Effect of Ultrasonic Vibration on Microstructure and Fluidity of Aluminum Alloy

Abstract

1. Introduction

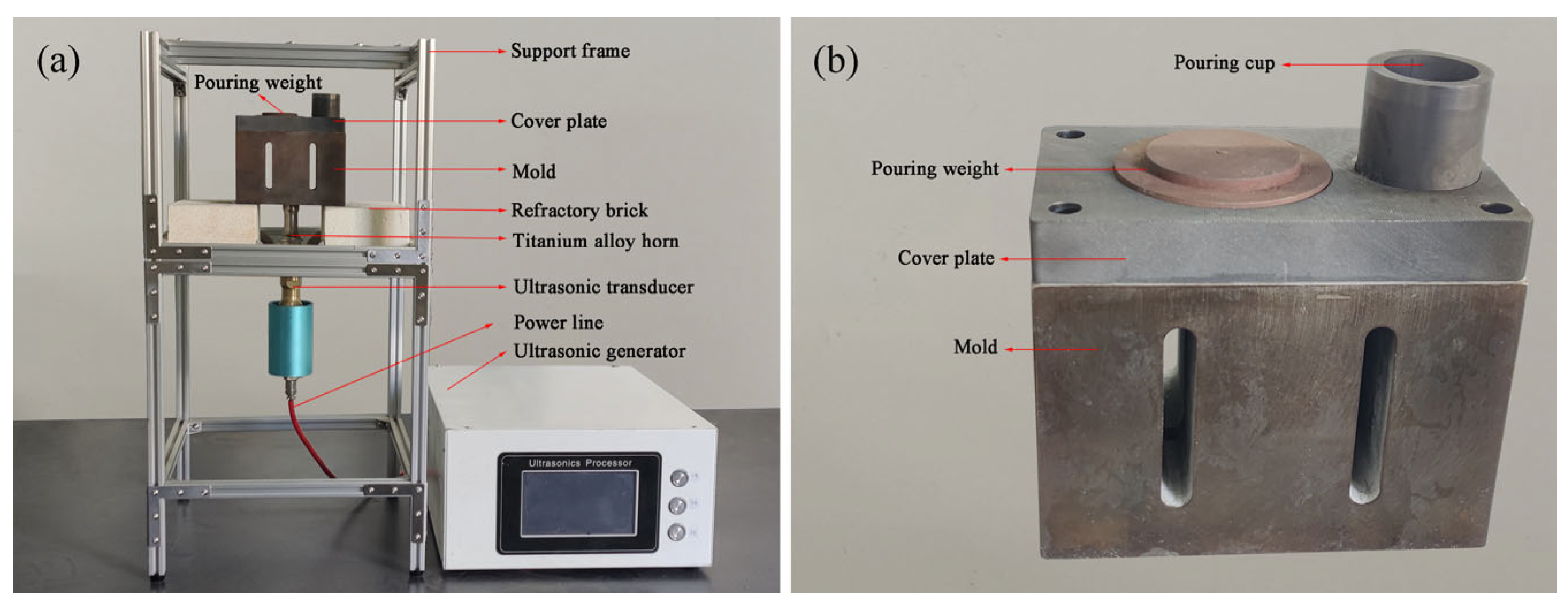

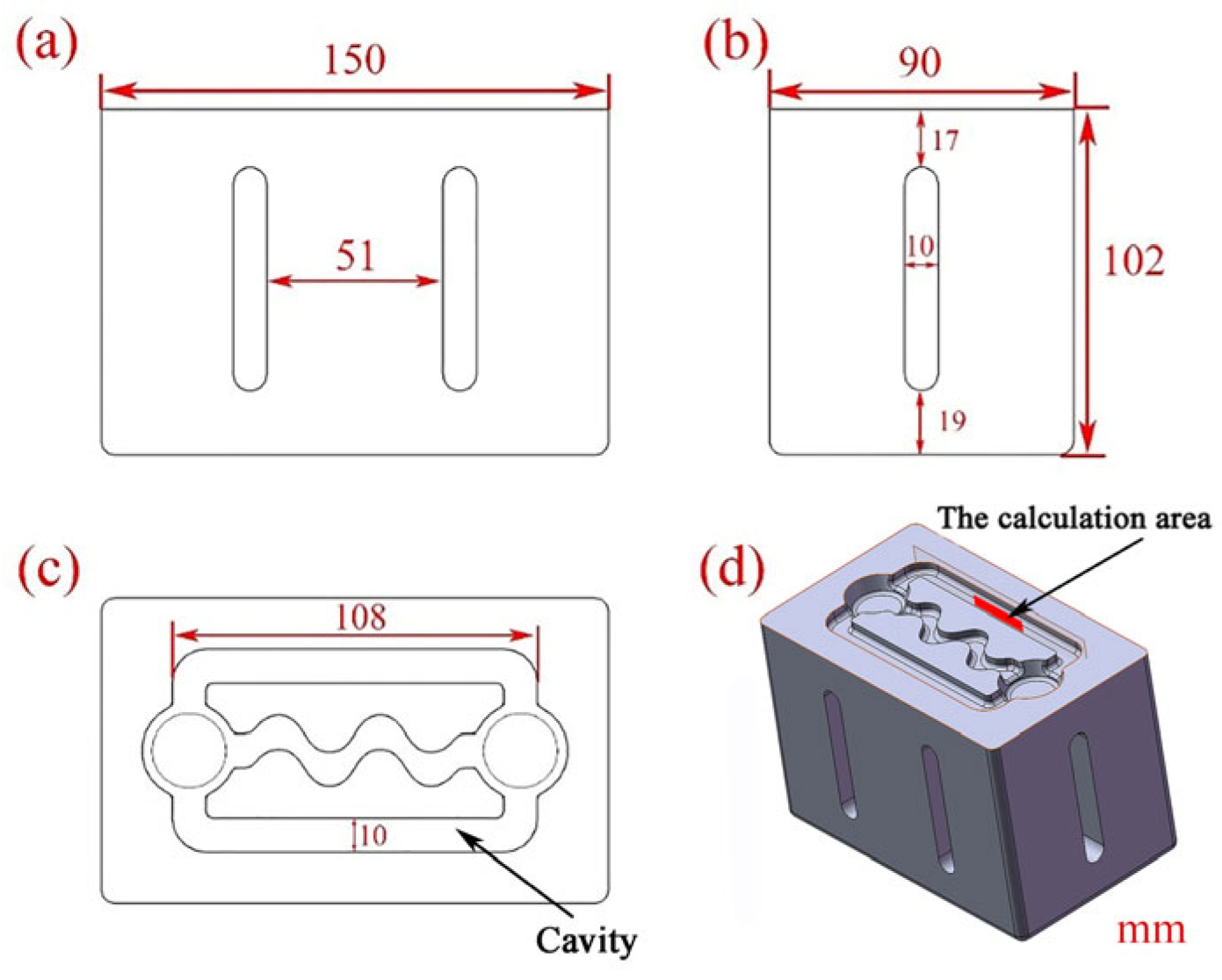

2. Experimental Procedure

3. Results and Discussion

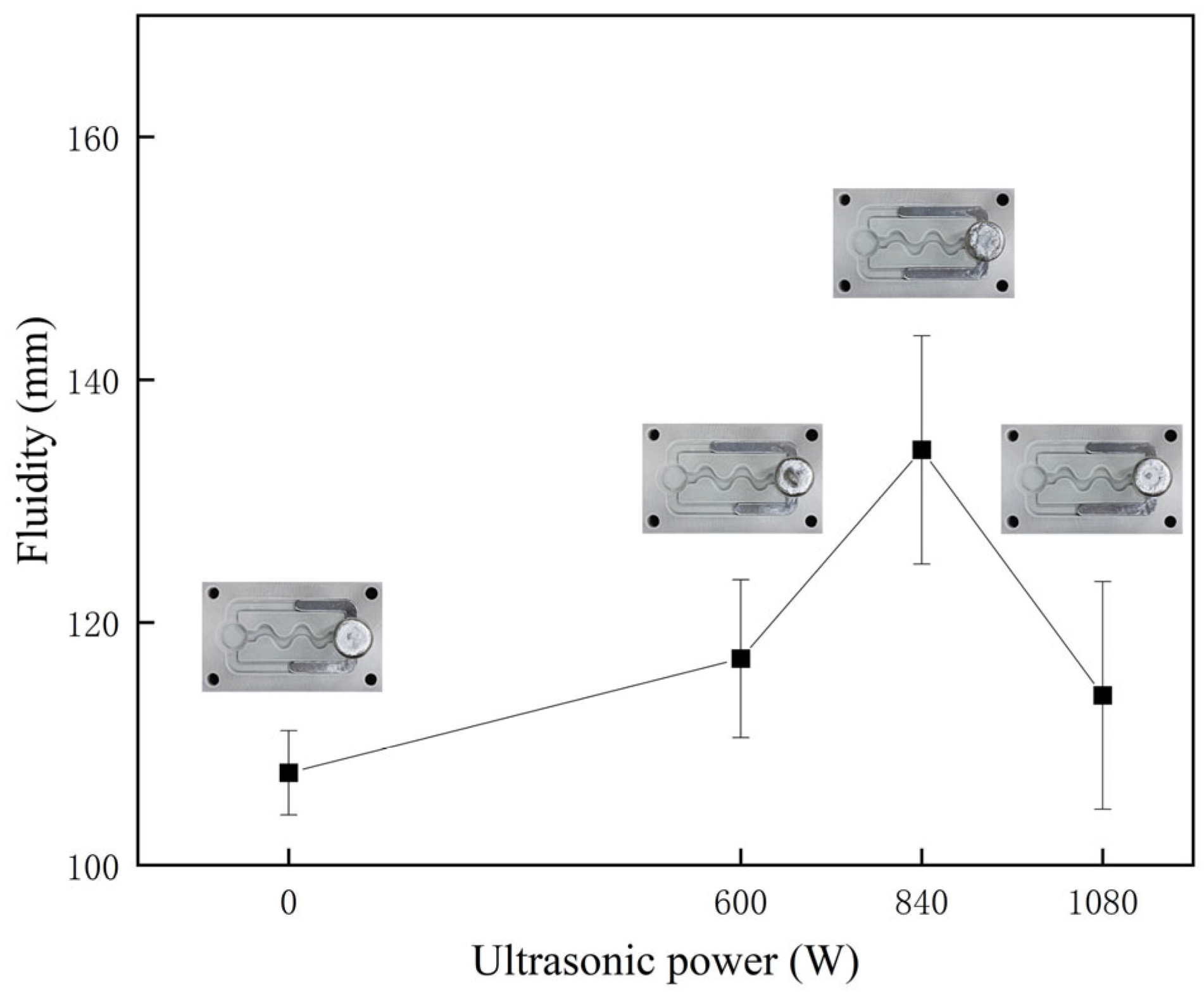

3.1. Effect of Ultrasonic Power on Alloy Fluidity

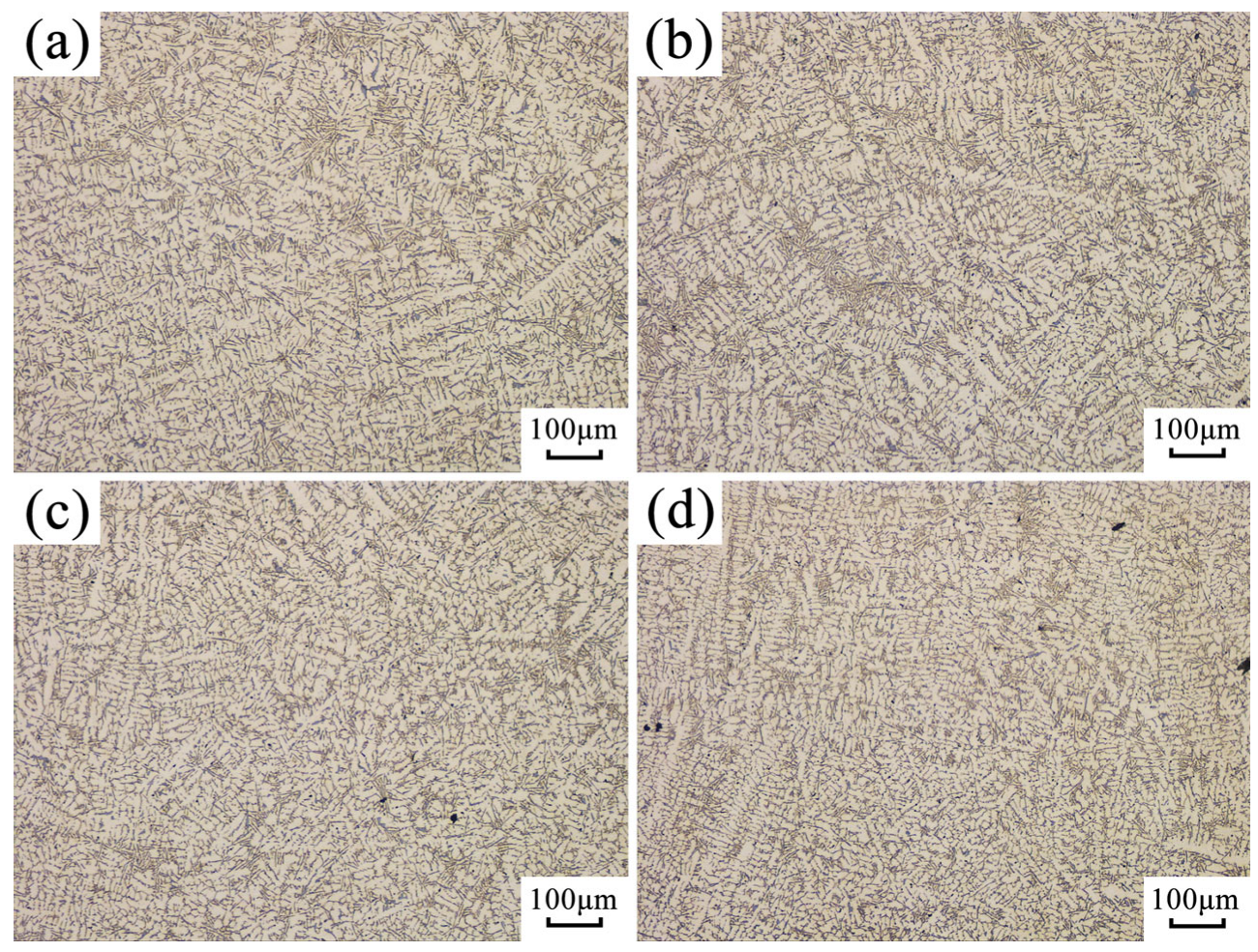

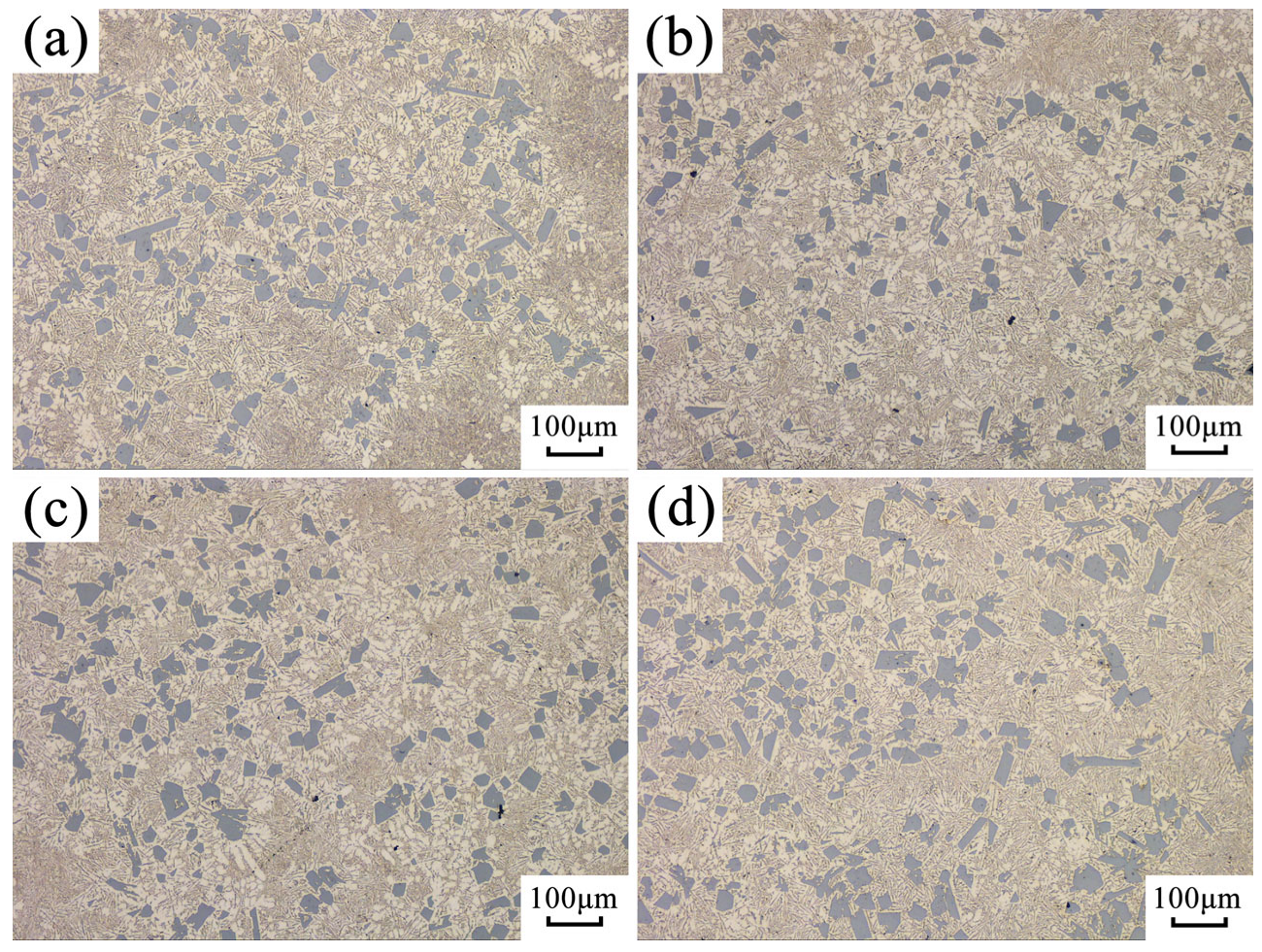

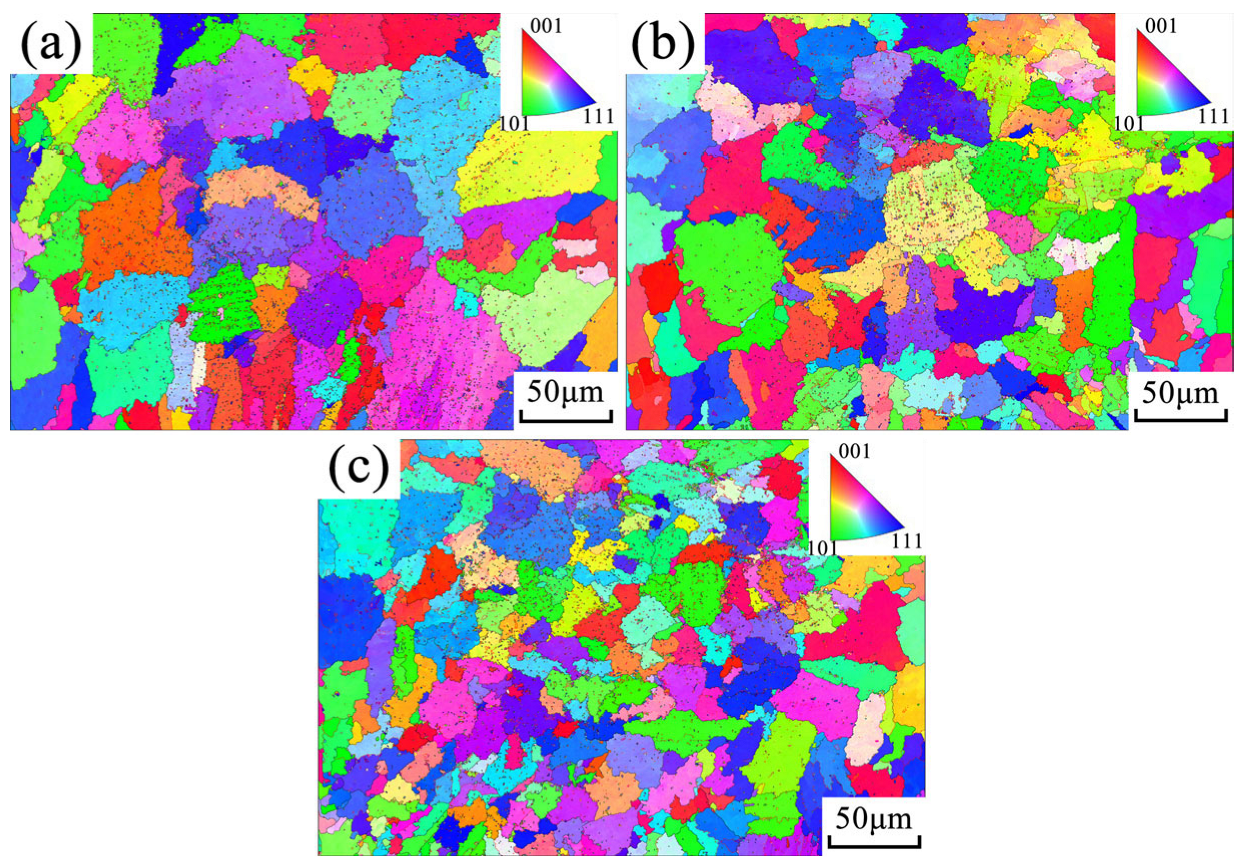

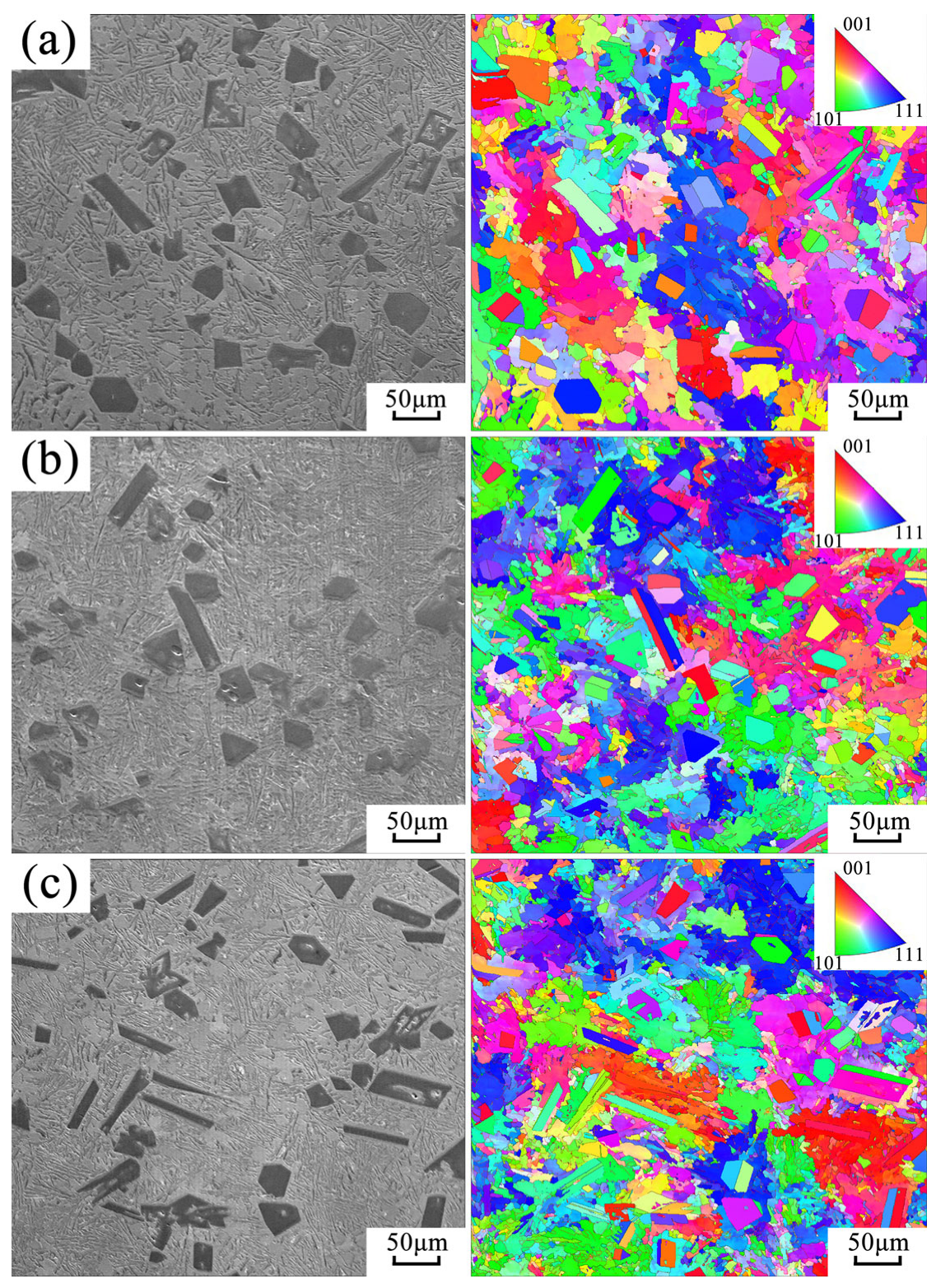

3.2. Effects of Ultrasonic Vibration on the Solidification Microstructure of Alloys

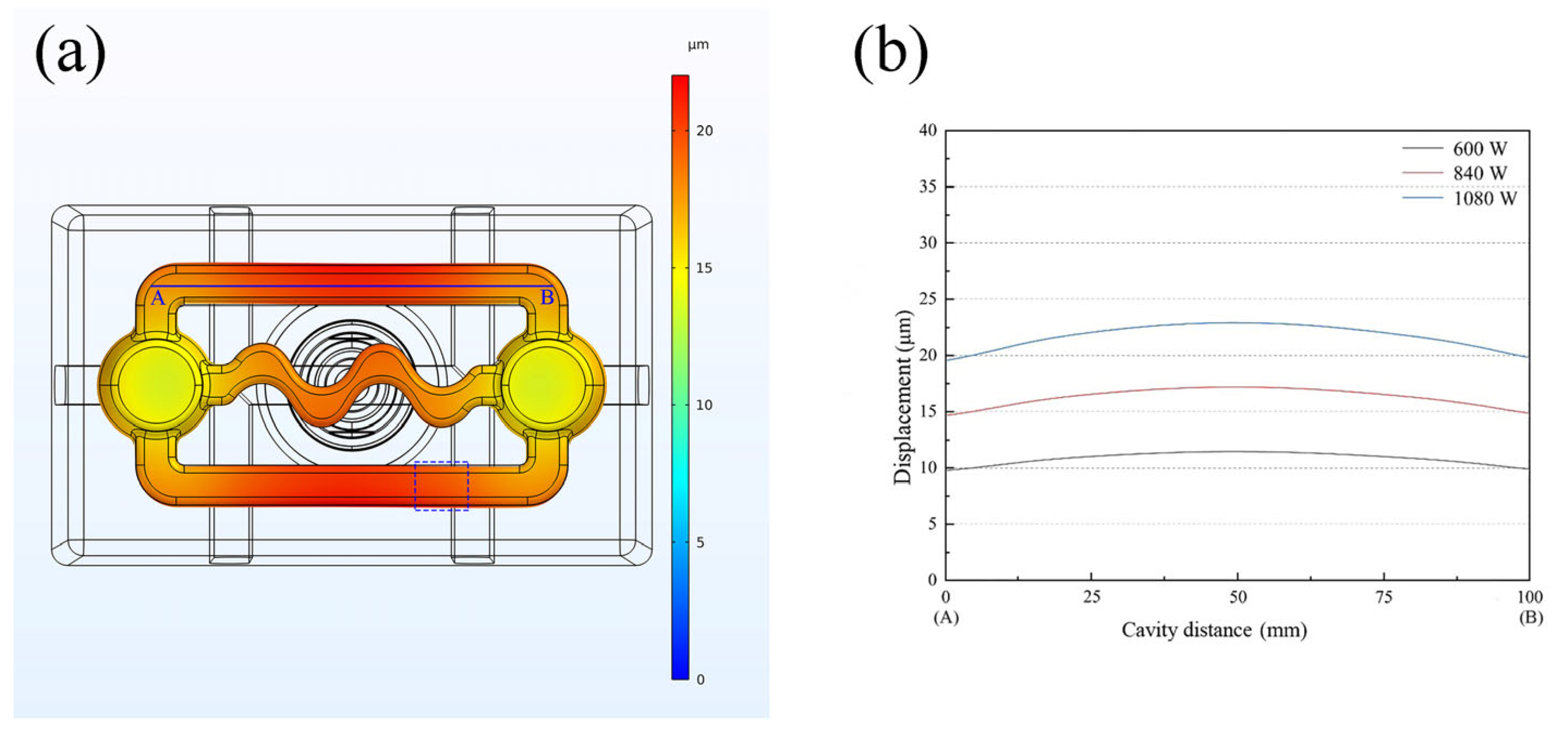

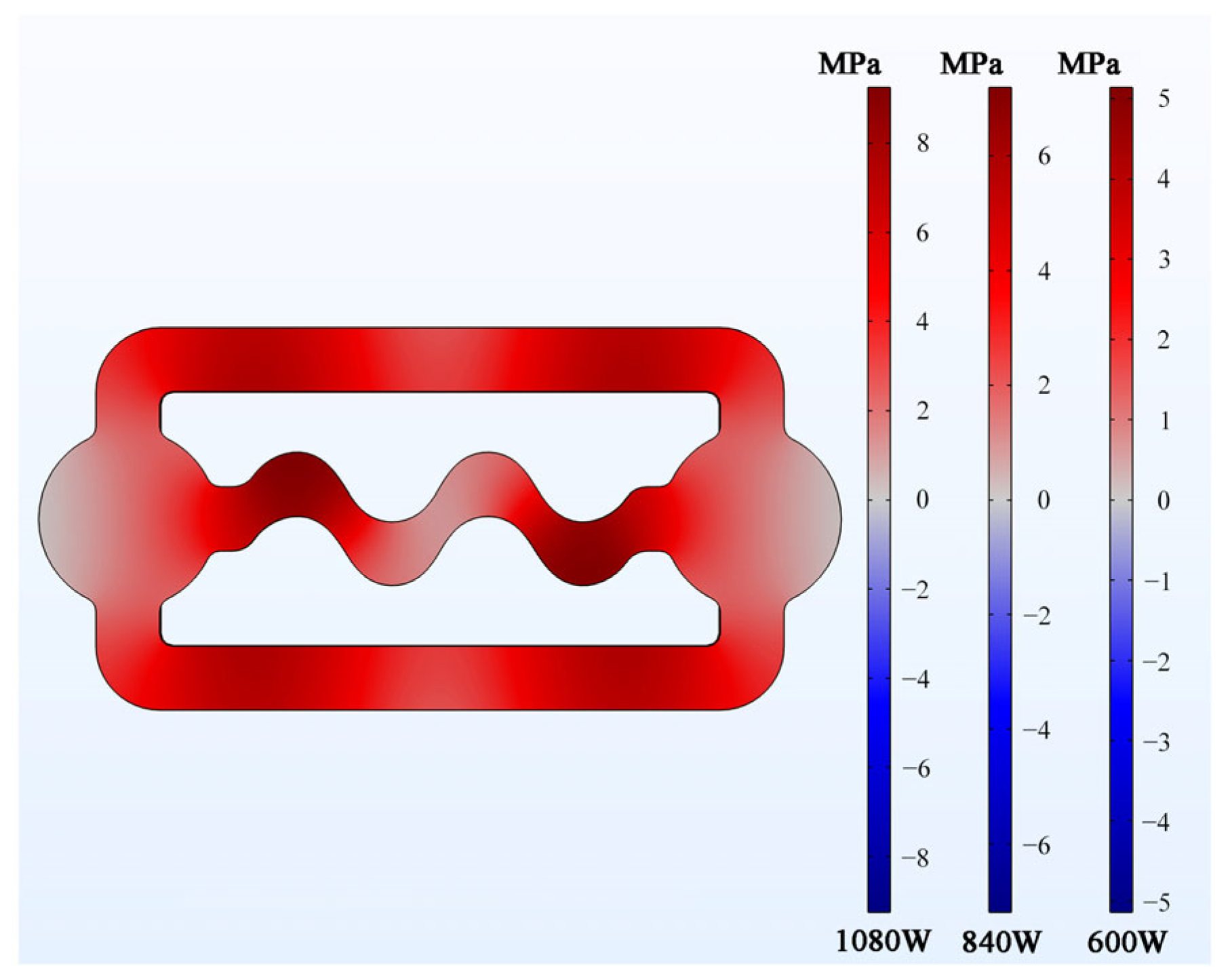

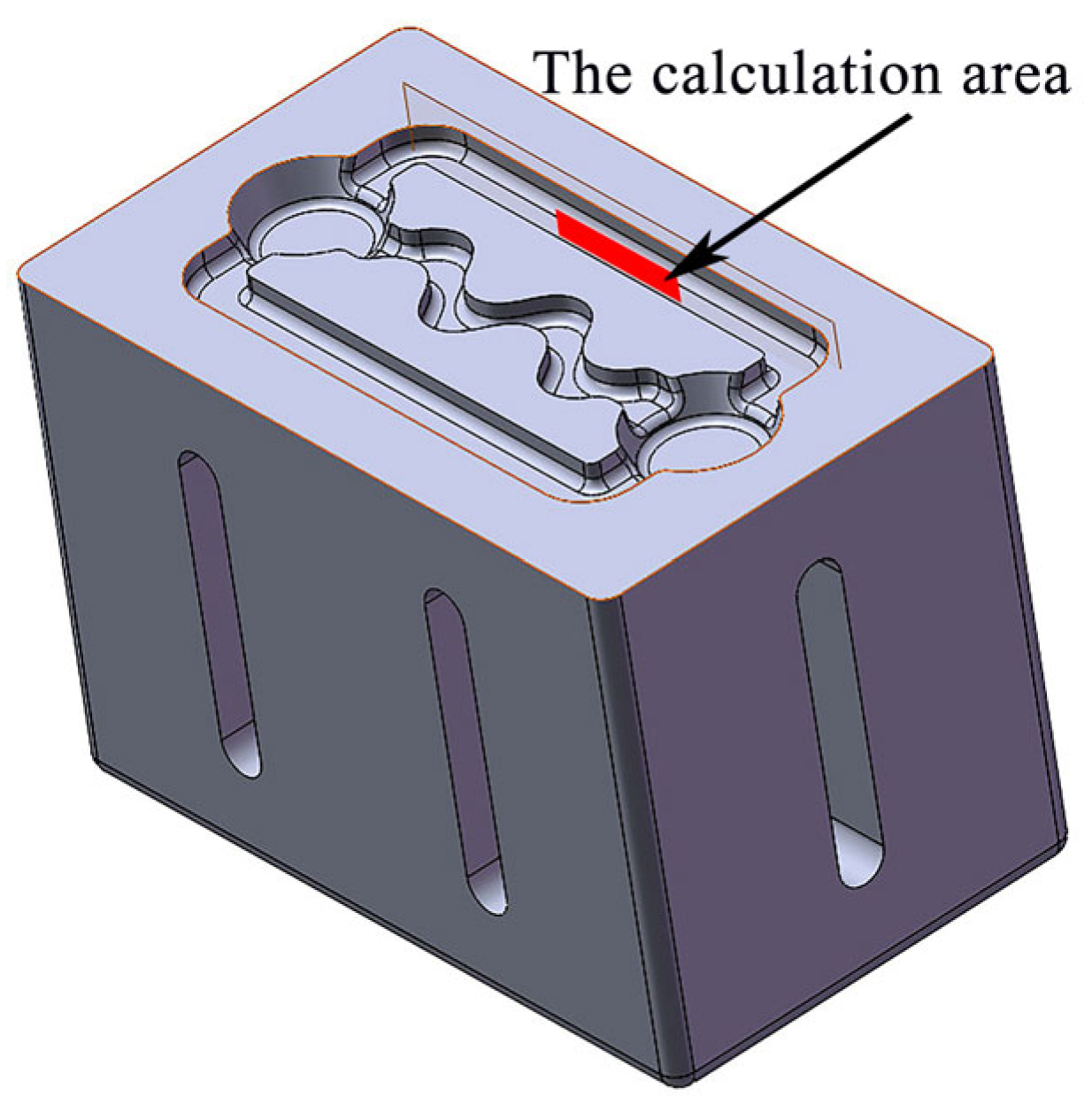

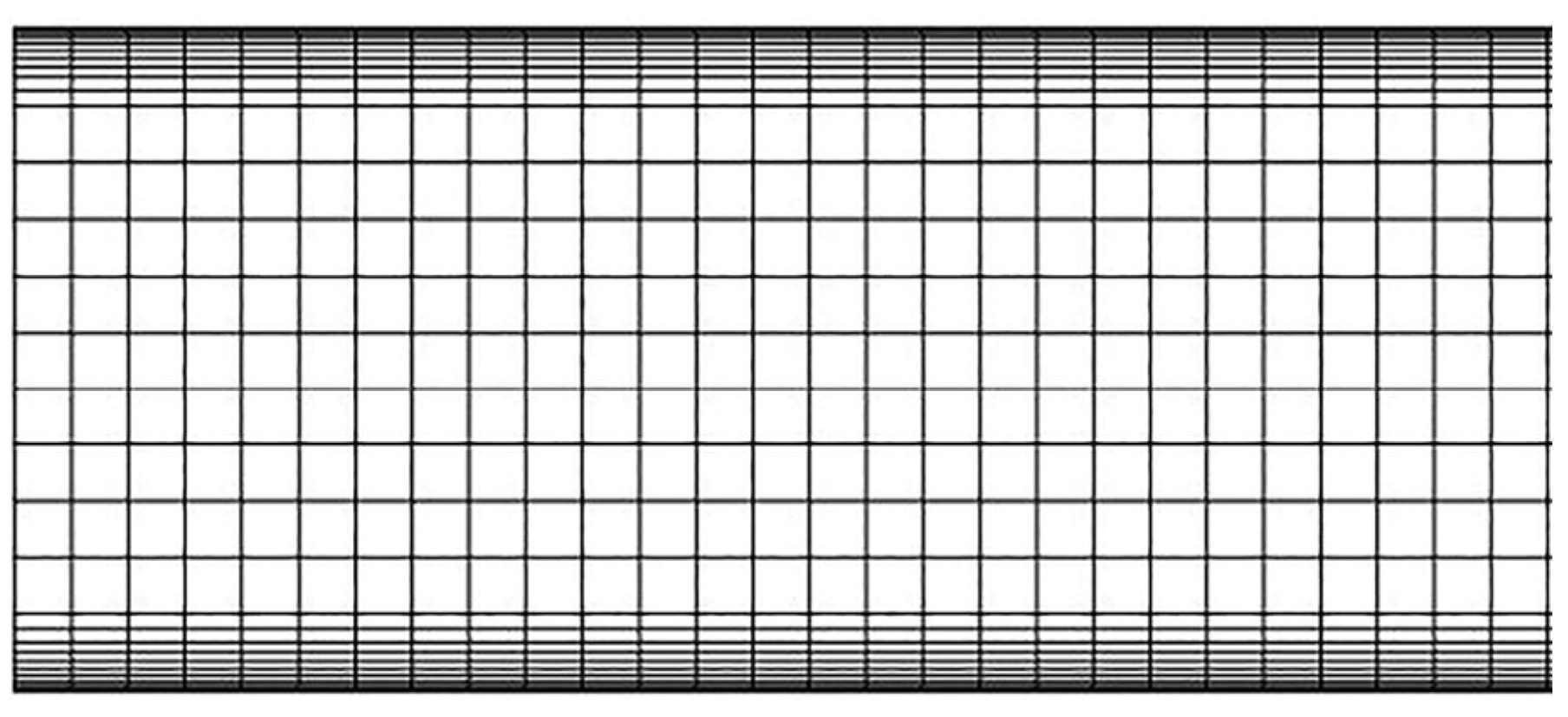

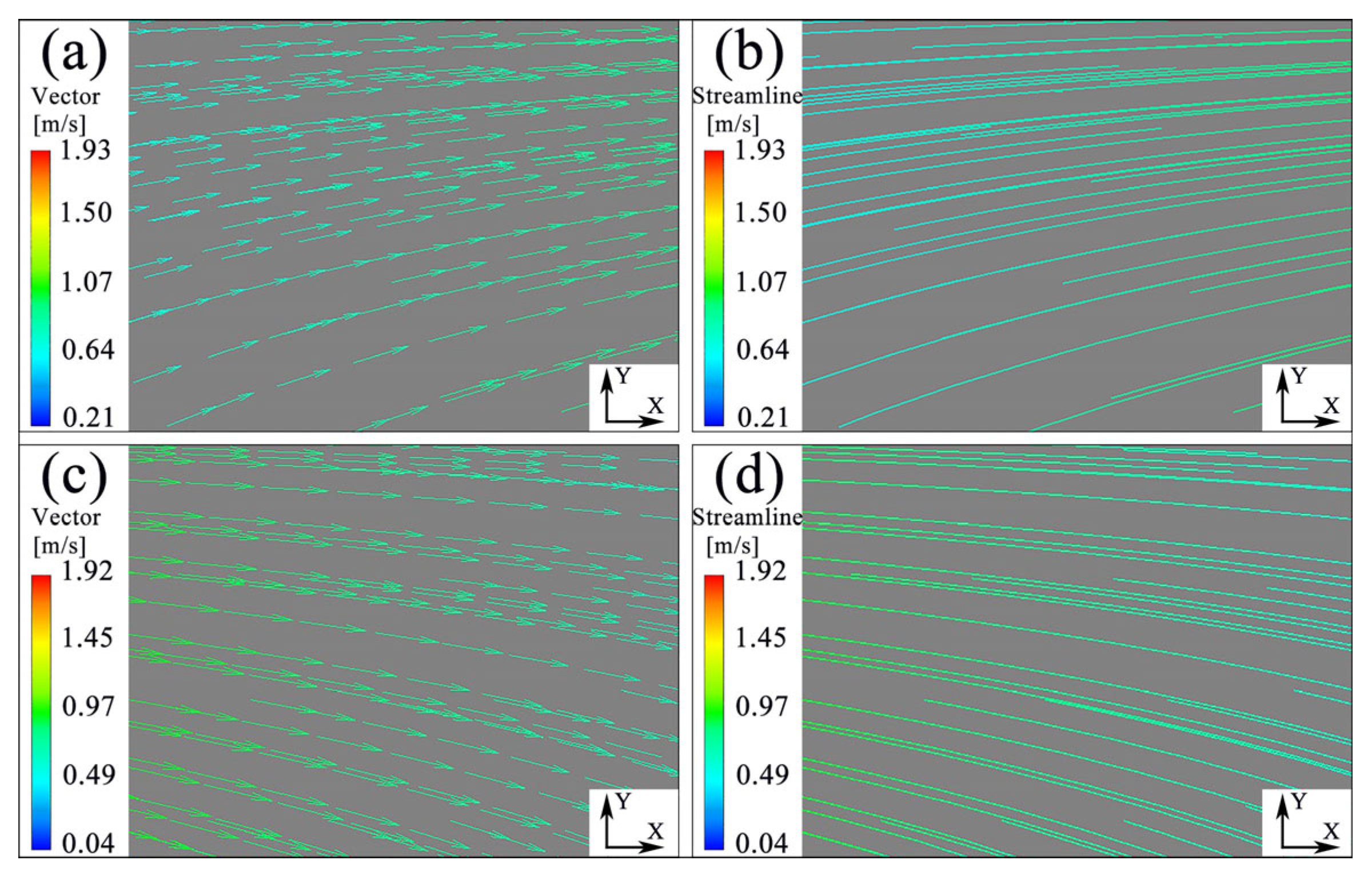

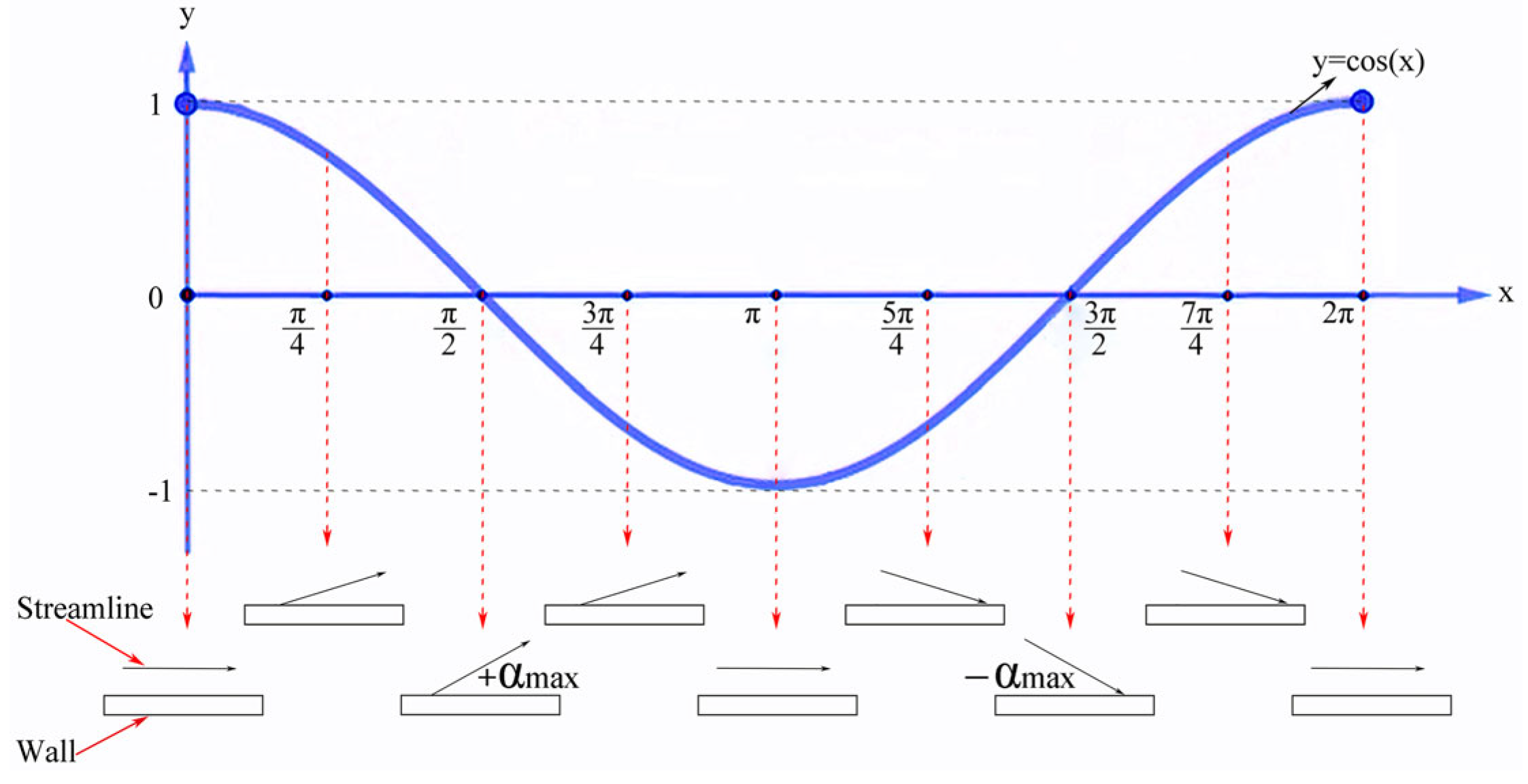

3.3. Effect of Ultrasonic Vibration on the Hydrodynamics of Melt Flow

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA; Gordon and Breach: London, UK, 2015. [Google Scholar]

- Xuan, Y.; Nastac, L. The role of ultrasonic cavitation in refining the microstructure of aluminum based nanocomposites during the solidification process. Ultrasonics 2018, 83, 94–102. [Google Scholar]

- Barbosa, J.; Puga, H. Ultrasonic melt processing in the low pressure investment casting of Al alloys. J. Mater. Process. Technol. 2017, 244, 150–156. [Google Scholar] [CrossRef]

- Chen, M.; Liu, Z.; Zheng, Q.; Sun, Q.; Zheng, B. Rapid preparation of B4Cp/Al composites with homogeneous interface via ul-trasound assisted casting method. J. Alloys Compd. 2021, 858, 157659. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Liu, Z.; Li, R.; Jiang, R.; Guan, S.; Liu, B. Scalable ultrasonic casting of large-scale 2219AA Al alloys: Experiment and simulation. Mater. Today Commun. 2021, 27, 102329. [Google Scholar]

- Qing-song, Y.; Gang, L.; Cheng, L.; Jia-li, S. Effect of synergistic action between ultrasonic power and solidification pressure on secondary dendrite arm spacing of vacuum counter–pressure casting aluminum alloy. Chin. J. Nonferrous Met. 2017, 27, 51–56. [Google Scholar]

- Lebon, G.S.B.; Salloum-Abou-Jaoude, G.; Eskin, D.; Tzanakis, I.; Pericleous, K.; Jarry, P. Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrason. Sonochem. 2019, 54, 171–182. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, X.; Li, R.; Jiang, R.; Zhang, L. Effects of high-intensity ultrasound on the microstructures and mechanical properties of ultra-large 2219 Al alloy ingot. Mater. Sci. Eng. A 2019, 19, 763. [Google Scholar] [CrossRef]

- Jiang, R.; Zhao, W.; Zhang, L.; Li, X.; Guan, S. Microstructure and corrosion resistance of commercial purity aluminum sheet manufactured by continuous casting direct rolling after ultrasonic melt pre-treatment. J. Mater. Res. Technol. 2023, 22, 1522–1532. [Google Scholar] [CrossRef]

- Mukkollu, S.R.; Kumar, A. Comparative study of slope casting technique in integration with ultrasonic mould vibration and conventional casting of aluminum alloy. Mater. Today Proc. 2020, 26, 1078–1081. [Google Scholar] [CrossRef]

- Yin, P.; Xu, C.; Pan, Q.; Guo, C.; Jiang, X. Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0. 3 alloy. Rev. Adv. Mater. Sci. 2021, 60, 946–955. [Google Scholar] [CrossRef]

- Bai, Y.; Mao, W.; Gao, S.; Tang, G.; Xu, J. Filling ability of semi-solid A356 aluminum alloy slurry in rheo-diecasting. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2008, 15, 48–52. [Google Scholar] [CrossRef]

- Prukkanon, W.; Srisukhumbowornchai, N.; Limmaneevichitr, C. Influence of Sc modification on the fluidity of an A356 aluminum alloy. J. Alloys Compd. 2009, 487, 453–457. [Google Scholar] [CrossRef]

- Dong, G.; Li, S.; Ma, S.; Zhang, D.; Bi, J.; Wang, J.; Starostenkov, M.D.; Xu, Z. Process optimization of A356 aluminum alloy wheel hub fabricated by low-pressure die casting with simulation and experimental coupling methods. J. Mater. Res. Technol. 2023, 24, 3118–3132. [Google Scholar] [CrossRef]

- Jung, W.J.; Mangiavacchi, N.; Akhavan, R. Suppression of turbulence in wall-bounded flows by high-frequency spanwise oscil-lations. Phys. Fluids A Fluid Dyn. 1992, 4, 1605–1607. [Google Scholar] [CrossRef]

- Laadhari, F.; Skandaji, L.; Morel, R. Turbulence reduction in a boundary layer by a local spanwise oscillating surface. Phys. Fluids 1994, 6, 3218–3220. [Google Scholar] [CrossRef]

- Trujillo, S.M.; Bogard, D.G.; Ball, K.S. Turbulent boundary layer drag reduction using an oscillating wall. In Proceedings of the 4th Shear Flow Control Conference, Snowmass Village, CO, USA, 29 June–2 July 1997; p. 1870. [Google Scholar]

- Choi, K.S.; Graham, M. Drag reduction of turbulent pipe flows by circular-wall oscillation. Phys. Fluids 1998, 10, 7–9. [Google Scholar] [CrossRef]

- Wu, X.J.; Wang, H.G. Study on the effect of rigid plate vibration on flow field. J. Eng. Therm. Energy Power 2020, 35, 162–168. [Google Scholar]

- Zhang, W.Y.; Yang, W.W.; Jiao, Y.H.; Zhang, D.W. Numerical study of periodical wall vibration effects on the heat transfer and fluid flow of internal turbulent flow. Int. J. Therm. Sci. 2022, 173, 107367. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental studies of ultrasonic melt processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef]

- Huang, H.; Qin, L.; Tang, H.; Shu, D.; Yan, W.; Sun, B.; Mi, J. Ultrasound cavitation induced nucleation in metal solidification: An analytical model and validation by real-time experiments. Ultrason. Sonochem. 2021, 80, 105832. [Google Scholar] [CrossRef]

- Wang, S.; Kang, J.; Guo, Z.; Lee, T.; Zhang, X.; Wang, Q.; Deng, C.; Mi, J. In situ high speed imaging study and modelling of the fatigue fragmentation of dendritic structures in ultrasonic fields. Acta Mater. 2019, 165, 388–397. [Google Scholar] [CrossRef]

- Priyadarshi, A.; Khavari, M.; Subroto, T.; Conte, M.; Prentice, P.; Pericleous, K.; Eskin, D.; Durodola, J.; Tzanakis, I. On the governing fragmentation mechanism of primary intermetallics by induced cavitation. Ultrason. Sonochem. 2021, 70, 105260. [Google Scholar] [CrossRef] [PubMed]

- Zi-Heng, H.; Zhi-Ming, W.; Zhi-Ping, S.; Bing-Rong, Z.; Wei-Feng, R. Influence of non-uniform ultrasonic vibration on casting fluidity of liquid aluminum alloy. China Foundry 2022, 19, 380–386. [Google Scholar]

- Wang, F.; Eskin, D.; Mi, J.; Wang, C.; Koe, B.; King, A.; Reinhard, C.; Connolley, T. A synchrotron X-radiography study of the fragmentation and refine-ment of primary intermetallic particles in an Al-35 Cu alloy induced by ultrasonic melt processing. Acta Mater. 2017, 141, 142–153. [Google Scholar] [CrossRef]

- Feng, H.K.; Yu, S.R.; Li, Y.L.; Gong, L.Y. Effect of ultrasonic treatment on microstructures of hypereutectic Al–Si alloy. J. Mater. Process. Technol. 2008, 208, 330–335. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Mi, J.; Connolley, T.; Lindsay, J.; Mounib, M. A refining mechanism of primary Al3Ti intermetallic particles by ultrasonic treatment in the liquid state. Acta Mater. 2016, 116, 354–363. [Google Scholar] [CrossRef]

| Materials | Density (kg·m−3) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| Structural steel | 7850 | 200 | 0.30 |

| Aluminum | 2700 | 70 | 0.33 |

| Ti-6Al-4V | 4510 | 113 | 0.34 |

| H13 | 7000 | 140 | 0.30 |

| Schemes | Alloy | Solidification Temperature Range (K) | Pouring Temperature (K) | Theoretical Degree of Superheat (K) | Ultrasonic Power (W) |

|---|---|---|---|---|---|

| 1 | AlSi9 | 865–807 | 973 | 108 | 0 |

| 2 | 600 | ||||

| 3 | 840 | ||||

| 4 | 1080 | ||||

| 5 | AlSi18 | 934–850 | 1003 | 69 | 0 |

| 6 | 600 | ||||

| 7 | 840 | ||||

| 8 | 1080 |

| Ultrasonic Power (W) | Average Secondary Dendrite Spacing (μm) |

|---|---|

| 0 | 12.45 ± 0.33 |

| 600 | 9.64 ± 0.34 |

| 840 | 8.42 ± 0.17 |

| 1080 | 7.55 ± 0.34 |

| Ultrasonic Power (W) | Average Grain Size (μm) |

|---|---|

| 0 | 352 ± 23 |

| 840 | 214 ± 37 |

| 1080 | 153 ± 16 |

| Amplitude (μm) | Reynolds Number |

|---|---|

| 0 | 284 |

| 5 | 314 |

| 10 | 338 |

| 15 | 362 |

| 20 | 2634 |

| 25 | 3246 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, A.; Wang, Z.; Sun, Z. Effect of Ultrasonic Vibration on Microstructure and Fluidity of Aluminum Alloy. Materials 2023, 16, 4110. https://doi.org/10.3390/ma16114110

Li A, Wang Z, Sun Z. Effect of Ultrasonic Vibration on Microstructure and Fluidity of Aluminum Alloy. Materials. 2023; 16(11):4110. https://doi.org/10.3390/ma16114110

Chicago/Turabian StyleLi, An, Zhiming Wang, and Zhiping Sun. 2023. "Effect of Ultrasonic Vibration on Microstructure and Fluidity of Aluminum Alloy" Materials 16, no. 11: 4110. https://doi.org/10.3390/ma16114110

APA StyleLi, A., Wang, Z., & Sun, Z. (2023). Effect of Ultrasonic Vibration on Microstructure and Fluidity of Aluminum Alloy. Materials, 16(11), 4110. https://doi.org/10.3390/ma16114110