Effect of Sulfate Concentration on Chloride Diffusion of Concrete under Cyclic Load

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

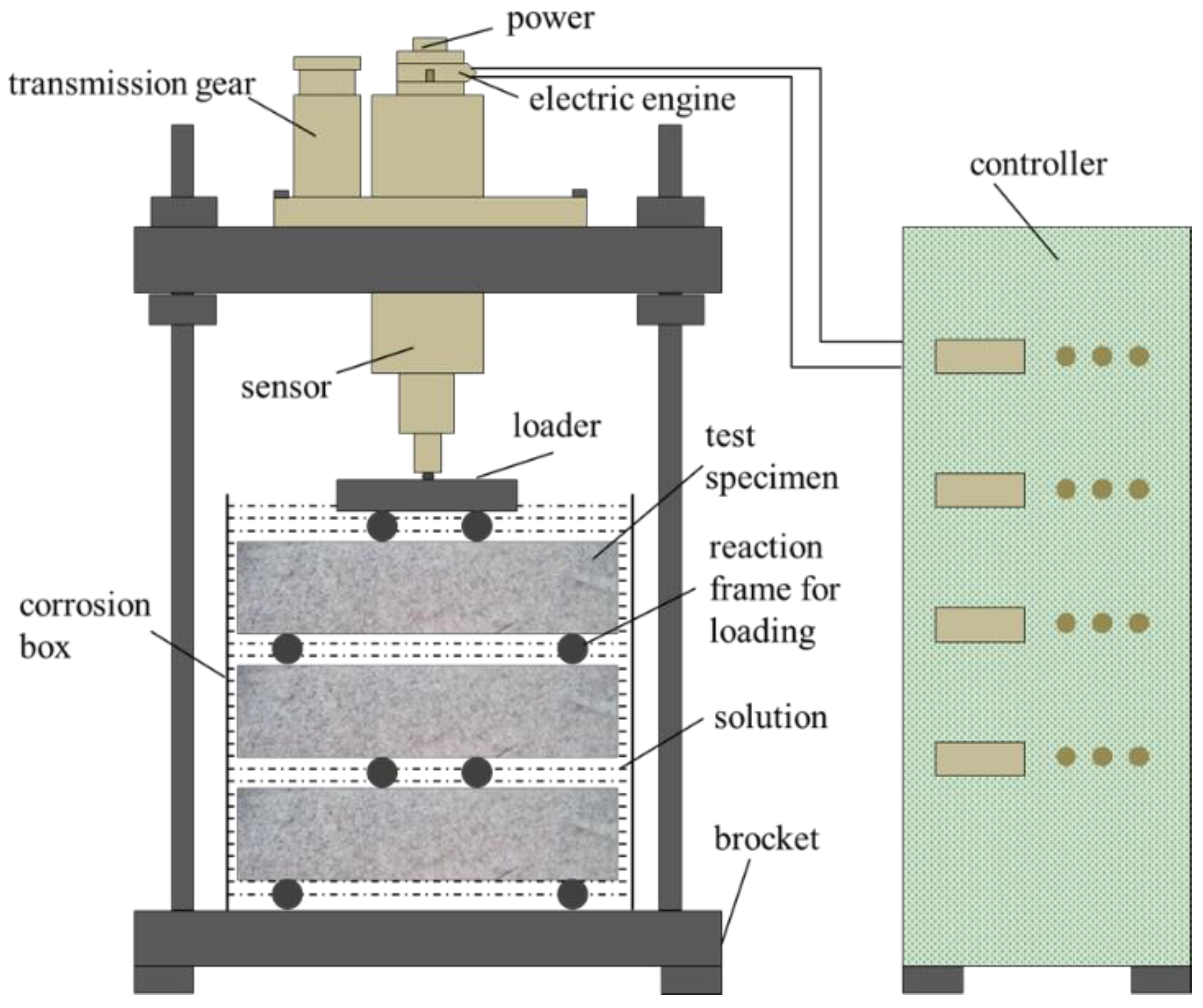

2.2. Dynamic Flexural Loading and Erosion Setup

2.3. Chloride Transport Behavior Evaluation of Concrete

2.3.1. Free Chloride Concentration

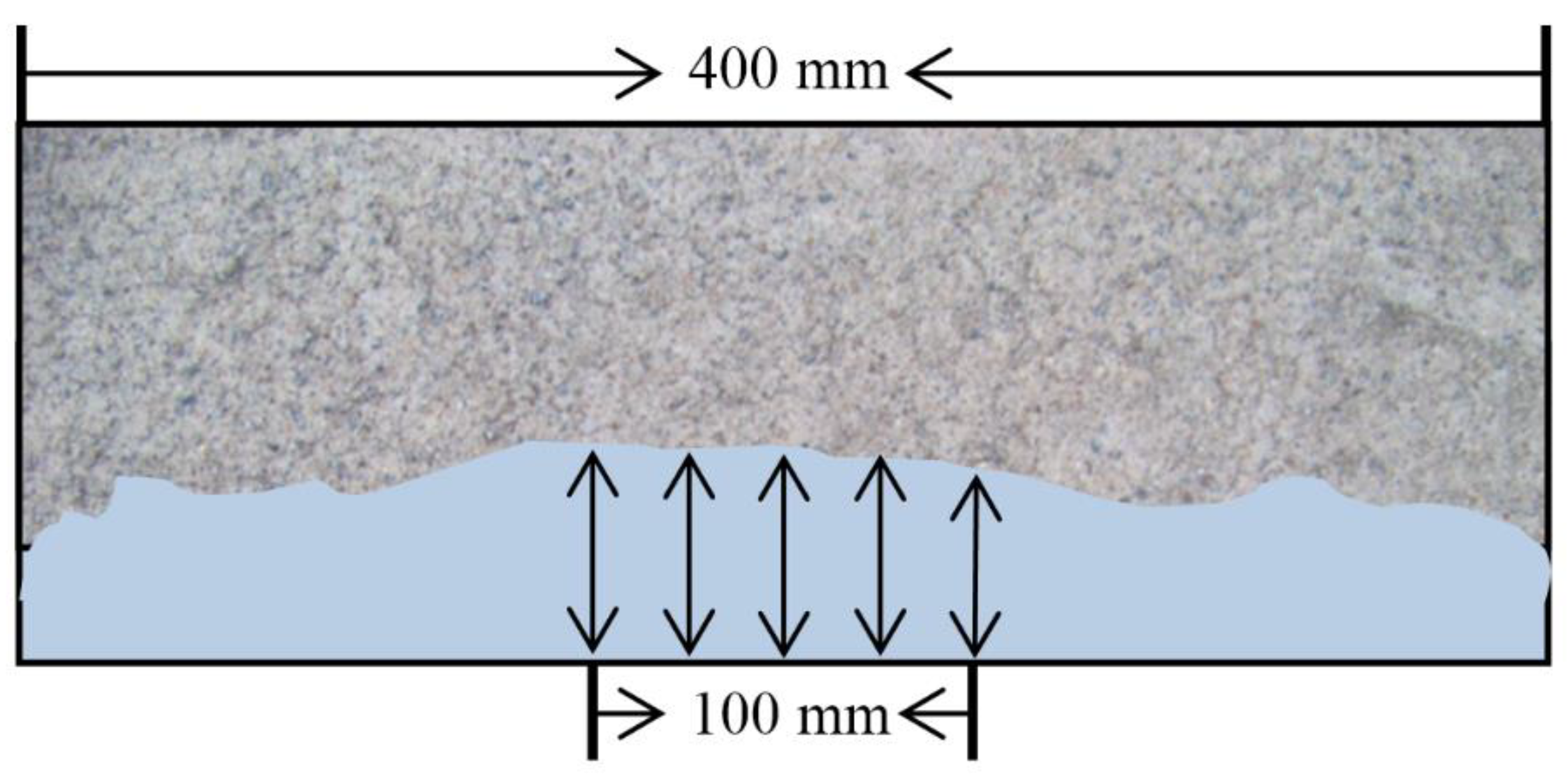

2.3.2. Chloride Erosion Depth

2.3.3. Apparent Diffusion Coefficient (Dapp) and Apparent Surface Chloride Ion Concentration (Cs)

2.4. Effect Coefficient K

3. Results and Discussion

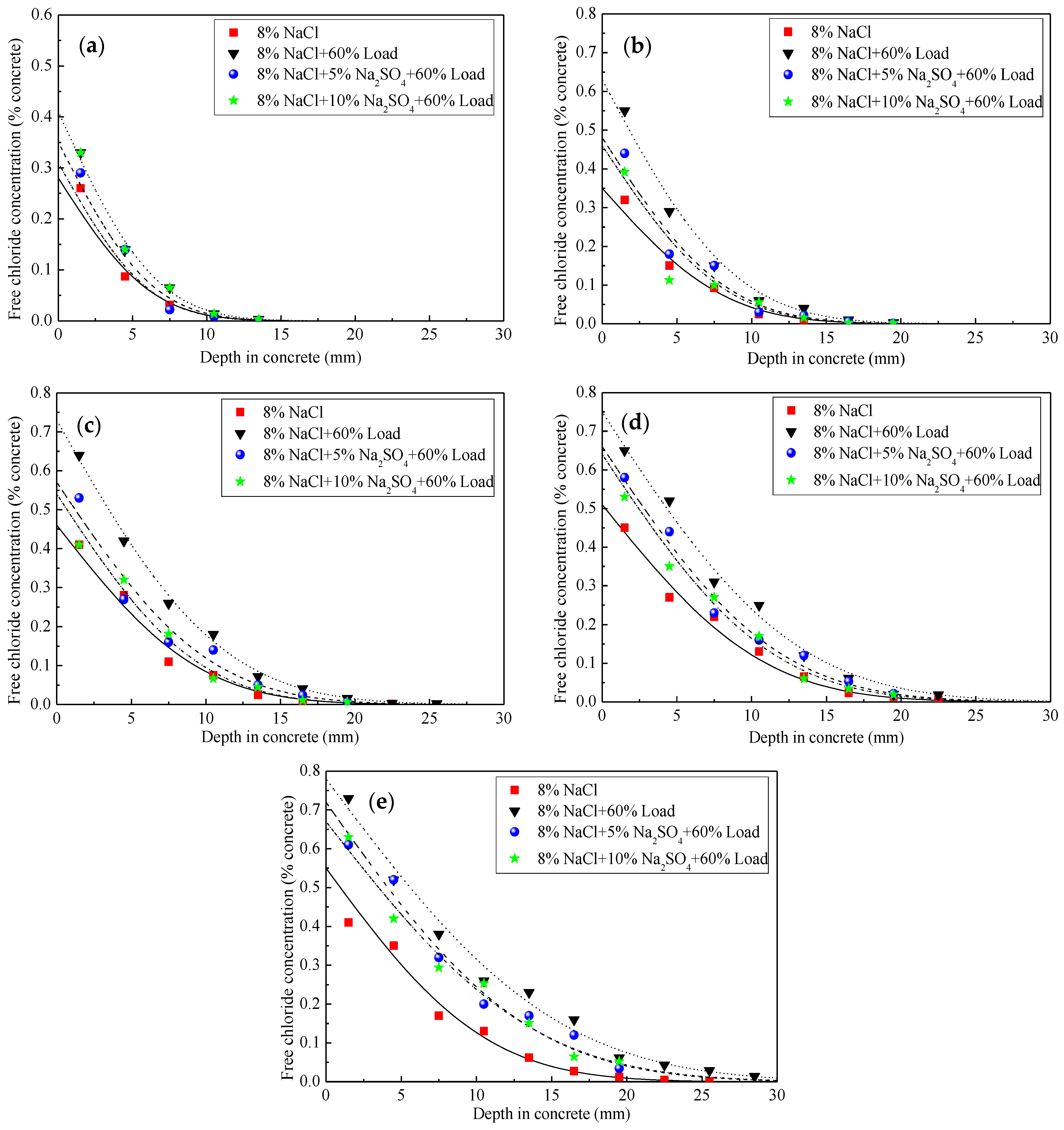

3.1. Concentration Distribution of Chloride Ion

3.2. The Time-Varying Law of Cs and Dapp

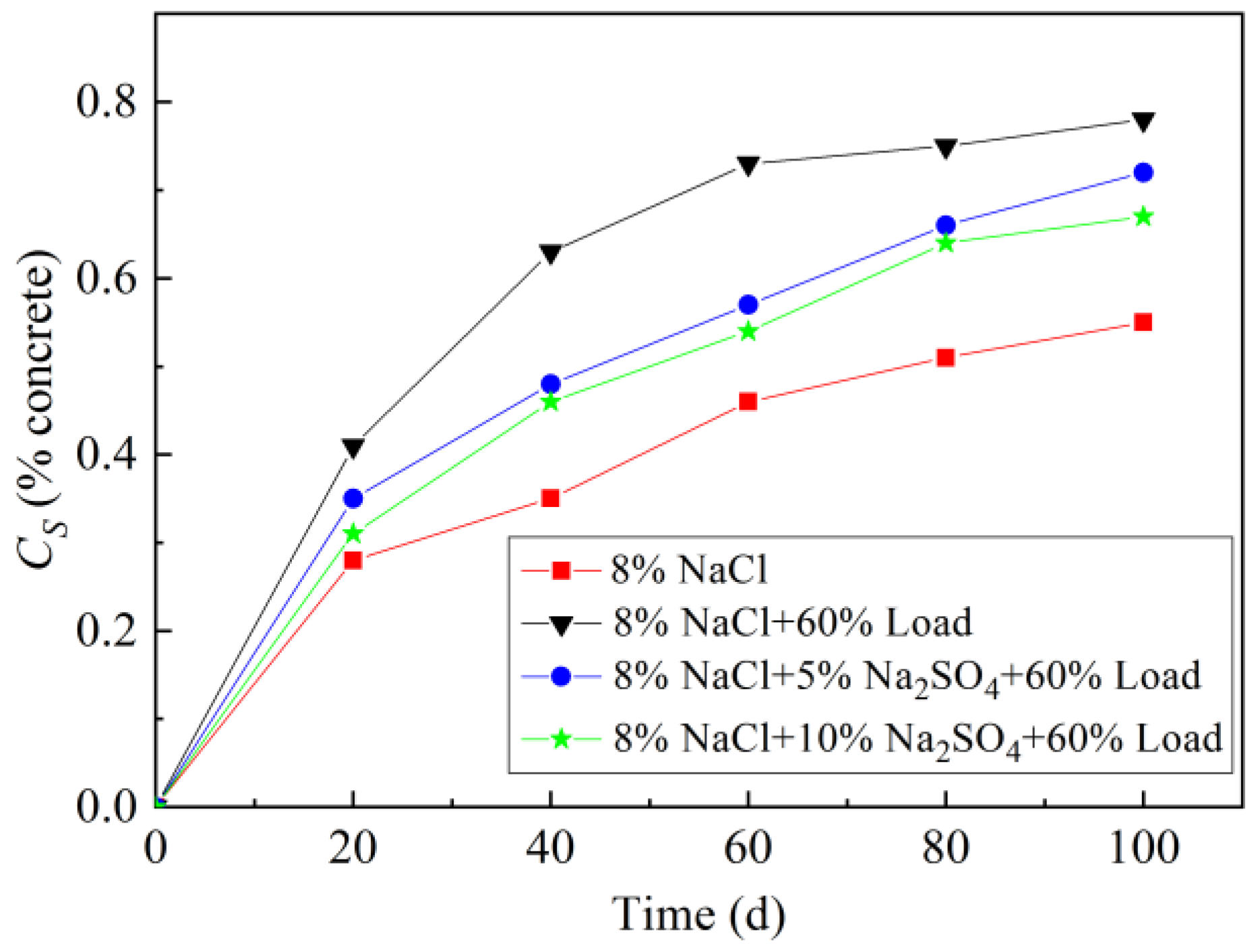

3.2.1. Apparent Surface Chloride Ion Concentration (Cs)

3.2.2. Apparent Diffusion Coefficient (Dapp)

3.3. Chloride Erosion Depth

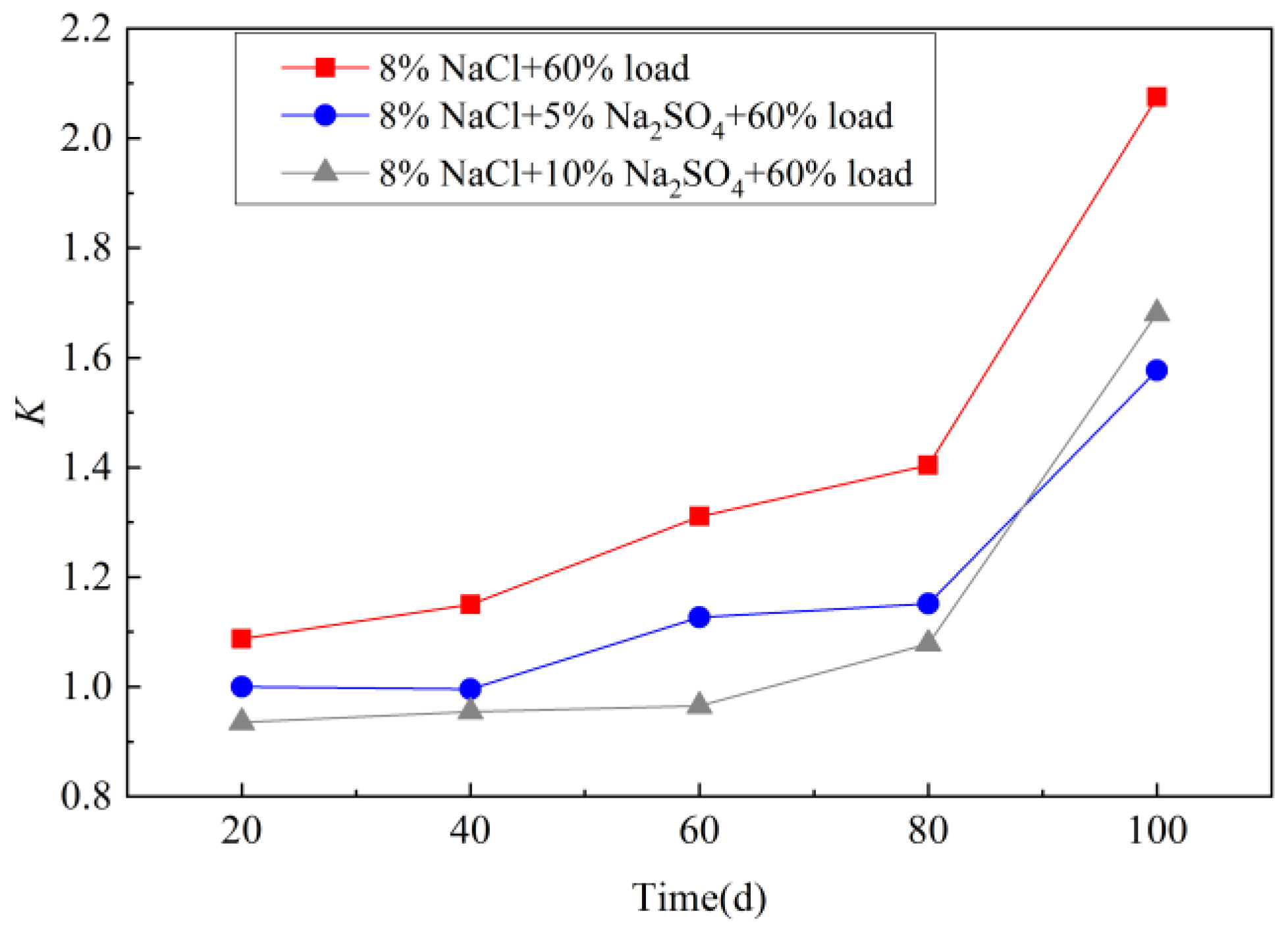

3.4. Effect Coefficient K

4. Conclusions

- The long-term distribution of the chloride ion in the concrete immersed in sodium sulfate and sodium chloride solutions coupled with the cyclic load is, as expected, in accordance with Fick’s second law.

- Compared with the results of the single immersion test, the existence of the cyclic load significantly reduces the chloride erosion resistance of concrete. When the erosion age was 100 d, the chloride ion concentration at the depth of 7.5 mm was about 2.11 times that of the single immersion.

- In a certain erosion time, the existence of sulfate ion slowed down the transport of chloride ions. The depth of erosion (Csmax) and apparent diffusion coefficient (Dapp) of concrete decreased with the increase of the sulfate solution concentration. Under the condition of the dual-salt immersion and loading, the K value decreased continuously with the increase of erosion age and was less than 1, indicating that the existence of sulfate ion improved the resistance of concrete to chloride ion penetration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, M.K.; Al-Kutti, W.A.; Shazali, M.A.; Baluch, M.H. Simulation of chloride migration in compression-induced damage in concrete. J. Mater. Civ. Eng. 2012, 24, 789–796. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, P.; Ma, J. Diffusion behavior of chloride ions in concrete box girder under the influence of load and carbonation. Materials 2020, 13, 2117. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Hong, F.; Zhao, T.; Wan, X. Condition assessment and preventive maintenance of concrete structures in severe marine environment. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; Volume 49149, pp. 325–330. [Google Scholar]

- Tegguer, A.D.; Bonnet, S.; Khelidj, A.; Baroghel-Bouny, V. Effect of uniaxial compressive loading on gas permeability and chloride diffusion coefficient of concrete and their relationship. Cem. Concr. Res. 2013, 52, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Zhang, Q. Investigation on water absorption in concrete after subjected to compressive cyclic loading. Constr. Build. Mater. 2021, 299, 123897. [Google Scholar] [CrossRef]

- Choinska, M.; Khelidj, A.; Chatzigeorgiou, G.; Pijaudier-Cabot, G. Effects and interactions of temperature and stress-level related damage on permeability of concrete. Cem. Concr. Res. 2007, 37, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.J.; Hyun, J.H.; Kim, Y.Y.; Shin, K.J. Chloride permeability of damaged high-performance fiber-reinforced cement composite by repeated compressive loads. Materials 2014, 7, 5802–5815. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, W.; Ba, H.; Chen, S. Effect of fly ash and repeated loading on diffusion coefficient in chloride migration test. Constr. Build. Mater. 2011, 25, 2269–2274. [Google Scholar] [CrossRef]

- Zhang, L.; Jia, J.; Meng, G.; Zhu, W. Chloride diffusion in concrete subjected to compressive loading. Mag. Concr. Res. 2014, 66, 991–997. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Q.; Liu, Q.; Sun, J.; Liu, X. Chloride ion diffusion of structural concrete under the coupled effect of bending cyclic load and chloride. Mater. Res. Innov. 2015, 19 (Suppl. S1), 181–184. [Google Scholar] [CrossRef]

- Hrabova, K.; Vorechovska, D.; Typly, B. Potential for the inclusion of sustainability aspects in limit states for concrete. In Proceedings of the 20th International Multidisciplinary Scientific GeoConference, SGEM 2020, Albena, Bulgaria, 18–24 August 2020; Volume 20, pp. 411–418. [Google Scholar]

- Gowripalan, N.; Sirivivatnanon, V.; Lim, C.C. Chloride diffusivity of concrete cracked in flexure. Cem. Concr. Res. 2000, 30, 725–730. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Liu, Z.; Chen, S. One and two dimensional chloride ion diffusion of fly ash concrete under flexural stress. J. Zhejiang Univ.-Sci. A 2011, 12, 692–701. [Google Scholar] [CrossRef]

- Wang, H.; Lu, C.; Jin, W.; Bai, Y. Effect of external loads on chloride transport in concrete. J. Mater. Civ. Eng. 2011, 23, 1043–1049. [Google Scholar] [CrossRef]

- Ahn, W.; Reddy, D.V. Galvanostatic testing for the durability of marine concrete under cyclic loading. Cem. Concr. Res. 2001, 31, 343–349. [Google Scholar] [CrossRef]

- Wang, C.; Sun, W.; Jiang, J.; Han, J.; Bangtu, Y. Chloride ion transport performance in slag mortar under cyclic loading. Sci. China Technol. Sci. 2012, 55, 1359–1364. [Google Scholar] [CrossRef]

- Jaffer, S.J.; Hansson, C.M. Chloride-induced corrosion products of steel in cracked-concrete subjected to different loading conditions. Cem. Concr. Res. 2009, 39, 116–125. [Google Scholar] [CrossRef]

- Cabeza, M.; Díaz, B.; Nóvoa, X.; Pérez, C.; Pérez, M. The effect of loading on the diffusivity of chlorides in mortar. Materials 2019, 12, 2527. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gontar, A.; Martin, P.; Popovics, S. Effects of cyclic loading on chloride permeability of plain concrete. Condition Monitoring of Materials and Structures. In Proceedings of the Engineering Mechanics Conference 2000, Austin, TX, USA, 21–24 May 2000; pp. 95–109. [Google Scholar]

- Qi, B.; Gao, J.; Chen, F.; Shen, D. Chloride penetration into recycled aggregate concrete subjected to wetting–drying cycles and flexural loading. Constr. Build. Mater. 2018, 174, 130–137. [Google Scholar] [CrossRef]

- Wang, C.; Sun, W.; Jing, J.; Han, J.; Rong, H. The transport properties of concrete under the simultaneous coupling of fatigue load and environment factors. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2012, 27, 181–186. [Google Scholar] [CrossRef]

- Yu, D.; Guan, B.; He, R.; Xiong, R.; Liu, Z. Sulfate attack of Portland cement concrete under dynamic flexural loading: A coupling function. Constr. Build. Mater. 2016, 115, 478–485. [Google Scholar] [CrossRef]

- ASTM Standard D512; Standard Test Methods for Chloride Ion in Water. ASTM International: West Conshohocken, PA, USA, 2012.

- Wang, Y.; Lin, C.; Cui, Y. Experiments of chloride ingression in loaded concrete members under the marine environment. J. Mater. Civ. Eng. 2014, 26, 362–376. [Google Scholar] [CrossRef]

- Song, H.; Lee, C.; Ann, K. Factors influencing chloride transport in concrete structures exposed to marine environments. Cem. Concr. Compos. 2008, 30, 113–121. [Google Scholar] [CrossRef]

- Kassir, M.K.; Ghosn, M. Chloride-induced corrosion of reinforced concrete bridge decks. Cem. Concr. Res. 2002, 32, 139–143. [Google Scholar] [CrossRef]

| Items | CaO | Al2O3 | SiO2 | Fe2O3 | MgO | Alkali | Insoluble | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|

| Weight (%) | 64.98 | 5.33 | 21.69 | 3.47 | 1.17 | 1.04 | 0.07 | 2.68 |

| W/C | Constituent (kg/m3) | Water Reducer (%) | Slump (mm) | 28d Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Cement | Water | Fine Aggregate | Coarse Aggregate | ||||

| 0.38 | 450 | 180 | 569 | 1211 | 0.3 | 40 | 6.87 |

| Group | NaCl Concentration (%) | Na2SO4 Concentration (%) | Dynamic Loading Level | Loading Frequency (Hz) | Time (d) | |

|---|---|---|---|---|---|---|

| Smin | Smax | |||||

| 1 | 8 | 0 | 0 | 0 | 0 | 20–100 |

| 2 | 8 | 0 | 10% | 60% | 0.02 | 20–100 |

| 3 | 8 | 5 | 10% | 60% | 0.02 | 20–100 |

| 4 | 8 | 10 | 10% | 60% | 0.02 | 20–100 |

| Experimental Condition | Csmax | σ2/Csmax | b | σ2/b | R2 |

|---|---|---|---|---|---|

| 8% NaCl | 0.57520 | 0.03566 | 0.02744 | 0.00448 | 0.93388 |

| 8% NaCl + 60% Load | 0.80118 | 0.01090 | 0.03740 | 0.00169 | 0.97870 |

| 8% NaCl + 5% Na2SO4 + 60% Load | 0.74761 | 0.03885 | 0.02710 | 0.00368 | 0.95134 |

| 8% NaCl + 10% Na2SO4 + 60% Load | 0.71781 | 0.02676 | 0.02597 | 0.00245 | 0.98098 |

| Experimental Condition | Measuring Point | Average Depth (mm) | Maximum Depth (mm) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| 8% NaCl | 15.9 | 18.6 | 14.1 | 19.6 | 14.8 | 16.59 | 19.6 |

| 8% NaCl + 60% Load | 25.4 | 19.9 | 26.6 | 24.5 | 26.9 | 24.67 | 26.9 |

| 8% NaCl + 5%Na2SO4 + 60% Load | 19.8 | 17.9 | 22.7 | 24.1 | 20.2 | 20.92 | 24.1 |

| 8% NaCl + 10% Na2SO4 + 60% Load | 15.4 | 22.3 | 19.8 | 20.0 | 17.2 | 18.96 | 22.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; Feng, C.; Fu, T.; Shen, A. Effect of Sulfate Concentration on Chloride Diffusion of Concrete under Cyclic Load. Materials 2022, 15, 2036. https://doi.org/10.3390/ma15062036

Yu D, Feng C, Fu T, Shen A. Effect of Sulfate Concentration on Chloride Diffusion of Concrete under Cyclic Load. Materials. 2022; 15(6):2036. https://doi.org/10.3390/ma15062036

Chicago/Turabian StyleYu, Demei, Chao Feng, Tengfei Fu, and Aiqin Shen. 2022. "Effect of Sulfate Concentration on Chloride Diffusion of Concrete under Cyclic Load" Materials 15, no. 6: 2036. https://doi.org/10.3390/ma15062036

APA StyleYu, D., Feng, C., Fu, T., & Shen, A. (2022). Effect of Sulfate Concentration on Chloride Diffusion of Concrete under Cyclic Load. Materials, 15(6), 2036. https://doi.org/10.3390/ma15062036