Compaction Characteristics and Permeability of Expansive Shale Stabilized with Locally Produced Waste Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory Tests

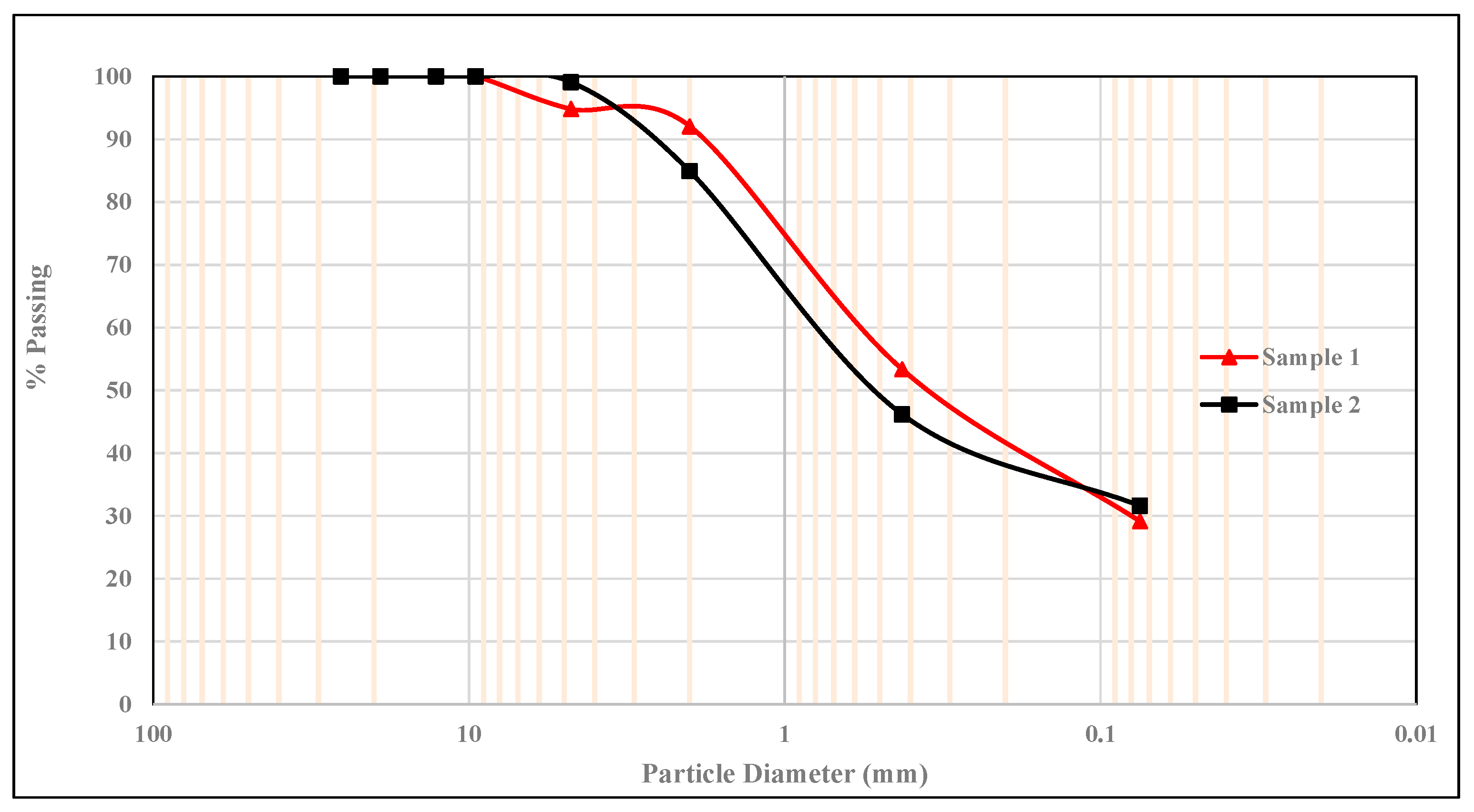

2.2. Expansive Clay

2.3. Marble Dust

2.4. Rice Husk and Rice Husk Ash

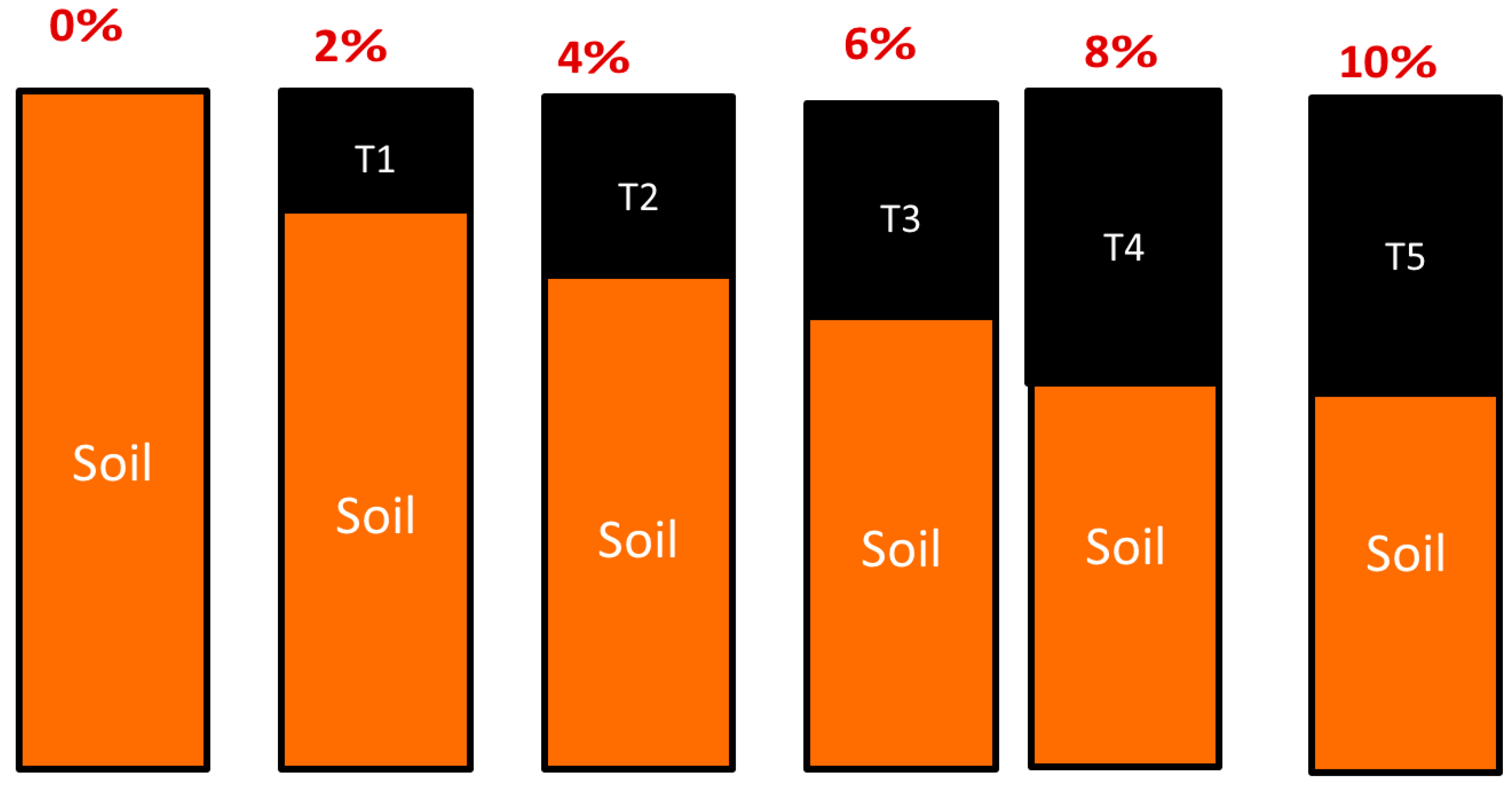

2.5. Cow Dung Ash

2.6. Saw Dust

2.7. Wheat Straw

3. Results and Discussion

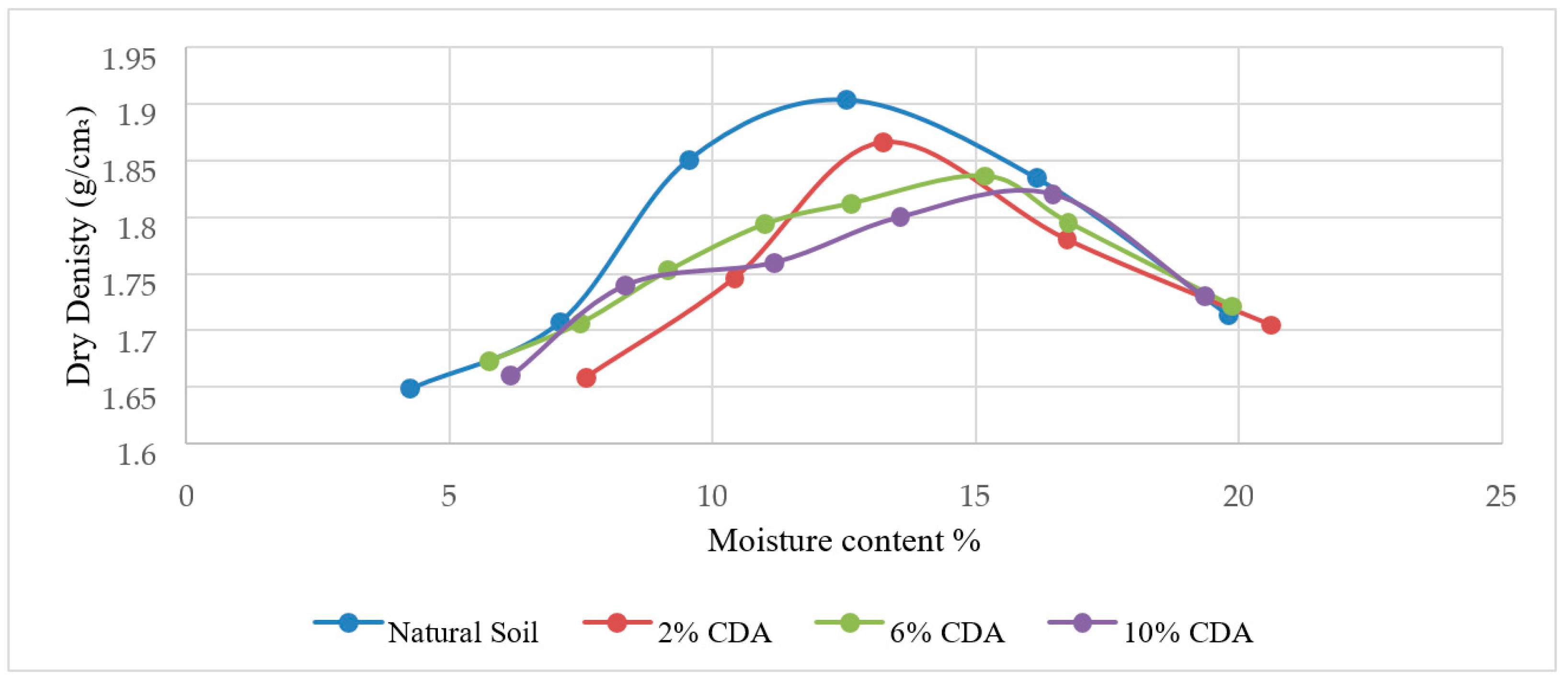

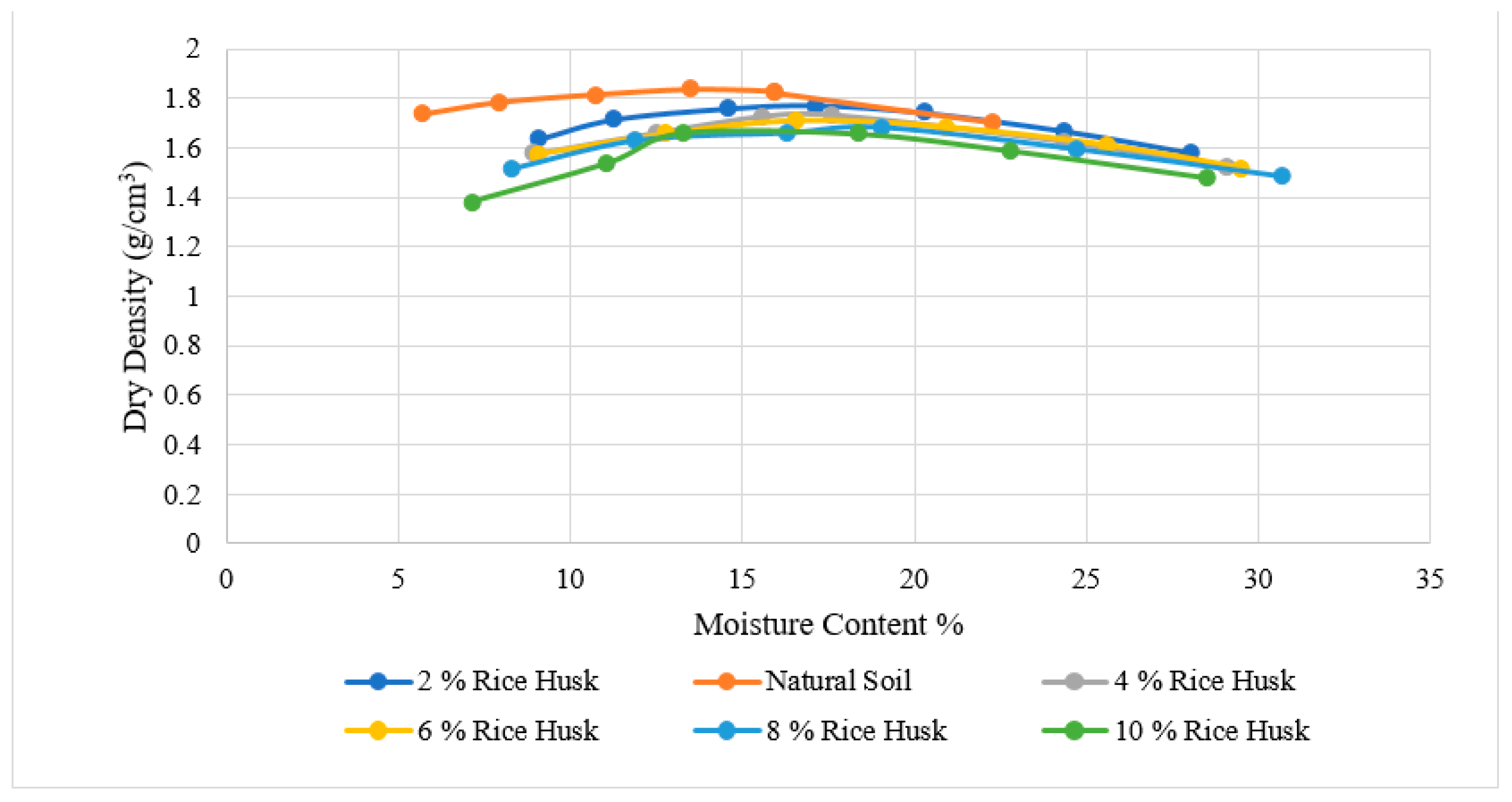

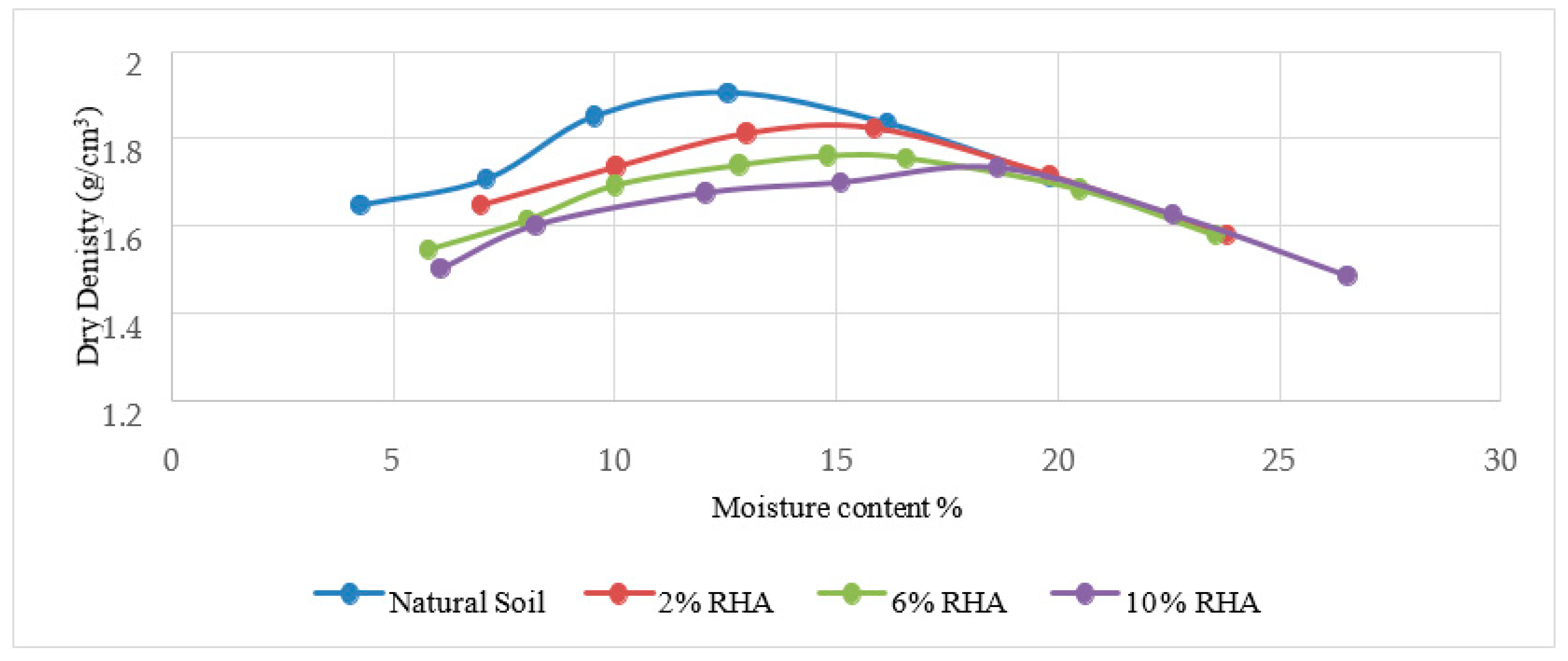

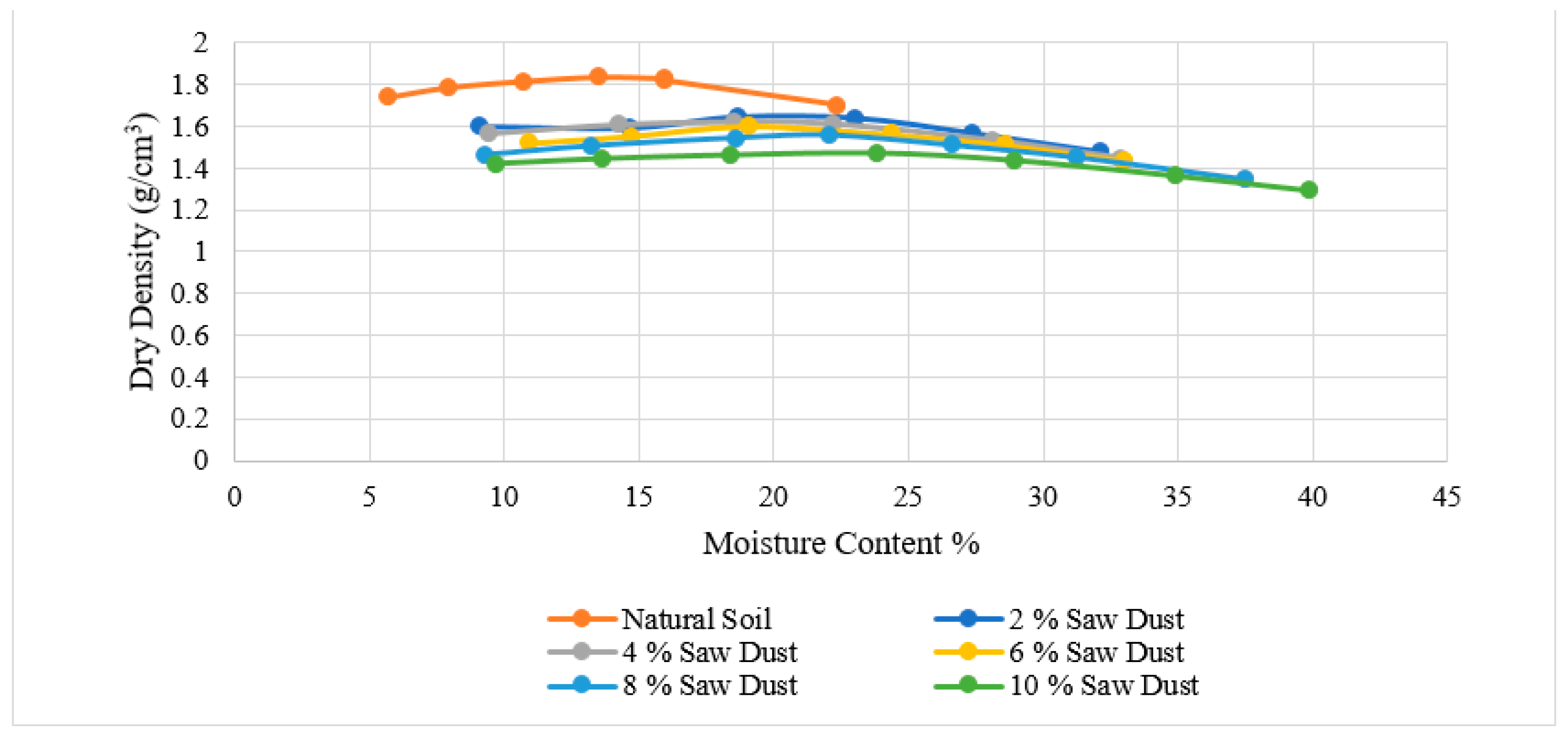

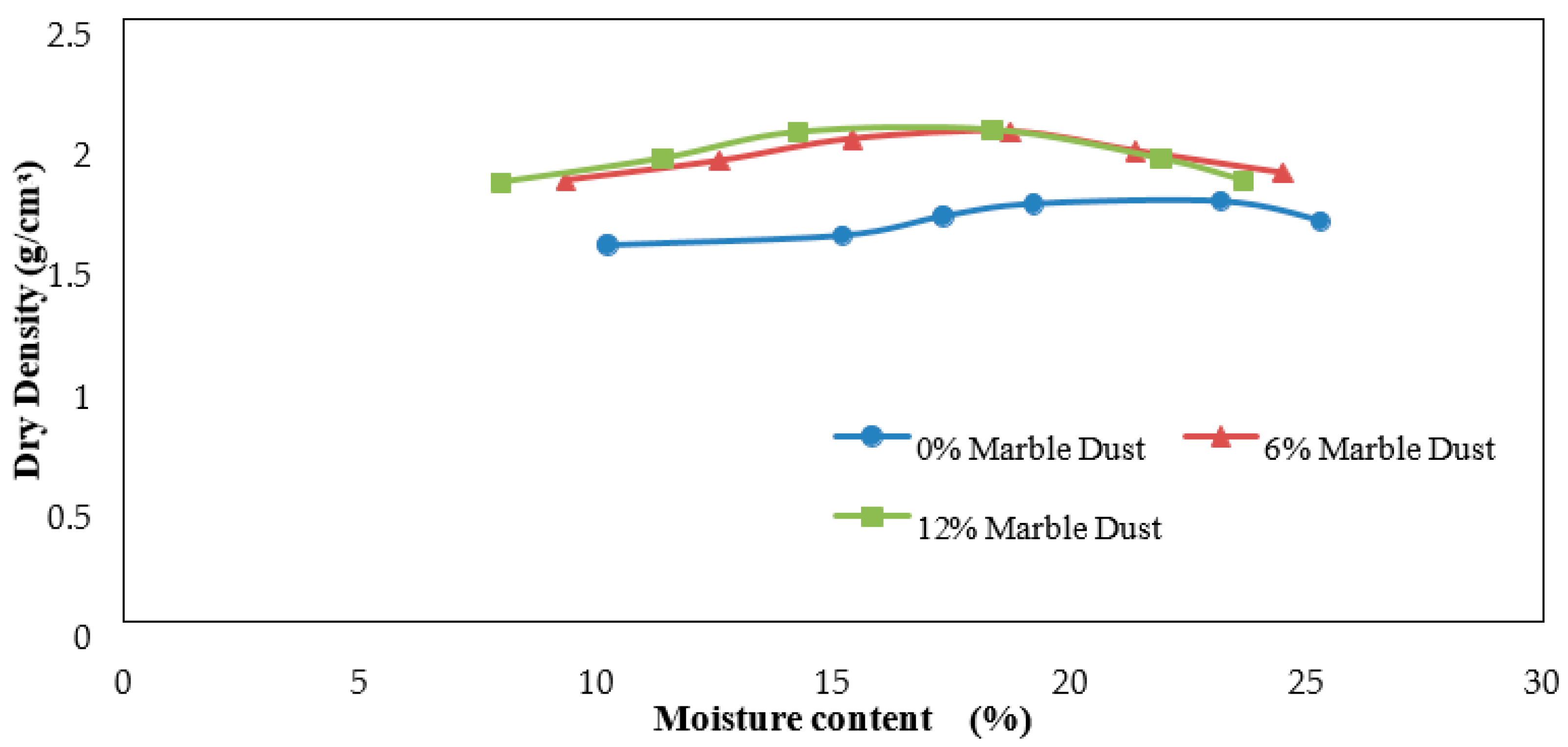

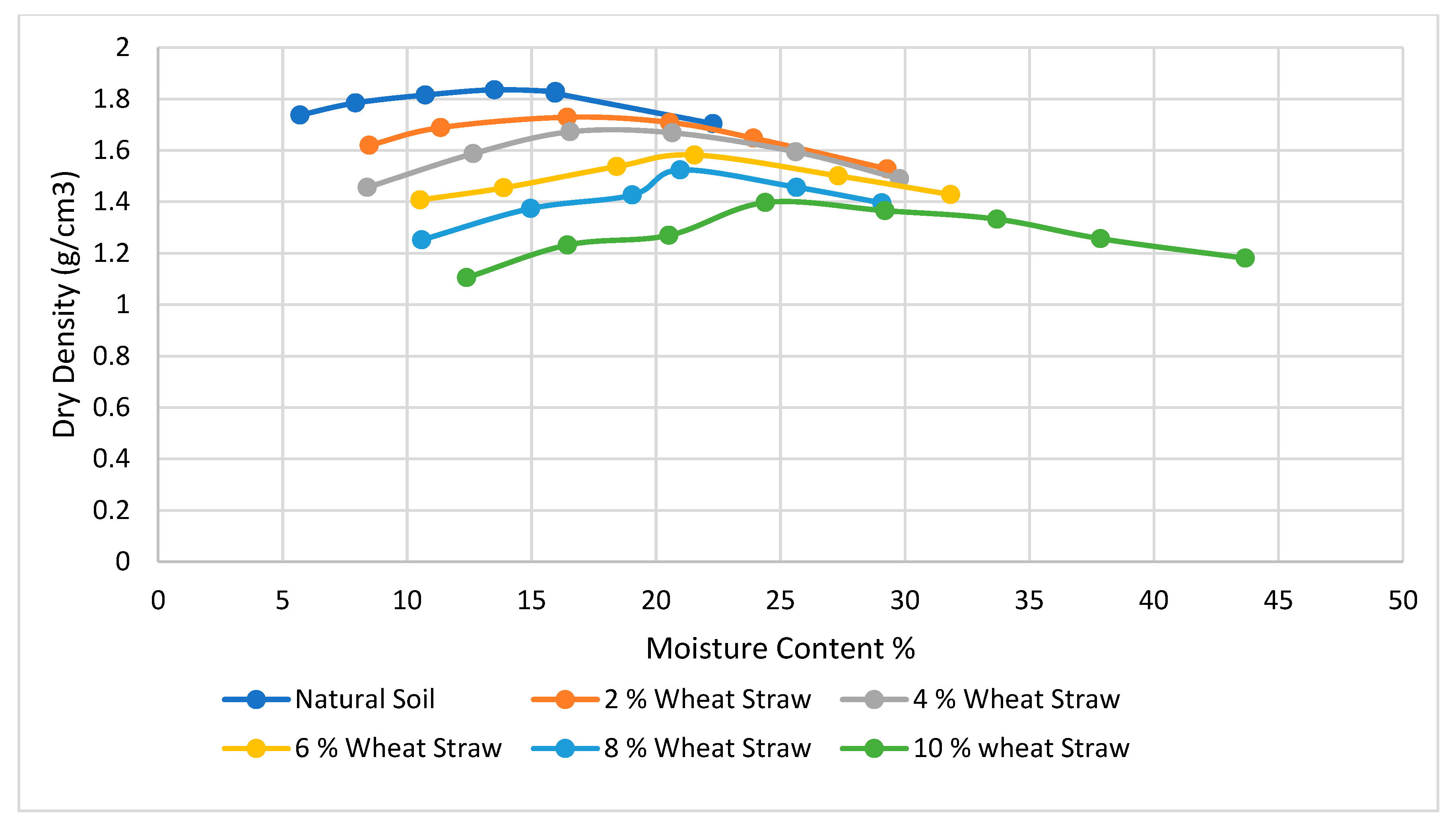

3.1. Compaction Characteristics of Stabilized Soil

3.2. Permeability of Stablised Soil

4. Conclusions

- The soil is classified as -7-5 according to AASHTO, and CH is based on the USCS classification system. The soil has a higher liquid and plasticity index, and, as the liquid limit increases, so does the swelling potential.

- The maximum dry density decreased, and the optimum moisture increased irrespective of the type of additive, except for an increase in the case of marble dust. This is due to low specific gravity and the non-plastic nature of additives.

- The permeability of soil increased with the addition of saw dust, wheat straw, and rice husk, and decreased with marble dust. The addition of 8% of rice husk ash significantly increased in permeability of the soil observed.

- The decrease in dry density and increase in permeability of the stabilized soil favors the reduction in the swelling potential of expansive soil.

- All these locally available waste materials positively impact the engineering properties of expansive clayey soil. For more favorable results, a higher percentage of these materials should be used. It can be used to build roads, especially low-cost, temporary highways, as well as earth fill.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Butt, W.A.; Gupta, K.; Jha, J.N. Strength behavior of clayey soil stabilized with saw dust ash. Int. J. Geo-Eng. 2016, 7, 18. [Google Scholar] [CrossRef]

- De, G.; Raja, S.; Mukherjee, A. Stabilization of Expansive Soil Using Saw Dust. In Sustainability in Environmental Engineering and Science; Springer: Berlin/Heidelberg, Germany, 2021; pp. 73–82. [Google Scholar]

- Haldar, S.K. Introduction to Mineralogy and Petrology; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Kolesnikov, A.; Zhakipbaev, B.Y.; Zhanikulov, N.; Kolesnikova, O.; Akhmetova, K.; Kuraev, R.; Shal, A. review of technogenic waste and methods of its processing for the purpose of complex utilization of tailings from the enrichment of non-ferrous metal ores as a component of the raw material mixture in the production of cement clinker. Rasayan J. Chem. 2021, 14, 997–1005. [Google Scholar] [CrossRef]

- Agung, P.; Damianto, B.; Yuwono, Y. A critical state approach to stability of clay shale for design structures of the sentul hill, west java, indonesia. In Proceedings of the EACEF-International Conference of Civil Engineering, Singapore, 26–27 June 2013. [Google Scholar]

- Alatas, I.M.; Kamaruddin, S.A.; Nazir, R.; Irsyam, M.; Himawan, A. Shear strength degradation of semarang bawen clay shale due to weathering process. J. Teknol. 2015, 77. [Google Scholar] [CrossRef][Green Version]

- Kolesnikov, A.S.; Naraev, V.; Natorhin, M.; Saipov, A.; Kolesnikova, O. Review of the processing of minerals and technogenic sulfide raw material with the extraction of metals and recovering elemental sulfur by electrochemical methods. Rasayan J. Chem. 2020, 13, 2420–2428. [Google Scholar] [CrossRef]

- Ali, M.; Abbas, S.; de Azevedo, A.R.G.; Marvila, M.T.; Khan, M.I.; Rafiq, W. Experimental and analytical investigation on the confinement behavior of low strength concrete under axial compression. Structures 2021, 36, 303–313. [Google Scholar] [CrossRef]

- Ali, M.; Abbas, S.; Khan, M.I.; Gad, M.A.; Ammad, S.; Khan, A. Experimental Validation of Mander’s Model for Low Strength Confined Concrete Under Axial Compression. In Proceedings of the 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs, Sakheer, Bahrain, 11–12 November 2020. [Google Scholar] [CrossRef]

- Ali, M.; Abbas, S.; Salah, B.; Akhter, J.; Saleem, W.; Haruna, S.; Room, S.; Abdulkadir, I. Investigating Optimal Confinement Behaviour of Low-Strength Concrete through Quantitative and Analytical Approaches. Materials 2021, 14, 4675. [Google Scholar] [CrossRef]

- Ali, M.; Masood, F.; Khan, M.I.; Azeem, M.; Qasim, M.; Ali, F.N. Evaluation of flexible pavement distresses—A Case Study of Northern Bypass Peshawar, Pakistan. In Proceedings of the 2021 Third International Sustainability and Resilience Conference: Climate Change, Sakheer, Bahrain, 15–16 November 2021; Institute of Electrical and Electronics Engineers: Piscataway Township, NJ, USA, 2021; pp. 399–404. [Google Scholar]

- Ali, M.; Room, S.; Khan, M.I.; Masood, F.; Memon, R.A.; Khan, R.; Memon, A.M. Assessment of local earthen bricks in perspective of physical and mechanical properties using Geographical Information System in Peshawar, Pakistan. Structures 2020, 28, 2549–2561. [Google Scholar] [CrossRef]

- Diana, W.; Hartono, E.; Muntohar, A. The Permeability of Portland Cement-Stabilized Clay Shal. IOP Conf. Ser. Mater. Sci. Eng. 2019, 650, 012027. [Google Scholar] [CrossRef]

- Vasilyeva, N.; Fedorova, E.; Kolesnikov, A. Big Data as a Tool for Building a Predictive Model of Mill Roll Wear. Symmetry 2021, 13, 859. [Google Scholar] [CrossRef]

- Room, S.; Ali, M.; Alam, M.A.; Khan, U.; Ammad, S.; Saad, S. Assessment of Lightweight Aggregate Concrete Using Textile Washing Stone. In Proceedings of the 2021 Third International Sustainability and Resilience Conference: Climate Change, Sakheer, Bahrain, 15–16 November 2021; pp. 327–333. [Google Scholar]

- Ali, M.; Dharmowijoyo, D.B.E.; de Azevedo, A.R.G.; Fediuk, R.; Ahmad, H.; Salah, B. Time-Use and Spatio-Temporal Variables Influence on Physical Activity Intensity, Physical and Social Health of Travelers. Sustainability 2021, 13, 12226. [Google Scholar] [CrossRef]

- Barreto, E.D.S.; Stafanato, K.V.; Marvila, M.T.; de Azevedo, A.R.G.; Ali, M.; Pereira, R.M.L.; Monteiro, S.N. Clay Ceramic Waste as Pozzolan Constituent in Cement for Structural Concrete. Materials 2021, 14, 2917. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Su, Y.; Namdar, A.; Zhou, G.; She, Y.; Yang, Q. Utilization of Cementitious Material from Residual Rice Husk Ash and Lime in Stabilization of Expansive Soil. Adv. Civ. Eng. 2019, 2019, 1–17. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V.; Savelev, R.; Kolesnikov, A. Synthetic Data Generation for Steel Defect Detection and Classification Using Deep Learning. Symmetry 2021, 13, 1176. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly Ash-Based Eco-Efficient Concretes: A Comprehensive Review of the Short-Term Properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Serikbaev, B.E.; Zolkin, A.L.; Kenzhibaeva, G.S.; Isaev, G.I.; Botabaev, N.E.; Shapalov, S.K.; Kolesnikova, O.G.; Iztleuov, G.M.; Suigenbayeva, A.Z.; et al. Processing of Non-Ferrous Metallurgy Waste Slag for its Complex Recovery as a Secondary Mineral Raw Material. Refract. Ind. Ceram. 2021, 62, 375–380. [Google Scholar] [CrossRef]

- Roohbakhshan, A.; Kalantari, B. Stabilization of Clayey Soil with Lime and Waste Stone Powder. Int. J. Sci. Res. Knowl. 2013, 1, 547. [Google Scholar] [CrossRef]

- Reethu, B.; Kumar, M.S.; Sharath, G.; Ramanjaneyulu, B.; Manchiryal, R.K. Stabilization of clayey soil using Gypsum. J. Stud. Res. 2020. [Google Scholar] [CrossRef]

- Alzaidy, M.N.J. Experimental study for stabilizing clayey soil with eggshell powder and plastic wastes. IOP Conf. Series: Mater. Sci. Eng. 2019, 518, 022008. [Google Scholar] [CrossRef]

- Dayioglu, M.; Cetin, B.; Nam, S. Stabilization of expansive Belle Fourche shale clay with different chemical additives. Appl. Clay Sci. 2017, 146, 56–69. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Marvila, M.T.; Ali, M.; Khan, M.I.; Masood, F.; Vieira, C.M.F. Effect of the addition and processing of glass polishing waste on the durability of geopolymeric mortars. Case Stud. Constr. Mater. 2021, 15, e00662. [Google Scholar] [CrossRef]

- Gad, M.A.; Riad, A.M.; Nikbakht, E.; Ali, M.; Ghanem, G.M. Structural Behavior of Slender Reinforced Concrete Columns Wrapped with Fiber Reinforced Polymers Subjected to Eccentric Loads. In Proceedings of the 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs (51154), Sakheer, Bahrain, 11–12 November 2020; pp. 1–5. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Bin Napiah, M.; Zoorob, S.E.; Al-Sabaeei, A.M.; Rafiq, W.; Ali, M.; Memon, A.M. Investigating the mechanical properties and fuel spillage resistance of semi-flexible pavement surfacing containing irradiated waste PET based grouts. Constr. Build. Mater. 2021, 304, 124641. [Google Scholar] [CrossRef]

- Lesovik, V.; Tolstoy, A.; Fediuk, R.; Amran, M.; Azevedo, A.; Ali, M.; Mosaberpanah, M.A.; Asaad, M.A. Four-component high-strength polymineral binders. Constr. Build. Mater. 2021, 316, 125934. [Google Scholar] [CrossRef]

- Masoomi, M.; Mosavi, A. The One-Way FSI Method Based on RANS-FEM for the Open Water Test of a Marine Propeller at the Different Loading Conditions. J. Mar. Sci. Eng. 2021, 9, 351. [Google Scholar] [CrossRef]

- Memon, A.M.; Sutanto, M.H.; Napiah, M.; Yusoff, N.I.M.; Memon, R.A.; Al-Sabaeei, A.M.; Ali, M. Physicochemical, rheological and morphological properties of bitumen incorporating petroleum sludge. Constr. Build. Mater. 2021, 297, 123738. [Google Scholar] [CrossRef]

- Nafees, A.; Amin, M.N.; Khan, K.; Nazir, K.; Ali, M.; Javed, M.F.; Aslam, F.; Musarat, M.A.; Vatin, N.I. Modeling of Mechanical Properties of Silica Fume-Based Green Concrete Using Machine Learning Techniques. Polymers 2021, 14, 30. [Google Scholar] [CrossRef]

- Nafees, A.; Javed, M.F.; Musarat, M.A.; Ali, M.; Aslam, F.; Vatin, N.I. FE Modelling and Analysis of Beam Column Joint Using Reactive Powder Concrete. Crystals 2021, 11, 1372. [Google Scholar] [CrossRef]

- Dehghani, E.; Ranjbar, S.; Atashafrooz, M.; Negarestani, H.; Mosavi, A.; Kovacs, L. Introducing Copula as a Novel Statistical Method in Psychological Analysis. Int. J. Environ. Res. Public Health 2021, 18, 7972. [Google Scholar] [CrossRef]

- Darban, S.; Tehrani, H.G.; Karballaeezadeh, N.; Mosavi, A. Application of Analytical Hierarchy Process for Structural Health Monitoring and Prioritizing Concrete Bridges in Iran. Appl. Sci. 2021, 11, 8060. [Google Scholar] [CrossRef]

- Ahmad, H.; Asghar, M.U.; Khan, A.; Mosavi, A.H. A Hybrid Deep Learning Technique for Personality Trait Classification From Text. IEEE Access 2021, 9, 146214–146232. [Google Scholar] [CrossRef]

- Rafiei-Sardooi, E.; Azareh, A.; Choubin, B.; Mosavi, A.H.; Clague, J.J. Evaluating urban flood risk using hybrid method of TOPSIS and machine learning. Int. J. Disaster Risk Reduct. 2021, 66, 102614. [Google Scholar] [CrossRef]

- Tavoosi, J.; Suratgar, A.; Menhaj, M.; Mosavi, A.; Mohammadzadeh, A.; Ranjbar, E. Modeling Renewable Energy Systems by a Self-Evolving Nonlinear Consequent Part Recurrent Type-2 Fuzzy System for Power Prediction. Sustainability 2021, 13, 3301. [Google Scholar] [CrossRef]

- Sadeghiravesh, M.H.; Khosravi, H.; Abolhasani, A.; Ghodsi, M.; Mosavi, A. Fuzzy Logic Model to Assess Desertification Intensity Based on Vulnerability Indices. Acta Polytech. Hung. 2021, 18, 7–24. [Google Scholar] [CrossRef]

- Meiabadi, M.S.; Moradi, M.; Karamimoghadam, M.; Ardabili, S.; Bodaghi, M.; Shokri, M.; Mosavi, A.H. Modeling the Producibility of 3D Printing in Polylactic Acid Using Artificial Neural Networks and Fused Filament Fabrication. Polymers 2021, 13, 3219. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Ahmed, H.U.; Mosavi, A. Survey of Mechanical Properties of Geopolymer Concrete: A Comprehensive Review and Data Analysis. Materials 2021, 14, 4690. [Google Scholar] [CrossRef]

- Janizadeh, S.; Pal, S.C.; Saha, A.; Chowdhuri, I.; Ahmadi, K.; Mirzaei, S.; Mosavi, A.H.; Tiefenbacher, J.P. Mapping the spatial and temporal variability of flood hazard affected by climate and land-use changes in the future. J. Environ. Manag. 2021, 298, 113551. [Google Scholar] [CrossRef]

- Ebrahimi-Khusfi, Z.; Taghizadeh-Mehrjardi, R.; Roustaei, F.; Ebrahimi-Khusfi, M.; Mosavi, A.H.; Heung, B.; Soleimani-Sardo, M.; Scholten, T. Determining the contribution of environmental factors in controlling dust pollution during cold and warm months of western Iran using different data mining algorithms and game theory. Ecol. Indic. 2021, 132, 108287. [Google Scholar] [CrossRef]

- D’Orazio, A.; Karimipour, A.; Mosavi, A. Develop lattice Boltzmann method and its related boundary conditions models for the benchmark oscillating walls by modifying hydrodynamic and thermal distribution functions. Eur. Phys. J. Plus 2020, 135. [Google Scholar] [CrossRef]

- ShahbazPanahi, S.; Tajara, M.K.; Faraj, R.H.; Mosavi, A. Studying the C–H Crystals and Mechanical Properties of Sustainable Concrete Containing Recycled Coarse Aggregate with Used Nano-Silica. Crystals 2021, 11, 122. [Google Scholar] [CrossRef]

- Zhao, T.; Khan, M.I.; Chu, Y. Artificial neural networking (ANN) analysis for heat and entropy generation in flow of non-Newtonian fluid between two rotating disks. Math. Methods Appl. Sci. 2021. [Google Scholar] [CrossRef]

- Zhao, T.-H.; Zhou, B.-C.; Wang, M.-K.; Chu, Y.-M. On approximating the quasi-arithmetic mean. J. Inequal. Appl. 2019, 2019, 42. [Google Scholar] [CrossRef]

- Zhao, T.-H.; Yang, Z.-H.; Chu, Y.-M. Monotonicity properties of a function involving the psi function with applications. J. Inequal. Appl. 2015, 2015, 181. [Google Scholar] [CrossRef]

- Zhao, T.-H.; Shi, L.; Chu, Y.-M. Convexity and concavity of the modified Bessel functions of the first kind with respect to Hölder means. Rev. Real Acad. Cienc. Exactas Fis. Nat. Ser. A Mat. 2020, 114, 96. [Google Scholar] [CrossRef]

- Smirnova, O. Compatibility of shungisite microfillers with polycarboxylate admixtures in cement compositions. ARPN J. Eng. Appl. Sci. 2019, 14, 600–610. [Google Scholar]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental Tests and Reliability Analysis of the Cracking Impact Resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Zhao, T.-H.; Chu, Y.-M.; Liu, B.-Y. Optimal Bounds for Neuman-Sándor Mean in Terms of the Convex Combinations of Harmonic, Geometric, Quadratic, and Contraharmonic Means. Abstr. Appl. Anal. 2012, 2012, 302635. [Google Scholar] [CrossRef]

- Zha, T.H.; Castillo, O.; Jahanshahi, H.; Yusuf, A.; Alassafi, M.O.; Alsaadi, F.E.; Chu, Y.M. A fuzzy-based strategy to suppress the novel coronavirus (2019-NCOV) massive outbreak. Appl. Comput. Math. 2021, 20, 160–176. [Google Scholar]

- Chu, Y.; Zhao, T.; Song, Y. Sharp bounds for Neuman-Sándor mean in terms of the convex combination of quadratic and first Seiffert means. Acta Math. Sci. 2014, 34, 797–806. [Google Scholar] [CrossRef]

- Sherwood, P. Soil Stabilization with Cement and Lime; Her Majesty Stationary Office: London, UK, 1993. [Google Scholar]

- Yadav, J.S.; Tiwari, S.K.; Shekhwat, P. Strength Behaviour of Clayey Soil Mixed with Pond Ash, Cement and Randomly Distributed Fibres. Transp. Infrastruct. Geotechnol. 2018, 5, 191–209. [Google Scholar] [CrossRef]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Rasul, J.M.; Ghataora, G.S.; Burrow, M. The effect of wetting and drying on the performance of stabilized subgrade soils. Transp. Geotech. 2018, 14, 1–7. [Google Scholar] [CrossRef]

- Rout, R.K.; Ruttanapormakul, P.; Valluru, S.; Puppala, A.J. Resilient Moduli Behavior of Lime-Cement Treated Subgrade Soils. In GeoCongress 2012 State of the Art and Practice in Geotechnical Engineering; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 1428–1437. [Google Scholar]

- Iqbal, A.; Wang, Y.; Miah, M.; Osman, M.S. Study on Date–Jimbo–Kashiwara–Miwa Equation with Conformable Derivative Dependent on Time Parameter to Find the Exact Dynamic Wave Solutions. Fractal Fract. 2021, 6, 4. [Google Scholar] [CrossRef]

- Chu, Y.-M.; Shankaralingappa, B.; Gireesha, B.; Alzahrani, F.; Khan, M.I.; Khan, S.U. Combined impact of Cattaneo-Christov double diffusion and radiative heat flux on bio-convective flow of Maxwell liquid configured by a stretched nano-material surface. Appl. Math. Comput. 2021, 419, 126883. [Google Scholar] [CrossRef]

- Chu, H.-H.; Zhao, T.-H.; Chu, Y.-M. Sharp bounds for the Toader mean of order 3 in terms of arithmetic, quadratic and contraharmonic means. Math. Slovaca 2020, 70, 1097–1112. [Google Scholar] [CrossRef]

- Hassan, H.J.A.; Rasul, J.; Samin, M. Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil. Transp. Infrastruct. Geotechnol. 2021, 8, 390–413. [Google Scholar] [CrossRef]

- Smirnova, O.M. Development of classification of rheologically active microfillers for disperse systems with portland cement and super plasticizer. Int. J. Civ. Eng. Technol. 2018, 9, 1966–1973. [Google Scholar]

- ASTM. Soil and Rock, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 Ft-Lbf/Ft3 (2,700 KN-M/M3)); ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM-D5084; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2016.

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of Recycled Concrete Aggregates in Production of Green Cement-Based Concrete Composites: A Review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Smirnova, O.M. Technology of increase of nanoscale pores volume in protective cement matrix. Int. J. Civ. Eng. Technol. 2018, 9, 1991–2000. [Google Scholar]

- Ghaemi, A.; Zhian, T.; Pirzadeh, B.; Monfared, S.H.; Mosavi, A. Reliability-based design and implementation of crow search algorithm for longitudinal dispersion coefficient estimation in rivers. Environ. Sci. Pollut. Res. 2021, 28, 35971–35990. [Google Scholar] [CrossRef]

- Eliaslankaran, Z.; Daud, N.; Yusoff, Z.; Rostami, V. Evaluation of the Effects of Cement and Lime with Rice Husk Ash as an Additive on Strength Behavior of Coastal Soil. Materials 2021, 14, 1140. [Google Scholar] [CrossRef] [PubMed]

- Garba, J.; Samsuri, W.A.; Othman, R.; Hamdani, M.S.A. Evaluation of Adsorptive Characteristics of Cow Dung and Rice Husk Ash for Removal of Aqueous Glyphosate and Aminomethylphoshonic Acid. Sci. Rep. 2019, 9. [Google Scholar] [CrossRef] [PubMed]

- Smirnova, O.M. Rheologically active microfillers for precast concrete. Int. J. Civ. Eng. Technol. 2018, 9, 1724–1732. [Google Scholar]

- Begich, Y.E.; Klyuev, S.V.; Jos, V.A.; Cherkashin, A.V. Fine-grained concrete with various types of fibers. Mag. Civ. Eng. 2020, 97, 9702. [Google Scholar]

- Al-Kiki, I.M.A.; Al-Juari, K.A.K.; Khattab, S.A.A. Strength, Durability and Hydraulic Properties of Clayey Soil Stabilized with Lime and Industrial Waste Lime. Al-Rafidain Eng. J. (AREJ) 2008, 16, 102–116. [Google Scholar] [CrossRef]

- Al-Khalili, A.M.; Ali, A.S.; Al-Taie, A.J. Effect of metakaolin and silica fume on the engineering properties of expansive soil. J. Phys. Conf. Ser. 2021, 1895, 012017. [Google Scholar] [CrossRef]

- Chernysheva, N.V.; Lesovik, V.S.; Glagolev, E.S.; Volodchenko, A.A. Effective Composites Employing Fast-Hardening Gypsum Cement Binders for Additive Manufacturing. In Proceedings of the International Conference “Actual Issues of Mechanical Engineering” 2017 (AIME 2017), Tomsk, Russia, 27–29 July 2017; Atlantis Press: Paris, France, 2017. [Google Scholar]

- De Azevedo, A.R.G.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; De Lima, T.E.S.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Neuzil, C. How permeable are clays and shales? Water Resour. Res. 1994, 30, 145–150. [Google Scholar] [CrossRef]

- Casey, B.; Germaine, J.; Flemings, P.; Reece, J.; Gao, B.; Betts, W. Liquid limit as a predictor of mudrock permeability. Mar. Pet. Geol. 2013, 44, 256–263. [Google Scholar] [CrossRef]

- Patil, N.; Sharma, S.; Sood, H. Permeability studies with blend of fly Ash and Rice Husk Ash stabilized soil subgrade. In Advances in Unsaturated Soil; CRC Press: Boca Raton, FL, USA, 2013; pp. 283–288. [Google Scholar]

- Khudyakova, T.M.; Kolesnikov, A.S.; Zhakipbaev, B.E.; Kenzhibaeva, G.S.; Kutzhanova, A.N.; Iztleuov, G.M.; Zhanikulov, N.N.; Kolesnikova, O.G.; Mynbaeva, E. Optimization of Raw Material Mixes in Studying Mixed Cements and Their Physicomechnical Properties. Refract. Ind. Ceram. 2019, 60, 76–81. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Hydraulic Conductivity and Leachate Characteristics of Stabilized Fly Ash. J. Environ. Eng. 1998, 124, 812–820. [Google Scholar] [CrossRef]

- Osinubi, K.J. Permeability of Lime-Treated Lateritic Soil. J. Transp. Eng. 1998, 124, 465–469. [Google Scholar] [CrossRef]

- Deb, T.; Pal, S.K. Effect of fly ash on geotechnical properties of local soil-fly ash mixed samples. Int. J. Res. Eng. Technol. 2014, 3, 507–515. [Google Scholar]

- Porbaha, A.; Pradhan, T.B.S.; Yamane, N. Time Effect on Shear Strength and Permeability of Fly Ash. J. Energy Eng. 2000, 126, 15–31. [Google Scholar] [CrossRef]

- Show, K.-Y.; Tay, J.-H.; Goh, A. Reuse of Incinerator Fly Ash in Soft Soil Stabilization. J. Mater. Civ. Eng. 2003, 15, 335–343. [Google Scholar] [CrossRef]

- Kim, B.; Prezzi, M.; Salgado, R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. J. Geotech. Geoenviron. Eng. 2005, 131, 914–924. [Google Scholar] [CrossRef]

- Kalkan, E.; Akbulut, S. The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng. Geol. 2004, 73, 145–156. [Google Scholar] [CrossRef]

- Wong, L.; Hashim, R.; Ali, F. Strength and Permeability of Stabilized Peat Soil. J. Appl. Sci. 2008, 8, 3986–3990. [Google Scholar] [CrossRef]

| Oxide Compounds | Marble Dust Percent by Weight |

|---|---|

| SiO2 | 26.53 |

| MgO | 18.31 |

| CaO | 38.45 |

| Fe2O3 | 13.70 |

| Al2O3 | 0.39 |

| NAME | Permeability cm/s | Compaction % | Proctor Dry Density g/cc |

|---|---|---|---|

| Natural Soil | 2.31 × 10−5 | 94.56 | 1.84 |

| 2% Rice Husk | 2.36 × 10−5 | 90.40 | 1.77 |

| 4% Rice Husk | 2.78 × 10−5 | 89.02 | 1.73 |

| 6% Rice Husk | 2.88 × 10−5 | 91.23 | 1.71 |

| 8% Rice Husk | 3.11 × 10−5 | 92.26 | 1.68 |

| 10% Rice Husk | 3.41 × 10−5 | 90.57 | 1.66 |

| 2% Wheat Straw | 2.04 × 10−5 | 93.22 | 1.73 |

| 4% Wheat Straw | 2.12 × 10−5 | 95.21 | 1.67 |

| 6% Wheat Straw | 2.37 × 10−5 | 92.41 | 1.58 |

| 8% Wheat Straw | 2.41 × 10−5 | 90.79 | 1.52 |

| 10% Wheat Straw | 2.46 × 10−5 | 89.29 | 1.40 |

| 2% Saw Dust | 1.84 × 10−5 | 93.94 | 1.65 |

| 4% Saw Dust | 1.89 × 10−5 | 91.02 | 1.67 |

| 6% Saw Dust | 1.90 × 10−5 | 93.13 | 1.60 |

| 8% Saw Dust | 2.06 × 10−5 | 91.67 | 1.56 |

| 10% Saw Dust | 2.52 × 10−5 | 93.88 | 1.47 |

| 2% Rice Husk Ash | 4.62 × 10−5 | 92.56 | 1.81 |

| 4% Rice Husk Ash | 5.76 × 10−5 | 91.44 | 1.75 |

| 6% Rice Husk Ash | 7.115 × 10−5 | 90.33 | 1.65 |

| 8% Rice Husk Ash | 3.15 × 10−4 | 93.21 | 1.63 |

| 10% Rice Husk Ash | 5.33 × 10−4 | 92.67 | 1.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hakro, M.R.; Kumar, A.; Almani, Z.; Ali, M.; Fediuk, R.; Klyuev, S.; Klyuev, A.; Sabitov, L.; Fathi, D. Compaction Characteristics and Permeability of Expansive Shale Stabilized with Locally Produced Waste Materials. Materials 2022, 15, 2138. https://doi.org/10.3390/ma15062138

Hakro MR, Kumar A, Almani Z, Ali M, Fediuk R, Klyuev S, Klyuev A, Sabitov L, Fathi D. Compaction Characteristics and Permeability of Expansive Shale Stabilized with Locally Produced Waste Materials. Materials. 2022; 15(6):2138. https://doi.org/10.3390/ma15062138

Chicago/Turabian StyleHakro, Muhammad Rehan, Aneel Kumar, Zaheer Almani, Mujahid Ali, Roman Fediuk, Sergey Klyuev, Alexander Klyuev, Linar Sabitov, and Dina Fathi. 2022. "Compaction Characteristics and Permeability of Expansive Shale Stabilized with Locally Produced Waste Materials" Materials 15, no. 6: 2138. https://doi.org/10.3390/ma15062138

APA StyleHakro, M. R., Kumar, A., Almani, Z., Ali, M., Fediuk, R., Klyuev, S., Klyuev, A., Sabitov, L., & Fathi, D. (2022). Compaction Characteristics and Permeability of Expansive Shale Stabilized with Locally Produced Waste Materials. Materials, 15(6), 2138. https://doi.org/10.3390/ma15062138