Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review

Abstract

:1. Introduction

- Heap leaching is the method of extracting metals from chemical solutions by allowing them to percolate. Low-grade ore that would otherwise not be economically sent through a milling process is often utilized in heap leaching. The crushed ore is placed into a heap on top of an impermeable layer, on a little slope, after mining, shipping and crushing to a constant gravel or golf ball size. The copper from the ore is dispersed in the leaching agent (diluted sulfuric acid), which is sprayed via sprinklers on top of the heap pile and allowed to flow down into the heap. A small pool is used to collect the copper sulfate and sulfuric acid “pregnant” leach solution that results. Currently, concentrations of the copper complex range from 60 to 70 percent.

- The second stage is solvent extraction, which involves stirring and allowing two immiscible (non-mixing) liquids to separate, causing the copper to transfer from one liquid to the other. A solvent is aggressively combined with the pregnant leach solution. The copper migrates into the solvent from the leach solution. The two liquids are then allowed to separate depending on solubility, with the contaminants staying in the leach solution while copper remain in solution in the solvent. The remaining leach solution is then recycled by adding more acid and returning it to the heap leaching sprinklers.

- The last stage is an electrolysis process known as electrowinning. An inert anode (positive electrode) and the copper solution from the prior phase, which functions as an electrolyte, are both contacted by an electrical current. Next, 99.99 percent pure copper is deposited onto a cathode (negative electrode) as positively charged copper ions (referred to as cations) emerge from solution. The manufacture process of copper slag in the industry is displayed in Figure 1. CPS is often a dark black color, as seen in Figure 2.

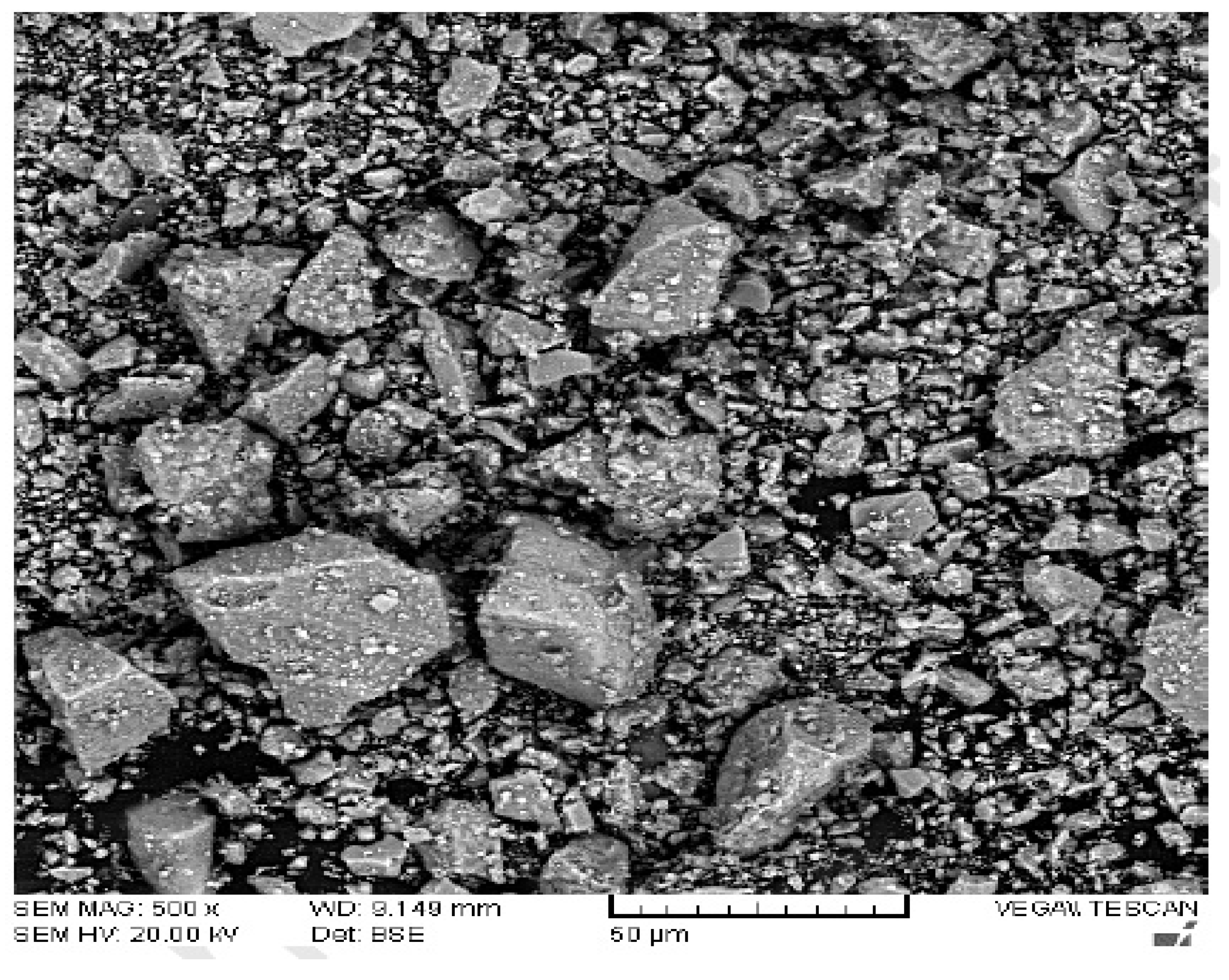

2. Physical and Chemical Compositions of CPS

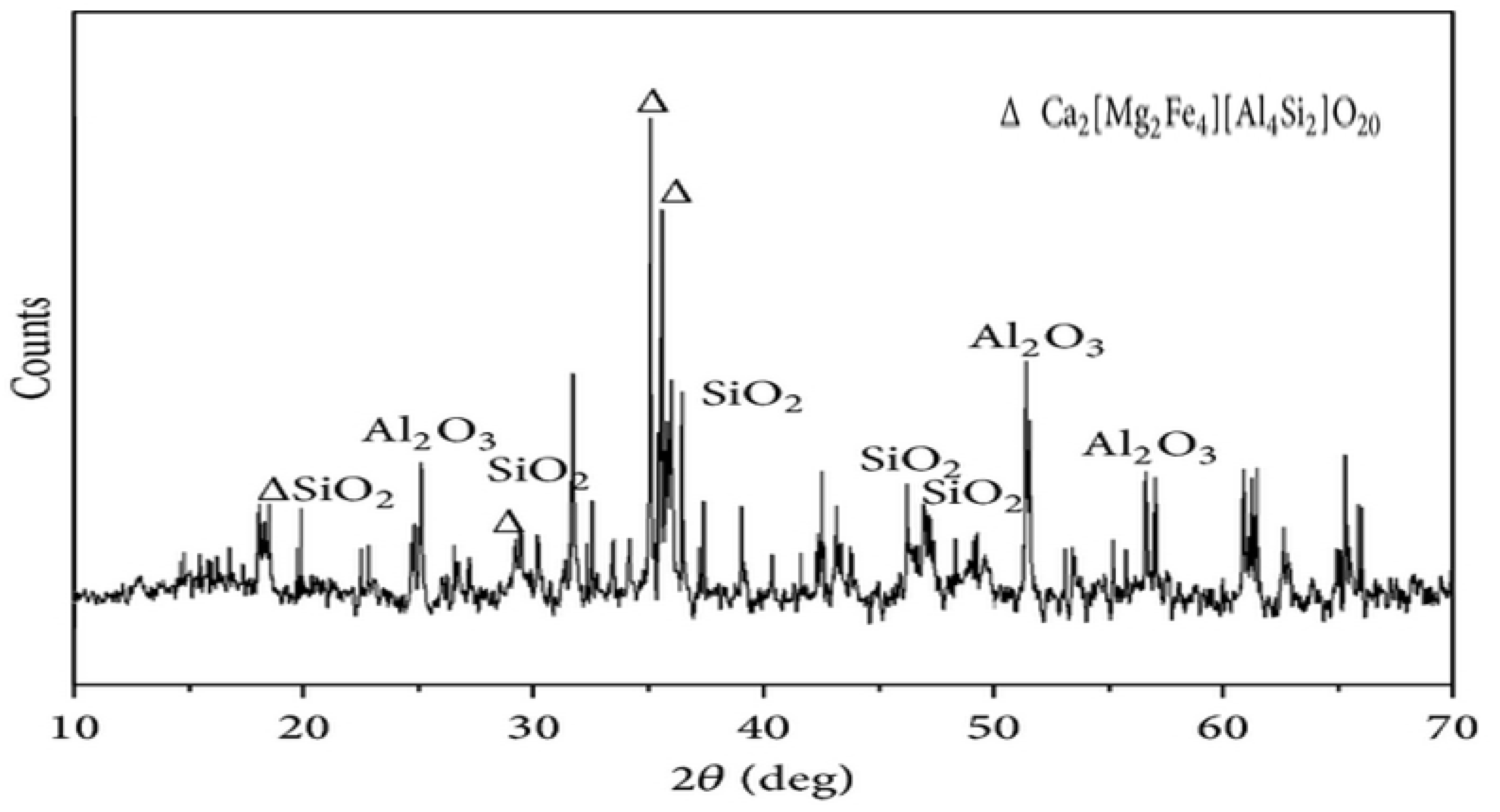

3. Fresh Properties

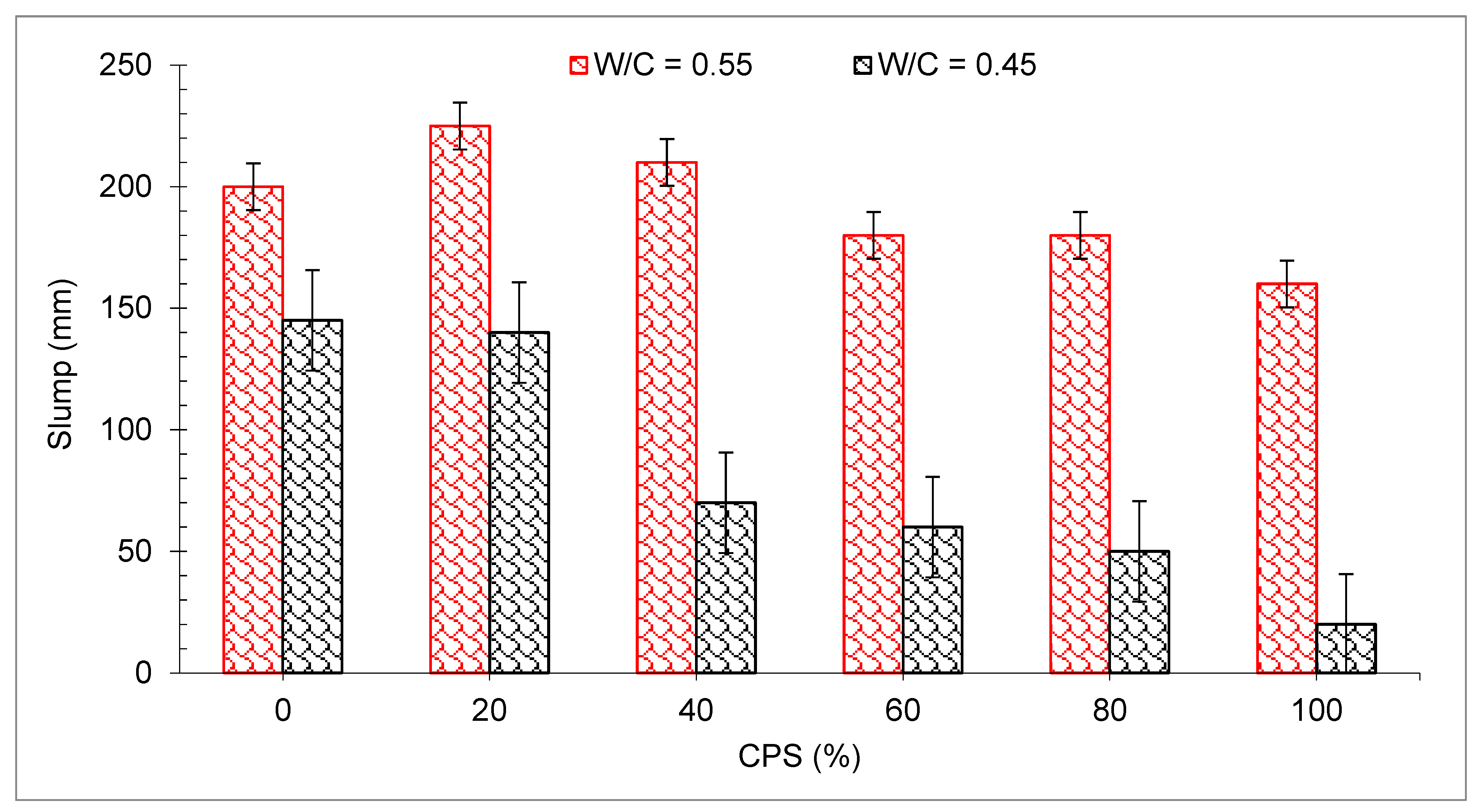

3.1. Workability of Concrete

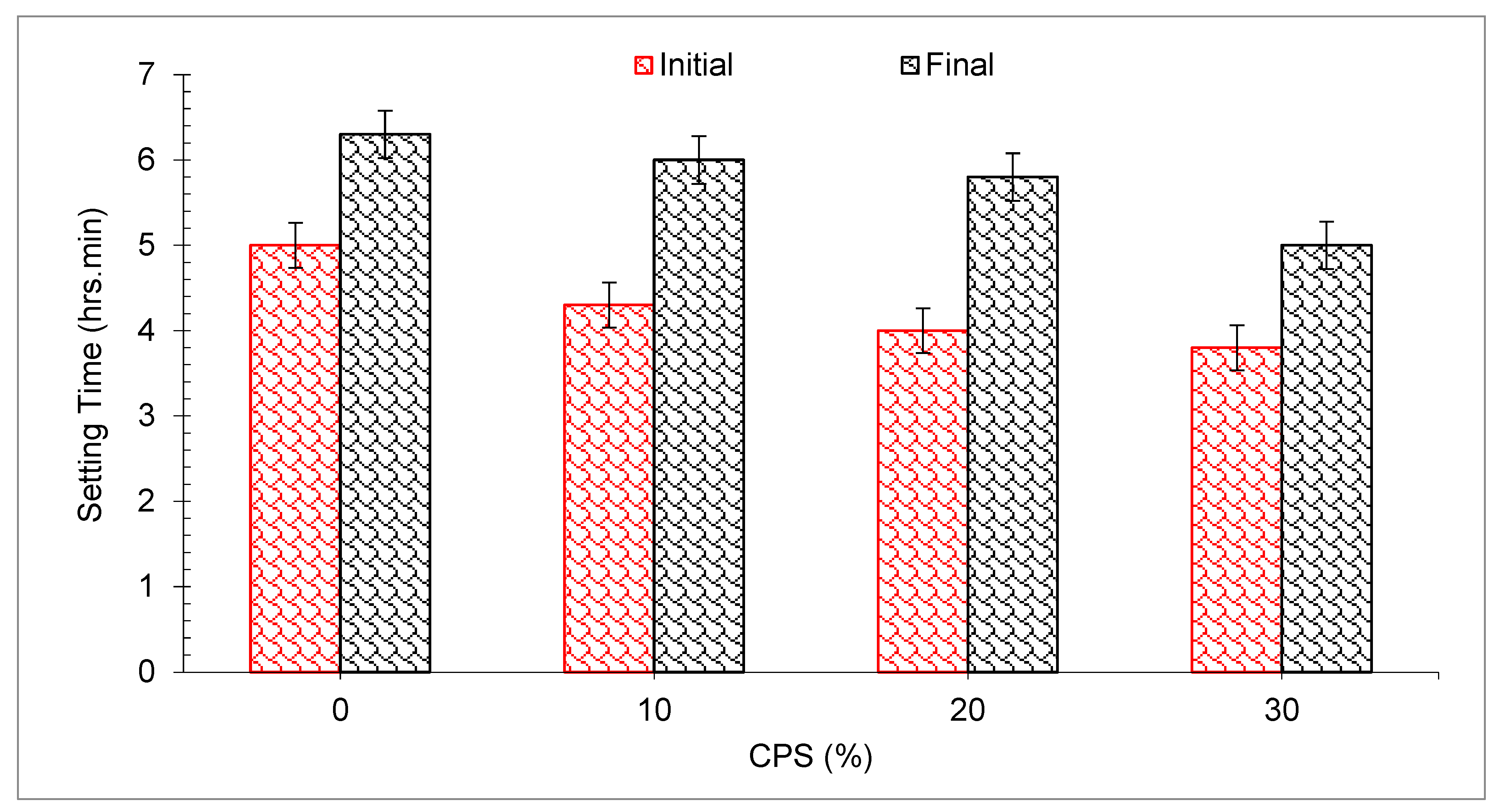

3.2. Setting Times of Mortar

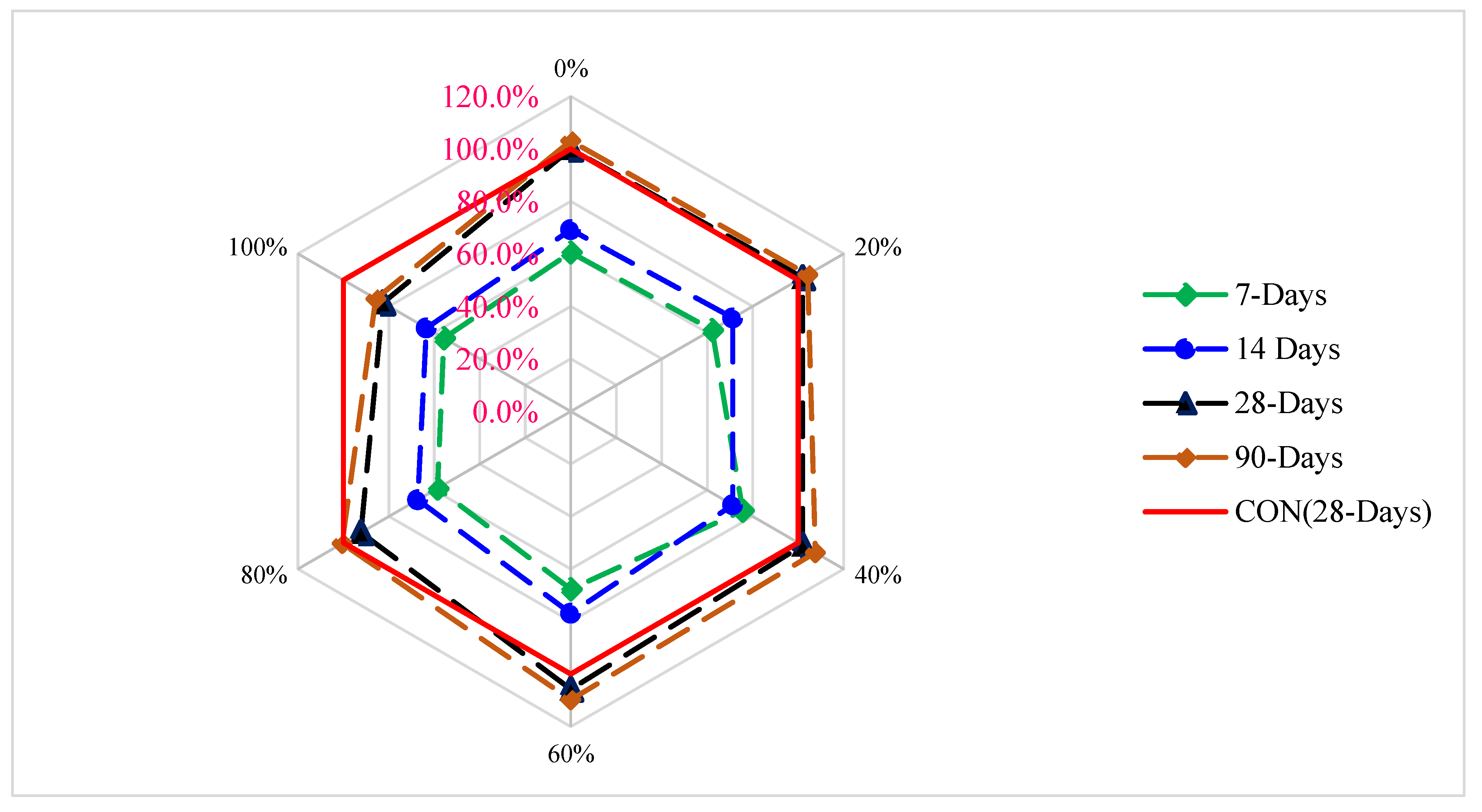

4. Mechanical Strength

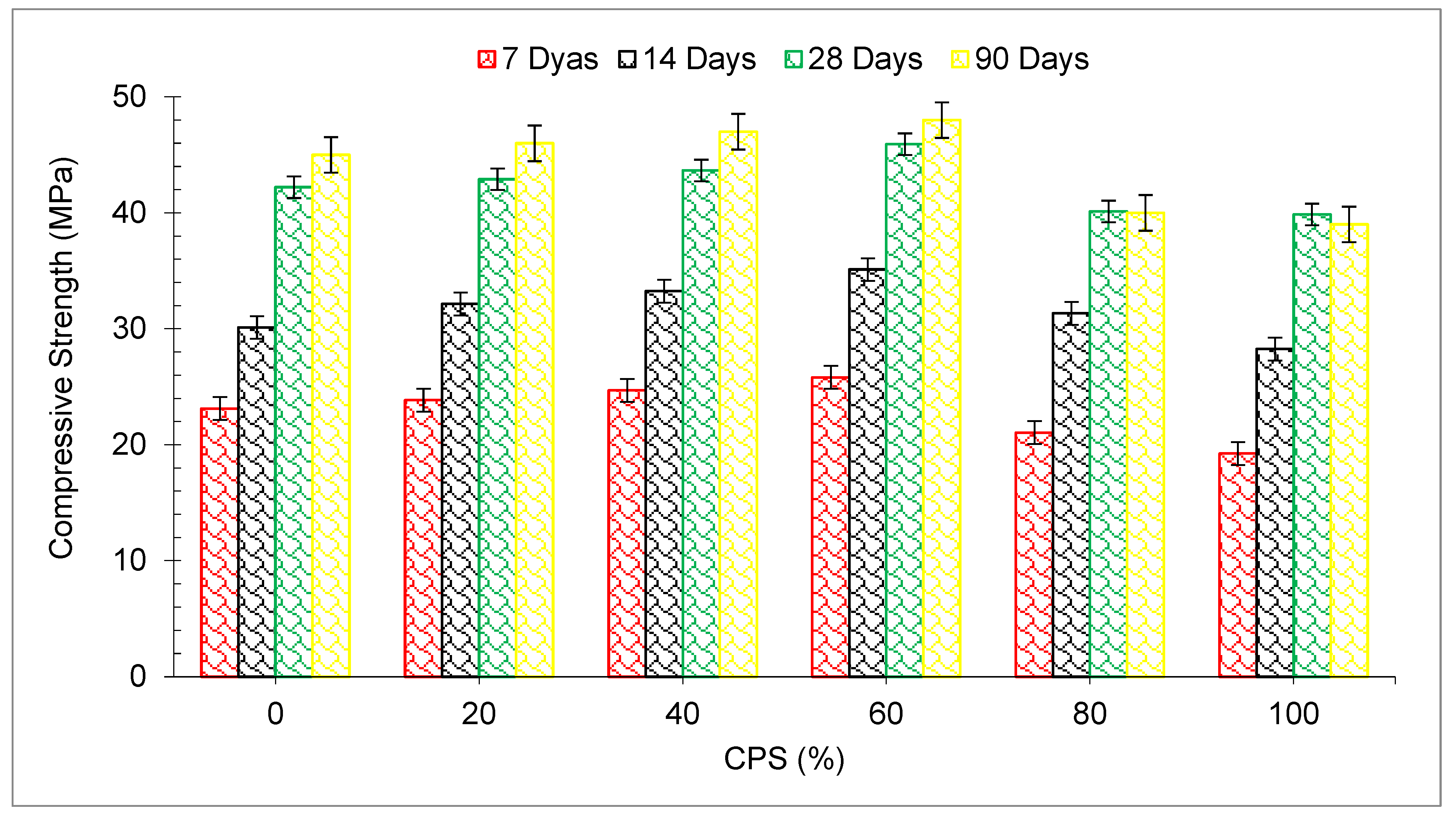

4.1. Compressive Strength (CMS) of Concrete

4.2. Split Tensile Strength (TS)

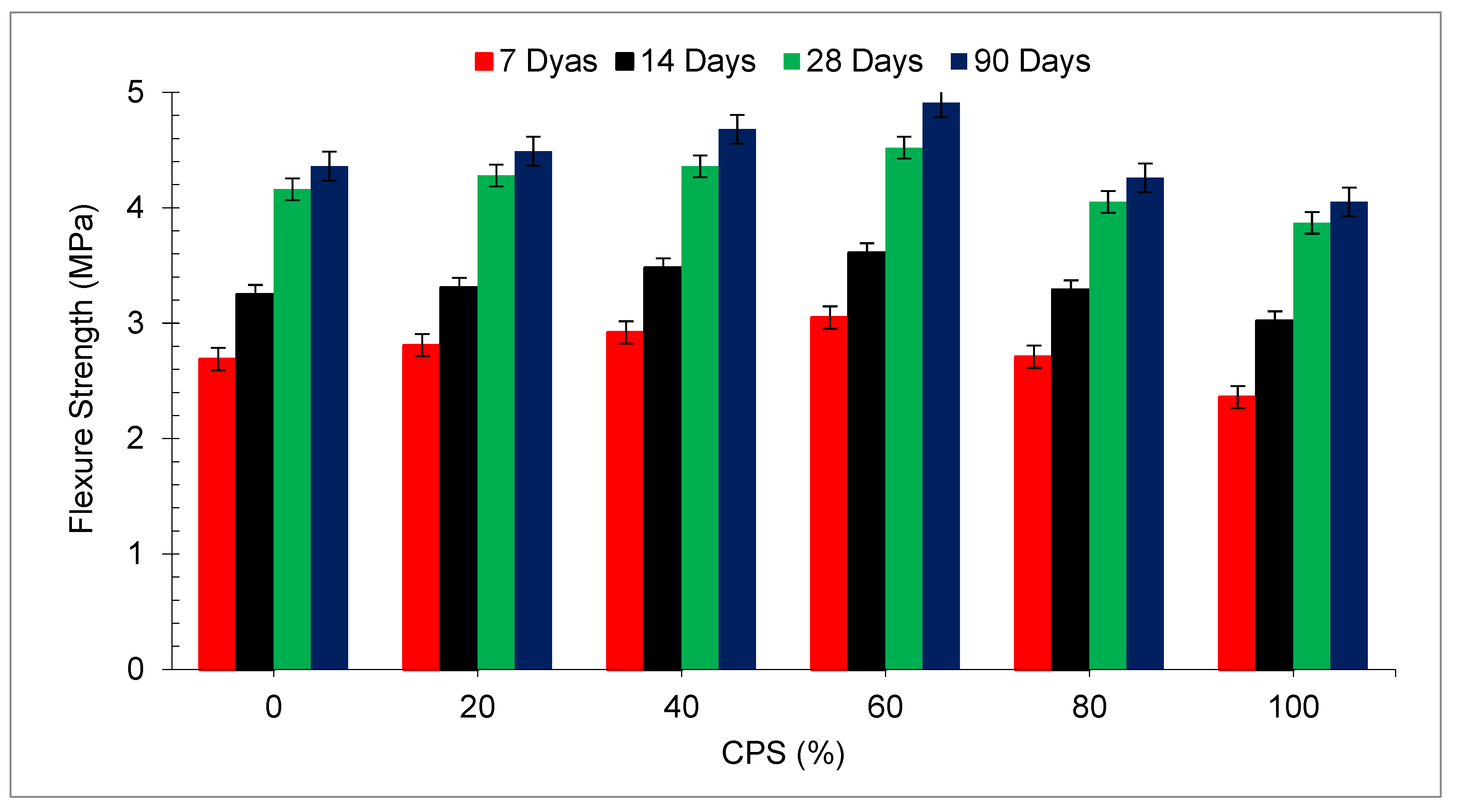

4.3. Flexural Strength (FS)

| Reference | Percentage of | Slump | Compression | Flexural | Split Tensile | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (CPS) | (mm) | Strength (MPa) | Strength (MPa) | Strength (MPa) | ||||||||||||||||||||||||||||

| [47] | W/C=0.55 | 7D | 28D | - | 7D | 28D | ||||||||||||||||||||||||||

| 0% | 200 | 23.9 | 34.6 | 2.4 | 2.7 | |||||||||||||||||||||||||||

| 20% | 225 | 29.0 | 38.6 | 2.5 | 2.8 | |||||||||||||||||||||||||||

| 40% | 210 | 25.7 | 33.2 | 2.3 | 2.7 | |||||||||||||||||||||||||||

| 60% | 180 | 25.8 | 34.0 | 2.4 | 2.8 | |||||||||||||||||||||||||||

| 80% | 180 | 24.5 | 32.8 | 2.3 | 2.6 | |||||||||||||||||||||||||||

| 100% | 160 | 23.6 | 30.7 | - | - | |||||||||||||||||||||||||||

| [30] | - | 7D | 28D | 56D | 90D | 28D | 28D | |||||||||||||||||||||||||

| 0% | 30 | 44 | 43 | 45 | 7 | 3.5 | ||||||||||||||||||||||||||

| 20% | 34 | 45 | 45 | 47 | 7 | 3.8 | ||||||||||||||||||||||||||

| 40% | 35 | 47 | 50 | 53 | 7.5 | 4 | ||||||||||||||||||||||||||

| 60% | 33 | 45 | 47 | 50 | 7 | 4 | ||||||||||||||||||||||||||

| 80% | 33 | 46 | 48 | 51 | 6.5 | 3.9 | ||||||||||||||||||||||||||

| 100% | 34 | 46 | 46 | 50 | 6.5 | 3.9 | ||||||||||||||||||||||||||

| [53] | - | 7D | 28D | 90D | 28D | 90D | 28D | 90D | ||||||||||||||||||||||||

| 0% | 29.7 | 40.0 | 44.0 | 3.28 | 3.35 | 3.74 | 4.05 | |||||||||||||||||||||||||

| 5% | 27.5 | 37.5 | 43.1 | 3.09 | 3.30 | 3.72 | 4.02 | |||||||||||||||||||||||||

| 10% | 25.2 | 36.0 | 41.7 | 3.02 | 3.17 | 3.71 | 4.02 | |||||||||||||||||||||||||

| 15% | 23.5 | 35.2 | 39.5 | 2.98 | 3.12 | 3.67 | 3.98 | |||||||||||||||||||||||||

| [54] | 0%CS | 65 | 7D | 28D | 56D | 90D | 28D | 28D | ||||||||||||||||||||||||

| 10%CPS+90%S | 80 | 23.3 | 24.6 | 25.3 | 27 | 7.7 | 3 | |||||||||||||||||||||||||

| 20%CPS+80%S | 80 | 29 | 31 | 34.7 | 36 | 7.2 | 3.5 | |||||||||||||||||||||||||

| 40%CPS+60%S | 110 | 30.6 | 39.8 | 40 | 42 | 6.5 | 3.8 | |||||||||||||||||||||||||

| 50%CPS+50%S | 130 | 30 | 42.7 | 44.5 | 50.3 | 7.3 | 4.1 | |||||||||||||||||||||||||

| 60%CPS+40%S | 165 | 28 | 39.2 | 42 | 47.8 | 6.3 | 3.6 | |||||||||||||||||||||||||

| 80%CPS+20%S | 190 | 26.8 | 35 | 40.1 | 44.8 | 7.2 | 3.6 | |||||||||||||||||||||||||

| 100%CPS | 200 | 23.3 | 26.1 | 32 | 35.5 | 5.9 | 3.4 | |||||||||||||||||||||||||

| [45] | 7D | 14D | 28D | 90D | 14D | 28D | 90D | 14D | 28D | 90D | ||||||||||||||||||||||

| 0% | 65 | 23.12 | 30.12 | 42.21 | 45 | 3.25 | 4.16 | 4.36 | 3.6 | 5.3 | 5.36 | |||||||||||||||||||||

| 20% | 70 | 23.85 | 32.15 | 42.90 | 46 | 3.31 | 4.28 | 4.49 | 3.7 | 5.3 | 5.42 | |||||||||||||||||||||

| 40% | 72 | 24.69 | 33.26 | 43.65 | 47 | 3.48 | 4.36 | 4.68 | 3.7 | 5.3 | 5.59 | |||||||||||||||||||||

| 60% | 75 | 25.81 | 35.12 | 45.92 | 48 | 3.61 | 4.52 | 4.91 | 4.0 | 5.5 | 5.71 | |||||||||||||||||||||

| 80% | 82 | 21.05 | 31.34 | 40.12 | 40 | 3.29 | 4.05 | 4.26 | 3.5 | 4.8 | 5.23 | |||||||||||||||||||||

| 100% | 80 | 19.25 | 28.26 | 39.86 | 39 | 3.02 | 3.87 | 4.05 | 3.3 | 4.3 | 4.69 | |||||||||||||||||||||

| [61] | 7D | 28D | 28D | 28D | ||||||||||||||||||||||||||||

| 0%CS | 28 | 76.9 | 93.9 | 14.6 | 5.4 | |||||||||||||||||||||||||||

| 10%CPS+90%S | 28 | 79.6 | 99.8 | 13 | 5.2 | |||||||||||||||||||||||||||

| 20%CPS+80%S | 50 | 74.5 | 95.3 | 12.4 | 6.2 | |||||||||||||||||||||||||||

| 40%CPS+60%S | 85 | 76.4 | 95.2 | 12.5 | 6.1 | |||||||||||||||||||||||||||

| 50%CPS+50%S | 115 | 77.8 | 96.8 | 12.9 | 6.1 | |||||||||||||||||||||||||||

| 60%CPS+40%S | 128 | 69.0 | 83.0 | 11.1 | 4.8 | |||||||||||||||||||||||||||

| 80%CPS+20%S | 143 | 63.8 | 83.6 | 10.3 | 4.7 | |||||||||||||||||||||||||||

| 100%CPS | 150 | 63.4 | 82.0 | 10.1 | 4.4 | |||||||||||||||||||||||||||

| [49] | 14D | 28D | - | 14D | 28D | |||||||||||||||||||||||||||

| 0% | 52 | 32.1 | 35.7 | 3.77 | 3.9 | |||||||||||||||||||||||||||

| 25% | 57 | 37.1 | 38.5 | 4.3 | 4.36 | |||||||||||||||||||||||||||

| 50% | 63 | 38.2 | 39.9 | 4.37 | 4.43 | |||||||||||||||||||||||||||

| 75% | 68 | 31.8 | 34.1 | 4.24 | 4.29 | |||||||||||||||||||||||||||

| 100% | 74 | 28.8 | 30.0 | 4.13 | 4.18 | |||||||||||||||||||||||||||

| [74] | - | 28D | 28D | - | ||||||||||||||||||||||||||||

| 0% | 93 | 6.2 | ||||||||||||||||||||||||||||||

| 20% | 97 | 6.5 | ||||||||||||||||||||||||||||||

| 40% | 100 | 7.1 | ||||||||||||||||||||||||||||||

| 60% | 95 | 6.9 | ||||||||||||||||||||||||||||||

| 80% | 91 | 6.4 | ||||||||||||||||||||||||||||||

| 100% | 87 | 6.1 | ||||||||||||||||||||||||||||||

| [75] | - | 7D | 28D | 7D | 28D | 7D | 28D | |||||||||||||||||||||||||

| 0% | 35 | 40 | 4.0 | 5.0 | 2.5 | 3.0 | ||||||||||||||||||||||||||

| 5% | 32 | 43 | 4.1 | 5.1 | 2.6 | 3.3 | ||||||||||||||||||||||||||

| 10% | 30 | 41 | 4.0 | 5.0 | 2.5 | 3.2 | ||||||||||||||||||||||||||

| 15% | 28 | 32 | 3.2 | 4.0 | 1.7 | 2.5 | ||||||||||||||||||||||||||

| [76] | - | 28D | 56D | 28D | 56D | 28D | 56D | |||||||||||||||||||||||||

| 0% | 45 | 49 | 3.6 | 4.0 | 3.6 | 4.0 | ||||||||||||||||||||||||||

| 5% | 50 | 55 | 3.5 | 4.5 | 3.5 | 4.5 | ||||||||||||||||||||||||||

| 10% | 47 | 51 | 3.3 | 4.4 | 3.3 | 4.4 | ||||||||||||||||||||||||||

| 15% | 45 | 49 | 3.1 | 4.2 | 3.1 | 4.2 | ||||||||||||||||||||||||||

| 20% | 40 | 47 | 3.0 | 4.0 | 3.0 | 4.0 | ||||||||||||||||||||||||||

| 25% | 38 | 44 | 2.9 | 3.9 | 2.9 | 3.9 | ||||||||||||||||||||||||||

| 30% | 36 | 42 | 2.6 | 3.6 | 2.6 | 3.6 | ||||||||||||||||||||||||||

| [77] | - | 7D | 14D | 28D | - | 7D | 14D | 28D | ||||||||||||||||||||||||

| 0% | 17.03 | 21.66 | 29.25 | 1.82 | 2.03 | 2.73 | ||||||||||||||||||||||||||

| 10% | 18.74 | 23.70 | 29.85 | 2.12 | 2.19 | 2.95 | ||||||||||||||||||||||||||

| 20% | 20.22 | 25.22 | 32.07 | 2.21 | 2.31 | 3.09 | ||||||||||||||||||||||||||

| 30% | 23.11 | 27.33 | 37.55 | 2.22 | 2.38 | 3.42 | ||||||||||||||||||||||||||

| 40% | 24.66 | 28.59 | 39.48 | 2.38 | 2.5 | 3.49 | ||||||||||||||||||||||||||

| 50% | 20.96 | 25.9 | 33.03 | 2.05 | 2.26 | 2.48 | ||||||||||||||||||||||||||

| 60% | 16.48 | 20.45 | 28.66 | 1.98 | 2.12 | 2.33 | ||||||||||||||||||||||||||

| [65] | - | 28D | 56D | - | 28D | 56D | ||||||||||||||||||||||||||

| 0% | 30 | 31 | 10.66 | 11.72 | ||||||||||||||||||||||||||||

| 20% | 35 | 37 | 9.94 | 10.59 | ||||||||||||||||||||||||||||

| 40% | 36 | 38 | 10.81 | 10.53 | ||||||||||||||||||||||||||||

| 60% | 39 | 38 | 10.43 | 11.14 | ||||||||||||||||||||||||||||

| 80% | 42 | 42 | 11.07 | 11.70 | ||||||||||||||||||||||||||||

| 100% | 36 | 36 | 12.18 | 1257 | ||||||||||||||||||||||||||||

| [33] | - | 7D | 28D | - | 7D | 28D | ||||||||||||||||||||||||||

| 0% | 24 | 33 | 2.8 | 3.3 | ||||||||||||||||||||||||||||

| 20% | 26 | 28 | 3.0 | 3.4 | ||||||||||||||||||||||||||||

| 40% | 31 | 37 | 3.3 | 3.5 | ||||||||||||||||||||||||||||

| 60% | 26 | 31 | 3.0 | 3.2 | ||||||||||||||||||||||||||||

| 80% | 25 | 28 | 2.9 | 3.1 | ||||||||||||||||||||||||||||

| 100% | 20 | 21 | 2.5 | 2.6 | ||||||||||||||||||||||||||||

| [78] | 28D | - | - | |||||||||||||||||||||||||||||

| 0% | 29 | 29.19 | ||||||||||||||||||||||||||||||

| 10% | 34 | 31.56 | ||||||||||||||||||||||||||||||

| 20% | 43 | 34.59 | ||||||||||||||||||||||||||||||

| 30% | 46 | 41.7 | ||||||||||||||||||||||||||||||

| 40% | 51 | 38.74 | ||||||||||||||||||||||||||||||

| 50% | 55 | 42.22 | ||||||||||||||||||||||||||||||

| 60% | 57 | 34.81 | ||||||||||||||||||||||||||||||

| 70% | 62 | 32.74 | ||||||||||||||||||||||||||||||

| 80% | 66 | 31.7 | ||||||||||||||||||||||||||||||

| 90% | 69 | 30.15 | ||||||||||||||||||||||||||||||

| 100% | 78 | 30 | ||||||||||||||||||||||||||||||

| [64] | - | 7D | 28D | 7D | 28D | - | ||||||||||||||||||||||||||

| 0% | 40 | 45 | 8.0 | 9.0 | ||||||||||||||||||||||||||||

| 10% | 42 | 47 | 10.0 | 10.0 | ||||||||||||||||||||||||||||

| 20% | 43 | 49 | 11.0 | 10.0 | ||||||||||||||||||||||||||||

| 30% | 45 | 50 | 11.5 | 12.5 | ||||||||||||||||||||||||||||

| [79] | - | 7D | 28D | 28D | ||||||||||||||||||||||||||||

| 0% | 42 | 62 | 3.5 | - | ||||||||||||||||||||||||||||

| 20% | 50 | 62 | 3.4 | |||||||||||||||||||||||||||||

| 40% | 52 | 70 | 3.5 | |||||||||||||||||||||||||||||

| 60% | 50 | 68 | 3.3 | |||||||||||||||||||||||||||||

| 80% | 40 | 60 | 3.2 | |||||||||||||||||||||||||||||

| 100% | 30 | 50 | 2 | |||||||||||||||||||||||||||||

| [80] | - | 7D | 14D | 28D | 56D | 28D | 7D | 14D | 28D | 56D | ||||||||||||||||||||||

| 0% | 17.70 | 25.20 | 37.35 | 41.15 | 25.41 | 4.02 | 5.20 | 6.91 | 8.54 | |||||||||||||||||||||||

| 15% | 22.66 | 30.04 | 39.90 | 44.20 | 25.87 | 4.39 | 5.69 | 7.90 | 9.14 | |||||||||||||||||||||||

| 30% | 25.90 | 32.40 | 43.94 | 50.39 | 6.16 | 5.21 | 7.14 | 9.57 | ||||||||||||||||||||||||

| 45% | 22.04 | 29.90 | 39.79 | 45.84 | 5.77 | 4.38 | 6.64 | 8.13 | 10.1 | |||||||||||||||||||||||

| 60% | 18.13 | 26.83 | 35.14 | 42.65 | 5.19 | 4.20 | 5.77 | 7.91 | 9.86 | |||||||||||||||||||||||

5. Durability

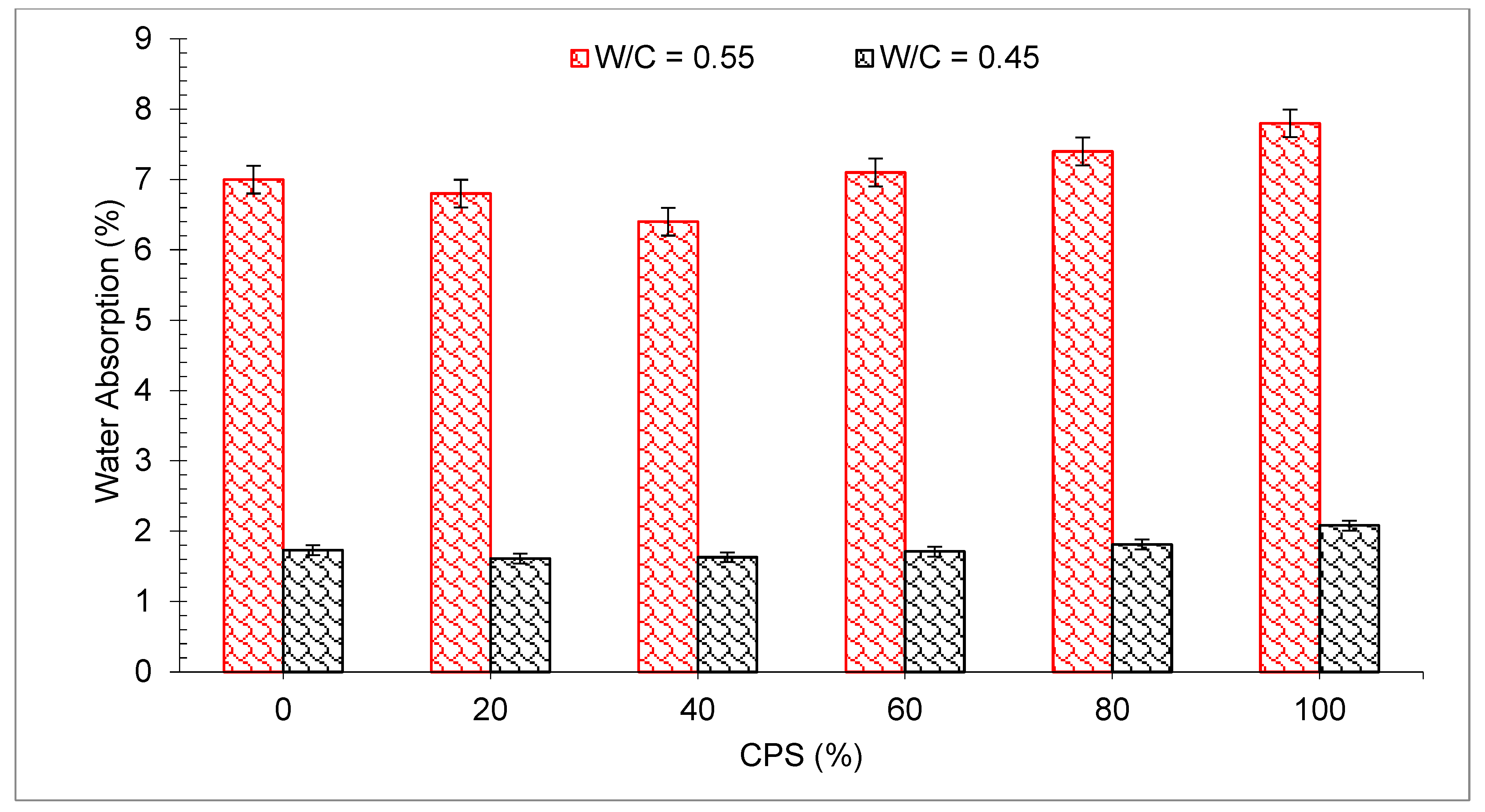

5.1. Water Absorption and Voids

5.2. Accelerated Corrosion Testing Results

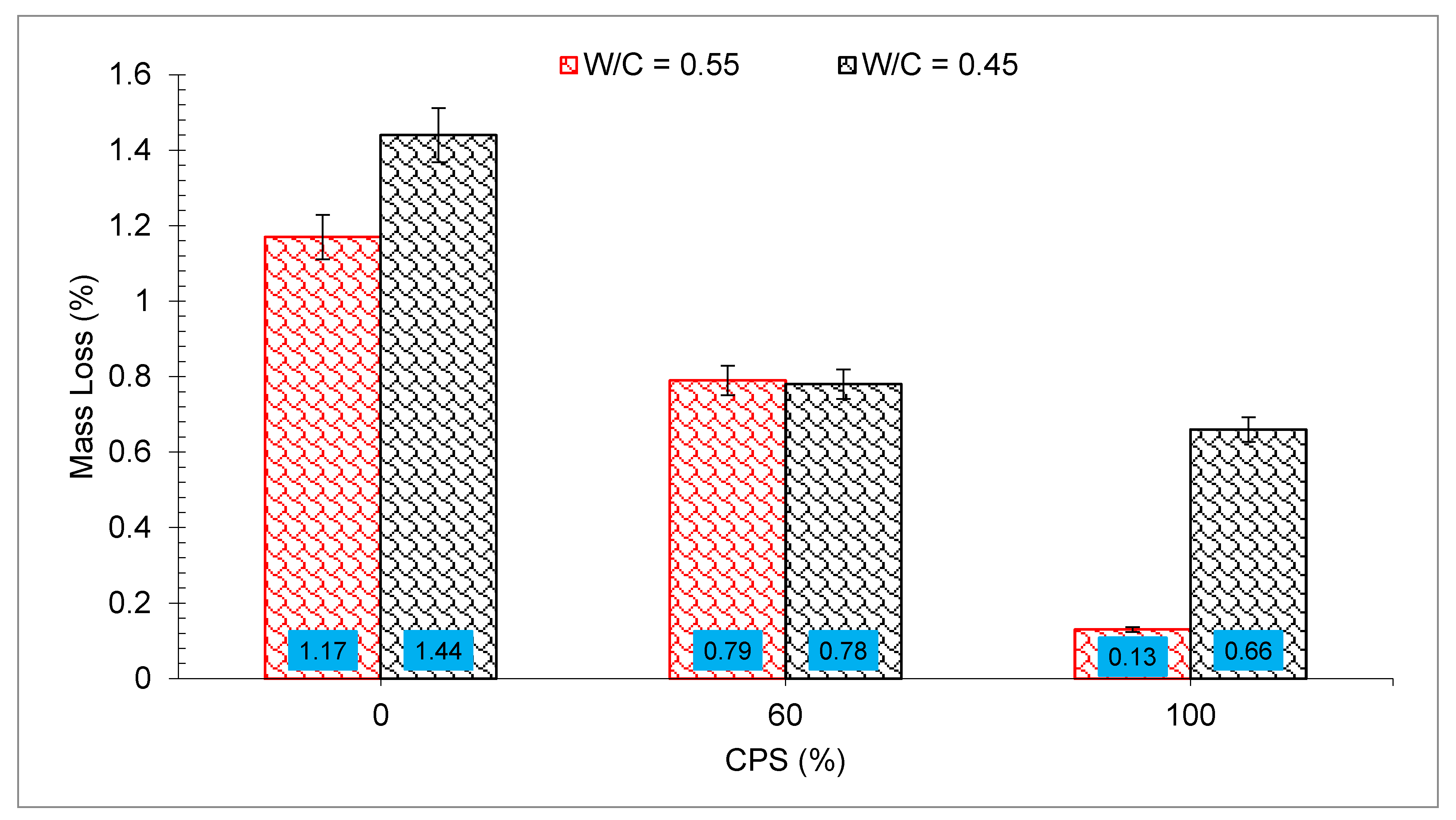

5.3. Acid Resistance

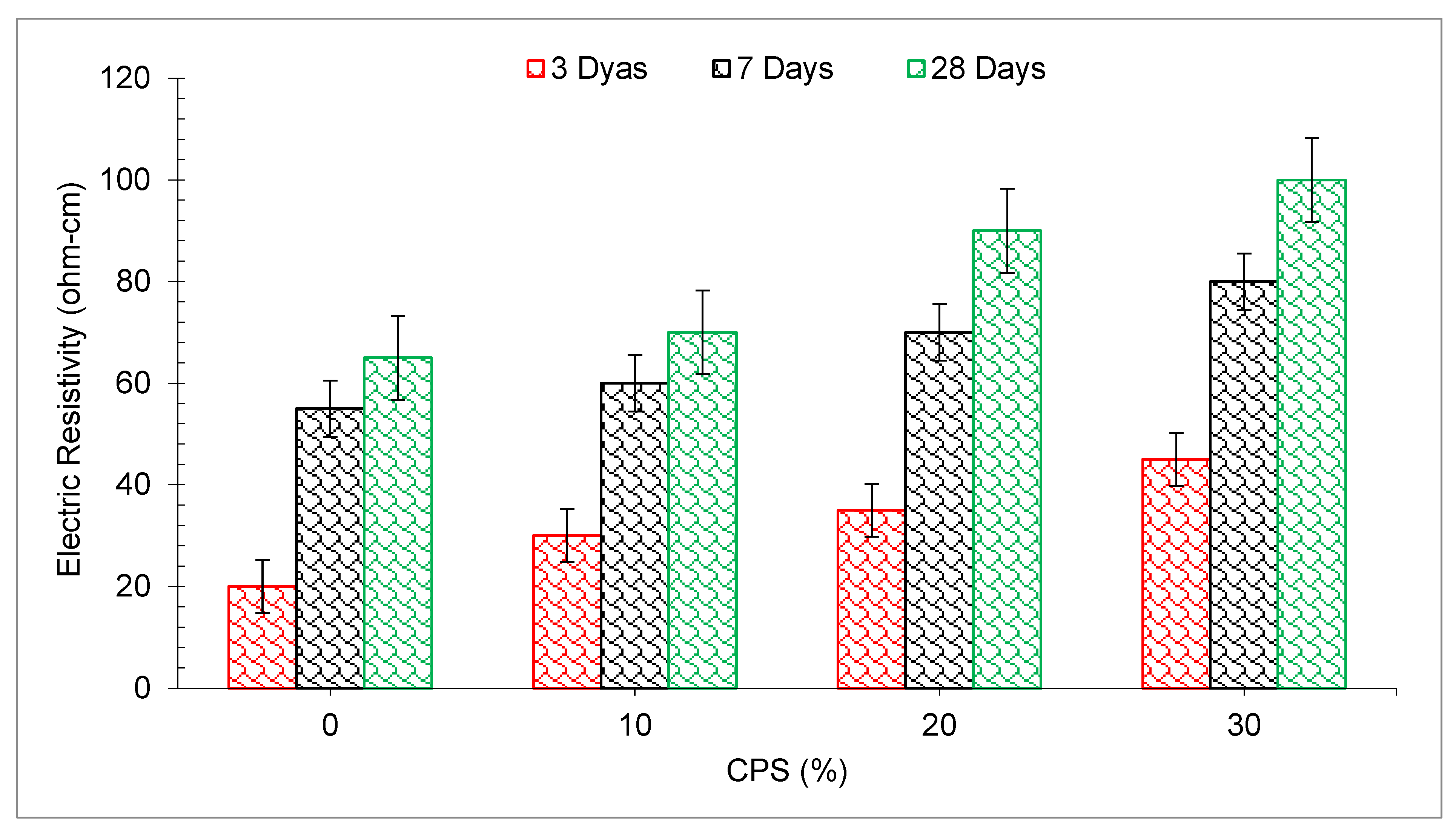

5.4. Electrical Resistivity Results

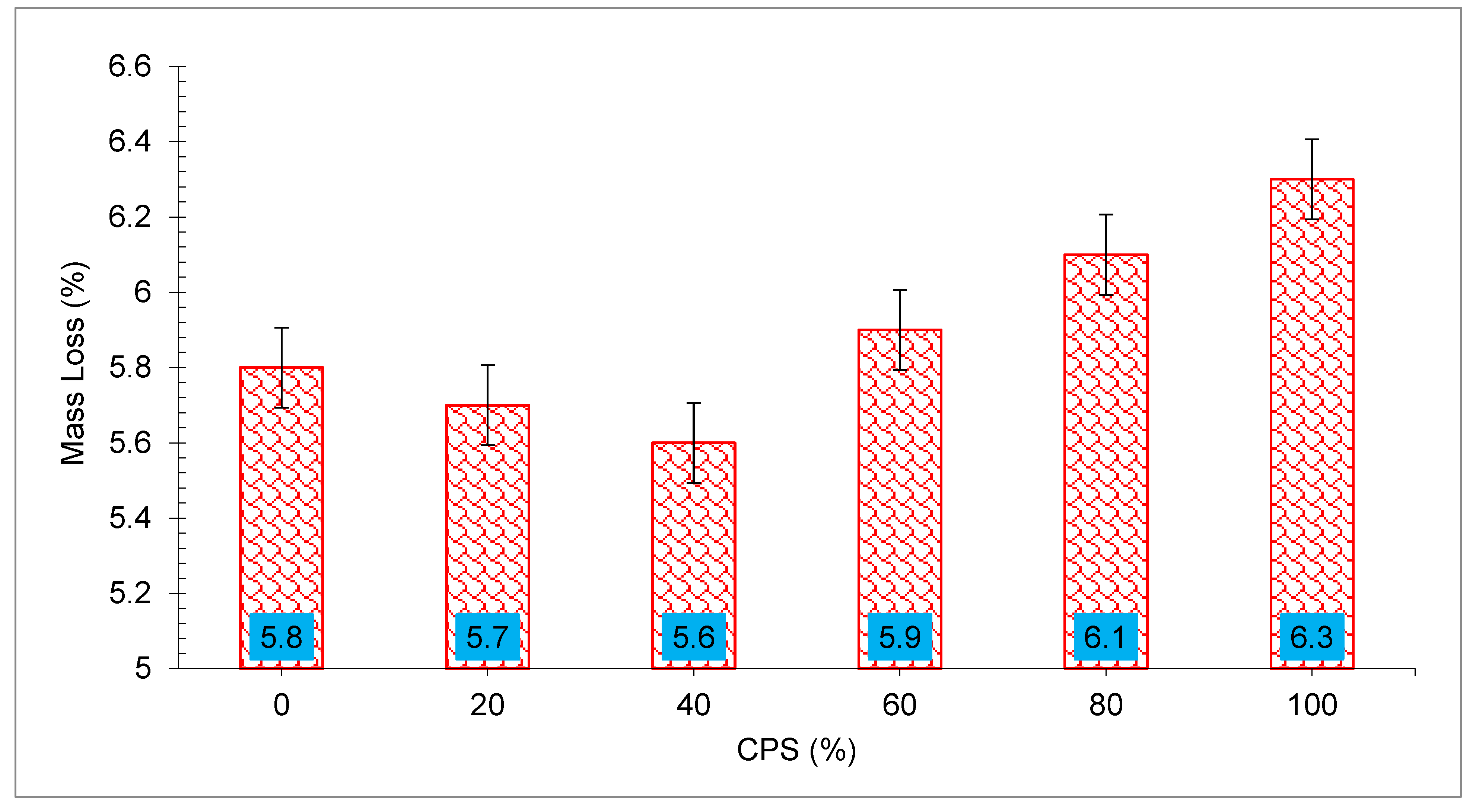

5.5. Sulfate Resistance

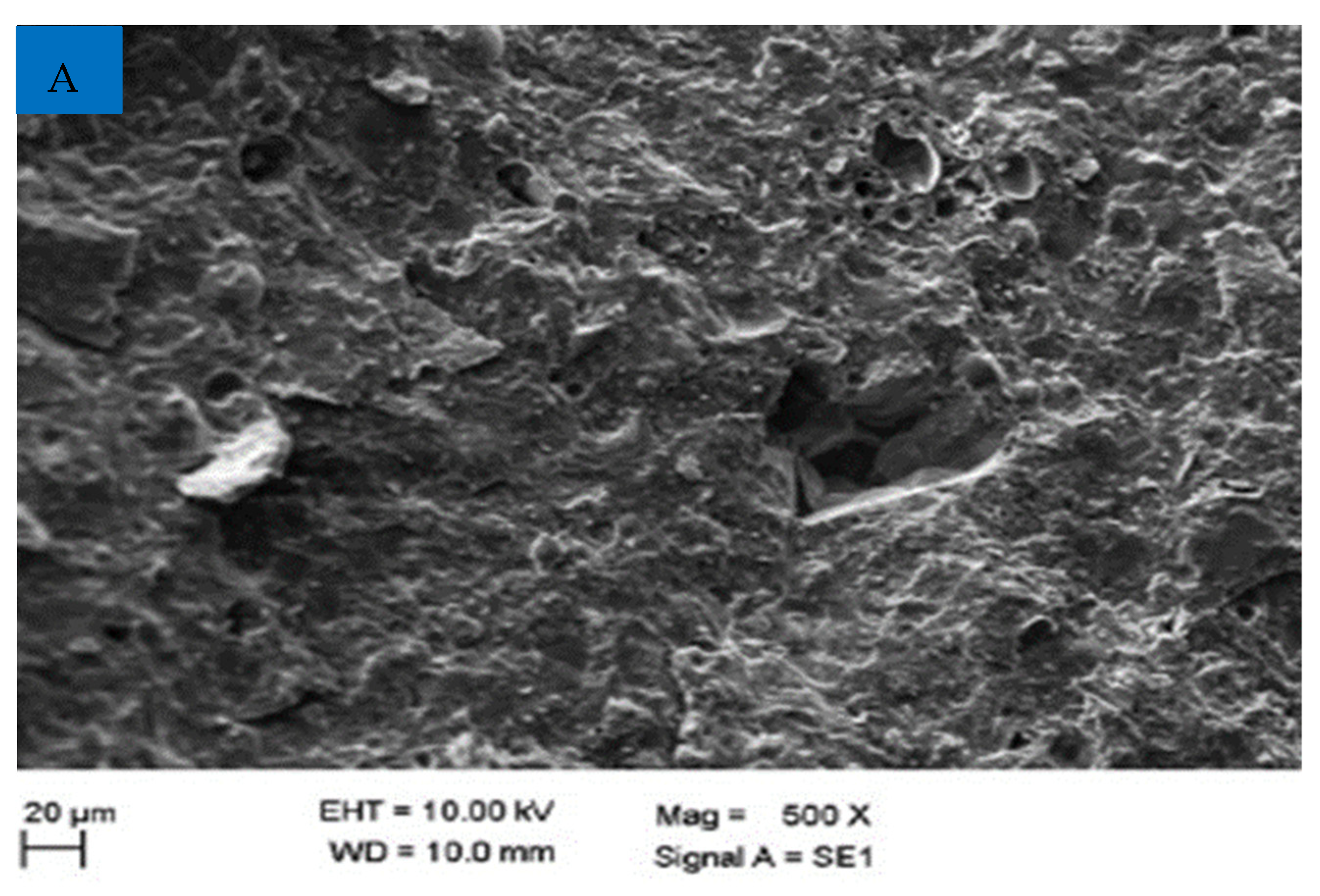

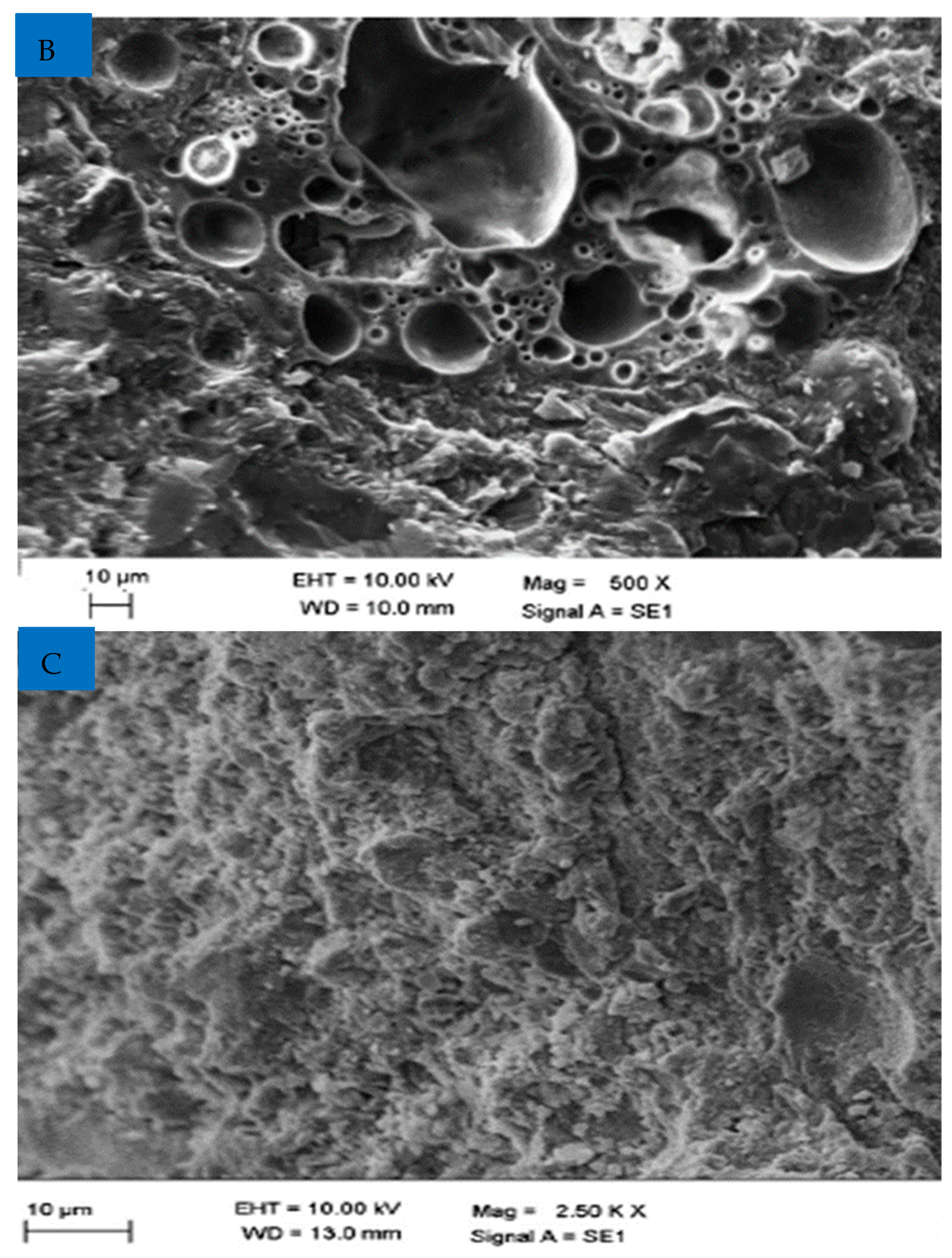

6. Scanning Electron Microscopy (SEM)

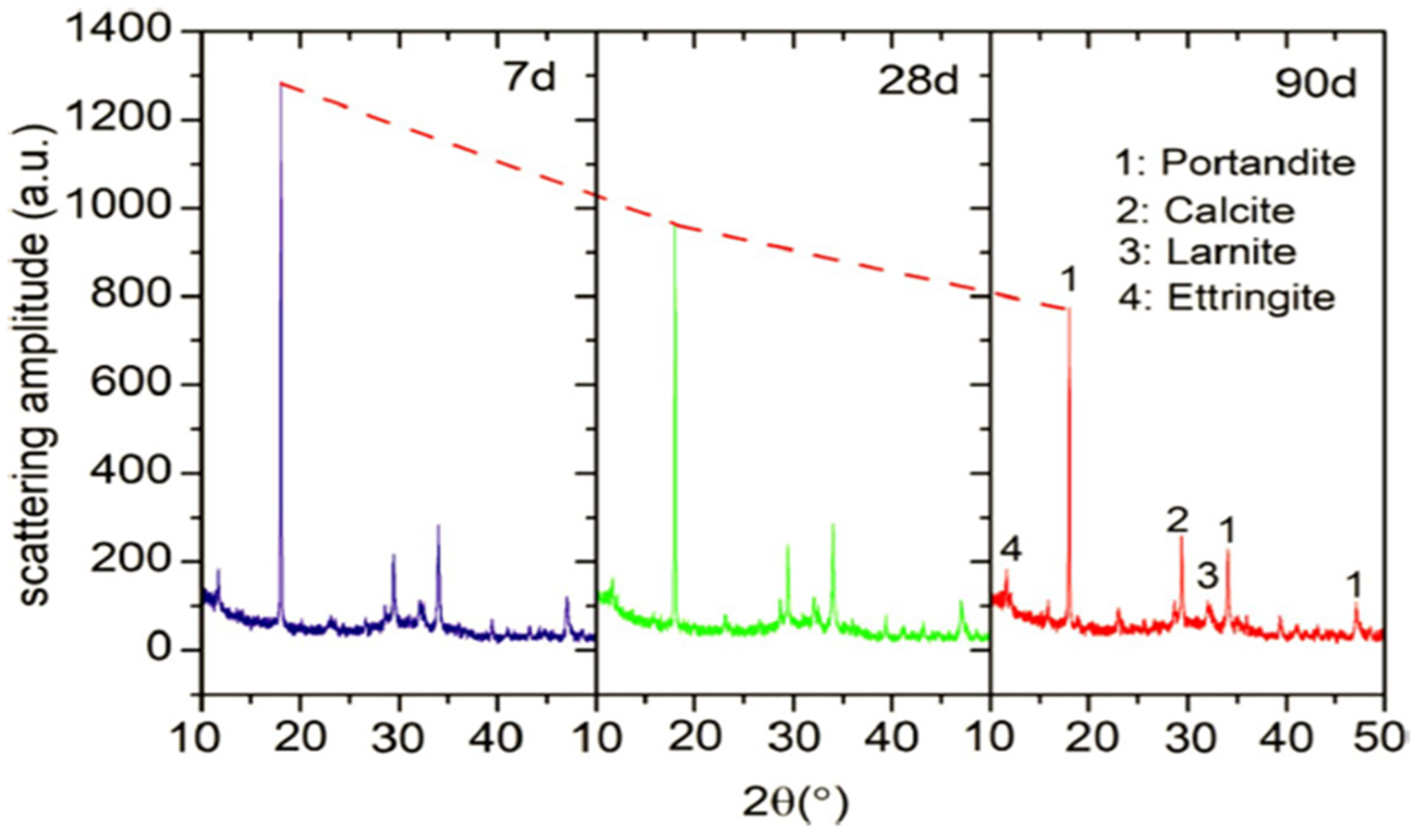

7. X-Ray Diffraction (XRD)

8. Hazards and Safety of Copper Slag

9. Conclusions

- The physical property of CPS shows that the particle nature of CPS is rough and angular which adversely affects the flowability of concrete.

- The chemical composition of CPS ensures that it can be used as binding material.

- The slump value of concrete was reduced with the replacement of CPS due to angular and rough surface texture.

- The setting time increased with CPS as the pozzolanic reaction proceeded slowly.

- CPS up to 60% can be used without any harmful impact on the mechanical strength of concrete. The improvement in compressive, split tensile strength and flexure at 28 days was 9%, 6% and 9% higher than control concrete, respectively.

- The higher dose of CPS (80 and 90%) resulted in a decline in the mechanical strength of concrete due to the absence of flowability.

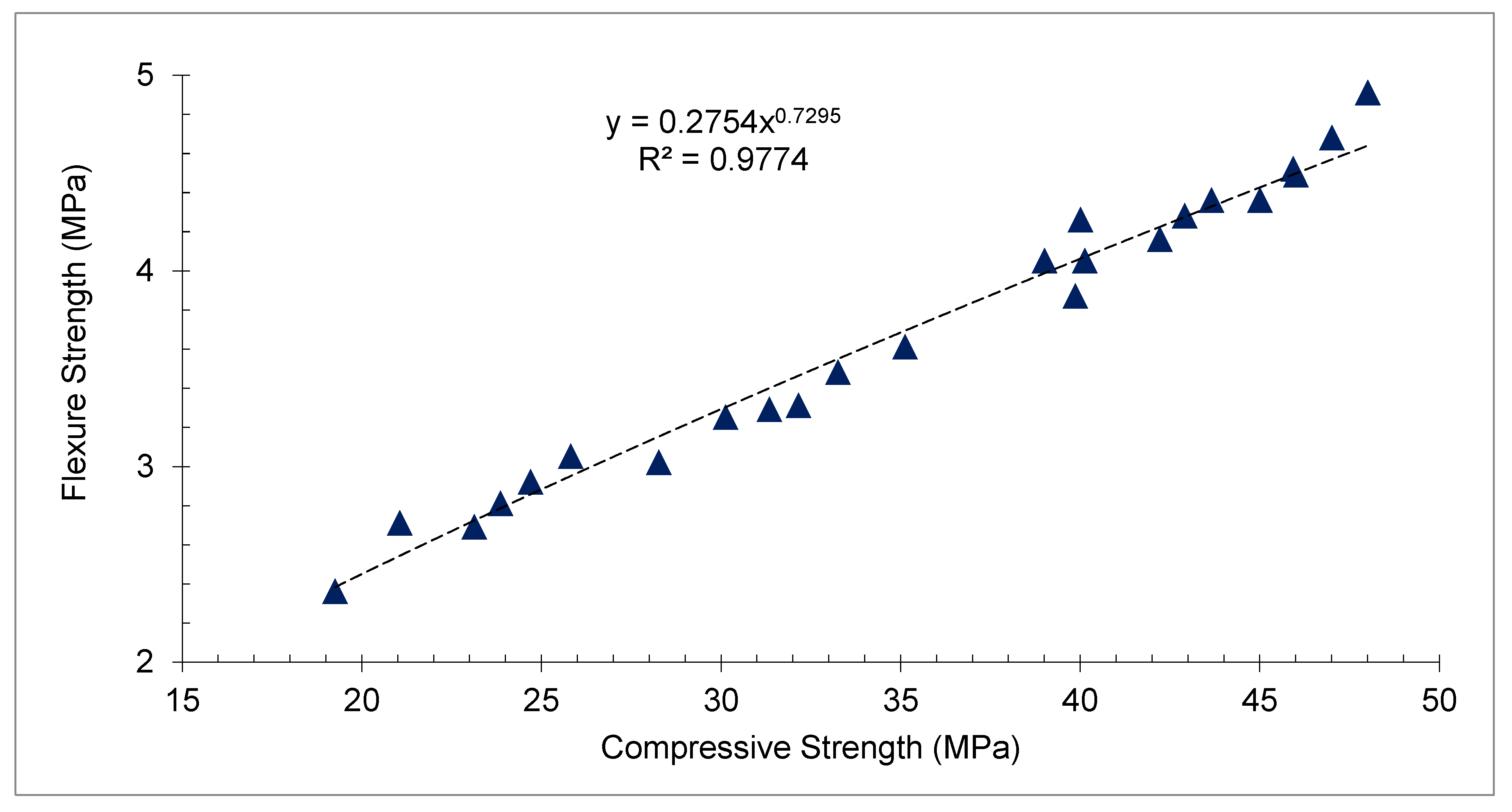

- A good correlation was observed between two specified strengths with an R2 value greater than 90%.

- The durability performance of concrete, such as water absorption and voids, corrosion resistance, acid resistance and electric resistivity increased with CPS.

- SEM results reveal that the performance of concrete with CPS can be improved with the addition of secondary cementitious materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, J.; Zaid, O.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. Mechanical and Durability Characteristics of Sustainable Coconut Fibers Reinforced Concrete with Incorporation of Marble Powder. Mater. Res. Express 2021, 8, 075505. [Google Scholar] [CrossRef]

- Taskin, A.; Fediuk, R.; Grebenyuk, I.; Elkin, O.; Kholodov, A. Effective Cement Binders on Fly and Slag Waste from Heat Power Industry of the Primorsky Krai, Russian Federation. Int. J. Sci. Technol. Res. 2020, 9, 3509–3512. [Google Scholar]

- Althoey, F.; Farnam, Y. The Effect of Using Supplementary Cementitious Materials on Damage Development Due to the Formation of a Chemical Phase Change in Cementitious Materials Exposed to Sodium Chloride. Constr. Build. Mater. 2019, 210, 685–695. [Google Scholar] [CrossRef]

- Singh, N.; Gupta, A.; Haque, M.M. A Review on the Influence of Copper Slag as a Natural Fine Aggregate Replacement on the Mechanical Properties of Concrete. Mater. Today Proc. 2022, 62, 3624–3637. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef] [PubMed]

- Dolage, D.A.R.; Dias, M.G.S.; Ariyawansa, C.T. Offshore Sand as a Fine Aggregate for Concrete Production. Br. J. Appl. Sci. Technol. 2013, 3, 813–825. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H. Mechanical and Durability Characteristics of Sustainable Concrete Modified with Partial Substitution of Waste Foundry Sand. Struct. Concr. 2021, 22, 2775–2790. [Google Scholar] [CrossRef]

- Amin, S.K.; Allam, M.E.; Garas, G.L.; Ezz, H. A Study of the Chemical Effect of Marble and Granite Slurry on Green Mortar Compressive Strength. Bull. Natl. Res. Cent. 2020, 44, 19. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, S.; Fan, M. Characteristics of Concrete with Waste Glass as Fine Aggregate Replacement. Int. J. Eng. Tech. Res. 2014, 2, 11–17. [Google Scholar]

- Corinaldesi, V.; Gnappi, G.; Moriconi, G.; Montenero, A. Reuse of Ground Waste Glass as Aggregate for Mortars. Waste Manag. 2005, 25, 197–201. [Google Scholar] [CrossRef]

- Du Plessis, C. A Strategic Framework for Sustainable Construction in Developing Countries. Constr. Manag. Econ. 2007, 25, 67–76. [Google Scholar] [CrossRef]

- Kansal, K.G.R. Waste Glass Powder as a Partial Replacement of PPC. Int. J. Sci. Res. 2016, 5, 1414–1418. [Google Scholar]

- Oh, D.-Y.; Noguchi, T.; Kitagaki, R.; Park, W.-J. CO2 Emission Reduction by Reuse of Building Material Waste in the Japanese Cement Industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Naik, T.R. Sustainability of Concrete Construction. Pract. Period. Struct. Des. Constr. 2008, 13, 98–103. [Google Scholar] [CrossRef] [Green Version]

- Vigneshpandian, G.V.; Shruthi, E.A.; Venkatasubramanian, C.; Muthu, D. Utilisation of Waste Marble Dust as Fine Aggregate in Concrete. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012007. [Google Scholar] [CrossRef] [Green Version]

- Xiao, R.; Huang, B.; Zhou, H.; Ma, Y.; Jiang, X. A State-of-the-Art Review of Crushed Urban Waste Glass Used in OPC and AAMs (Geopolymer): Progress and Challenges. Clean. Mater. 2022, 4, 100083. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef] [Green Version]

- Singh Shekhawat, B.; Aggarwal, V. Utilisation of Waste Glass Powder in Concrete-A Literature Review. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 3297, 2319–8753. [Google Scholar]

- Council, W.B. World Business Council for Sustainable Development. Cem. Sustain. Initiat. Cem. Ind. Energy CO2 Perform. Get. Numbers Right 2009. [Google Scholar] [CrossRef]

- Humphreys, D. Long-Run Availability of Mineral Commodities. Miner. Econ. 2013, 26, 1–11. [Google Scholar] [CrossRef]

- Müller, N.; Harnisch, J. How to Turn Around the Trend of Cement Related Emissions in the Developing World; WWF—Lafarge Conservation Partnership: Gland, Switzerland, 2008. [Google Scholar]

- Smith, R.A.; Kersey, J.R.; Griffiths, P.J. The Construction Industry Mass Balance: Resource Use, Wastes and Emissions. Construction 2002, 4, 680. [Google Scholar]

- Cui, X.; Sun, S.; Han, B.; Yu, X.; Ouyang, J.; Zeng, S.; Ou, J.; Khushnood, R.A.; Nawaz, A.A.; Siddique, R.; et al. Evaluation of the Reinforcement Efficiency of Low-Cost Graphite Nanomaterials in High-Performance Concrete. Constr. Build. Mater. 2018, 47, 3875–3882. [Google Scholar] [CrossRef]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance Evaluation of Concrete Incorporating Glass Powder and Glass Sludge Wastes as Supplementary Cementing Material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Yushin, A.M. The Use of Fly Ash the Thermal Power Plants in the Construction. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2015, 93, 12070. [Google Scholar] [CrossRef]

- Handayani, L.; Aprilia, S.; Rahmawati, C.; Al Bakri, A.M.M.; Aziz, I.H.; Azimi, E.A. Synthesis of Sodium Silicate from Rice Husk Ash as an Activator to Produce Epoxy-Geopolymer Cement. Proc. J. Phys. Conf. Ser. 2021, 1845, 12072. [Google Scholar] [CrossRef]

- Srinivas, D.; Suresh, N.; Lakshmi, N.H. Experimental Investigation on Bagasse Ash Based Geopolymer Concrete Subjected to Elevated Tempreture. Proc. IOP Conf. Ser. Earth Environ. Sci. 2021, 796, 12028. [Google Scholar] [CrossRef]

- Abdelgader, H.; Fediuk, R.; Kurpińska, M.; Elkhatib, J.; Murali, G.; Baranov, A.V.; Timokhin, R.A. Mechanical Properties of Two-Stage Concrete Modified by Silica Fume. Mag. Civ. Eng. 2019, 89, 26–38. [Google Scholar]

- Suda, V.B.R.; Rao, P.S. Experimental Investigation on Optimum Usage of Micro Silica and GGBS for the Strength Characteristics of Concrete. Mater. Today Proc. 2020, 27, 805–811. [Google Scholar] [CrossRef]

- Raju, S.; Dharmar, B. Mechanical Properties of Concrete with Copper Slag and Fly Ash by DT and NDT. Period. Polytech. Civ. Eng. 2016, 60, 313–322. [Google Scholar] [CrossRef] [Green Version]

- Nassar, R.-U.-D.; Soroushian, P. Green and Durable Mortar Produced with Milled Waste Glass. Mag. Concr. Res. 2012, 64, 605–615. [Google Scholar] [CrossRef]

- Belouadah, M.; Rahmouni, Z.E.A.; Tebbal, N. Experimental Characterization of Ordinary Concretes Obtained by Adding Construction Waste (Glass, Marble). Procedia Comput. Sci. 2019, 158, 153–162. [Google Scholar] [CrossRef]

- Maharishi, A.; Singh, S.P.; Gupta, L.K. Strength and Durability Studies on Slag Cement Concrete Made with Copper Slag as Fine Aggregates. Mater. Today Proc. 2021, 38, 2639–2648. [Google Scholar] [CrossRef]

- Sharifi, Y.; Afshoon, I.; Asad-Abadi, S.; Aslani, F. Environmental Protection by Using Waste Copper Slag as a Coarse Aggregate in Self-Compacting Concrete. J. Environ. Manage. 2020, 271, 111013. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K. Characteristics and Utilisation of Copper Slag—A Review. Resour. Conserv. Recycl. 2003, 39, 299–313. [Google Scholar] [CrossRef]

- Liu, J.; Guo, R.; Shi, P.; Huang, L. Hydration Mechanisms of Composite Binders Containing Copper Slag at Different Temperatures. J. Therm. Anal. Calorim. 2019, 137, 1919–1928. [Google Scholar] [CrossRef]

- Murari, K.; Siddique, R.; Jain, K.K. Use of Waste Copper Slag, a Sustainable Material. J. Mater. Cycles Waste Manag. 2015, 17, 13–26. [Google Scholar] [CrossRef]

- Liu, J.; Guo, R. Hydration Properties of Alkali-Activated Quick Cooled Copper Slag and Slow Cooled Copper Slag. J. Therm. Anal. Calorim. 2020, 139, 3383–3394. [Google Scholar] [CrossRef]

- Firdous, R.; Stephan, D. Effect of Silica Modulus on the Geopolymerization Activity of Natural Pozzolans. Constr. Build. Mater. 2019, 219, 31–43. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. Hydration Products of Alkali Activated Slag Cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Brough, A.R.; Atkinson, A. Sodium Silicate-Based, Alkali-Activated Slag Mortars: Part I. Strength, Hydration and Microstructure. Cem. Concr. Res. 2002, 32, 865–879. [Google Scholar] [CrossRef]

- Chakrawarthi, V.; Avudaiappan, S.; Amran, M.; Dharmar, B.; Raj Jesuarulraj, L.; Fediuk, R.; Aepuru, R.; Vatin, N.I.; Saavedra Flores, E. Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete. Materials 2021, 14, 7735. [Google Scholar] [CrossRef]

- Wang, G.C. The Utilization of Slag in Civil Infrastructure Construction; Woodhead Publishing: Sawston, UK, 2016; ISBN 0081003978. [Google Scholar]

- Wang, R.; Shi, Q.; Li, Y.; Cao, Z.; Si, Z. A Critical Review on the Use of Copper Slag (CS) as a Substitute Constituent in Concrete. Constr. Build. Mater. 2021, 292, 123371. [Google Scholar] [CrossRef]

- Manjunatha, M.; Reshma, T.V.; Balaji, K.; Bharath, A.; Tangadagi, R.B. The Sustainable Use of Waste Copper Slag in Concrete: An Experimental Research. Mater. Today Proc. 2021, 47, 3645–3653. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Taha, R.A.; Al-Hashmi, A.; Al-Harthy, A.S. Effect of Copper Slag and Cement By-Pass Dust Addition on Mechanical Properties of Concrete. Constr. Build. Mater. 2006, 20, 322–331. [Google Scholar] [CrossRef]

- Mavroulidou, M. Mechanical Properties and Durability of Concrete with Water Cooled Copper Slag Aggregate. Waste Biomass Valorization 2017, 8, 1841–1854. [Google Scholar] [CrossRef] [Green Version]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M. Assessment of Strength and Durability Characteristics of Copper Slag Incorporated Ultra High Strength Concrete. J. Clean. Prod. 2019, 208, 402–414. [Google Scholar] [CrossRef]

- Esfahani, S.M.R.A.; Zareei, S.A.; Madhkhan, M.; Ameri, F.; Rashidiani, J.; Taheri, R.A. Mechanical and Gamma-Ray Shielding Properties and Environmental Benefits of Concrete Incorporating GGBFS and Copper Slag. J. Build. Eng. 2021, 33, 101615. [Google Scholar] [CrossRef]

- Mirhosseini, S.R.; Fadaee, M.; Tabatabaei, R.; Fadaee, M.J. Mechanical Properties of Concrete with Sarcheshmeh Mineral Complex Copper Slag as a Part of Cementitious Materials. Constr. Build. Mater. 2017, 134, 44–49. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.N.N.; Sarker, P.K. Value Added Utilization of By-Product Electric Furnace Ferronickel Slag as Construction Materials: A Review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Siddique, R. Strength Properties and Micro-Structural Analysis of Self-Compacting Concrete Made with Iron Slag as Partial Replacement of Fine Aggregates. Constr. Build. Mater. 2016, 127, 144–152. [Google Scholar] [CrossRef]

- Najimi, M.; Pourkhorshidi, A.R. Properties of Concrete Containing Copper Slag Waste. Mag. Concr. Res. 2011, 63, 605–615. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of Copper Slag as a Fine Aggregate on the Properties of Cement Mortars and Concrete. Constr. Build. Mater. 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Chithra, S.; Kumar, S.R.R.S.; Chinnaraju, K. The Effect of Colloidal Nano-Silica on Workability, Mechanical and Durability Properties of High Performance Concrete with Copper Slag as Partial Fine Aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Kubissa, W.; Jaskulski, R.; Gil, D.; Wilińska, I. Holistic Analysis of Waste Copper Slag Based Concrete by Means of EIPI Method. Buildings 2019, 10, 1. [Google Scholar] [CrossRef] [Green Version]

- ASTM ASTM D6868 Standard; Specification for Biodegradable Plastics Used as Coatings on Paper and Other Compostable Substrates. ASTM International: West Conshohocken, PA, USA, 2017.

- Mantry, S.; Jha, B.B.; Satapathy, A. Evaluation and Characterization of Plasma Sprayed Cu Slag-Al Composite Coatings on Metal Substrates. J. Coat. 2013, 2013, 1–7. [Google Scholar] [CrossRef] [Green Version]

- De Schepper, M.; Verlé, P.; Van Driessche, I.; De Belie, N. Use of Secondary Slags in Completely Recyclable Concrete. J. Mater. Civ. Eng. 2015, 27, 4014177. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.; Siddique, R. Strength and Micro-Structural Properties of Self-Compacting Concrete Incorporating Copper Slag. Constr. Build. Mater. 2019, 224, 894–908. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Hisada, M.; Al-Oraimi, S.K.; Al-Saidy, A.H. Copper Slag as Sand Replacement for High Performance Concrete. Cem. Concr. Compos. 2009, 31, 483–488. [Google Scholar] [CrossRef]

- Ting, L.; Qiang, W.; Shiyu, Z. Effects of Ultra-Fine Ground Granulated Blast-Furnace Slag on Initial Setting Time, Fluidity and Rheological Properties of Cement Pastes. Powder Technol. 2019, 345, 54–63. [Google Scholar] [CrossRef]

- Ayano, T.; Sakata, K. Durability of Concrete with Copper Slag Fine Aggregate. In Proceedings of the 5th International CanMET/ACI Conference on Durability of Concrete 2000, Barcelona, Spain, 4–9 June 2000; American Concrete Institute: Farmington Hills, MI, USA, 2000; pp. 141–157. [Google Scholar]

- Gopalakrishnan, R.; Nithiyanantham, S. Microstructural, Mechanical, and Electrical Properties of Copper Slag Admixtured Cement Mortar. J. Build. Eng. 2020, 31, 101375. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, M.; Jain, M. Recycling Copper Slag in Steel Fibre Concrete for Sustainable Construction. J. Clean. Prod. 2020, 271, 122559. [Google Scholar] [CrossRef]

- Kwon, Y.-H.; Kang, S.-H.; Hong, S.-G.; Moon, J. Acceleration of Intended Pozzolanic Reaction under Initial Thermal Treatment for Developing Cementless Fly Ash Based Mortar. Materials 2017, 10, 225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, R.; Khan, R.A. Durability Assessment of Self Compacting Concrete Incorporating Copper Slag as Fine Aggregates. Constr. Build. Mater. 2017, 155, 617–629. [Google Scholar] [CrossRef]

- Caliskan, S.; Behnood, A. Recycling Copper Slag as Coarse Aggregate: Hardened Properties of Concrete. In Proceedings of the 7th International Conference on Concrete Technology in Developing Countries, Kuala Lumpur, Malaysia, 5–8 October 2004; pp. 91–98. [Google Scholar]

- Khanzadi, M.; Behnood, A. Mechanical Properties of High-Strength Concrete Incorporating Copper Slag as Coarse Aggregate. Constr. Build. Mater. 2009, 23, 2183–2188. [Google Scholar] [CrossRef]

- Sambangi, A.; Arunakanthi, E. Fresh and Mechanical Properties of SCC with Fly Ash and Copper Slag as Mineral Admixtures. Mater. Today Proc. 2021, 45, 6687–6693. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sustainable Use of Copper Slag in Self Compacting Concrete Containing Supplementary Cementitious Materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Tangadagi, R.B.; Manjunatha, M.; Bharath, A.; Preethi, S. Utilization of Steel Slag as an Eco-Friendly Material in Concrete for Construction. J. Green Eng. 2020, 10, 2408–2419. [Google Scholar]

- Li, Q.; Zhang, L.; Gao, X.; Zhang, J. Effect of Pulverized Fuel Ash, Ground Granulated Blast-Furnace Slag and CO2 Curing on Performance of Magnesium Oxysulfate Cement. Constr. Build. Mater. 2020, 230, 116990. [Google Scholar] [CrossRef]

- Babu, K.M.; Ravitheja, A. Effect of Copper Slag as Fine Aggregate Replacement in High Strength Concrete. Mater. Today Proc. 2019, 19, 409–414. [Google Scholar] [CrossRef]

- Junwei, S.; Shenglei, F.; Xiong, R.; Ouyang, Y.; Qingli, Z.; Jielu, Z.H.U.; Zhang, C. Mechanical Properties, Pozzolanic Activity and Volume Stability of Copper Slag-Filled Cementitious Materials. Mater. Sci. 2020, 26, 218–224. [Google Scholar]

- Afshoon, I.; Sharifi, Y. Use of Copper Slag Microparticles in Self-Consolidating Concrete. ACI Mater. J. 2017, 114, 691–699. [Google Scholar] [CrossRef]

- Jayapal Naganur, C. Effect of Copper Slag as a Partial Replacement of Fine Aggregate on the Properties of Cement Concrete. Int. J. Res. 2014, 1, 8. [Google Scholar]

- Sambhaji, Z.K.; Autade, P.B. Effect of Copper Slag as a Fine Aggregate on Properties of Concrete. Int. Res. J. Eng. Techn. 2016, 3, 410–414. [Google Scholar]

- Li, X.M.; Zou, S.H.; Zhao, R.G.; Deng, L.Y.; Ji, N.; Ren, C.L. Preparation and Mechanical Properties of Steel Fiber Reinforced High Performance Concrete with Copper Slag as Fine Aggregate. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2019, 531, 12037. [Google Scholar] [CrossRef]

- Tiwary, A. Effect of Copper Slag and Fly Ash on Mechanical Properties of Concrete. Int. J. Civ. Eng. Technol. 2018, 9, 354–362. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman: London, UK, 1995. [Google Scholar]

- Velumani, M.; Nirmalkumar, K. Durability and Characteristics of Copper Slag as Fine Aggregate and Fly Ash as Cement in Concrete. In Proceedings of the Second International Conference on Current Trends in Engineering and Technology-ICCTET, Coimbatore, India, 8 July 2014; IEEE: New York, NY, USA, 2014; pp. 222–227. [Google Scholar]

- Brindha, D.; Baskaran, T.; Nagan, S. Assessment of Corrosion and Durability Characteristics of Copper Slag Admixed Concrete. Int. J. Civ. Struct. Eng. 2010, 1, 192. [Google Scholar]

- Hassaan, M.Y.; El Desoky, M.M.; Salem, S.M.; Yousif, A.A. Some Physical Properties of Anhydrous and Hydrated Brownmillerite Doped with NaF. Cem. Concr. Res. 2003, 33, 697–702. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water Absorption and Electrical Resistivity of Concrete with Recycled Concrete Aggregates and Fly Ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Durability of Metakaolin Concrete to Sulfate Attack. Cem. Concr. Res. 2006, 36, 1727–1734. [Google Scholar] [CrossRef]

- Sharifi, Y.; Afshoon, I.; Nematollahzade, M.; Ghasemi, M.; Momeni, M.-A. Effect of Copper Slag on the Resistance Characteristics of SCC Exposed to the Acidic Environment. Asian J. Civ. Eng. 2020, 21, 597–609. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sulfate Resistance of Self Compacting Concrete Incorporating Copper Slag as Fine Aggregates with Mineral Admixtures. Constr. Build. Mater. 2021, 287, 122985. [Google Scholar] [CrossRef]

- Singh, G.; Siddique, R. Effect of Iron Slag as Partial Replacement of Fine Aggregates on the Durability Characteristics of Self-Compacting Concrete. Constr. Build. Mater. 2016, 128, 88–95. [Google Scholar] [CrossRef]

- Najimi, M.; Sobhani, J.; Pourkhorshidi, A.R. Durability of Copper Slag Contained Concrete Exposed to Sulfate Attack. Constr. Build. Mater. 2011, 25, 1895–1905. [Google Scholar] [CrossRef]

- Gevaudan, J.P.; Caicedo-Ramirez, A.; Hernandez, M.T.; Srubar III, W. V Copper and Cobalt Improve the Acid Resistance of Alkali-Activated Cements. Cem. Concr. Res. 2019, 115, 327–338. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; El Ouni, M.H.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 1–22. [Google Scholar] [CrossRef]

- Alvee, A.R.; Malinda, R.; Akbar, A.M.; Ashar, R.D.; Rahmawati, C.; Alomayri, T.; Raza, A.; Shaikh, F.U.A. Experimental Study of the Mechanical Properties and Microstructure of Geopolymer Paste Containing Nano-Silica from Agricultural Waste and Crystalline Admixtures. Case Stud. Constr. Mater. 2022, 16, e00792. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling Phosphogypsum and Construction Demolition Waste for Cemented Paste Backfill and Its Environmental Impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. A Reaction Engineering Approach to the Problem of Concrete Carbonation. AIChE J. 1989, 35, 1639–1650. [Google Scholar] [CrossRef]

- El-Didamony, H.; Sharara, A.M.; Helmy, I.M.; Abd El-Aleem, S. Hydration Characteristics of β-C2S in the Presence of Some Accelerators. Cem. Concr. Res. 1996, 26, 1179–1187. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Q.; Chen, Q.; Wang, D.; Guo, H.; Liu, L.; Yang, Q. Hydration and Strength Development in Blended Cement with Ultrafine Granulated Copper Slag. PLoS ONE 2019, 14, e0215677. [Google Scholar] [CrossRef] [PubMed]

- Alter, H. The Composition and Environmental Hazard of Copper Slags in the Context of the Basel Convention. Resour. Conserv. Recycl. 2005, 43, 353–360. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Huang, Z. Reuse of Copper Slag as a Supplementary Cementitious Material: Reactivity and Safety. Resour. Conserv. Recycl. 2020, 162, 105037. [Google Scholar] [CrossRef]

- Shanmuganathan, P.; Lakshmipathiraj, P.; Srikanth, S.; Nachiappan, A.L.; Sumathy, A. Toxicity Characterization and Long-Term Stability Studies on Copper Slag from the ISASMELT Process. Resour. Conserv. Recycl. 2008, 52, 601–611. [Google Scholar] [CrossRef]

- Shirdam, R.; Amini, M.; Bakhshi, N. Investigating the Effects of Copper Slag and Silica Fume on Durability, Strength, and Workability of Concrete. Int. J. Environ. Res. 2019, 13, 909–924. [Google Scholar] [CrossRef]

| Authors | Manjunatha et al. [45] | Jabri et al. [46] | Mavroulidou et al. [47] | Raju et al. [30] | Maharishi et al. [33] |

|---|---|---|---|---|---|

| Specific gravity | 3.51 | 2.4 | - | 3.52 | 3.30 |

| Water absorption (%) | 0.36 | - | 0.11 | - | 0.36 |

| Fineness modulus | 3.11 | - | 2.97 | 3.68 | 3.18 |

| Moisture content (%) | - | - | - | - | - |

| Density (kg/m3) | - | - | 3.73 | - | - |

| Specific surface area, (m2/kg) | - | - | - | - | - |

| Initial setting (min) | - | 250 | - | - | - |

| Fineness (cm2/g) | - | 1261 | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Majdi, A.; Deifalla, A.F.; Isleem, H.F.; Rahmawati, C. Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review. Materials 2022, 15, 5196. https://doi.org/10.3390/ma15155196

Ahmad J, Majdi A, Deifalla AF, Isleem HF, Rahmawati C. Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review. Materials. 2022; 15(15):5196. https://doi.org/10.3390/ma15155196

Chicago/Turabian StyleAhmad, Jawad, Ali Majdi, Ahmed Farouk Deifalla, Haytham F. Isleem, and Cut Rahmawati. 2022. "Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review" Materials 15, no. 15: 5196. https://doi.org/10.3390/ma15155196

APA StyleAhmad, J., Majdi, A., Deifalla, A. F., Isleem, H. F., & Rahmawati, C. (2022). Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review. Materials, 15(15), 5196. https://doi.org/10.3390/ma15155196