Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation and Characterization of the Fillers

2.3. Preparation and Characterization of the Composites

- First heating from 30 to 220 °C at 10 °C/min.

- Cooling from 220 to −30 °C at 10 °C/min.

- Second heating from −30 to 220 °C at 10 °C/min.

3. Results and Discussion

3.1. Characteristics of the Fillers

3.2. Color Measurements of the PLA-Based Composites

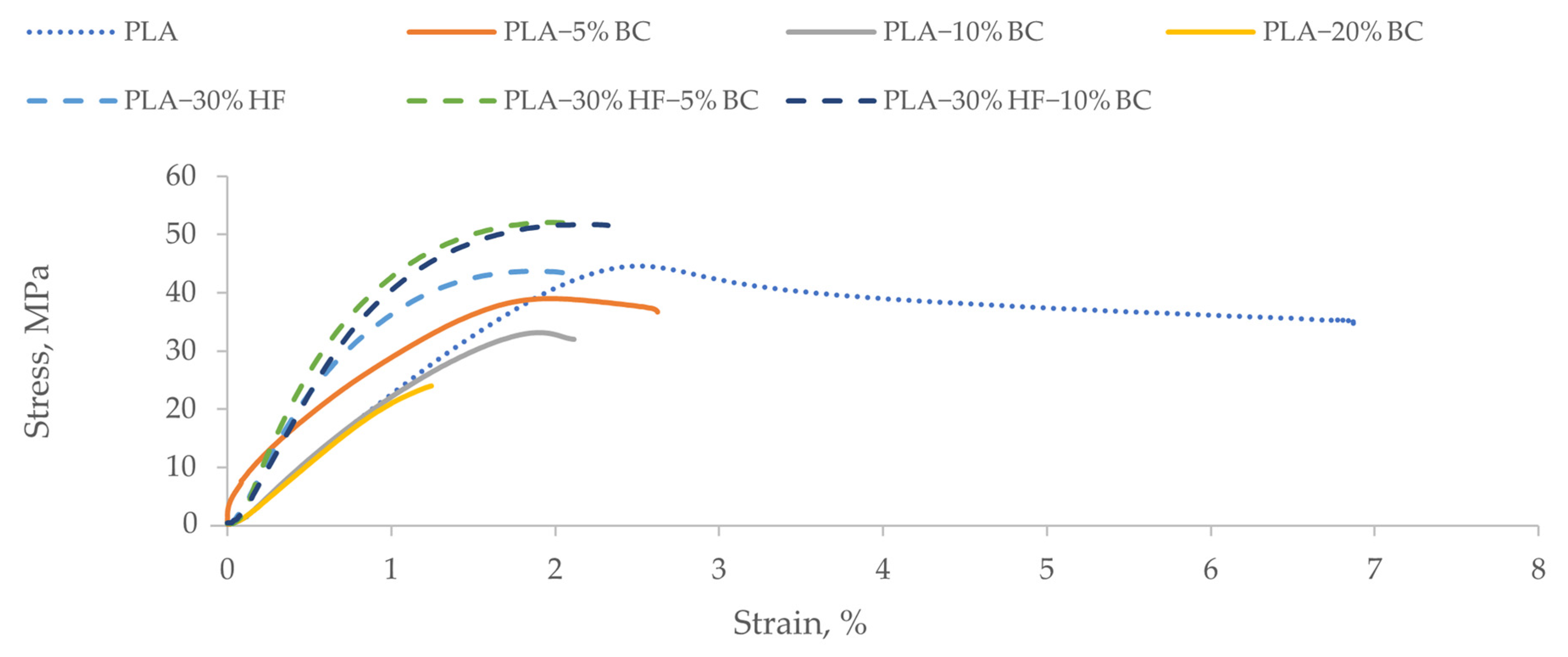

3.3. Influence of Biochar Content on the Mechanical Properties of the PLA-Based Composites

3.4. Thermal Properties

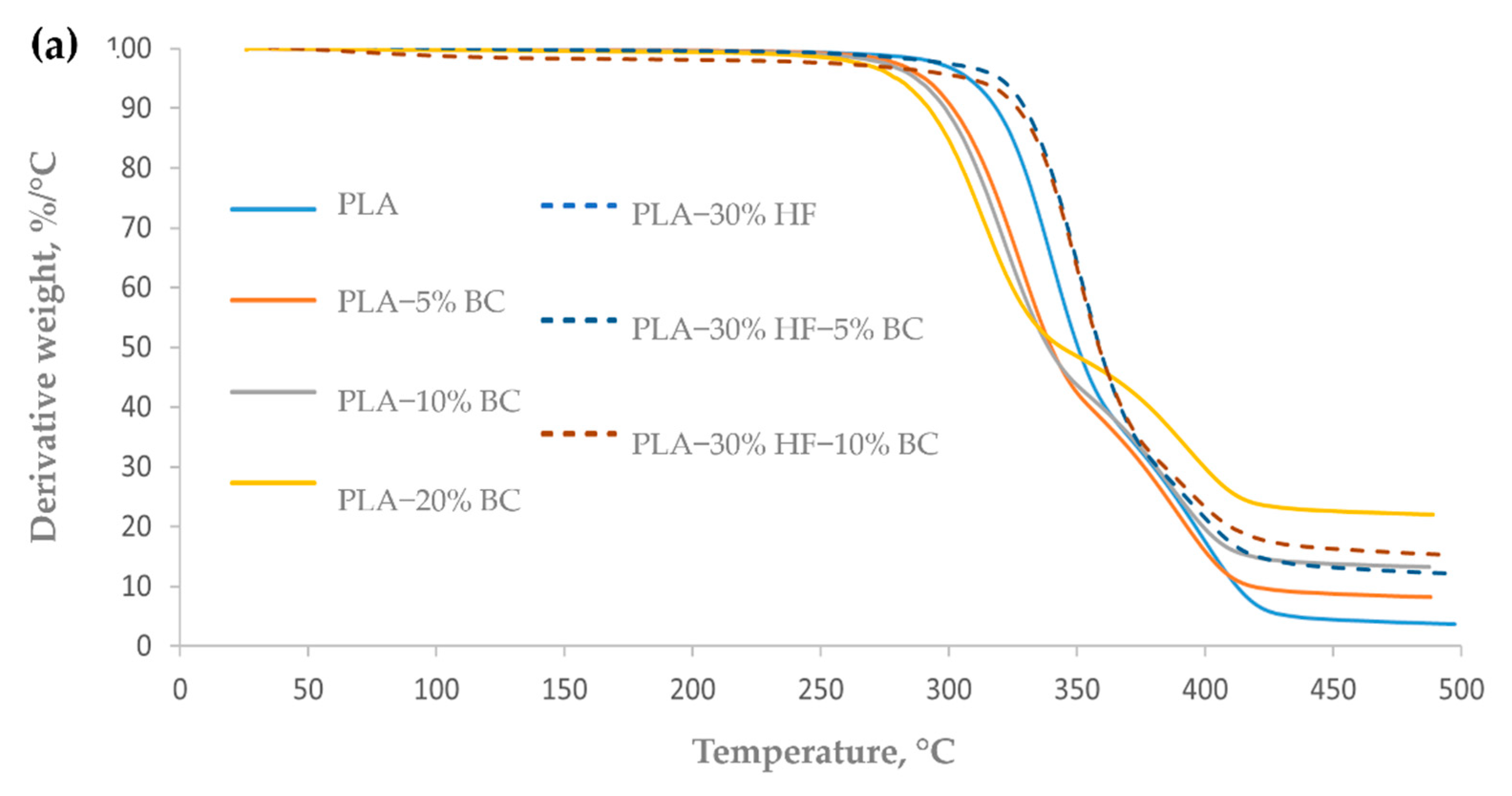

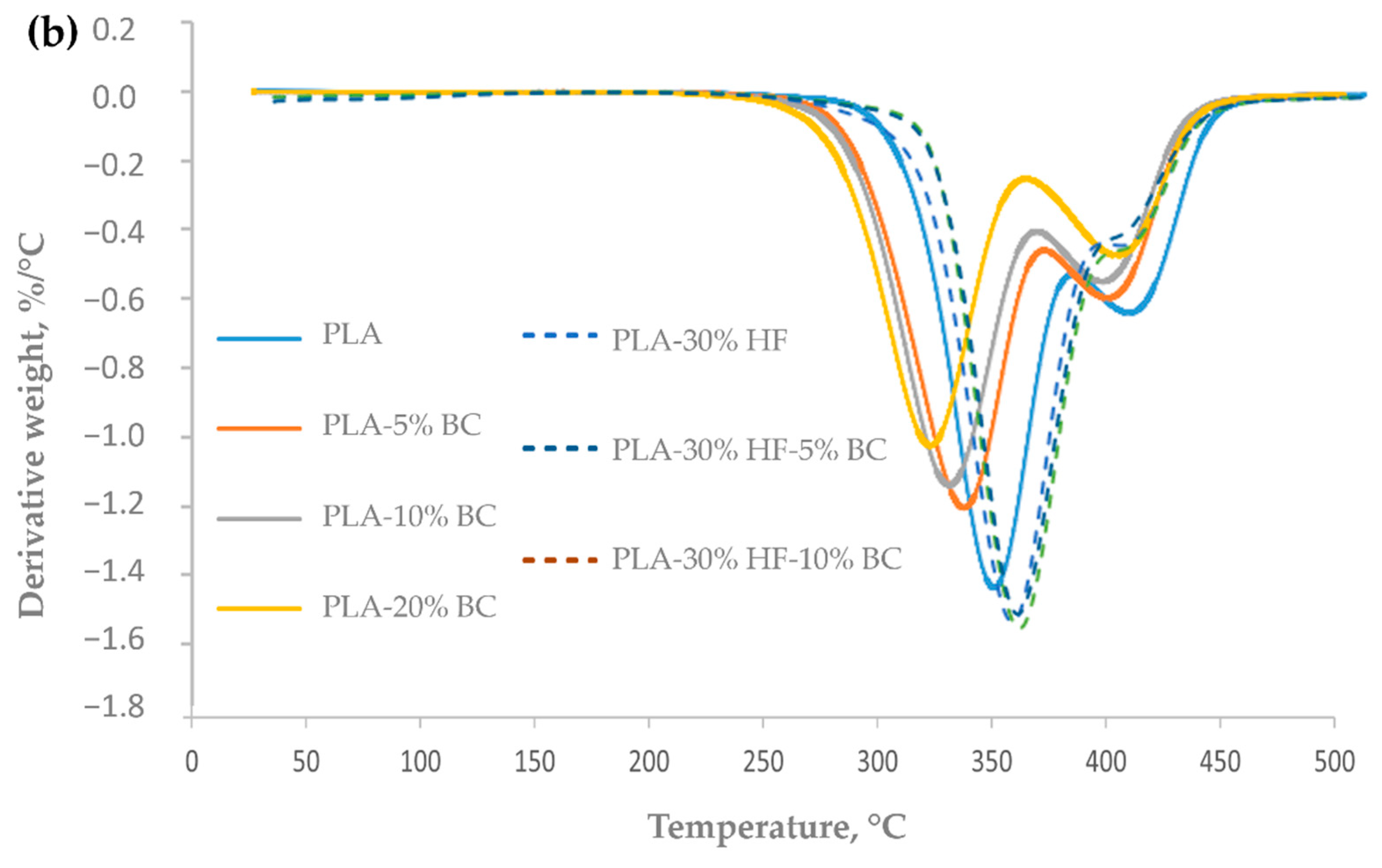

3.4.1. Thermogravimetric Analysis (TGA)

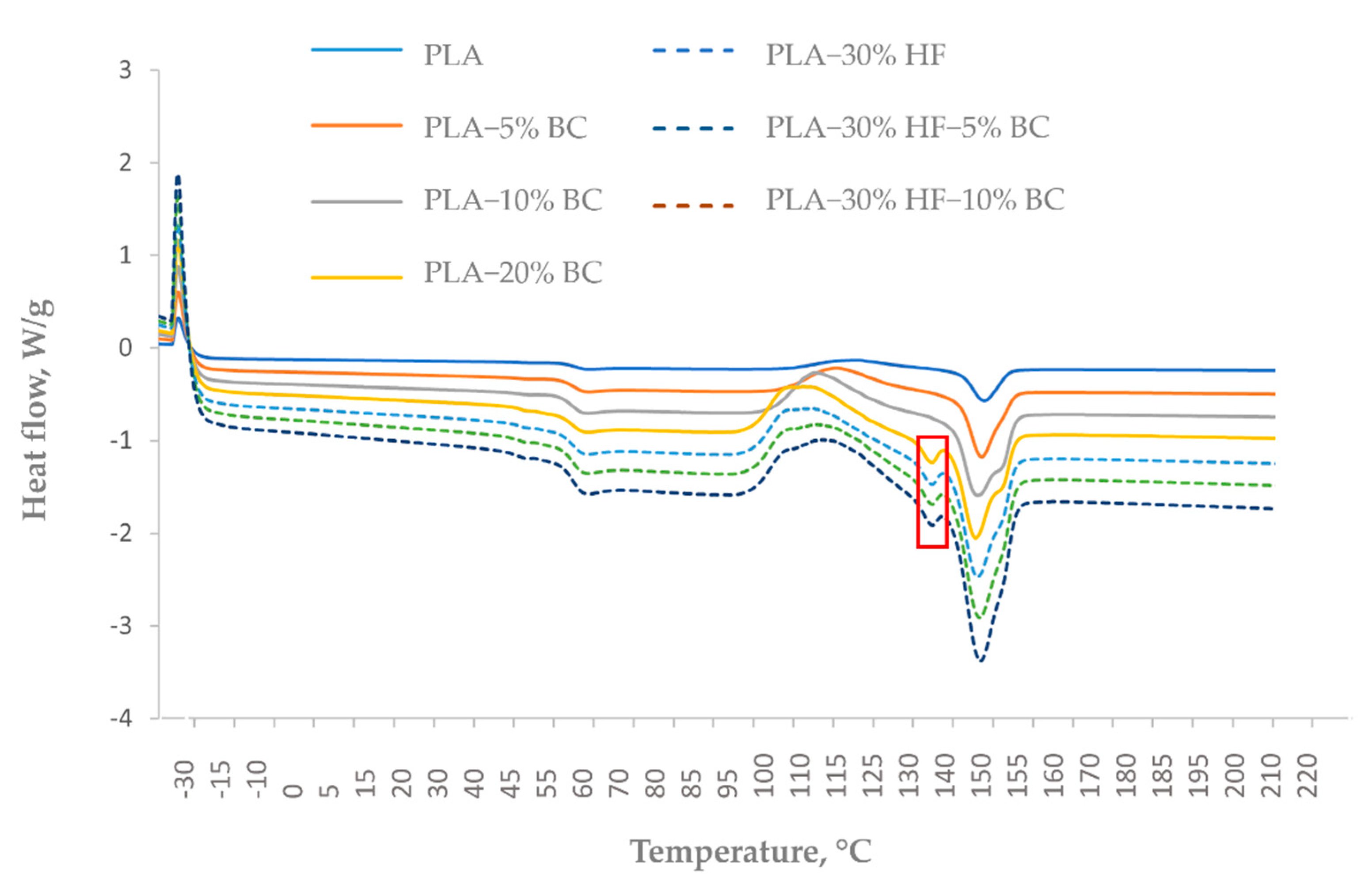

3.4.2. Differential Scanning Calorimetry (DSC)

3.5. Hygroscopic Properties

3.5.1. Water Contact Angle Measurements

3.5.2. Water Absorption Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Hartmann, M.H. High molecular weight polylactic acid polymers. In Biopolymers from Renewable Resources; Kaplan, D.L., Ed.; Springer: Berlin/Heidelberg, Germany, 1998; pp. 367–411. [Google Scholar] [CrossRef]

- Auras, R.A.; Harte, B.; Selke, S.; Hernandez, R. Mechanical, Physical, and Barrier Properties of Poly(Lactide) Films. J. Plast. Film Sheeting 2003, 19, 123–135. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Rasal, R.M.; Hirt, D.E. Toughness decrease of PLA-PHBHHx blend films upon surface-confined photopolymerization. J. Biomed. Mater. Res. Part A 2009, 88, 1079–1086. [Google Scholar] [CrossRef] [PubMed]

- Le Duigou, A.; Davies, P.; Baley, C. Macroscopic analysis of interfacial properties of flax/PLLA biocomposites. Compos. Sci. Technol. 2010, 70, 1612–1620. [Google Scholar] [CrossRef] [Green Version]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Alao, P.F.; Marrot, L.; Burnard, M.D.; Lavrič, G.; Saarna, M.; Kers, J. Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale. Polymers 2021, 13, 851. [Google Scholar] [CrossRef]

- Alao, P.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of Hemp Fiber Surface Treatment on the Moisture/Water Resistance and Reaction to Fire of Reinforced PLA Composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef] [PubMed]

- Marrot, L.; Alao, P.F.; Mikli, V.; Kers, J. Properties of Frost-Retted Hemp Fibers for the Reinforcement of Composites. J. Nat. Fibers 2021, 10, 1–12. [Google Scholar] [CrossRef]

- Sohi, S.P. Carbon Storage with Benefits. Science 2012, 338, 1034–1035. [Google Scholar] [CrossRef] [PubMed]

- Basu, P. Pyrolysis. In Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 147–176. [Google Scholar] [CrossRef]

- Vivekanandhan, S. Biochar as sustainable reinforcement for polymer composites. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 10–22. [Google Scholar] [CrossRef]

- Chen, N.; Pilla, S. A comprehensive review on transforming lignocellulosic materials into biocarbon and its utilization for composites applications. Compos. Part C: Open Access 2021, 7, 100225. [Google Scholar] [CrossRef]

- Zornoza, R.; Moreno-Barriga, J.A.; Acosta, J.A.; Muñoz, M.A.; Faz, A. Stability, nutrient availability and hydrophobicity of biochars derived from manure, crop residues, and municipal solid waste for their use as soil amendments. Chemosphere 2016, 144, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Giorcelli, M.; Bartoli, M. Development of Coffee Biochar Filler for the Production of Electrical Conductive Reinforced Plastic. Polymers 2019, 11, 1916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marrot, L.; Candelier, K.; Valette, J.; Lanvin, C.; Horvat, B.; Legan, L.; DeVallance, D.B. Valorization of Hemp Stalk Waste Through Thermochemical Conversion for Energy and Electrical Applications. Waste Biomass Valorization 2021, 13, 2267–2285. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Holz Als Roh- Und Werkst. 2010, 69, 649–657. [Google Scholar] [CrossRef] [Green Version]

- Aup-Ngoen, K.; Noipitak, M. Effect of carbon-rich biochar on mechanical properties of PLA-biochar composites. Sustain. Chem. Pharm. 2020, 15, 100204. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2015, 50, 1161–1168. [Google Scholar] [CrossRef]

- DeVallance, D.B.; Oporto, G.S.; Quigley, P. Investigation of hardwood biochar as a replacement for wood flour in wood–polypropylene composites. J. Elastomers Plast. 2015, 48, 510–522. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Gunjal, J.; Chauhan, S. Effect of carbonization temperature on properties of natural fiber and charcoal filled hybrid polymer composite. Compos. Part B: Eng. 2021, 217, 108846. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Mohanty, K.A.; Singh, A.S.P.; Ng, P.K.W. Preparation and Properties of Biodegradable Multilayer Films Based on Soy Protein Isolate and Poly(lactide). Ind. Eng. Chem. Res. 2006, 45, 3059–3066. [Google Scholar] [CrossRef]

- Crombie, K.; Mašek, O.; Sohi, S.P.; Brownsort, P.; Cross, A. The effect of pyrolysis conditions on biochar stability as determined by three methods. GCB Bioenergy 2012, 5, 122–131. [Google Scholar] [CrossRef] [Green Version]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Condon, J.B. Surface Area and Porosity Determinations by Physisorption: Measurements and Theory; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Zhao, S.-X.; Ta, N.; Wang, X.-D. Effect of Temperature on the Structural and Physicochemical Properties of Biochar with Apple Tree Branches as Feedstock Material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef] [Green Version]

- Masís-Meléndez, F.; Segura-Chavarría, D.; A García-González, C.; Quesada-Kimsey, J.; Villagra-Mendoza, K. Variability of Physical and Chemical Properties of TLUD Stove Derived Biochars. Appl. Sci. 2020, 10, 507. [Google Scholar] [CrossRef] [Green Version]

- Etaati, A.; Pather, S.; Rahman, M.; Wang, H. Ground Hemp Fibers as Filler/Reinforcement for Thermoplastic Biocomposites. Adv. Mater. Sci. Eng. 2015, 2015, 24–35. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.-C. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [Green Version]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of Torrefied Coffee Grounds as Reinforcing Agent To Produce High-Quality Biodegradable PBAT Composites for Food Packaging Applications. ACS Sustain. Chem. Eng. 2016, 5, 1906–1916. [Google Scholar] [CrossRef]

- Ho, M.-P.; Lau, K.-T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic Acid)–Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paiva, M.C.; Zhou, B.; Fernando, K.A.S.; Lin, Y.; Kennedy, J.M.; Sun, Y.-P. Mechanical and morphological characterization of polymer–carbon nanocomposites from functionalized carbon nanotubes. Carbon 2004, 42, 2849–2854. [Google Scholar] [CrossRef]

- Tanguy, M.; Bourmaud, A.; Beaugrand, J.; Gaudry, T.; Baley, C. Polypropylene reinforcement with flax or jute fibre; Influence of microstructure and constituents properties on the performance of composite. Compos. Part B: Eng. 2018, 139, 64–74. [Google Scholar] [CrossRef]

- Ausias, G.; Bourmaud, A.; Coroller, G.; Baley, C. Study of the fibre morphology stability in polypropylene-flax composites. Polym. Degrad. Stab. 2013, 98, 1216–1224. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fibre reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319. [Google Scholar] [CrossRef]

- Angin, N.; Caylak, S.; Ertas, M.; Cavdar, A.D. Effect of alkyl ketene dimer on chemical and thermal properties of polylactic acid (PLA) hybrid composites. Sustain. Mater. Technol. 2022, e00386, in press. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Chen, Z.-J.; Tsou, C.-H.; Tsai, M.-L.; Guo, J.; De Guzman, M.R.; Yang, T.; Gao, C.; Lei, Y.; Gan, P.-W.; Chen, S.; et al. Barrier properties and hydrophobicity of biodegradable poly(lactic acid) composites reinforced with recycled chinese spirits distiller’s grains. Polymers 2021, 13, 2861. [Google Scholar] [CrossRef] [PubMed]

- Bassett, D.C.; Olley, R.H.; AL Alraheil, I.A.M. On crystallization phenomena in PEEK. Polymer 1988, 29, 1745–1754. [Google Scholar] [CrossRef]

- Cebe, P.; Hong, S.-D. Crystallization behaviour of poly(ether-ether-ketone). Polymer 1986, 27, 1183–1192. [Google Scholar] [CrossRef]

- Jonas, A.M.; Russell, T.P.; Yoon, D.Y. Synchrotron X-ray Scattering Studies of Crystallization of Poly(ether-ether-ketone) from the Glass and Structural Changes during Subsequent Heating-Cooling Processes. Macromolecules 1995, 28, 8491–8503. [Google Scholar] [CrossRef]

- Lee, Y.; Porter, R.S.; Lin, J.S. On the double-melting behavior of poly(ether ether ketone). Macromolecules 1989, 22, 1756–1760. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Zhang, N.; Wang, T.; Hao, M.Y. Analysis of crystallization and melting behavior of composites before and after annealing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 733, 012025. [Google Scholar] [CrossRef]

- Campbell, D.; Qayyum, M.M. Melt crystallization of polypropylene: Effect of contact with fiber substrates. J. Polym. Sci. Polym. Phys. Ed. 1980, 18, 83–93. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Thermal Properties of Wood-Plastic Composites with Different Compositions. Materials 2019, 12, 881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Law, K.-Y. Definitions for Hydrophilicity, Hydrophobicity, and Superhydrophobicity: Getting the Basics Right. J. Phys. Chem. Lett. 2014, 5, 686–688. [Google Scholar] [CrossRef] [PubMed]

- Kinney, T.J.; Masiello, C.A.; Dugan, B.; Hockaday, W.C.; Dean, M.R.; Zygourakis, K.; Barnes, R.T. Hydrologic properties of biochars produced at different temperatures. Biomass Bioenergy 2012, 41, 34–43. [Google Scholar] [CrossRef]

- Silva, C.G.; Campini, P.A.L.; Rocha, D.B.; Rosa, D.S. The influence of treated eucalyptus microfibers on the properties of PLA biocomposites. Compos. Sci. Technol. 2019, 179, 54–62. [Google Scholar] [CrossRef]

- Jose, J.P.; Abraham, J.; Maria, H.J.; Varughese, K.T.; Thomas, S. Contact Angle Studies in XLPE Hybrid Nanocomposites with Inorganic Nanofillers. Macromol. Symp. 2016, 366, 66–78. [Google Scholar] [CrossRef]

- Eselini, N.; Tirkes, S.; Akar, A.O.; Tayfun, U. Production and characterization of poly (lactic acid)-based biocomposites filled with basalt fiber and flax fiber hybrid. J. Elastomers Plast. 2019, 52, 701–716. [Google Scholar] [CrossRef]

| Sample | PLA (wt%) | Hemp Fibers (wt%) | Biochar (wt%) |

|---|---|---|---|

| PLA | 100 | 0 | 0 |

| PLA-5% BC | 95 | 0 | 5 |

| PLA-10% BC | 90 | 0 | 10 |

| PLA-20% BC | 80 | 0 | 20 |

| PLA-30% HF | 70 | 30 | 0 |

| PLA-30% HF-5% BC | 65 | 30 | 5 |

| PLA-30% HF-10% BC | 60 | 30 | 10 |

| Proximate Analysis | Particles Size Analysis | ||||||

|---|---|---|---|---|---|---|---|

| Parameters | 1 M, % | 2 V, % | Ash, % | 3 FC, % | D10, µm | D50, µm | D90, µm |

| Results | 4.1 ± 0.1 | 16.3 ± 0.2 | 1.8 ± 0.1 | 77.8 ± 0.3 | 11 ± 1 | 60 ± 7 | 155 ± 5 |

| Physisorption gas | 4 SA, m2/g | 5 TPV, cc/g | 6 PW, nm | ||||

| Nitrogen | 230.8 | 0.131 | 2.351 | ||||

| CO2 | 480.0 | 0.133 | 0.349 | ||||

| Sample | CIE L* | CIE a* | CIE b* |

|---|---|---|---|

| PLA | 90.3 ± 0.4 | −0.4 ± 0.0 | 4.8 ± 0.1 |

| PLA-5% BC | 27.8 ± 0.8 | −0.5 ± 0.1 | −6.7 ± 0.1 |

| PLA-10% BC | 24.2 ± 0.7 | −0.4 ± 0.1 | −4.6 ± 0.3 |

| PLA-20% BC | 13.8 ± 0.5 | 0.1 ± 0.0 | −0.6 ± 0.3 |

| PLA-30% HF | 40.0 ± 2.5 | 2.9 ± 1.0 | 7.7 ± 2.7 |

| PLA-30% HF-5% BC | 21.2 ± 1.2 | −0.1 ± 0.0 | −1.5 ± 0.6 |

| PLA-30% HF-10% BC | 16.4 ± 0.3 | −0.2 ± 0.0 | −1.9 ± 0.1 |

| Sample | Tensile Modulus of Elasticity, MPa | Tensile Strength, MPa | Strain at Break, % |

|---|---|---|---|

| PLA | 2418 ± 237 | 39 ± 5 | 6.8 ± 0.7 |

| PLA-5% BC | 3334 ± 256 | 37 ± 3 | 2.7 ± 0.3 |

| PLA-10% BC | 2649 ± 648 | 31 ± 6 | 1.8 ± 0.3 |

| PLA-20% BC | 2269 ± 115 | 16 ± 7 | 0.8 ± 0.3 |

| PLA-30% HF | 5158 ± 652 | 44 ± 1 | 2.0 ± 0.1 |

| PLA-30% HF-5% BC | 5841 ± 792 | 49 ± 5 | 2.1 ± 0.1 |

| PLA-30% HF-10% BC | 4992 ± 757 | 51 ± 0.4 | 2.0 ± 0.3 |

| Sample | 1T5%, °C | 2T10%, °C | 3Tmax, °C | Residue500 °C, % |

| PLA | 301.36 ± 6.38 | 312.88 ± 5.58 | 335.93 ± 0.47 | 3.92 ± 0.20 |

| PLA-5% BC | 297.76 ± 2.26 | 308.34 ± 2.57 | 331.68 ± 0.86 | 8.35 ± 0.11 |

| PLA-10% BC | 297.08 ± 5.69 | 304.86 ± 6.00 | 329.24 ± 0.71 | 13.15 ± 0.12 |

| PLA-20% BC | 289.76 ± 1.54 | 302.42 ± 1.68 | 323.70 ± 0.94 | 22.09 ± 0.04 |

| PLA-30% HF | 314.58 ± 13.63 | 328.31 ± 8.92 | 352.55 ± 1.64 | 8.54 ± 0.02 |

| PLA-30% HF-5% BC | 318.99 ± 2.59 | 330.34 ± 1.36 | 351.08 ± 0.63 | 11.72 ± 0.48 |

| PLA-30% HF-10% BC | 311.71 ± 1.98 | 327.00 ± 0.75 | 349.66 ± 1.49 | 15.21 ± 0.04 |

| Sample | Tg, °C | Tcc, °C | Tm, °C | Tc, °C | Xc, % |

|---|---|---|---|---|---|

| PLA | 58.8 ± 0.3 | 121.1 ± 0.8 | 149.6 ± 0.2 | 83.4 ± 0.1 | 5.7 ± 0.1 |

| PLA-5% BC | 59.3 ± 0.3 | 116.6 ± 0.4 | 149.1 ± 0.4 | 84.9 ± 0.2 | 2.5 ± 0.1 |

| PLA-10% BC | 57.7 ± 0.9 | 112.8 ± 0.9 | 147.1 ± 0.5 | 84.9 ± 0.1 | 4.1 ± 0.0 |

| PLA-20% BC | 52.9 ± 0.2 | 107.8 ± 0.3 | 146.5 ± 0.7 | 84.3 ± 0.1 | 4.5 ± 0.1 |

| PLA-30% HF | 58.6 ± 0.3 | 125.5 ± 0.4 | 150.3 ± 0.1 | 86.5 ± 0.1 | 4.1 ± 0.0 |

| PLA-30% HF-5% BC | 58.7 ± 0.1 | 121.5 ± 0.5 | 150.0 ± 0.2 | 87.6 ± 0.2 | 10.9 ± 0.2 |

| PLA-30% HF-10% BC | 58.6 ± 0.1 | 121.6 ± 1.0 | 150.0 ± 0.1 | 87.2 ± 0.1 | 6.7 ± 0.1 |

| Sample | WCA, ° | Ewet, mJ/m2 | Water Absorption, % | |

|---|---|---|---|---|

| _ | _ | 24 h | 48 h | |

| PLA | 122 ± 4 | 5 ± 0 | 0.4 ± 0.0 | 0.6 ± 0.1 |

| PLA-5% BC | 118 ± 2 | 22 ± 3 | 0.6 ± 0.1 | 0.8 ± 0.0 |

| PLA-10% BC | 117 ± 2 | 29 ± 2 | 0.9 ± 0.3 | 1.1 ± 0.3 |

| PLA-20% BC | 73 ± 3 | 43 ± 2 | 1.4 ± 0.2 | 1.9 ± 0.1 |

| PLA-30% HF | 109 ± 2 | 6 ± 1 | 1.7 ± 0.0 | 2.3 ± 0.1 |

| PLA-30% HF-5% BC | 114 ± 3 | 3 ± 0 | 1.5 ± 0.0 | 2.1 ± 0.1 |

| PLA-30% HF-10% BC | 107 ± 3 | 10 ± 1 | 1.8 ± 0.0 | 3.5 ± 0.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. https://doi.org/10.3390/ma15062271

Zouari M, Devallance DB, Marrot L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials. 2022; 15(6):2271. https://doi.org/10.3390/ma15062271

Chicago/Turabian StyleZouari, Mariem, David B. Devallance, and Laetitia Marrot. 2022. "Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites" Materials 15, no. 6: 2271. https://doi.org/10.3390/ma15062271

APA StyleZouari, M., Devallance, D. B., & Marrot, L. (2022). Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials, 15(6), 2271. https://doi.org/10.3390/ma15062271