A Study on an Easy-Plane FeSi3.5 Composite with High Permeability and Ultra-Low Loss at the MHz Frequency Band

Abstract

1. Introduction

2. Experiment

3. Result

3.1. Morphology and Microstructure

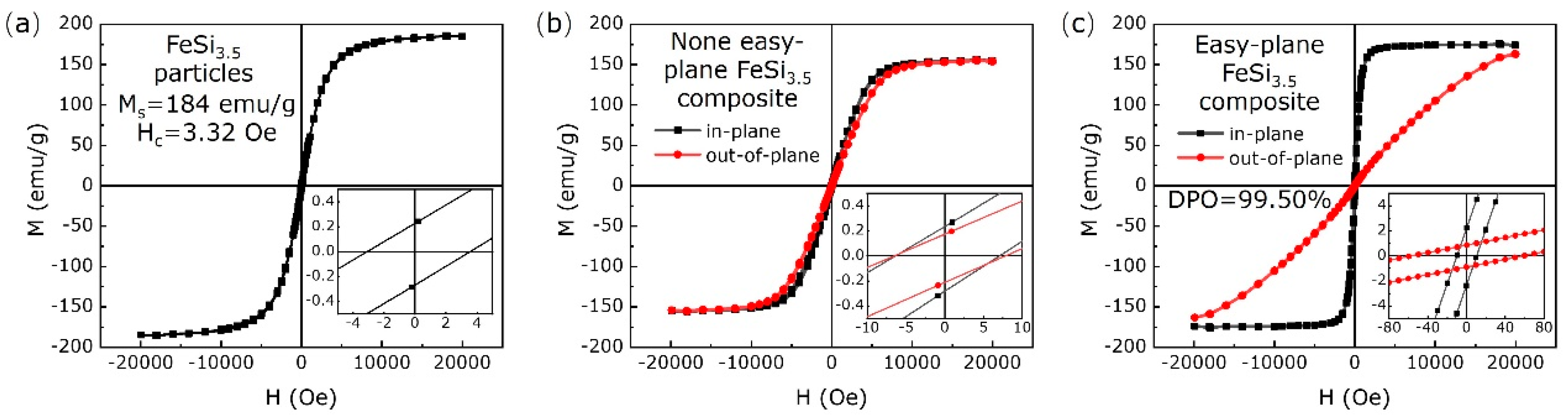

3.2. Static Magnetic Performance and Degree of the Plane Orientation

3.3. Complex Permeability and Magnetic Spectra Simulation

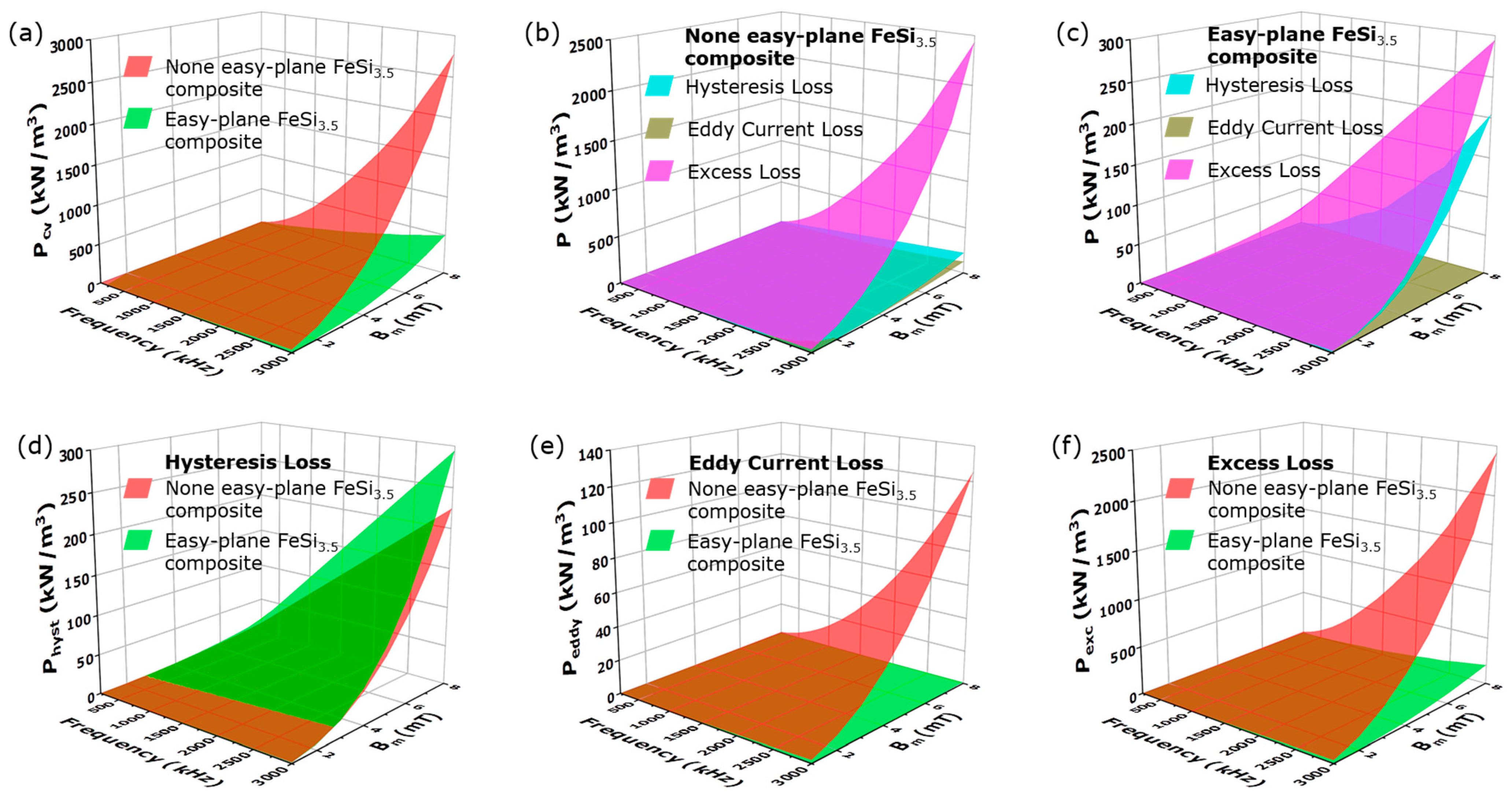

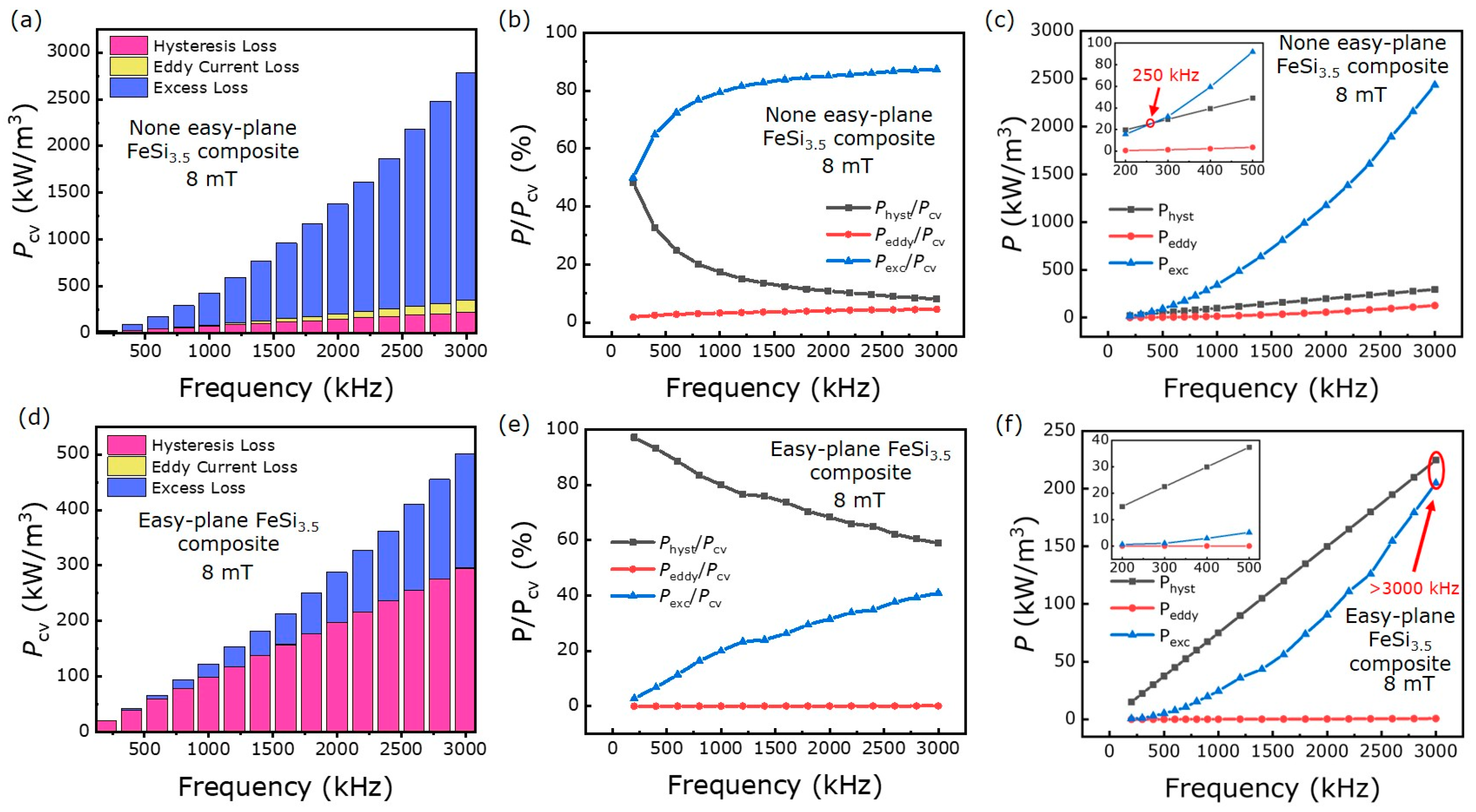

3.4. Power Loss and Loss Separation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Gilbert, I.P.; Moorthy, V.; Bull, S.J.; Evans, J.T.; Jack, A.G. Development of soft magnetic composites for low-loss applications. J. Magn. Magn. Mater. 2002, 242, 232–234. [Google Scholar] [CrossRef]

- Ozols, A.; Pagnola, M.; García, D.I.; Sirkin, H. Electroless coating of Permalloy powder and DC-resistivity of alloy composites. Surf. Coat. Technol. 2006, 200, 6821–6825. [Google Scholar] [CrossRef]

- Nowicki, M.; Szewczyk, R.; Charubin, T.; Marusenkov, A.; Nosenko, A.; Kyrylchuk, V. Modeling the Hysteresis Loop of Ultra-High Permeability Amorphous Alloy for Space Applications. Materials 2018, 11, 2079. [Google Scholar] [CrossRef]

- Bensalem, R.; Tebib, W.; Alleg, S.; Suñol, J.J.; Bessais, L.; Greneche, J.M. Magnetic properties of nanostructured Fe92P8 powder mixture. J. Alloys Compd. 2009, 471, 24–27. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, 418. [Google Scholar] [CrossRef]

- Li, W.C.; Wang, W.; Lv, J.J.; Ying, Y.; Yu, J.; Zheng, J.W.; Qiao, L.; Che, S.L. Structure and magnetic properties of iron-based soft magnetic composite with Ni-Cu-Zn ferrite–silicone insulation coating. J. Magn. Magn. Mater. 2018, 456, 333–340. [Google Scholar] [CrossRef]

- Li, J.X.; Yu, J.; Li, W.C.; Che, S.L.; Zheng, J.W.; Qiao, L.; Ying, Y. The preparation and magnetic performance of the iron-based soft magnetic composites with the Fe@Fe3O4 powder of in situ surface oxidation. J. Magn. Magn. Mater. 2018, 454, 103–109. [Google Scholar] [CrossRef]

- Wu, C.; Huang, M.Q.; Luo, D.H.; Jiang, Y.Z.; Yan, M. SiO2 nanoparticles enhanced silicone resin as the matrix for Fe soft magnetic composites with improved magnetic, mechanical and thermal properties. J. Alloys Compd. 2018, 741, 35–43. [Google Scholar] [CrossRef]

- Zhou, B.; Chi, Q.; Dong, Y.Q.; Liu, L.; Zhang, Y.Q.; Chang, L.; Pan, Y.; He, A.; Li, J.W.; Wang, X.M. Effects of annealing on the magnetic properties of Fe-based amorphous powder cores with inorganic-organic hybrid insulating layer. J. Magn. Magn. Mater. 2020, 494, 165827. [Google Scholar] [CrossRef]

- Li, W.C.; Cai, H.W.; Kang, Y.; Ying, Y.; Yu, J.; Zheng, J.W.; Qiao, L.; Jiang, Y.; Che, S.L. High permeability and low loss bioinspired soft magnetic composites with nacre-like structure for high frequency applications. J. Acta Mater. 2019, 167, 267–274. [Google Scholar] [CrossRef]

- Ling, X.; Li, M.; Cheng, W.J.; Fan, H.W.; Liu, G.; Sun, Y.H. Magnetic Properties and Eddy Current Losses in Fe-based Soft Magnetic Composites. Int. J. Appl. Electromagn. Mech. 2016, 52, 1433–1441. [Google Scholar]

- Zhang, C.; Liu, X.S.; Li, M.L.; Liu, C.C.; Li, H.H.; Meng, X.Y. Preparation and soft magnetic properties of γ’-Fe4N particles. J. Mater. Sci. Mater. Electron. 2018, 29, 1254–1257. [Google Scholar] [CrossRef]

- Wang, W.; Kan, X.C.; Liu, X.S.; Feng, S.J. Effect of Cu on microstructure, magnetic properties of antiperovskite nitrides CuxNFe4−x. J. Mater. Sci. Mater. Electron. 2019, 30, 10383–10390. [Google Scholar] [CrossRef]

- Duan, B.F.; Zhang, J.M.; Wang, G.W.; Wang, P.; Wang, D.; Qiao, L.; Wang, T.; Li, F.S. Microwave absorption properties of easy-plane anisotropy Fe–Si powders with surface modification in the frequency range of 0.1–4 GHz. J. Mater. Sci. Mater. Electron. 2019, 30, 13810–13819. [Google Scholar] [CrossRef]

- Gu, X.; Tan, G.; Chen, S.; Man, Q.; Chang, C.; Wang, X.; Li, R.W.; Che, S.; Jiang, L. Microwave absorption properties of planar-anisotropy Ce2Fe17N3-δ powders/Silicone composite in X-band. J. Magn. Magn. Mater. 2017, 424, 39–43. [Google Scholar] [CrossRef]

- Zuo, W.L.; Ying, L.; Qiao, L.; Wang, T.; Li, F.S. High frequency magnetic properties of Pr2Fe17N3−δ particles with planar anisotropy. J. Phys. B Condens. Matter. 2010, 405, 4397–4400. [Google Scholar] [CrossRef]

- Chi, X.; Yi, H.B.; Zuo, W.L.; Qiao, L.; Wang, T.; Li, F.S. Complex permeability and microwave absorption properties of Y2Fe17 micropowders with planar anisotropy. J. Phys. D Appl. Phys. 2011, 44, 52–55. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.; Yi, X.; Yao, Z.; Zhu, Y.; Hu, G. Improved magnetic properties of FeSiCr amorphous soft magnetic composites by adding carbonyl iron powder. J. Non-Cryst. Solids 2021, 559, 120673. [Google Scholar] [CrossRef]

- Long, H.M.; Wu, X.J.; Lu, Y.K.; Zhang, H.; Hao, J. Effect of Polyimide-Phosphating Double Coating and Annealing on the Magnetic Properties of Fe-Si-Cr SMCs. Materials 2022, 15, 3350. [Google Scholar] [CrossRef]

- Kim, H.R.; Jang, M.S.; Nam, Y.G.; Kim, Y.S.; Yang, S.S.; Jeong, J.W. Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids. Metals 2021, 11, 1220. [Google Scholar] [CrossRef]

- Thao, N.G.M.; Fujisaki, K.; That, L.T.; Motozuka, S. Magnetic Comparison between Experimental Flake Powder and Spherical Powder for Inductor Cores at High Frequency. IEEE Trans. Magn. 2020, 57, 8400407. [Google Scholar]

- Wu, P.; Zhang, Y.D.; Hao, H.B.; Qiao, L.; Liu, X.; Wang, T.; Li, F.S. Effects of Nitriding and Ni Doping the Position of Domain Wall Resonance Peak and High-frequency Magnetic Performance of Easy-Plane Y2Fe17. J. Magn. Magn. Mater. 2022, 549, 168962. [Google Scholar] [CrossRef]

- Wohlfarth, E.P. Ferromagnetic Materials; North-Holland: Amsterdam, The Netherlands, 1980; p. 370. [Google Scholar]

- Tsutaoka, T. Frequency dispersion of complex permeability in Mn-Zn and Ni-Zn spinel ferrites and their composite materials. J. Appl. Phys. 2003, 93, 2789. [Google Scholar] [CrossRef]

- Nakamura, T. Low-temperature sintering of Ni-Z-Cu ferrite and its permeability spectra. J. Magn. Magn. Mater. 1997, 168, 285–291. [Google Scholar] [CrossRef]

- Han, M.; Liang, D.; Deng, L. Analyses on the dispersion spectra of permeability and permittivity for NiZn spinel ferrites doped with SiO2. Appl. Phys. Lett. 2007, 90, 192507. [Google Scholar] [CrossRef]

- Liu, X.; Wu, P.; Wang, P.; Wang, T.; Qiao, L.; Li, F.S. High permeability and bimodal resonance structure of flaky soft magnetic composite materials. Chin. Phys. B 2020, 29, 077506. [Google Scholar] [CrossRef]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 2002, 24, 621–630. [Google Scholar] [CrossRef]

| In-Plane | Out-of-Plane | DPO | |||||

|---|---|---|---|---|---|---|---|

| None easy-plane FeSi3.5 | 154.45 | 0.24 | 6.71 | 153.78 | 0.18 | 7.18 | |

| Easy-Plane FeSi3.5 | 173.53 | 2.28 | 10.19 | 163.00 | 0.87 | 57.79 | 99.50% |

| Domain Wall Motion | Spin Rotation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| β | α | ||||||||

| None easy-plane FeSi3.5 | 28 | 13 | 120 | 9 | 1 × 1010 | 14 | 0.35 | 0.05 | 7 |

| Easy-Plane FeSi3.5 | 66 | 45 | 840 | 100 | 4 × 1010 | 20 | 7 | 1.5 | 5 |

| α | x | y | |||||

|---|---|---|---|---|---|---|---|

| None easy-plane FeSi3.5 composite | 9.2463 | 2.43 | 5.14 × 10−12 | 2.18 × 10−4 | 4.02 × 10−4 | 2.21 | 1.76 |

| Easy-Plane FeSi3.5 composite | 42.897 | 2.69 | 8.18 × 10−7 | 3.78 × 10−7 | 4.16 × 10−6 | 2.43 | 1.97 |

| SMCs | Initial Permeability | Power Loss | (under 500 kW/m3) | |

|---|---|---|---|---|

| The easy-plane FeSi3.5 composite | 62.5 | 500.42 kW/m3 (3 MHz, 8 mT) | 23.96 | This work |

| Amorphous FeSiCr + carbonyl iron @ resin | 37 | 560 kW/m3 (1 MHz, 20 mT) | 16 | [19] |

| Amorphous Fe73Si6B10P5C3Mo3 @ epoxy resin | 34.63 | ~500 kW/m3 (1 MHz, 20 mT) | 20 | [21] |

| Amorphous FeSiCr/phosphating process and polyimide coating | 47.5 | 7086 kW/m3 (1 MHz, 50 mT) | 5 | [20] |

| Flake pure iron @ binder composite | 67 (at 1 MHz) | 306.6 kW/m3 (1 MHz, 3 mT) | ~5 | [22] |

| 10 (at 3.5 MHz) | 3.285 kW/m3 (3.5 MHz, 0.1 mT) | ~15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, P.; Yang, S.; Huang, Y.; Wang, G.; Cui, J.; Qiao, L.; Wang, T.; Li, F. A Study on an Easy-Plane FeSi3.5 Composite with High Permeability and Ultra-Low Loss at the MHz Frequency Band. Materials 2023, 16, 5133. https://doi.org/10.3390/ma16145133

Wu P, Yang S, Huang Y, Wang G, Cui J, Qiao L, Wang T, Li F. A Study on an Easy-Plane FeSi3.5 Composite with High Permeability and Ultra-Low Loss at the MHz Frequency Band. Materials. 2023; 16(14):5133. https://doi.org/10.3390/ma16145133

Chicago/Turabian StyleWu, Peng, Shengyu Yang, Yuandong Huang, Guowu Wang, Jinghao Cui, Liang Qiao, Tao Wang, and Fashen Li. 2023. "A Study on an Easy-Plane FeSi3.5 Composite with High Permeability and Ultra-Low Loss at the MHz Frequency Band" Materials 16, no. 14: 5133. https://doi.org/10.3390/ma16145133

APA StyleWu, P., Yang, S., Huang, Y., Wang, G., Cui, J., Qiao, L., Wang, T., & Li, F. (2023). A Study on an Easy-Plane FeSi3.5 Composite with High Permeability and Ultra-Low Loss at the MHz Frequency Band. Materials, 16(14), 5133. https://doi.org/10.3390/ma16145133