Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective

Abstract

:1. Introduction

1.1. General Framework

1.2. Goal of the Study

- Highlight the importance of simultaneously evaluating repairing, recycling and using bio-based materials in CFRP sectors from a Circular Economy perspective to define the main drivers both on the environment and the economy;

- Couple LCA with LCC to obtain a broad assessment of the composites;

- Emphasize the importance of providing a preliminary environmental and economical assessment of emerging technologies;

- Outline the importance of needed efforts on repairing composite products to reduce their environmental impact, resource depletion and cost.

1.3. Life Cycle Assessment on Composites

1.4. Economic Sustainability of Composites EoL

2. Materials and Methods

2.1. Environmental Assessment

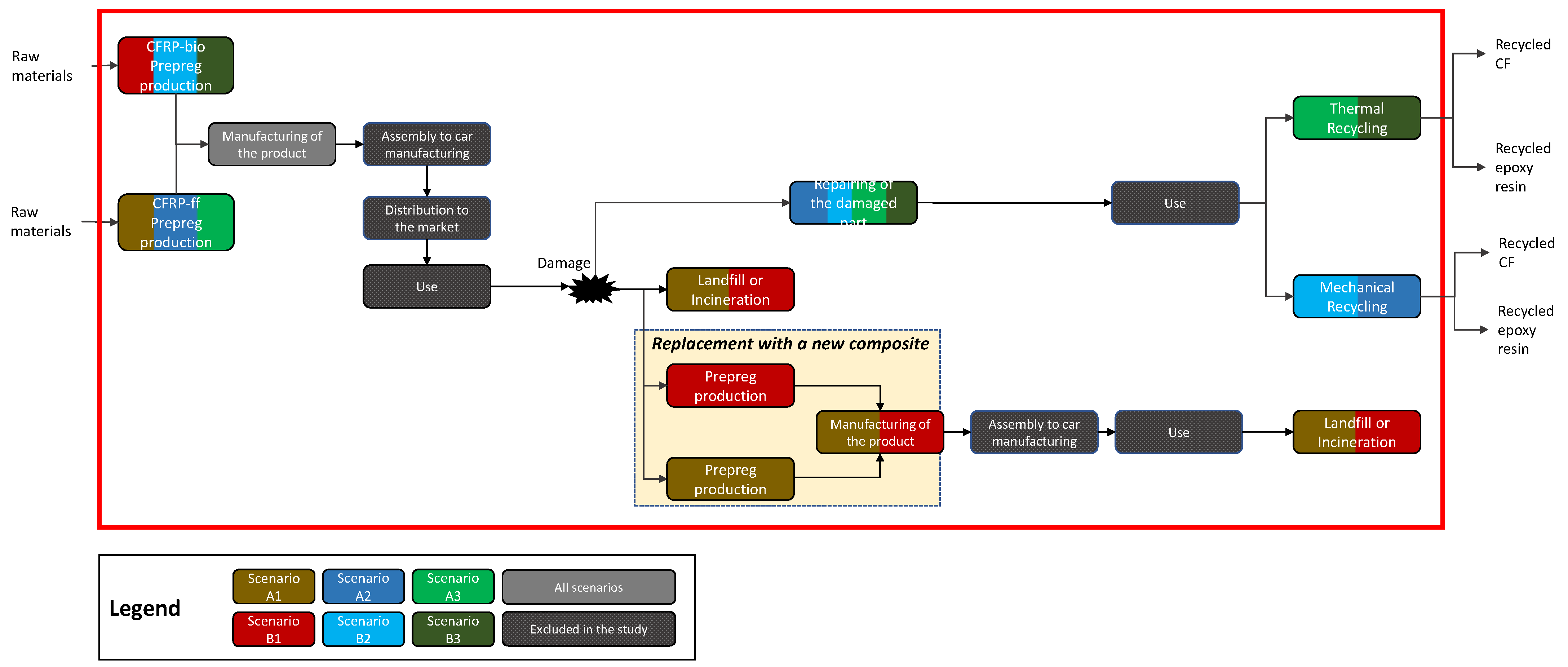

2.1.1. Goal and Scope Definition

- Type of materials used for the production of the CFRP product;

- Possibility of repairing the damaged part of the CFRP product;

- Different End-of-Life (EoL) of the CFRP.

Scenario Description

2.1.2. Life Cycle Inventory

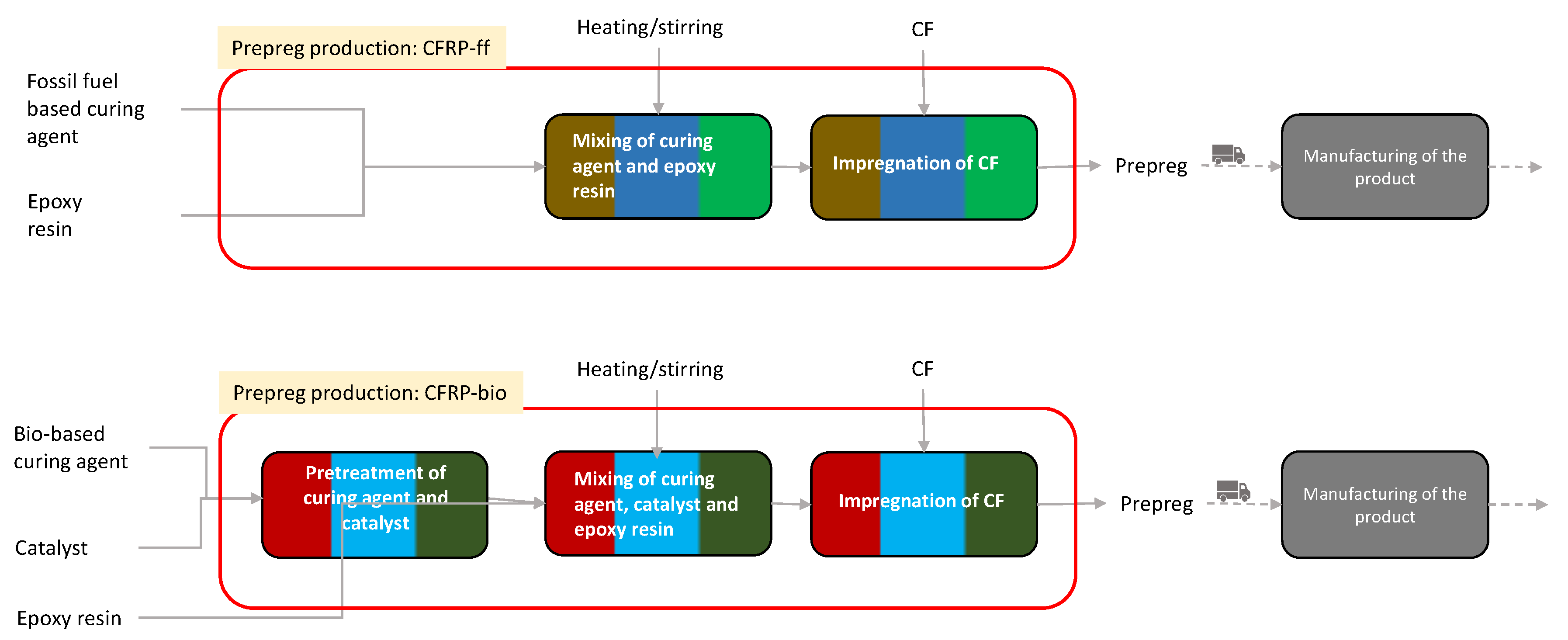

Production of the Prepreg

Manufacturing the Product

Use and Repairing

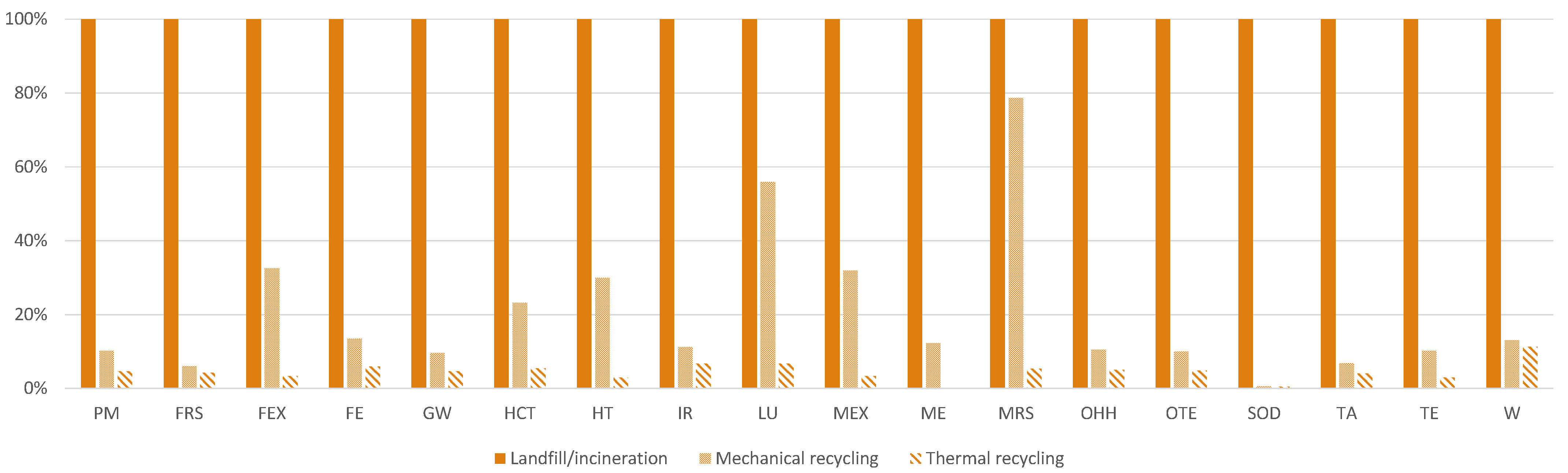

End of Life

Transportation

2.1.3. Life Cycle Impact Assessment Method

2.2. Economic Sustainability Assessment

2.2.1. Case Study Definition

- Two main industrial cases are taken into account for the repair producer. One case investigates the economic sustainability of the repair business when the paddle shifter is made from CFRP-ff, and the other assesses the profitability when the product is made from CFRP-bio.

- One main industrial case is taken into account for the thermal recyclers receiving either CFRP-ff or CFRP-bio waste. From an economic standpoint, the recycling processes of CFRP-ff waste or CFRP-bio waste are very much alike for the recycler for the following three reasons. First, the recycling process of both materials is precisely the same. Second, the acquisition cost of CFRP-ff and CFRP-bio wastes is the same for a recycler. Based on the interview with the operation manager of a recycling company, it is hypothesized that the recycler would pay no waste acquisition cost since companies in charge of dismantling would be relieved from sustaining recycling costs. In this framework, the recycler only bears the transportation cost of waste to its plant. Finally, since the percentage of CF in new CFRPs materials is almost the same (49% for CFRP-ff and 48% for CFRP-bio), it becomes evident that the financial results of a recycler receiving CFRP-ff waste or CFRP-bio are almost the same. In addition, in this study, the economic modeling of the recycler is not only restricted to the paddle shifter. Since recycling is a high-volume business in which its sustainability is based on the economy of scales, and the baseline product considered in our case study is a low-volume niche component produced with a limited quantity of raw materials. Thus, we hypothesized that the recycler receives various products from multiple customers built with the new recyclable material in order to aggregate massive volumes to be treated.

2.2.2. Cost and Revenue Breakdown Structure of Manufacturer

- The manufacturing cost includes the machinery, depreciation, labor, energy and overhead cost. Due to data confidentiality, the manufacturing cost of product is shown as a percentage of the whole product cost;

- The material cost of a product represents the cost of new repairable/recyclable composites: CFRP-ff or CFRP-bio. Due to data confidentiality, the material cost of product is shown as a percentage of the whole product cost;

- The investment cost of repair facilities includes purchasing the laser technology and its accessories;

- The maintenance cost includes one operator cleaning and taking care of the optics of laser technology;

- The repair cost consists of the energy consumption and labor needed to repair the damaged area. As described in Section ‘Use and Repairing’, the dimension of the damaged area is considered to be 1 cm. Given that the energy consumption of 1 cm is 0.111 kWh, and as the time needed to heal the damaged part is 5 s, the total repair cost of 1 cm is EUR 0.045 (as shown in Equations (1)–(3)).

- Selling of the product made either from CFRP-ff or CFRP-bio. Here, it is important to mention that the selling price of the paddle shifter made from the new repairable/recyclable CFRP is assumed to be the same as the product made from conventional CFRP. Since, based on the interviews with the case study company, the market might not accept an increase in the product price, and the best strategy is to keep the selling price at the same level of the conventional product. Here, it is also important to mention that the profit margin of this product is relatively high (50%) due to the high value-added of composite in the high-end automotive market.

2.2.3. Cost and Revenue Breakdown Structure of Recycler

- The investment cost includes purchasing the CO-assisted pyrolysis facilities. The investment cost of thermal recycling is EUR 550,000 for a plant of 250 ton/year;

- The maintenance cost includes the price of 1 h of work of an operator who cleans, lubricates and adjusts the thermal recycling machine after every 8 h cycle;

- The recycling cost includes the processing cost in terms of the depreciation, labor and energy cost;

- The overhead cost includes all administrative and accounting fees;

- The transportation cost includes delivering the EoL of CFRP waste to thermal recycler facilities. As mentioned in Table 9, the distance between the waste management company and the recycler is assumed to be 1000 km. Within these assumptions, the operation manager of the recycling company provided us the transportation cost of waste to be 0.20 EUR/kg, with a coefficient of +0.05 EUR/kg and −0.05 EUR/kg.

- Selling of the recycled CF to secondary applications. As mentioned in Table 8, the recovery rate of CF within the CO-assisted pyrolysis is 99%. Here, it is important to mention that the market price for selling the recycled CF is 5 EUR/kg, with a coefficient of +1 EUR/kg and −1 EUR/kg.

2.2.4. Assumptions

- The cost estimation of new repairable/recyclable composites is an important piece of information that is needed to carry out the LCC of the repair business model of a manufacturer using CFRP-ff or CFRP-bio in its production system. From the laboratory data, it is evident that the costs of the two new CF composites are higher than the conventional ones. Thus, proper cost estimation of the new material is critical. In this study, the top-down approach is applied to calculate the relative costs of CFRP-ff and CFRP-bio. The rationale behind using this method is the fact that there are uncertainties for cost analysis of the new CF composites that do not allow a detailed level cost analysis of the product. These uncertainties arise from the fact that these materials are developed in the laboratory, where the material costs are much higher and not comparable to the industry costs. For the top-down method, the expert judgement is used to calculate the relative costs of CFRP-ff and CFRP-bio. Three experts were selected and interviewed to evaluate the relative cost of the new CFRPs. A production manager, technical manager and the senior R&D manager of the case study company are all experienced in composite materials’ formulation and production and composite production technologies and processes. To estimate the industrial cost of the CFRP-ff and CFRP-bio (prepreg), the first step was to add up the costs of the production material and manufacturing as the initial building blocks of the total cost. Given that the production procedure of the CFRP-ff and CFRP-bio is the same as the conventional procedure, the manufacturing cost of the new materials was considered similar to that of the conventional materials. In other words, the main difference between newly developed CFRP and the conventional one lies in the material cost. Using the top-down method first, the relative material cost of the CFRP-ff and CFRP-bio is compared to the price of conventional CFRP. According to composite experts, the relative material cost of the CFRP-ff at the industrial scale can be 30% higher than the price of a conventional one with the coefficient of −20% to +20%. In other words, a 30% cost increase in the CFRP cost is considered as the base case, while the best case is where material increases by 10%, and the worst case is when a material cost increases by 50%. On the other hand, as the material cost of CFRP-bio is more expensive than the CFRP-ff, experts’ judgment indicated that the relative material cost for CFRP-bio can be 50% higher than the conventional CFRP with the coefficient of −20% and +20%. To estimate the final production cost of the new CFRP in addition to the material cost, it also important to know the cost breakdown structure of the CFRP. According to Graf et al. [89], in CFRP components, the material cost accounts for 36%, followed by 64% for the manufacturing cost. Based on this cost structure, when the material cost of CFRP-ff increases by 10%, 30% or 50%, the total cost of CFRP increases by 3.6%, 10.8% and 18%. Concerning CFRP-bio, when the material cost increases by 30%, 50% and 70%, the total cost increases by 10.8%, 18% and 25.2%.

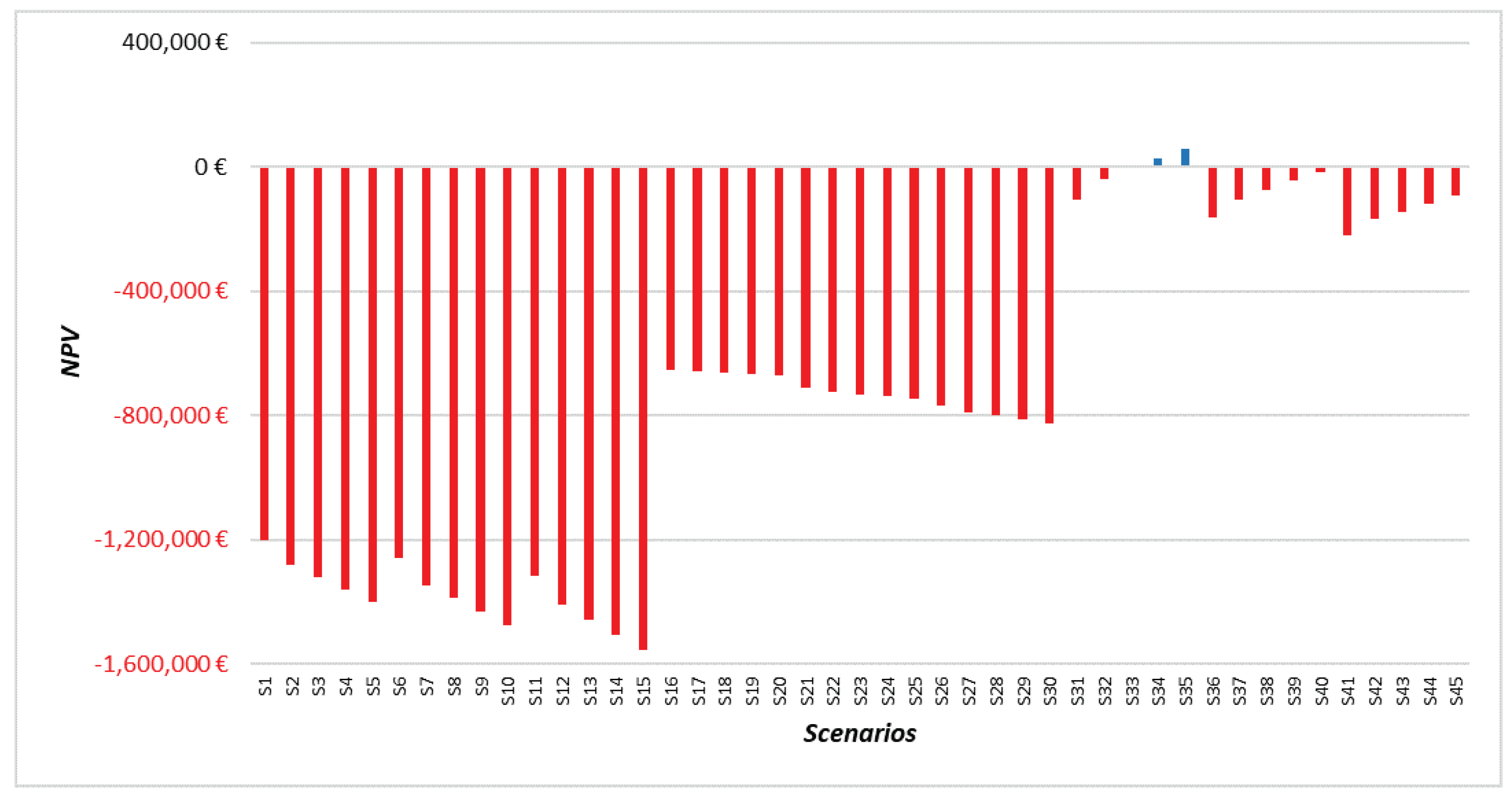

- In this study, a net present value (NPV) and discounted payback period of the investment are used to evaluate the economic performance of a system. The discount rate is assumed to be 10%, and the NPV is calculated over a period of 10 years.

2.2.5. Sensitivity Analysis

- Identification of the uncertain parameters;

- Definition of the potential ranges for the parameters resulting in various scenarios;

- The economic assessment of producer and thermal recycler carried out through feeding different value parameters into the economic model.

3. Results and Discussion

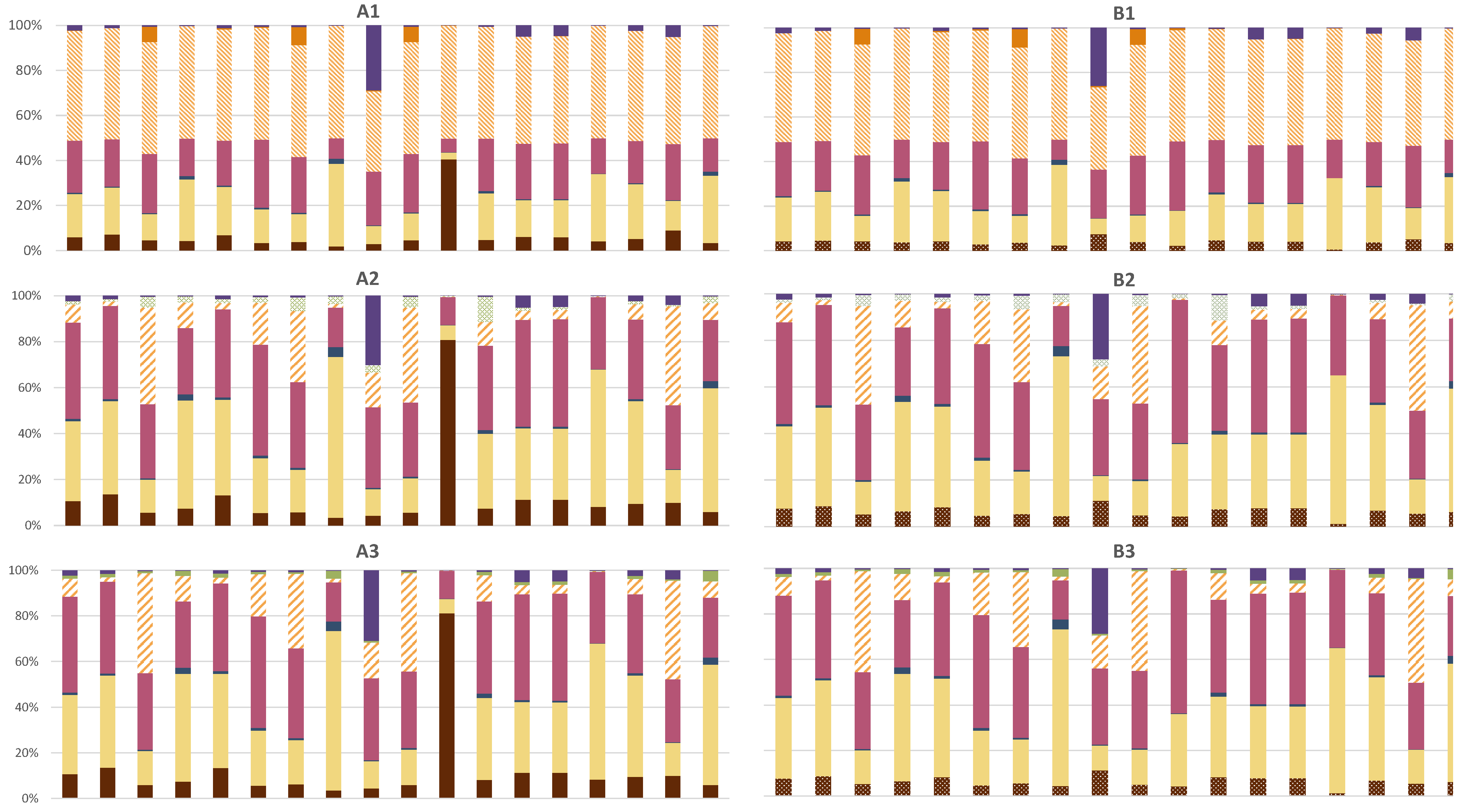

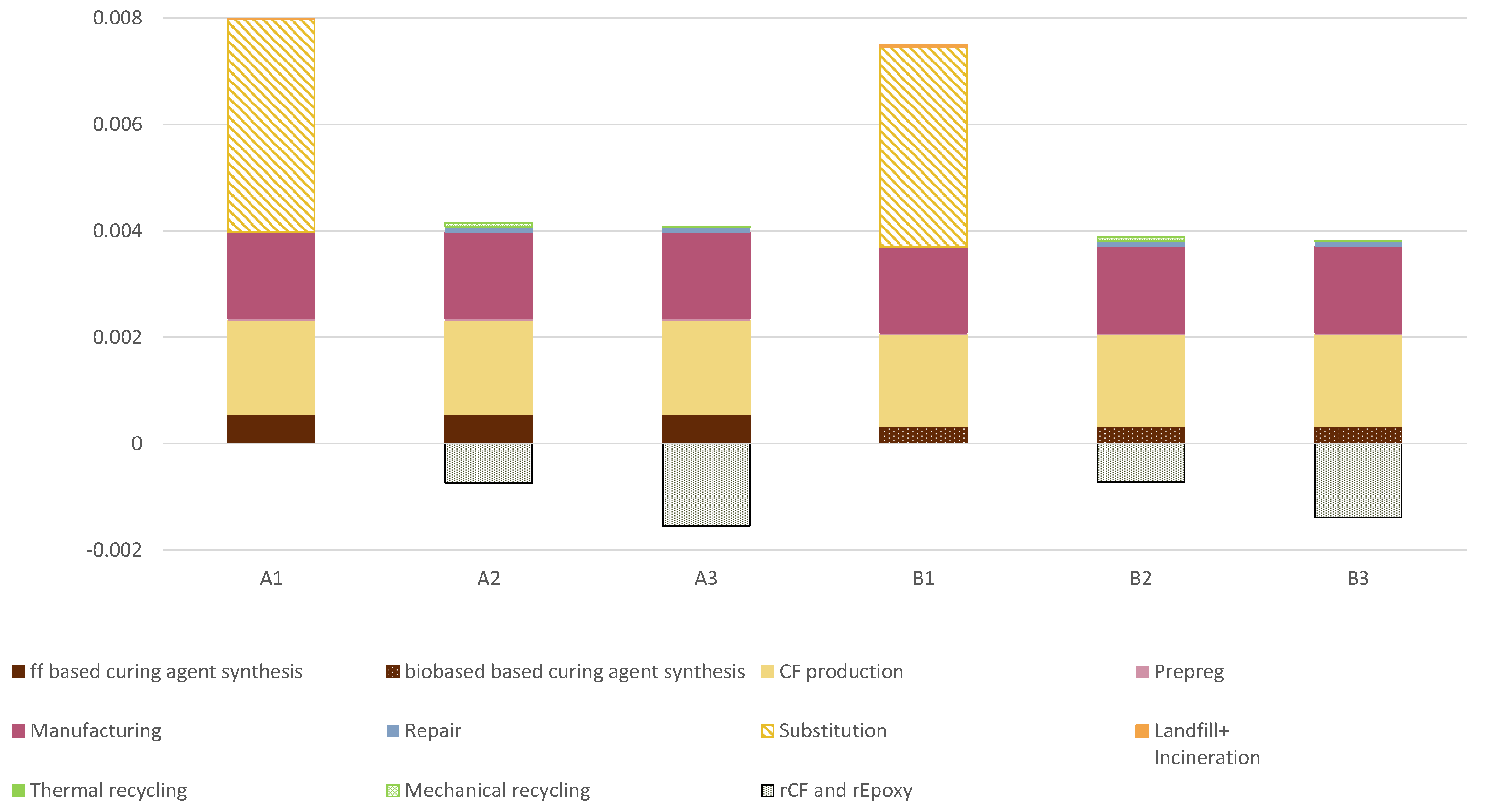

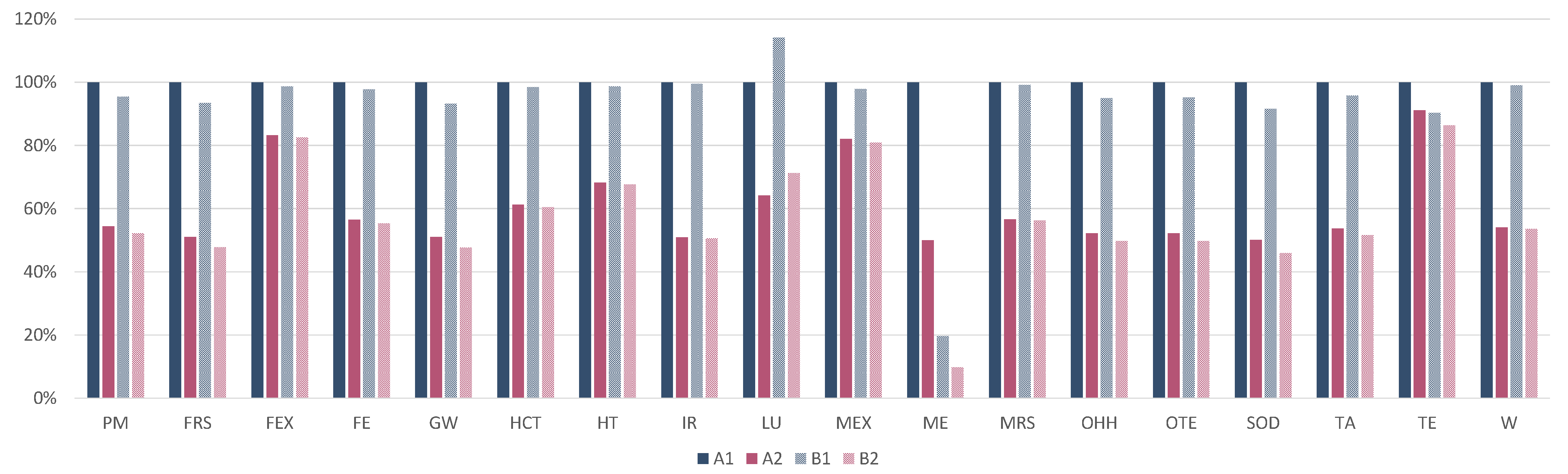

3.1. LCA Results

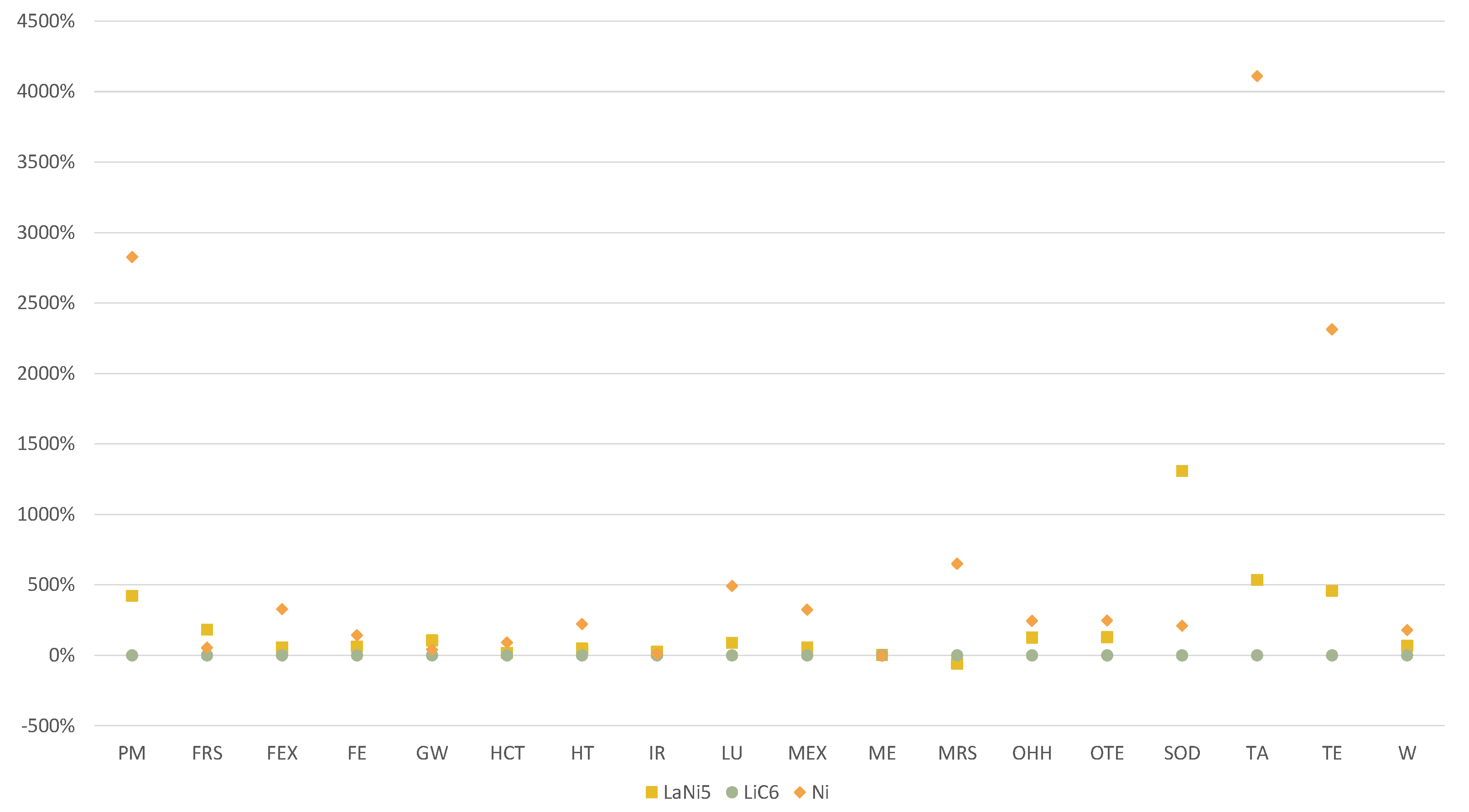

3.1.1. Sensitivity Analysis of LCA

- Fossil-fuel-based dynamic curing agent modeling;

- Electrodes modeling for mechanical recycling;

- Different EoLs of the damaged product in scenario A1.

3.2. LCC Results

3.2.1. Repair Business Model of a Producer

3.2.2. Thermal Recycling for a Recycler

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2014, 48, 593–608. [Google Scholar] [CrossRef]

- Altin Karataş, M.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Luzuriaga, A.R.D.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodriguez, J.; Odriozola, I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horizons 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Assocompositi. 2020 State of the Industry Report; Technical Report; Assocompositi: Milano, Italy, 2020. [Google Scholar]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef] [Green Version]

- Duflou, J.R.; De Moor, J.; Verpoest, I.; Dewulf, W. Environmental impact analysis of composite use in car manufacturing. Cirp Ann.—Manuf. Technol. 2009, 58, 9–12. [Google Scholar] [CrossRef]

- Scelsi, L.; Bonner, M.; Hodzic, A.; Soutis, C.; Wilson, C.; Scaife, R.; Ridgway, K. Potential emissions savings of lightweight composite aircraft components evaluated through life cycle assessment. Express Polym. Lett. 2011, 5, 209–217. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef] [Green Version]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Witten, E.; Sauer, M.; Kuhnel, M. Composites Market Report 2017; AVK (Federation of Reinforced Plastics): Frankfurt, Germany, 2017; pp. 1–44. [Google Scholar]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Eco-Efficiency in Industry and Science: Delft, The Netherlands, 2002. [Google Scholar] [CrossRef]

- Shafiee, M.; Alghamdi, A.; Sansom, C.; Hart, P.; Encinas-Oropesa, A. A through-life cost analysis model to support investment decision-making in concentrated solar power projects. Energies 2020, 13, 1553. [Google Scholar] [CrossRef] [Green Version]

- Jacquemin, L.; Pontalier, P.y.; Sablayrolles, C. Life cycle assessment ( LCA ) applied to the process industry: A review. Int. J. Life Cycle Assess. 2012, 17, 1028–1041. [Google Scholar] [CrossRef] [Green Version]

- Fortunato, G.; Anghileri, L.; Griffini, G.; Turri, S. Simultaneous recovery of matrix and fiber in carbon reinforced composites through a diels-alder solvolysis process. Polymers 2019, 11, 1007. [Google Scholar] [CrossRef] [Green Version]

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An eco-audit comparison. J. Clean. Prod. 2019, 212, 1268–1281. [Google Scholar] [CrossRef] [Green Version]

- Hadi, P.; Ning, C.; Ouyang, W.; Xu, M.; Lin, C.S.; McKay, G. Toward environmentally-benign utilization of nonmetallic fraction of waste printed circuit boards as modifier and precursor. Waste Manag. 2015, 35, 236–246. [Google Scholar] [CrossRef]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef] [Green Version]

- Ghobadi, A. Common Type of Damages in Composites and Their Inspections. World J. Mech. 2017, 7, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Jacques, K.; Bax, L.; Vasiliadis, H.; Magallon, I.; Ong, K. Polymer Composites for Automotive Sustainability; Technical Report; SUSCHEM: Bruxelles, Belgium, 2016. [Google Scholar]

- Delogu, M.; Zanchi, L.; Dattilo, C.A.; Ierides, M. Parameters affecting the sustainability trade-off between production and use stages in the automotive lightweight design. Procedia CIRP 2018, 69, 534–539. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2000/53/EC on end-of-life vehicles. Off. J. Eur. Union 2000. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32000L0053&from=EN (accessed on 15 February 2022).

- Marcelo, G.; Cherubini, E.; Orsi, P.; Roberto, S. Waste management Life Cycle Assessment: The case of a reciprocating air compressor in Brazil. J. Clean. Prod. 2014, 70, 164–174. [Google Scholar] [CrossRef]

- Yin, Z.; Li, C.; Tie, Y.; Duan, Y. Impact damage detection in patch-repaired CFRP laminates using nonlinear lamb waves. Sensors 2021, 21, 219. [Google Scholar] [CrossRef] [PubMed]

- Zaman, A.U.; Gutub, S.A.; Soliman, M.F.; Wafa, M.A. Sustainability and human health issues pertinent to fibre reinforced polymer composites usage: A review. J. Reinf. Plast. Compos. 2014, 33, 1069–1084. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Svanström, M. Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J. Clean. Prod. 2019, 223, 946–956. [Google Scholar] [CrossRef]

- Cucurachi, S.; Van Der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.B.; Christiansen, K.; Klüppel, H.J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- ISO. BS EN ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; Technical Report; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Rovelli, D.; Brondi, C.; Andreotti, M.; Abbate, E.; Zanforlin, M.; Ballarino, A. A Modular Tool to Support Data Management for LCA in Industry: Methodology, Application and Potentialities. Sustainability 2022, 14, 3746. [Google Scholar] [CrossRef]

- Fazeni, K.; Lindorfer, J.; Prammer, H. Methodological advancements in Life Cycle Process Design: A preliminary outlook. Resour. Conserv. Recycl. 2014, 92, 66–77. [Google Scholar] [CrossRef]

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A critical view on the current application of LCA for new technologies and recommendations for improved practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Walczak, K.A.; Hutchins, M.J.; Dornfeld, D. Energy system design to maximize net energy production considering uncertainty in scale-up: A case study in artificial photosynthesis. Procedia CIRP 2014, 15, 306–312. [Google Scholar] [CrossRef] [Green Version]

- Villares, M.; Işildar, A.; Mendoza Beltran, A.; Guinee, J. Applying an ex-ante life cycle perspective to metal recovery from e-waste using bioleaching. J. Clean. Prod. 2016, 129, 315–328. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to conduct prospective life cycle assessment for emerging technologies? A systematic review and methodological guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- Hesser, F. Environmental advantage by choice: Ex-ante LCA for a new Kraft pulp fibre reinforced polypropylene composite in comparison to reference materials. Compos. Part B Eng. 2015, 79, 197–203. [Google Scholar] [CrossRef]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life cycle assessment of emerging technologies: A review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Cornago, S.; Rovelli, D.; Brondi, C.; Crippa, M.; Morico, B.; Ballarino, A.; Dotelli, G. Stochastic consequential Life Cycle Assessment of technology substitution in the case of a novel PET chemical recycling technology. J. Clean. Prod. 2021, 311, 127406. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Hung, C.R.; Ellingsen, L.A.W.; Majeau-Bettez, G. LiSET: A Framework for Early-Stage Life Cycle Screening of Emerging Technologies. J. Ind. Ecol. 2020, 24, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Sain, M. Life cycle assessment and cost analysis of hybrid fiber-reinforced engine beauty cover in comparison with glass fiber-reinforced counterpart. Environ. Impact Assess. Rev. 2017, 65, 111–117. [Google Scholar] [CrossRef]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Raugei, M.; Morrey, D.; Hutchinson, A.; Winfield, P. A coherent life cycle assessment of a range of lightweighting strategies for compact vehicles. J. Clean. Prod. 2015, 108, 1168–1176. [Google Scholar] [CrossRef] [Green Version]

- La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Latteri, A.; Cicala, G. Recycling treatment of carbon fibre/epoxy composites: Materials recovery and characterization and environmental impacts through life cycle assessment. Compos. Part B Eng. 2016, 104, 17–25. [Google Scholar] [CrossRef]

- Rankine, R.K.; Chick, J.P.; Harrison, G.P. Energy and carbon audit of a rooftop wind turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2006, 220, 643–654. [Google Scholar] [CrossRef] [Green Version]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.M.; da Silva Moris, V.A.; de Paiva, J.M.F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess. 2018, 23, 1825–1838. [Google Scholar] [CrossRef] [Green Version]

- Duflou, J.R.; Yelin, D.; Van Acker, K.; Dewulf, W. Comparative impact assessment for flax fibre versus conventional glass fibre reinforced composites: Are bio-based reinforcement materials the way to go? Cirp Ann.—Manuf. Technol. 2014, 63, 45–48. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Khalil, Y.F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain. Prod. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Ahmed, I.M.; Tsavdaridis, K.D. Life cycle assessment (LCA) and cost (LCC) studies of lightweight composite flooring systems. J. Build. Eng. 2018, 20, 624–633. [Google Scholar] [CrossRef]

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental performance analysis of insulated composite facade panels using life cycle assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Mohammadi, S.; Yousefi, M.; Khazaei, M. A review on composite patch repairs and the most important parameters affecting its efficiency and durability. J. Reinf. Plast. Compos. 2021, 40, 3–15. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Norton, A.; Potter, K.D.; Hamerton, I. An evaluation of life cycle assessment and its application to the closed-loop recycling of carbon fibre reinforced polymers. Compos. Part B Eng. 2020, 184, 107665. [Google Scholar] [CrossRef]

- Roy, P.; Defersha, F.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Evaluation of the life cycle of an automotive component produced from biocomposite. J. Clean. Prod. 2020, 273, 123051. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Greco, S.; Tosto, C.; Cicala, G. LCA and LCC of a chemical recycling process of waste CF-thermoset composites for the production of novel CF-thermoplastic composites. Open loop and closed loop scenarios. J. Clean. Prod. 2021, 304, 127158. [Google Scholar] [CrossRef]

- Norris, G.A. Integrating life cycle cost analysis and LCA. Int. J. Life Cycle Assess. 2001, 6, 118–120. [Google Scholar] [CrossRef]

- Ghosh, C.; Maiti, J.; Shafiee, M.; Kumaraswamy, K.G. Reduction of life cycle costs for a contemporary helicopter through improvement of reliability and maintainability parameters. Int. J. Qual. Reliab. Manag. 2018, 35, 545–567. [Google Scholar] [CrossRef]

- Bernhard, R.H. Engineering Economics for Capital Investment Analysis; Rentice Hall: Englewood Cliffs, NJ, USA, 1992; Volume 38, pp. 72–73. [Google Scholar] [CrossRef]

- Strogonov, K.V. Energy and economic assessment of composite products production on the example of pipe products. In Proceedings of the 2021 3rd International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), Moscow, Russia, 11–13 March 2021; pp. 5–8. [Google Scholar]

- Castella, P.S.; Blanc, I.; Ferrer, M.G.; Ecabert, B.; Wakeman, M.; Manson, J.A.; Emery, D.; Han, S.H. Integrating life cycle costs and environmental impacts of composite rail car-bodies for a Korean train. Int. J. Life Cycle Assess. 2009, 14, 429–442. [Google Scholar] [CrossRef] [Green Version]

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite recycling in the construction industry. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1216–1222. [Google Scholar] [CrossRef]

- Gharfalkar, M.; Court, R.; Campbell, C.; Ali, Z.; Hillier, G. Analysis of waste hierarchy in the European waste directive 2008/ 98/EC. Waste Manag. 2015, 39, 305–313. [Google Scholar] [CrossRef] [PubMed]

- Henriksen, M.L.; Ravnsbæk, J.B.; Bjerring, M.; Vosegaard, T.; Daasbjerg, K.; Hinge, M. Epoxy Matrices Modified by Green Additives for Recyclable Materials. ChemSusChem 2017, 10, 2936–2944. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Forcellese, A.; Marconi, M.; Simoncini, M.; Vita, A. Life cycle impact assessment of different manufacturing technologies for automotive CFRP components. J. Clean. Prod. 2020, 271, 122677. [Google Scholar] [CrossRef]

- Duflou, J.R.; Deng, Y.; Van Acker, K.; Dewulf, W. Do fiber-reinforced polymer composites provide environmentally benign alternatives? A life-cycle-assessment-based study. MRS Bull. 2012, 37, 374–382. [Google Scholar] [CrossRef] [Green Version]

- Isola, C.; Sieverding, H.L.; Raghunathan, R.; Sibi, M.P.; Webster, D.C.; Sivaguru, J.; Stone, J.J. Life cycle assessment of photodegradable polymeric material derived from renewable bioresources. J. Clean. Prod. 2017, 142, 2935–2944. [Google Scholar] [CrossRef] [Green Version]

- Ashcroft, W.R. Curing agents for epoxy resins. In Chemistry and Technology of Epoxy Resins; Springer: Dordrecht, The Netherlands, 1993; pp. 37–71. [Google Scholar] [CrossRef]

- White, H.J. Amine curing agents for epoxy resins. J. Prot. Coat. Linings 1989, 6, 47–56. [Google Scholar]

- Davidson, M.G.; Elgie, S.; Parsons, S.; Young, T.J. Production of HMF, FDCA and their derived products: A review of life cycle assessment (LCA) and techno-economic analysis (TEA) studies. Green Chem. 2021, 23, 3154–3171. [Google Scholar] [CrossRef]

- Dessbesell, L.; Souzanchi, S.; Venkateswara Rao, K.T.; Carrillo, A.A.; Bekker, D.; Hall, K.A.; Lawrence, K.M.; Tait, C.L.J.; Xu, C. Production of 2,5-furandicarboxylic acid (FDCA) from starch, glucose, or high-fructose corn syrup: Techno-economic analysis. Biofuels Bioprod. Biorefining 2019, 13, 1234–1245. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.; Ahn, Y.; Lee, J.; Won, W. Sustainable Production of Bioplastics from Lignocellulosic Biomass: Technoeconomic Analysis and Life-Cycle Assessment. ACS Sustain. Chem. Eng. 2020, 8, 12419–12429. [Google Scholar] [CrossRef]

- Zervas, E.; Lazarou, C. Influence of European passenger cars weight to exhaust CO2 emissions. Energy Policy 2008, 36, 248–257. [Google Scholar] [CrossRef]

- Weh, A. High Voltage Pulse Fragmentation Technology to Recycle Fibre-Reinforced Composites; European Commission: Geneva, Switzerland, 2015; p. 12. [Google Scholar]

- Shuaib, N.A.; Mativenga, P.T. Carbon Footprint Analysis of Fibre Reinforced Composite Recycling Processes. Procedia Manuf. 2017, 7, 183–190. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Saviano, L. Recycling of Fibreglass Waste. (Original Version in Italian: “Riciclo dei Rifiuti in Vetroresina”. Korec. 2020. Available online: http://www.ko-rec.com/wp-content/uploads/2020/01/impaginato-pubblicato_bassa-risoluzione.pdf (accessed on 15 February 2022).

- Korec. Innovative Technology for the Fibreglass Waste Recycling. (Original version in Italian: “Processo Innovativo per il Riciclo dei Rifiuti in Vetroresina”. Available online: http://www.ko-rec.com/ (accessed on 15 February 2022).

- Da Via, F.; Suriano, R.; Boumezgane, O.; Grande, A.M.; Tonelli, C.; Turri, S. Self-healing behavior in blends of PDMS-based polyurethane ionomers. Polym. Adv. Technol. 2022, 33, 556–565. [Google Scholar] [CrossRef]

- European Commission. Electricity Price Statistics. 2021. Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics (accessed on 15 February 2022).

- European Commission. Wages and Labour Cost. 2020. Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Wages_and_labour_cost (accessed on 15 February 2022).

- Graf, J.; Gruber, K.; Shen, Y.; Reinhart, G. An Approach for the Sensory Integration into the Automated Production of Carbon Fiber Reinforced Plastics. Procedia CIRP 2016, 52, 280–285. [Google Scholar] [CrossRef]

- Alam, S.; Hedayati Dezfuli, F. Experiment-Based Sensitivity Analysis of Scaled Carbon-Fiber-Reinforced Elastomeric Isolators in Bonded Applications. Fibers 2016, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Yazdani, M.; Gonzalez, E.D.; Chatterjee, P. A multi-criteria decision-making framework for agriculture supply chain risk management under a circular economy context. Manag. Decis. 2019, 59, 1801–1826. [Google Scholar] [CrossRef]

- Brillinger, A.S.; Els, C.; Schäfer, B.; Bender, B. Business model risk and uncertainty factors: Toward building and maintaining profitable and sustainable business models. Bus. Horizons 2019, 63, 121–130. [Google Scholar] [CrossRef]

- Pegoretti, T.D.S.; Mathieux, F.; Evrard, D.; Brissaud, D.; Arruda, J.R.D.F. Use of recycled natural fibres in industrial products: A comparative LCA case study on acoustic components in the Brazilian automotive sector. Resour. Conserv. Recycl. 2014, 84, 1–14. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- National Institute for Public Health and Environment; Ministry of Health Welfare and Sport. Normalization scores ReCiPe 2016. 2020. Available online: https://www.rivm.nl/en/documenten/normalization-scores-recipe-2016 (accessed on 15 February 2022).

| Number of Scenario | Name of Composite | Composition | Repairing | End-of-Life |

|---|---|---|---|---|

| A1 | CFRP-ff | curing agent 1+epoxy resin+CF | No | 50% Landfill + 50% Incineration |

| A2 | Yes | Mechanical recycling | ||

| A3 | Yes | Thermal recycling | ||

| B1 | CFRP-bio | curing agent 2+epoxy resin+CF | No | 50% Landfill + 50% Incineration |

| B2 | Yes | Mechanical recycling | ||

| B3 | Yes | Thermal recycling |

| Production Process | Laboratory Scale (Unit = [g]) | Industrial Scale (Unit = [kg or t]) |

|---|---|---|

| Heating | Temperature, Duration | Energy and auxiliary material consumption |

| Stirring | Temperature, Rotation velocity, Duration | Energy and auxiliary material consumption |

| Grinding | Duration, Dimension of particles | Energy and auxiliary material consumption |

| Filtration | Auxiliary materials, Duration | energy and auxiliary material consumption |

| Production Process | Calculation |

|---|---|

| Heating | |

| Stirring | |

| Grinding | 8–16 kWh/ton |

| Filtration | 1–10 kWh/ton |

| Input | CFRP-ff | CFRP-bio |

|---|---|---|

| Epoxy resin (kg) | 0.7 | 0.70 |

| Fossil fuel based curing agent (kg) | 0.3 | - |

| Bio-based curing agent (kg) | - | 0.27 |

| Catalyst (kg) | - | 0.03 |

| Electricity (kWh) | 5.9 × 10 | 1.3 × 10 |

| Steam (kg) | - | 33.4 |

| Cooling water (kg) | - | 0.59 |

| Other auxiliary materials (kg) | - | 21.8 |

| Input | CFRP-ff | CFRP-bio |

|---|---|---|

| Epoxy resin (kg) | 0.51 | 0.52 |

| Carbon Fiber (CF) (kg) | 0.49 | 0.48 |

| Electricity (MJ) | 40 | 40 |

| Material | Quantity (kg) |

|---|---|

| Input | |

| Prepreg (CFRP-ff or CFRP-bio) | 15.7 |

| Electric energy (kWh) | 17.074 |

| Master mold in polyurethane foam | 30.5 |

| Mold (in CFRP) | 0.095 |

| Polyamide 66 (PA66) | 0.5 |

| Polyethylene terephthalate (PET) | 0.375 |

| Polytetrafluoroethylene (PTFE) | 0.055 |

| Organic solvent | 0.03 |

| output | |

| Paddle shifters | 11 |

| scraps of prepreg | 4.7 |

| scraps of master mold | 9.5 |

| Material | Quantity |

|---|---|

| Input | |

| Paddle shifters waste (kg) | 1 |

| Electric consumption (kWh) | 1 |

| electrodes (item) | 0.005 |

| Water (L) | 5 |

| output | |

| recycled CFRP (kg) | 0.6 |

| waste CFRP (kg) | 0.4 |

| Water losses (L) | 0.25 |

| Material | Quantity |

|---|---|

| Input | |

| Paddle shifters waste (kg) | 1 |

| Electric consumption (MJ) | 54 |

| output | |

| CFs recycling efficiency (%) | 0.99 |

| Epoxy resin recycling efficiency (%) | 0.85 |

| solid residue (kg) | 0.25 |

| Transportation | Distance (km) |

|---|---|

| CF to prepreg production site | 20,145 |

| Fossil-fuel-based epoxy resin to prepreg production site | 10,130 |

| Bio-based epoxy resin to prepreg production site | 10,130 |

| Prepreg production to paddle shifter manufacturing site | 1600 |

| CFRP waste to landfill/incineration | 50 |

| CFRP waste to repairing site | 150 |

| CFRP waste to mechanical recycling | 1000 |

| CFRP waste to thermal recycling | 1000 |

| Data | Unit of Measure | Value |

|---|---|---|

| Yearly product volume | piece/year | 800 |

| Cost of conventional CFRP (prepreg) | EUR/kg | 50 |

| Profit margin | % | 50 |

| Defect rate | % | 20 |

| Material cost compared to the total product cost | % | 2.2 |

| Manufacturing cost compared to the total product cost | % | 97.8 |

| Data | Unit of Measure | Value |

|---|---|---|

| Investment cost | EUR | 200k |

| Yearly maintenance cost of laser facility | EUR | 10k |

| Dimension of damage area | cm | 1 |

| Electricity consumption to repair the damage area | kWh | 0.111 |

| Electrical power cost | EUR/kWh | 0.1254 |

| Personnel wages | EUR/h | 28 |

| Time needed to repair the damage area | seconds | 5 |

| Data | Unit of Measure | Value |

|---|---|---|

| Investment cost of thermal recycling facilities | EUR | 550k |

| Capacity of plants | ton/year | 250 |

| Working days per year | day | 240 |

| Working hours per day | hour | 8 |

| Electrical power cost | EUR/kWh | 0.1254 |

| Personnel wages | EUR/h | 28 |

| Overhead and administration cost | % | 20 |

| Maintenance time (after every cycle of 8 h) | hour | 1 |

| Gas cost (CO) | EUR/ton | 150 |

| Transport cost | EUR/kg | 0.2 |

| Recycled CF price | EUR | 5 |

| Range | Relative Cost Increase Compared to the Conventional CFRP(%) | Cost of CFRP-ff (EUR/kg) |

|---|---|---|

| R1 | 3.6% | 51.8 |

| R2 | 10.8% | 55.4 |

| R3 | 18% | 59 |

| Range | Relative Cost Increase Compared to the Conventional CFRP(%) | Cost of CFRP-bio (EUR/kg) |

|---|---|---|

| R1 | 10.8% | 55.4 |

| R2 | 18% | 59 |

| R3 | 25.2% | 62.6 |

| Ranges | Price of Recycled CF (EUR/kg) | Transportation Cost (EUR/kg) | Annual Amount of Waste (ton/Year) |

|---|---|---|---|

| R1 | 4 | 0.15 | 187.5 |

| R2 | 5 | 0.20 | 212.5 |

| R3 | 6 | 0.25 | 225 |

| R4 | - | - | 237.5 |

| R5 | - | - | 250 |

| Impact Category | Unit | A1 | A2 | A3 | B1 | B2 | B3 |

|---|---|---|---|---|---|---|---|

| PM | kgPMeq | 1.20 × 10 | 6.66 × 10 | 5.43 × 10 (+) | 1.15 × 10 | 6.39 × 10 (−) | 5.41 × 10 |

| FRS | kgoileq | 2.67 × 10 (+) | 1.38 × 10 | 1.89 × 10 | 2.50 × 10 | 1.29 × 10 (−) | 1.80 × 10 |

| FEX | kg1,4-DCB | 3.89 × 10 | 3.16 × 10 | 4.60 × 10 (+) | 3.84 × 10 | 3.14 × 10 (−) | 4.57 × 10 |

| FE | kgPeq | 2.89 × 10 | 1.68 × 10 | 1.17 × 10 (+) | 2.83 × 10 | 1.65 × 10 (−) | 1.17 × 10 |

| GW | kgCOeq | 8.13 × 10 (+) | 4.21 × 10 | 4.14 × 10 | 7.60 × 10 | 3.94 × 10 | 3.87 × 10 (−) |

| HCT | kg1,4-DCB | 3.51 × 10 (+) | 2.19 × 10 | 3.34 × 10 | 3.46 × 10 | 2.17 × 10 (−) | 3.32 × 10 |

| HT | kg1,4-DCB | 6.54 × 10 (+) | 4.37 × 10 | 4.19 × 10 | 6.47 × 10 | 4.33 × 10 | 4.15 × 10 (−) |

| IR | kBqCo-60eq | 1.02 × 10 (+) | 5.37 × 10 | 5.29 × 10 | 1.02 × 10 | 5.35 × 10 | 5.26 × 10 (−) |

| LU | ma crop eq | 6.99 × 10 | 4.76 × 10 | 4.71 × 10 (−) | 7.70 × 10 (+) | 5.12 × 10 | 5.06 × 10 |

| MEX | kg1,4-DCB | 5.09 × 10 (+) | 4.08 × 10 | 3.89 × 10 | 4.99 × 10 | 4.03 × 10 | 3.84 × 10 (−) |

| ME | kgNeq | 1.13 × 10 (+) | 5.65 × 10 | 5.69 × 10 | 2.23 × 10 | 1.12 × 10 (−) | 1.16 × 10 |

| MRS | kgCueq | 2.04 × 10 (+) | 1.30 × 10 | 1.16 × 10 | 2.02 × 10 | 1.29 × 10 | 1.15 × 10 (−) |

| OHH | kgNOeq | 1.73 × 10 (+) | 9.16 × 10 | 9.67 × 10 | 1.65 × 10 | 8.76 × 10 (−) | 9.27 × 10 |

| OTE | kgNOeq | 1.83 × 10 (+) | 9.69 × 10 | 1.07 × 10 | 1.74 × 10 | 9.26 × 10 (−) | 1.03 × 10 |

| SOD | kgCFC11eq | 5.64 × 10 | 2.83 × 10 | 2.14 × 10 (+) | 5.17 × 10 | 2.59 × 10 (−) | 2.14 × 10 |

| TA | kgSOeq | 3.32 × 10 (+) | 1.81 × 10 | 1.78 × 10 | 3.18 × 10 | 1.74 × 10 | 1.72 × 10 (−) |

| TE | kg1,4-DCB | 1.86 × 10 (+) | 1.68 × 10 | 1.67 × 10 | 1.69 × 10 | 1.60 × 10 | 1.59 × 10 (−) |

| W | m | 3.11 × 10 (+) | 1.73 × 10 | 1.69 × 10 | 3.08 × 10 | 1.72 × 10 | 1.67 × 10 (−) |

| Scenarios | Cost of CFRP-ff (EUR/kg) | NPV (EUR) | Discounted Payback Period (Years) |

|---|---|---|---|

| S1 | 51.8 | +168,302 | 5 |

| S2 | 55.4 | +167,629 | 5 |

| S3 | 59 | +166,957 | 5 |

| Scenarios | Cost of CFRP-bio (EUR/kg) | NPV (EUR) | Discounted Payback Period (Years) |

|---|---|---|---|

| S1 | 55.4 | +167,629 | 5 |

| S2 | 59 | +166,957 | 5 |

| S3 | 62.6 | +166,284 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbate, E.; Mirpourian, M.; Brondi, C.; Ballarino, A.; Copani, G. Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective. Materials 2022, 15, 2986. https://doi.org/10.3390/ma15092986

Abbate E, Mirpourian M, Brondi C, Ballarino A, Copani G. Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective. Materials. 2022; 15(9):2986. https://doi.org/10.3390/ma15092986

Chicago/Turabian StyleAbbate, Elisabetta, Maryam Mirpourian, Carlo Brondi, Andrea Ballarino, and Giacomo Copani. 2022. "Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective" Materials 15, no. 9: 2986. https://doi.org/10.3390/ma15092986

APA StyleAbbate, E., Mirpourian, M., Brondi, C., Ballarino, A., & Copani, G. (2022). Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective. Materials, 15(9), 2986. https://doi.org/10.3390/ma15092986