Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons

Abstract

1. Introduction

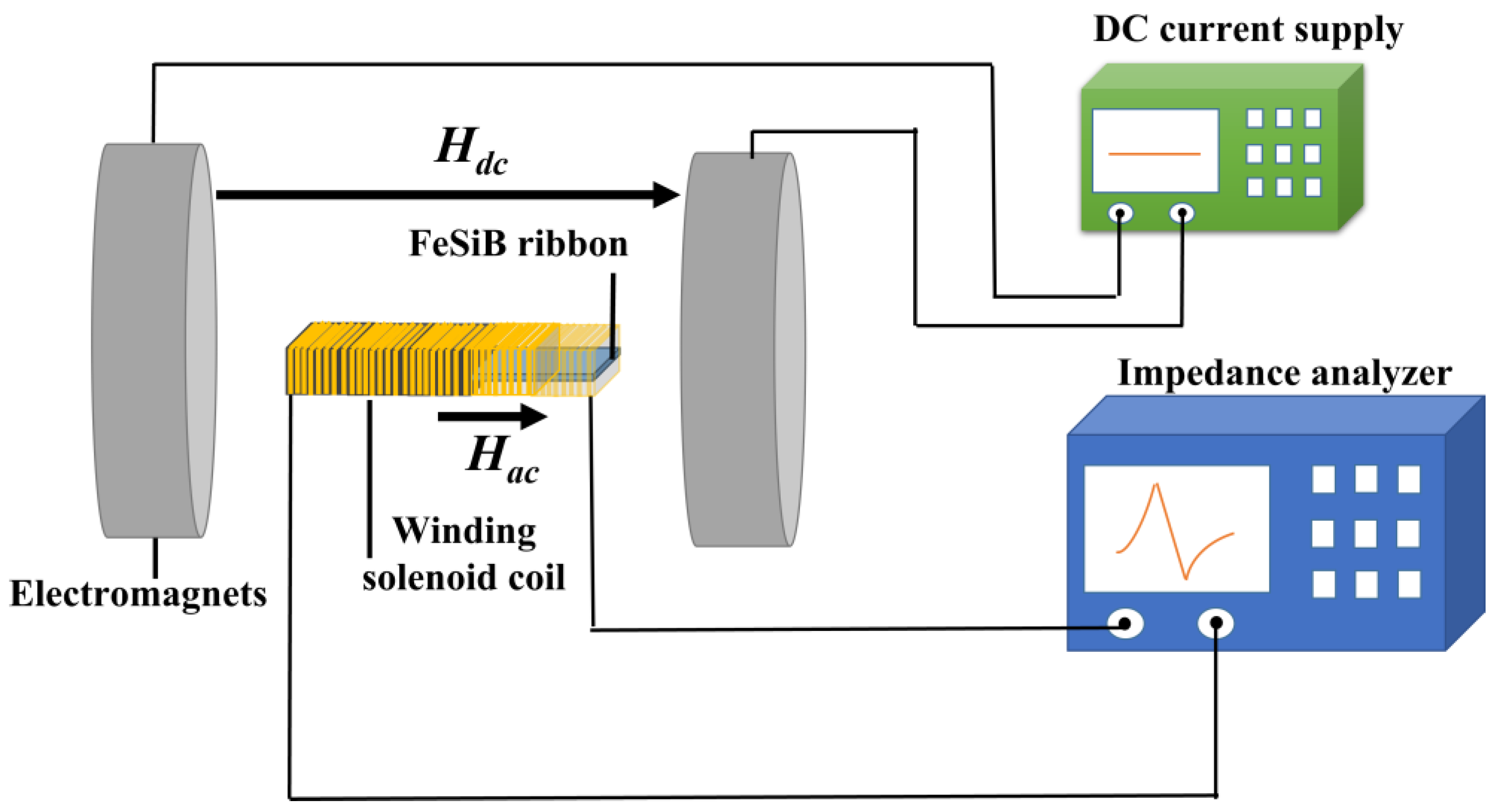

2. Experimental Method

3. Theoretical Analysis and Measurement

3.1. Eddy Current Loss

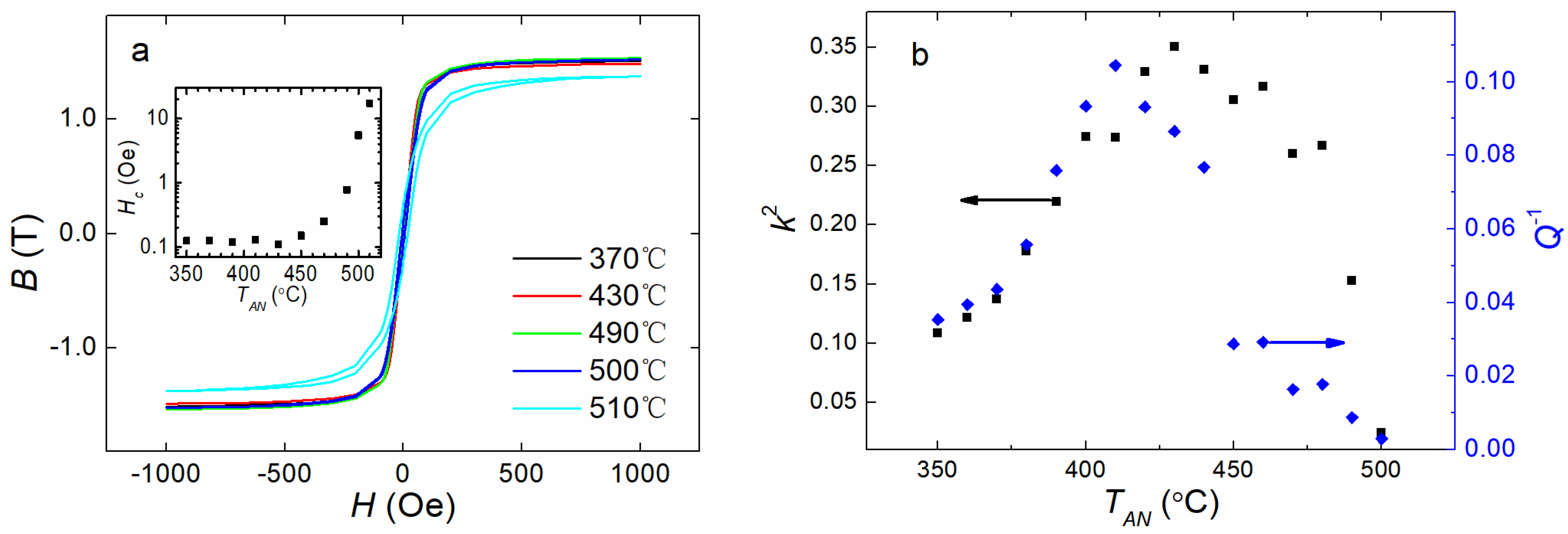

3.2. Magnetic and Magnetomechanical Properties

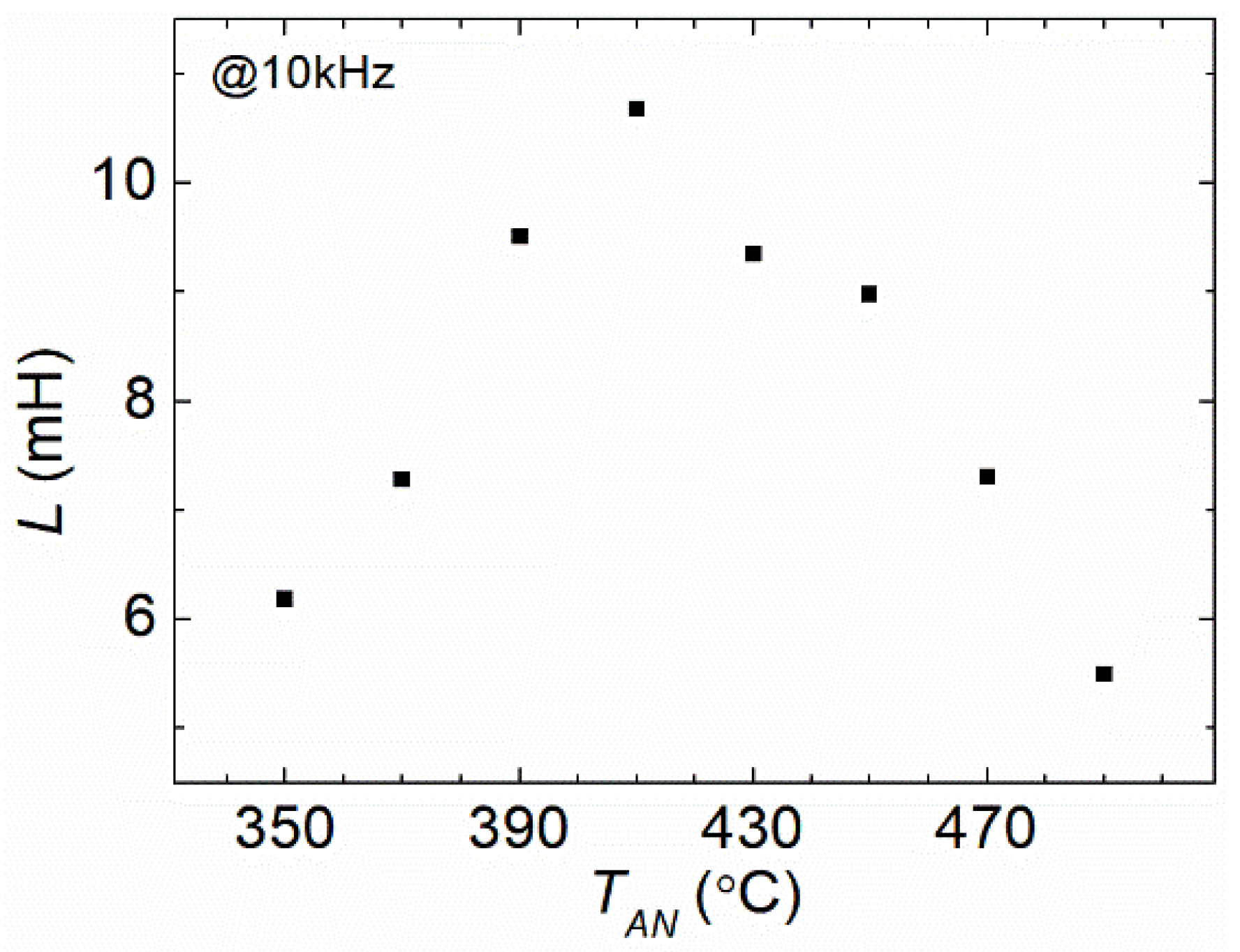

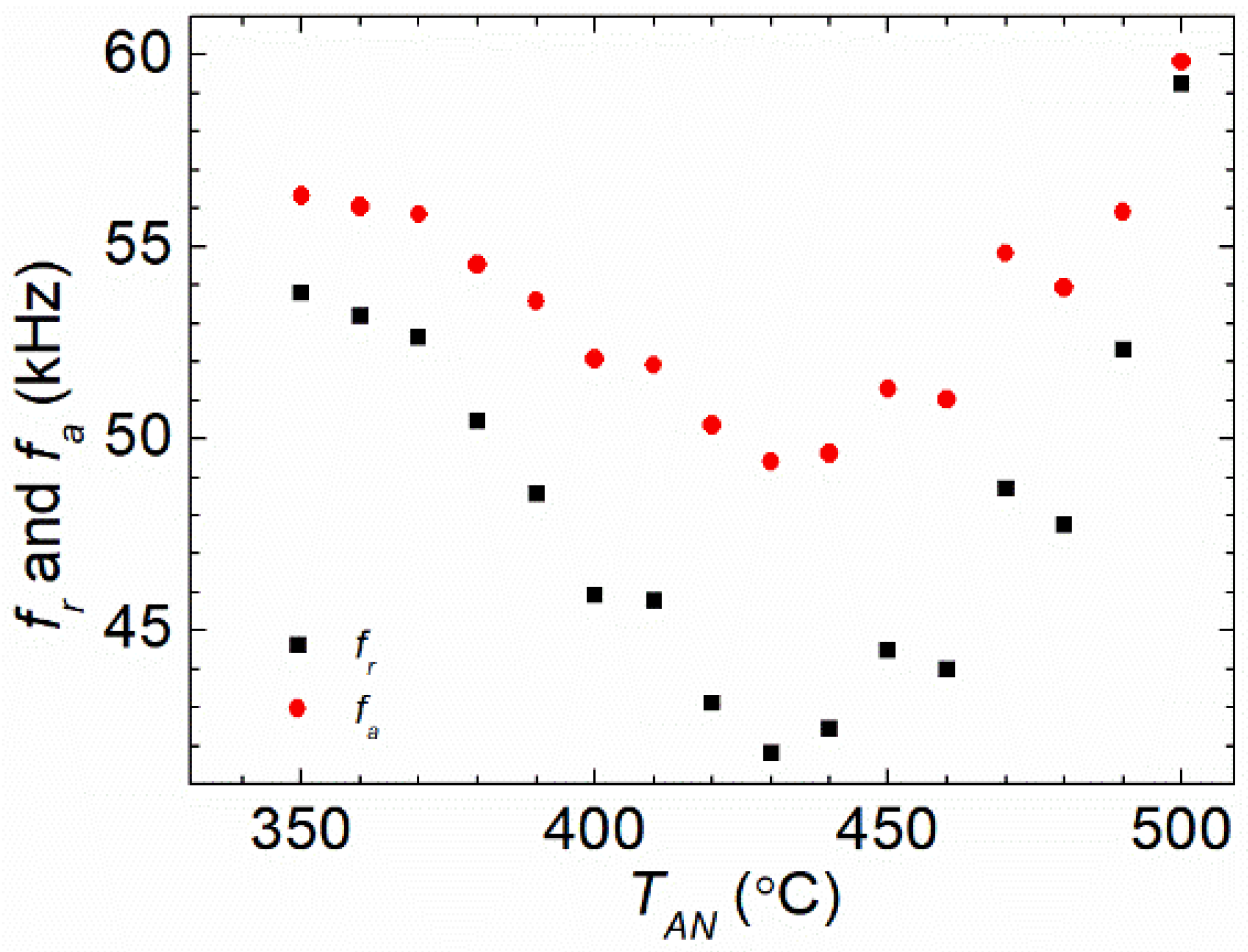

3.3. Softening of Magnetic and Elastic Properties

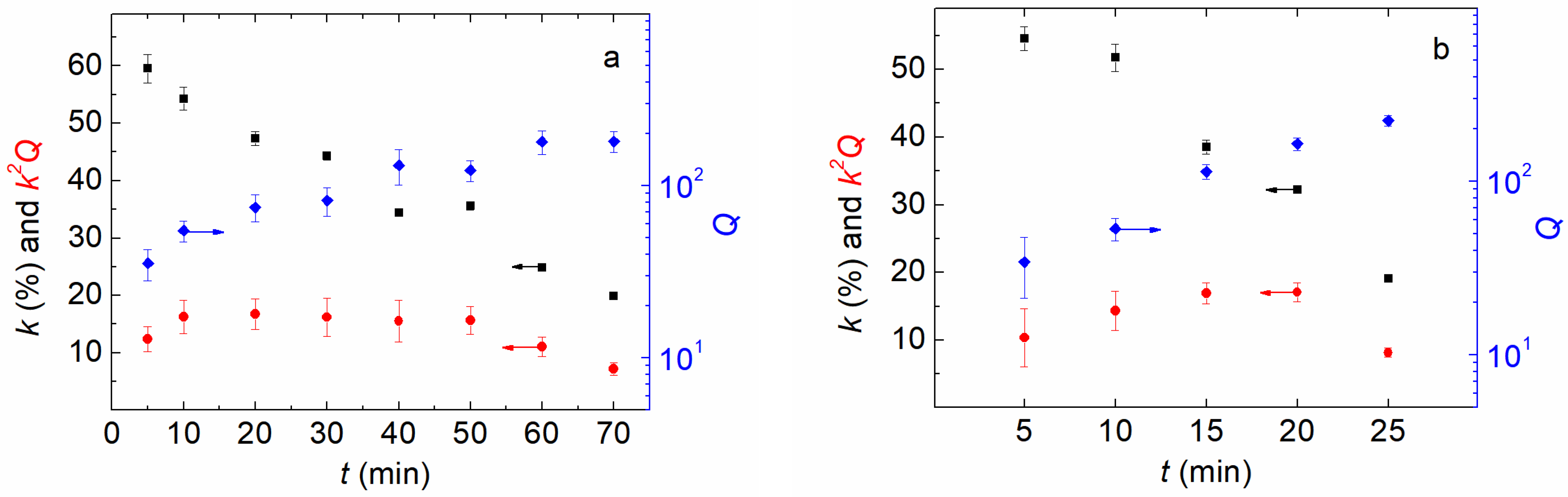

3.4. Time–Temperature Equivalence for Annealing

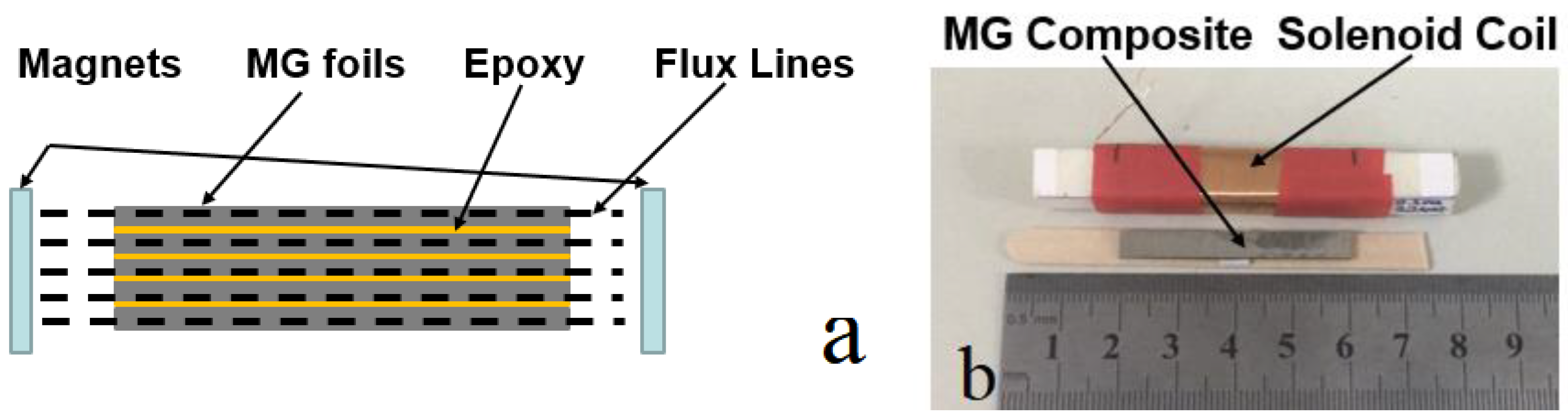

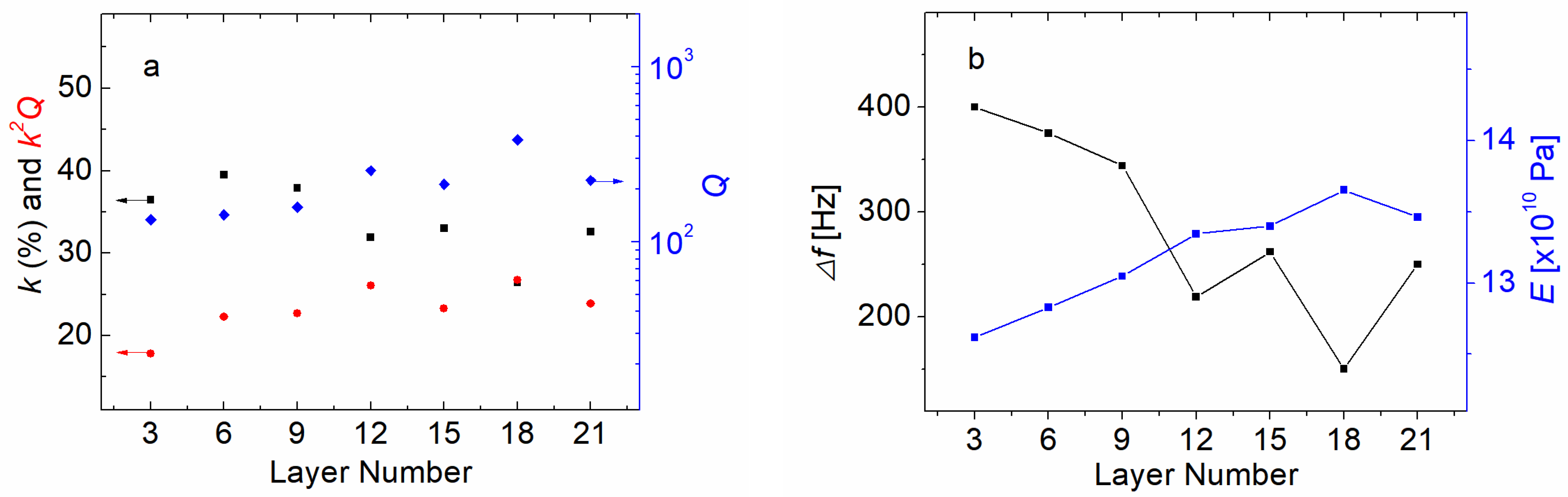

3.5. Magnetomechanical Properties in Epoxy–Ribbon Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Channagoudra, G.; Dayal, V. Magnetoelectric Coupling in Ferromagnetic/Ferroelectric Heterostructures: A Survey and Perspective. J. Alloys Compd. 2022, 928, 167181. [Google Scholar] [CrossRef]

- Leung, C.M.; Li, J.; Viehland, D.; Zhuang, X. A Review on Applications of Magnetoelectric Composites: From Heterostructural Uncooled Magnetic Sensors, Energy Harvesters to Highly Efficient Power Converters. J. Phys. D Appl. Phys. 2018, 51, 263002. [Google Scholar] [CrossRef]

- Narita, F.; Fox, M. A Review on Piezoelectric, Magnetostrictive, and Magnetoelectric Materials and Device Technologies for Energy Harvesting Applications. Adv. Eng. Mater. 2018, 20, 1700743. [Google Scholar] [CrossRef]

- Zhuang, X.; Xu, X.; Zhang, X.; Sun, Y.; Yan, B.; Liu, L.; Lu, Y.; Zhu, W.; Fang, G. Tailoring the Magnetomechanical Power Efficiency of Metallic Glasses for Magneto-Electric Devices. J. Appl. Phys. 2022, 132, 104502. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Barandiarán, J.M.; Nielsen, O.V. Magnetoelastic Properties of Some Fe-Rich Fe-Co-Si-B Metallic Glasses. Phys. Status Solid 1989, 111, 279–283. [Google Scholar] [CrossRef]

- Leung, C.M.; Zhuang, X.; Xu, J.; Li, J.; Zhang, J.; Srinivasan, G.; Viehland, D. Enhanced Tunability of Magneto-Impedance and Magneto-Capacitance in Annealed Metglas/PZT Magnetoelectric Composites. AIP Adv. 2017, 8, 055803. [Google Scholar] [CrossRef]

- Stoyanov, P.G.; Grimes, C.A. A Remote Query Magnetostrictive Viscosity Sensor. Sens. Actuators A Phys. 2000, 80, 8–14. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Wu, S.; Zhuang, X.; Yan, B.; Zhu, W.; Dolabdjian, C.; Fang, G. Magnetomechanical Properties of Fe-Si-B and Fe-Co-Si-B Metallic Glasses by Various Annealing Temperatures for Actuation Applications. Sensors 2023, 23, 299. [Google Scholar] [CrossRef]

- Qiao, K.; Hu, F.; Zhang, H.; Yu, Z.; Liu, X.; Liang, Y.; Long, Y.; Wang, J.; Sun, J.; Zhao, T.; et al. Unipolar Electric-Field-Controlled Nonvolatile Multistate Magnetic Memory in FeRh/(001)PMN-PT Heterostructures over a Broad Temperature Span. Sci. China Phys. Mech. Astron. 2021, 65, 217511. [Google Scholar] [CrossRef]

- Pal, M.; Srinivas, A.; Asthana, S. Enhanced Magneto-Electric Properties and Magnetodielectric Effect in Lead-Free (1-x)0.94Na0.5Bi0.5TiO3-0.06BaTiO3–x CoFe2O4 Particulate Composites. J. Alloys Compd. 2022, 900, 163487. [Google Scholar] [CrossRef]

- Li, T.X.; Li, R.; Lin, Y.; Bu, F.; Li, J.; Li, K.; Hu, Z.; Ju, L. Study of Enhanced Magnetoelectric Coupling Behavior in Asymmetrical Bilayered Multiferroic Heterostructure with Two Resonance Modes. J. Alloys Compd. 2022, 895, 162674. [Google Scholar] [CrossRef]

- Kaczkowski, Z. Magnetomechanical Properties of Rapidly Quenched Materials. Mater. Sci. Eng. A 1997, 226–228, 614–625. [Google Scholar] [CrossRef]

- Kabacoff, L.T. Thermal, Magnetic, and Magnetomechanical Properties of Metglas 2605 S2 and S3. J. Appl. Phys. 1982, 53, 8098–8100. [Google Scholar] [CrossRef]

- Savage, H.; Clark, A.; Powers, J. Magnetomechanical Coupling and ΔE Effect in Highly Magnetostrictive Rare Earth—Fe2compounds. IEEE Trans. Magn. 1975, 11, 1355–1357. [Google Scholar] [CrossRef]

- Kaczkowski, Z.; Vlasák, G.; Švec, P.; Duhaj, P. Magnetostriction and Magnetomechanical Coupling of Heat-Treated Fe54Ni20Nb3Cu1Si13B9 Metallic Glass. Mater. Sci. Eng. A 2004, 375–377, 1062–1064. [Google Scholar] [CrossRef]

- Chen, H.S.; Leamy, H.J.; Barmatz, M. The Elastic and Anelastic Behavior of a Metallic Glass. J. Non Cryst. Solids 1971, 5, 444–448. [Google Scholar] [CrossRef]

- Morito, N.; Egami, T. Correlation of the Shear Modulus and Internal Friction in the Reversible Structural Relaxation of a Glassy Metal. J. Non Cryst. Solids 1984, 61–62, 973–978. [Google Scholar] [CrossRef]

- Soshiroda, T.; Koiwa, M.; Masumoto, T. The Internal Friction and Elastic Modulus of Amorphous Pd–Si and Fe–P–C Alloys. J. Non Cryst. Solids 1976, 22, 173–187. [Google Scholar] [CrossRef]

- Xu, D.D.; Zhou, B.L.; Wang, Q.Q.; Zhou, J.; Yang, W.M.; Yuan, C.C.; Xue, L.; Fan, X.D.; Ma, L.Q.; Shen, B.L. Effects of Cr Addition on Thermal Stability, Soft Magnetic Properties and Corrosion Resistance of FeSiB Amorphous Alloys. Corros. Sci. 2018, 138, 20–27. [Google Scholar] [CrossRef]

- Lin, J.; Li, X.; Zhou, S.; Zhang, Q.; Li, Z.; Wang, M.; Shi, G.; Wang, L.; Zhang, G. Effects of Heat Treatment in Air on Soft Magnetic Properties of FeCoSiBPC Amorphous Core. J. Non Cryst. Solids 2022, 597, 121932. [Google Scholar] [CrossRef]

- Murugaiyan, P.; Mitra, A.; Jena, P.S.M.; Mahato, B.; Ghosh, M.; Roy, R.K.; Panda, A.K. Grain Refinement in Fe-Rich FeSiB(P)NbCu Nanocomposite Alloys through P Compositional Modulation. Mater. Lett. 2021, 295, 129852. [Google Scholar] [CrossRef]

- Fang, Z.; Nagato, K.; Liu, S.; Sugita, N.; Nakao, M. Investigation into Surface Integrity and Magnetic Property of FeSiB Metallic Glass in Two-Dimensional Cutting. J. Manuf. Process. 2021, 64, 1098–1104. [Google Scholar] [CrossRef]

- Wang, C.; Guo, Z.; Wang, J.; Sun, H.; Chen, D.; Chen, W.; Liu, X. Industry-Oriented Fe-Based Amorphous Soft Magnetic Composites with SiO2-Coated Layer by One-Pot High-Efficient Synthesis Method. J. Magn. Magn. Mater. 2020, 509, 166924. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Ma, E. Atomic-Level Structure and Structure-Property Relationship in Metallic Glasses. Prog. Mater. Sci. 2011, 56, 379–473. [Google Scholar] [CrossRef]

- Czyż, O.; Kusiński, J.; Radziszewska, A.; Liao, Z.; Zschech, E.; Kąc, M.; Ostrowski, R. Study of Structure and Properties of Fe-Based Amorphous Ribbons after Pulsed Laser Interference Heating. J. Mater. Eng. Perform. 2020, 29, 6277–6285. [Google Scholar] [CrossRef]

- Zhang, J.; Shan, G.; Li, J.; Wang, Y.; Shek, C.H. Structures and Physical Properties of Two Magnetic Fe-Based Metallic Glasses. J. Alloys Compd. 2018, 747, 636–639. [Google Scholar] [CrossRef]

- Li, Y.; Chen, W.-Z.; Dong, B.-S.; Zhou, S.-X. Effects of Phosphorus and Carbon Content on the Surface Tension of FeSiBPC Glass-Forming Alloy Melts. J. Non Cryst. Solids 2018, 496, 13–17. [Google Scholar] [CrossRef]

- Lopatina, E.; Soldatov, I.; Budinsky, V.; Marsilius, M.; Schultz, L.; Herzer, G.; Schäfer, R. Surface Crystallization and Magnetic Properties of Fe84.3Cu0.7Si4B8P3 Soft Magnetic Ribbons. Acta Mater. 2015, 96, 10–17. [Google Scholar] [CrossRef]

- Ok, H.N.; Morrish, A.H. Origin of the Perpendicular Anisotropy in Amorphous Fe82B12Si6 Ribbons. Phys. Rev. B 1981, 23, 2257–2261. [Google Scholar] [CrossRef]

- Gemperle, R.; Kraus, L.; Kroupa, F.; Schneider, J. Influence of Surface Oxidization on Induced Anisotropy of Amorphous (FeNi) PB Wires. Phys. Status Solidi (a) 1980, 60, 265–272. [Google Scholar] [CrossRef]

- Ok, H.N.; Morrish, A.H. Amorphous-to-Crystalline Transformation of Fe82B12Si6. Phys. Rev. B 1980, 22, 3471–3480. [Google Scholar] [CrossRef]

- Keupers, A.; De Schepper, L.; Knuyt, G.; Stals, L.M. Chemical and Topological Short Range Order in Amorphous Fe40Ni38Mo4B18 (Metglas 2826MB). J. Non Cryst. Solids 1985, 72, 267–278. [Google Scholar] [CrossRef]

- Morito, N. Surface Crystallization Induced by Selective Oxidation of Boron in Fe-B-Si Amorphous Alloy. Key Eng. Mater. 1990, 40–41, 63–68. [Google Scholar] [CrossRef]

- Herzer, G. Magnetomechanical Damping in Amorphous Ribbons with Uniaxial Anisotropy. Mater. Sci. Eng. A 1997, 226–228, 631–635. [Google Scholar] [CrossRef]

- Tong, X.; Zhang, Y.; Wang, Y.; Liang, X.; Zhang, K.; Zhang, F.; Cai, Y.; Ke, H.; Wang, G.; Shen, J.; et al. Structural Origin of Magnetic Softening in a Fe-Based Amorphous Alloy upon Annealing. J. Mater. Sci. Technol. 2022, 96, 233–240. [Google Scholar] [CrossRef]

- Herrero-Gómez, C.; Marín, P.; Hernando, A. Bias Free Magnetomechanical Coupling on Magnetic Microwires for Sensing Applications. Appl. Phys. Lett. 2013, 103, 142414. [Google Scholar] [CrossRef]

- Hernando, A.; Madurga, V.; Barandiarán, J.M.; Liniers, M. Anomalous Eddy Currents in Magnetostrictive Amorphous Ferromagnets: A Large Contribution from Magnetoelastic Effects. J. Magn. Magn. Mater. 1982, 28, 109–116. [Google Scholar] [CrossRef]

- Kaczkowski, Z.; Vlasák, G.; Švec, P.; Duhaj, P.; Ruuskanen, P.; Barandiarán, J.M.; Gutiérrez, J.; Minguez, P. Influence of Heat-Treatment on Magnetic, Magnetostrictive and Piezomagnetic Properties and Structure of Fe64Ni10Nb3Cu1Si13B9 Metallic Glass. Mater. Sci. Eng. A 2004, 375–377, 1065–1068. [Google Scholar] [CrossRef]

- Herzer, G. Modern Soft Magnets: Amorphous and Nanocrystalline Materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Séran, H.C.; Fergeau, P. An Optimized Low-Frequency Three-Axis Search Coil Magnetometer for Space Research. Rev. Sci. Instrum. 2005, 76, 044502. [Google Scholar] [CrossRef]

- Egami, T. Structural Relaxation in Amorphous Fe40Ni40P14 B6 Studied by Energy Dispersive X-ray Diffraction. J. Mater. Sci. 1978, 13, 2587–2599. [Google Scholar] [CrossRef]

- Herzer, G. Effect of Domain Size on the Magneto-Elastic Damping in Amorphous Ferromagnetic Metals. Int. J. Mater. Res. 2022, 93, 978–982. [Google Scholar] [CrossRef]

- Egami, T. Structural Relaxation in Amorphous Alloys—Compositional Short Range Ordering. Mater. Res. Bull. 1978, 13, 557–562. [Google Scholar] [CrossRef]

- Setiadi, R.N.; Schilling, M. Sideband Sensitivity of Fluxgate Sensors Theory and Experiment. Sens. Actuators A Phys. 2019, 285, 573–580. [Google Scholar] [CrossRef]

- Hasegawa, R.; Ramanan, V.R.V.; Fish, G.E. Effects of Crystalline Precipitates on the Soft Magnetic Properties of Metallic Glasses. J. Appl. Phys. 1982, 53, 2276–2278. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Sun, Y.; Yan, B.; Zhuang, X. Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons. Materials 2023, 16, 4990. https://doi.org/10.3390/ma16144990

Zhang X, Sun Y, Yan B, Zhuang X. Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons. Materials. 2023; 16(14):4990. https://doi.org/10.3390/ma16144990

Chicago/Turabian StyleZhang, Xu, Yu Sun, Bin Yan, and Xin Zhuang. 2023. "Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons" Materials 16, no. 14: 4990. https://doi.org/10.3390/ma16144990

APA StyleZhang, X., Sun, Y., Yan, B., & Zhuang, X. (2023). Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons. Materials, 16(14), 4990. https://doi.org/10.3390/ma16144990