Parametric Optimization for Quality of Electric Discharge Machined Profile by Using Multi-Shape Electrode

Abstract

:1. Introduction

2. Methodology

2.1. Experimental Setup

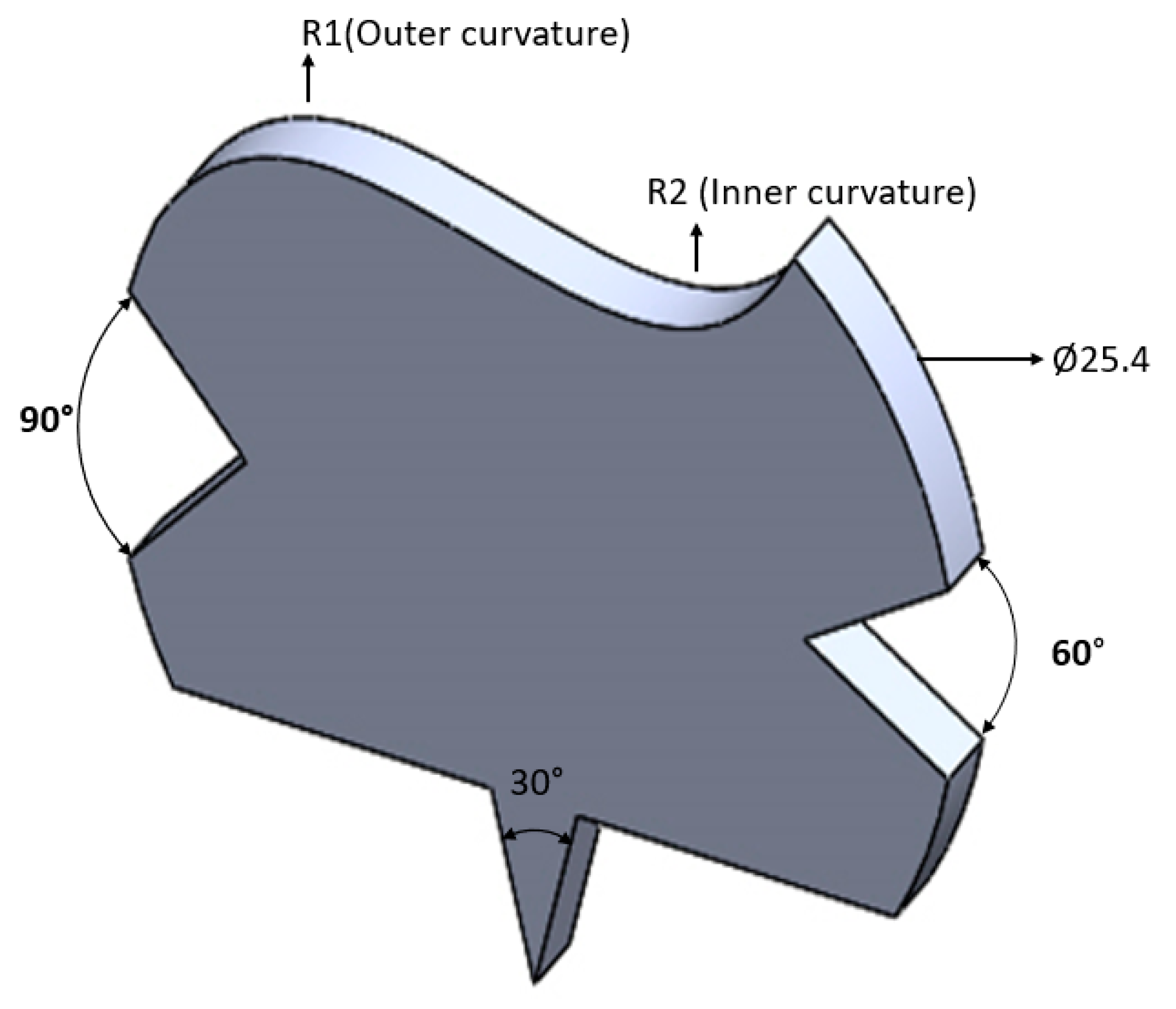

2.2. Tool Shape

2.3. Fixed EDM Conditions

3. Experiments and Results

4. Data Analysis for Accuracy of Profile

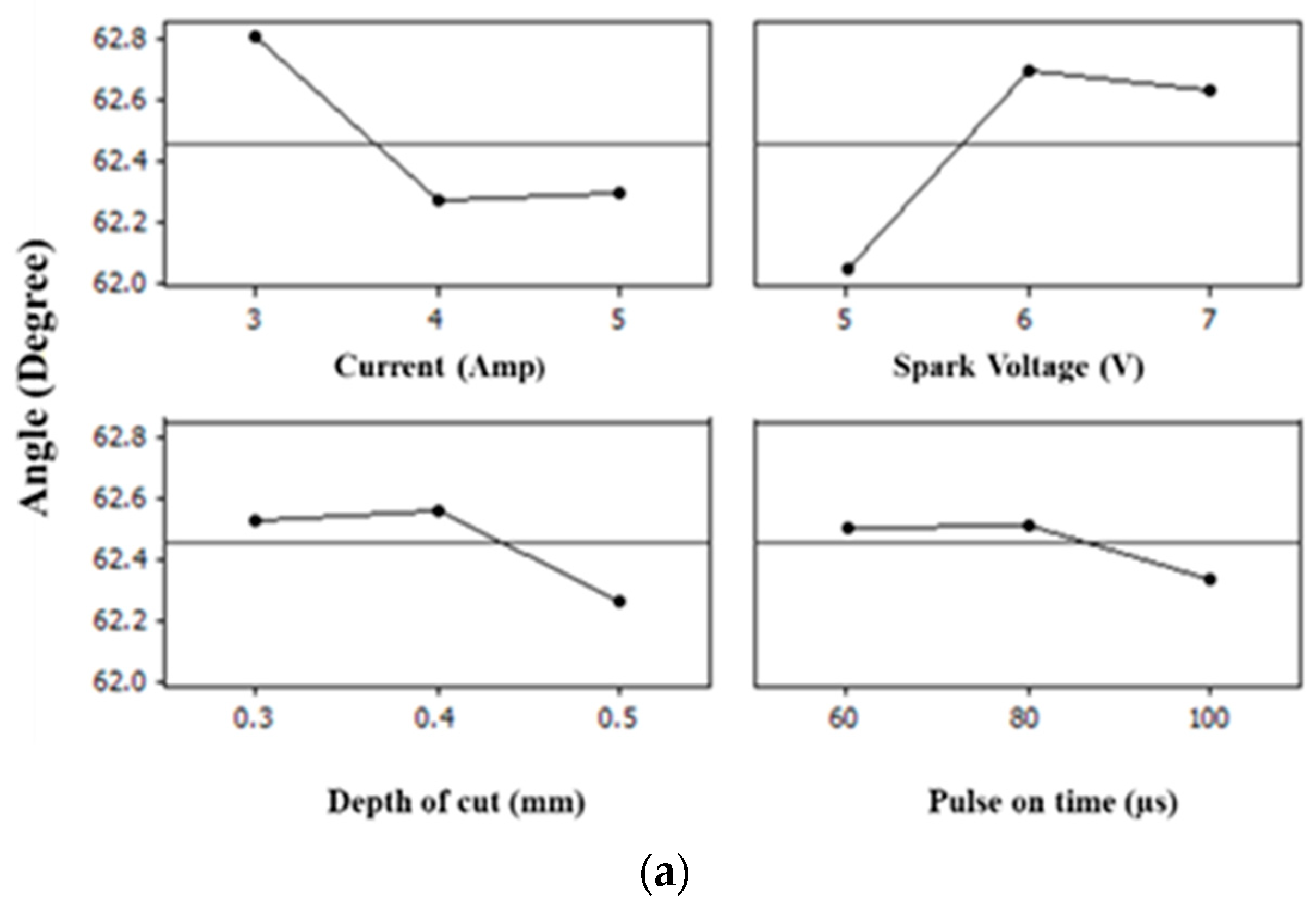

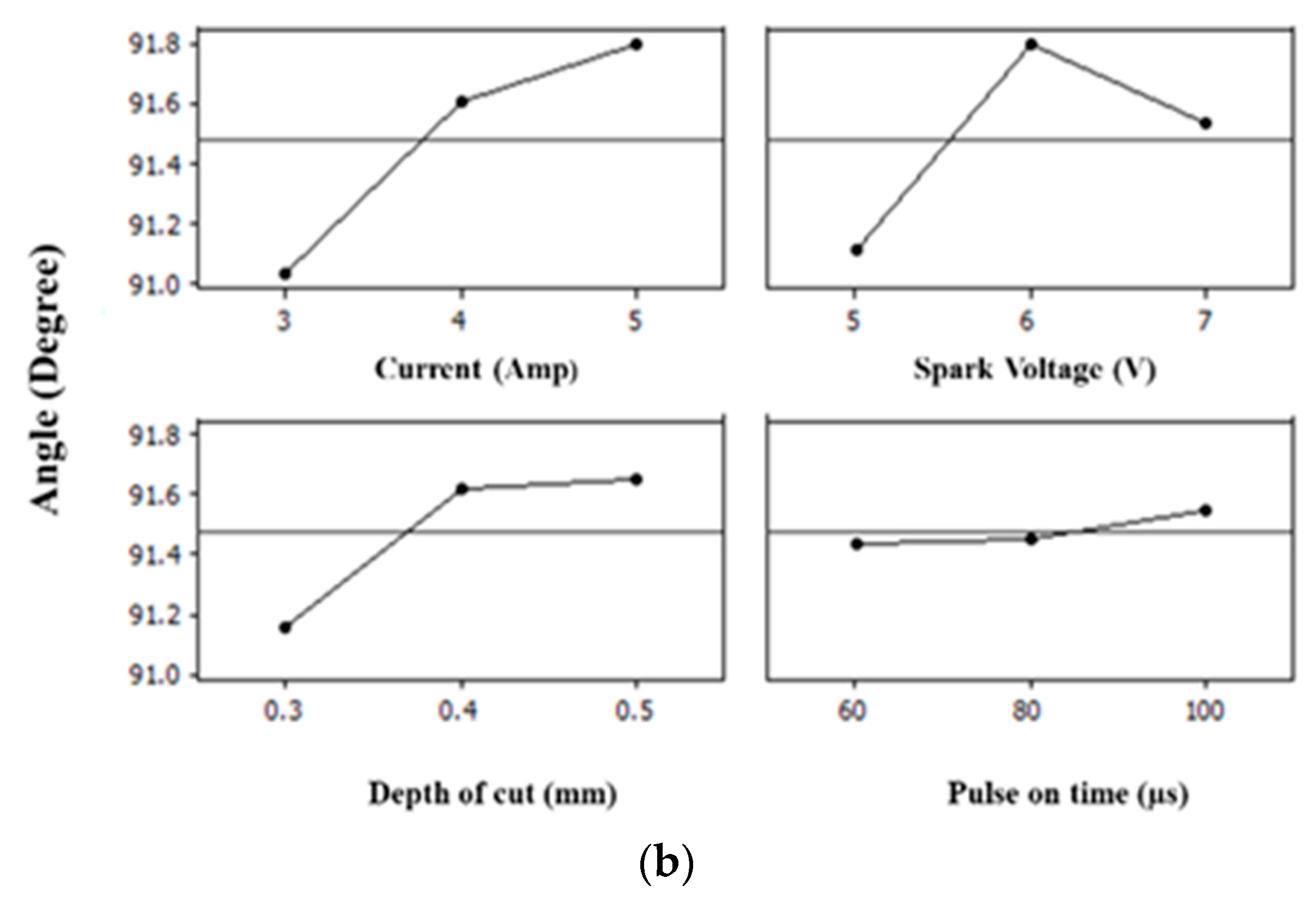

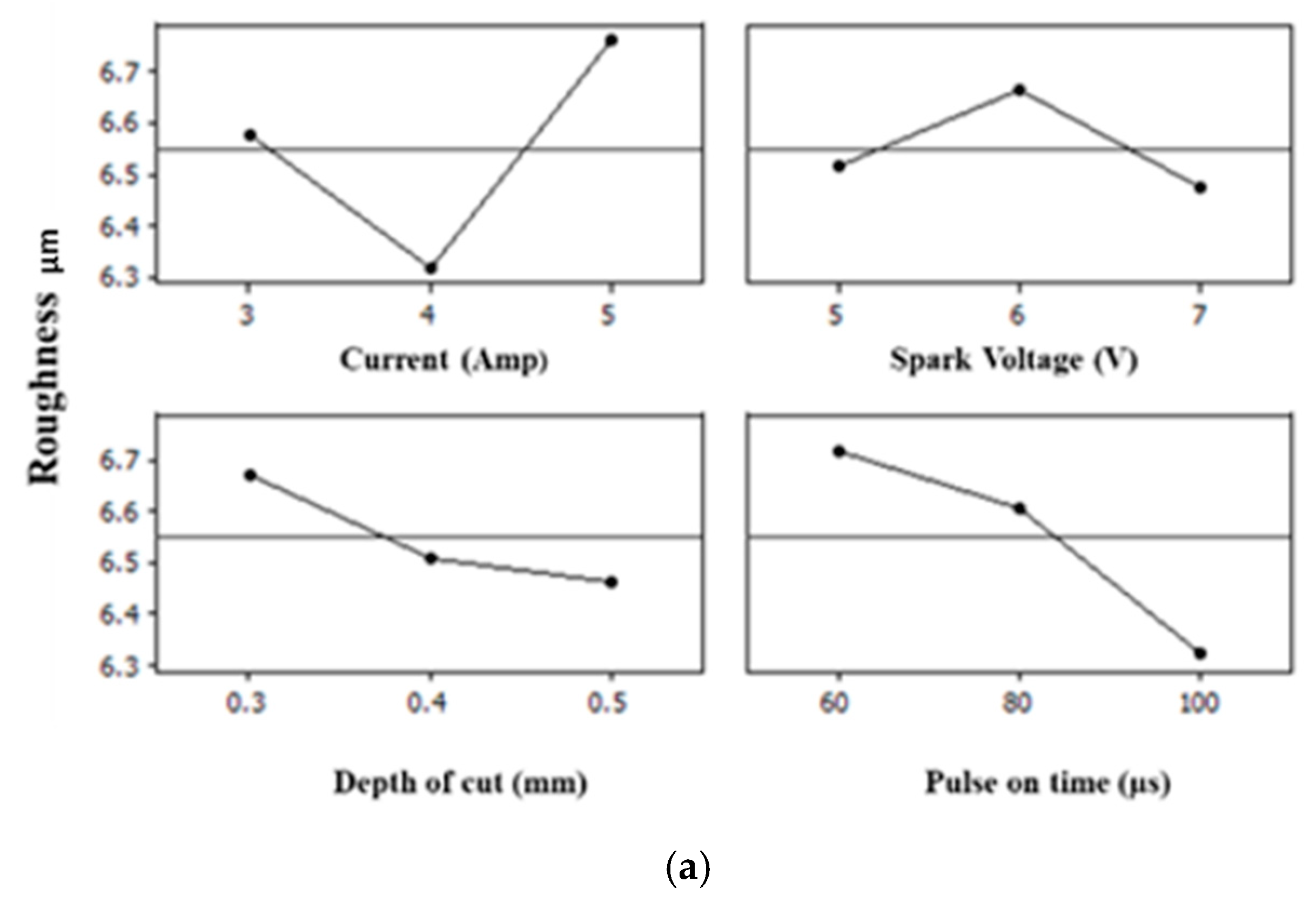

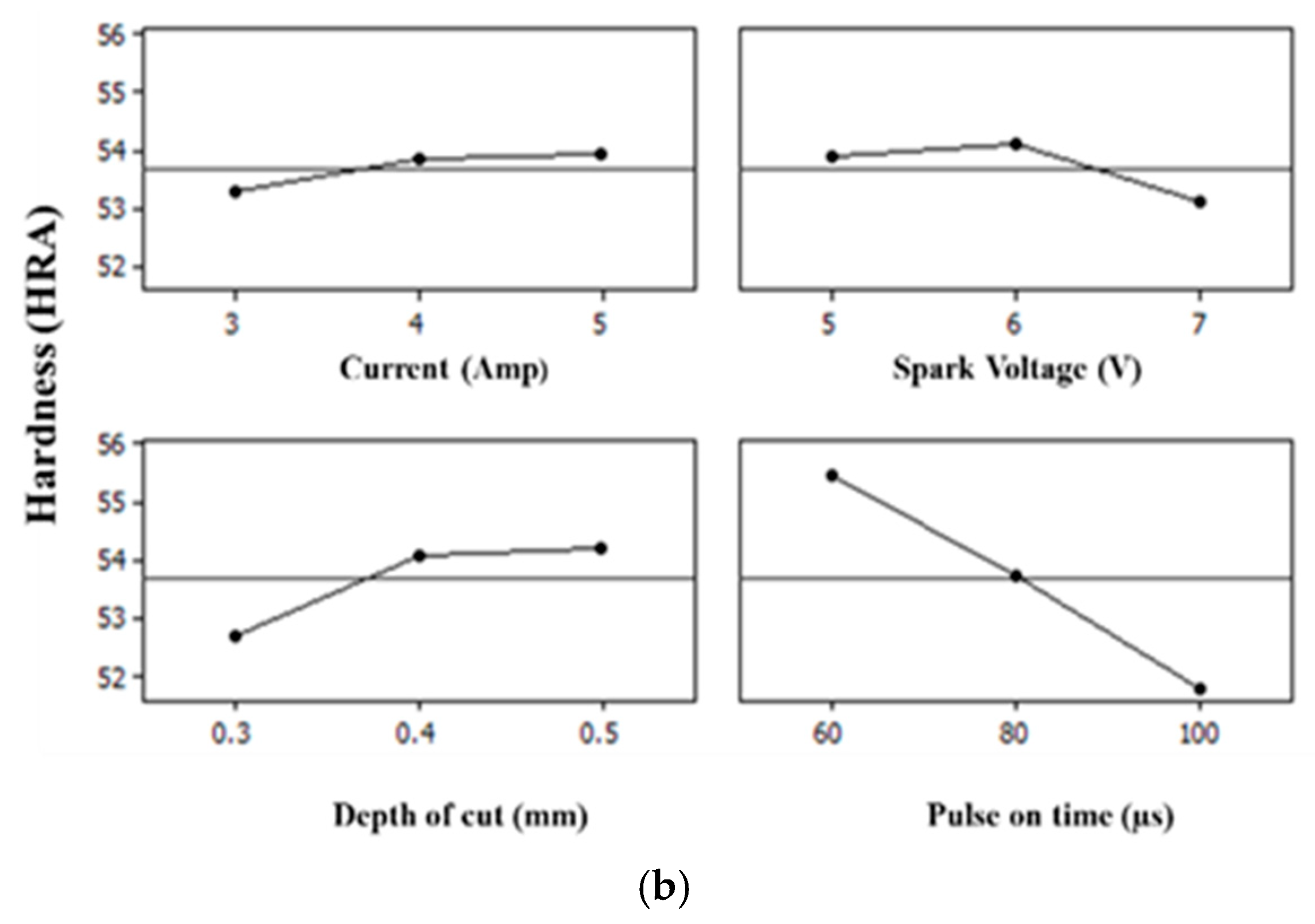

5. Main Effect Plots

6. Discussions

Effects of Process Parameters on Performance Measures

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of Variance |

| IP | Current |

| DOE | Design of Experiments |

| EDM | Electric Discharge Machining |

| TON | Pulse-on Time |

| DOC | Depth of Cut |

| MRR | Material Removal Rate |

| VP | Spark Voltage |

References

- Kumar, A.; Jadoun, R.S.; Choudhary, S.K. Investigations on Tool Wear Rate of AISI D2 Die Steel in EDM Using Taguchi Methods. Chem. Process Eng. Res. 2015, 37, 114–122. [Google Scholar]

- Abulais, S. Current Research Trends in Electric Discharge Machining (EDM). Int. J. Sci. Eng. Res. 2014, 5, 100–118. [Google Scholar]

- Das, V.C. Optimization of Machining Parameters for EDM Operations Based on Central Composite Design and Desirability Approach. Int. J. Adv. Sci. Eng. 2016, 2, 117–124. [Google Scholar]

- Luis, C.J.; Puertas, I.; Villa, G. Material Removal Rate and Electrode Wear Study on the EDM of Silicon Carbide. J. Mater. Process. Technol. 2005, 164, 889–896. [Google Scholar] [CrossRef]

- Xu, C.S. Working Principle and Performance of Wire Electrical Discharge Machining. In Advanced Materials Research; Trans Tech Publ.: Kapellweg, Switzerland, 2012; Volume 507, pp. 180–183. [Google Scholar]

- Gangil, M.; Pradhan, M.K. Modeling and Optimization of Electrical Discharge Machining Process Using RSM: A Review. Mater. Today Proc. 2017, 4, 1752–1761. [Google Scholar] [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P.; Mohandas, E. Electrical Discharge Machining of Al (6351) Alloy: Role of Electrode Shape. Int. J. Mater. Prod. Technol. 2016, 53, 86–97. [Google Scholar] [CrossRef]

- Dalai, H.; Dewangan, S.; Datta, S.; Patel, S.K.; Mahapatra, S.S. A Case Study on Quality and Productivity Optimization in Electric Discharge Machining (EDM). In Advanced Materials Research; Trans Tech Publ.: Kapellweg, Switzerland, 2012; Volume 445, pp. 27–32. [Google Scholar]

- Senthilkumar, N.; Ganapathy, T.; Tamizharasan, T. Optimisation of Machining and Geometrical Parameters in Turning Process Using Taguchi Method. Aust. J. Mech. Eng. 2014, 12, 233–246. [Google Scholar] [CrossRef]

- Lodhi, B.K.; Agarwal, S. Optimization of Machining Parameters in WEDM of AISI D3 Steel Using Taguchi Technique. Proc. CIRP 2014, 14, 194–199. [Google Scholar] [CrossRef] [Green Version]

- Subrahmanyam, S.V.; Sarcar, M.M.M. Evaluation of Optimal Parameters for Machining with Wire Cut EDM Using Grey-Taguchi Method. Int. J. Sci. Res. Publ. 2013, 3, 768–776. [Google Scholar]

- Purohit, R.; Rana, R.S.; Dwivedi, R.K.; Banoriya, D.; Singh, S.K. Optimization of Electric Discharge Machining of M2 Tool Steel Using Grey Relational Analysis. Mater. Today Proc. 2015, 2, 3378–3387. [Google Scholar] [CrossRef]

- Mandaloi, G.; Singh, S.; Kumar, P.; Pal, K. Effect on Crystalline Structure of AISI M2 Steel Using Copper Electrode through Material Removal Rate, Electrode Wear Rate and Surface Finish. Measurement 2015, 61, 305–319. [Google Scholar] [CrossRef]

- Khan, F.; Soota, T. Optimization of EDM Process Parameter for Stainless Steel D3. Mater. Today Proc. 2020, 25, 635–638. [Google Scholar] [CrossRef]

- Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Mahajan, A.; Singh, G.; Devgan, S.; Sidhu, S.S. Surface Characterization and Tribological Performance Analysis of Electric Discharge Machined Duplex Stainless Steel. Micromachines 2020, 11, 926. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Jadoun, R.S. Current Advanced Research Development of Electric Discharge Machining (EDM): A Review. Int. J. Res. Advent Technol. 2014, 2, 273–297. [Google Scholar]

- Choudhary, S.K.; Jadoun, R.S. Current Research Issue, Trend & Applications of Powder Mixed Dielectric Electric Discharge Machining (PM-EDM): A Review. Int. J. Eng. Sci. Res. Technol. 2014, 3, 335–358. [Google Scholar]

- Gill, A.S.; Kumar, S. Surface Alloying of H11 Die Steel by Tungsten Using EDM Process. Int. J. Adv. Manuf. Technol. 2015, 78, 1585–1593. [Google Scholar] [CrossRef]

- Sharma, D.; Hiremath, S.S. Review on Tools and Tool Wear in EDM. Mach. Sci. Technol. 2021, 25, 802–873. [Google Scholar] [CrossRef]

- Kumar, P.; Dewangan, S.; Pandey, C. Analysis of Surface Integrity and Dimensional Accuracy in EDM of P91 Steels. Mater. Today Proc. 2020, 33, 5378–5383. [Google Scholar] [CrossRef]

- Butola, R.; Kanwar, S.; Tyagi, L.; Singari, R.M.; Tyagi, M. Optimizing the Machining Variables in CNC Turning of Aluminum Based Hybrid Metal Matrix Composites. SN Appl. Sci. 2020, 2, 1356. [Google Scholar] [CrossRef]

- Baburaj, E.; Sundaram, K.M.; Senthil, P. Effect of High Speed Turning Operation on Surface Roughness of Hybrid Metal Matrix (Al-SiC p-Fly Ash) Composite. J. Mech. Sci. Technol. 2016, 30, 89–95. [Google Scholar] [CrossRef]

- Kumar, S.; Batra, U. Surface Modification of Die Steel Materials by EDM Method Using Tungsten Powder-Mixed Dielectric. J. Manuf. Process. 2012, 14, 35–40. [Google Scholar] [CrossRef]

- Singh, A.K.; Singhal, D.; Kumar, R. Machining of Aluminum 7075 Alloy Using EDM Process: An ANN Validation. Mater. Today Proc. 2020, 26, 2839–2844. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Jadoun, R.S. Latest Research Trend of Optimization Techniques in Electric Discharge Machining (EDM). Small 2014, 1, 5. [Google Scholar]

- Chandramouli, S.; Eswaraiah, K. Optimization of EDM Process Parameters in Machining of 17-4 PH Steel Using Taguchi Method. Mater. Today Proc. 2017, 4, 2040–2047. [Google Scholar] [CrossRef]

- Nayim, S.T.I.; Hasan, M.Z.; Jamwal, A.; Thakur, S.; Gupta, S. Recent Trends & Developments in Optimization and Modelling of Electro-Discharge Machining Using Modern Techniques: A Review. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; Volume 2148, p. 030051. [Google Scholar]

- Niamat, M.; Sarfraz, S.; Ahmad, W.; Shehab, E.; Salonitis, K. Parametric Modelling and Multi-Objective Optimization of Electro Discharge Machining Process Parameters for Sustainable Production. Energies 2020, 13, 38. [Google Scholar] [CrossRef] [Green Version]

- Singari, R.M.; Mathiyazhagan, K.; Kumar, H. Advances in Manufacturing and Industrial Engineering: Select Proceedings of ICAPIE 2019, 1st ed.; Springer Nature: Singapore, 2021. [Google Scholar]

- Ahmad, T.; Khan, N.Z.; Ahmad, B.; Maqbool, A. Recent Advances in Machining of Composites and Super Alloys by Using Wire-EDM. A Review. Recent Adv. Manuf. Autom. Des. Energy Technol. 2022, 115–123. [Google Scholar] [CrossRef]

- Maurya, N.; Ahmad, M.M. A Parametric Experimental Design Study of EDM Process Parameters in Machining of Titanium Grade 2. Int. J. Aerosp. Mech. Eng. 2016, 3, 20–23. [Google Scholar]

- Paik, N.M.; Davis, R.; Sahu, P.; Ekka, M.N.; Sudheer, D.; Samson, S. Experimental Investigation of the Effect of Control Parameters of Edm on Surface Roughness and Tool Wear Rate Using Regression Analysis. Int. J. Aerosp. Mech. Eng. 2016, 3, 10–16. [Google Scholar]

- D2 Tool Steel—High-Carbon, High-Chromium, Cold-Work Steel (UNS T30402). Available online: https://www.azom.com/article.aspx?ArticleID=6214 (accessed on 26 February 2022).

- Phanphet, S.; Bangphan, S. Application of Full Factorial Design for Optimization of Production Process by Turning Machine. J. Tianjin Univ. Sci. Technol. 2021, 54, 35–55. [Google Scholar]

- Newton, T.R.; Melkote, S.N.; Watkins, T.R.; Trejo, R.M.; Reister, L. Investigation of the Effect of Process Parameters on the Formation and Characteristics of Recast Layer in Wire-EDM of Inconel 718. Mater. Sci. Eng. A 2009, 513–514, 208–215. [Google Scholar] [CrossRef]

- Khan, M.A.R.; Rahman, M.M.; Kadirgama, K. An Experimental Investigation on Surface Finish in Die-Sinking EDM of Ti-5Al-2.5Sn. Int. J. Adv. Manuf. Technol. 2015, 77, 1727–1740. [Google Scholar] [CrossRef]

- Parhad, P.; Likhite, A.; Bhatt, J.; Peshwe, D. The Effect of Cutting Speed and Depth of Cut on Surface Roughness during Machining of Austempered Ductile Iron. Trans. Indian Inst. Met. 2015, 68, 99–108. [Google Scholar] [CrossRef]

- Suresh, S.; Jamil, M.A.; Sulaiman, S.; Shokor, M.R.M. Optimization of Electrode Material for EDM Die-Sinking of Titanium Alloy Grade 5-Ti6Al4V. Int. J. Adv. Sci. Eng. Inf. Technol. 2016, 6, 534–539. [Google Scholar] [CrossRef] [Green Version]

| Fixed Specifications | Values |

|---|---|

| Incoming voltage | (220/380) V |

| Maximum average output | (30–200) A |

| No load output | 100 µs |

| On-time setting range | (1–9999) µs |

| Off-time setting range | (1–9999) µs |

| Electro-spark frequency | 500 Hz–500 KHz |

| Dielectric used | Kerosene |

| Material | % Composition |

|---|---|

| C | 1.4–1.6 |

| Mn | 0.6 |

| Si | 0.6 |

| Co | 1 |

| Cr | 11–13 |

| Mo | 0.7–1.20 |

| V | 1.10 |

| P | 0.03 |

| Ni | 0.30 |

| Cu | 0.25 |

| S | 0.30 |

| Mechanical Properties | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C | 62 | 62 |

| Hardness, Vickers | 748 | 748 |

| Izod impact unnotched | 70.0 J | 56.8 |

| Poisson’s ratio | 0.27–0.30 | 0.27–0.30 |

| Elastic modulus Ksi | 190–210 GPa | 27,557–30,457 |

| Process Parameter | Symbol | Unit | Level-1 | Level-2 | Level-3 |

|---|---|---|---|---|---|

| Spark voltage | Vp | Volt | 5 | 6 | 7 |

| Pulse-on time | TON | µ-s | 60 | 80 | 100 |

| Depth of cut | DOC | mm | 0.3 | 0.4 | 0.5 |

| Current | Ip | Amp | 3 | 4 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gillani, F.; Zahid, T.; Bibi, S.; Khan, R.S.U.; Bhutta, M.R.; Ghafoor, U. Parametric Optimization for Quality of Electric Discharge Machined Profile by Using Multi-Shape Electrode. Materials 2022, 15, 2205. https://doi.org/10.3390/ma15062205

Gillani F, Zahid T, Bibi S, Khan RSU, Bhutta MR, Ghafoor U. Parametric Optimization for Quality of Electric Discharge Machined Profile by Using Multi-Shape Electrode. Materials. 2022; 15(6):2205. https://doi.org/10.3390/ma15062205

Chicago/Turabian StyleGillani, Fouzia, Taiba Zahid, Sameena Bibi, Rana Sami Ullah Khan, Muhammad Raheel Bhutta, and Usman Ghafoor. 2022. "Parametric Optimization for Quality of Electric Discharge Machined Profile by Using Multi-Shape Electrode" Materials 15, no. 6: 2205. https://doi.org/10.3390/ma15062205

APA StyleGillani, F., Zahid, T., Bibi, S., Khan, R. S. U., Bhutta, M. R., & Ghafoor, U. (2022). Parametric Optimization for Quality of Electric Discharge Machined Profile by Using Multi-Shape Electrode. Materials, 15(6), 2205. https://doi.org/10.3390/ma15062205