Experimental and Numerical Study on Friction and Wear Performance of Hot Extrusion Die Materials

Abstract

:1. Introduction

2. Experiment Procedure

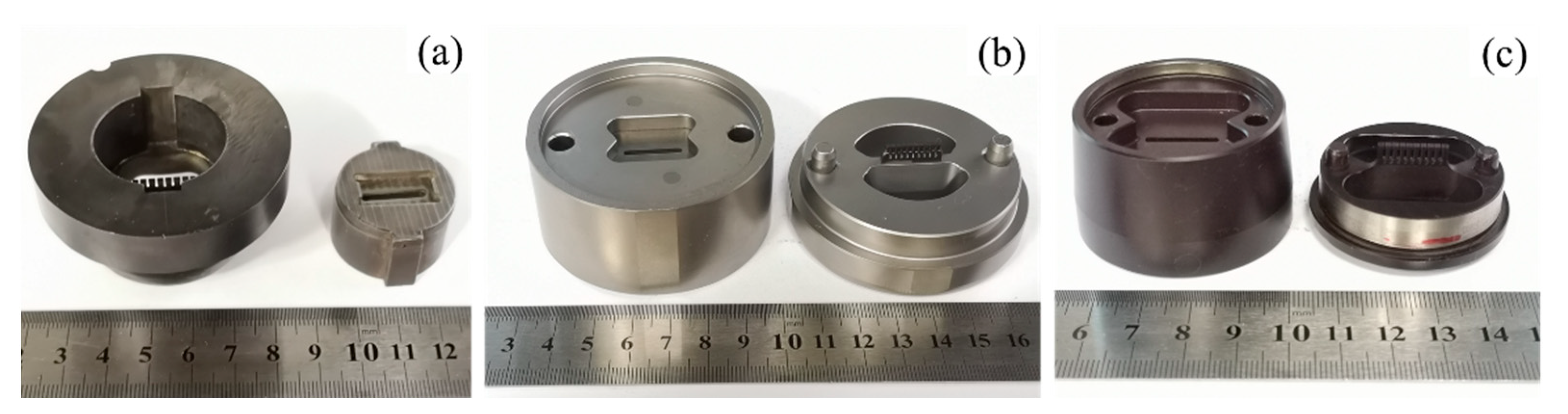

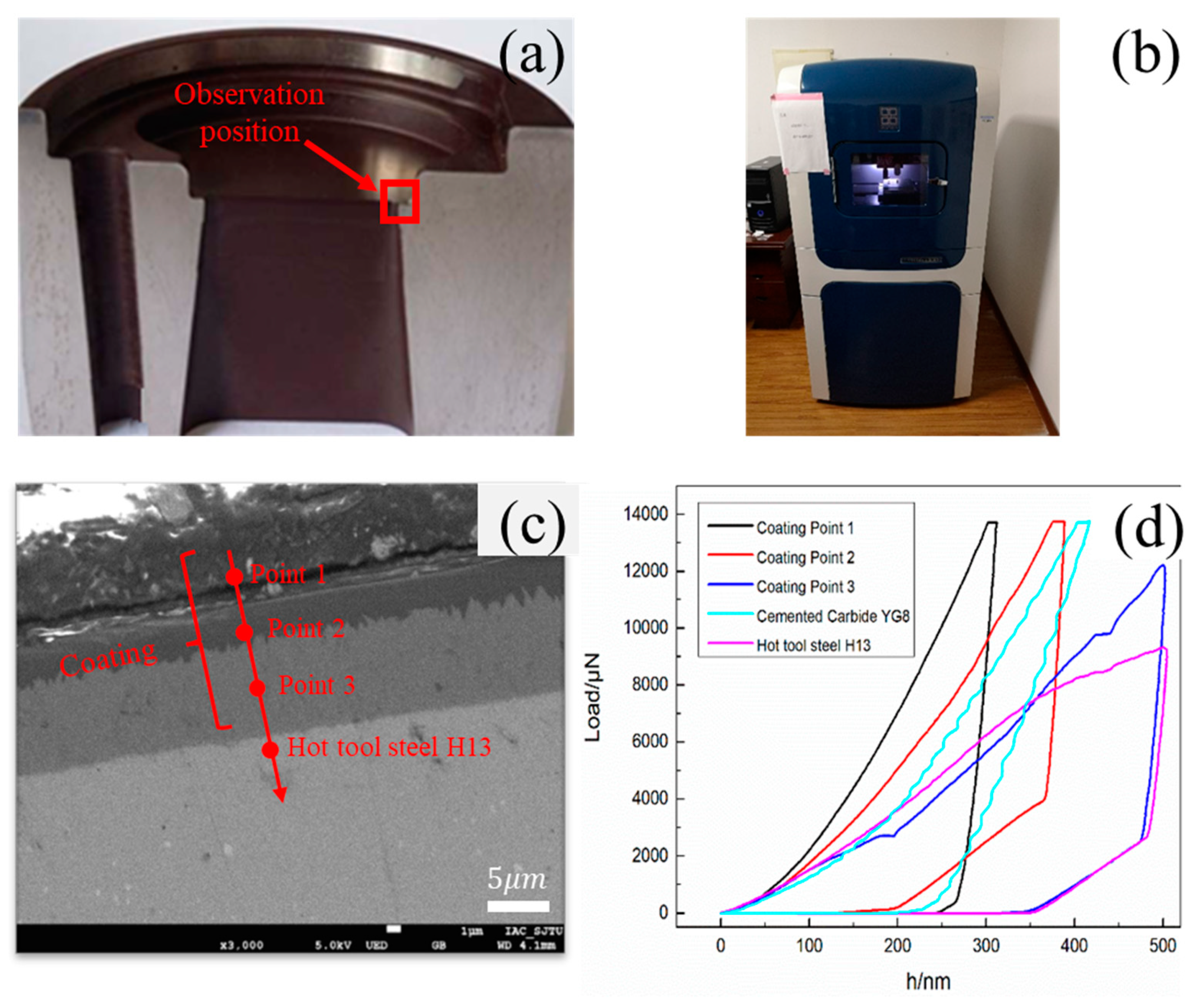

2.1. Materials and Specimens

2.2. Test Equipment

2.3. Test Procedures

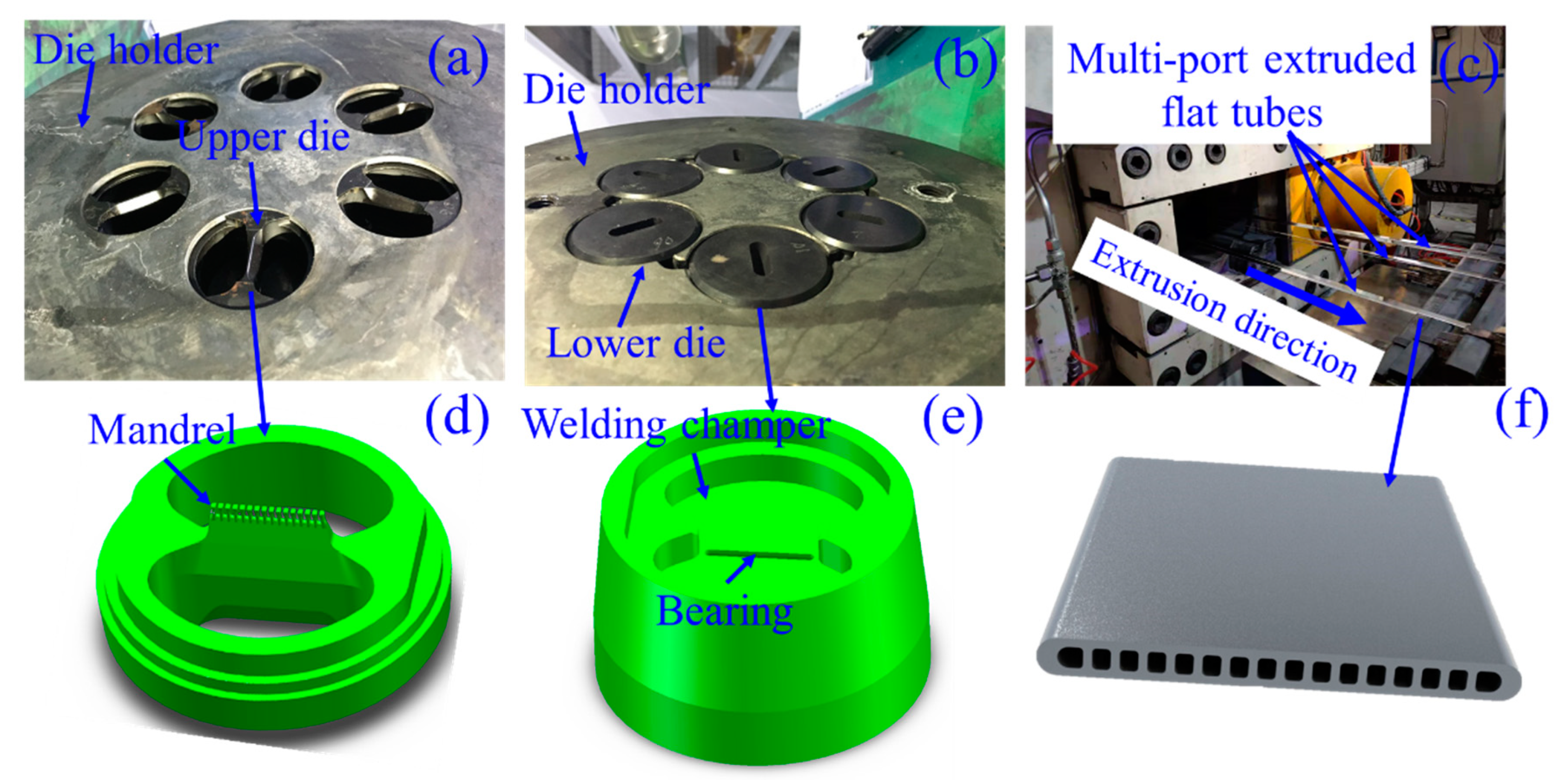

3. Extrusion Experiment and Simulation

3.1. Extrusion Experiment

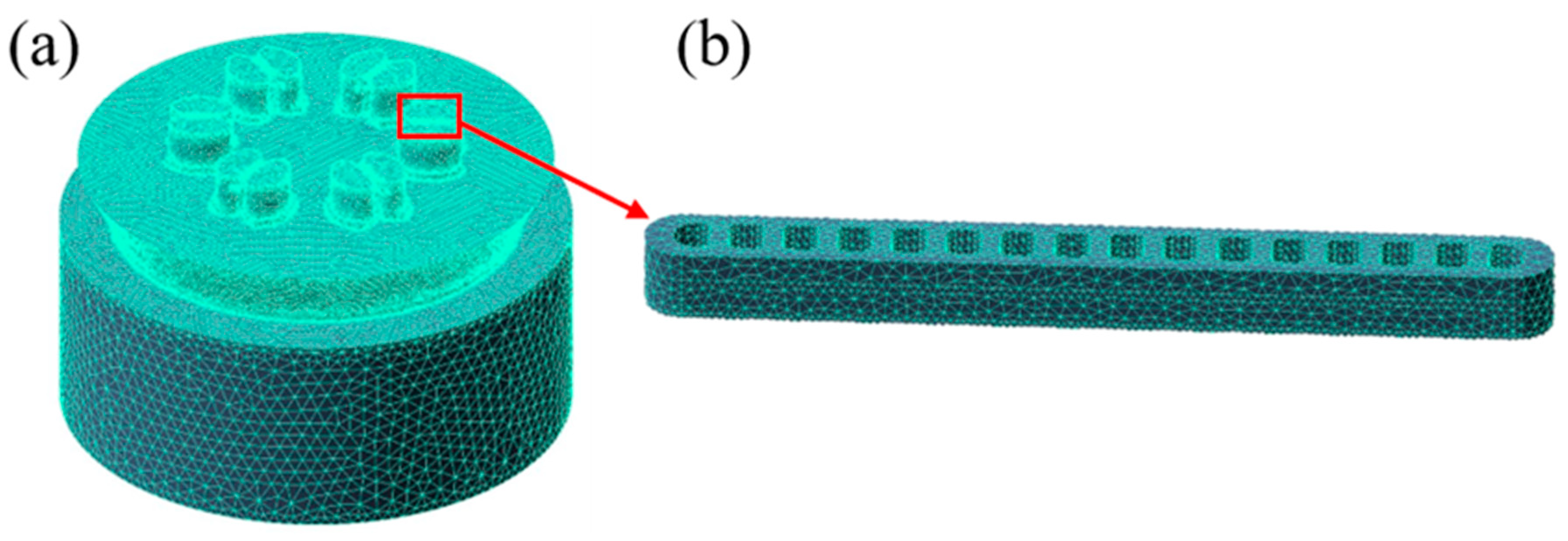

3.2. Finite Element Simulation

4. Results and Discussion

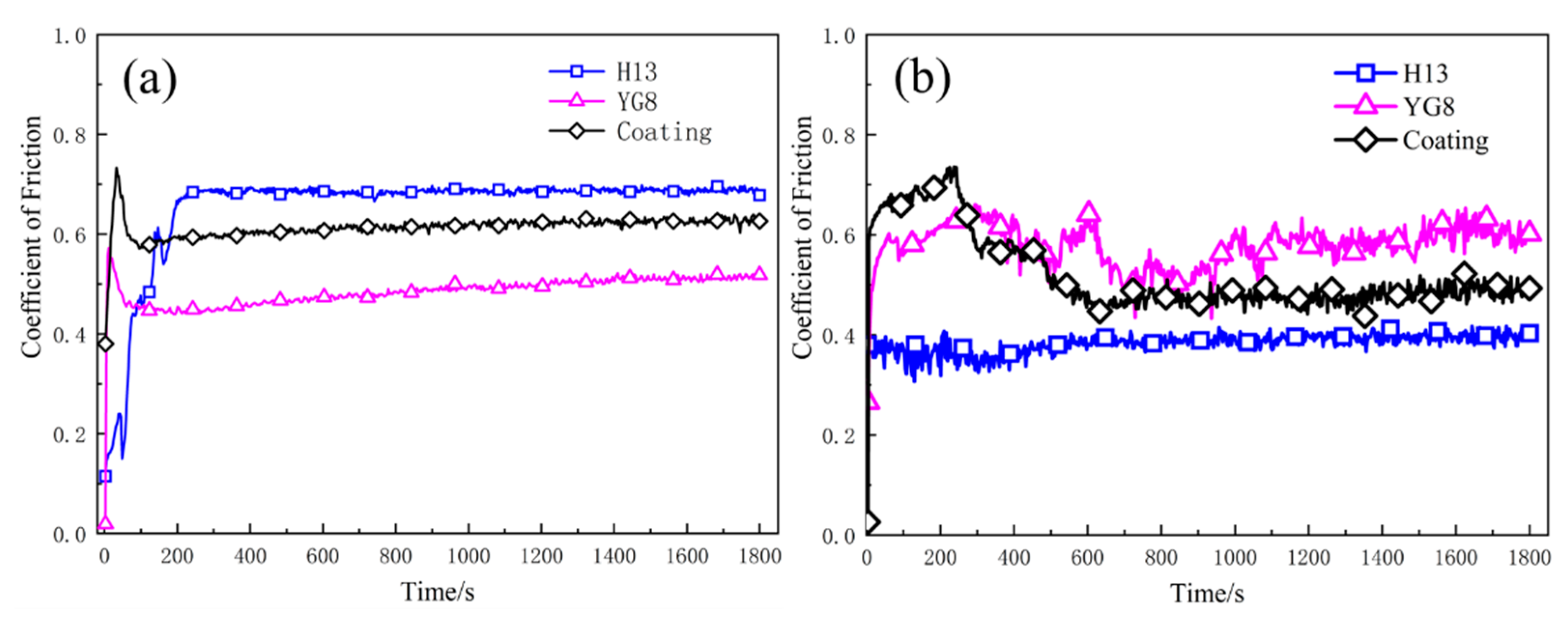

4.1. Coefficient of Friction

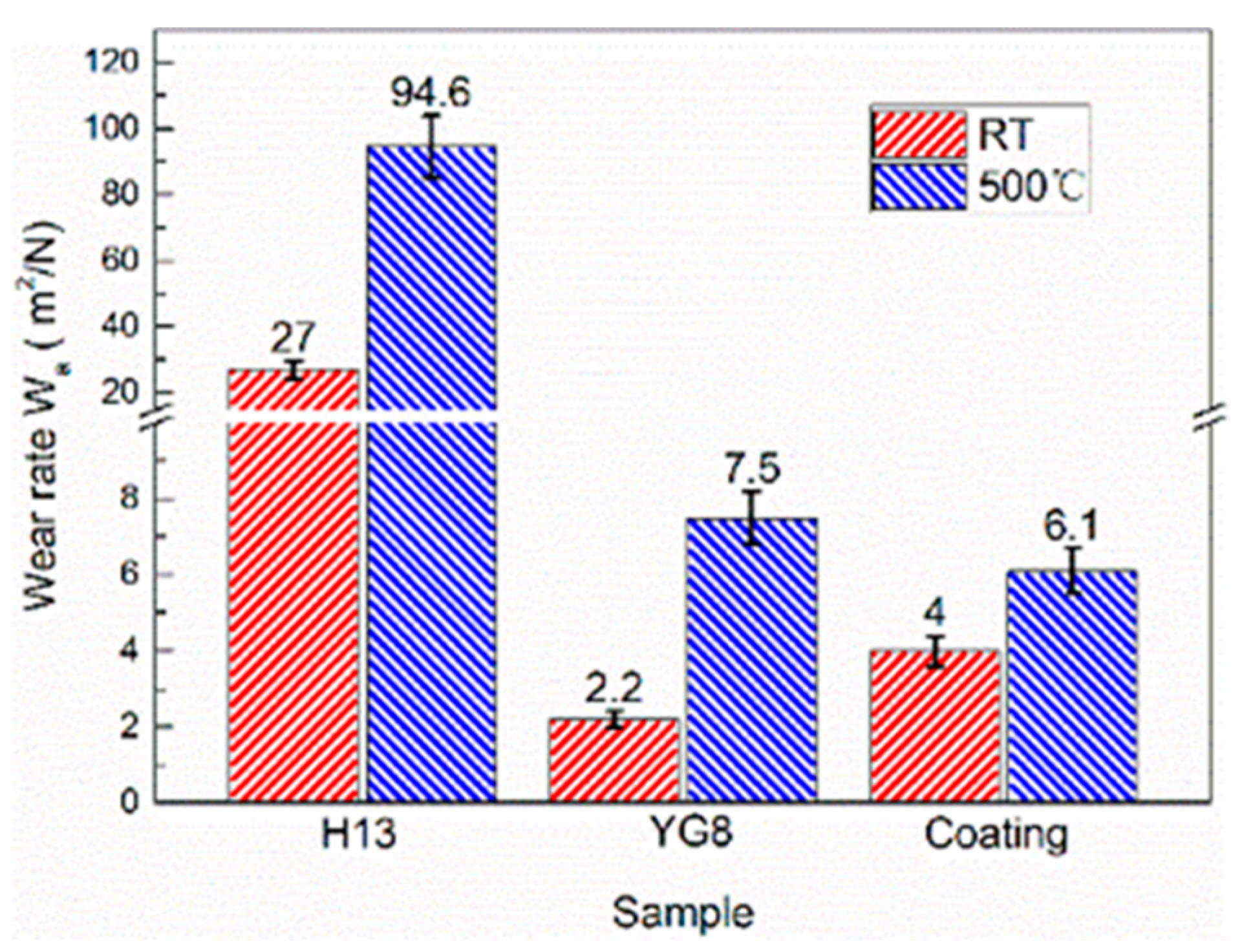

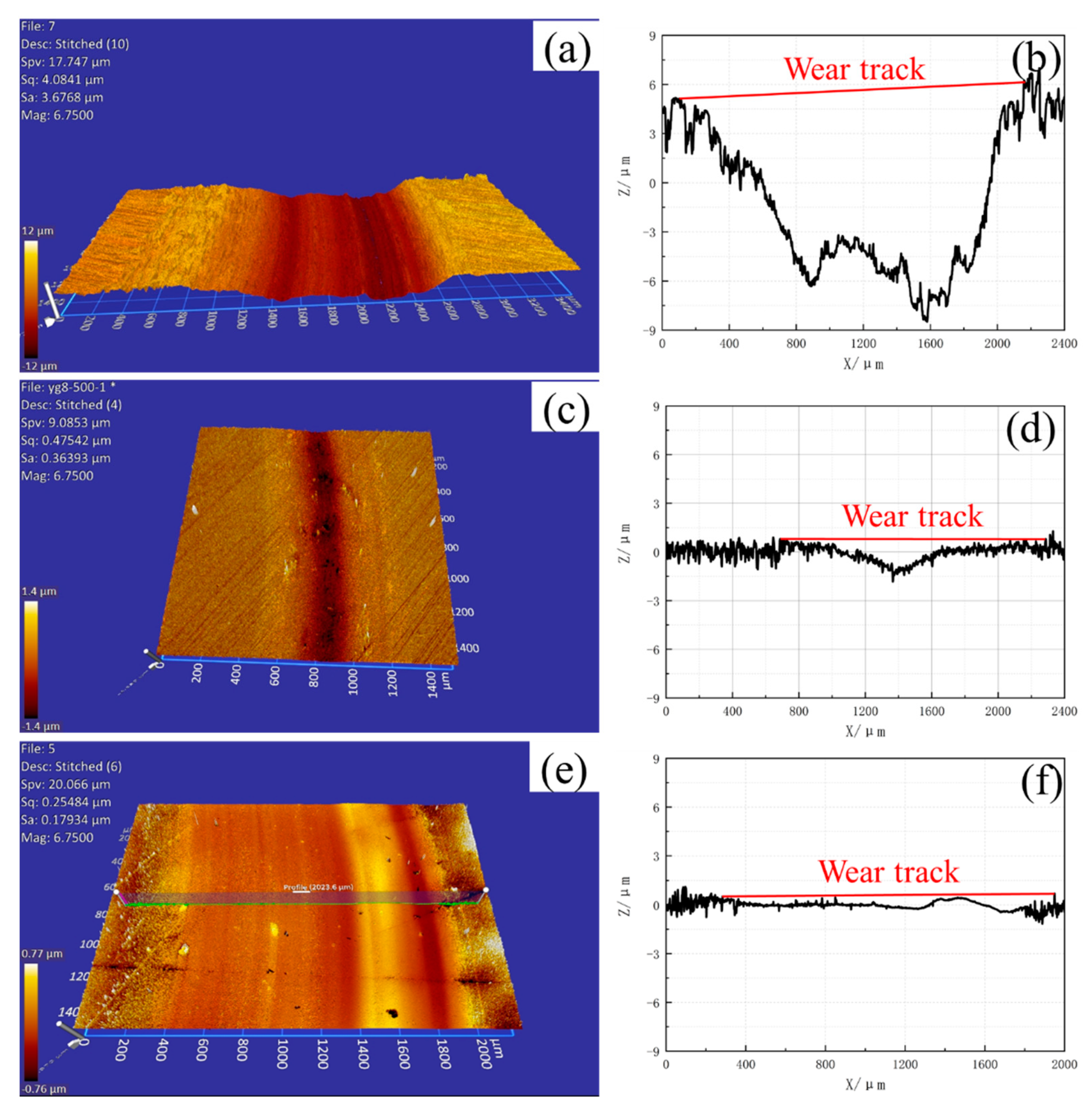

4.2. Wear Rate

4.3. Effect of Coefficient of Friction on Extrusion Load

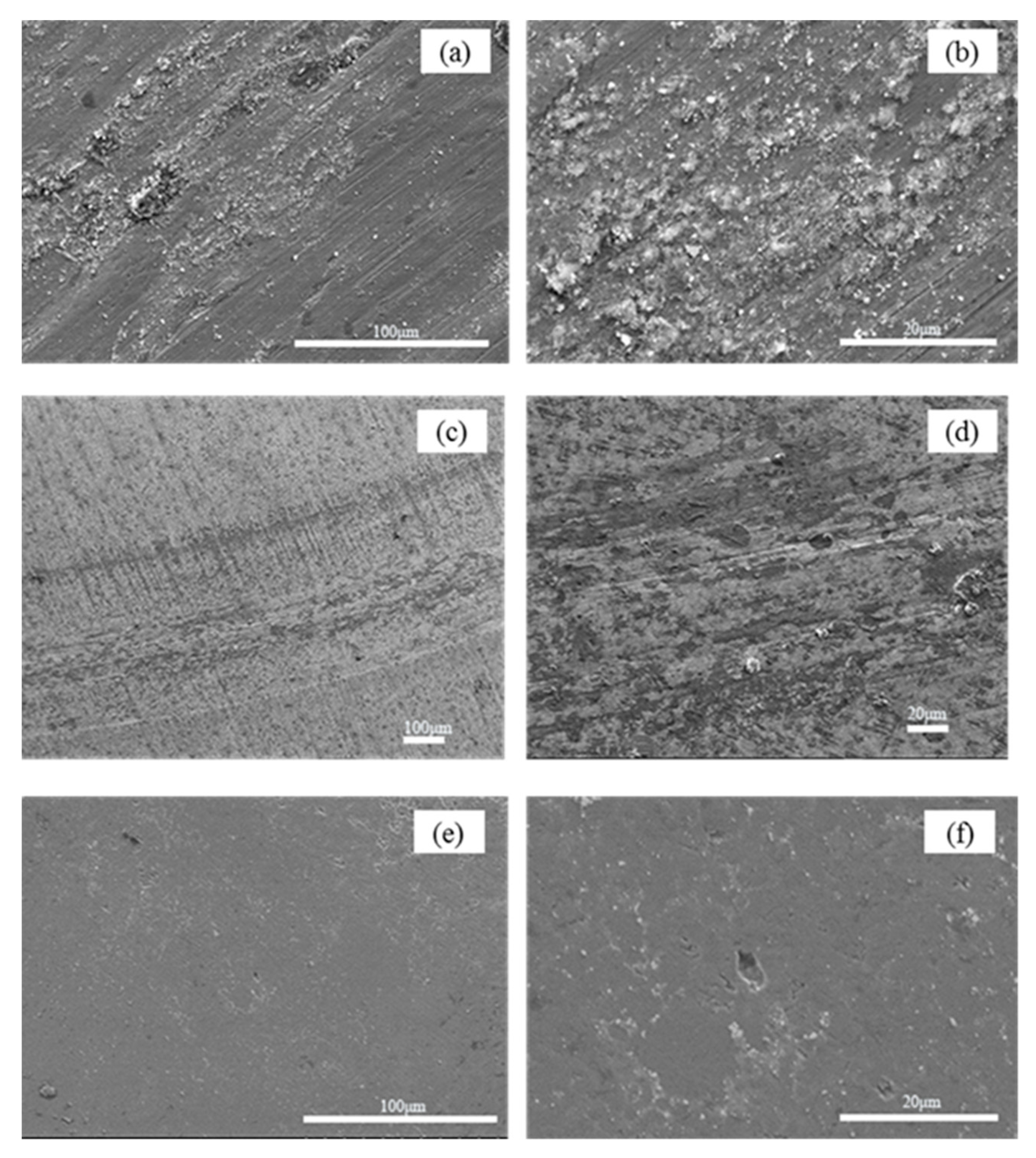

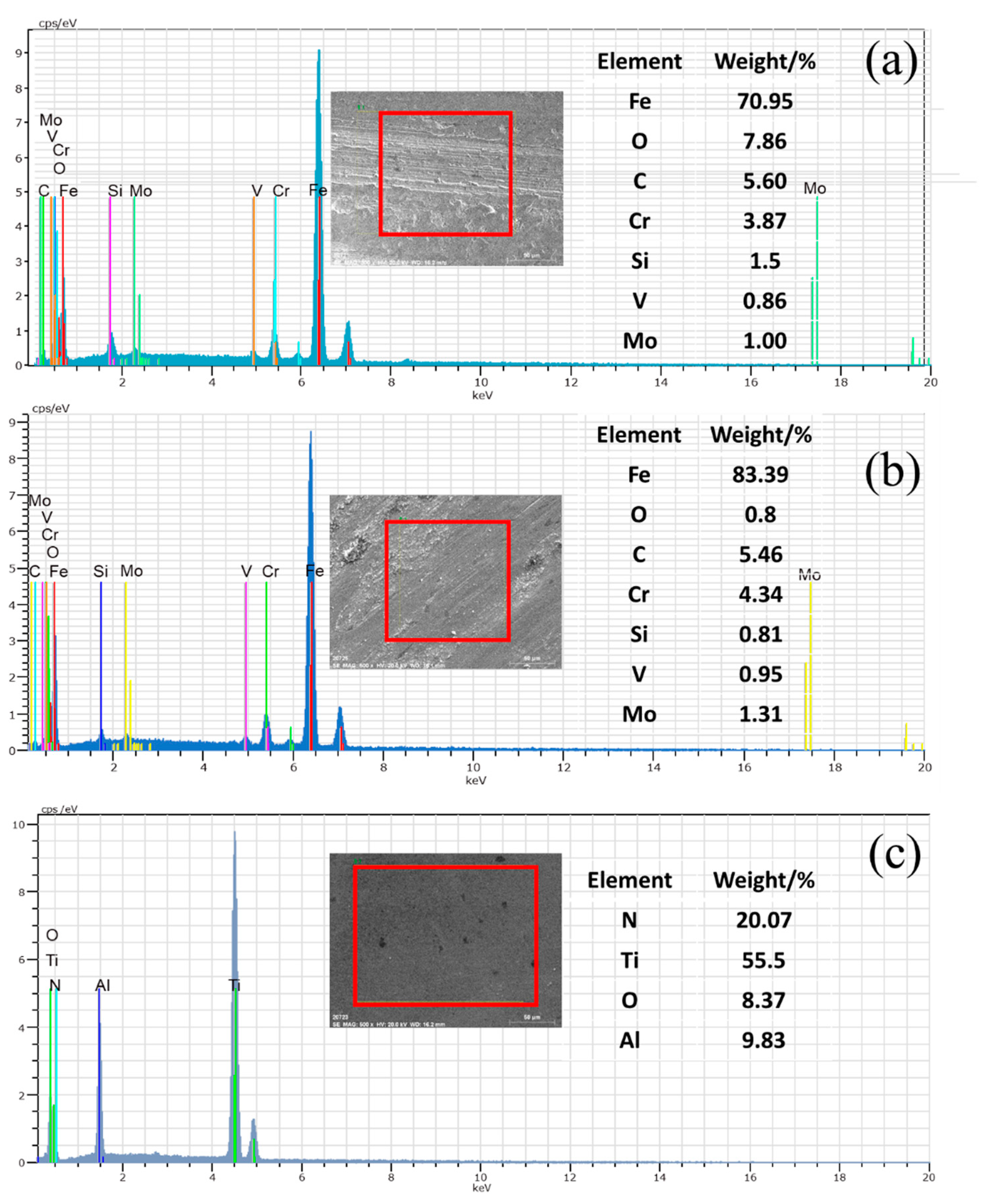

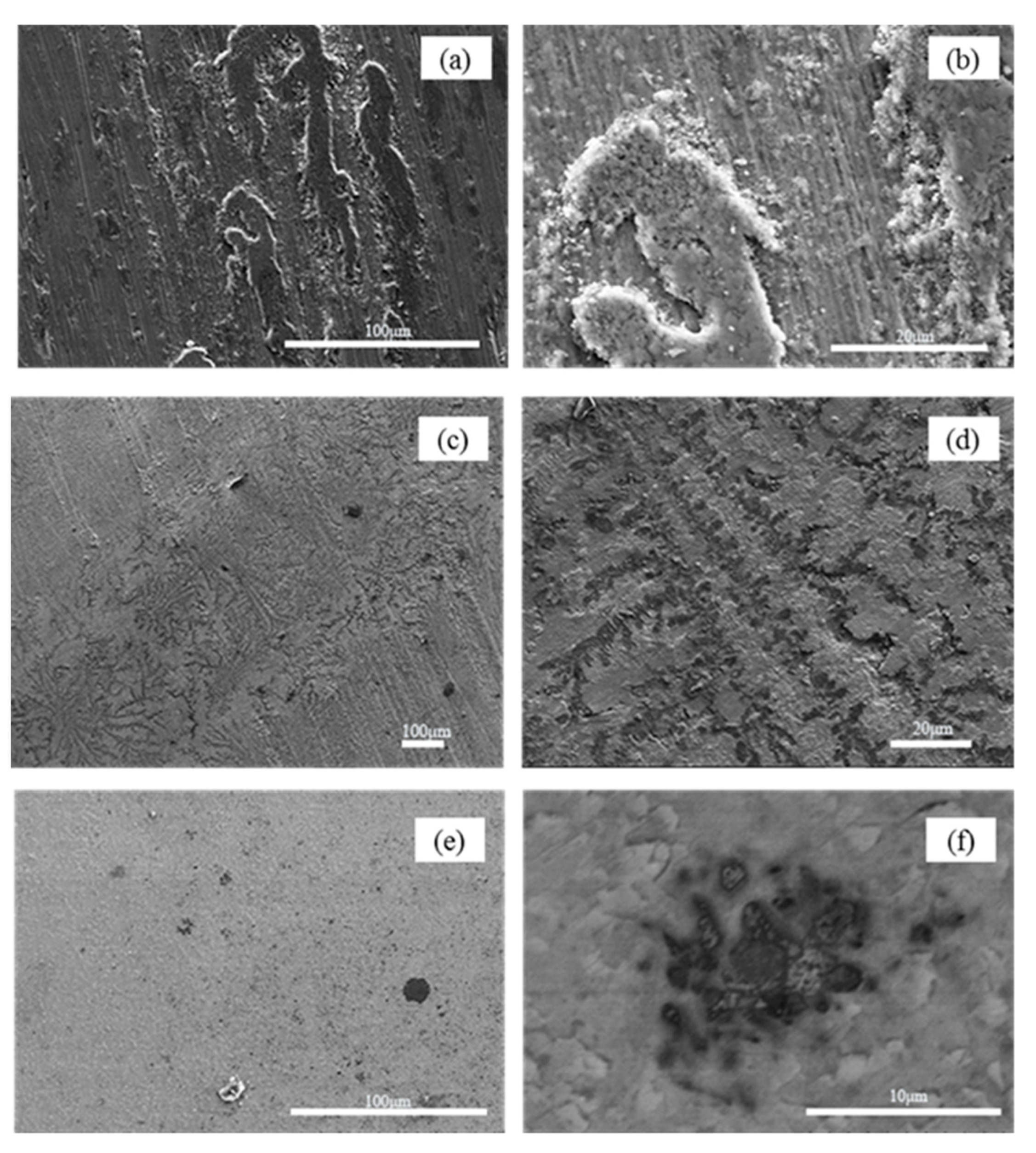

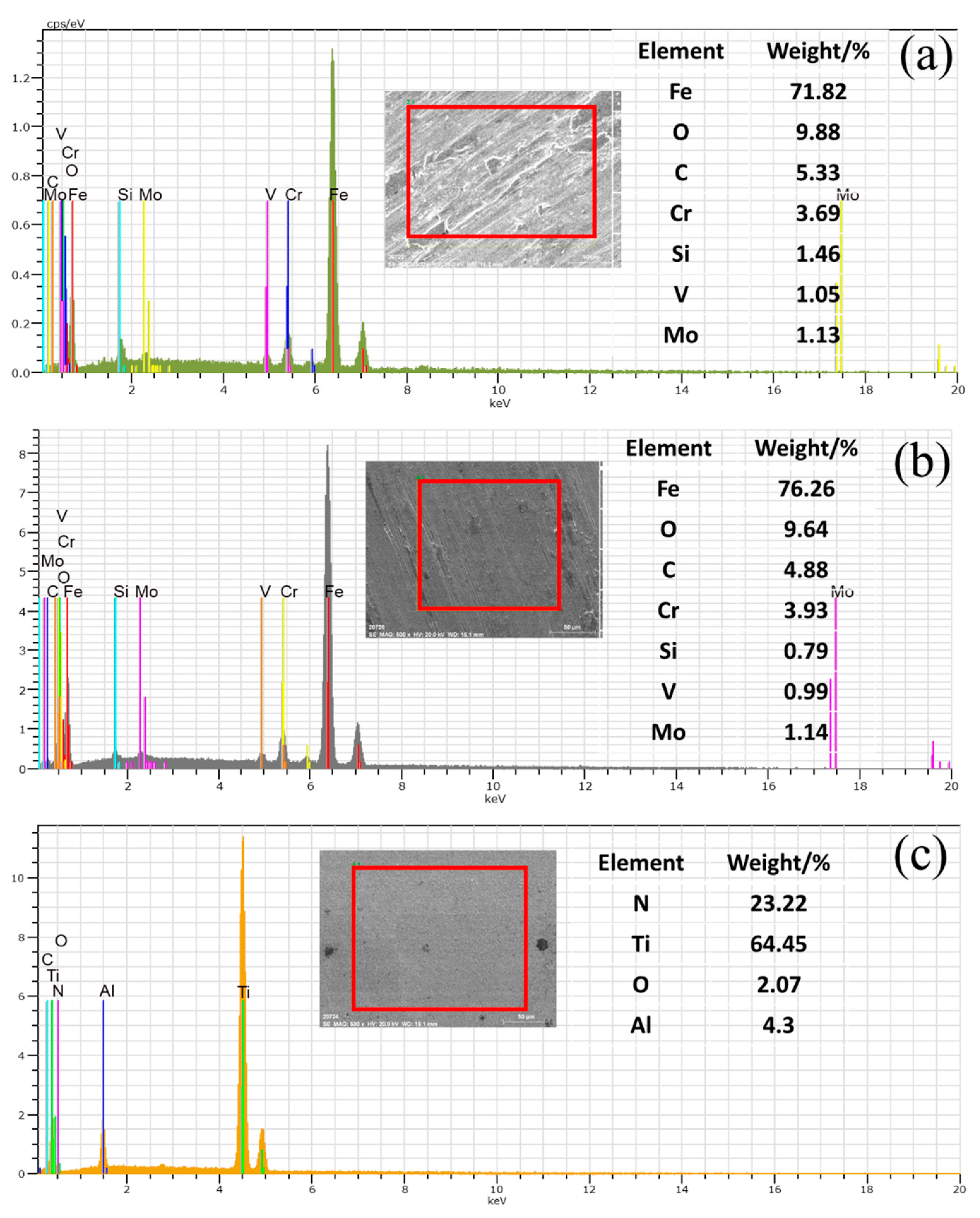

4.4. Wear Mechanism

5. Conclusions

- (1)

- The H13 hot work tool steel sample exhibited the lowest hardness among the three tested materials, which further weakened due to thermal softening. It experienced the most extensive wear damage, showing that the traditional hot extrusion dies material needs to be improved.

- (2)

- The COFs of CVD coatings and H13 hot work tool steel specimens were smaller under the hot extrusion condition than at room temperature. As the extrusion experiment validates the friction boundary conditions of the FE model, the results of the tribology test are suitable for the numerical simulation of hot extrusion.

- (3)

- Due to the fact that cemented carbide YG8 exhibits the best wear resistance and friction reduction at room temperature, and CVD coating exhibits the best wear resistance at high temperature, cemented carbide YG8 is more suitable for extrusion dies working at room temperature, while CVD coating can be used to extend the service life of extrusion dies working at a high temperature.

- (4)

- The wear mechanisms of H13 hot work tool steel, cemented carbide YG8, and CVD coatings at 500 °C are adhesion wear, abrasive wear, and fatigue wear, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Bakri, B.A.R.; Ricco, P. Condensation heat transfer coefficient for rectangular multiport microchannels at high ambient temperature. Int. J. Heat Mass Transf. 2019, 138, 866–878. [Google Scholar] [CrossRef]

- Wei, L.; Lu, Z.; Cao, F.; Zhang, L.; Yang, X.; Yu, X.; Jin, L. A comprehensive study on thermal conductivity of the lithium-ion battery. Int. J. Energy Res. 2020, 44, 9466–9478. [Google Scholar] [CrossRef]

- Kim, N.-H. Condensation heat transfer and pressure drop of R-410A in flat aluminum multi-port tubes. Heat Mass Transf. 2017, 54, 523–535. [Google Scholar] [CrossRef]

- Tang, D.; Chen, X.; Zhao, L.; Zou, T.; Wang, H.; Li, D.; Peng, Y.; Wu, P. Study on the Pressure Bearing Capability of Folded Multi-Port Flat Tube. Materials 2019, 12, 3744. [Google Scholar] [CrossRef] [Green Version]

- Giarmas, E.; Tzetzis, D. Optimization of die design for extrusion of 6xxx series aluminum alloys through finite element analysis: A critical review. Int. J. Adv. Manuf. Technol. 2022, 1, 1–23. [Google Scholar] [CrossRef]

- Tercelj, M.; Kugler, G.; Turk, R.; Cvahte, P.; Fajfar, P. Measurement of temperature on the bearing surface of an industrial die and assessment of the heat transfer coefficient in hot extrusion of aluminium: A case study. Int. J. Veh. Des. 2005, 39, 93–109. [Google Scholar] [CrossRef]

- Mori, T.; Takatsuji, N.; Matsuki, K.; Aida, T.; Murotani, K.; Uetoko, K. Measurement of pressure distribution on die surface and deformation of extrusion die in hot extrusion of 1050 aluminum rod. J. Mater. Process. Technol. 2002, 130–131, 421–425. [Google Scholar] [CrossRef]

- Björk, T.; Bergström, J.; Hogmark, S. Tribological simulation of aluminium hot extrusion. Wear 1999, 224, 216–225. [Google Scholar] [CrossRef]

- Abtahi, S.; Welo, T. Interface Mechanisms on the Bearing Surface in Extrusion. In Proceedings of the 6th International Extrusion Technology Seminar, Chicago, IL, USA, 14–17 May 1996; pp. 125–131. [Google Scholar]

- Wang, L.; Yang, H. Friction in aluminium extrusion—part 2: A review of friction models for aluminium extrusion. Tribol. Int. 2012, 56, 99–106. [Google Scholar] [CrossRef]

- Beste, U.; Hammerström, L.; Engqvist, H.; Rimlinger, S.; Jacobson, S. Particle erosion of cemented carbides with low Co content. Wear 2001, 250, 809–817. [Google Scholar] [CrossRef]

- Beste, U.; Hartzell, T.; Engqvist, H.; Axén, N. Surface damage on cemented carbide rock-drill buttons. Wear 2001, 249, 324–329. [Google Scholar] [CrossRef]

- Engqvist, H.; Beste, U.; Axén, N. The influence of pH on sliding wear of WC-based materials. Int. J. Refract. Met. Hard Mater. 2000, 18, 103–109. [Google Scholar] [CrossRef]

- Exner, H.E. Physical and chemical nature of cemented carbides. Int. Mater. Rev. 1979, 24, 149–173. [Google Scholar] [CrossRef]

- Gee, M. Model scratch corrosion studies for WC/Co hardmetals. Wear 2010, 268, 1170–1177. [Google Scholar] [CrossRef]

- O’Quigley, D.; Luyckx, S.; James, M. An empirical ranking of a wide range of WC-Co grades in terms of their abrasion resistance measured by the ASTM standard B 611-85 test. Int. J. Refract. Met. Hard Mater. 1997, 15, 73–79. [Google Scholar] [CrossRef]

- Khatter, C.P.; Sethi, B.L.; Pandey, O.P. Failure analyses of cemented tungsten carbide extrusion die. Tribol. Mater. Surf. Interfaces 2009, 3, 62–67. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Géhin, D.; Gomez, S.; Manaud, J.; Le Petitcorps, Y.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Birol, Y.; Isler, D. Response to thermal cycling of CAPVD (Al,Cr)N-coated hot work tool steel. Surf. Coat. Technol. 2010, 205, 275–280. [Google Scholar] [CrossRef]

- Srivastava, A.; Joshi, V.; Shivpuri, R.; Bhattacharya, R.; Dixit, S. A multilayer coating architecture to reduce heat checking of die surfaces. Surf. Coat. Technol. 2003, 164, 631–636. [Google Scholar] [CrossRef]

- Wang, Y. A study of PVD coatings and die materials for extended die-casting die life. Surf. Coat. Technol. 1997, 94–95, 60–63. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Brugnara, R.; Kruppe, N. CrN/AlN and CrN/AlN/Al2O3 coatings deposited by pulsed cathodic arc for aluminum die casting applications. Surf. Coat. Technol. 2015, 284, 222–229. [Google Scholar] [CrossRef]

- Mitterer, C.; Holler, F.; Üstel, F.; Heim, D. Application of hard coatings in aluminium die casting—Soldering, erosion and thermal fatigue behaviour. Surf. Coat. Technol. 2000, 125, 233–239. [Google Scholar] [CrossRef]

- Miller, T.; Lin, J.-M.; Pirolli, L.; Coquilleau, L.; Luharuka, R.; Teplyakov, A.V. Investigation of thin titanium carbonitride coatings deposited onto stainless steel. Thin Solid Film 2012, 522, 193–198. [Google Scholar] [CrossRef]

- Devia, D.M.; Restrepo-Parra, E.; Arango, P. Comparative study of titanium carbide and nitride coatings grown by cathodic vacuum arc technique. Appl. Surf. Sci. 2011, 258, 1164–1174. [Google Scholar] [CrossRef]

- Kainz, C.; Schalk, N.; Tkadletz, M.; Mitterer, C.; Czettl, C. Microstructure and mechanical properties of CVD TiN/TiBN multilayer coatings. Surf. Coat. Technol. 2019, 370, 311–319. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Amaral, M.; Almeida, F.; Fernandes, A.; Oliveira, F.; Silva, R. Mechanical performance upgrading of CVD diamond using the multilayer strategy. Surf. Coat. Technol. 2013, 236, 380–387. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, X.; Nie, Z.; Tan, C.; Wang, F.; Cai, H.; Li, Y.; Wang, F.; Cai, H. Microstructure and growth mechanism of tungsten carbide coatings by atmospheric CVD. Surf. Coat. Technol. 2018, 344, 85–92. [Google Scholar] [CrossRef]

- Sun, Y.; Kandan, K.; Shivareddy, S.; Farukh, F.; Bailey, R. Effect of sliding conditions on the macroscale lubricity of multilayer graphene coatings grown on nickel by CVD. Surf. Coat. Technol. 2018, 358, 247–255. [Google Scholar] [CrossRef]

- Garg, R.; Rajagopalan, N.; Pyeon, M.; Gönüllü, Y.; Fischer, T.; Khanna, A.S.; Mathur, S. Plasma CVD grown Al2O3 and MgAl2O4 coatings for corrosion protection applications. Surf. Coat. Technol. 2018, 356, 49–55. [Google Scholar] [CrossRef]

- Björk, T.; Berger, M.; Westergård, R.; Hogmark, S.; Bergström, J. New physical vapour deposition coatings applied to extrusion dies. Surf. Coat. Technol. 2001, 146–147, 33–41. [Google Scholar] [CrossRef]

- Müller, K. Deposition of hard films on hot-working steel dies for aluminium. J. Mater. Process. Technol. 2002, 130–131, 432–437. [Google Scholar] [CrossRef]

- Karadogan, C.; Grueebler, R.; Hora, P. A New Cone-Friction Test for Evaluating Friction Phenomena in Extrusion Processes. Key Eng. Mater. 2009, 424, 161–166. [Google Scholar] [CrossRef] [Green Version]

- Maier, J.; Tran, T.; Beckert, R.H. Wear investigation on high temperature (HT) and medium temperature (MT) CVD coating for extrusion die application. Met. Form. 2014, 25, 229–240. [Google Scholar]

- Zhang, C.; Zhao, G.; Chen, H.; Guan, Y.; Kou, F. Numerical simulation and metal flow analysis of hot extrusion process for a complex hollow aluminum profile. Int. J. Adv. Manuf. Technol. 2011, 60, 101–110. [Google Scholar] [CrossRef]

- Velasco, F.J.; Martinez, M.A.; Calabrés, R.; Bautista, A.; Abenojar, J.; Bautista, M.A. Friction of PM ferritic stainless steels at temperatures up to 300 °C. Tribol. Int. 2009, 42, 1199–1205. [Google Scholar] [CrossRef]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Pin-on-disc study of a friction material dry sliding against HVOF coated discs at room temperature and 300 °C. Tribol. Int. 2017, 115, 89–99. [Google Scholar] [CrossRef]

- Wei, M.; Wang, S.; Wang, L.; Cui, X.; Chen, K. Effect of tempering conditions on wear resistance in various wear mechanisms of H13 steel. Tribol. Int. 2011, 44, 898–905. [Google Scholar] [CrossRef]

- Oh, H.-K.; Yeon, K.-H.; Kim, H.Y. The influence of atmospheric humidity on the friction and wear of carbon steels. J. Mater. Process. Technol. 1999, 95, 10–16. [Google Scholar] [CrossRef]

- Wang, S.; Wei, M.; Wang, F.; Zhao, Y. Transition of elevated-temperature wear mechanisms and the oxidative delamination wear in hot-working die steels. Tribol. Int. 2010, 43, 577–584. [Google Scholar] [CrossRef]

| WC | Co | C | Si | Cr | Mn | V | Mo | Fe | Others | |

|---|---|---|---|---|---|---|---|---|---|---|

| H13 | - | - | 0.42 | 1.04 | 5.15 | 0.43 | 0.9 | 1.45 | bal. | - |

| YG8 | 92 | 8 | - | - | - | - | - | - | - | trace |

| YG6 | 94 | 6 | - | - | - | - | - | - | - | trace |

| Material (Type) | Nano Hardness (GPa) | Macro Hardness (HRC) | |

|---|---|---|---|

| CVD coating | Surface layer | 2.893 ± 0.145 | 75.9 ± 3.795 |

| Middle layer | 1.688 ± 0.084 | ||

| Lower layer | 0.771 ± 0.039 | ||

| Cemented Carbide (YG8) | 1.529 ± 0.076 | 70.7 ± 3.535 | |

| Cemented Carbide (YG6) | 3.896 ± 0.195 | 87.9 ± 4.395 | |

| Hot tool steel (H13) | 0.532 ± 0.027 | 63.78 ± 3.189 | |

| Process Parameters | Value |

|---|---|

| Diameter of the billet (mm) | 228 |

| Length of the billet (mm) | 1100 |

| Initial temperature of the billet (°C) | 500 |

| Initial temperature of the tool (°C) | 480 |

| Extrusion speed (mm/s) | 3 |

| Heat convection coefficient (W/m2 °C) | 30,000 |

| Physical Properties | AA3003 | H13 Steel |

|---|---|---|

| Density (kg/m3) | 2635 | 7870 |

| Thermal conductivity (W/(m K)) | 180 | 24.3 |

| Specific heat (J/(kg K)) | 1090 | 460 |

| Young’s modulus (Pa) | 6.9 × 1010 | 2.1 × 1011 |

| Poisson’s ratio | 0.3 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Zhou, K.; Tang, D.; Wang, H.; Li, D.; Peng, Y. Experimental and Numerical Study on Friction and Wear Performance of Hot Extrusion Die Materials. Materials 2022, 15, 1798. https://doi.org/10.3390/ma15051798

Zhao L, Zhou K, Tang D, Wang H, Li D, Peng Y. Experimental and Numerical Study on Friction and Wear Performance of Hot Extrusion Die Materials. Materials. 2022; 15(5):1798. https://doi.org/10.3390/ma15051798

Chicago/Turabian StyleZhao, Leilei, Kecheng Zhou, Ding Tang, Huamiao Wang, Dayong Li, and Yinghong Peng. 2022. "Experimental and Numerical Study on Friction and Wear Performance of Hot Extrusion Die Materials" Materials 15, no. 5: 1798. https://doi.org/10.3390/ma15051798

APA StyleZhao, L., Zhou, K., Tang, D., Wang, H., Li, D., & Peng, Y. (2022). Experimental and Numerical Study on Friction and Wear Performance of Hot Extrusion Die Materials. Materials, 15(5), 1798. https://doi.org/10.3390/ma15051798