Study on Alkali-Activated Prefabricated Building Recycled Concrete Powder for Foamed Lightweight Soils

Abstract

1. Introduction

2. Materials and Methods

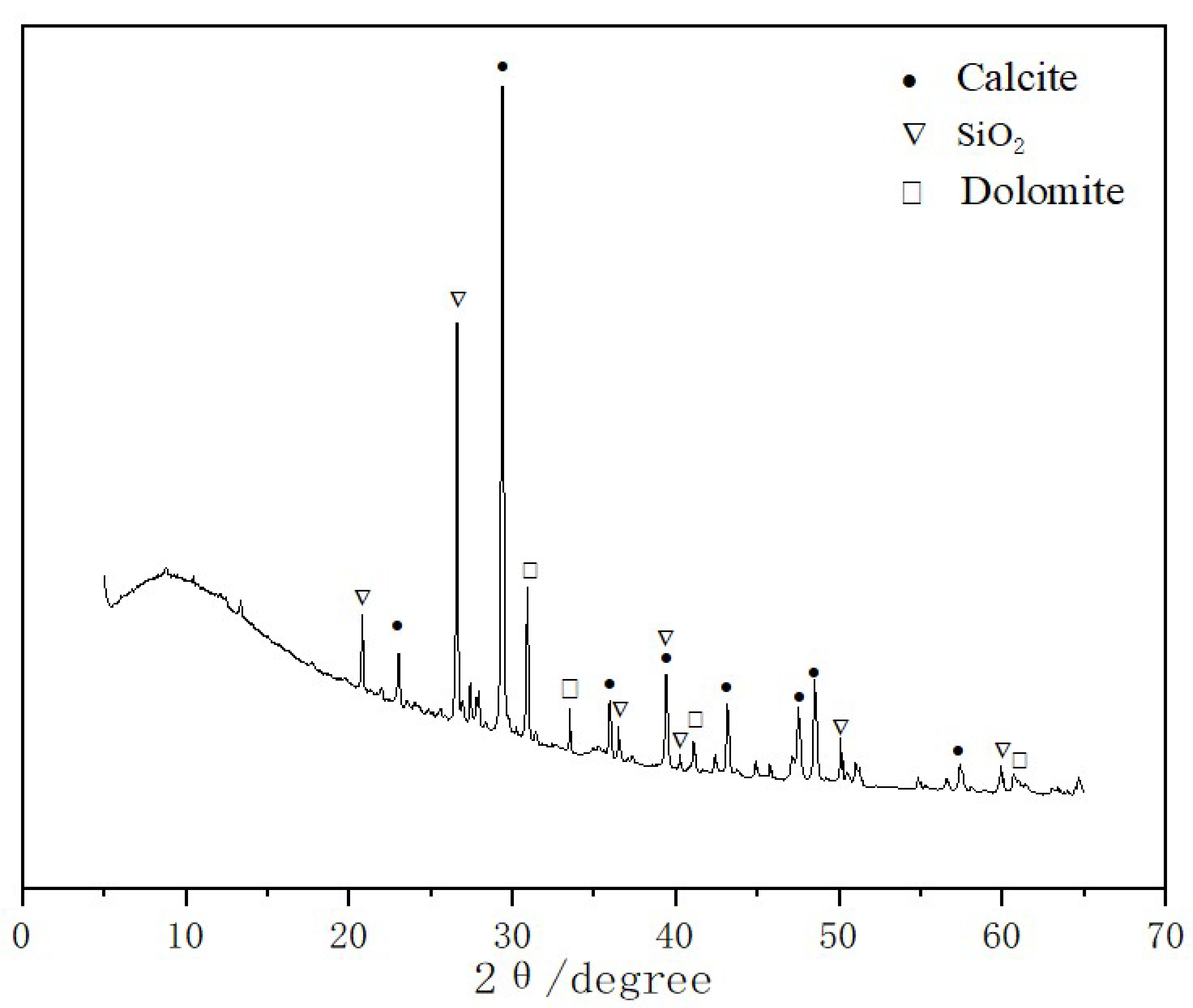

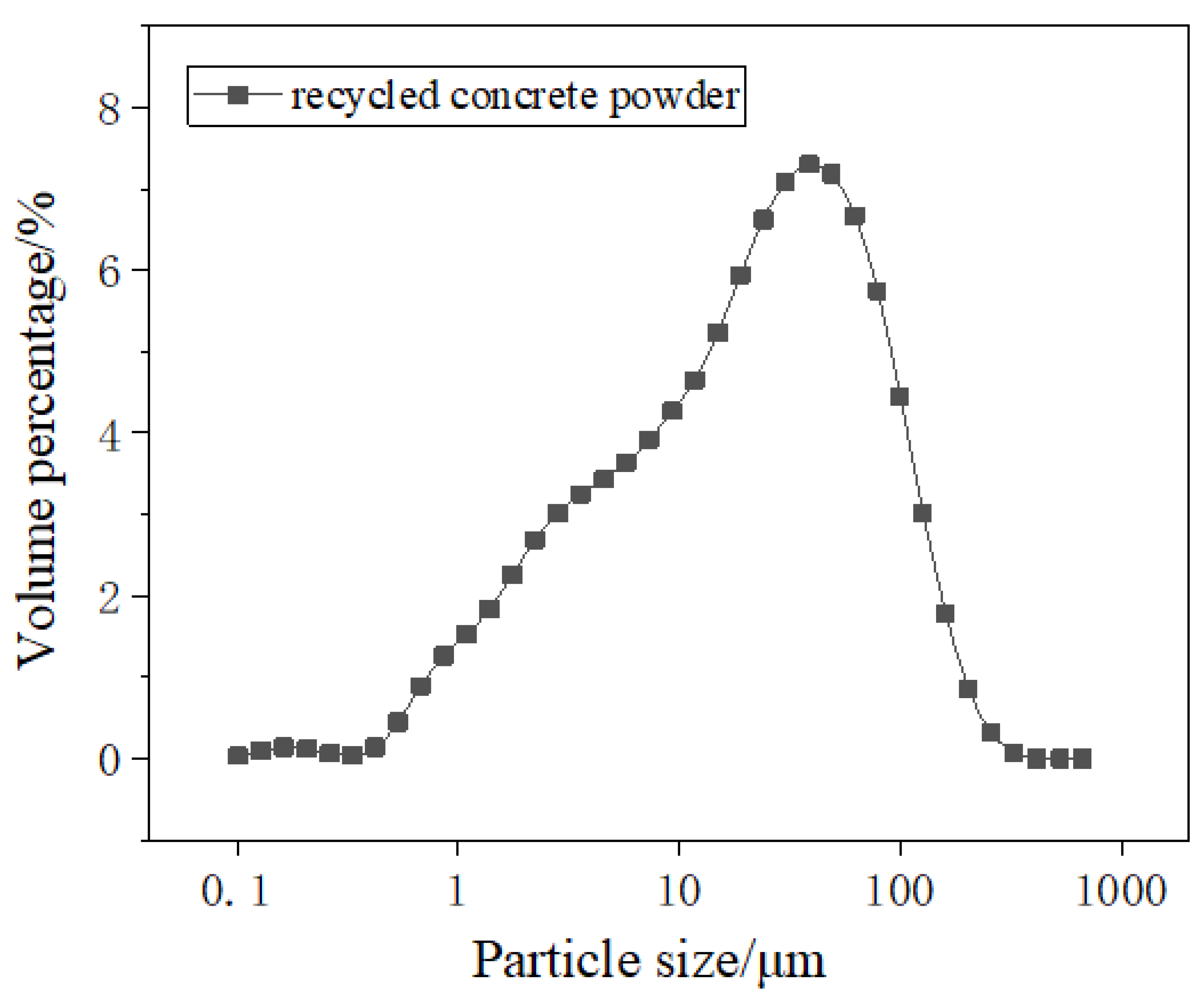

2.1. Raw Materials

2.2. Design of Mix Proportion

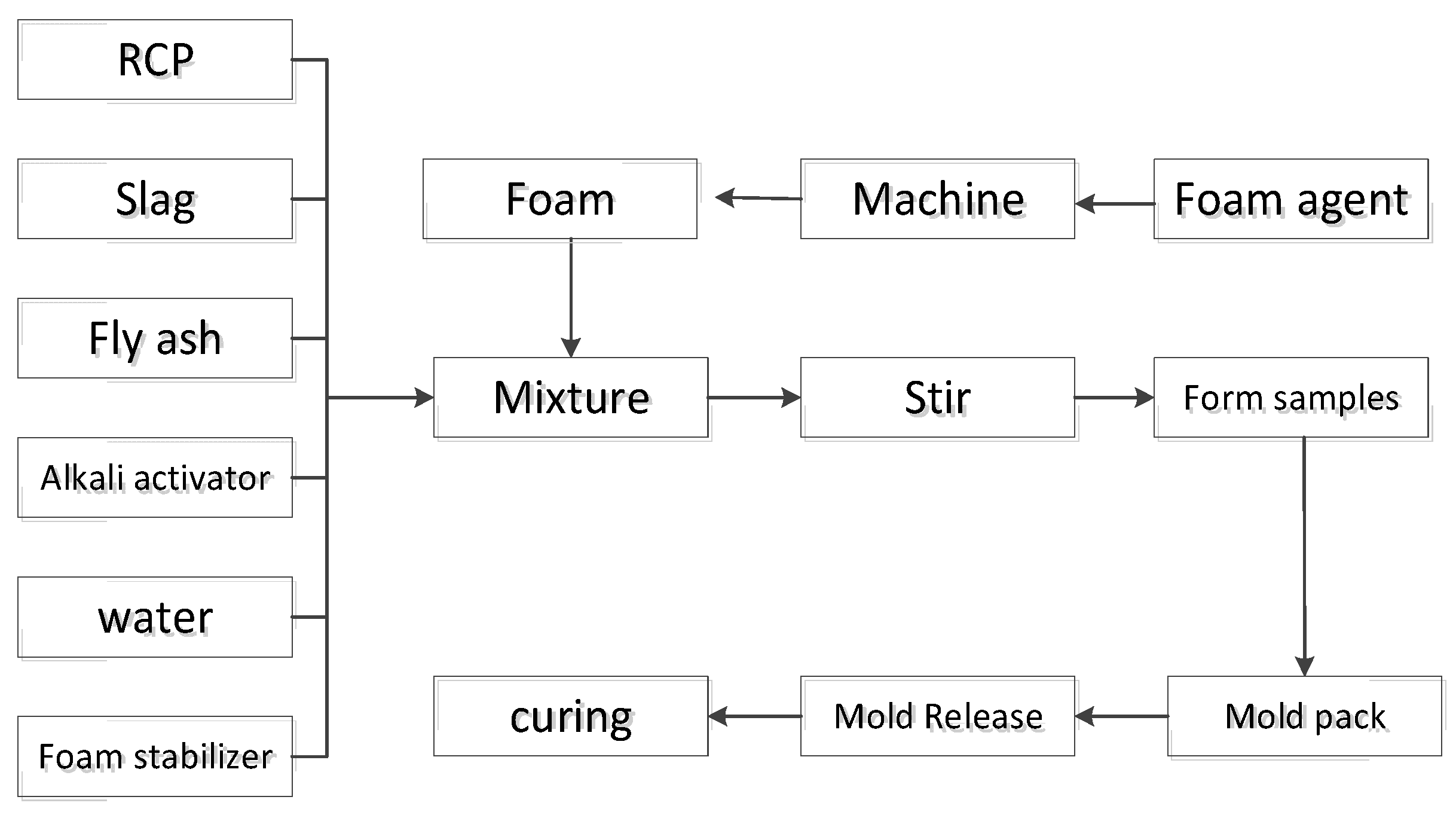

2.3. Preparation

2.4. Methods

3. Results

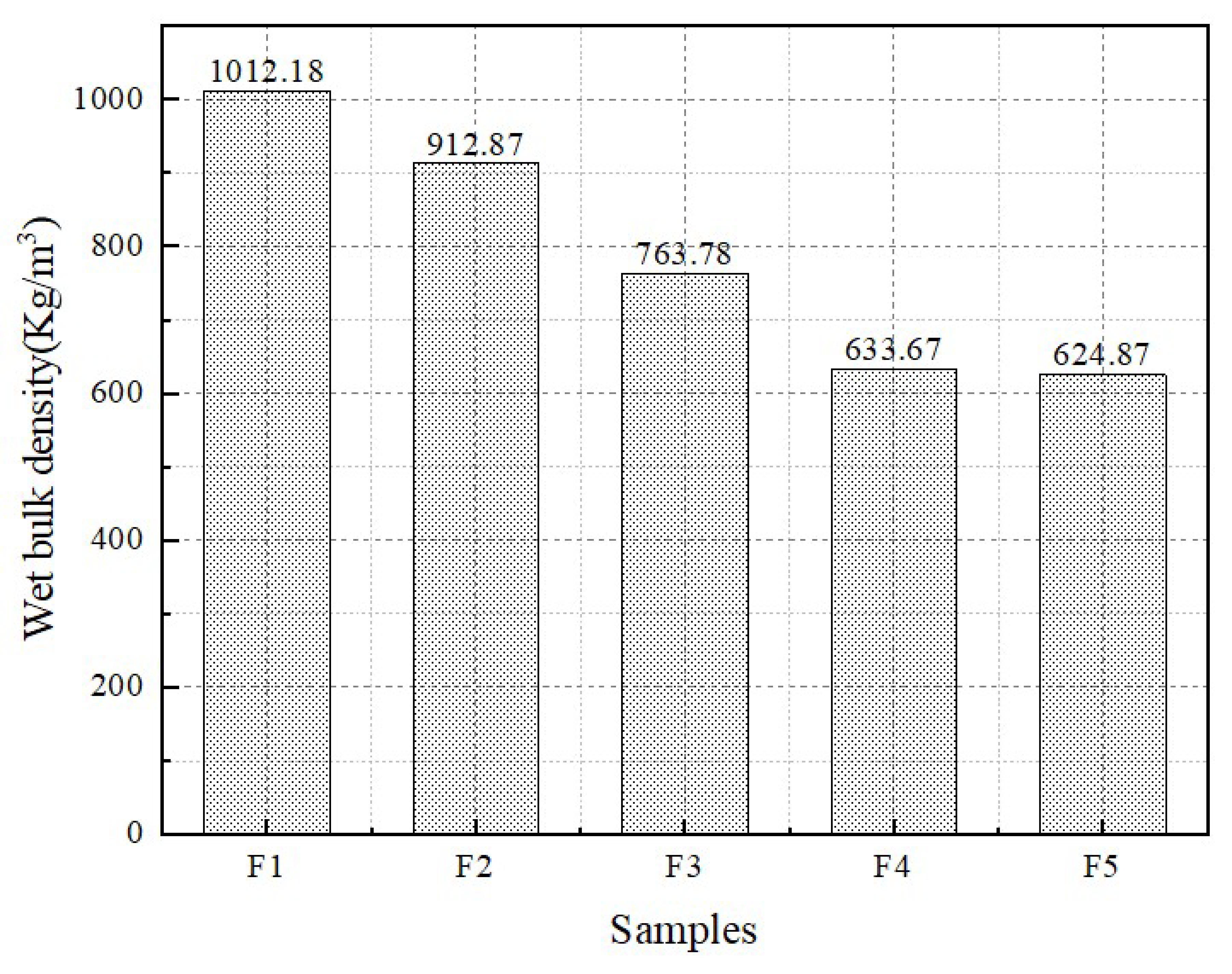

3.1. Wet Bulk Density

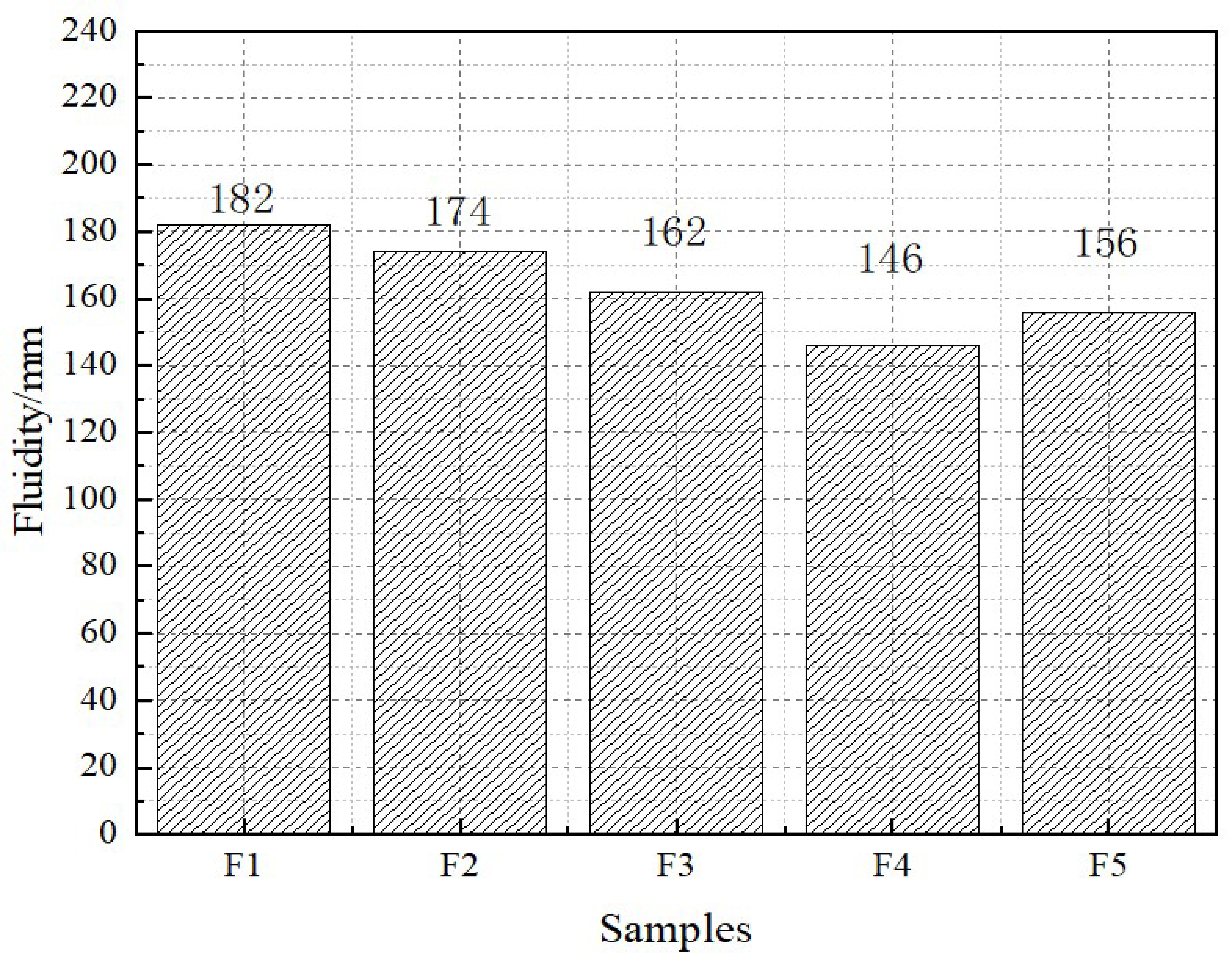

3.2. Fluidity

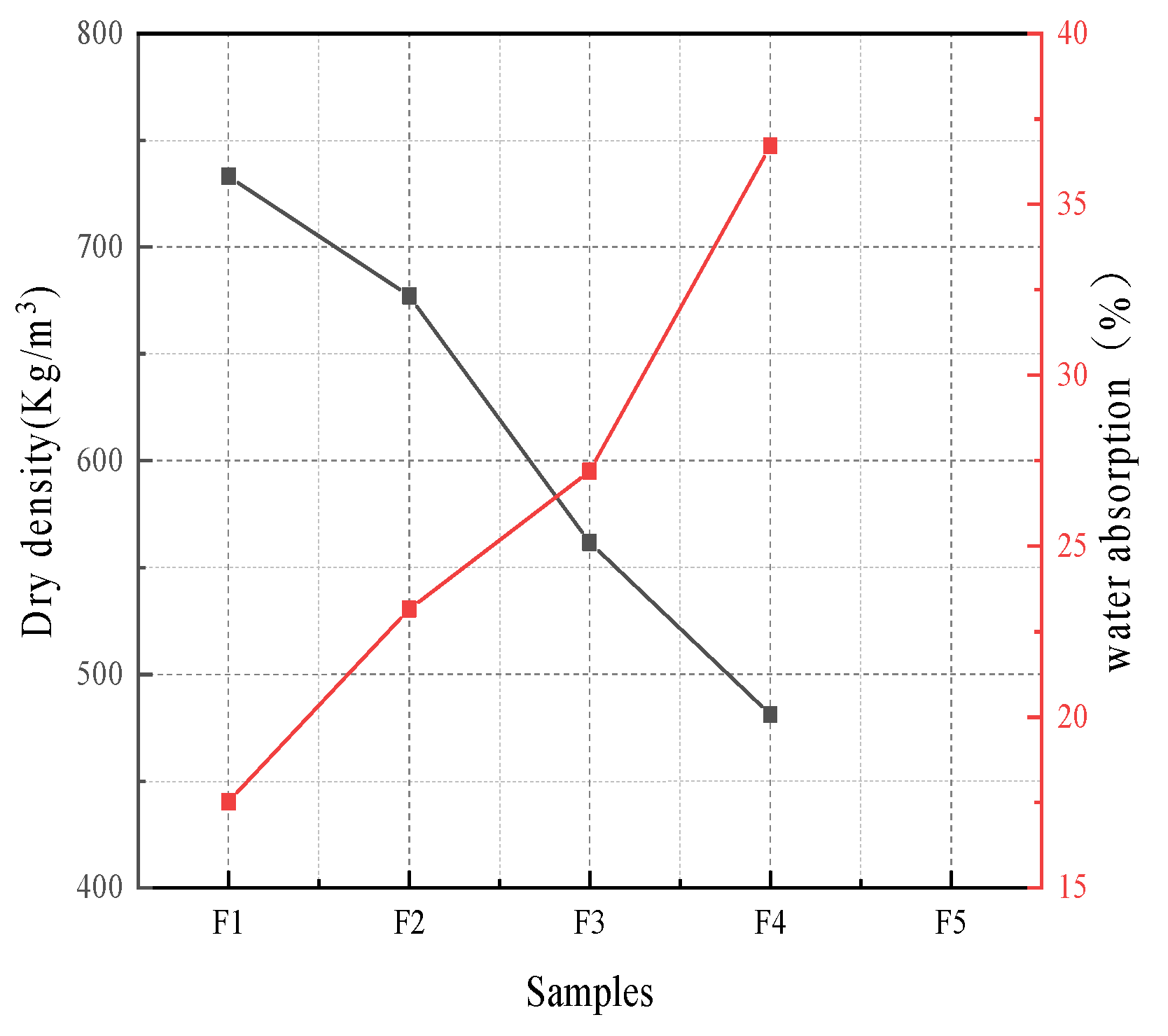

3.3. Dry Density and Water Absorption

3.4. Unconfined Compressive Strength

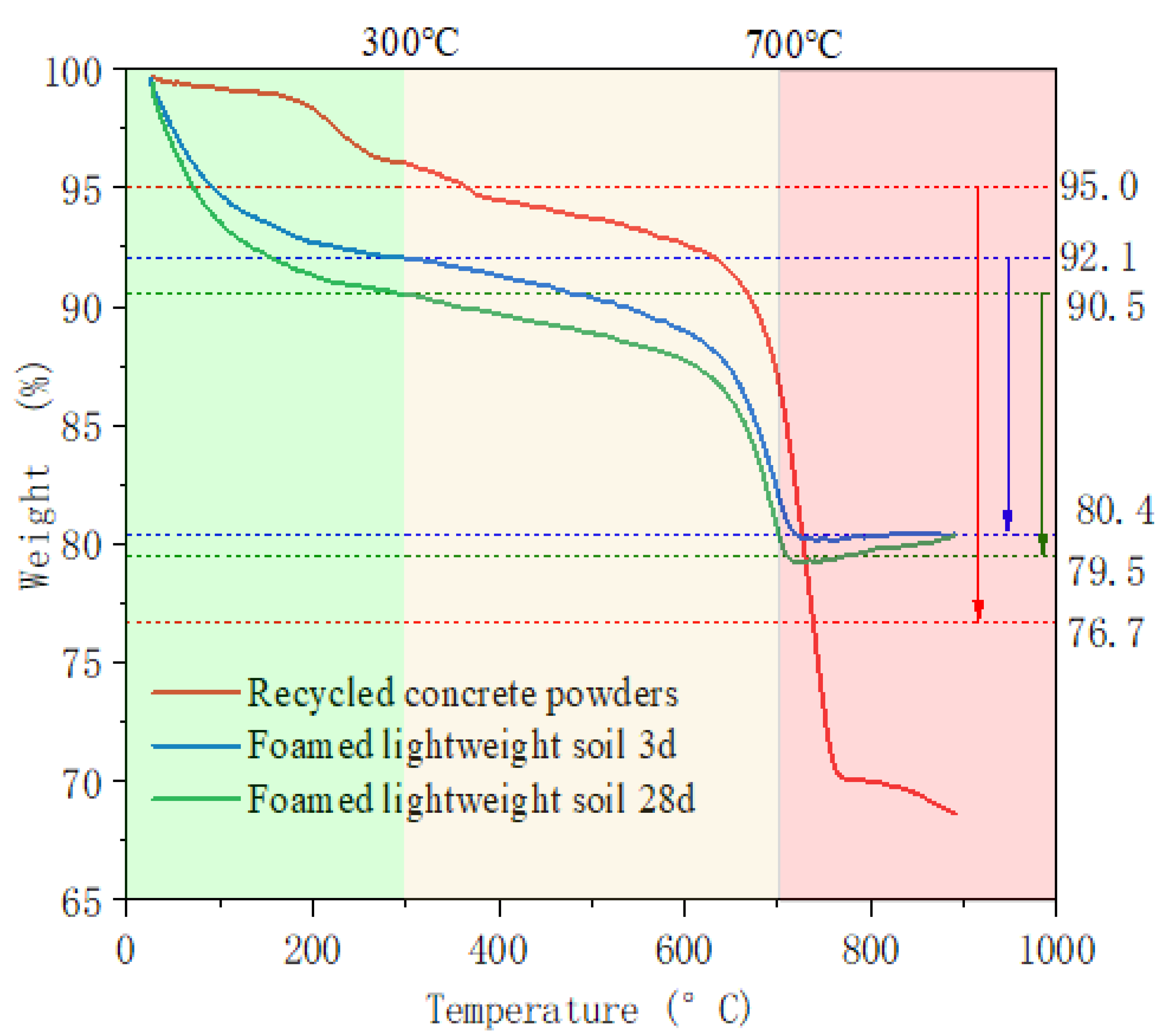

3.5. TG Analysis

3.6. Phase Analysis Results of FTIR

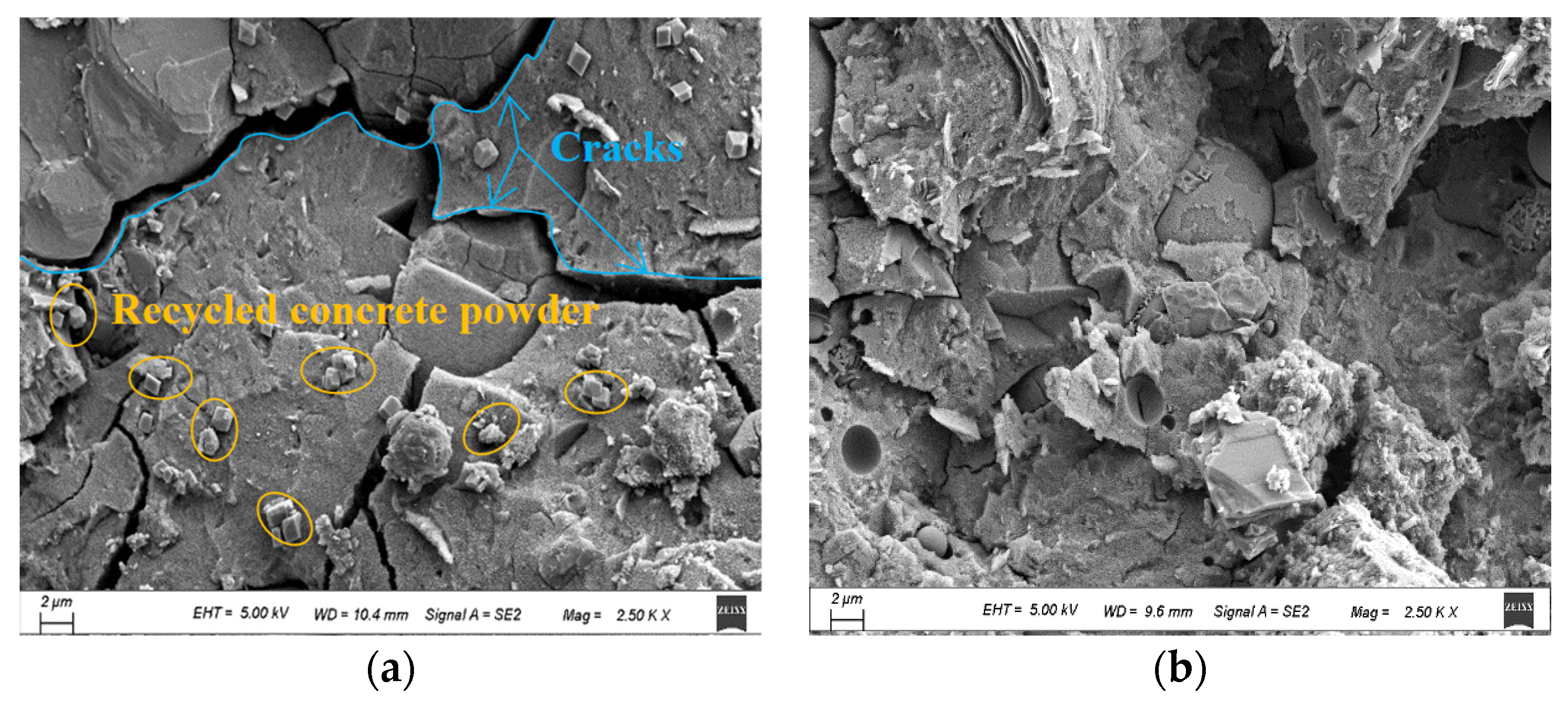

3.7. Microstructure Results of SEM

4. Conclusions

- As alkali-activated raw materials, when the recycled powder, fly ash, and slag occupied 60%, 20%, and 20%, respectively, it can be used to prepare foamed lightweight soil. The wet bulk density is 912.87 kg/m3, the fluidity is 174 mm, the water absorption is 23.16%, and the strength is 1.53 MPa, all of which can meet the requirements for light soil for highway embankment.

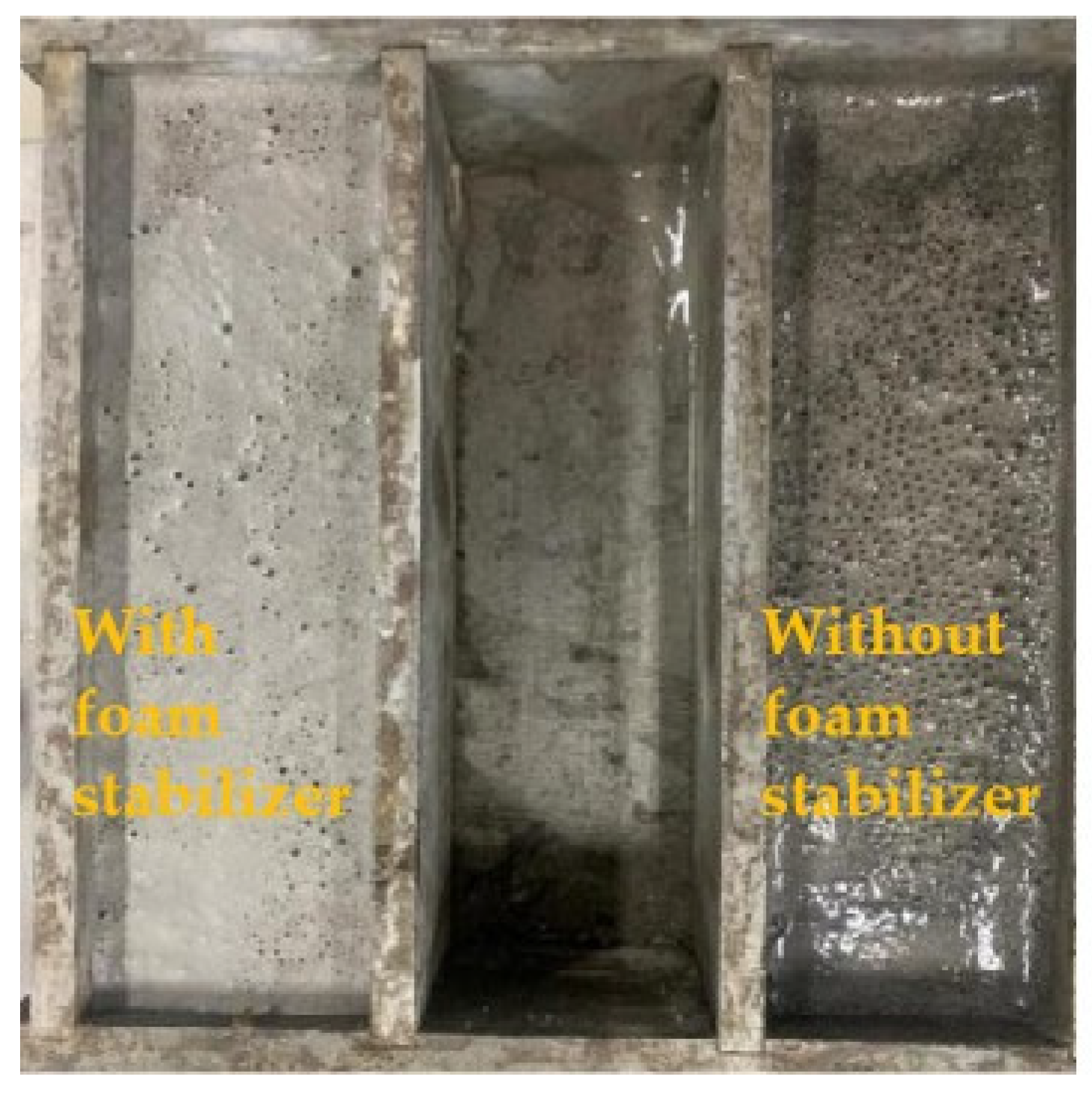

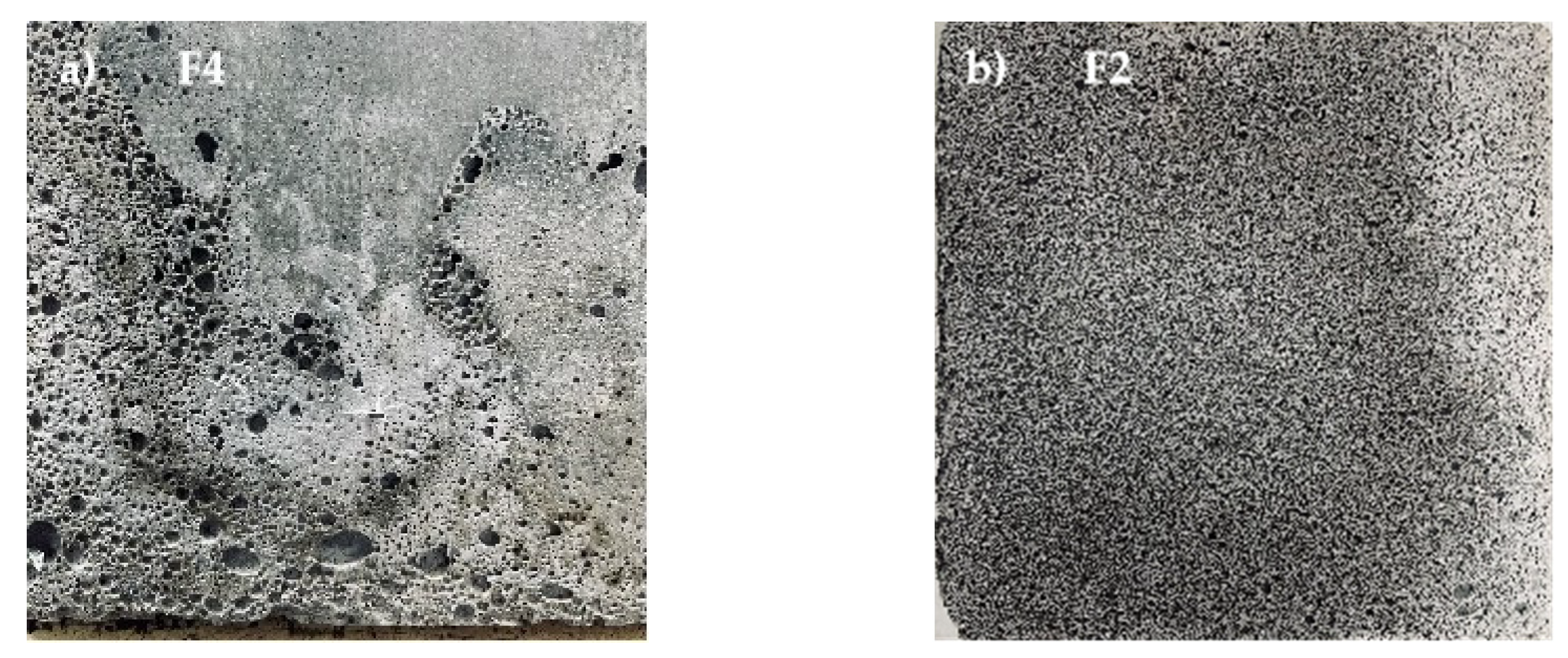

- The addition of an appropriate amount of foam stabilizer greatly improves the foam retention of the material. When the foam content ranges from 55% to 70%, it results in an increase in the proportion of foam and a decrease in the material’s wet bulk density. When the foam content is low, the slurry does not wrap the excess foam well, and the material’s fluidity decreases significantly. Too much foam increases the number of open pores and it can easily merge into large foam without stability, which reduces water absorption. At a higher foam content, there are fewer slurry components and lower strength.

- There are more cracks in the surface of early hydration products, as the reaction progresses, the foamed lightweight soil can effectively fill gaps between early hydration products. However, the hydration of alkali-activated foamed lightweight soils is a continuous process and cannot fully react in the early stages.

- Compared with the general fill soil or reinforced soil, foamed lightweight soil is convenient for construction without compaction. It is a construction material that can be constructed quickly and reduce post construction settlement, and has higher economic benefits, and is therefore worth spreading and applying.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Ren, L.; Yang, L. Excellent carbonation behavior of rankinite prepared by calcining the C-S-H: Potential recycling of waste concrete powders for prefabricated building products. Materials 2018, 11, 1474. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Investigation of waste clay brick as partial replacement in geopolymer binder. Constr. Build. Mater. 2023, 365, 130107. [Google Scholar] [CrossRef]

- Zeybek, O.; Ozkilic, Y.O.; Karalar, M.; Celik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of replacing cement with waste glass on mechanical properties of concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Sosa, M.E.; Zega, C.J. Experimental and estimated evaluation of drying shrinkage of concrete made with fine recycled aggregates. Sustainability 2023, 15, 7666. [Google Scholar] [CrossRef]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance review of prefabricated building systems and future research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef]

- Liu, X.; Liu, E.; Fu, Y. Reduction in Drying Shrinkage and Efflorescence of Recycled Brick and Concrete Fine Powder–Slag-Based Geopolymer. Appl. Sci. 2023, 13, 2997. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, Y.; Liu, D.; Lv, W.; Zhang, Z. The basic mechanical properties and shrinkage properties of recycled micropowder UHPC. Materials 2023, 16, 1570. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.; Kim, J.; Sicakova, A. Effect of aggregate size on recycled aggregate concrete under equivalent mortar volume mix design. Appl. Sci. 2021, 11, 11274. [Google Scholar] [CrossRef]

- Shi, Y.N.; Weng, H.X.; Yu, J.Q.; Gong, Y.F. Study on modification and mechanism of construction waste to solidified silt. Materials 2023, 16, 2780. [Google Scholar] [CrossRef]

- Bondar, D.; Nanukuttan, S. External sulphate attack on alkali-activated slag and slag/fly ash concrete. Buildings 2022, 12, 94. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Hekimoglu, G.; Ustaoglu, A.; Sarı, A.; Kaplan, G.; Bayraktar, O.Y.; Sutcu, M.; Ozbakkaloglu, T. Foam concrete produced with recycled concrete powder and phase change materials. Sustainability 2022, 14, 7458. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.M.; Wu, H.X.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.H.; Wu, Z.G.; Gong, Y.F.; Xiao, P. The effect of mechanical-thermal synergistic activation on the mechanical properties and microstructure of recycled powder geopolymer. J. Clean. Prod. 2021, 327, 129477. [Google Scholar] [CrossRef]

- Bun, P.; Cyr, M.; Laniesse, P.; Idir, R.; Bun, K.N. Concrete made of 100% recycled materials-Feasibility study. Resour. Conserv. Recycl. 2022, 180, 106199. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-Torgal, F.; Lopes, A. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Fořt, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Rovnaníková, P.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.Z.; Duan, Z.H.; Li, S.S. Geopolymers made of recycled brick and concrete powder—A critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Liu, M.; Hu, R.H.; Zhang, Y.C.; Wang, C.Q.; Ma, Z.M. Effect of ground concrete waste as green binder on the micro-macro properties of eco-friendly metakaolin-based geopolymer mortar. J. Build. Eng. 2023, 68, 106191. [Google Scholar] [CrossRef]

- Kim, J.; Jang, H. Closed-loop recycling of C&D waste: Mechanical properties of concrete with the repeatedly recycled C&D powderas partial cement replacement. J. Clean. Prod. 2022, 343, 130977. [Google Scholar]

- Gong, Y.F.; Fang, Y.H.; Yan, Y.R.; Chen, L.Q. Investigation on alkali activated recycled cement mortar powder cementitious material. Mater. Res. Innov. 2014, 18, 784–787. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; de Gutiérrez, R.M. Reuse of powders and recycled aggregates from mixed construction and demolition waste in alkali-activated materials and precast concrete units. Sustainability 2022, 14, 9685. [Google Scholar] [CrossRef]

- Wang, X.; Yan, Y.; Tong, X.; Gong, Y. Investigation of mineral admixtures on mechanical properties of alkali-activated recycled concrete powders cement. Buildings 2022, 12, 1234. [Google Scholar] [CrossRef]

- Rovnanik, P.; Rovnanikova, P.; Vysvaril, M. Rheological properties and microstructure of binary waste red brick powder/metakaolin geopolymer. Constr. Build. Mater. 2018, 188, 924–933. [Google Scholar] [CrossRef]

- Bassani, M.; Tefa, L.; Coppola, B.; Palmero, P. Alkali-activation of Aggregate Fines from Construction and Demolition Waste: Valorisation in View of Road Pavement Subbase Applications. J. Clean. Prod. 2019, 234, 71–84. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. Strength development and acid resistance of geopolymer based on waste clay brick powder and phosphorous slag. Struct. Concr. 2019, 20, 1596–1606. [Google Scholar] [CrossRef]

- Yang, D.Y.; Liu, M.; Zhang, Z.B.; Yao, P.P.; Ma, Z.M. Properties and modification of sustainable foam concrete including eco-friendly recycled powder from concrete waste. Case Stud. Constr. Mater. 2022, 16, e00826. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Ma, Z.M.; Sui, T.B.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Xuan, D.X.; Tang, P.; Poon, C.S. MSWIBA-based cellular alkali-activated concrete incorporating waste glass powder. Cem. Concr. Compos. 2019, 95, 128–136. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2019, 243, 118636. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Tashima, M.M.; Monzo, J.; Borrachero, M.V.; Paya, J. One-partEEco-cellular concrete for the precast industry: Functional features and life cycle assessment. J. Clean Prod. 2020, 269, 122203. [Google Scholar] [CrossRef]

- Wan, X.; Li, H.; Che, X.; Xu, P.; Li, C.; Yu, Q. A study on the application of recycled concrete powder in an alkali-activated cementitious system. Processes 2023, 11, 203. [Google Scholar] [CrossRef]

- Tefa, L.; Bassani, M.; Coppola, B.; Palmero, P. Strength development and environmental assessment of alkali-activated construction and demolition waste fines as stabilizer for recycled road materials. Constr. Build. Mater. 2021, 289, 123017. [Google Scholar] [CrossRef]

- Ma, Z.; Tang, Q.; Wu, H.; Xu, J.; Liang, C. Mechanical properties and water absorption of cement composites with various fineness and contents of waste brick powder from C&D waste. Cem. Concr. Compos. 2020, 114, 103758. [Google Scholar]

- Aiken, T.A.; Gu, L.; Kwasny, J.; Huseien, G.F.; McPolin, D.; Sha, W. Acid resistance of alkali-activated binders: A review of performance, mechanisms of deterioration and testing procedures. Constr. Build. Mater. 2022, 342, 128057. [Google Scholar] [CrossRef]

- Swanepoel, J.; Strydom, C. Utilisation of fly ash in a geopolymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- Ghanbari, M.; Hadian, A.; Nourbakhsh, A.; MacKenzie, K. Modeling and optimization of compressive strength and bulk density of metakaolin-based geopolymer using central composite design: A numerical and experimental study. Ceram. Int. 2017, 43, 324–335. [Google Scholar] [CrossRef]

| NO. | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | K2O | TiO2 | Na2O | Others |

|---|---|---|---|---|---|---|---|---|---|

| RCP (%) | 34.3 | 42.1 | 8.2 | 6.2 | 4.5 | 1.2 | 1.0 | 1.0 | 1.5 |

| Slag (%) | 30.0 | 38.1 | 13.6 | 0.6 | 12.5 | 0.4 | 0.6 | 0.3 | 3.9 |

| Fly ash (%) | 61.9 | 2.4 | 28.8 | 2.5 | 0.8 | 1.5 | 1.04 | 0.3 | 0.76 |

| Sample | W/C | Components (kg/m3) | (kg/m3) | ||||

|---|---|---|---|---|---|---|---|

| RCP | Slag | Fly Ash | Water Glass | Foam | |||

| F1 | 0.45 | 535 | 178 | 178 | 53.5 | 1090 | 1000 |

| F2 | 476 | 159 | 159 | 47.6 | 1189 | 900 | |

| F3 | 416 | 139 | 139 | 41.6 | 1288 | 800 | |

| F4 | 357 | 119 | 119 | 35.7 | 1387 | 700 | |

| F5 | 278 | 99 | 99 | 29.8 | 1986 | 600 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Wu, Z.; Gong, Y. Study on Alkali-Activated Prefabricated Building Recycled Concrete Powder for Foamed Lightweight Soils. Materials 2023, 16, 4167. https://doi.org/10.3390/ma16114167

Xiao Y, Wu Z, Gong Y. Study on Alkali-Activated Prefabricated Building Recycled Concrete Powder for Foamed Lightweight Soils. Materials. 2023; 16(11):4167. https://doi.org/10.3390/ma16114167

Chicago/Turabian StyleXiao, Yao, Zhengguang Wu, and Yongfan Gong. 2023. "Study on Alkali-Activated Prefabricated Building Recycled Concrete Powder for Foamed Lightweight Soils" Materials 16, no. 11: 4167. https://doi.org/10.3390/ma16114167

APA StyleXiao, Y., Wu, Z., & Gong, Y. (2023). Study on Alkali-Activated Prefabricated Building Recycled Concrete Powder for Foamed Lightweight Soils. Materials, 16(11), 4167. https://doi.org/10.3390/ma16114167