1N-F | 2075/2046 | 35.0 | 41.5 | 34.1 | 47.0 | 37.8 | 48.6 | 13.3 | 3502/3532 |

| CSM2/CSM2-F | 2042/2047 | 41.2 | 48.5 | 41.2 | 56.8 | 37.9 | 55.8 | 17.1 | 3746/3614 |

| CSM2N/CSM2N-F | 2032/2079 | 35.8 | 40.0 | 40.8 | 48.0 | 17.6 | 47.8 | 20.0 | 4049/3947 |

| CFSM1/CFSM1-F | 2030/2034 | 40.4 | 45.2 | 44.3 | 45.2 | 2.0 | 47.0 | 0.0 | 3320/3389 |

| CFSM1N/ CFSM1N-F | 2010/1953 | 34.0 | 38.1 | 36.5 | 39.1 | 7.1 | 41.2 | 2.6 | 3367/3425 |

| CFSM2/CFSM2-F | 1983/2031 | 42.0 | 46.4 | 42.0 | 46.4 | 10.5 | 45.6 | 0.0 | 3205/3228 |

| CFSM2N/CFSM2N-F | 2055/1974 | 38.1 | 41.2 | 39.2 | 45.5 | 16.1 | 46.2 | 10.4 | 3607/3636 |

| FPCM/ECC | 1937/1878 | 43.5 | 50.0 | 52.5 | 56.2 | 7.0 | 60.4 | 12.4 | 4133/3977 |

| Mix ID | Peak Load (kN) | Peak Displacement (mm) | Fracture Energy (N/m) | Elastic Modulus (Em) (GPa) | Fracture Toughness (Km) (MPa m1/2) | Crack Tip Toughness (Jtip) (J/m2) |

|---|---|---|---|---|---|---|

| Composites/Mortars | ||||||

| ECC/FPCM | 1.65/0.33 | 9.01/0.62 | 4954/95 | 1.06/1.14 | 1.61/0.19 | 2457/10 |

| CSM1-F/CSM1 | 0.84/0.57 | 9.43/0.29 | 3424/65 | 1.24/1.74 | 0.99/0.24 | 793/34 |

| CSM1N-F/CSM1N | 1.19/0.24 | 7.19/0.78 | 3467/73 | 1.44/0.54 | 1.22/0.20 | 1028/76 |

| CSM2-F/CSM2 | 1.06/0.55 | 8.44/0.19 | 4988/38 | 1.15/1.77 | 1.30/0.28 | 1471/45 |

| CSM2N-F/CSM2N | 1.86/0.23 | 11.09/0.66 | 7787/94 | 1.49/0.76 | 1.96/0.23 | 2567/69 |

| CFSM1-F/CFSM1 | 1.04/0.66 | 13.14/0.36 | 4596/73 | 0.73/1.42 | 0.85/0.42 | 983/121 |

| CFSM1N-F/CFSM1N | 1.79/0.08 | 12.96/1.03 | 8245/38 | 1.24/0.64 | 1.77/0.08 | 2538/9 |

| CFSM2-F/CFSM2 | 1.39/0.39 | 11.53/0.32 | 5239/47 | 0.87/1.13 | 1.10/0.30 | 1386/78 |

| CFSM2N-F/CFSM2N | 1.00/0.69 | 10.27/0.41 | 4435/78 | 1.30/1.06 | 1.26/0.39 | 1219/145 |

| Mix ID | (MPa) | Peak Load (kN)/Flexural Strength (MPa) | Deflection (mm) | Ductility Index | Absorbed Energy (J) | ||

|---|---|---|---|---|---|---|---|

| At 50% Post-Peak Load | At 85% Post-Peak Load | ||||||

| Control ECC * | |||||||

| ECC | 5.85 | 6.11/9.7 | 0.37 | 4.17 | 11.27 | 24.95 | 22.18 |

| Fiber-reinforced alkali-activated binary composites * | |||||||

| CSM1-F | 6.07 | 6.08/9.65 | 0.65 | 6.04 | 9.29 | 37.81 | 37.46 |

| CSM1N-F | 4.65 | 3.44/5.31 | 0.32 | 2.36 | 7.38 | 8.12 | 6.76 |

| CSM2-F | 5.97 | 6.87/10.85 | 0.49 | 5.92 | 12.08 | 71.76 | 65.04 |

| CSM2N-F | 5.33 | 7.13/11.28 | 0.52 | 5.06 | 9.73 | 38.13 | 36.59 |

| Fiber-reinforced alkali-activated ternary composites * | |||||||

| CFSM1-F | 6.26 | 5.09/8.06 | 0.64 | 4.50 | 7.03 | 26.21 | 25.58 |

| CFSM1N-F | 6.06 | 6.05/9.58 | 0.38 | 3.99 | 10.50 | 24.90 | 23.11 |

| CFSM2-F | 5.16 | 5.14/8.13 | 0.47 | 6.85 | 14.57 | 44.56 | 42.98 |

| CFSM2N-F | 4.03 | 2.92/4.63 | 0.26 | 2.40 | 9.23 | 8.90 | 6.30 |

| Mix ID | (MPa) | (%) | (GPa) | Max. Bridging or (MPa) | (%) | ||

|---|---|---|---|---|---|---|---|

| 28/365 Days | |||||||

| ECC | 4.5/4.4 | 0.15/0.25 | 3.0/1.8 | 5.7/7.4 | 2.3/3.0 | 15.3/12.0 | 1.3/1.7 |

| CSM1-F | 1.2/4.0 | 0.05/0.14 | 2.5/2.9 | 3.8/7.0 | 2.4/2.6 | 48.0/18.6 | 3.1/1.7 |

| CSM1N-F | 4.8/5.9 | 0.15/0.31 | 3.2/1.9 | 4.9/6.0 | 3.2/3.0 | 21.3/9.7 | 1.0/1.0 |

| CSM2-F | 2.1/4.5 | 0.13/0.24 | 1.6/1.9 | 5.0/6.4 | 3.7/2.9 | 28.5/12.1 | 2.4/1.4 |

| CSM2N-F | 6.7/4.2 | 0.37/0.25 | 1.8/1.7 | 7.5/5.9 | 2.8/2.7 | 7.6/10.8 | 1.1/1.4 |

| CFSM1-F | 1.0/4.0 | 0.04/0.23 | 2.6/1.8 | 3.6/5.0 | 2.5/3.2 | 62.5/13.9 | 3.5/1.2 |

| CFSM1N-F | 5.8/4.3 | 0.27/0.32 | 2.1/1.3 | 6.5/5.4 | 3.7/2.5 | 13.7/7.8 | 1.1/1.3 |

| CFSM2-F | 2.1/4.3 | 0.07/0.19 | 2.9/2.3 | 3.0/6.0 | 2.5/2.8 | 35.7/14.7 | 1.4/1.4 |

| CFSM2N-F | 4.2/3.6 | 0.28/0.28 | 1.5/1.3 | 4.7/4.8 | 3.2/3.0 | 11.4/10.7 | 1.1/1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, K.M.A.; Sood, D. The Strength and Fracture Characteristics of One-Part Strain-Hardening Green Alkali-Activated Engineered Composites. Materials 2023, 16, 5077. https://doi.org/10.3390/ma16145077

Hossain KMA, Sood D. The Strength and Fracture Characteristics of One-Part Strain-Hardening Green Alkali-Activated Engineered Composites. Materials. 2023; 16(14):5077. https://doi.org/10.3390/ma16145077

Chicago/Turabian StyleHossain, Khandaker M. Anwar, and Dhruv Sood. 2023. "The Strength and Fracture Characteristics of One-Part Strain-Hardening Green Alkali-Activated Engineered Composites" Materials 16, no. 14: 5077. https://doi.org/10.3390/ma16145077

APA StyleHossain, K. M. A., & Sood, D. (2023). The Strength and Fracture Characteristics of One-Part Strain-Hardening Green Alkali-Activated Engineered Composites. Materials, 16(14), 5077. https://doi.org/10.3390/ma16145077